- Design and types of diesel boilers

- Power and required fuel volumes for the winter

- Boiler installation

- How to save on fuel? Criteria for choosing heating equipment

- Video - Diesel heating boiler - fuel consumption

- How to calculate pellet consumption

- Automation (control)

- Overview of models from leading companies

- Universal boilers ACV Delta Pro

- EnergyLogyc units - intelligent automation

- Buderos Logano - German quality

- Boilers of the Korean company Kiturami

- Calculation of fuel consumption for a diesel boiler

- Servicing the heating device

- How to make a solar oven yourself?

- "Miracle oven"

- Drop oven

- Features of the arrangement of heating on diesel fuel

- medium quality pellets

- Choosing a solar burner

- Views (with sample models)

- By type of fuel

- By type of fuel supply to the boiler

- For the intended purpose

- By type of burners

- Advantages and disadvantages

- Design and operational features

- Nuances of choice

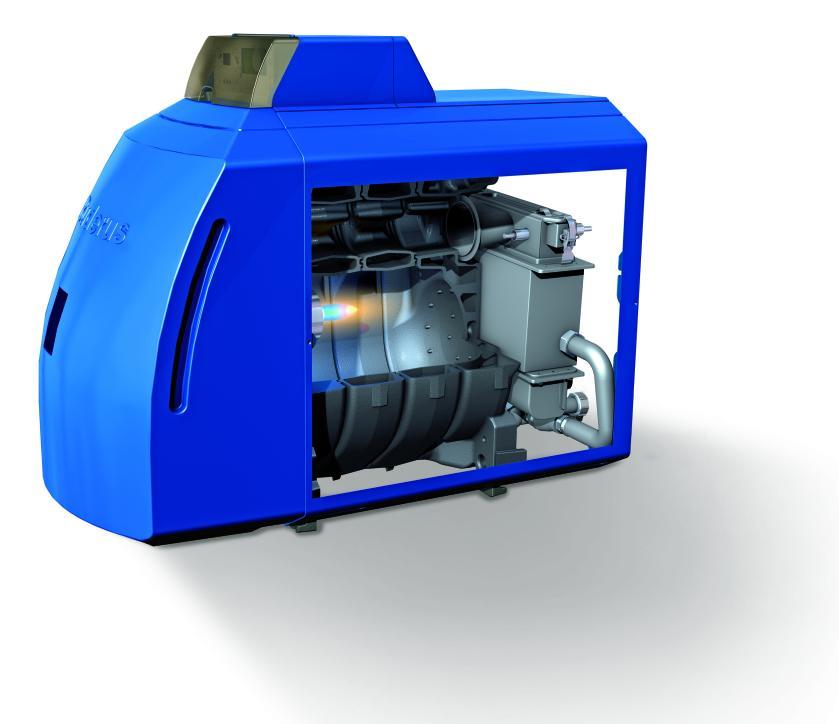

Design and types of diesel boilers

Modern diesel heating boilers for summer cottages and cottages are made in the form of a floor structure. Which allows not only to heat water for the heating system, but also gives off heat through its walls to the boiler room.

The latest modern models have a special outer casing - a protective coating. It guarantees the absence of burns in case of accidental contact with a hot boiler.

According to the type of heating of the coolant, all boilers can be divided into three groups:

- with one circuit (single-circuit) - they will provide only room heating;

- with two circuits (double-circuit) - in addition to heating, due to the presence of a flow heater, they are able to heat water for hot water supply or a warm water floor;

- with two circuits plus a built-in boiler - a unit that will provide heat, hot water in sufficient volume for consumption by the whole family and heated water for the pool.

According to the method of extracting exhaust gases, boilers are distinguished:

- with natural draft - a conventional vertical chimney;

- and with forced draft - models with a closed firebox and a built-in chimney.

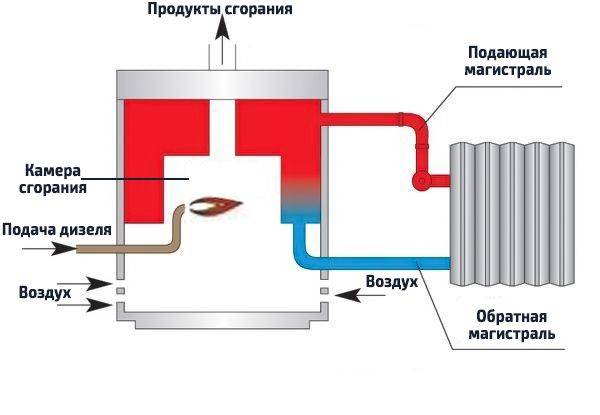

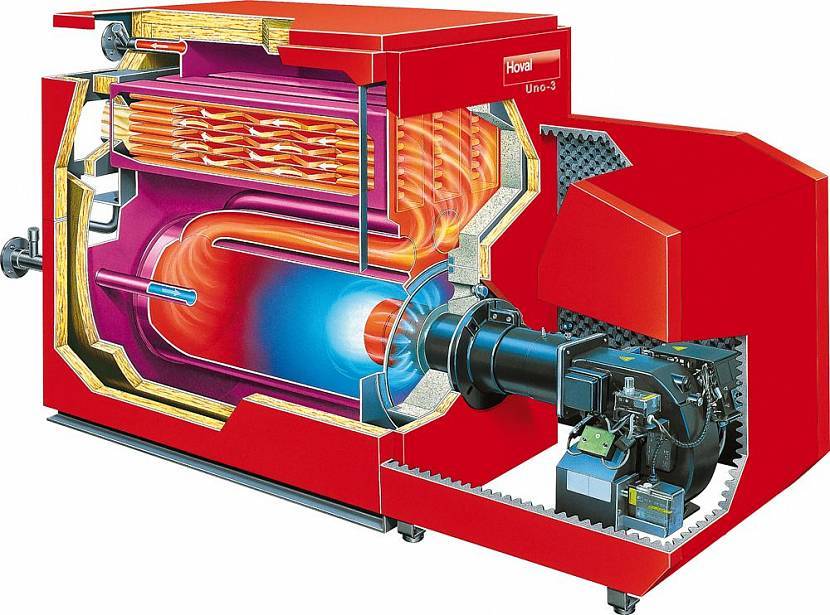

In fact, the most important device in a diesel boiler is its fan burner. It pumps and regulates the air flow, and hence the oxygen in the furnace. The burner controls the amount of fuel supplied to the combustion chamber. The forced air guarantees the complete burning of the fuel, which ensures the high efficiency of such a boiler.

The burner is an undeniable advantage of a diesel boiler, but it is also its indisputable disadvantage. The noise from its functioning scares away many who want to buy one. Manufacturers are trying by any means to reduce its noise, but it is still recommended to make soundproofing in the boiler room.

The second most important component of a diesel heating boiler for a summer residence is a heat exchanger. It is made of steel or cast iron. The first is lighter, in terms of dimensions and weight it turns out much less. But cast iron can last up to half a century, since its thick walls are much more resistant to corrosion.

Power and required fuel volumes for the winter

For convenience, it is believed that for comfort in the house for every ten square meters, 1 kW of heater power is needed.Then the resulting figure is multiplied with a correction factor of 0.6 - 2. It depends on the climatic zone of residence. In the southern regions - 0.6, and in the far north up to 2.

Fuel consumption per hour of operation, which can be calculated by multiplying the power by 0.1, does not operate at full capacity during the winter. It is believed that the heating season lasts 200 days. Half of them he works to the fullest, and half of them half-heartedly. The result is another coefficient - 0.75.

As a result, averaged over the winter for heating a house of 250 square meters will be burned = 250 * 0.1 (required power) * 0.1 (consumption per hour) * 24 (hours per day) * 200 * 0.75 (heating season) = 9000 kg of diesel. That is, in the warm south it will take a little more than 5, and in the north about 18 tons.

The given figures are approximate, but you can start from them when choosing the boiler power and the size of the fuel tank. In order to reduce them, you should also perform high-quality insulation of the entire dwelling and carefully adjust the automation.

Also interesting: when arranging your home, do not forget about the yard! High-quality paving slabs will transform your site and create the desired comfort. Good luck!

Boiler installation

First, the box is welded. It is necessary to ensure that the duct that runs in the wall goes out into the street or into the furnace compartment. Next, a chimney is installed, and stones are laid out on the top cover of the boiler. Then the boiler itself is mounted on the foundation.

If water heating is provided, then piping can be done after installing a diesel boiler and a coolant tank instead of stones.

In order to make a furnace screen, refractory bricks are usually used. The screen is built in different ways.

For example, you can overlay the boiler with bricks on all sides or build a furnace screen in the form of an ordinary wall, but 50-60 centimeters wider than the boiler.

According to the rules, the lower part of the combustion screen must have holes through which air will circulate.

Practically, in order to build a boiler on diesel do-it-yourself fuel, it is absolutely not necessary to know all the subtleties and nuances of its construction and be able to do too much.

Scheme of work and assembly the boiler is quite simple, and even a non-professional stove-maker without special education and experience can figure it out. Having the material at hand, the necessary tools and desire, you can always achieve the desired result.

In regions where there are problems with gas supplies, solid fuel boilers are very popular. Along with them, liquid-fuel units operating on diesel fuel compete, since in terms of ease of use they are comparable to gas devices. Many masters make such heating on their own. First of all, you need to figure out how you can make a diesel burner with your own hands. It is the key ingredient.

How to save on fuel? Criteria for choosing heating equipment

Units consuming liquid fuel are calculated for both one and two circuits. And it is quite obvious that in the second case, the fuel consumption will be large, because of which the costs will only increase. For this reason, the best option for dual-circuit appliances may only be to reduce the consumption of hot water consumed, which will help save on fuel.

Experts advise one more thing. According to them, it is possible to reduce fuel consumption by setting the lowest temperature for the heat carrier.And the final point - it is advisable to install a thermostat in the warmest room. If you follow all these recommendations, you will be able to reduce the fuel consumption required for the operation of the boiler, and save a certain amount of money.

On many thematic forms, users are interested in: which units are more economical - diesel or electric? And what is the fuel consumption of a diesel heating boiler? It is rather difficult to answer this question unambiguously, since it depends on a number of points, including:

- the quality of the thermal insulation of the building;

- the cost of the fuel used;

- the area of the heated room;

- features of a particular climatic zone;

- number of people in the house.

And if you know about all these factors, then you can roughly calculate the consumption of both fuels by comparing costs. And now - a few more practical tips regarding the choice of a heating unit.

- Heating equipment that consumes diesel fuel, in the presence of a combustion chamber made of steel, will be immune to temperature changes. However, steel undergoes a rusting process, so it does not last as long as, for example, cast iron.

- The higher the cost of a heating boiler, the higher the risk that its maintenance will cost you a lot (compared to models that have a lower cost).

- Devices that are equipped with a cast iron furnace chamber can last up to twenty years, but temperature changes affect them, moreover, very significantly. In this kind of heating systems, it is necessary to install valves that will mix the heated liquid into the "return" pipeline. All this is required so that the combustion chamber simply does not crack.

Video - Diesel heating boiler - fuel consumption

Why diesel fuel?

When choosing a heating boiler, each user is guided by specific individual requirements. And if, for example, you live in a locality where there is no centralized gas supply or there are often drops in the supply of electricity, then diesel fuel boilers, the consumption of which, as we have already found out, are insignificant, will be the best option.

Moreover, such devices have one more advantage that we did not talk about - the fuel tank can be installed in any place convenient for you. And this has become a decisive factor for the fact that the popularity of diesel equipment has only increased in recent years.

How to calculate pellet consumption

Given the fact that the fuel is supplied in bulk or in bags, it is not difficult in principle to calculate the consumption of pellets per 1 kW or 1 m2. There is no need to convert units of weight to volume, since the delivery is always in kilograms, and the calorific value of the fuel is also measured in kW per 1 kg of weight.

Good quality pellets have excellent calorific value, almost 5 kW of thermal energy is released from burning 1 kg of such fuel. Accordingly, in order to get 1 kW of heat for heating a house, it is required to burn about 200 grams of pellets. The average consumption of granules per unit area is easy to determine based on the fact that 100 W of energy is required to heat each 1 m2 of area.

One condition is important: the height of the ceilings should be within 2.8-3 m. 100 W of heat will be obtained from 20 grams of granules, which would seem to be simple arithmetic.But it was not there

The figures presented above are correct if the pellet boiler has absolute efficiency - 100% efficiency, and this does not happen in real life. In fact, the efficiency of such heat generators, although higher than that of solid fuel boilers, is still only 85%. This means that after burning 1 kg of pellets in the furnace of the unit, not 5 kW of energy will be received, but 5 x 0.85 = 4.25 kW. Conversely, to release 1 kW of heat in pellet boilers, 1/4.25 = 0.235 kg or 235 grams of fuel is spent. This is the first nuance

But it was not there. The figures presented above are correct if the pellet boiler has absolute efficiency - 100% efficiency, and this does not happen in real life. In fact, the efficiency of such heat generators, although higher than that of solid fuel boilers, is still only 85%. This means that after burning 1 kg of pellets in the furnace of the unit, not 5 kW of energy will be received, but 5 x 0.85 = 4.25 kW. Conversely, to release 1 kW of heat in pellet boilers, 1/4.25 = 0.235 kg or 235 grams of fuel is spent. This is the first nuance.

The second nuance is that 100 W of heat per 1 m2 of the room is required when the ambient temperature is the lowest, which lasts for 5 days. On average, during the heating season, the cost of thermal energy is half as much. And this means that the specific heat transfer per unit area is only 50 watts. It will be incorrect to determine the consumption of pellets in a pellet boiler for 1 hour relative to 1 m2, the figure will be small and inconvenient. It would be more correct to calculate the weight of the pellets burned per day.

Since a watt is a unit of power related to 1 hour, then 50 W x 24 hours = 1200 W or 1.2 kW per day will be needed for each square of the room.For this purpose, you will need to burn the following mass of pellets per day:

1.2 kW / 4.25 kW/kg = 0.28 kg or 280 grams.

Knowing the specific fuel consumption, we can finally obtain values that are useful for financial calculations, for example, the average weight of pellets per season used per day and per month in a house with an area of 100 m2:

- per day - 0.28 x 100 = 28 kg;

- per month - 28 x 30 \u003d 840 kg.

It turns out that 8.4 kg of fuel is spent on heating 1 m2 of a building per month. At the same time, according to user reviews on various forums, it takes about 550 kg of pellets to heat a well-insulated house of 100 m2, located in the middle lane, which, in terms of the square, is 5.5 kg / m2. This means that the consumption of pellets in the boiler in the amount of 840 kg per month with a building square of 100 m2 is very enlarged and is suitable for calculations of poorly insulated houses.

Let us summarize some results in the form of calculation results for dwellings of various sizes. The following monthly costs of pellets for heating a private house were obtained:

- 100 m2 - 840 kg with weak insulation, 550 kg for good thermal insulation;

- 150 m2 - 1260 kg and 825 kg, respectively;

- 200 m2 - 1680 kg and 1100 kg under the same conditions.

For reference. In many boiler systems, the controller has a function that allows you to see on the display the consumption of pellets in kilograms over a certain period.

Automation (control)

According to its characteristics, the boiler can independently supply fuel, it does not need to be thrown up like firewood

Therefore, in boilers of this type, maximum attention is paid to automatic control, which minimizes the presence of a person in the operation of the boiler.

Using the example of the Kiturami boilers that came to me, let's see what is included in the automation of the boiler. On the body we see sensors for fuel level, temperature, overheating.There is an electronic remote control unit. Boiler indicators allow you to monitor the temperature of the coolant in the heat exchanger, circulation pump, burner, power supply. Tricky buttons "Sleep", "Shower", also elements of universal automation. This is a plus.

Overview of models from leading companies

A worthy niche in the heating equipment market is occupied by liquid fuel boilers from foreign manufacturers: ACV, EnergyLogyc, Buderos Logano, Saturn, Ferolli and Viessmann. Among domestic companies, Lotos and TEP-Holding have proven themselves well.

Universal boilers ACV Delta Pro

The Belgian company ACV sells models of the Delta Pro S line - double-circuit boilers with a built-in boiler. The power of heating units is from 25 to 56 kW.

Delta Pro S boilers are supplied with a burner of the customer's choice - either BMV1 for oil or BG2000 for propane and natural gas

Technical and operational features:

- heat exchanger material - steel;

- polyurethane foam insulation of the body;

- work on diesel fuel or gas;

- control panel with thermometer, regulating thermostat.

The oil-fired boiler "adjusts" to the season - a winter / summer switch is provided.

The efficiency of Delta Pro S boilers is 92.8%. The time for heating water for a DHW system depends on the capacity of the installation and ranges from 16 to 32 minutes

EnergyLogyc units - intelligent automation

Waste oil boilers from the American company EnergyLogyc differ from their counterparts in automated burner adjustment and fuel combustion processes.

Waste oil, diesel fuel, vegetable oil or kerosene are used as fuel.

In the device, the size of the furnace and the cross-section of the fire tubes are increased - this allows you to effectively use the "working out" and reduces the number of work on cleaning the boiler

EnergyLogyc liquid fuel units are available in three versions:

- EL-208V - power 58.3 kW, fuel consumption - 5.3 l / h,

- EL-375V - productivity 109 kW, fuel consumption - 10.2 l / h;

- EL-500V - thermal power - 146 kW, fuel material consumption - 13.6 l / h.

The maximum temperature of the heat carrier in the presented models is 110°С, the working pressure is 2 bar.

The EL-208V boiler is suitable for heating premises for various purposes: cottages, greenhouses, car services, production workshops, warehouses, private houses and offices

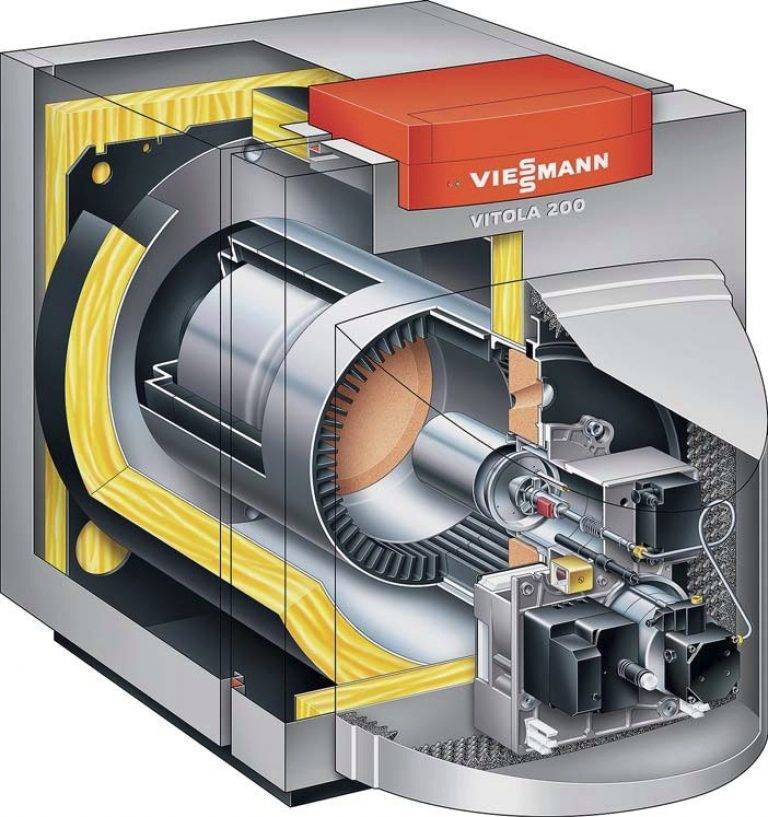

Buderos Logano - German quality

The Buderos company (Germany) produces diesel boilers, nozzles, burners and other equipment necessary for the operation of the heating system. The range of power characteristics of the units is 25-1200 kW.

The efficiency of Buderos liquid fuel boilers is 92-96%. The equipment operates in a fully automatic mode, the fuel material is diesel fuel. Heat exchanger made of gray cast iron or steel

Buderos Logano boiler plants are produced in two series:

- Buderos Logano category "G" - designed for private use, their power is 25-95 kW;

- Buderos Logano category "S" - equipment for industrial use.

The units are characterized by a streamlined design, a convenient control system, and a built-in silencer.

Domestic boilers Buderos Logano are supplied with built-in and adjusted burners for diesel fuel. The device can be completed with a pump group, a security system and an expansion tank

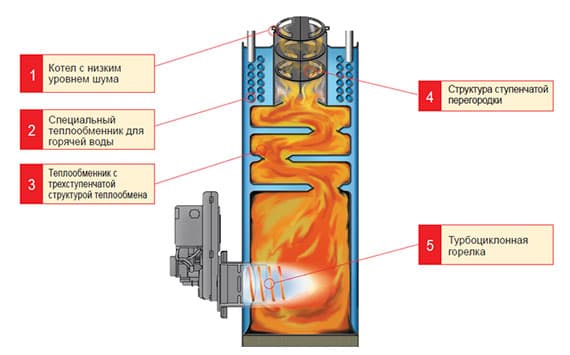

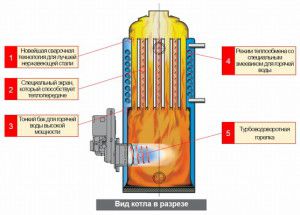

Boilers of the Korean company Kiturami

Floor double-circuit coppers of Kiturami of the Turbo series are intended for household use. The power of the units is 9-35 kW.

Distinctive features of the model:

- provision of heating and hot water supply for premises up to 300 sq.m;

- the boiler heat exchanger is made of high-alloy steel;

- additional DHW heat exchanger is 99% copper, which increases the heating efficiency;

- antifreeze and water are suitable as a coolant.

A distinctive feature of Turbo models is the presence of a turbocyclone burner. It functions on the principle of a turbocharged car engine.

In a special metal plate, secondary combustion occurs due to high temperature. This allows you to economically consume fuel and reduce the emission of harmful substances into the atmosphere.

Kiturami Turbo can work in the following modes: "Shower", "Sleep", "Presence", "Work/Check" and "Timer". The control panel is moved to the front side of the case

Calculation of fuel consumption for a diesel boiler

Knowing the power of the equipment and the area of \u200b\u200bthe house, as well as some other technical parameters, you can calculate how much fuel you need to stock up in order to be ready for even the most severe cold. The consumption of a diesel heating boiler depends not only on the equipment itself, but also on the insulation of the house, the height of the ceilings, installed plastic windows and some other parameters.

Much depends on the weather conditions of the region. On average, for heating a large house, the area of \u200b\u200bwhich is 200 square meters. m, it will take up to 6 liters of fuel at a temperature of -5 degrees and more than 20 liters at a 30-degree frost.

When calculating, you can rely not only on your own weather observations, but also on studies conducted by specialists. At an average Russian temperature in winter of -20 degrees, the consumption will be about 16 liters, with more severe cold weather or with insufficient insulation, this figure reaches 20 liters.

If you choose a diesel heating boiler, fuel consumption can be reduced using the possibilities of automation. There are many models with automatic mode switching, in addition, you can put a thermostat that will maintain a constant temperature in the rooms. If you program the equipment to increase heating only at certain hours when family members are at home, this will significantly reduce costs.

Can used car oil be used to heat a house? It is possible, but this requires a special boiler, which in itself is very expensive.

Although in the future he will save, the cost of acquiring it will be prohibitive, and it is better to just buy high-quality diesel fuel. In addition, mining will have to be collected and transported home, which will require additional costs and time.

Servicing the heating device

It is necessary to service the diesel fuel boiler regularly and this can be done at home with your own hands. Basically it consists in cleaning the burner. The burner component is a fuel filter, it must be cleaned as it becomes dirty. It depends on the quality of the fuel. Sometimes this should be done once a week.

Cleaning the chimney is also very important for the normal operation of the heating boiler. It can be carried out less frequently than cleaning the burner, approximately 2 times per season. Chimney cleaning can be done by hand.

Ignition electrodes, which may be supplied with the burner, must also be cleaned 2 times a season. This should be done with a swab soaked in solvent. The nozzle that makes up the burner cannot be cleaned. If it gets dirty, you need to change it (this can be done at home with your own hands, since this is not a difficult process). If the replacement is not done on time, then the burner does not function well. And as a result, low efficiency and poor operating parameters of the unit for heating. In some heating models, you need to change the nozzle in the burner once a season. In order not to adjust the burner again, you need to install the same nozzle as before.

Sometimes, after cleaning the filters and replacing the nozzle, the burner does not start the first time. This happens because the lines are not filled with fuel. It is necessary to turn the burner on and off several times, and it will start. But still, if the fire does not light up, you need to make sure that the fuel is of high quality without impurities, water.

There are several reasons why the burner does not work:

- Fuel is not supplied to the heating boiler;

- Air does not enter. If, when the heating boiler is turned on, there is no noise from the operation of the air pump, this means that it does not work;

- No spark. This problem can occur if the ignition electrodes are too clogged or the distance between them is incorrect;

- Too much oxygen enters the system. The instructions for using the burner indicate which parameters to change in order to restore normal air supply. This can be done by hand. But this will only help if all the components are in order.

The solar heating boiler is made of steel or cast iron. Models made of cast iron are considered to be of better quality heating installations.Since the operation of the cast-iron unit (in particular the burner) is much longer, and it is not afraid of corrosion that occurs from the appearance of condensate.

Rice. 4 Model with cast iron heat exchanger

A steel heating boiler, of course, is cheaper and lighter, but it also breaks down faster. At the same time, corrosion processes shorten the service life.

How to make a solar oven yourself?

To heat one room without permanent residence of people, for example, a workshop or a garage, you can make a home-made diesel stove. The two most popular options are:

"Miracle oven"

This unit is similar to a dumbbell installed vertically: two containers are located one above the other and are connected using a pipe in which several holes are drilled.

The idea is this:

- Diesel fuel or waste oil (up to half of the volume) is poured into the lower container through a neck cut into it, which is then set on fire.

- As a result of combustion, the temperature in the tank rises, due to which the liquid fuel begins to evaporate intensively.

- Combustible vapors rush up and enter the pipe, where they mix with the air entering through the holes made in it.

Miracle oven

Next, the fuel-air mixture enters the upper tank of the furnace, where it burns.

Drop oven

A somewhat more complex unit, but also more practical. Assembled in the following sequence:

- A piece of pipe is taken and welded tightly on one side, and a cover is installed on the other. This will be the case that needs to be placed vertically with the cap up.

- A piece of pipe of a smaller diameter is installed inside - this will be an afterburner.

- A bowl is placed in the afterburner, into which fuel flows by gravity from a container suspended at a certain height through a hose. A valve can be used to dispense it, but there is an easier option: the hose can be pinched to the desired section using a clamp.

Next, a fan is installed in the furnace, which will force air into the afterburner.

Features of the arrangement of heating on diesel fuel

Solar boiler diagram

Solar boiler diagram

The operation of a diesel heating device is almost completely identical to the operation of a car engine. All autonomous diesel heating boilers must have a special burner. It is also a source of thermal energy.

Structurally, the burner consists of the following elements:

- Supply line. Ensures the flow of fuel into the zone of its combustion;

- Turbine. Designed to create pressure;

- The nozzle is used to spray diesel fuel, as a result of which a combustible mixture is formed;

- Devices for power control and control of the state of the flame.

It is noteworthy that you can use a conventional boiler. To do this, the dimensions of the combustion chamber door must correspond to the installation dimensions of the burner. Thus, solar heating can be done on the basis of an existing system. To do this, it is necessary to carry out some modernization.

medium quality pellets

In the above calculations, the calorific value characteristic of high quality white granules, the so-called elite ones, was used. They are made from the waste of good wood and practically do not have foreign inclusions, such as tree bark.Meanwhile, various impurities increase the ash content of the fuel and reduce its calorific value, but the price per ton of such wood pellets is much lower than elite ones. By reducing the cost, many homeowners are trying to make their pellet heating more economical.

In addition to elite fuel pellets, cheaper pellets are produced from agricultural waste (usually from straw), whose color is somewhat darker. Their ash content is low, but the calorific value is reduced to 4 kW / kg, which will ultimately affect the amount consumed. In this case, the consumption per day for a house of 100 m2 will be 35 kg, and per month - as much as 1050 kg. The exception is pellets made from rapeseed straw, their calorific value is not worse than that of birch or coniferous pellets.

There are other pellets that are made from a wide variety of waste from woodworking enterprises. They contain all sorts of impurities, including bark, from which malfunctions and even malfunctions occur in modern pellet boilers. Naturally, the unstable operation of the equipment always causes increased fuel consumption. Especially often heat generators with retort burners in the form of a bowl facing upwards are capricious from low-quality granules. There, the auger supplies fuel to the lower part of the "bowl", and around there are holes for the passage of air. Soot gets into them, due to which the intensity of combustion decreases.

In order to avoid such situations and the efficiency of the boiler does not decrease, it is advisable to choose fuel with a low ash content and in no case wet.Otherwise, problems with the screw feed will begin because the wet granules crumble and turn into dust that clogs the mechanism. It is possible to use cheaper fuel for heating a house with pellets when the boiler is equipped with a torch-type burner. Then the ash covers the walls of the furnace and falls down without falling back into the burner. The only condition is that the combustion chamber and burner elements will have to be serviced and cleaned more often, as they get dirty.

Choosing a solar burner

Diesel burner design

The burner is the main element of the diesel fuel heating system. Reviews will help create an objective opinion about its quality and durability. But in addition to this, you need to know the basic technical parameters of the device.

The main selection criterion is power. It directly depends on the area of \u200b\u200bheating a private house with diesel fuel. It is recommended to use the ratio - 1 kW of thermal energy must be generated per 10 m2 of the room. Such an indicator must be taken into account for heating on diesel fuel, made by oneself. But this rule is applicable only with good thermal insulation of the house. To ensure a power reserve, 15-20% must be added to the figure obtained. But it should be remembered that this will directly affect the consumption of diesel fuel for heating the house.

In addition to this indicator, the following factors are taken into account when choosing.

- Burner dimensions. The possibility of mounting the device in the boiler depends on this;

- Operating mode. Single-stage models operate only at constant power. For two-stage it is possible to adjust the degree of heating - maximum and medium.Modular ones are optimal, since they have different options for heating a house with diesel fuel - starting from the minimum value and ending with 100% heating of the coolant;

- Price. The most popular LAMBORGHINI burners cost between 20,000 and 40,000 rubles.

It is also important to pay attention to the possibility of switching from diesel fuel to used engine oil. To do this, the design must provide for the function of replacing the nozzle of a model with a large nozzle diameter.

Views (with sample models)

They are divided according to different parameters.

By type of fuel

-

Heating equipment using only pellets as fuel. For the successful operation of such a unit, stable and timely fuel supplies will be needed.

Example: pellet boiler Roteks-15

-

Conditionally combined. A firebox of a special shape makes it possible to burn, in addition to pellets, other types (briquettes or firewood). Combustion of alternative fuels in a wood pellet boiler is an emergency function. Continuous operation in this mode will lead the wood pellet boiler to failure.

Model example: pellet boiler Faci 15

- Pellet combined. They have built-in special combustion chambers designed to use their type of fuel. Such heaters, although universal, have a couple of drawbacks: large sizes and a very high price.

Model example: STROPUVA S20P

By type of fuel supply to the boiler

-

Automatic. Automation of the process is the main advantage of such boilers. To calculate the required power and set up such an automated pellet boiler, the services of specialists are needed.

Example: Termodinamik EKY/S 100

-

Semi-automatic.The power is set manually by the regulator, subsequently the supply of granules occurs in automatic mode.

Pellet boiler UNITECH Multi 15

-

Mechanical loading of granules. Such a unit requires the constant presence of a person for periodic loading of pellets.

STROPUVA MINI S8P

For the intended purpose

-

Heating medium (water). Most often, it is located in the basement and has a rather serious size, their appearance is purely utilitarian.

Pellet boiler SIME SOLIDA 8

-

Convection oven-fireplace for heating the surrounding atmosphere. Installed in the living room, has a compact size and nice design.

Pellet fireplace Termal-10 BASIC

- Hybrid heating schemes. They combine heating with a water coolant with direct heating of the ambient air at the location. Outwardly, they are very similar to fireplace stoves. Some models are equipped with a cooking surface and in some cases an oven.

Heating boiler Kupper OVK 10 with pellet burner APG25

By type of burners

-

Torch. They are the most widespread and most often used in private homes. Low power burners for small combustion chambers are simple and reliable, and quite easy to set up. The disadvantage in them is the unidirectionality of the torch fire, which leads to the local heating of the boiler wall. Very demanding on the quality of the pellets.

Model example - Lavoro LF 42

-

Bulk combustion. Such burners have more power, are used in industrial equipment, but they also found their niche in conventional boilers. A huge plus of such burners is undemanding to the quality of the granules, but their use has led to a significant increase in the mass of the device.

Representative - Radijator COMPACT 20

-

Fireplace. In such a boiler, pellets, falling into the bowl, burn out. This is the safest type of burner, in addition, the operation of this type of heating equipment does not create much noise. The downside is the scarcity of adjustment settings and the demands on the quality of the granules. This is the most economical pellet boiler of the entire line.

Pellet fireplace Termal-6

It is interesting: Finishing the facade of a private siding at home: write down the main thing

Advantages and disadvantages

The main advantages of such equipment for heating include:

- Equipment autonomy;

- Permissive documentation is not required to install such a boiler;

- These units have high power;

- No special design of the chimney is provided, due to the turbine, which pushes the combustion products out;

- It can be easily transferred to heating from gas (replace the burner);

- Such heating equipment can be made by hand.

As with any heating equipment, solar heating boilers have their drawbacks:

- The diesel fuel that is used must be of good quality, since the frequency of replacing nozzles and servicing the heating installation as a whole depends on this;

- Such boilers are installed in a separate boiler room, as the smell of diesel fuel and noise are emitted during operation.

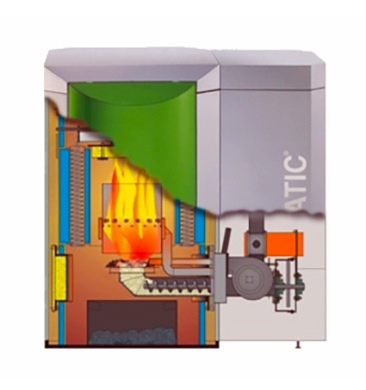

Design and operational features

The efficiency of boilers operating on diesel fuel reaches 95%, and in some cases even exceeds this figure. This is achieved through the use of nozzles that create an atomized fuel mixture in the air stream in order to achieve maximum heat release.

The air flow is created by a fan.The mixture is ignited using an ignition device.

Nuances of choice

When choosing a heating boiler for diesel fuel, it is recommended to give preference to models with a replaceable burner. This will make it possible, if necessary, to convert the boiler to use natural gas. According to the principle of operation, liquid fuel and gas boilers are very similar - their only difference lies in the type of burner.

Boilers with a replaceable burner are more expensive than those models where it is built-in without the possibility of replacement. In this case, the built-in burners can be designed for the use of gas and diesel fuel. True, such devices have low efficiency and are distinguished by their “capricious nature”. The cheapest are boilers with a built-in burner that can only run on liquid fuel.