- What is a wiring box

- Buying cable channels: what to look for?

- Advantages and disadvantages of open wiring

- Mounting Features

- Fixation methods

- How and what to cut

- Installation of cable channels

- Stage number 1 - preparatory

- Stage number 2 - assembly

- Making joints

- Cabling

- Corrugated plastic pipes

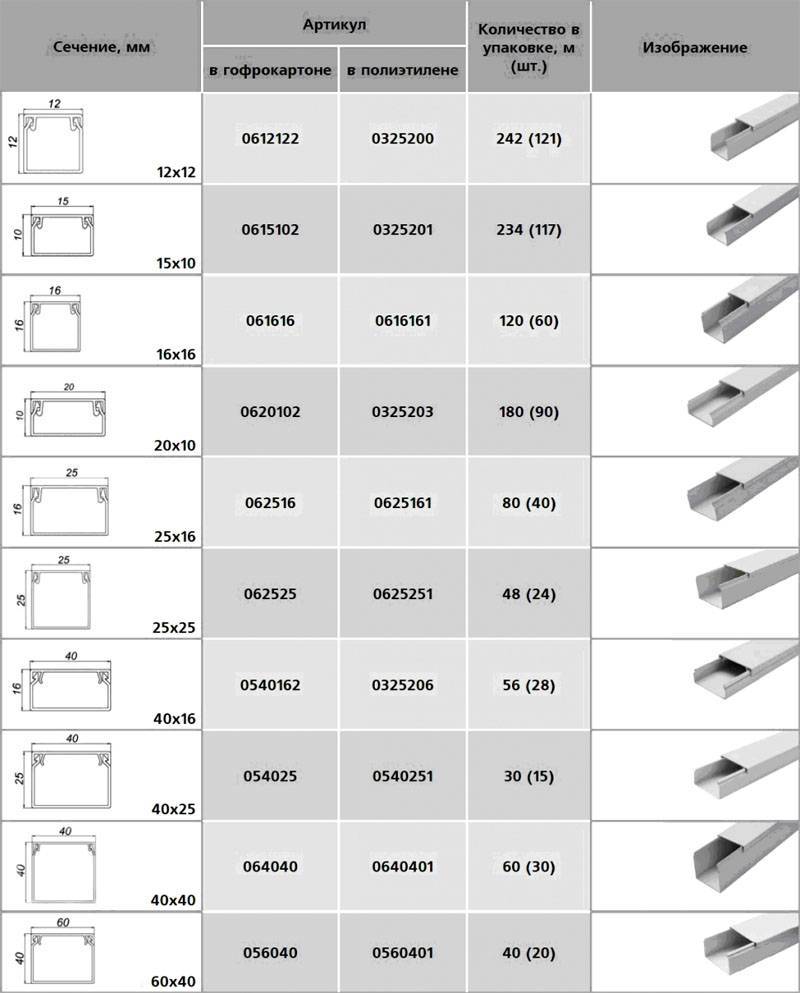

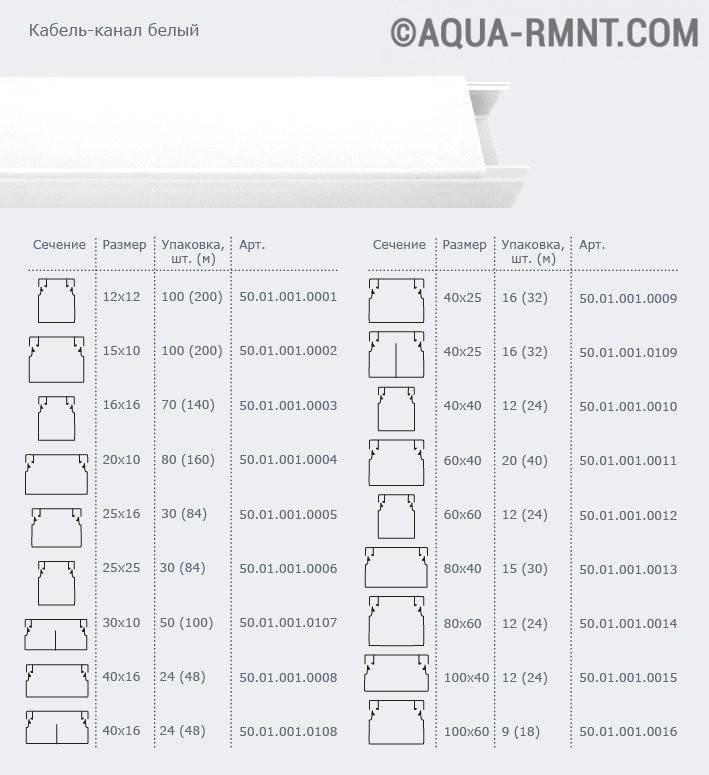

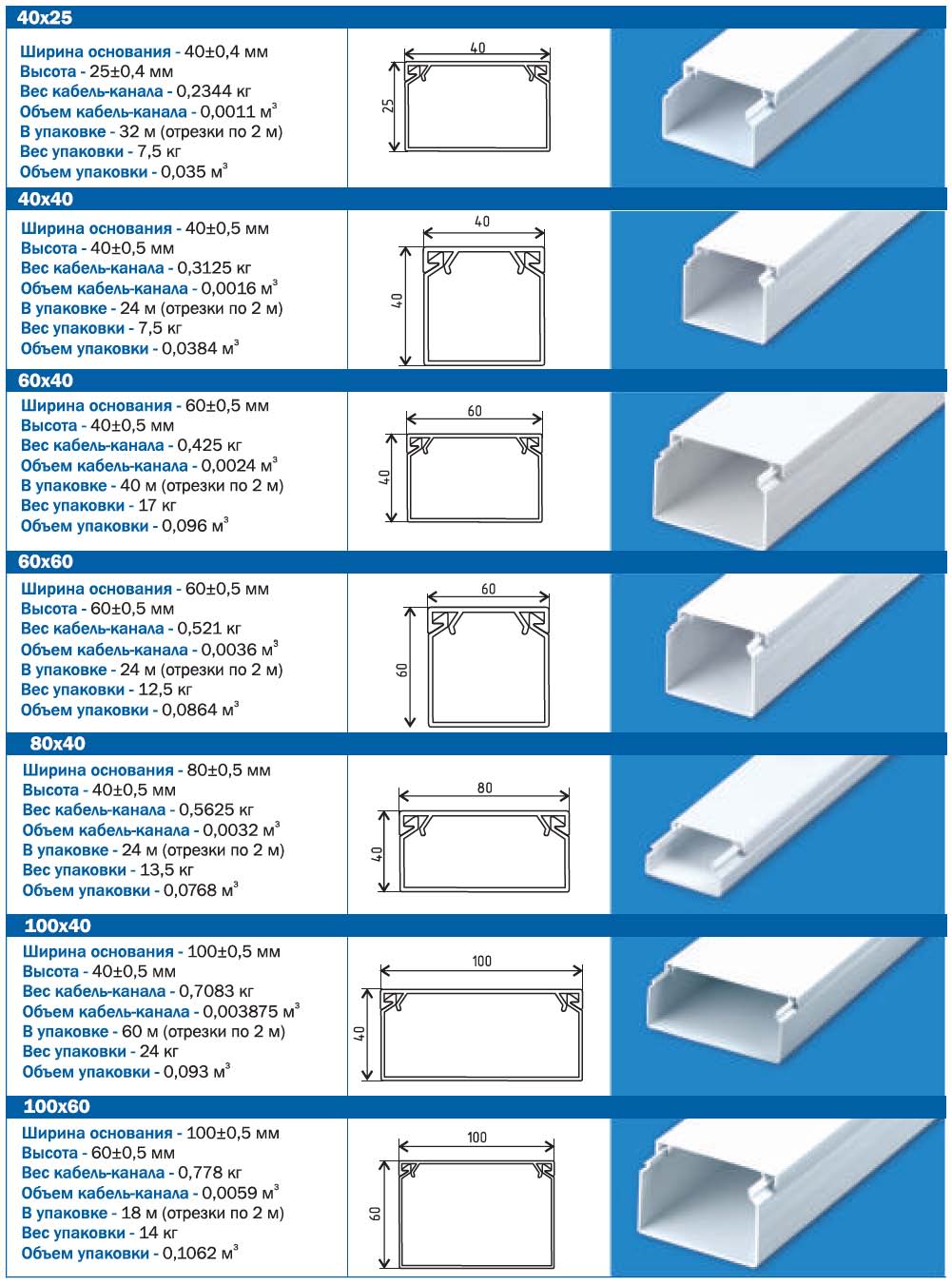

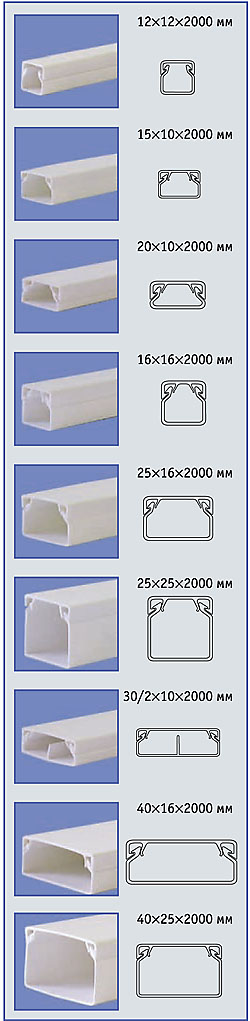

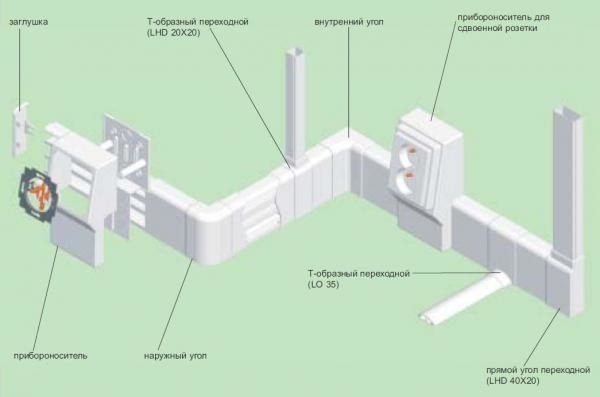

- Dimensions and accessories

- Open wiring in retro style

- Materials used for the manufacture of cable channels, their advantages and disadvantages

- Metal boxes for laying cables: types and features of installation

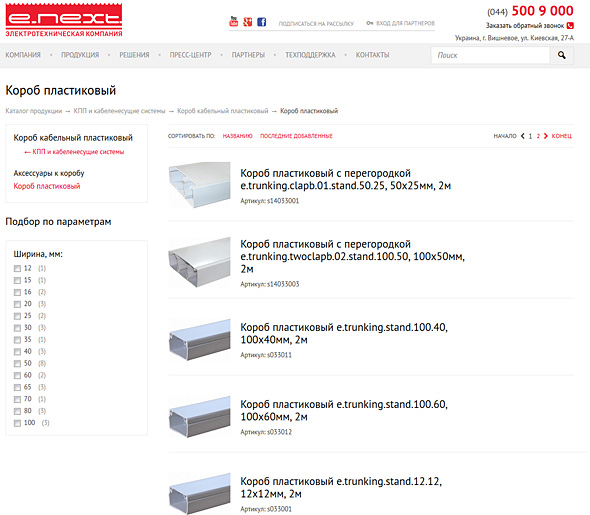

- Varieties and features of plastic boxes for wires

- How to choose a cable channel for wiring?

- What do electricians think about exposed wiring?

- Restrictions

- Main varieties

What is a wiring box

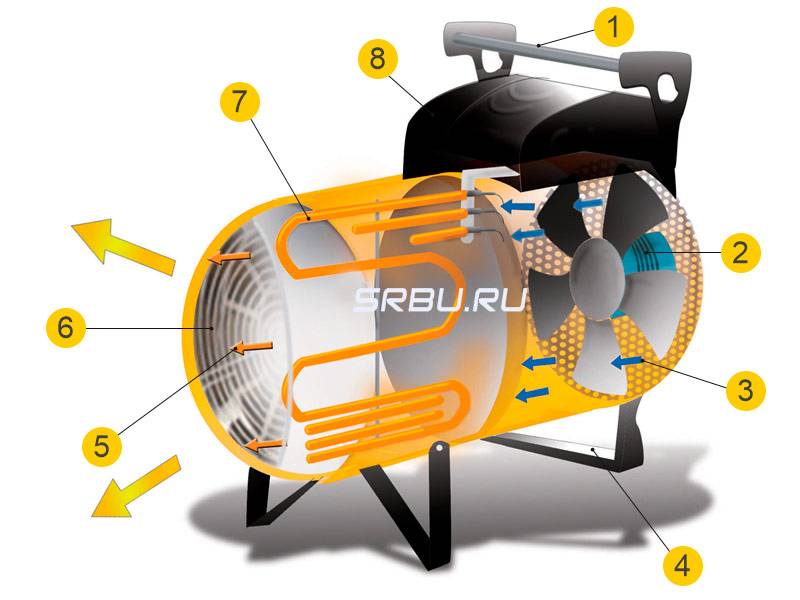

An electrical box, or cable channel, is an electrical product that intended for installation of cables and wires on the wall, floor or ceiling. The shape of the cable channel can be rectangular or triangular, the cross section looks like a closed profile, inside which power or low-current wires are laid. Unlike the corrugation, which performs similar functions, the wiring box is collapsible and consists of the inner cavity of the channel and the cover.The main place of application of the electrical box is the organization of network provision where internal wiring is not considered appropriate.

Power or low-current cables are bred in ducts in cases where installation of hidden wiring is not advisable

Buying cable channels: what to look for?

It is recommended to purchase a cable channel according to the following algorithm:

- Draw up a wiring diagram. It calculates the required number of purchased cables, their cross section. It is also recommended to buy wires before purchasing cable channels (to take into account the thickness of the insulation).

- Calculate the length of all required boxes for wiring. The standard length of one cable channel is 2 meters. This is not true for flexible strobes, as they are produced in coils. An additional 10 - 15% in reserve should be added to the resulting length.

- Decide on the type of cable channels required: plastic - for the room, metal - for the street, plastic rounded - for the floor.

- Approximately calculate the required size of the cable channel. For calculations, you can use the cross-sectional area of \u200b\u200bthe strobe (often indicated in the technical documentation for cable channels) and cable bundles (the area of \u200b\u200bone wire is calculated by the formula S \u003d πr2, where r is the section radius, taking into account insulation).

- Make a purchase in the store. It is recommended to buy complete cable channels, which are supplied immediately with fittings, plugs, corner adapters, locks. If you buy all this separately, it will turn out more expensive.

As for fire safety, with plastic ones it is enough to set fire to a small piece of the cable channel. It will melt, but should not ignite and smoke heavily.These are the basic safety requirements for such strobes. As for metal, it is recommended to purchase only with a material thickness of 0.15 mm and thicker. Thinner strobes are short-lived; when placed on the street, they will quickly become covered with rust.

A popular cable channel for offices - this way you can connect a workplace without any visible wires at all. Minimalism is in trend now

A popular cable channel for offices - this way you can connect a workplace without any visible wires at all. Minimalism is in trend now

Advantages and disadvantages of open wiring

Electrician on open wiring installation in one living room he spends several hours, an amateur will do the same work in a few days. Low labor intensity is the main advantage of this method. To lay a cable, install sockets in the house, you do not need to do dirty work:

- first make strobes, then plaster the walls;

- drill mounting holes.

The second plus is a quick modification of the power grid when new loads appear or a radical rearrangement of furniture in the apartment.

It is not difficult to install an additional, transfer to another place old socket (switch), connect a new lamp to the network

It is not difficult to install an additional, transfer to another place old socket (switch), connect a new lamp to the network

Note! The protection class of switches, sockets, junction boxes must be IP68. The method has disadvantages

The first is related to the interior. There are only a few styles in which an open cable fits harmoniously, these are steampack, techno, country, retro

The method has disadvantages. The first is related to the interior. There are only a few styles in which an open cable fits harmoniously, these are steampack, techno, country, retro.

country style nursery

country style nursery

The second minus is the high requirements for the cable and wiring modules when laying open wires in bathrooms, other rooms with high air humidity.

Mounting Features

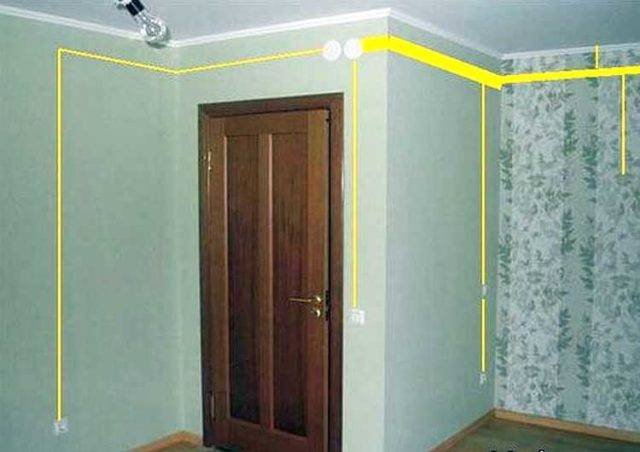

During installation, the cable channels are arranged horizontally or vertically. Sloping areas are only allowed on stairs or attic floors. Junction boxes are placed at the branch points, in which all connections take place.

Only vertical and horizontal

Fixation methods

There are two ways to mount the cable channels: on dowels / self-tapping screws and on glue / adhesive double-sided tape. The first way is universal. Suitable for all types of bases. Only the types of dowels need to be selected (there are fasteners for drywall and foam blocks). When choosing fasteners, look for dowels or self-tapping screws with caps of large diameters - so as not to tear the plastic. If these are not found, washers can be used.

The number of fasteners per 2 meter tray (standard length) depends on how flat the wall is. If it is perfectly aligned, 3 fasteners are enough - at the beginning, at the end and in the middle. If the wall is curved, more fasteners are needed so that the tray fits snugly against the wall and “does not bulge”. With a large number of cables or very curved walls, it may be necessary to install every 20 cm.

So that when installing cable channels on self-tapping screws or dowels, they do not burst, holes are first drilled in them slightly smaller than the diameter fasteners. Then the tray is applied to the wall, the holes are marked with a marker / pencil / felt-tip pen. Remove the cable channel, drill holes, install plastic plugs. Then apply the tray, fix it with dowel-nails).

When tightening fasteners, be careful not to damage the plastic

In some cases, you do not want to drill the surface. Then you can use glue or sticky tape. Glue should be taken with a quick initial fixation.The tray does not weigh very much, but if the fixation force is insufficient, it will “creep” down. To prevent this from happening, you can install spacers in the opposite wall (if distances allow) or fix the box with pieces of adhesive tape.

Floor adhesive tape requires a smooth, dust-free base. It is better to take it on a foam basis. In this case, the requirements for the "smoothness" of the wall are reduced. Due to the foam base, small pits / protrusions are smoothed out.

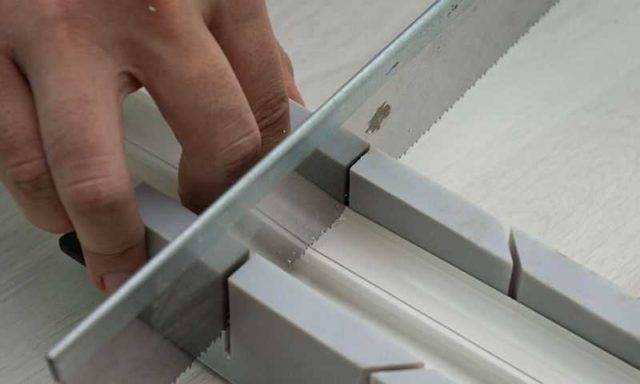

How and what to cut

If it is necessary to cut a piece of the channel cable of a certain length, first put on the cover, align the edges. Then, with a felt-tip pen, a mark is made on the tray and on the lid. After that, you can cut the cable channel separately: tray and cover. In this case, their length will be the same.

To achieve an exact match at the places of cuts, you can use a joiner's miter box. Even better is to find a special saw for plastic. In this case, the cut will be neat and, after a little processing of the edge with sandpaper, everything will match perfectly.

How to cut plastic straight

It is better to cut cable trays with a metal saw with a fine tooth. The edge is even. It can be sanded if necessary. sandpaper with fine grain. You can also use metal shears, but then there is a high probability that the edges will wrinkle and / or lose their ideal geometry.

Installation of cable channels

It would seem that the installation of plastic boxes is not a very complicated matter, but there is one point here, on which the quality of the installation depends. This is the quality of the surfaces on which the boxes will be installed and fixed.That's why the assembly process divided into two stage.

Stage number 1 - preparatory

First of all, the installation surfaces must be leveled. Their curvature is the gaps between them and the back of the panel, this is the curvature of the boxes themselves, which will simply be impossible to align. Therefore, the main requirement for a presentable appearance of installed fixtures is a flat surface.

A sharp knife is suitable for cutting the cable channel

The preparatory stage includes the preparation of tools. What do you need for this?

- For trimming, you can use a hacksaw, a jigsaw, a grinder, a sharp knife. That is, the tool that you work with the most. If you have chosen a grinder, then keep in mind that a lot of dust is released during its operation, so do not forget to wear goggles and a respirator.

- For marking, it is best to use a simple pencil.

There are certain nuances with the mounting tool. For example, if the walls in the house are already aligned and wallpaper is pasted on them, if the wall is wood, drywall, fiberboard or chipboard, then the best option is to put wire boxes on liquid nails. You can use other adhesives. But keep in mind that it is impossible to lay the wires in the box until the adhesive is completely dry.

Stage number 2 - assembly

If the wall is a tree, then it is better to fix the box on self-tapping screws. And for this you need either a screwdriver or a screwdriver. In some boxes, the rear mounting plate is made of thick plastic, so the self-tapping screw may not cut through it. So, you will need a drill with a thin drill bit for metal.

If the walls are brick or concrete, then the installation is done with self-tapping screws on plastic dowels.

- First, holes are drilled in the back panel.

- It is installed on the wall, marking is made through the holes with a pencil.

- According to the markings, holes are drilled with a drill, where plastic dowels are inserted.

- Fastening with self-tapping screws.

The best option for attaching a plastic box, if the base allows it, is liquid nails

Let's face it, this is the most troublesome option, so some masters drill in the mounting panel and in the wall in one operation, setting the panel to the wall and drilling one hole in them right away.

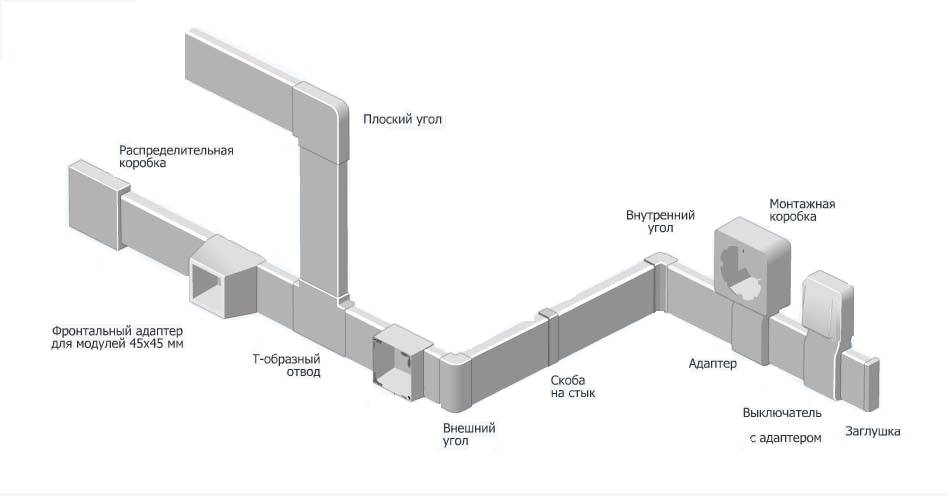

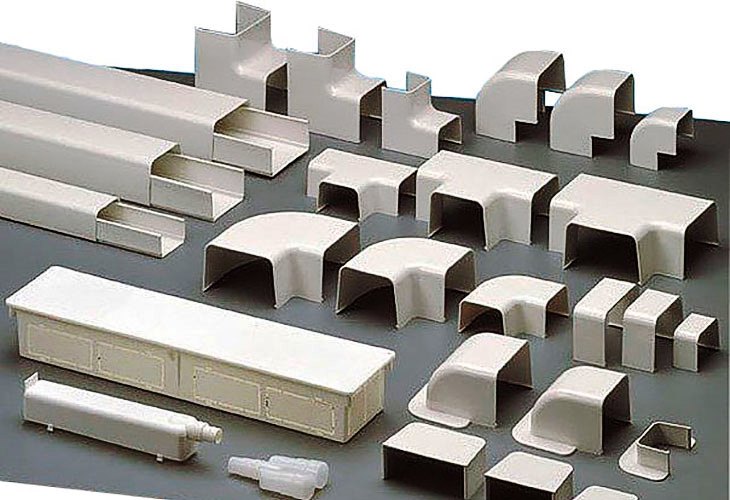

Making joints

This operation must be brought to a separate stage, because, as the wizards say, this is the most difficult moment in the entire installation process. Most often, joints are the connection of horizontal and vertical circuits of electrical wiring. Here the main goal is to create a transition without gaps and gaps so that it looks presentable.

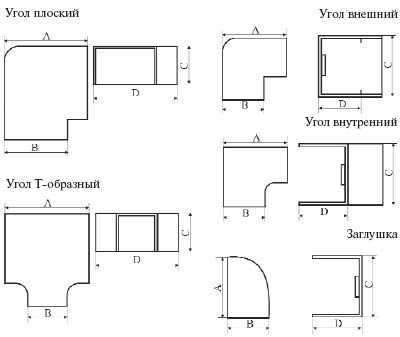

It is for these purposes that the accessories are used. If it is not, you will have to use different methods of fitting. For example, cut the back panel and cover at 45º, and then join the two sections at a right angle. By the way, for angular adjustment, it is necessary to take into account the fact that horizontally and vertically installed boxes should be one size.

Scheme-image of accessories for cable channels

Cabling

It seems to be a simple process, but even here there are nuances. We recommend choosing cable boxes with longitudinal baffles in their design. You can easily lay cables in them, so to speak, floor by floor, so that they do not interfere with each other

If the cable channel is a box without partitions, then pay attention to cover fastening quality

It is important here that it is not squeezed out under the pressure of the weight of all the laid wires.

Corrugated plastic pipes

If cable channels, plastic or metal, are more suitable for flat surfaces, then in the case of frequent transitions between planes or turns, their installation will be extremely difficult due to the need to use a large number of additional components. In such conditions, flexible pipes that bend at any angle and are attached along the entire length to standard clips will be a more suitable material.

Externally, a corrugated plastic pipe looks like an elastic channel of circular cross section. It is used for laying any cables and wires, providing them additional protection against humidity and mechanical damage. It is mainly used in the installation of electrical circuits with a complex trajectory of laying wires - raised floors, suspended ceilings, electrical wiring behind plasterboard walls.

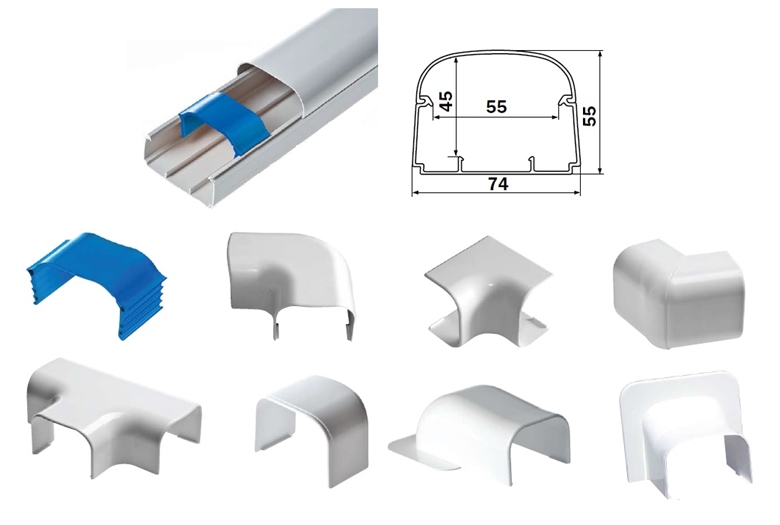

Dimensions and accessories

PVC is used for the production of corrugated plastic pipes.

Most often, products with an internal diameter of 16 to 32 mm are used, but when choosing, you must additionally pay attention to the purpose of the corrugation - it can be light or heavy

The first are standard products that are used for the installation of electrical circuit lines inside buildings. Heavy corrugations give more solid protection and can be used outdoors, and in some cases under water.

Since it is not always possible to push a wire through a pipe without auxiliary parts in long lines, additional corrugations can be equipped with probes made of metal single-core "steel", however, usually installers have their own.

Dimensions of corrugated pipes for cable:

| header | Outer diameter, mm | Inner diameter, mm |

|---|---|---|

| Corrugated PVC pipe without probe | 16 | 10,7 |

| 14,1 | ||

| 25 | 18,3 | |

| 32 | 24,3 | |

| 40 | 31,2 | |

| 50 | 39,6 | |

| 63 | 5,6 | |

| Corrugated PVC pipe with probe | 16 | 10,7 |

| 20 | 14,1 | |

| 25 | 18,3 | |

| 32 | 24,3 | |

| 40 | 31,2 | |

| 50 | 39,6 | |

| 63 | 50,6 |

+ Advantages of plastic corrugated pipes

- Indispensable for laying wires on uneven surfaces or, if necessary, making frequent turns of the line.

- They are usually sealed along the entire length, so they reliably protect the wires from high humidity.

- Additional protection of cables from mechanical damage, and people from electric shock.

- Mounting on clips is one of the easiest to install and maintain - you can insert or remove the corrugation from them without additional tools.

- Plus to fire safety - the plastic from which the corrugation is made contains additives that prevent combustion. When the wiring is closed, the corrugation will not flare up, but simply melt.

- Cons of plastic corrugated pipes

- They do not tolerate negative temperatures well - when supercooled, they lose their elasticity and break, therefore they are more suitable for interior work.

- With an excessively large number of turns and bends, pulling the cable inside the corrugation will be very difficult, and sometimes impossible, so you will first have to tighten the wires inside and then perform the general installation.

Open wiring in retro style

retro way

It is now so beautifully called, but before it was the only option for open wiring. It was used not only in the bath, but also in residential premises. The wires were fixed on porcelain insulator rollers.

For such wiring, electrical wires must be only single-core, the cups are fixed at a distance of no more than ten centimeters, plus one at every turn. The wires had to be twisted, and this is a long and tedious task. In addition, white insulation became dusty and dirty for a short time, various spider bugs very often settled in it for permanent residence.

Electrical wiring in retro style

Today, open wiring by the described method is mounted only by great lovers of antiquity, who do not know what it will look like in a few years.

Open wiring in retro style

Materials used for the manufacture of cable channels, their advantages and disadvantages

For the manufacture of cable channels for electrical wiring, various materials are used. This determines not only appearance of manufactured productsbut also their technical characteristics. Do not think that the wire boxes perform an exclusively decorative function. Their main purpose is to protect people inside the building from the consequences of an emergency, such as a short circuit. Given the load on the electrical network, most often mounted inside residential premises plastic productsand in industrial plants. Each type has its own distinctive features, which you should definitely familiarize yourself with before buying.

Choices must be made on an individual basis.

Choices must be made on an individual basis.

Metal boxes for laying cables: types and features of installation

The appearance of metal boxes for electrical wiring can hardly be called attractive. However, in terms of safety, they are significantly superior to plastic counterparts. They can be open and closed.

Metal products are highly durable

Metal products are highly durable

When laying a power supply system in an industrial enterprise, open steel products are often used, mounted on walls or fixed directly under the ceiling. This metal wiring box is wide enough to fit thick cable bundles inside.

Open models are popular in industrial plants

Open models are popular in industrial plants

The use of closed products is abandoned because of the inevitable heating of the cable due to the meeting of the magnetic fields of adjacent wires. This can cause ignition of the electrical wiring and shutdown of the automation. In open systems, natural ventilation provides timely heat dissipation.

Metal is a good conductor. To guarantee the safety of people nearby, when installing electrical steel boxes, grounding is mandatory.

Related article:

Grounding is mandatory

Grounding is mandatory

Another type of metal cable ducts are anodized aluminum products. They are mainly used in the laying of power supply systems in industrial enterprises. Sometimes they are used in home interiors decorated in Hi-Tech style. They consist of a box with a lid, a column, polycarbonate mounts and wiring.

The advantages of such products include:

- Possibility of protection against electromagnetic influence;

- High impact strength;

- UV resistance;

- fire resistance;

- The ability to withstand significant temperature fluctuations without loss of geometric shape.

The disadvantages include the complexity of the installation work. Dowels are used to fasten the box and cover, which greatly complicates installation and requires a special tool.

Anodized aluminum box

Anodized aluminum box

Varieties and features of plastic boxes for wires

Plastic boxes for electrical wiring cost much less than their metal counterparts. They can be open and closed. Considering that plastic is not among the electrically conductive materials, grounding is not provided for when installing plastic systems.

Plastic products are presented in a wide range

Plastic products are presented in a wide range

For their manufacture, self-extinguishing PVC is used, which eliminates the possibility of flame spread in the event of an emergency. In closed products, the lid fits snugly against the channel. This also contributes to an increase in the level of safety, since full combustion becomes impossible due to limited oxygen access.

Plastic plinth will hide the wires

Plastic plinth will hide the wires

Despite the fact that the PVC cable channel can be purchased at a relatively low price, their use in industrial enterprises is limited. Due to low strength characteristics, such products have a limited service life. Open models are purchased when laying a small amount of cables.

closed plastic cable channels are widely used when installing household wiring. Manufacturers offer products of various colors, shapes and sizes, and therefore choosing the right option for a particular room will not be difficult.

A wide range of sizes will allow you to choose the right option

A wide range of sizes will allow you to choose the right option

How to choose a cable channel for wiring?

Even an insignificant, at first glance, characteristic of the wiring box can be a key factor in choosing the right option.

So, what properties can be considered when buying a product:

Material

draw attention to safety, durability, level of protection in case of possible fire.

Construction type. Cable channels for wiring installation can be produced in the form of smooth or corrugated pipes, tracks, trays, etc.

d.

Application specifics. Characteristics of systems used for industrial premises, private houses or equipment may vary significantly.

For example, more stringent requirements are imposed on the fire safety of a cable box used for wiring in wooden houses, and static structures are not suitable for wiring used in moving mechanisms.

In addition, pay attention to color. This factor is relevant in the case of arranging open wiring, in which the elements of the cable channel are visible and must meet aesthetic requirements.

Cable channels are produced in various colors. The most popular colors are white, steel, gray, black, natural wood color.

What do electricians think about exposed wiring?

The disadvantages of open (external) wiring are much greater than those of hidden (internal).

Cables covered with plaster are not damaged, do not interfere with repairs and are completely invisible. Open wiring is devoid of such advantages, and in the event of a short circuit, it is more likely to catch fire than hidden. An open method of wiring is often chosen for wooden houses.

In wooden houses, laying an electric cable in an open way is a necessary measure, because. Hidden cabling can be difficult or even impossible

There are still some advantages to the open mounting method:

- Simplification of installation. When laying electrical cables, you do not have to ditch the walls. This reduces labor costs and the amount of work.After installation, there is practically no construction debris left.

- Cheaper. Here we are talking about saving on electric bills.

- Possibility to change the cabling scheme. If the plans for the future include redevelopment of the wiring, then it is better to choose an open installation method.

When choosing an open method of laying electrical wires, it should be taken into account that they will have to be masked and protected from external influences. There is always the possibility of moisture ingress or accidental damage.

When installing boxes, sockets, switches, difficulties often arise. Before starting work, you need to carefully study features of their installation or entrust the work to an electrician

If the house is residential, you need to weigh everything three times. It is advisable to consult an experienced electrician, and installation must take into account the increased risks and especially carefully monitor compliance with safety measures.

Restrictions

What will happen in the event of a short circuit. in a box? Will it ignite and cause a fire?

The answer to both questions is negative. Plastic boxes for wires are made of a very specific polymer - polyvinyl chloride, which does not support combustion.

However, there are limitations. Laying wiring in a vinyl box is strictly prohibited in wooden houses. In them, the wires must be bred in a metal pipe and only in it.

The use of vinyl boxes in a wooden house is contrary to the rules for the operation of electrical installations and fire safety

Why is it impossible to lay wiring along wooden walls in a box?

You see, if the wiring is short-circuited (for example, when it is overloaded and the insulation melts), the walls of the box will not light up, but they will not prevent the ignition of adjacent structures either. They will just melt. But metal pipe even shorting directly to its walls will last a time sufficient for the circuit breaker to operate in the shield.

What types of pipes are used for wiring in wooden buildings:

| Image | Type of pipes |

|

| Steel water pipes. Their advantage is low price, the disadvantage is the tendency to corrosion at high humidity. |

|

| Copper. Here the picture is reversed: the walls of the pipes are not afraid of rust, but the wiring in the pipe will cost the owner a significant amount. |

|

| Stainless corrugated metal hoses. They represent a reasonable balance of cheapness and durability: a linear meter of pipe will cost the buyer 135-200 rubles, and it serves indefinitely even in damp rooms. |

Main varieties

Depending on the modification, the dimensions of the cable channels, their shape, material of manufacture and technical indicators differ. In everyday life or for wiring in offices, the most common are:

| Name | Peculiarities | Applications |

| Mini | Box with a small section. They fit up to 3 small cables. Installation of mini cable channels is carried out using self-tapping screws. When turning the wires, the joints are poured at an angle of 45 ° or plugs are placed. Typical dimensions vary from 10x10mm to 60x80mm | Most often used in the conduct of the Internet, television and telephony. |

| Flattened floor | Oval profile, which is used if it is not possible to run cables around the perimeter of an office or apartment. When installing, one edge of the box is fixed to the floor with screws, then closed with a lid and plugs are placed at the joints. Made of aluminium, galvanized or hard plastic. Size variations: from 16×6.5 cm to 7.5×1.5 cm. Among the colors are white, black gray, brown and a natural wood option. | They are laid in offices where it is necessary to lower the wire to office equipment or a workplace in the center of the wall. Suitable for one or more medium size cables. |

| Parapet guides | The main (parapet) boxes are made of plastic. There are several variations depending on the type of profile: similar to the “P” cloak without a partition, to “W” - with three sections, to “G” for corners, figured and universal. The main advantage is the ability to adjust the angle of rotation in the range from 7 to 45 ° using adapters. Dimensions from 10×6 cm to 1×2 cm. | They are used in any domestic premises. |

| Perforated with open access | Made made of plastic or metal is 30-40% lighter than conventional options with easier installation. They are provided good air circulation, there is constant access to the wire in different parts of the network and can be installed on curved surfaces. | Used for communication wires between each other when entering into electrical panels or in production workshops where the appearance of the wiring is not important. |

| Skirting floor | This type of cable channel is fastened with self-tapping screws to the walls or floor.By design, they resemble hollow sections with a lid on top. The main selection parameter is the width of the diagonal wall (5 and 7 cm). The advantages include versatility for residential and office premises, variability in color performance and immunity to ultraviolet rays. After dismantling the plinth cable channel, it can be reused. | Offices, administrative buildings, apartments and private houses. |

| Flexible | Prefabricated structures made of metal or plastic. They are available in different colors, there are corrugated models. Such cable channels protect against mechanical damage, vibration or chemical reactions with the external environment. Such a box is flexible, able to reduce noise levels and give free access to wiring. At the same time, it is easy to replace a single element, and installation does not take much time. By diameter, the following subtypes can be found:

| When connecting wires to machines and other equipment in production. |

| Corner ceiling | Installation of the corner cable channel is carried out at the joint between the wall and the ceiling. The triangular shape of the design fits perfectly into a flat corner. The maximum dimensions of the internal cavity are 4 by 4 cm. Simple installation and light weight design are among the positive sides of the box. Such cable channels are fixed only under the ceiling due to their fragility. | Any office and residential premises. |

| Transparent with backlight | Outwardly similar to the corner ceiling models. They have a fully transparent lid tilted at an angle of 45°. They have built-in lighting. | They are used to decorate the lighting system under the ceiling, frame kitchen cabinets and other decorative elements. |

| Industrial wire | Made from metal wire. They provide free air circulation, quick access to wires and do not accumulate dust inside the structure. | They are mounted in warehouses and workshops, as well as behind stretch ceilings. |

The types of cable channels listed can be divided according to the degree of rigidity, the presence of a cover or the type of locks at the joints. However, the installation of boxes for wiring in the apartment carried out according to one principle and with general rules.