- Air duct from the hood and grille with non-return valve

- Pipes for hoods: tips and tricks for choosing

- Shapes and sizes of ventilation pipes: selection rules

- How to calculate the minimum dimensions of a plastic pipe

- Installation of air ducts

- Basic installation rules

- Connection rules for all types of pipes

- Rules for laying the duct from the hood to the opening of the ventilation shaft

- Features and nuances of do-it-yourself installation

- Necessary tools and materials

- Installing an indoor air duct

- Thermal insulation of pipes in the attic

- How to hide pipes from the hood in the kitchen

- Arrangement of a hood without a box

- Plastic fittings

- The cross section of the duct and the basic principles of its selection

- Guidelines for choosing an air duct

- Telescopic hood modifications

- Varieties and materials for the production of plastic pipes

- Polyvinyl chloride (PVC)

- Polyurethane

- Polypropylene

- Deciding on sizes

- Types of air ducts for exhaust: advantages and disadvantages

- Plastic air ducts for exhaust

- Corrugated air duct

- Duct diameter calculation

- Box design and operation

Air duct from the hood and grille with non-return valve

First - instead of a corrugation, a plastic pipe is taken (for example, d-125mm), and through one or more elbows it is led into the hole of the ventilation duct.At the same time, a certain division is made in the hole itself under the ceiling.

An entry under the pipe is mounted on top, and a small rectangle is left through the grate with a valve below for natural inflow.

Moreover, the grid should be exactly below, and not above. Otherwise, the air flow from the hood will blow up and lift, the so-called non-return valve.

Although, of course, if you have a more advanced valve design - a circle or a rectangle with an offset axis, and not simple strips of polyethylene, or there is a solid partition, then you can safely put it as you want - from above, from the side, from below.

However, in fact, this whole design often does not work as intended. When you turn on the exhaust unit and create pressure, a small part of the dust still seeps through the cracks, micro-holes, after which it safely enters your kitchen on the dining table.

No check valves are 100% safe. The bulk of the air, of course, goes outside, but the gradual formation of dust inside the apartment is a fact.

And when the hood is turned off due to a decrease in the diameter of the original hole, natural ventilation through narrow gratings will be much worse.

Everything can be done much better.

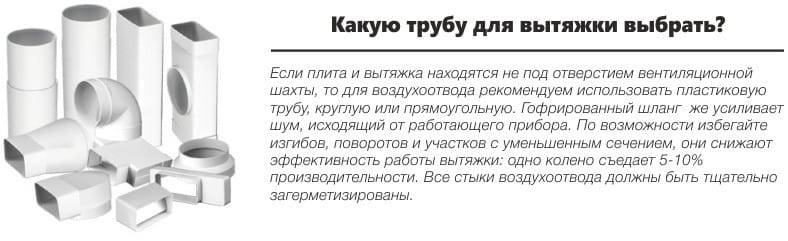

Pipes for hoods: tips and tricks for choosing

When choosing pipes for an air duct, most consumers are primarily guided by aesthetic considerations, which is quite justified. Therefore, before buying, it is recommended to determine exactly how the box will be mounted: outside or behind furniture, behind a false wall or above a false ceiling.

A shiny corrugated pipe definitely spoils the interior of the kitchen, so if we are talking about an open location, then most often they choose smooth plastic pipes that can be painted in a color that matches the design of the ceiling or walls. The most beautifully fits into an open interior is a rectangular or square pipe for the kitchen. A round hood is less aesthetically pleasing, but creates minimal airflow resistance, minimizing noise.

If we are talking about a hidden laying method, then it is better to give preference to a corrugated metal pipe. It is much easier to mount it, since it does not require the use of adapters and corners. If it is necessary to overcome an obstacle on the way to the ventilation duct, it is enough to simply bend such a pipe. However, additional costs will be required to mask corrugated products. In addition, if access to the duct is required, then the entire conspiracy will have to be dismantled.

Shapes and sizes of ventilation pipes: selection rules

The diameter of the round ventilation pipes must correspond to the cross section of the outlet pipe on the kitchen hood. It should be remembered that it is round boxes that create minimal resistance to air flow. As for the shape, a straight pipe is optimal, however, sharp corners are not allowed during the installation of air ducts.

Plastic pipes with a circular cross section can have a diameter in the range of 10-20 cm

The ideal length of the duct should be no more than 3 m. If this figure is higher, then the fan must be of maximum power. The corrugation diameters used in household ventilation are 10, 12.5 and 15 cm.

The standard sizes of plastic pipes for square and rectangular ventilation are as follows: 8×8, 10×10, 12.5×12.5, 5.5×11, 5×12, 6×20.4 and 9×22 cm. Diameter plastic pipes can be 10, 12.5, 15 and 20 cm.

How to calculate the minimum dimensions of a plastic pipe

The cross-section of square and rectangular plastic ventilation pipes must be equal to the cross-sectional area of the round hood pipe. If the diameter is narrowed, then the performance of the system will deteriorate, the fan will be overloaded, and the noise will increase. As a result, vibration will occur and the fasteners will weaken. The minimum section size is allowed only when a powerful fan is installed in the hood, but it is not used to the maximum.

Properly selected pipe size affects the quality of the hood

It is best to take a pipe whose cross section will be slightly larger than the diameter of the nozzle. If the diameter of the pipe significantly exceeds the cross-sectional area of the fitting, then this will entail additional costs and problems with its masking.

It is not necessary to calculate the size of the section of the hood hood. It should be equal to the diameter of the outlet pipe. If the hood has a certain power reserve, but is not used at full capacity, then the cross section can be slightly narrowed. To calculate its minimum value, the formula will help:

Smin=Sp*(Qr*Qmax), where:

Smin is the minimum cross-sectional index;

Sp is the section of the branch pipe indicated in the product passport;

Qp is the volume of air to be removed;

Qmax - the maximum indicator of the volume of air to be removed, it is indicated in the passport of the hood.

Qr is calculated using a different formula: Qr = Vkitchen * 12 * 1.3 m³. Vkitchen is the area of the room.According to sanitary standards, 12 is an indicator of air exchange, that is, the air in the kitchen should change 12 times per hour. 1.3 is the power loss factor in the duct and ventilation shaft.

The size of a plastic pipe can be calculated using a special formula

Installation of air ducts

Basic installation rules

The air duct must be stretched as much as possible when it is installed. To cut the plastic, you first need to measure its length and make an appropriate mark with a marker. Then cut it with a knife.

Before connecting the duct to the hood, it is necessary to carry out the sealing process. After that, the duct itself needs to be fixed with a clamp.

After these operations, the start-up and testing of the ventilation system begins. If you do this not with your own hands, but with the help of a master, then you will pay more than 1000 rubles for installation and connection.

Are there any errors in the installation of plastic air ducts? Yes, and the main one is the following: the air flow in a spiral is not taken into account. This error can result in rapid wear of the ventilation equipment.

To avoid this error, it is enough to consult with the seller and take a plastic air duct of a slightly larger diameter.

Connection rules for all types of pipes

Recommendations:

- The air duct must be carefully sealed at all joints.

- The system should contain a minimum number of adapters, turns, narrowing - they lead to a decrease in efficiency.

- The boxes must be securely attached to walls and ceilings using special clamps. If the boxes are mobile, the system will vibrate, the noise level will increase and the seal will be broken.

Rules for laying the duct from the hood to the opening of the ventilation shaft

For the correct laying of the duct, it is necessary, if possible, to choose the shortest path from the hood to the opening in the ventilation shaft. If the duct is too long, consider another possible way to remove the polluted air, such as outside.

The shape of the air ducts should have a minimum of turns. Each 90° turn of the channel reduces the extraction efficiency by 10%. If possible, it is necessary to make a smooth turn of the pipe using two 135° bends or different angle bends (see 6 in the figure). It is impossible to turn the box at an acute angle - this will completely stop the movement of air in the pipeline.

If the length of the duct is too long, it is necessary to recalculate the power loss in the duct and the required fan power with the help of specialists.

Features and nuances of do-it-yourself installation

Installation of ventilation pipes from the hood is a simple task, quite feasible for a home master, even with little experience. If you carefully follow our advice, the installation of ventilation ducts will pass without problems.

Necessary tools and materials

To complete the work you will need:

- Drill.

- Screwdriver.

- Hacksaw or grinder.

- Sealant.

- Boxes, bends, adapters of the required section.

- Check valve.

- Ventilation grille for connecting ducts to the ventilation shaft.

Installing an indoor air duct

For the installation of boxes, it is necessary to carefully mark and measure the entire route of the system. The grate on the hole in the shaft is dismantled, if necessary, the shaft is cleaned of dust, soot and cobwebs.

After installing the exhaust equipment, connect the box to the exhaust pipe. All joints are sealed with sealant. Heat-resistant sealant is not needed - the temperature of the exhaust air is not too high.

Then the system is mounted by inserting individual elements one into the other. Pipes are shortened to the desired length by cutting with a hacksaw or grinder. The box is fixed on the wall with special holders or clamps. The distance between the fasteners is no more than 500 mm.

For installation of the system, only pipes, adapters and connectors of industrial production are used - you should not reinvent the wheel, the industry produces fittings for any geometry of ventilation ducts and transitions from a round pipe to a rectangular one.

After installing the system, it is tested:

- If a leak is found, coat the gap with sealant.

- If rattling occurs when the system comes into contact with any structures, in this case it is necessary to lay a gasket made of expanded polystyrene or foamed polyethylene.

Thermal insulation of pipes in the attic

Water must not enter the air ducts. The fan will quickly fail if exposed to water. In order to prevent moisture from settling on the walls of ventilation pipes and ducts, it is necessary to make insulation. For this, plates made of foamed polyurethane foam or mineral wool are used. From above, the insulation is covered with roofing material or fiberglass and fixed with wire.

How to hide pipes from the hood in the kitchen

There are several options for hiding pipes:

- False ceiling cladding.

- Laying through kitchen cabinets.

- Laying over lockers and closing with a decorative screen.

- Painting or decor to match the color of the walls and ceiling.

- Closing with decorative boxes.

Closing with a screen imitating a wall, for example, from drywall.

When installing boxes behind a false wall or false ceiling, one should take into account the fact that it will not be easy to disassemble and clean or repair the system - you will have to disassemble the wall or dismantle the ceiling structures.

Arrangement of a hood without a box

The circulation type hoods are more compact than flow-through ones, their installation is easier. The hood without pipes is simply attached to the wall or suspended from the ceiling (if the stove is placed in the middle of the kitchen on the island).

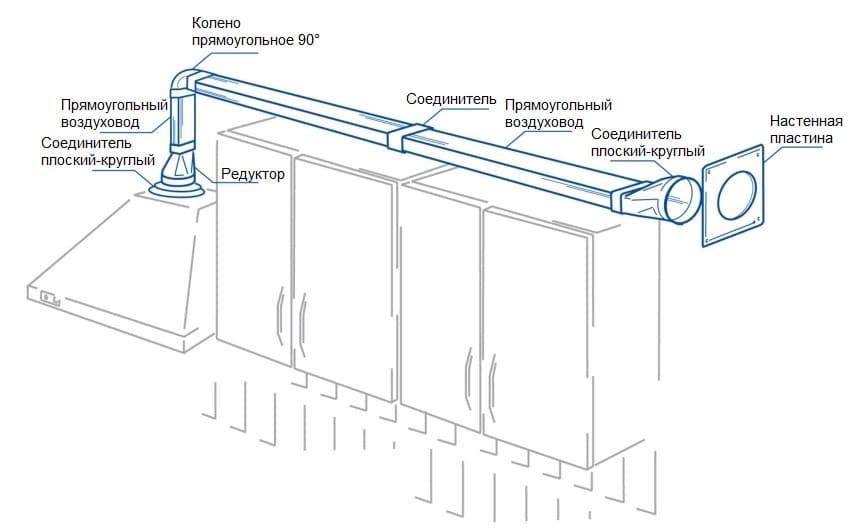

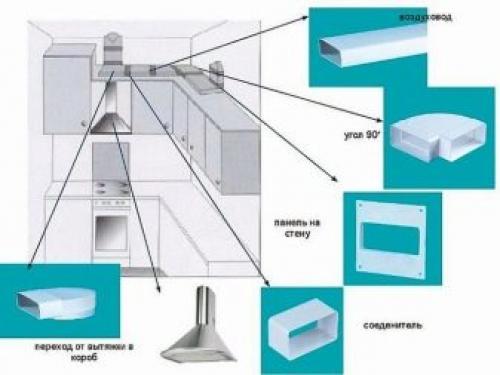

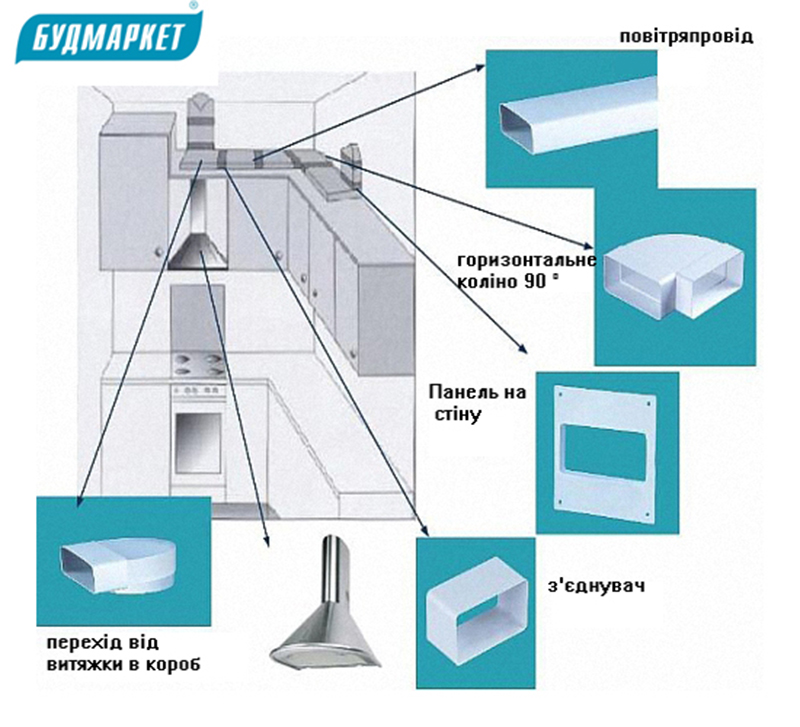

Plastic fittings

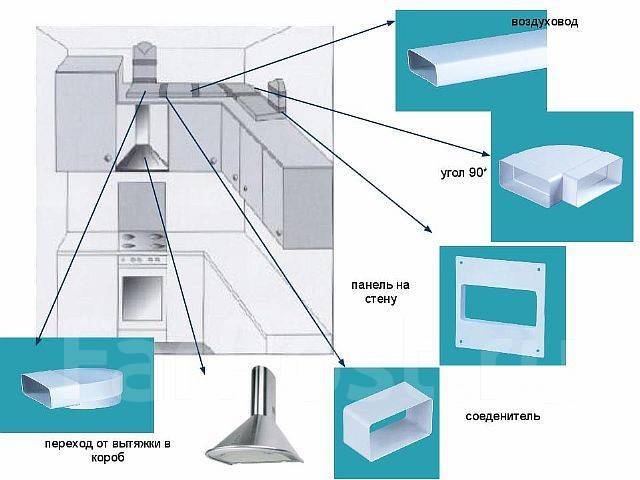

Ventilation systems from the hood to the shaft have different geometry and topology due to individual approaches to the layout of kitchens. Therefore, special elements are provided for the implementation of almost any configuration of the plastic box.

Ventilation ducts are straight duct elements of a rectangular or round shape. Their standard length is 0.35; 0.5; one; 1.5 and 2 meters, however, you can cut off a segment of the required size using a hacksaw or a grinder.

If you need to get a straight section with a length of more than two meters, then it is mounted using several fragments of standard length using special connectors for plastic channels.

In this case, there is no increase in the length of the section due to the size of the connector.

Another necessary element is the knee, with which the duct is rotated at an angle of 90 or 45 degrees. For rectangular boxes, there are elements for changing the direction horizontally and vertically.

To turn at angles that are not multiples of 45 degrees, the so-called multi-angle knee is used.Cut off one side of the connector depending on the required angle.

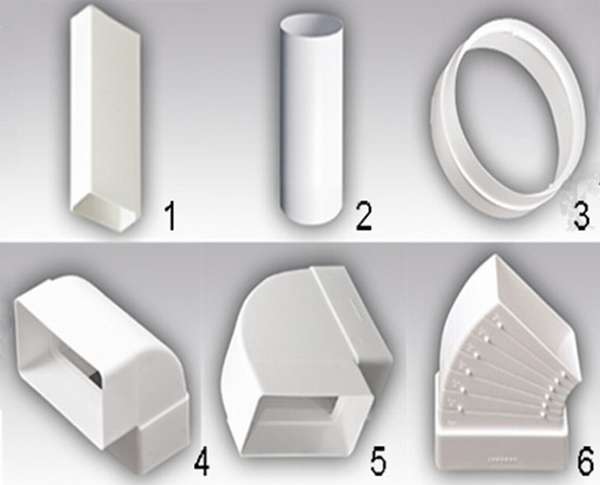

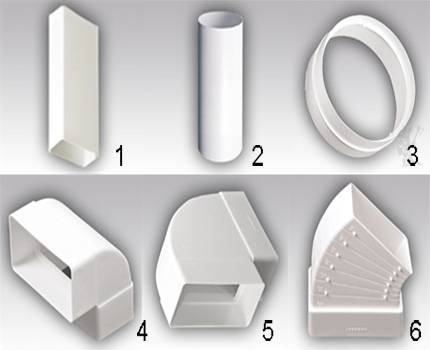

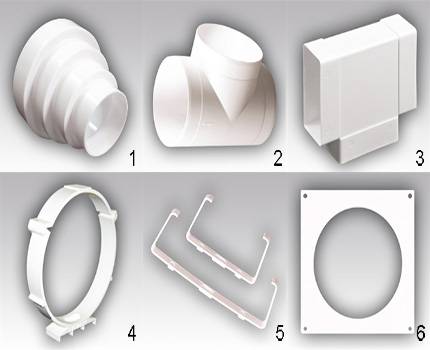

Shaped elements: 1 - rectangular channel; 2 - round channel; 3 - connector of round channels; 4 - vertical knee; 5 - horizontal knee; 6 - different angle knee

To change the shape of the box from round to rectangular (or vice versa), special adapters are used.

Their use, as a rule, is due to the difference in the shape of the ventilation ducts with the outlet funnel of the hood or a hole in the overhead grille. They can be either straight or angled.

The following transition options are most common for sale:

- from a diameter of 100 mm to a size of 110x55 mm;

- from a diameter of 100 mm to a size of 120x60 mm;

- from a diameter of 125 mm to a size of 204x60 mm.

If you need to change to another size of plastic box without changing it forms, reducers are used. For round versions, there is a special universal adapter that can be used to connect all standard sizes.

For designs with complex topology, tees are provided, with the help of which air flows from several hoods, for example from the kitchen and from the bathroom, can be connected towards the outlet.

They can be rectangular, round, as well as a combined shape.

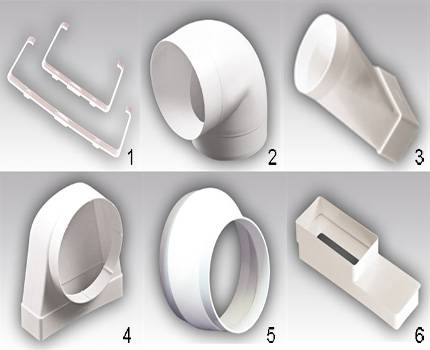

Shaped elements: 1 - connector of flat channels; 2 - the knee is round; 3 - straight adapter; 4 - corner adapter; 5 - round reducer; 6 - rectangular gearbox

The elements of the box are fastened to the wall using holders. Since plastic structures differ from metal structures in their low weight, their installation is not a difficult task.

These factory-made parts are inexpensive and fit well into the interior of the room, so the use of home-made structures is impractical.

A wall plate or grate is mounted over a hole in the wall leading to a ventilation shaft or to the street. The grate, if necessary, may contain additional slots for natural ventilation.

In this case, it is necessary to provide protection against penetration through these openings of the air flow generated by the hood back into the room.

To prevent the occurrence of reverse thrust when the hood is not working, a check valve is used. It can be integrated into the connector of the plastic channel, or its function can be performed by the louvres of the ventilation grille.

In the absence of such a device, air can enter the room from the street or from the ventilation shaft.

Shaped elements: 1 - universal round reducer; 2 - round tee; 3 – rectangular tee; 4 - round holder; 5 – rectangular holder; 6 - overlay for round channels

The cross section of the duct and the basic principles of its selection

The size of the duct section is selected depending on the size of the section of the exhaust pipe. This parameter of the ventilation device is indicated in the technical data sheet. The cross section of the box is also determined depending on how intensively the air purification device will work. Since no standard standards have been developed in this regard, an average indicator calculated using a special formula is used.If the kitchen is small in size and it is not planned to turn on the maximum speed in a constant mode, you can use a box with a section that decreases proportionally in the direction from the hood to the stove.

The choice of the diameter of the box section should be made with the utmost care, and preferably under the guidance of a specialist. An unprofessional and incorrectly selected value can lead to negative consequences and a significant reduction in the life of the hood. At the same time, experts note that a value greater than the required one will cause additional financial costs and distort the design of the kitchen.

Guidelines for choosing an air duct

Experienced experts give a number of tips to make it easier for owners to choose products for arranging a ventilation system. Some of them:

It is best to buy products in company stores or specialized outlets.

In addition to the product, the kit should include instructions for use, as well as a warranty card.

If there is no such documentation, it is better to refuse the purchase.

It is necessary to take into account the design of products so that they organically fit into the interior of the room.

The manufacturer is important. It is advisable to choose high-quality branded models.

No need to rely on low prices

Of course, a high-quality and reliable ventilation system will be quite expensive, especially if good materials are used. However, you need to understand that high-quality models will serve for many years without any complaints.

Products must have sufficient performance.If the ventilation system is weak, the hood will not be able to do its main task well, so the exhaust air masses will remain in the room.

In addition, when choosing the constituent elements of the ventilation system, it is necessary to take into account the main functions of the kitchen hood. The latter must meet the following characteristics:

- Attractive appearance is important in order for the device to organically fit into the interior, complementing it.

- Low noise level during operation.

- The ability to quickly and in the right amount to remove odors.

We invite you to familiarize yourself with the hood for the kitchen without a vent to the ventilation (25 photos): models without an air duct

A significant selection criterion for homeowners is the price, aesthetics and performance of ventilation ducts fade into the background. The flexible corrugation definitely wins here, it is much cheaper than other options, and fittings are not needed.

We will offer our recommendations on how to choose a ventilation duct for your hood:

- Under the outer gasket, 2 types of channels are suitable - plastic and metal. The first ones are cheaper, but they look worse, they are better hidden above cabinets or behind decorative cladding.

On the left in the photo, the installation of the ventilation duct behind the plasterboard sheathing, on the right - the gasket inside the furniture

- For a hidden gasket, you can take any air duct: corrugated, PVC, galvanized. If you don't care about noise levels, get a cheap aluminum sleeve.

- In a country house, a summer kitchen or a veranda with a stove, connect the hood with a corrugated pipe. Plastic in such rooms quickly becomes contaminated, it is rather difficult to remove yellowness.

- If an expensive repair has been made in the apartment, it is impossible to save and disfigure the interior.Match the steel box, fittings and grate to the color of the hood. Stainless steel is perfect for a nickel-plated surface, copper is perfect for a golden one.

The exhaust air is removed through a pipe, which may differ in the following ways:

- by material;

- the diameter or dimensions of the sides of the box;

- section shape;

- flexibility.

Telescopic hood modifications

The assembly of the telescopic hood box is similar to the standard design. The main difference is in the build order. Initially, the upper plane and side parts are mounted. The size of the structure is carefully adjusted for the hood, if necessary, tightened.

At the last stage of manufacturing the model, the lower part is fixed.

It is important to make a hole for the corrugation before fixing the lower horizon. After assembly, it is quite difficult to perform carpentry work

The functionality of the device is based on a retractable element that allows you to use the hood during cooking.

The device must take into account the main parameters, ensuring the practicality and ease of operation of the device. It is not advisable to use plastic as a material for the supporting structure; it can be used exclusively for decorative purposes. The box will reliably hide the visual imperfections of the elements of the exhaust device. Proper manufacturing and assembly will provide an aesthetic appearance of the exhaust device, give the interior a decorative effect and completeness.

Varieties and materials for the production of plastic pipes

There are several types of modern plastics:

- Polyvinyl chloride (PVC).

- Polyurethane.

- Polypropylene.

Each has its own advantages and almost all have one single drawback.

The use of polypropylene pipes for arranging ventilation of an industrial building

Polyvinyl chloride (PVC)

This is the cheapest, lightest and most durable option, easily processed both industrially and at home. Under normal climatic conditions, it is practically eternal and harmless: it decomposes, if not hundreds, then certainly decades, so that ventilation ducts and various products from it will outlive the house itself.

But there is one severe limitation in use. This plastic contains chlorine, and the decomposition temperature of PVC (160-180°C) is lower than the plasticity temperature (200-220°C). Therefore, it cannot be formed with a burner and, moreover, it cannot be used where relatively high temperatures are used.

Round ventilation pipe made of polyvinyl chloride (PVC)

During decomposition, chlorine compounds and, first of all, HCl will be released. This gas with moisture forms hydrochloric acid itself, therefore it is dangerous for the eyes and respiratory tract, although in everything else it is simply unpleasant or almost invisible.

Thus, polyvinyl chloride is an ideal plastic for ventilation, partially excluding the kitchen, water heater, fireplace and those places where temperatures in excess of 120 ° C can occur (it is believed that this is the “top bar” for human safety).

Rectangular flat PVC pipes for arranging air ducts

Polyurethane

This plastic differs little from PVC, but can withstand temperatures up to 280 ° C without problems. At a higher temperature, decomposition begins with the release of nitrogen compounds, which is many times more dangerous than chlorine compounds.

Its high cost is considered a relative disadvantage, but it combines two seemingly incongruous factors: ductility and wear resistance.The plasticity of polyurethanes exceeds the resistance of granite and steel to fracture stresses. The finished product made of polyurethane can be bent an infinite number of times - it will not crack and will retain its original shape as soon as the stress disappears.

Polyurethane is ideal for domestic temperature parts, especially where shifts and distortions are possible: coupling rings, all kinds of nozzles and areas where there may be high domestic temperatures.

Polyurethane hose for installation of exhaust ventilation systems

Polypropylene

This plastic is ideal for molding. Already at 180°C, it is surprisingly plastic, so that any pipe can be twisted even just in hot steam, and the burner can be bent at any angle. At the same time, it is durable, and at high temperatures it does not emit anything dangerous by itself (impurity dyes or special additives can be dangerous). It is in the middle price category, but sufficient to make it not only the components of plastic ventilation systems, but also heating batteries.

Polypropylene is a relatively expensive but versatile safe plastic.

Ventilation pipes and components made of polypropylene

Deciding on sizes

The dimensions of the air duct section must correspond to the outlet of the exhaust equipment. If the pipe diameter is smaller than the mating hole, the system will make excessive noise, and the hood motor will work under increased load. The combination of these troubles will create uncomfortable conditions for the user and lead to a quick failure of an expensive installation.

Standard opening sizes for domestic exhaust systems are:

- 90x90 mm;

- 126x126 mm;

- diameter 100 mm;

- diameter 120 - 125 mm.

IMPORTANT! If you choose a duct whose configuration differs from the shape of the outlet, you will also have to purchase adapters - elements designed to go from a square to a circle (or vice versa)

Types of air ducts for exhaust: advantages and disadvantages

When choosing a pipe for a kitchen hood, you need to consider the following parameters:

- material cost;

- Pipe diameter and its compatibility with the hood and ventilation shaft;

- Possibilities of mounting the structure;

- Technical characteristics of the pipe - noise insulation, resistance to pollution;

- The appearance of the product and the possibility of its disguise.

Having decided on these points, you will easily come to the choice of the most successful version of the ventilation pipe for the hood in the kitchen.

In this section, we will consider the types of pipe materials for the hood in the kitchen, used as an air duct. Each material has its own advantages and disadvantages, which can affect the choice of buyers.

Plastic air ducts for exhaust

Plastic pipes for air duct have a rigid structure and a smooth surface. They can be made in the form of a cylinder or a rectangle. The round section is more preferable in this case, since it creates better traction inside the pipe. However, rectangular models fit better into the interior and are subject to disguise behind the kitchen set.

When installing plastic pipes, it is worth taking care of the purchase of adapters and clamps, as well as the tight connection of all parts of the structure. Working with the material of the duct itself is not difficult - the pipe can be cut with a simple knife.

The plastic ventilation duct in the kitchen has several advantages:

- Resistant to dirt and easy to clean both inside and outside the product;

- Neat appearance. If necessary, you can cover the structure with paint to match the kitchen or mask it;

- Low noise performance;

- Resistance to external factors - humidity, heat, mechanical damage;

- Long service life - a guarantee of 10 years.

Among the disadvantages of such systems are:

- High price compared to other materials;

- The complexity of the installation process and the need to purchase components for connecting the pipe.

Corrugated air duct

Often, corrugated pipes made of lightweight aluminum are used for hoods. Outwardly, they resemble a soft metal accordion. Such models are sold in the form of segments that can be stretched to the desired size - therefore this material is very profitable. It is also worth noting that the corrugation can be laid under any bend, if this does not interfere with the draft inside the duct for the kitchen hood.

pros corrugated air duct can be defined in several ways:

- Ease of installation - the pipe can be cut off at any place and easily connected with a special fastener;

- The absence of corners in the pipe that can trap air flows;

- Low cost.

There is also a significant disadvantage of using corrugated metal:

- Unattractive appearance. In most cases, in a home kitchen, such a duct will need to be masked;

- Rapid contamination of the internal parts of the pipe - dirt accumulates in the folds of the corrugation;

- When stretching the "accordion", it is impossible to return it to its original form.

Duct diameter calculation

In addition to the material from which the pipe is made, the key point in its purchase and installation is the calculation of the required diameter of the product. The air vent must be tightly and hermetically connected both to the hood and to the opening of the ventilation shaft of the house, where the polluted air will be discharged.

Incorrect calculation of the pipe diameter can lead to a decrease in the efficiency of the hood and air duct in the kitchen. Noise indicators will increase, the load on the joints of the structure and the efficiency will decrease. This can lead to a complete breakdown of the exhaust system, as a result of which it will have to be replaced.

Therefore, the installation of an exhaust duct must begin with the selection of the exact diameter of the ventilation pipe. To do this, you need to calculate the dimensions of the exhaust pipe (it is indicated in the instructions for the device) and the diameter of the home ventilation duct. Ideally, the size of the pipe section should exactly match the outlet openings of the ventilation elements. If the duct is smaller in size, you will have to buy parts for connection and ensure the complete tightness of the system.

There are standard dimensional grids for ventilation pipes of various shapes:

- For models with a round section, the minimum diameter is 8 cm, the maximum is 30 cm. The size grid is 1 cm, so the buyer can easily choose a pipe of the desired diameter. Air ducts with diameters of 180 and 200 mm are most widely used in everyday life.

- Rectangular air ducts have a more modest dimensional grid. They are designed mainly for built-in T-shaped hoods. The most popular sizes are 5x10 cm, as well as 8x15 cm. Adapters are needed for the installation of such structures.

Box design and operation

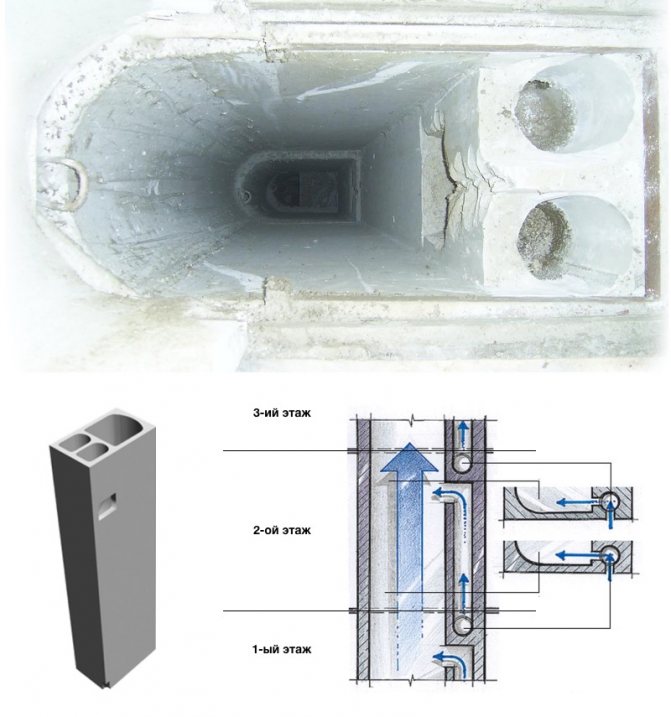

In order for the house to be provided with good ventilation and air conditioning, it needs a special air duct. Typically, air ducts are located in the kitchen, bathroom and corridor. The internal structure of the box consists of three channels. The first is a common ventilation shaft, and the second and third are air ducts. Usually they work in two different rooms - a bathroom and a kitchen. Their function is to ensure the inflow or outflow of air containing various impurities: dust, dirt, soot, moisture, etc.

A ventilation duct with three channels is considered the most common option. Its main channel is a square-shaped shaft, 300x600 mm in size. The shaft must pass through all floors of the building, capturing the basement and attic. During repairs in some area, it will be necessary to install a partition made of moisture-resistant and non-combustible material between the mine itself and the air ducts.

Ventilation ducts look like sleeves with a round or square section. In the bathroom or kitchen, exhaust air flows through the ventilation windows into the air ducts. If the ventilation ducts function correctly, then the kitchen air, filled with all sorts of smells, should not mix with clean air from other rooms.

When restoring the duct, attention should be paid on the material of the ventilation duct. It can be concrete or plaster

Based on the parameters of these materials, products are divided into straight and oblique (conical).

Box restoration process

There are times when irresponsible builders deliberately reduce the size of the box in order to increase the kitchen space.Such actions are unacceptable, and illegal, since all residents of the entrance will have to suffer. Polluted air streams, instead of going out into the street, will penetrate into the apartments of neighbors from below.

Due to complaints from neighbors, the culprit of the problem may face a fine with the subsequent restoration of the duct, or even a lawsuit if normal ventilation is not restored within 30 days.

Restoration of the box or a change in its size should take place in accordance with all the rules and not affect the ventilation efficiency. It is necessary to carry out the following preparatory and repair work:

Open access to air channels. To do this, it is necessary to dismantle the ceilings and walls. In some cases, you can not do without cutting a few tiles on the floor.

Choose quality materials

Attention should be paid to the material of the partition and pipes for ventilation ducts.

To create a box, foam blocks or gypsum boards are usually used. They have a number of advantages:

- impenetrability;

- strength;

- fire resistance;

- provide good sound insulation.

The thickness of the material is also important so that the ventilation duct does not turn out to be too wide, or, conversely, narrow. Do not use materials such as drywall, plywood sheets, chipboard or fiberboard as a partition. Despite their more attractive price and seeming benefit, they will bring only problems and further rework as a result.

As ventilation ducts that go from the box itself, plastic pipes of various section shapes or flexible structures are used. We talked about this above.

- Checking the ventilation.This can be done on your own or you can resort to the help of specialists, which you still have to do in order to get a work acceptance certificate, where the restoration of the duct will be evidenced.

- Decorative finish. After the ventilation operation has been checked, you can proceed to the finishing work. To do this, putty the joints, level the surface and choose the right material for lining the ventilation box, depending on the design of the kitchen.

To independently check the operation of ventilation, it is necessary to bring a lit match or lighter to the grate that closes the vent. In normal operation, the flame should deflect towards the opening. You can also use loose paper, which should attract and hold onto the grate.

Before starting work on the restoration of the ventilation duct, all surfaces should be covered with a film to protect furniture and other objects from dust.