- Popular furnace options for factory assembly, their characteristics

- Do-it-yourself stove made of sheet metal and pipes

- How to weld a simple oven

- Compliance with safety regulations when operating home-made stoves

- The principle of operation and the advantages of homemade boilers

- Ease of operation and installation

- Fire safety measures

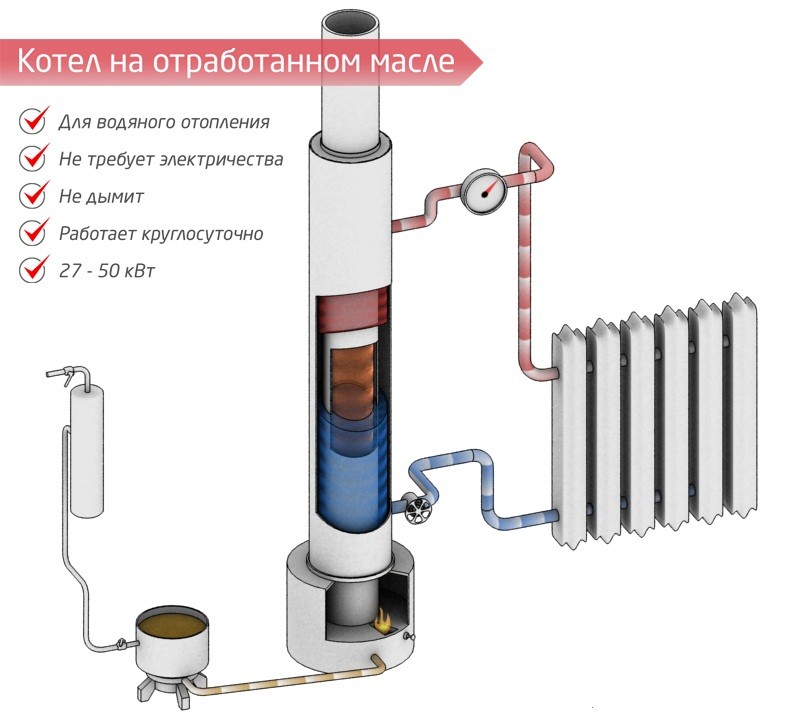

- What is a waste oil boiler

- Assembly and commissioning

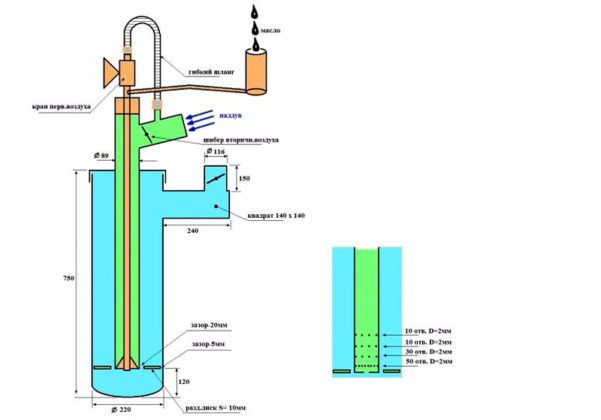

- How to make a waste oil boiler with your own hands

- Tools and materials

- Manufacturing process

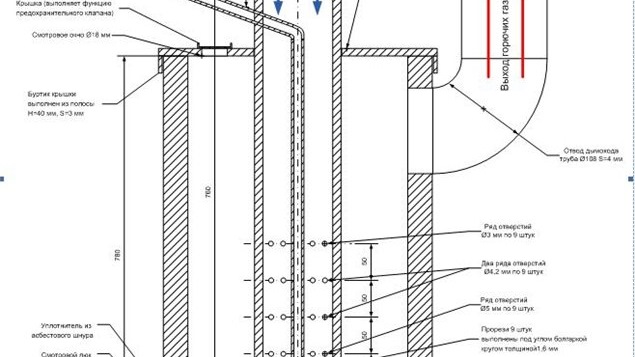

- Construction of a more powerful boiler

- Overview of Russian-made waste oil boilers

- Expensive domestic waste oil boilers

Popular furnace options for factory assembly, their characteristics

The Teplamos NT-612 stove is often chosen as the device used for garage heating. The power of such drip fanless heater can vary in the range of 5-15 kW. Fuel consumption is 0.5-1.5 l/h.

This oven working out for garage refers to devices of a closed type. It is equipped with a chimney, an air supply pipe and a built-in tank for 8 liters of fuel. The combustion of fuel takes place in the inner chamber.The operation of the device begins with the electric heating of the plasma bowl. When the required temperature is reached, fuel is supplied and air is forced into the combustion chamber. The average cost of the device is 30 thousand rubles.

Another popular model is the Zhar-25 (MS-25) oven. This device can work not only on waste oil, but also on diesel fuel. The device operates from the mains, which feeds the internal fan. The thermal power of the furnace varies from 25 to 50 kW. She calculated for space heating up to 500 sq. m. The maximum fuel consumption is 4.5 l / h. The device is large. Its weight reaches 130 kg. This stove needs to be equipped with a good chimney. You can buy it for 45 thousand rubles.

The mining furnace is equipped with a chimney, an air supply pipe and a built-in tank

Do-it-yourself stove made of sheet metal and pipes

Depending on the type of device, the structure can be created from pipes of different diameters or from iron sheets. To work, you will need the following tools:

- grinder with cutting and grinding wheel;

- sheet metal and pipes;

- welding machine and electrodes;

- metal corners;

- paint for metal that can withstand high temperatures.

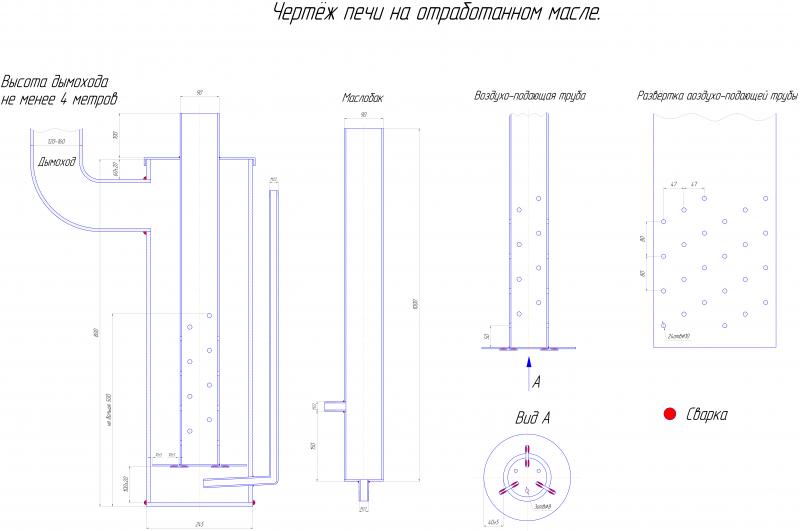

Before making a furnace for testing, a detailed drawing of the apparatus is performed. You can create it yourself or use ready-made options that are easy to find on sites on the Internet.

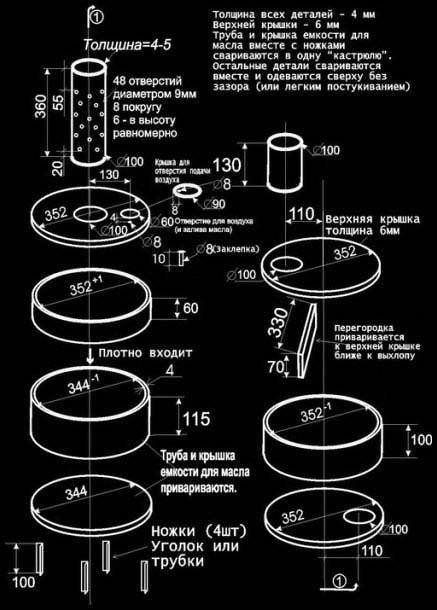

The first stage is the manufacture of the lower part of the chamber, which is connected to the fuel tank. It looks like a rounded or straight tank with a lid, where two pipes are located. The first is used for oil supply, and the second - to strengthen the pipe, which goes into the middle part of the apparatus. Elements for the tank are cut out by a grinder and connected according to the drawing.

Depending on the type of device, the structure can be created from pipes of different diameters or from iron sheets.

The bottom and metal corners are welded to the walls of the tank, which act as the legs of the structure. To create a cover, a sheet of metal is taken in which holes are made. The first, with a diameter of 100 mm, is located in the center; the second, 60 mm in size, is closer to the edge. The lid should be removable, which will facilitate the cleaning of the stove.

For oxygen supply, a pipe about 37 cm long and 100 mm in diameter is used. In it, along the entire length of the element, holes are made that are necessary for the supply of oxygen. The pipe is welded perpendicular to the cover at the bottom of the apparatus. An air damper is fixed on it, which will be fastened with rivets or bolts. The hole under the damper should be 6 cm in size. It is designed to supply oil and ignite fuel.

The design of the upper tank is carried out by analogy with the device of the lower tank according to the drawing of a do-it-yourself waste oil furnace. The walls of the product must have a thickness of at least 350 mm. A bottom with a diameter of 10 cm is cut out in the bottom of the tank, which must be placed closer to the edge. A small piece of pipe with a diameter of 11 cm is welded to the bottom of the hole. This is necessary to connect the element to the gas combustion tank.

Before making a furnace for testing, a detailed drawing of the apparatus is performed

Since the top cover of the furnace in a pressurized mining high temperature, for its manufacture, a metal sheet with a thickness of at least 6 mm should be used. An opening is made in the lid for the chimney pipe, which must coincide with the opening at the bottom of the container. Between these elements, a partition made of a dense metal sheet is mounted, located near the smoke hole. A pipe is attached to the top of the cover, which connects to the chimney part. In detail, the process of self-manufacturing can be seen on the video of the furnace for testing.

How to weld a simple oven

It makes no sense to explain how to make the standard and most common design shown below in the assembly drawing. Firstly, the scheme is very clear, and secondly, there is no shortage of information of this kind.

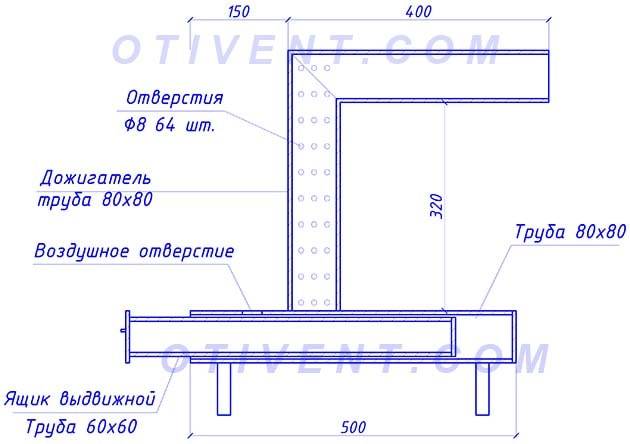

Let's move on to a more complex version of the heater with an afterburner bent at 90° (the angle of rotation can be made larger, but not sharper). The purpose of the event is simple - to organize the removal of heat from hot flue gases, and not immediately throw them out into the street. The second difference is a drawer with oil instead of a traditional closed container, which is inconvenient to clean. The design of the furnace with dimensions is shown in the drawing.

The dimensions of the unit are arbitrary and may change when selecting pipes of a different section

A step-by-step instruction for assembling a furnace for burning mining looks like this:

- Cut blanks for the body, drawer and afterburner. For the latter, the pipes must be cut at an angle of 45 °.

- In a profile of a smaller section, cut out one wall with a grinder, and weld plugs on the sides to make an open container. Attach a handle to the front of the drawer.

- Weld the structure as shown in the drawing, drill an air hole on top of the fuel chamber and perforate your bent pipe. The heater is ready.

Here, for better heat dissipation, the master attached convection fins from a 40 mm steel strip

A few words about how to choose the number and diameter of afterburner holes. In our example, its cross section is 80 x 80 = 6400 mm², for the calculation you need to take half - 3200 mm². If you use an 8 mm drill, then the area of \u200b\u200beach hole will be 50 mm². We divide 3200 by 50 and we get 64 pieces that need to be drilled during the assembly process, when adjusted, their number will increase.

One of the simplest ways to extract heat is to connect the stove to a horizontal pipe 3-4 m long, which runs at an angle along the wall of the room. Make sure that there are no wooden shelves or fuel cans above it and the heater. It is better to protect the walls near the stove with sheet iron.

Now it remains to ignite, warm up and adjust the furnace. Your task is to achieve minimal black smoke emissions into the street, indicating a lack of combustion air. It is necessary to drill 3-5 additional holes in the afterburner and check the operation of the unit again until the emission becomes as transparent as possible.

Compliance with safety regulations when operating home-made stoves

Before connecting the boiler, it is necessary to consider not only the method of installation and placement of additional devices and shut-off and control valves, but also the method of bringing the chimney out.If it passes through a ceiling built using flammable materials, then a metal case twice as large in diameter is installed in it. The free space between the pipes is filled with asbestos or other non-combustible material with good thermal insulation properties.

For this purpose, a centrifugal pump and a membrane-type expansion tank are installed on the return line just before entering the boiler. It is necessary so that the system does not depressurize with increasing temperature and pressure. A pressure line is connected to the upper pipe, and to regulate the temperature of consumers, a thermostatic head or other control device (three-way valve, valve to reduce the cross section of the supply pipe, etc.) is installed in front of each radiator. To remove air pockets, an air vent is installed at the top of the system.

Piping scheme for a waste oil boiler

The piping of the unit working at mining requires taking into account the inertia of this type of equipment. In other words, the change in the temperature of the coolant occurs gradually, so the unit must be equipped with a safety valve. It will allow you to relieve pressure when it rises to a critical level.

When they want to insure themselves in case of a shortage of used oil, an electric one is installed next to a home-made boiler. There are two ways to connect an additional unit - in series or in parallel. The advantage of the first method is that the coolant heated with the help of a flame bowl will flow into an electric boiler, which can be adjusted to a certain response temperature.

Parallel connection implies independent operation of two heating units and is characterized by the absence of these disadvantages. Unfortunately, this method is not without its drawbacks, one of which is the need to install a hydraulic arrow and precisely coordinate the operating mode and supply of the return line.

The quality of automotive waste, as a rule, leaves much to be desired. When using them, carbon deposits can form, which will have to be cleaned off from time to time.

You can see how hot a boiler that uses waste oil as fuel can get: you can’t dry your socks near it, put a kettle of water on it, or lay out dry boards

In addition, the following safety precautions must be observed.

- The diameter of the chimney should not be less than 10 cm. A sandwich chimney is preferable: less soot is deposited on its surface.

- Combustible substances, including the fuel tank, must not be near the boiler. Only at a safe distance.

- Do not allow water or other liquids to enter the hot oil chamber. The consequences of such a leak are presented in the video in the final part of this article.

- During the operation of the boiler on waste oil, the heating temperatures significantly exceed those achieved during the combustion of solid fuel. Therefore, thick-walled materials are chosen for this design.

- It is advisable to equip the boiler room with a forced air circulation system.

The principle of operation and the advantages of homemade boilers

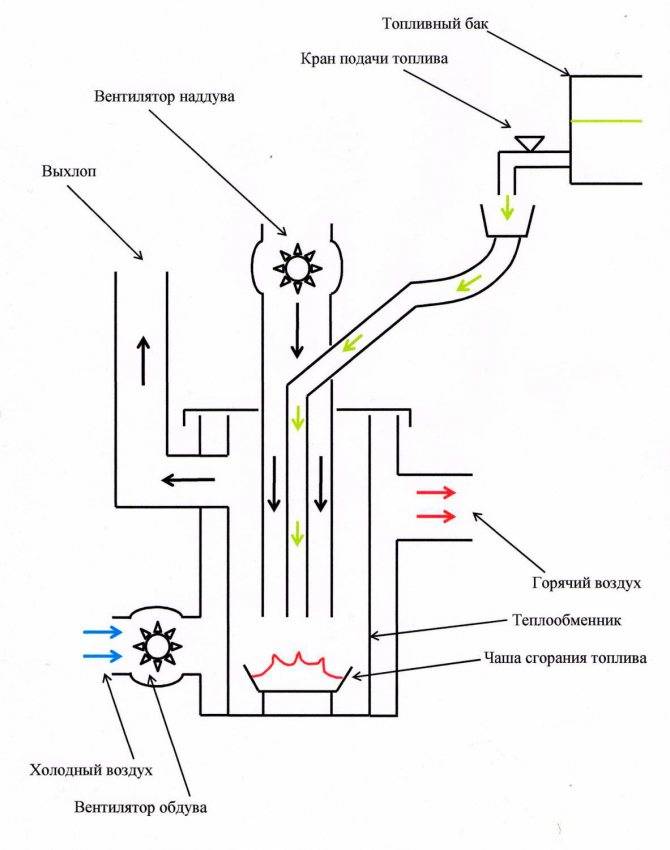

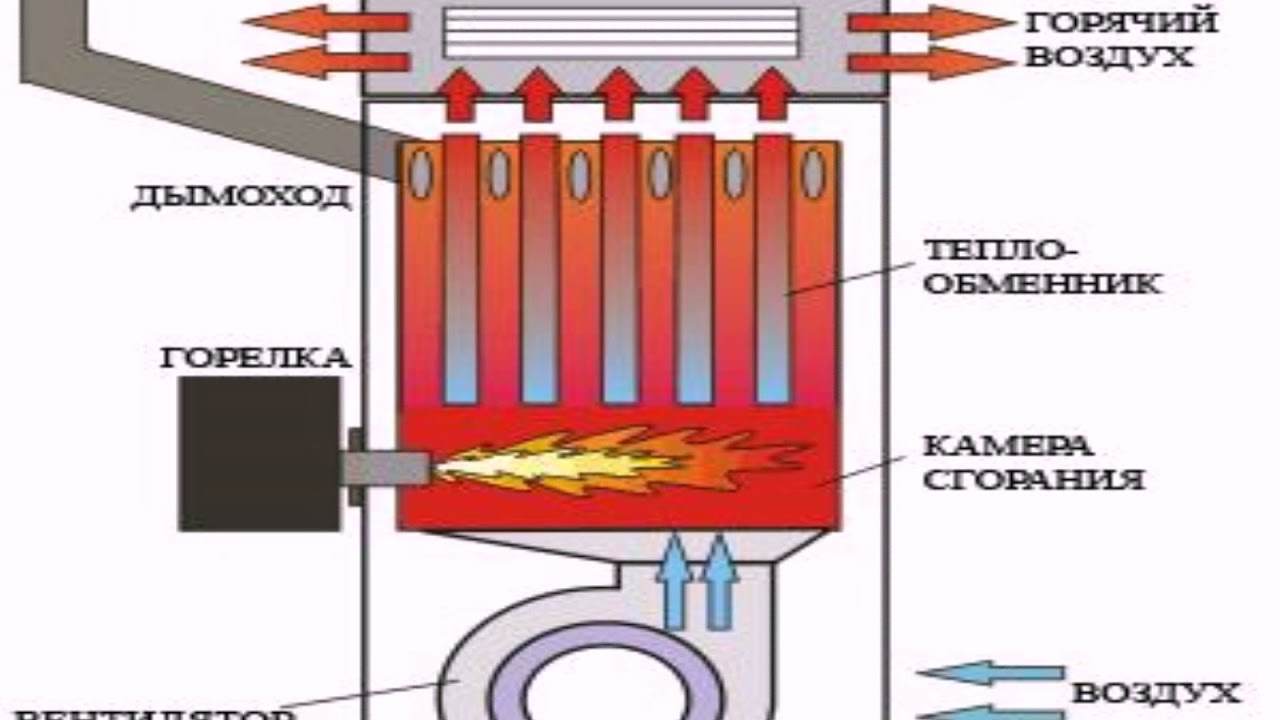

To heat a room or an entire building using the thermal energy of burning old oils, boilers of this type operate on a principle that is vaguely reminiscent of pyrolysis.The fuel at the bottom of the chamber is first heated until combustible vapors appear. They rise up, mix with air and burn, releasing heat. It is transferred directly to the water jacket of the unit through the walls of the chamber. To understand the process, a diagram of a waste oil boiler is shown below.

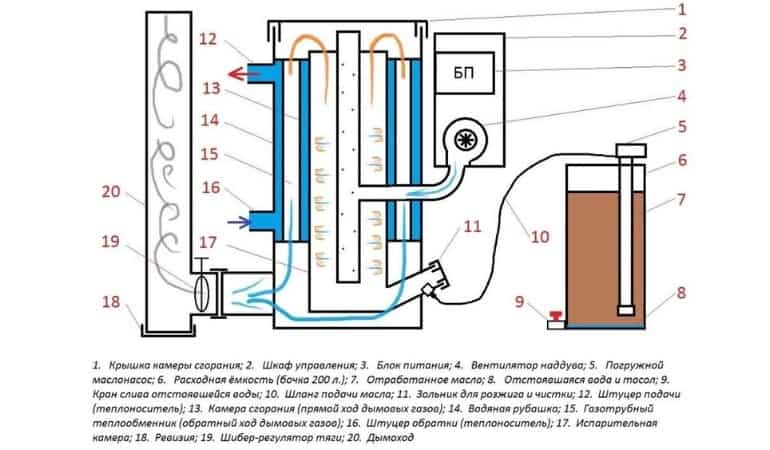

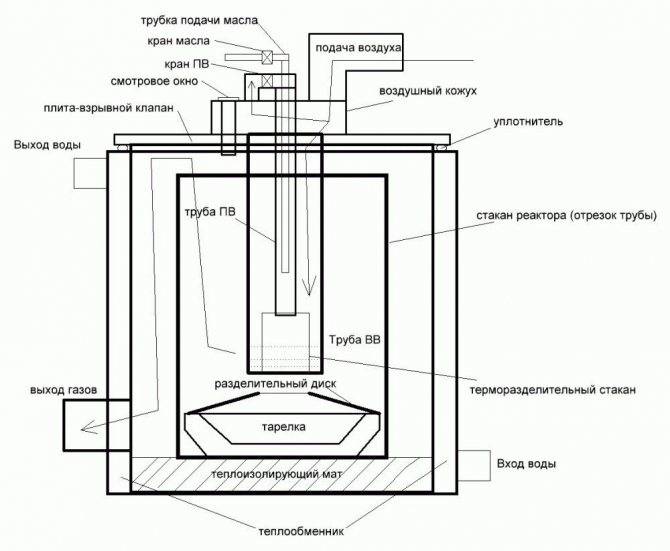

Boiler device

1 - top cover; 2 - control cabinet; 3 - power supply; 4 - fan; 5 - pump; 6 – fuel tank; 7 - oil processing; 8 - sump; 9 - tap for emptying; 10 - oil pipeline; 11 - door for ignition and maintenance; 12, 16 - respectively, the supply and return pipelines, the heating system is connected to them; 13 - pipe for supplying air to the combustion zone; 14 - water jacket; 15 - flame tubes; 17 - combustion chamber; 18 - condensate collector; 19 - damper - draft regulator; 20 - chimney.

To understand whether it is worth doing this business, or is it better to just buy a factory-made boiler, you need to analyze what advantages home-made units have. They are pretty significant:

- Low cost. Even if you entrust the work to experienced craftsmen, pay for it and buy all the materials, then a home-made boiler for testing will cost you half as much as a factory one.

- You can burn any type of used oils, and if necessary, diesel fuel.

- There is always the possibility of improving the design or supplementing it with automation tools.

- Since the use of waste oil as fuel involves a small amount of ash after combustion, maintenance of the heat source will not take much time.

- A well-assembled unit with a set of automation during operation does not require constant attention and frequent visits to the furnace, you just need to fill the tank with fuel in time.

Among the shortcomings, some inertia can be distinguished, it lies in the fact that after the air supply to the combustion zone is stopped, the process does not stop immediately, this requires some time, during which the coolant continues to warm up. Further, after the flame has faded, the mining boilers will need to be ignited manually, unless a special device is provided for this.

Home-made boilers for heating on the development of an improved design are endowed with the “idle” function, when very little air is supplied to the chamber. This is done in order to maintain a small flame when intensive heating of the coolant is not required. After it cools down, the air supply resumes and the heat generator enters the operating mode.

When you decide to make heating work off, you need to understand that the furnace will not be as clean as when using gas or electricity. This is an inevitable attribute of the use of spent fuel, as is the presence of a specific smell. In addition, it will be necessary to organize oil filtration from metal chips and other solid inclusions so that they do not clog the fuel path.

Ease of operation and installation

The use of this type of heating equipment is available even to those who have a remote idea of handling such devices. The operation of the boiler is characterized by a high degree of automatism, which is one of the most important properties of modern equipment.

Easy operation is ensured by the simple design of the boiler. It is so elementary that some even make such equipment with their own hands. We want to warn you against such a step, as it can cause disastrous consequences. Boilers produced by specialized enterprises are tested before reaching a potential user. Homemade equipment does not always pass such a test.

Fire safety measures

It should be understood that such a home-made design must be made clearly in accordance with established fire safety standards.

To protect the premises from fire, we also recommend that you adhere to the following rules:

- The chimney diameter must be at least 100 mm. Ideally, use sandwich pipes, on the surface of which a minimum amount of soot is formed.

- In the immediate vicinity of the tanks, it is forbidden to store flammable objects (fuel tanks).

- All joints must be sealed.

- The thickness of the walls of the tanks where the combustion of fuel takes place must be at least 4 mm.

- To ensure the flow of fresh air into the room and to avoid smoke, it is necessary to equip the boiler room with a forced circulation system. The rate of air exchange per 1 cubic meter of area is 180 m3/hour.

What is a waste oil boiler

Today, heating equipment that operates in development is very popular. This is due to a number of distinctive advantages of the device.First of all, this is the low cost of installation and the availability of fuel, which can be bought for a nominal fee. Heating at mining does not require the use of resources in the form of electricity and gas, which makes it economically viable.

Despite its numerous advantages, the mining boiler also has its drawbacks. Pay attention! The recycling of waste products in full has a beneficial effect on the environment, excluding the disposal of oil and its ingress onto the ground and into water bodies.

When the boiler is properly adjusted, the waste oil is burned completely, so no toxic combustion products are formed. The device consists of a minimum number of parts, which can be seen on the boiler diagrams. This increases the reliability and durability of the structure. It doesn't take long to heat up the boiler. Forced convection contributes to a rapid increase in the temperature in the room.

Despite its numerous advantages, the mining boiler also has disadvantages. During the operation of the device, moisture evaporates from the air and oxygen is burned, which negatively affects human health. Therefore, the boiler must be located in a non-residential area with a good ventilation system. Workout devices get dirty quickly. This is especially true for the plasma bowl and chimney.

For such a boiler, different versions of waste oil can be used, which is characterized by an abundance of various impurities. Therefore, in order to ensure a long period of operation of the device, in the place where oil is supplied to the boiler, a filter should be installed, which must be changed as it gets dirty.

The waste oil boiler should be located in a non-residential area with a good ventilation system.

The waste oil boiler should be located in a non-residential area with a good ventilation system.

Assembly and commissioning

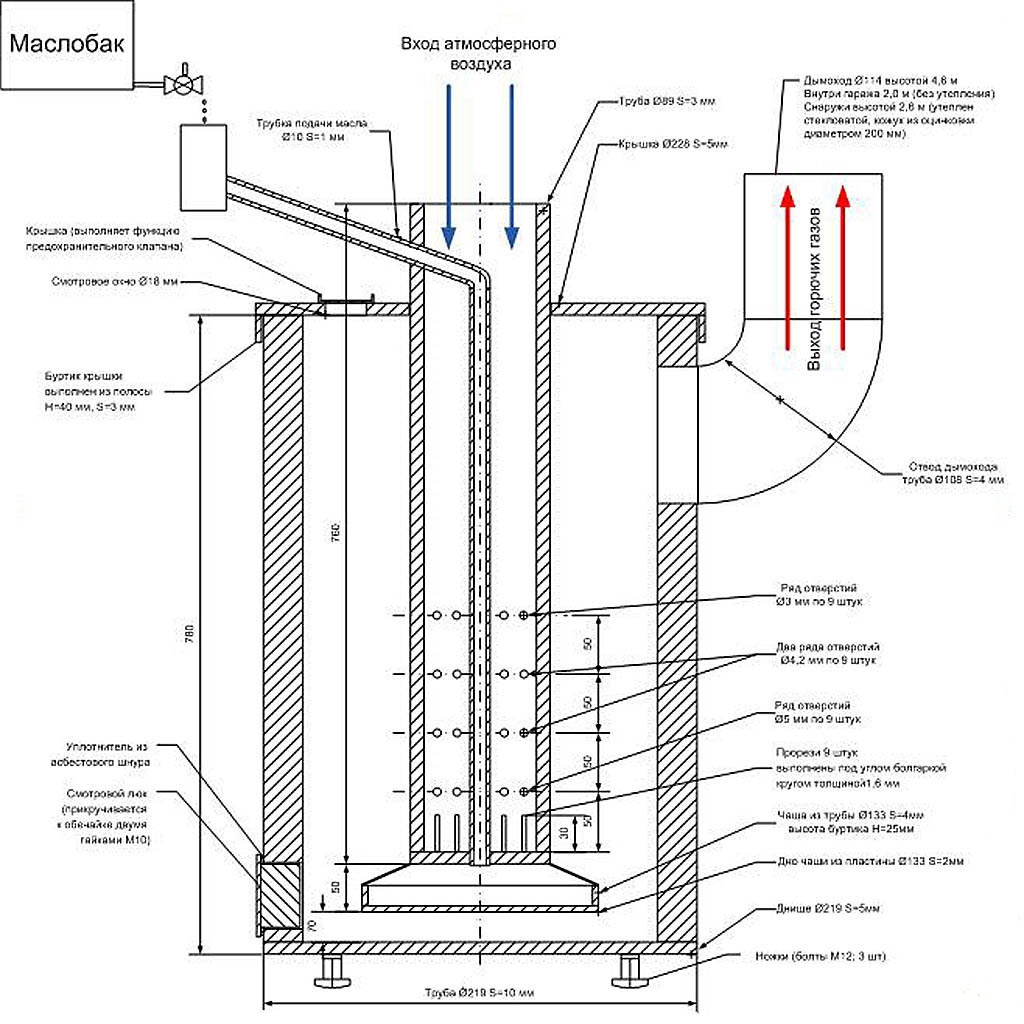

The bodies of such boilers consist of two pipes inserted into each other, the radius of which should differ from each other by 30–40 mm. The outer part must be equipped with 2 outlets - for direct and reverse supply of coolant. And inside a smaller diameter pipe, a combustion chamber is arranged. The mining tank is located next to the boiler - a pump is immersed in it to supply fuel to the pyrolysis chamber.

The further installation process includes the following steps:

- Placement at the bottom of another oil tank, with openings in it for gas vapor to enter the secondary combustion chamber;

- Conducting contacts for electric ignition of the burner through the furnace door;

- Insertion of a fitting, due to which the formation of a gas-air mixture, into the wall of the chamber;

- Creation of a chimney with a slide damper for the removal of combustion products, which the scheme provides;

- Placement of a gas outlet tube lowered to the level of the bowl with oil;

- Installation of a circulation pump on the return line, and a safety group on the straight line.

Before starting the operation of the equipment, the degree of sealing of the seams is checked by filling the appropriate containers with oil and water. The first launch is recommended to be carried out by pouring only a 10 mm layer of oil purified from mechanical impurities with the addition of 100 ml of kerosene. The working off is set on fire with the help of a wick soaked in the ignition fluid, which is lowered to the bottom of the container.

How to make a waste oil boiler with your own hands

The simplicity of the design of such heaters allows you to make them yourself.In this case, it is necessary to have locksmith and welding skills.

Tools and materials

To make a boiler with your own hands, the following devices are required:

- Bulgarian;

- welding machine;

- a hammer.

To make a waste oil boiler with your own hands, do not forget the grinder

As a material for the heating structure, you must purchase:

- refractory asbestos cloth;

- heat-resistant sealant;

- steel sheet 4 mm thick;

- metal pipe with a cross section of 20 and 50 centimeters;

- compressor;

- ventilation pipe;

- drives;

- bolts;

- steel adapters;

- half-inch corners;

- tees;

- reinforcement with a cross section of 8 millimeters;

- pump;

- expansion tank.

The body of the boiler for heating small rooms can be made from a pipe; for a device with a higher power, it is best to use steel sheets.

Manufacturing process

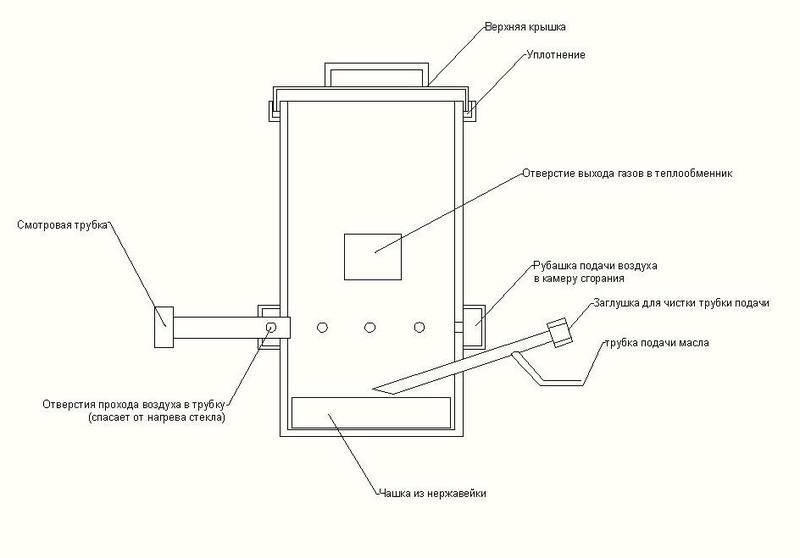

The waste oil unit can be built in any shape. To heat a garage or small agricultural buildings, it is best to make a small boiler out of pipes.

The manufacture of such a heating device consists of the following steps:

- A metal pipe with a large cross section is cut so that its size corresponds to one meter. Two circles corresponding to a diameter of 50 centimeters are prepared from steel.

- The second pipe with a smaller diameter is shortened to 20 centimeters.

- In the prepared round plate, which will serve as a cover, a hole is cut corresponding to the size of the chimney.

- In the second metal circle, intended for the bottom of the structure, an opening is made, to which the end of a pipe of a smaller diameter is joined by welding.

- We cut out a cover for a pipe with a cross section of 20 centimeters.All prepared circles are welded as intended.

- Legs are constructed from reinforcement, which are attached to the bottom of the case.

- Small holes are drilled in the pipe for ventilation. A small container is installed below.

- In the lower part of the case, with the help of a grinder, an opening for the door is cut out.

- A chimney is attached to the top of the structure.

To operate such a simple boiler in mining, you just need to pour oil into the tank from below and set it on fire with a wick. Before this, the new design should be checked for tightness and integrity of all seams.

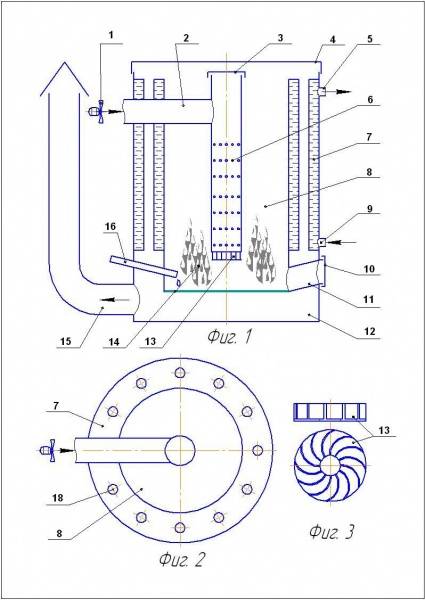

Construction of a more powerful boiler

Two boxes are made of strong sheet steel, which are connected using a perforated pipe. In the design, it is used as an air vent.

The subsequent manufacturing process of the heater has some features:

- A hole is made in the lower body of the boiler to supply oil to the evaporation tank. A damper is fixed opposite this container.

- The box located in the upper part is complemented by a special hole for the chimney pipe.

- The design is equipped with an air compressor, an oil supply pump and a container into which fuel is poured.

Do-it-yourself waste oil boiler

If water heating is required, then an additional circuit is connected, which requires the installation of a burner. You can build it yourself:

- half-inch corners are connected by spurs and tees;

- a fitting is fixed to the oil pipeline using adapters;

- all connections are pre-treated with a sealant;

- a burner cover is cut out of sheet steel, corresponding to the nests on the manufactured boiler;

- two different sizes of steel plates are used to install the burner;

- the inside of the tube adapter is tightly covered with an asbestos sheet, which is fastened with sealant and fixed with wire;

- the burner is inserted into the housing intended for it;

- after that, a smaller plate is fixed in the nest and covered with four layers of asbestos;

- a large plate is mounted as a mounting plate;

- holes are drilled in it for fastenings, and an asbestos sheet is applied on top;

- two prepared plates are connected with bolts.

To prevent the burner from disintegrating during the operation of the boiler, all parts should be carefully and tightly fastened. The device is ignited by a glow plug.

Waste oil boilers are considered economical and practical appliances. They can be purchased at a specialized store or built independently. When using such heating devices, it is necessary to remember the safety rules, which include the mandatory installation of a chimney, the presence of a ventilation system and the proper storage of liquid fuel.

Overview of Russian-made waste oil boilers

Boilers of domestic production using waste oil are manufactured mainly in Voronezh, where the manufacturer has all the necessary documents related to the production of products. There are other small businesses as well. However, most of them do not have a state certificate for the manufacture of heating equipment.

This should be taken into account when buying a boiler.

Powerful boiler Stavpech STV1 is characterized by high efficiency

The double-circuit waste oil boiler Teploterm GMB 30-50 kW is characterized by high quality workmanship every detail. It, thanks to the multifunctional microprocessor, is equipped with an automatic control system. The device has many options that simplify the operation of the device, making it safe. Fuel consumption - 3-5.5 l / hour. The cost of the model is 95 thousand rubles.

A popular model is the Gecko 50 pyrolysis boiler. The device can work not only on mining, but also on crude oil, diesel fuel, fuel oil of all brands, kerosene, fats and various types of oil. The boiler is undemanding to the quality and viscosity of the fuel. There is no need for its pre-filtering and heating.

The design has small dimensions (46x66x95 cm) and a weight of 160 kg. The device is characterized by high efficiency, reliability of all elements and connecting nodes, ease of maintenance and repair. The maximum temperature in the device reaches 95 °C. The fuel consumption is 2-5 l/h. The power consumption is 100 W. The price of a waste oil heating boiler is 108 thousand rubles.

Combined boiler KChM 5K has a cast-iron reliable body

The Stavpech STV1 boiler is characterized by high efficiency. The power of the device is 50 kW. The flow rate of the fuel mixture is 1.5-4.5 l/h. Housing dimensions - 60x100x50 cm. The device is equipped with a reliable modulated burner for a waste oil boiler, which has a high emission rate. The device is equipped with a fuel filter, a pump and a water tank. Various types of oil, diesel fuel and kerosene can be used as fuel. The price of the boiler is 100 thousand rubles.

Combined apparatus KChM 5K has a cast-iron body.It can work not only on mining, but also on gas, as well as on solid fuel. The power of the device is 96 kW. The model differs in high quality of production of details, safety in operation and durability. You can buy a boiler for 180 thousand rubles.

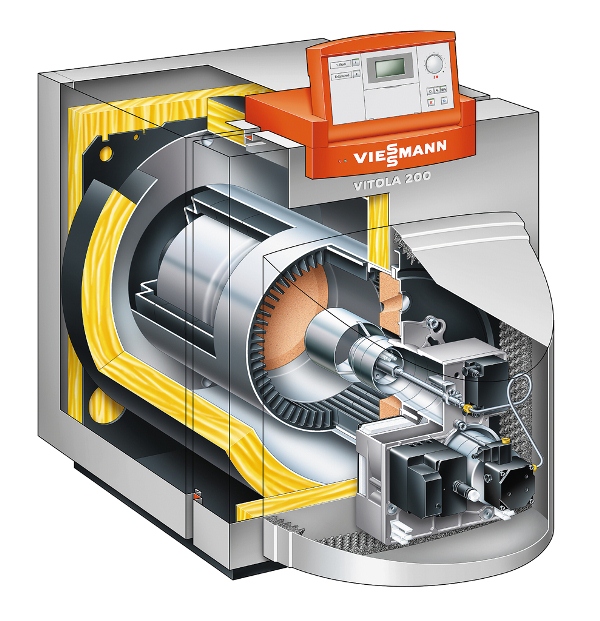

Expensive domestic waste oil boilers

The domestic automatic waste oil boiler Teplamos NT-100 is characterized by an expanded configuration. A double-circuit boiler can be used not only for heating, but also for providing hot water in the house. The model is characterized by high quality workmanship of all components. The exterior parts are powder coated to protect them from corrosion. The case has an internal heat-insulating coating in the form of high-density glass wool.

The exhaust boiler Ecoboil-30/36 can be used to heat a room up to 300 sq. m

For convenience of management the device is equipped with the remote control that allows it to work in the automatic mode. It consists of a switch, a thermostat, a thermohygrometer and an emergency thermostat.

The boiler has dimensions 114x75x118 cm and weight 257 kg. The maximum power consumption reaches 99 kW. The consumption of combustible substance fluctuates within 5-6 l/hour. The price of a waste oil boiler is 268 thousand rubles.

Ecoboil-30/36 single-circuit heating apparatus for mining can be used to heat a room up to 300 sq. m. It has dimensions of 58x60x110 cm. The power of the device is 28 kW. Fuel consumption can vary from 0.9 to 1.6 l/h. The boiler works on any type of oil, regardless of its quality. You can also use kerosene and alcohol for it. The cost of the boiler is 460 thousand rubles.

Hot water fire-tube boiler Belamos NT 325, having a capacity of 150 kW, is able to heat a room with an area of more than 500 square meters. m. Fuel consumption reaches 1.8-3.3 l / h. Due to the presence of a heat exchanger, it has a high efficiency. Equipped with a control unit with a smooth adjustment function and the ability to maintain the set temperature of the coolant. It can work on any type of liquid fuel that does not need filtration and heating. The price of the boiler is 500 thousand rubles.

The double-circuit boiler Teplamos NT 100 can be used not only for heating, but also for providing hot water in the house