- Overview of Russian-made waste oil boilers

- Expensive domestic waste oil boilers

- Installation Tips

- Disadvantages of mining boilers

- General principle of operation

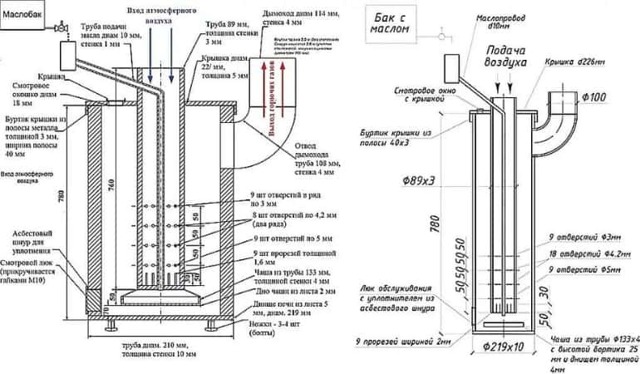

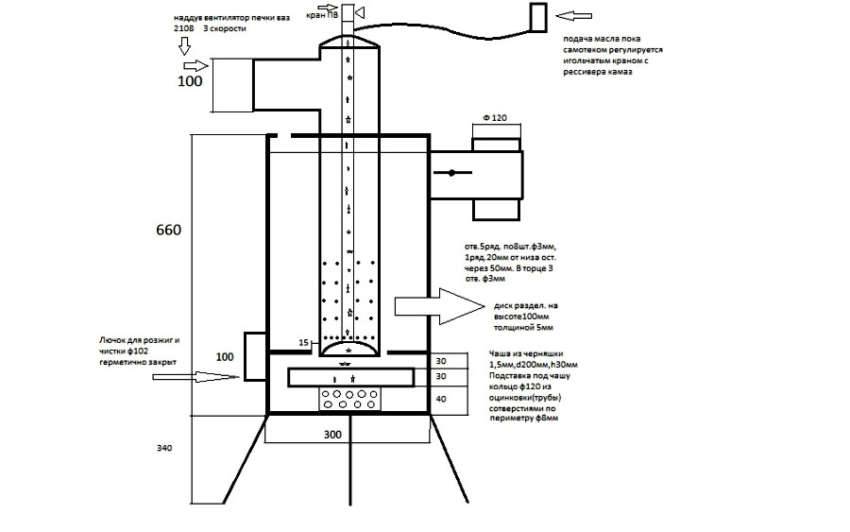

- Application of perforated tube

- Using the Plasma Bowl

- Features of self-assembly

- How to prepare the base and walls

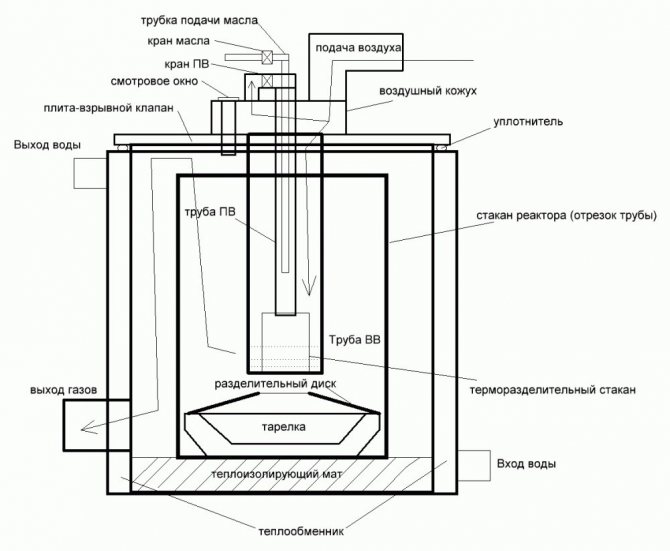

- How to make an inner tank

- How to make an outer tube casing

- How the air supply channel is made

- Chimney installation

- How is the water circuit connected?

- Design and principle of operation

- Disadvantages of mining boilers

- Advantages and disadvantages of oil boilers

- How to make a waste oil boiler with your own hands

- Tools and materials

- Manufacturing process

- Construction of a more powerful boiler

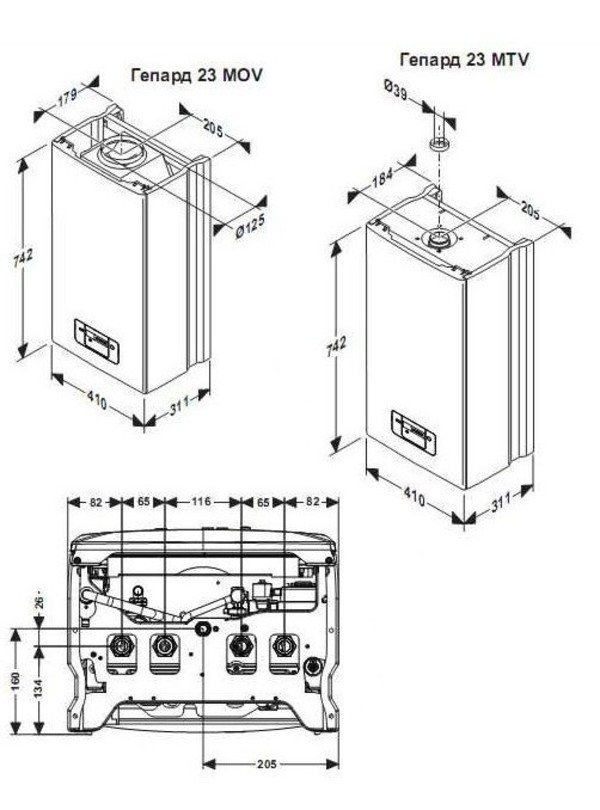

Overview of Russian-made waste oil boilers

Boilers of domestic production using waste oil are manufactured mainly in Voronezh, where the manufacturer has all the necessary documents related to the production of products. There are other small businesses as well. However, most of them do not have a state certificate for the manufacture of heating equipment.

This should be taken into account when buying a boiler.

Powerful boiler Stavpech STV1 is characterized by high efficiency

The double-circuit waste oil boiler Teploterm GMB 30-50 kW is characterized by the high quality of every detail. It, thanks to the multifunctional microprocessor, is equipped with an automatic control system. The device has many options that simplify the operation of the device, making it safe. Fuel consumption - 3-5.5 l / hour. The cost of the model is 95 thousand rubles.

A popular model is the Gecko 50 pyrolysis boiler. The device can work not only on mining, but also on crude oil, diesel fuel, fuel oil of all brands, kerosene, fats and various types of oil. The boiler is undemanding to the quality and viscosity of the fuel. There is no need for its pre-filtering and heating.

The design has small dimensions (46x66x95 cm) and a weight of 160 kg. The device is characterized by high efficiency, reliability of all elements and connecting nodes, ease of maintenance and repair. The maximum temperature in the device reaches 95 °C. The fuel consumption is 2-5 l/h. The power consumption is 100 W. The price of a waste oil heating boiler is 108 thousand rubles.

Combined boiler KChM 5K has a cast-iron reliable body

The Stavpech STV1 boiler is characterized by high efficiency. The power of the device is 50 kW. The flow rate of the fuel mixture is 1.5-4.5 l/h. Housing dimensions - 60x100x50 cm. The device is equipped with a reliable modulated burner for a waste oil boiler, which has a high emission rate. The device is equipped with a fuel filter, a pump and a water tank. Various types of oil, diesel fuel and kerosene can be used as fuel. The price of the boiler is 100 thousand rubles.

Combined apparatus KChM 5K has a cast-iron body.It can work not only on mining, but also on gas, as well as on solid fuel. The power of the device is 96 kW. The model differs in high quality of production of details, safety in operation and durability. You can buy a boiler for 180 thousand rubles.

Expensive domestic waste oil boilers

The domestic automatic waste oil boiler Teplamos NT-100 is characterized by an expanded configuration. A double-circuit boiler can be used not only for heating, but also for providing hot water in the house. The model is characterized by high quality workmanship of all components. The exterior parts are powder coated to protect them from corrosion. The case has an internal heat-insulating coating in the form of high-density glass wool.

The exhaust boiler Ecoboil-30/36 can be used to heat a room up to 300 sq. m

For convenience of management the device is equipped with the remote control that allows it to work in the automatic mode. It consists of a switch, a thermostat, a thermohygrometer and an emergency thermostat.

The boiler measures 114x75x118 cm and weighs 257 kg. The maximum power consumption reaches 99 kW. The consumption of combustible substance fluctuates within 5-6 l/hour. The price of a waste oil boiler is 268 thousand rubles.

Ecoboil-30/36 single-circuit heating apparatus for mining can be used to heat a room up to 300 sq. m. It has dimensions of 58x60x110 cm. The power of the device is 28 kW. Fuel consumption can vary from 0.9 to 1.6 l/h. The boiler works on any type of oil, regardless of its quality. You can also use kerosene and alcohol for it. The cost of the boiler is 460 thousand rubles.

Hot water fire-tube boiler Belamos NT 325, having a capacity of 150 kW, is able to heat a room with an area of more than 500 square meters. m. Fuel consumption reaches 1.8-3.3 l / h. Due to the presence of a heat exchanger, it has a high efficiency. Equipped with a control unit with a smooth adjustment function and the ability to maintain the set temperature of the coolant. It can work on any type of liquid fuel that does not need filtration and heating. The price of the boiler is 500 thousand rubles.

The double-circuit boiler Teplamos NT 100 can be used not only for heating, but also for providing hot water in the house

Installation Tips

The installation of a boiler using used oil is practically the same as the installation of other types of heaters. There is one advantage: due to the presence of turbocharging and smokeless combustion of liquid fuel, it is not necessary to raise the chimney by 6-7 meters. It is enough to remove the chimney head from the wind backwater zone and raise it to a height of 4 m.

Regarding the correct installation, we will give the following recommendations:

- The boiler and steel chimneys not protected by insulation are located at a distance of 0.5 m from combustible walls and other elements of a wooden house. The minimum distance from fireproof structures is 100 mm.

- Pass through the outer wall and the entire outer section of the flue with an insulated pipe - a sandwich, otherwise there will be a lot of condensate and soot. The technology of the chimney device is described in detail in a separate material.

- Be sure to install a safety group on the heating supply line.

- Arrange a good hood in the furnace to remove odors. Air intake for combustion can be provided from the street.

- Equip the supercharger with a speed regulator, and the oil line with a valve.This will allow you to control the power of the heat generator manually. Do not confuse the control valve with a conventional faucet; valves are placed on pipelines in any case.

- Make a primitive automatic emergency stop - put on the supply thermostat that turns off the fan and oil pump in case of overheating of the coolant.

Installation option for a heat generator with a lower flue connection

If mining is supplied by gravity, then for the sake of safety it is advisable to put an electric shut-off valve on the fuel line. One subtlety: after an emergency shutdown, the boiler will not start on its own, you will have to kindle the oil manually or make automatic ignition.

It is highly desirable to insure the operation of the boiler in case of a power outage. A car fan, designed for a voltage of 12 volts, can be powered from a conventional battery, the rest of the equipment - pumps, thermostats - through an uninterruptible power supply.

The supply of waste oil to the combustion chamber of the boiler is easiest to organize by gravity - from a container suspended from the wall. But such a system must be constantly monitored, plus as it is emptied, the interval between drops increases, and the intensity of combustion decreases.

Disadvantages of mining boilers

The main disadvantage of such a device is that its reaction to shutting off the air supply to the furnace will not be instantaneous. Consequently, the combustion process will not stop immediately, but after a certain period of time, during which the heating of the coolant will continue. When the flame finally goes out, it will need to be rekindled.This is done manually, unless the design provides for any other approach.

Another drawback of the mining boiler is its contamination compared to other heating appliances. This is primarily due to the fuel used. If the structure is assembled correctly, then an unpleasant odor will not come from it. If the technology is violated, such a smell will penetrate into the room to one degree or another.

Another, no less significant, disadvantage of such boilers in comparison with other designs is the need to purify the fuel from various solid impurities, which may include pieces of metal or metal shavings. If you do not establish a filtration system, then the device will fail after a certain time, and it will be very problematic to return it to working condition.

General principle of operation

If we want to get high-quality heating based on mining, the oil cannot simply be taken and set on fire, because it will smoke and stink. In order not to experience these unpleasant and dangerous side effects, you need to heat the fuel so that it begins to evaporate.

The volatiles obtained as a result of heating will burn. This is the basic principle of operation of the heating unit during mining.

Application of perforated tube

To implement this principle in the design of the stove, two chambers are provided, which are interconnected by a pipe with holes. Fuel enters the lower chamber through the filler hole, which is heated here. The resulting volatile substances rise up the pipe, being saturated with atmospheric oxygen through the perforation.

The schematic diagram of a two-chamber stove with a connecting perforated pipe allows you to understand exactly how a simple unit works at mining

The resulting combustible mixture ignites already in the pipe, and its complete combustion occurs in the upper afterburner chamber, separated from the chimney by a special partition. If the process technology is properly observed, soot and smoke are practically not formed during combustion. But the heat will be enough to heat the room.

Using the Plasma Bowl

In order to achieve maximum efficiency of the process, you can go a more complicated way. Recall that our goal is to release volatile components from the fuel by heating it. To do this, a metal bowl should be placed in the only chamber of the unit, which must not only be heated, but heated.

Through a special dispenser from the fuel tank, mining will come into the chamber in a thin stream or drops. Getting on the surface of the bowl, the liquid will instantly evaporate, and the resulting gas will burn.

The efficiency of such a model is higher, since the fuel supplied by the drip burns better, and the problem of topping it up during the operation of the furnace disappears by itself.

If everything is done correctly, the combustion of gases should be accompanied by a bluish-white flame. A similar flame can be observed when a plasma burns, so a red-hot bowl is often called a plasma bowl. And the technology itself is called drip supply: after all, fuel with it must be supplied in exceptionally small doses.

With all the variety of designs, the operation of all waste fuel heating units is based on the principle described above.

Features of self-assembly

The materials and tools required for self-assembly of the structure are indicated in the plate:

| materials | Tools |

| Metal angles for supports, metal sheet for the tank, sealant (the main criterion is resistance to high temperatures), metal sheet for the cover, adapters (steel), chimney pipe, oil pump. | Welding (electrodes must be included), a grinder, a set of keys, a construction pencil, a hammer, a tape measure, a drill (drills must be specially designed to work with metal material). |

How to prepare the base and walls

The most important recommendation is that the walls should be made of a material that is not resistant to fire.

Concrete screed

Concrete screed

If they are made of wood, then a canvas should be laid between them and the installation, which is made of high-quality asbestos. A concrete screed is made under the boiler itself.

tiling

tiling

If you want the room to be not only warm, but also beautiful, it is recommended to tile the walls and floor. You need to process the wall in which the installation adjoins.

How to make an inner tank

The instruction is:

- “Arm” with a grinder, cut the bottom of the tank.

- Form a pipe. Diameter - 600 mm.

- Weld the bottom.

- Make a hole in the bottom to remove the bowl (the size should be such that a hand can freely pass into it).

- Measure from the top edge of the pipe a distance of 100-150 mm. Make a round hole (diameter - 140 mm).

- Weld the necks to the holes made (thickness - 50 mm).

- Weld a ring to the bottom of the pipe (width - 30 mm).

How to make an outer tube casing

Instruction:

- In the outer pipe, cut a hole for the chimney, supply pipes, doors. The procedure is performed with the participation of a grinder.

- Make a hole at the bottom of the pipe, which makes it possible to return the heat carrier.

- The inside closes well with the outside.

- Weld hermetically both bases of the product.

- At the top, weld the ring (its main purpose is to eliminate the resulting distance).

- Make a stub.

- Make sure that the water circuit is sufficiently tight.

- Cut out a few circles with a grinder (diameter - 660 mm).

- In one of the circles, make a hole for the air supply pipe (diameter is 1.3 cm).

- Weld the circle to the structure.

How the air supply channel is made

Instruction:

A pipe is measured on a metal sheet (diameter - 60-80 mm).

Cut the pipe with a grinder (the length of the resulting product should exceed the overall design by 100-150 mm).

Measure 500 mm from one end and make a hole.

Take a piece of pipe (the length is 80 mm), weld it to the other end of the pipe (the diameter is the same, the length at an angle is 500 mm)

This will be the channel through which fuel will be supplied to the stove.

Carefully install the oil supply pipe into the air supply pipe.

From one of the sides, make a tie-in for the compressor.

Connect the pump that supplies fuel.

Connect the circulation pump.

Carefully place the container in the oven.

Fix the door.

Chimney installation

Chimney length - 350-400 cm. The vertical tube is made without horizontal sections.

How the chimney is installed

How the chimney is installed

Instruction:

- Connect the chimney pipe to the outgoing boiler pipe.

- Mark up (depending on which scheme the chimney will be removed from. This can happen through the roof or wall).

- If the chimney is run through the wall, the pipe is led through the ceiling.

- Lay fiber (asbestos) around the chimney.

- Attach a casing resistant to elevated temperatures to the ceiling.

- Equip the chimney with a damper (metal). This will help regulate the tension.

- Pull the chimney over the roof.

How is the water circuit connected?

Instruction:

- Lay a network of batteries around the room.

- Connect the boiler to the radiator (the diameter of the pipe used must be 4.3 cm).

- Fix the container made of metal to the stove with bolts. In order to ensure proper fastening reliability, you can weld the container.

- Make a hole at the top of the container.

- Weld a pipe (it is needed to supply hot water to the system).

A pipe should be placed below, which is intended for supplying cold water to the tank.

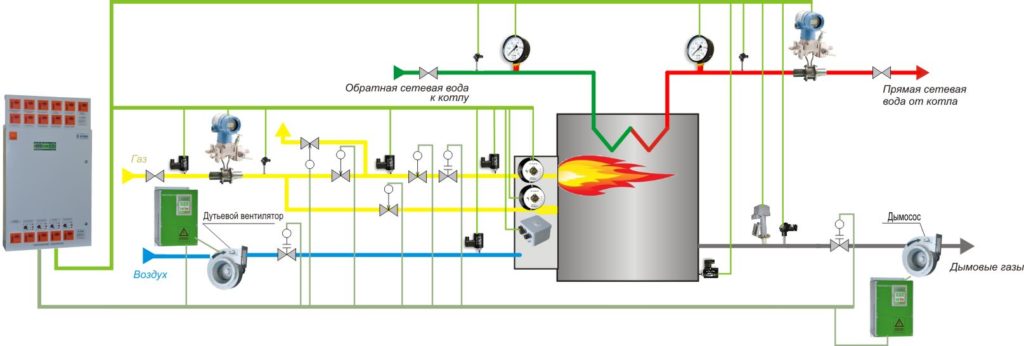

Design and principle of operation

The waste oil boiler consists of two tanks connected to each other. In the first (lower) combustion of used oil takes place, and in the second - the vapors generated during the initial combustion. The design of the connecting pipe in simple models provides for the presence of holes so that air, the oxygen of which is necessary for the process in the second tank, enters the upper tank along with the combustion products. A chimney pipe must come out of it to remove combustion residues.

Complex models use burners, filters and pumps to create thrust and keep the unit running smoothly.To create a water circuit, a heat exchanger is installed in the upper tank, which can then be connected to the heating system of a building or a specific room.

Disadvantages of mining boilers

The main disadvantage of such a device is that its reaction to shutting off the air supply to the furnace will not be instantaneous. Consequently, the combustion process will not stop immediately, but after a certain period of time, during which the heating of the coolant will continue. When the flame finally goes out, it will need to be rekindled. This is done manually, unless the design provides for any other approach.

Another drawback of the mining boiler is its contamination compared to other heating appliances. This is primarily due to the fuel used. If the structure is assembled correctly, then an unpleasant odor will not come from it. If the technology is violated, such a smell will penetrate into the room to one degree or another.

Another, no less significant, disadvantage of such boilers in comparison with other designs is the need to purify the fuel from various solid impurities, which may include pieces of metal or metal shavings. If you do not establish a filtration system, then the device will fail after a certain time, and it will be very problematic to return it to working condition.

Advantages and disadvantages of oil boilers

The use of used oil as a fuel has clear advantages:

- Profitability. Waste oil is recycled, the price of which is several times lower than for other types of fuel. You can buy it at enterprises with a large number of cars, service stations and even in private garages.

- Autonomy.You do not depend on the gas pipeline, but when installing the battery and on electricity. This allows you to heat rooms that are far from civilization.

- Simplicity of design. Reliability and durability of work is ensured by the simplicity of the device and the predictability of the principle of operation. With proper use and regular cleaning, the machine has a long service life.

- Fast heating time. Already in the first minutes of work, you will feel the temperature increase. This is especially noticeable when using hot air devices such as heat guns.

- Fire safety. Waste oil itself is not flammable. This simplifies storage conditions and increases safety during use.

- You can install such equipment yourself, you will not need additional permits and specialist services, as is necessary if you install a gas boiler.

- If your working out ends abruptly, you can heat another type of liquid fuel. To do this, you will need to change the settings and in some cases replace the nozzle.

Scheme of a liquid fuel boiler

However, this method of heating has its drawbacks:

The need for regular cleaning. Since initially unpurified fuel is used, it contains a number of unnecessary impurities that clog the components of the device

For a longer service life, it is important to clean it regularly.

Fuel search. Before purchasing a boiler of this type, you need to look at what sources are available in your area.

Compared with other types of fuelused oil is harder to find.

Oil freezes at low temperatures. This leads to the need for a special room for storing mining during the cold season.

Initially, the high cost of such equipment.

How to make a waste oil boiler with your own hands

The simplicity of the design of such heaters allows you to make them yourself. In this case, it is necessary to have locksmith and welding skills.

Tools and materials

To make a boiler with your own hands, the following devices are required:

- Bulgarian;

- welding machine;

- a hammer.

To make a waste oil boiler with your own hands, do not forget the grinder

As a material for the heating structure, you must purchase:

- refractory asbestos cloth;

- heat-resistant sealant;

- steel sheet 4 mm thick;

- metal pipe with a cross section of 20 and 50 centimeters;

- compressor;

- ventilation pipe;

- drives;

- bolts;

- steel adapters;

- half-inch corners;

- tees;

- reinforcement with a cross section of 8 millimeters;

- pump;

- expansion tank.

The body of the boiler for heating small rooms can be made from a pipe; for a device with a higher power, it is best to use steel sheets.

Manufacturing process

The waste oil unit can be built in any shape. To heat a garage or small agricultural buildings, it is best to make a small boiler out of pipes.

The manufacture of such a heating device consists of the following steps:

- A metal pipe with a large cross section is cut so that its size corresponds to one meter. Two circles corresponding to a diameter of 50 centimeters are prepared from steel.

- The second pipe with a smaller diameter is shortened to 20 centimeters.

- In the prepared round plate, which will serve as a cover, a hole is cut corresponding to the size of the chimney.

- In the second metal circle, intended for the bottom of the structure, an opening is made, to which the end of a pipe of a smaller diameter is joined by welding.

- We cut out a cover for a pipe with a cross section of 20 centimeters. All prepared circles are welded as intended.

- Legs are constructed from reinforcement, which are attached to the bottom of the case.

- Small holes are drilled in the pipe for ventilation. A small container is installed below.

- In the lower part of the case, with the help of a grinder, an opening for the door is cut out.

- A chimney is attached to the top of the structure.

To operate such a simple boiler in mining, you just need to pour oil into the tank from below and set it on fire with a wick. Before this, the new design should be checked for tightness and integrity of all seams.

Construction of a more powerful boiler

Two boxes are made of strong sheet steel, which are connected using a perforated pipe. In the design, it is used as an air vent.

The subsequent manufacturing process of the heater has some features:

- A hole is made in the lower body of the boiler to supply oil to the evaporation tank. A damper is fixed opposite this container.

- The box located in the upper part is complemented by a special hole for the chimney pipe.

- The design is equipped with an air compressor, an oil supply pump and a container into which fuel is poured.

Do-it-yourself waste oil boiler

If water heating is required, then an additional circuit is connected, which requires the installation of a burner. You can build it yourself:

- half-inch corners are connected by spurs and tees;

- a fitting is fixed to the oil pipeline using adapters;

- all connections are pre-treated with a sealant;

- a burner cover is cut out of sheet steel, corresponding to the nests on the manufactured boiler;

- two different sizes of steel plates are used to install the burner;

- the inside of the tube adapter is tightly covered with an asbestos sheet, which is fastened with sealant and fixed with wire;

- the burner is inserted into the housing intended for it;

- after that, a smaller plate is fixed in the nest and covered with four layers of asbestos;

- a large plate is mounted as a mounting plate;

- holes are drilled in it for fastenings, and an asbestos sheet is applied on top;

- two prepared plates are connected with bolts.

To prevent the burner from disintegrating during the operation of the boiler, all parts should be carefully and tightly fastened. The device is ignited by a glow plug.

Waste oil boilers are considered economical and practical appliances. They can be purchased at a specialized store or built independently. When using such heating devices, it is necessary to remember the safety rules, which include the mandatory installation of a chimney, the presence of a ventilation system and the proper storage of liquid fuel.