- How does a mining boiler work

- How does a heater work

- A few words about processing

- 2 How it works

- Terms of use

- Fuel

- How to properly and safely pour fuel into the boiler?

- Balance of advantages and disadvantages

- Equipment operating rules

- Waste oil furnace manufacturing technology

- How to connect a water circuit to the furnace for working out

- How Gecko Boilers Work

- Waste oil heating for a private house

- Features of use

- Types of fuel. How much heat is produced by burning one liter?

- Pros and cons

- How is oil processed?

- What does not apply to such fuel?

- Working out boiler: principle of operation

- Where to apply and how to refine?

- Disadvantages of mining boilers

- Kinds

- Precautionary measures

- Types of aggregates

- Heating structures

- Water heaters

- Appliances

- How exactly does oil evaporate?

How does a mining boiler work

The principle of operation of a solid fuel boiler in mining is to burn oil - the process is similar to blowtorch operation, that is, the fuel is converted into gas during combustion, and air is drawn in by the nozzle to maintain the flame.

Let us single out several features of the operation of the boiler during mining:

- the design provides for two tanks located one above the other;

- for conjugation of containers, a pipe is used through which air moves;

- used oil is poured into the lower container;

- when heated, the oil evaporates and moves to the burner;

- vapors ignite when exposed to air;

- the mixture of burning gases with oxygen moves to the upper tank, where it burns out completely, and the waste is evacuated into the chimney.

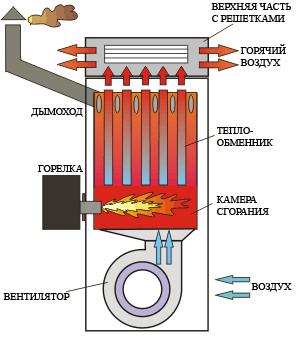

How does a heater work

The design of the boiler is extremely simple. It includes two compartments: evaporation and combustion. In the first, the process of preparing the oil for combustion takes place, in the second, it burns out.

Everything happens as follows. From the recovery tank, the pump supplies the waste oil to the evaporation chamber, which is located at the bottom of the device. It maintains a temperature sufficient for the mining to heat up and begin to evaporate.

This is how a boiler works with oil evaporation and forced air supply (+)

Oil vapor rises to the top of the housing where the combustion chamber is located. It is equipped with an air duct, which is a pipe with holes. With the help of a fan, air is supplied through the duct and mixed with oil vapor.

The oil-air mixture burns almost without residue - the resulting heat heats up the heat exchanger, the combustion products are sent to the chimney.

Oil preheating is an essential part of the process. It must be understood that mining contains a large amount of impurities and toxic substances. All this is decomposed into simple carbohydrates, which are subsequently burned.

After that, water vapor, carbon dioxide and nitrogen are formed - completely harmless elements. However, this result is only possible under certain temperature conditions.

Complete oxidation or combustion of hydrocarbons occurs only at a temperature of +600°C. If it is lower or higher by 150-200°C, then a large amount of various toxic substances is formed during the combustion process. They are not safe for humans, so the combustion temperature must be exactly observed.

A few words about processing

Waste oil is a waste of fuels and lubricants, it is a dark oily liquid that has a strong specific smell of petroleum products.

Mining contains metal microparticles, therefore, it is not recommended to use it as a lubricant for the engine or transmission. However, mining burns as well as ordinary mineral oil, so it is widely used as heating oil. Waste burning can be called one of the ways to reuse fuels and lubricants. Due to the low cost of mining, the boiler operating with its use is environmentally friendly and economical.

2 How it works

During the combustion of gasoline, the oil heats up, boils and begins to evaporate. During a lack of air, oil vapors burn poorly, so they must be enriched with oxygen. For this, a perforated pipe is used. At the same time, the active combustion of the oil-air composition takes place directly in the pipe and in the upper part of the furnace structure.

The temperature of the chamber, which is located below, does not exceed 400 ° C, while the upper one warms up to 1000 ° C. When manually pouring fuel in the lower chamber, a hole is made for fuel and ignition. With automatic feeding, a pipe is inserted into it, which is connected to the tank located outside.Also in this chamber it is necessary to make a hole with a damper, with which you can adjust the oxygen supply, temperature and draft.

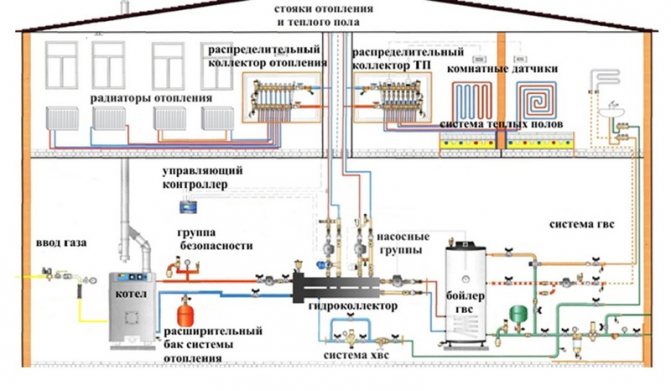

During natural circulation, the length of the water circuit is slightly longer to prevent significant overheating. Forced circulation using pumping equipment makes it possible to reduce the size of the water tank. Experts recommend equipping the heating system with a pressure gauge and a thermometer so that it is possible to control the parameters of the coolant in the circuit.

Terms of use

In order for the boiler to serve for a long time without service, it is necessary to pay attention to the rules of use

Fuel

Waste oil for the functioning of the boiler can be used for almost any purpose. The main thing is that it meets a number of requirements that are imposed by device manufacturers.

Photo 4. Draining used oil into a special container. The liquid itself is dark brown in color.

If you have additional filtration systems, feel free to use them. The cleaner the used oil is, the more efficient the combustion process will be. This also affects the fact that you will carry out less maintenance work during operation.

If the analysis reveals that the fuel contains a large amount of water and antifreeze, then it is necessary to filter the fuel completely. There are specific guidelines on how to remove such impurities.

Manufacturers, most often, advise hydraulic, engine, transmission oils, as well as oil from an automatic transmission for use. But it is not recommended to use fuel oil in the device.

Calculation of fuel for the boiler takes place in accordance with the heat loss for each specific room. It is necessary to take into account data on the insulation of the place, its glazing, the operating mode of the boiler, as well as the required set temperature. Depending on the manufacturer, the calculation will be performed according to individual formulas. It is best to contact the manufacturer directly to identify this issue.

The most commonly used formula is:

B = d*(h1-h2) + d*(h1+h2) /qn

Where: h1 is the efficiency factor,

h2 is the fuel enthalpy,

d is the calorific value of the fuel,

qn are the temperature and specific heat capacity of the oil.

How to properly and safely pour fuel into the boiler?

Before starting work, you need to carry out a number of actions that will ensure the safety of using the device:

- Open the liquid container. This is necessary so that it has time to interact with oxygen.

- After that, disconnect the device from the mains and power supply, check the degree of sealing of the seams.

- Fill the collection screen with oil. You need to pour a 10 mm layer. The oil must be clean.

- Add 100 ml of kerosene to this liquid.

- Take the wick and soak it in the kindle.

- Lower to the bottom of the container.

- Set the work on fire.

- Watch how the seams and oil behave. All actions must be carried out with gloves.

- Close the lid.

- After that, the device will start working, and you can check how efficiently it functions.

Photo 5. Refueling a homemade boiler with used oil. Fuel is poured into the lower part of the unit.

Do not get oil on foreign areas and parts of the device.During operation, all additional sources of oxygen supply, such as doors or windows, must be closed.

Balance of advantages and disadvantages

It would seem that the idea is practically devoid of flaws, but it is not. To make an informed decision about the use of such heating in your home, you need to see not only the pros of its use, but also the cons.

Let's start with the advantages of the method. So, if you have regular access to junk fuel, which is essentially mining, then you can efficiently use and dispose of this material at the same time. Proper use of technology allows you to get heat with complete combustion of the material without the emission of harmful substances into the atmosphere.

Other pluses include:

- uncomplicated design of the heating unit;

- low fuel and equipment costs;

- the possibility of using any oil that is on the farm: vegetable, organic, synthetic;

- combustible material can be used even if the pollution is a tenth of its volume;

- high efficiency.

The shortcomings of the method should be taken seriously. If the process technology is not observed, incomplete combustion of the fuel may occur. Its fumes are dangerous to others.

If there were more disadvantages to heating during mining than advantages, such factory-made products would not appear on sale, which are sold out like hot cakes, despite the rather high prices

It is not for nothing that the main requirement for arranging heating at mining is the presence of ventilation in the room where the boiler will be operated.

Here are some other cons:

- since good draft requires a high-quality chimney, it must be straight, and its length must be from five meters;

- the chimney and the plasma bowl must be cleaned regularly and thoroughly;

- the complexity of the drip technology lies in the problematic ignition: at the time of fuel supply, the bowl should already be red-hot;

- operation of the boiler causes drying of the air and burnout of oxygen;

- self-creation and use of water-heating structures can contribute to lowering the temperature in the combustion zone, which jeopardizes the efficiency of the process as a whole.

To solve the last of the above problems, you can mount a water jacket where it cannot affect the quality of combustion - on the chimney. These shortcomings have led to the fact that the product without significant modifications is practically not used for heating residential premises.

If there is no desire or time to build the unit with your own hands, you can take advantage of the numerous offers from workshops involved in the production and installation of metal structures of various sizes:

Equipment operating rules

The assembled water boiler must be used, observing certain rules, the main of which is the use of a chimney with a suitable cross-sectional diameter. The smoke exhaust system is necessarily equipped with a damper for draft control, and the section of its passage through the ceiling and roof is insulated with a heat-resistant casing. And when using the boiler, it is not allowed to add fuel to the heated chamber, cool the boiler with water and turn off the forced draft fan.Compliance with these rules will ensure the efficient operation of the equipment and increase the life of the heating system.

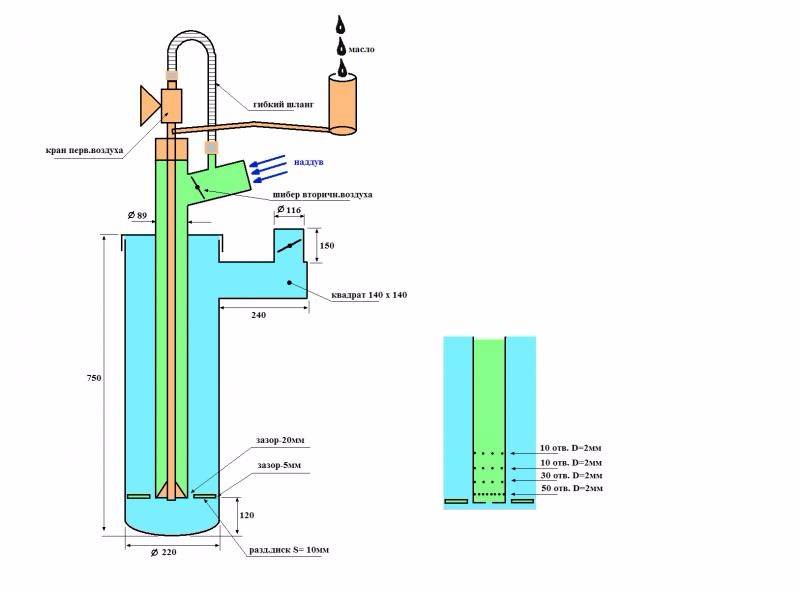

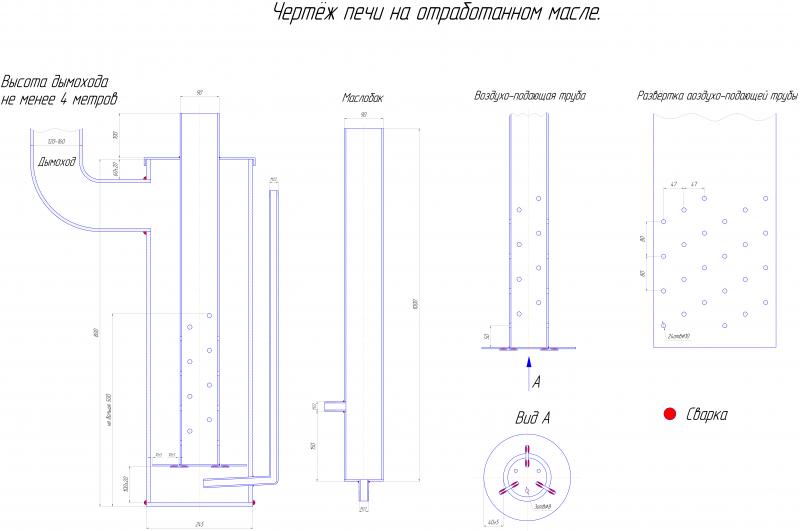

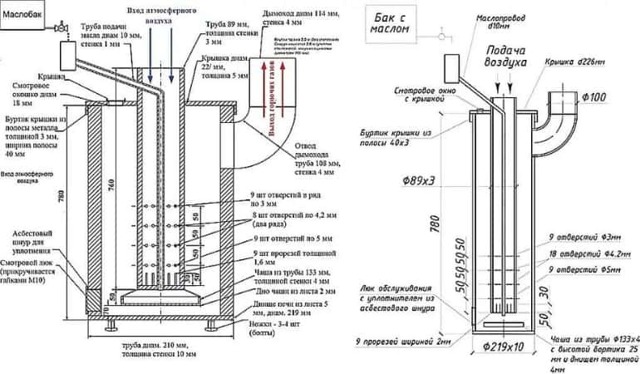

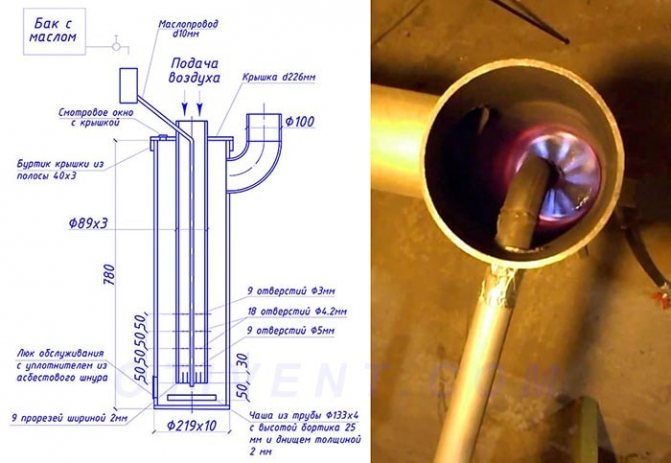

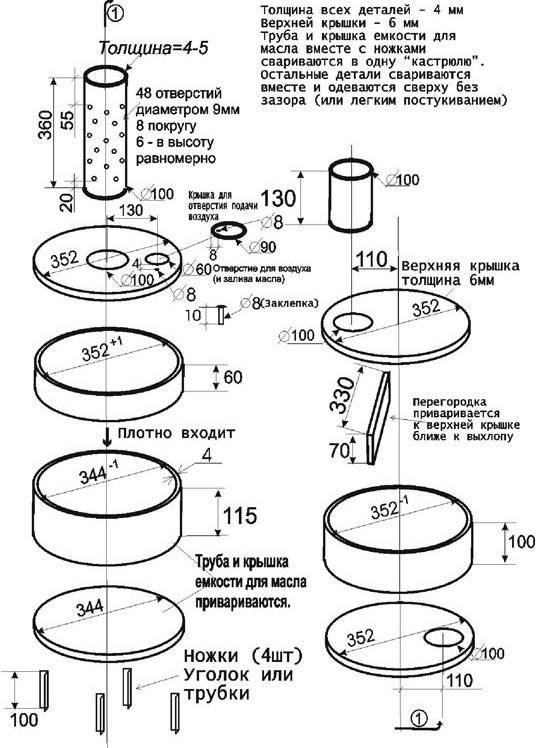

Waste oil furnace manufacturing technology

Below are drawings of the most common mining furnace. It is made from the remains of a pipe Ø352 mm, sheet steel 4 mm and 6 mm, you will also need trimming a thick-walled pipe Ø100 mm and a corner for legs.

Its dimensions will allow heating a room with a standard ceiling height of up to 80 m2, with a larger area, the size of the furnace and the diameter of the chimney pipe should be increased.

Required tool:

- welding machine;

- grinder with a cutting wheel;

- grinding wheel for cleaning seams;

- drill or drilling machine, drills;

- roulette.

You also need a solvent and silicone heat-resistant paint - this is usually sold in spray cans and is used to paint the highly heated surfaces of furnaces.

Do-it-yourself manufacturing sequence:

- Prepare blanks according to drawings. All parts are cut out from the material indicated in the drawing and the cut points are cleaned to eliminate burrs.

- The parts of the lower tank are connected by welding: a body made of a pipe Ø344 mm h = 115 mm, a bottom made of sheet metal 4 mm, as well as legs from a corner of arbitrary size. Instead of a corner, you can use trimmings of an inch pipe.

- In a pipe section Ø100 mm h = 360 mm, a drill is used to perforate according to a sketch - 48 holes with a diameter of 9 mm.

- The parts of the lower tank cover are connected by welding: a billet from a pipe Ø352 mm h = 60 mm, a cover made of sheet steel 4 mm with two holes and a perforated pipe.

- The damper for the air supply hole on the lid of the lower tank is attached to the rivet.

- The parts of the upper chamber are connected by welding: a workpiece from a pipe Ø352 mm h = 100 mm and a bottom made of sheet steel 4 mm with a hole for a perforated pipe.

- A chimney Ø100 mm h = 130 mm is welded to the cover of the upper chamber, on the inside of the cover - a partition made of sheet steel 4 mm with dimensions of 70x330 mm. The baffle is designed to cut off the flame and increase the heating efficiency of the upper chamber. It should be located closer to the smoke hole.

- Weld the upper chamber and the lid with the chimney.

- The upper chamber is welded to the top of the perforated pipe; to increase the rigidity of the structure, you can make rod ties between the lower tank cover and the upper chamber.

- The upper part of the furnace is put on the lower tension tank.

- To extend the service life, the furnace is coated with organosilicon paint, having previously cleaned the welds from scale, and the metal from rust with a solvent.

- Connect the stove to the chimney. Its height should be at least 4 meters to improve traction. Since the chimney will often have to be cleaned of soot, you need to make it as straight as possible, without bends.

A similar furnace can be made from sheet metal, in which case its chambers will be square. Detailed technology is shown in the video.

Making a furnace for testing: video

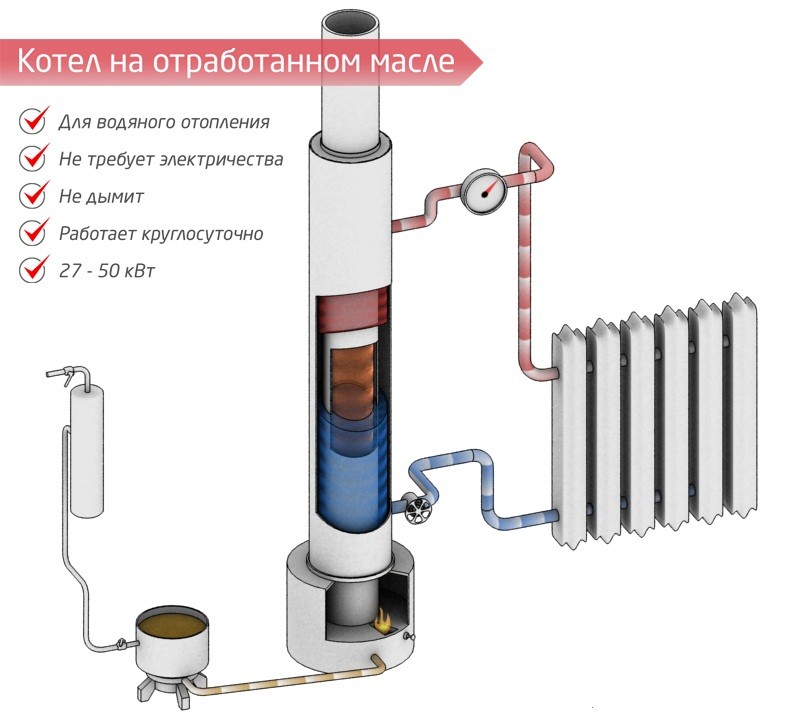

How to connect a water circuit to the furnace for working out

The water circuit is connected to the boiler installed on the upper chamber. It can be welded directly onto the surface of the stove, but it is safer to make a separate tank: if the bottom of the tank burns out, water will enter the combustion chamber, which can cause a splash of burning oil and a sharp ignition.

The tank can be of any shape and height, the main condition is a snug fit to the upper chamber and chimney for more efficient heating. Two fittings are cut into the walls of the tank: in the upper part for heated water, in the lower part for the cooled return.

At the outlet of the tank, a thermometer and a pressure gauge are installed. A circulation pump and an expansion tank are placed on the return pipe in the immediate vicinity of the boiler.

How Gecko Boilers Work

To get acquainted with the general principle of operation, it is necessary to familiarize yourself with the stages of converting fuel into thermal energy.

- Through the fuel line (9), the used oil enters the evaporator (11).

- Under the influence of temperature, the above-described transformation into a gas occurs.

- Since it is lighter than air, the vapors rise along the vortex device (14).

- Passing through the holes in this element, they ignite in the afterburner.

- The air blower enriches the mixture with oxygen, which increases the heat output.

- The transfer of energy to the coolant (water, antifreeze) occurs through the walls of the heat exchanger. They are in the afterburner.

To remove carbon monoxide, a gas duct is provided in the design. It is also designed to create thrust that circulates air flows inside the combustion chamber.

Making such a design with your own hands is not problematic. The main thing is to choose the right material for manufacturing and act in accordance with the developed technological scheme, taking into account the specifics of the drawing.

Waste oil heating for a private house

Waste oil for heating was originally used together with diesel fuel. This method has proven to be effective and economical.Then they decided to reduce the cost of the product even more and removed the diesel fuel from the composition. Waste oil is similar in its characteristics to diesel fuel, but it costs an order of magnitude cheaper.

Photo 1. This is what used oil looks like, which is used for heating. Dark brown liquid.

Features of use

Mining as fuel is used in a special boiler or in a furnace. Only this guarantees complete combustion of the product without the formation of a fumes. The refurbishment of the heating system or the installation of a new circuit pays off in the first year of using the product.

Types of fuel. How much heat is produced by burning one liter?

Burning one liter of such fuel gives 10-11 kW of heat in 60 minutes. The pre-treated product has more power. Burning it gives 25% more heat.

Types of used oils:

- engine oils and lubricants used in various modes of transport;

- industrial products.

Pros and cons

Fuel advantages:

- Economic benefit. Consumers save money on fuel, but businesses benefit the most. The implementation of mining eliminates the costs of storage, transportation and disposal of the product.

- Conservation of energy resources. Refusing to use gas and electricity for heating prevents the depletion of sources.

- Environmental Protection. Due to the high cost of disposal, business and vehicle owners disposed of oil by dumping it into water bodies or into the ground. This had a negative impact on the environment. With the beginning of the use of mining as a fuel, such manipulations ceased.

Fuel cons:

- represents a health hazard if the product does not burn completely;

- large dimensions of the chimney - 5 m in length;

- the difficulty of ignition;

- the plasma bowl and chimney quickly become clogged;

- the operation of the boiler leads to the combustion of oxygen and the evaporation of moisture from the air.

How is oil processed?

Mining is obtained by burning any type of oil, but oil refining from internal combustion engines is usually used for space heating.

Also from industrial mechanisms, compressors and power equipment.

What does not apply to such fuel?

List of products not related to mining:

- processed oils of vegetable and animal origin, which are used for domestic purposes;

- solid waste with mining;

- solvents;

- products that are not subject to the same processing as mining;

- oil fuel of natural origin from the spill;

- other unused petroleum products.

Working out boiler: principle of operation

The calorific value of used engine oil is higher than that of pure diesel fuel

This nuance must be taken into account if you are making a heating boiler for testing on your own

The principle of operation of the boiler is quite simple. The oil pump sends the waste oil through a hose straight to the evaporation chamber. This element of the boiler is made of durable metal that can withstand high temperatures. At the same time, at the very bottom, the oil evaporates. Oil vapors mix with the air inside and heat up the water jacket. This mixture enters the combustion chamber, where it burns completely and heats the coolant. The products of combustion themselves enter the chimney and are brought out.

Operating rules:

- Do not leave working devices unattended for a long time;

- In addition to oil, do not burn other materials in the boiler - this can damage the unit;

- Make sure that water does not get inside the boiler, especially on its hot areas;

- Do not cover the burner;

- Do not add oil to the boiler during operation.

Experts warn that the constant operation of the boiler at full power can lead to malfunction of the unit or its rapid failure.

Where to apply and how to refine?

Due to a significant list of disadvantages, waste oil heaters are rarely used in housing. Their use is possible only in utility rooms and in the case of a trouble-free supply and exhaust ventilation. But they are widely used for heating technical and industrial areas.

Motorists use them as heaters for garages, and then in the case of a good exhaust device. Gardeners install in greenhouses, livestock breeders - in outbuildings. At car washes, at service stations, in warehouses where there are no combustible materials, there is always a place for them.

If the operation of the boiler in mining for heating residential premises causes concern, then in the conditions of a garage, service stations and car washes this model is always in demand

Often the basic designs are subject to various modifications. For example, for these purposes, a water jacket or water heating coils are used. Such equipment is included in the composition of water heating. Furnaces of this type must operate using automation, otherwise their functioning will have to be vigilantly monitored.

Disadvantages of mining boilers

The main disadvantage of such a device is that its reaction to shutting off the air supply to the furnace will not be instantaneous. Consequently, the combustion process will not stop immediately, but after a certain period of time, during which the heating of the coolant will continue. When the flame finally goes out, it will need to be rekindled. This is done manually, unless the design provides for any other approach.

Another drawback of the mining boiler is its contamination compared to other heating appliances. This is primarily due to the fuel used. If the structure is assembled correctly, then an unpleasant odor will not come from it. If the technology is violated, such a smell will penetrate into the room to one degree or another.

Another, no less significant, disadvantage of such boilers in comparison with other designs is the need to purify the fuel from various solid impurities, which may include pieces of metal or metal shavings. If you do not establish a filtration system, then the device will fail after a certain time, and it will be very problematic to return it to working condition.

Kinds

Extraction boilers can heat the air directly. Such systems are characterized by impressive performance and can warm up the air for a long time even in large houses. The peculiarity is manifested in the fact that the fuel container is most often placed on the floor, and the heating block is attached to the wall or even to the ceiling. In addition to this version, there are oil boilers with water circuit or even with a couple of such contours.A single-circuit apparatus is capable of supplying hot water only to the heating system, if boilers and distribution equipment are not used.

Industrial models of oil boilers are often equipped with automatic control units.

All such modifications are not air, but water, and various tasks fall on automation:

-

air temperature monitoring;

-

checking the heating of the coolant;

-

checking the pressure in the heating circuit;

-

error signaling.

Precautionary measures

The main question of interest to the consumer is how safe heating is by mining. The complaints that arise about the unpleasant smell from the combustion of oil indicate non-compliance with the rules for operating the heating device.

It is important to make the right choice of mining. It should not contain substances that can easily ignite, such as gasoline or acetone, and there should also be no third-party additives. They are the ones that pollute the burner section.

When heating, the following safety precautions must be observed:

It is they who pollute the department with the burner. When heating, the following safety precautions must be observed:

- The cross section of the pipe must be at least 10 cm. The best option would be to use a sandwich chimney. A small amount of soot forms on its surface.

- Do not store fuel tanks near the machine.

- Oil containers must be hermetically sealed. If water gets into the fuel, splashing will occur during the operation of the burner, and this increases the risk of fire.

- The temperature effect on a waste oil boiler is much greater than on solid fuel boilers. Therefore, the wall thickness of the heat exchanger and combustion chamber (2 mm) must be observed.

To avoid smoke and gas contamination of the boiler room, the presence of a forced air circulation system is necessary. It is recommended to observe air exchange with the following parameters: 180 cubic meters per hour per 1 sq. m. Only if these requirements are met for heating a country house, safe operation of the heating system is possible.

Self-made heating is quite economical and worthy of competing with other types of heating. Its specificity lies precisely in the used oil. Such a system is good if there are no other options or there is an adequate supply of fuel. The main scope of such structures is industrial enterprises, where there is a large amount of waste oil.

Types of aggregates

If you need to organize heating in the house, it is better to purchase a boiler in a standard version. Such designs currently have sufficient autonomy and safety. Comfort and ease of use is also due to the fact that there are no specific odors emitted by the fuel.

The boiler works in automatic mode. This makes it possible to use it without special knowledge and experience. The process of burning oil is arranged in such a way that it burns completely without being accompanied by fumes and smell of gas.

Heating structures

Such units should not be installed in residential premises. Usually, special extensions are used for this. Although the boilers are equipped with modern filters, the smell of machine oil can be smelled during operation.

A heating unit is built into the design of the device, consisting of a water pipe and a pump, which operates not only from the mains voltage, but also from the energy of the device itself. Thanks to it, water circulates evenly in the system.

The principle of operation of such devices is based on the combustion of a mixture of fuel and air supplied by a compressor fan. The strength of the fire is regulated using a conventional hose, at the end of which a valve is installed.

Water heaters

The function of these devices is to heat water. They can be called ordinary boilers. They have a platform principle of operation: a tank with water is installed on a heated plane. A pump built into the outlet serves to correct and equalize the pressure inside the system.

This is interesting: the principle of operation of the boiler.

It should be noted that it will be quite difficult to adjust the constant temperature of the liquid. Inside the tank it can reach +80…100°С. Often, in such heating systems, containers for a coolant with a volume of 60–140 liters are used. The process during which the water is heated lasts about 2 hours, which is almost half as much as in the boiler.

At the hot water boiler boiler two modes of operation. When fast, cold water is heated in the shortest possible time (the automatic switch is in the “wick” mode). In this case, a lot of fuel is consumed, and if the tank is small, carbon monoxide emissions are likely.

Appliances

Another subspecies of devices of this kind are household boilers. These are multifunctional devices. More often, such designs are used in houses that do not have a water heating circuit.They are endowed with a fairly good gas cleaning system that eliminates soot and smoke during operation of the device.

Fuel consumption is very low compared to previous types. Mobility is the main advantage of such a device. It can be transported even in the trunk of a car and used on trips, for example, to nature. In this case, it performs the functions of a stove for cooking, as well as a heater. The main thing is to provide a fireproof platform necessary for installation or a recess in the ground by 30–40 cm.

How exactly does oil evaporate?

There are 2 main ways of burning fuel and evaporating oil:

- Ignition of a liquid substance. This releases steam. For its afterburning, a special chamber is used.

- Pouring over a hot surface. A white-hot "white-hot" bowl made of metal is used. Mining is dripping onto its surface. When the fuel comes into contact with hot metal, it evaporates. The "cooperation" of air and steam is called "diffusion". When air enters the tank, the steam flares up and ignites. The result of this is the generation of heat.

Fuel consumption is quite economical. From ½ to 1 liter is used per hour.

European boilers, despite the excellent efficiency, do not allow such a principle of operation to be possible. This is true only in the case of boilers of a domestic manufacturer.

The easiest way is to soak the wick with gasoline, set fire to it and throw it into the tank. When the bowl warms up well, you can start serving oil.

It is important that the oil is supplied evenly. It is recommended to use a drip approach. To ensure the desired level of extraction filtration, an automotive filter should be used.

It is put on a tube, one of the ends of which must be lowered into a container with working out

An automotive filter should be used to provide the desired level of extraction filtration. It is put on a tube, one of the ends of which must be lowered into a container with mining.

The filter should be replaced at least once every 30 days. If the fuel cannot be called clean, then it is recommended to do this 1 time / 15 days.

The amount of oil dripping onto the bowl should be optimal. The most important thing is to ensure that it burns evenly. It shouldn't choke.

If the owner of the boiler has decided to change the fuel, the frequency of drops must be adjusted each time.

The installation should also be given maximum protection. Do not allow the oil to boil - this can lead to unpredictable consequences. The same applies to fuel overflow.

If the level of fuel in the tank is higher than in the stove itself, a fire may occur. The only way to deal with it is with a fire extinguisher.

Do not pour oil into the boiler when the unit is running - this can be very dangerous. It is best to mount an additional container. It will be possible to place the main supply of fuel in it.