- Varieties of convectors depending on the heating elements

- Advantages and disadvantages

- Embedded in window sill

- Floor

- Built-in heating systems

- Advantages of the latest technology

- Installation

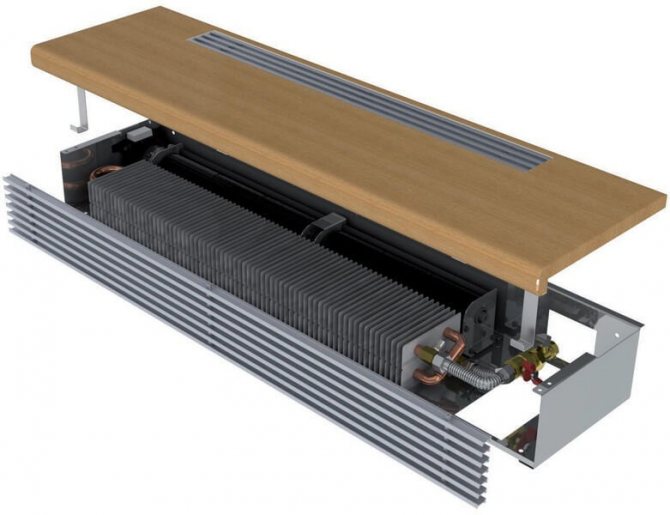

- The device of convectors for window sills

- Mounting

- Preparation of materials and tools

- Step by step process

- Sample installation

- Approximate order of work

- Characteristics of parapet convectors

- The device of convectors for window sills

- Installation Recommendations

- Design features

Varieties of convectors depending on the heating elements

Convectors for the installation of a heating system in rooms, depending on the energy source used, are divided into several types:

electrical. Devices of this type are very convenient, effective. They are powered by electricity. For their device, it is not necessary to install a complex system of pipes. Electrical appliances are equipped with closed-type heating elements - heating elements. Additional plates are installed on them to increase the heat transfer area. Heating elements are made of aluminum, steel and copper. The durability of the entire system and its efficiency depend on the quality of the heating elements;

water. The working element of the system is hollow tubes, which are equipped with welded or pressed plates.A certain coolant circulates inside - water, antifreeze, and others. The type of liquid depends on the instrument model. Connection to an existing heating system is made through threaded pipes. The circulation of the coolant is most often forced. The wiring of the system is one- or two-pipe. Pipes are made of copper, aluminum, ordinary and galvanized steel. The first option is characterized by the highest cost. To reduce the price, a combination of copper and aluminum is often used. The cheapest models are made of galvanized steel;

gas. Devices of this type are characterized by efficiency due to the low price of the energy carrier. A significant drawback of the use of such units in residential buildings is the high explosiveness of gas

But with all the precautions, these devices show their best side.

Advantages and disadvantages

Built-in convectors have a number of positive qualities, thanks to which the popularity of these heaters is only growing. The benefits include several factors.

- Compact size and neat design compared to classic radiators. Convectors do not take up much space and do not catch the eye. The only visible part of the structure is the metal grills for air intake.

- Safe. Since their case is hidden, and the device itself does not heat up to high temperatures, it is impossible to get burned on it. This makes it an ideal choice for installations in apartments with small children.

- Efficiency. Built-in models of radiators do not differ in result from classic models and perfectly heat any room in terms of area.

- Do not spoil the interior, invisible.More and more designers offer to install floor convectors in their projects. They do not overload the interior with unnecessary details and are combined with any style - both classic and modern.

- Rapid heating of the room. This is possible thanks to the tangential fans installed in such radiators. They provide additional, forced convection.

However, such radiators also have disadvantages.

- High price. Built-in models have always been and will cost more than classic convectors. This does not allow them to be used for mass purposes.

- The installation process can be difficult. Especially often, difficulties are encountered when embedding convectors into ready-made window sills. For this reason, many install radiators before replacing windows or during the construction phase of a home.

Hidden convectors are divided into several types depending on the installation location.

Embedded in window sill

Such models are installed under the window. Its main functions are:

- blocking the penetration of cold air into the room from the windows;

- protection of glasses from fogging and freezing;

- protection of slopes from the formation of condensate and, as a result, mold.

According to statistics, up to half of the heat in a room can leave the room through the windows. In addition, condensation on the windows will invariably lead to an increase in the overall humidity in the home and increase the risk of mold formation. Convectors built into the window sill perfectly cope with these tasks, becoming the first line of defense against cold and dampness in the apartment.

Complemented by tangential fans, the models will provide forced convection, which will significantly increase the energy efficiency of the device.

Floor

Often on sale you can find the so-called water fan coil. It is sometimes called electric because it is supplemented by tangential fans that are powered by the mains. The power range of such devices is from 750 to 3000 kilowatts. They differ from standard models only in the shape of the body and the location of the grilles for air intake.

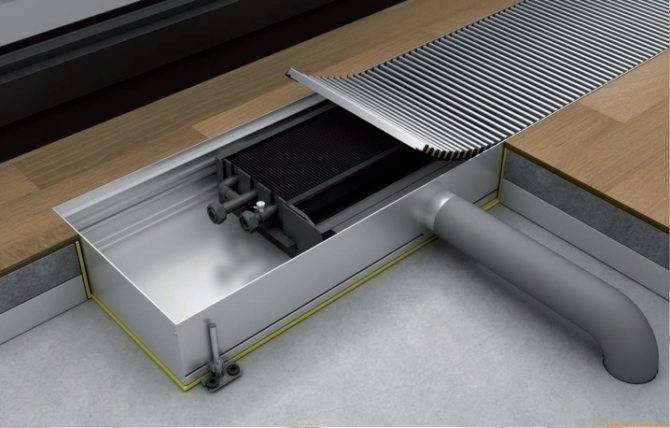

Built-in heating systems

Heating built into the floor must have a special recess in the floor. To do this, a niche is made before laying the floors. An electric convector or underfloor convectors for water heating are mounted in it. Such systems are widely used in houses with panoramic glass panels. They do not spoil the look of the interior of the rooms. The built-in heater, is closed by a decorative grid flush with a floor. This allows you to heat not only the room, but also doors and windows.

Underfloor water convectors are more economical than an electric unit built into the floor.

Materials for the manufacture of water heating systems are diverse. Heat-conducting properties of the metal from which the pipes and fins of the models are made:

- Iron - 47 W / Mk

- Brass - 111 W / Mk

- Aluminum - 236 W/Mk

- Copper - 390 W / Mk

Devices

Copper, have a greater thermal power. Combined options such as copper-aluminum (aluminum fins) or copper-brass (brass fins) have a lower cost. Although they are not inferior to copper in thermal conductivity. Iron water systems built into the floor are the cheapest. Their thermal power is significantly inferior to the listed specimens.

Electric convectors built into the floor are made of heating elements to which current is supplied.The heaters are usually protected by ceramic jackets. Heat-conducting metal plates are mounted on their body. They increase the heat transfer area.

Water heating convectors are built-in, they can have forced or natural air convection. With natural circulation, the heated air itself rises. It is pushed out by the cold lower layers of air. For forced convection, one or more small fans must be built in. They contribute to a more intensive exchange of air through the heater. This helps to heat up the desired room faster. The fans are connected to an AC or DC power supply. Such devices are also equipped with electric convectors that are built into the floor.

Built-in heating can be equipped with temperature sensors that are connected to the smart home system. This helps to improve efficiency during operation.

Water

Convector floor water, can be used in the summer as an air conditioner. For such purposes, systems with four pipes are used. They are connected simultaneously to the heating and to the chiller (liquid cooler). Such models are called fan coil units.

Advantages of the latest technology

Infrared film is used not only for heating window sills, it is used in underfloor heating systems and baseboards. Installation of this device is simple, and special tools and skills are not required.

The heating film has the following qualities:

It heats up in a very short time: one to two minutes, and it is in the operating temperature range.It warms up qualitatively, evenly, affecting the entire area.

The power consumption is striking in its economy - 20 watts. Three window sills - three 20 W each are equal in energy consumption to one incandescent bulb.

Great aesthetic look. It does not spoil the base at all, since for installation it does not require either a cement screed or an adhesive solution: it is applied to the surface by a dry method

This is very important: in case of its failure, you do not need to do “dirty” work. Replacement will take about an hour of free time.

It is sold in sets that include all the necessary fixtures and elements for its installation: special adhesive tape, mounting wires, an insulating block, several clamps.

To control such a heating system, a convenient electronic control has been created.

There are both simple manual devices and programmable ones with an LCD display.

Invisible to prying eyes. It is more convenient to measure the thickness not in millimeters, but in microns.

Installation

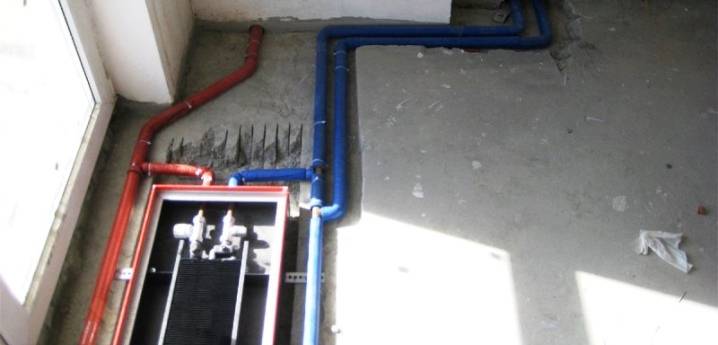

The first step in the installation of floor convectors is always the preparation of a special niche for installing the device. In the case of floor-mounted convectors, this can be either an ordinary concrete screed or installation in a raised floor. Both installation options for such convectors are possible only if the repair in the room has not yet been completed, and the floors have not yet been installed.

When choosing a niche for heating units, you should pay attention to the following indicators

- Hole depth. The depth of the niche should be approximately 10-15 mm greater than the height of the device itself. This figure is most often indicated by manufacturers in the user manual of individual models.Safety millimeters will allow you to correctly align the box of the device, as well as the grate with the floor level.

- Niche width and length. Here, experts advise adding to the dimensions of the device from 5 to 10 mm - so you can competently strengthen the body of the device and will not experience difficulties when laying communications.

- Distance from windows and walls. Experts recommend leaving 5 to 15 cm between the installed unit and the window (or panoramic windows). If we are talking about the distance from the device to the walls, then here it should be kept from 15 to 30 cm in order to avoid the formation of mold in the corners and the accumulation of heat only on the walls.

- Curtains. Curtains or tulle are an indispensable element in most style decisions. Keep in mind that they should not interfere with air circulation, therefore, they should not close the heaters from the room. The ideal option for built-in convectors would be small and light curtains in country or Provence style, blinds or twisted fabric models.

- insulation and heat loss. Illiterate placement of the heating device leads to a decrease in the heating efficiency and the efficiency of the device itself. When installing, be sure to use insulating material, otherwise all the heat generated by the unit will not heat the room, but the next 1-2 square meters of the floor

- Sustainability. The device is mounted to a state of complete stability and stability. To adjust a comfortable height, special supports or brackets can be used. As additional stabilization of the device in the niche, various fixing working solutions can be used.Such stabilization of the position of the unit is necessary for the future installation of pipe communications, which, with the slightest displacement of the wiring, can lead to flooding of the room and damage to the flooring.

When installing a water-powered convector built into the floor, there are only 2 ways to connect communications.

Flexible. Such a connection involves the use of flexible communications or hoses that supply the coolant to the heat exchanger. A definite plus of such a connection is that the communications are easily removed during the cleaning of the unit, and then freely fixed back. The disadvantage of such a connection is the relative fragility and vulnerability of flexible communications.

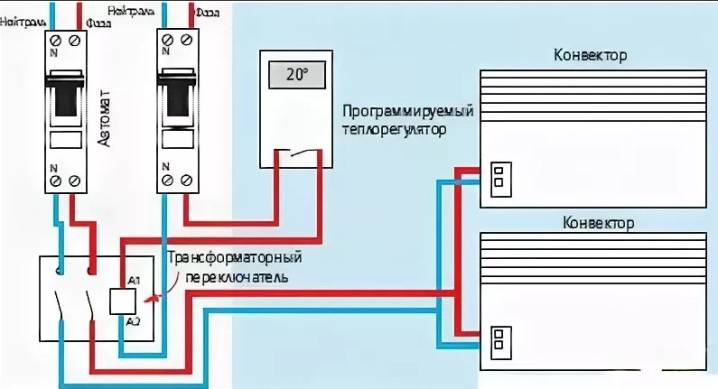

In the case of connecting an electric convector built into the floor, it is enough for you to correctly lay the wires and connect the device to a 220 volt network. Grounding in this case is not required, since communications in modern floor convectors are made a priori with grounding. Make sure that all wiring is hidden under the floor - so you protect yourself from injury, and the device itself from premature breakage.

Additional tips for installing floor convectors.

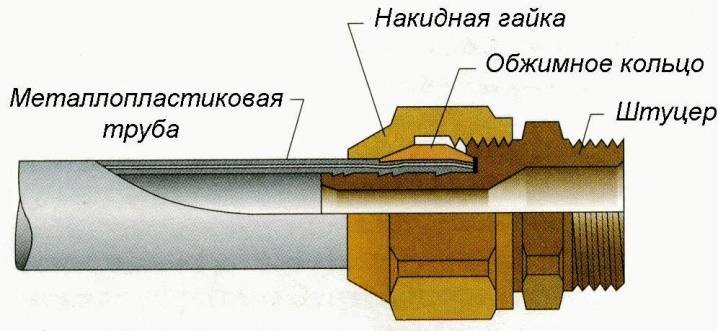

- Metal-plastic pipes or communications are considered the best material in tying built-in convectors. They simultaneously have sufficient strength for long-term use and ductility for easy placement in any laying conditions.

- Communications, regardless of their type, should be embedded in a concrete coating or covered with a raised floor. There should be no extra connections or switches in this section of laying communications, which is why purely metal options are impractical here.In the case of laying a raised floor, it is possible to install communications of any type, however, metal-plastic or polypropylene remains the recommended materials here.

- When installing the unit and then laying the grille or decorative frame, gaps and free space between the decking may be formed. Experts advise filling it with silicone.

- The installation of the pipes of the circuit to the device should be carried out using special union nuts (they are also called "Americans").

The device of convectors for window sills

All convection heaters work by natural convection. The heating elements installed in them provide heating of the air, as a result of which it rises, displacing part of the air masses down. A kind of circulation is formed, due to which all the air masses in the room are heated and mixed. After some time, after turning on the heating in the rooms, it becomes noticeably warmer.

Convectors built into the window sill are fairly simple heating devices, similar in design to floor models. Often they are called parapets. Their main distinguishing feature is their small dimensions - they are built under the window sills, so they should not take up too much space.

.

These built-in heaters consist of the following parts:

Device parapet convection heater.

- Metal cases - they are completely hidden under the window sills, so they are not visible from the side;

- Heating elements - made of steel and non-ferrous metals, provide air heating;

- Tangential fans - provide intensive air circulation;

- Thermoregulation systems - provide maintenance of the set temperature.

Thus, built-in convectors in the window sill are not much different from the usual convector appliances.

Temperature controllers and transformers for powering tangential fans are most often supplied separately, but can also be included in the basic package of built-in convective devices.

Please note that there are two categories of convectors built into window sills on the market - with and without complete window sills. The first are structurally finished devices that can only be installed under the window and connected to the heating system. In their upper part one can see a narrow grate through which warm air is ejected.

In their upper part one can see a narrow grate through which warm air is ejected.

Convectors without window sills are designed to be inserted into existing windows - in this case, you will have to suffer thoroughly over their embedding. In some cases it is easier to buy a device with ready-made window sills made to order. In order for them to match the appearance of the premises, models of various colors are presented for the choice of consumers. Air is taken in and removed through decorative grilles.

Mounting

Water convector

Warm window slabs are an expensive pleasure, unless they are made by hand.

A simple solution is to equip the load-bearing base with a heater, and form 1-2 convection grates in the window sill.A more complex and time-consuming, but no less effective (or maybe more) design is a concrete block with heating elements (heating elements or water pipes).

Preparation of materials and tools

The following tools and materials may be needed to install the heating device:

- grinder (UShM) with a set;

- perforator and various nozzles (chipper, mixer);

- welded metal mesh;

- foil isolon;

- adhesive solution (tile adhesive or the like);

- cement with sand (for a monolithic concrete window sill);

- copper tube (for water coolant);

- heating elements (for electrical device);

- materials for creating formwork, etc.

Step by step process

Let's consider two main ways of installation of heating. Let's start with the arrangement of the base, on which the window sill with convection gratings will be attached.

Water coolant

Sample installation

- Before installing the heating, prepare the base. To do this, using a perforator, it is deepened by 5-6 cm.

- A formwork is formed from the side of the room with a height of 2-3 cm: two slopes, the bottom of the window block and a wooden board make up a container, which will later be filled with a screed.

- The foil isolon is placed in it with the foil up.

- A screed is poured with a thickness of about 1 cm.

- A foil is laid on it, on which heating elements (electric or water) are placed. They must be fixed in any convenient way (glue, screws, etc.), the main thing is not to damage them.

- Everything is filled with cement mortar.

After the mortar has hardened, a window sill is attached to the resulting base. As a binder, you can not use products with high thermal insulation properties, for example, mounting foam.

The resulting device is connected to a heat source. If water is used as a heat carrier, then the heater must be equipped with shut-off valves and a Mayevsky valve. When installing the electrical system, you need a step-down transformer, a control unit and a protection system.

Video about another installation option:

Approximate order of work

The simplest design solution is the formation of a concrete slab with heating elements or water pipes placed inside.

Heater from scratch

- Preparing a form for pouring a concrete slab. In accordance with the required dimensions, a plywood sheet of a suitable shape is selected. Plywood is better to choose high-quality with a smooth surface. This will avoid the stage of finishing putty. Sidewalls are attached to it, sufficient for pouring a layer of concrete of the required thickness.

- In the resulting form, a copper water pipe of small diameter or an electric heating wire is laid at a distance of at least 1 cm from the plywood. You can fix these elements in any convenient way. For pipes, fastening for polypropylene pipes is used.

- A metal welded reinforcing mesh is laid on top of the heating elements. You can attach it to a knitting wire or plastic ties.

- Pipes must be equipped with a Mayevsky crane and other fittings.

- A concrete solution is being prepared for pouring: the ratio of materials is maintained in accordance with the brand of Portland cement.

- Concrete hardens within one day, and gains strength after 2 days.

- The draft window sill is ready, proceed to its finishing. Round the corners with a grinder. If necessary, when there are defects on the front side, the surface should be puttied.

- It is covered with paint and installed in place.

- Connect to electricity or heating

Characteristics of parapet convectors

Enclosed heating device EVA COIL - KBP, mounted in the window sill - the optimal solution. The heating device is constantly ready for operation and does not take up additional space.

These products can serve as a parallel heating to the main heating, or they can replace it, working independently. The room is constantly warm, as the parapet convector is able to provide optimal air exchange.

Built using stainless steel parts, this EVA brand equipment is reliable and designed to last a long time without breakdowns. The device is mounted on a window sill, at least 260 mm wide.

They are produced in different styles and using all sorts of colors. Another advantage of such a convector is a lower cost than that of foreign analogues.

To understand the operation of the convector, you need to understand the characteristic features of its design and the essence of the work. The device has a built-in aluminum heat exchanger and a fan.

Warm air moves from the device in a natural way, and if the luver is turned on, then it is forced. Thus, air exchange will occur until the heat is evenly distributed throughout the room.

The convector blocks the exit of cold air streams from the glazed window unit. At the same time, hybrid use is allowed with complex systems of underfloor heating, water heating and even ventilation.

The device is built into a single-circuit or double-circuit heating line.In large rooms, two heat exchangers equipped with electric fans can be used.

This is especially topical for removing condensate from window openings, and the efficiency of the convector directly depends on the direction of the fan relative to the window.

Some devices are manufactured with a customized drainage system and automatic thermoregulation. And also convectors are produced complete with window sills, which remains to be installed and connected. If you buy one device, then you need to embed it into the installed window sill, which complicates the installation of such a heater.

Rice. 2. Heat output of EVA enclosed convector

The device of convectors for window sills

All convection heaters work by natural convection. The heating elements installed in them provide heating of the air, as a result of which it rises, displacing part of the air masses down. A kind of circulation is formed, due to which all the air masses in the room are heated and mixed. After some time, after turning on the heating in the rooms, it becomes noticeably warmer.

Convectors built into the window sill are fairly simple heating devices, similar in design to floor models. Often they are called parapets. Their main distinguishing feature is their small dimensions - they are built under the window sills, so they should not take up too much space.

These built-in heaters consist of the following parts:

- Metal cases - they are completely hidden under the window sills, so they are not visible from the side;

- Heating elements - made of steel and non-ferrous metals, provide air heating;

- Tangential fans - provide intensive air circulation;

- Thermoregulation systems - provide maintenance of the set temperature.

Thus, built-in convectors in the window sill are not much different from the usual convector appliances.

Temperature controllers and transformers for powering tangential fans are most often supplied separately, but can also be included in the basic package of built-in convective devices.

Please note that there are two categories of convectors built into window sills on the market - with and without complete window sills. The first are structurally finished devices that can only be installed under the window and connected to the heating system

In their upper part one can see a narrow grate through which warm air is ejected.

Convectors without window sills are designed to be inserted into existing windows - in this case, you will have to suffer thoroughly over their embedding. In some cases, it is easier to buy a device with ready-made window sills made to order. In order for them to match the appearance of the premises, models of various colors are presented for the choice of consumers. Air is taken in and removed through decorative grilles.

Installation Recommendations

Mounting the convector inside the floor is simple and can be done by hand. Before starting the installation, you should study the manufacturer's instructions for installing the heating device and carefully follow all the recommendations. Competently installed floor convector will not only last much longer, but also ensure safety and trouble-free operation.

It is very important to choose the right place for installation. Built-in convectors can be installed not only on the floor and window sill, but also in walls, in niches, in flights of stairs, on steps

Attention: it is forbidden to install any built-in convectors behind curtains, blinds, doors or screens, as well as under openings for ventilation of the room. This will make the instrument difficult to operate and may be unsafe.

When the choice of a safe and convenient place is made, it is necessary to determine the dimensions that the niche will have. Each heater has its own dimensions. The depth of the opening for installation is the main parameter. It ensures not only the correct installation of the radiator grille, but also sufficient and correct convection operation. The radiator itself should be one centimeter (no more!) Above or below the floor. And you should also leave technological clearances for landing. Usually they are from 10 to 25 mm.

The width of the niche for mounting consists of the width of the battery itself and the technological gap of 30-50 mm. This is necessary in order to be able to fix the radiator with cement material, as well as to adjust the height of the device using special bolts and subsequent docking with the floor covering.

Important: when installing convectors in rooms with a high level of humidity, a drainage pipeline is connected to the bottom of the device. In this case, a radiator is mounted with a slope of 20 degrees to the pipe

This will ensure timely removal of condensate from the built-in convector and its long uninterrupted operation.

All built-in radiators are supplied complete with the necessary fasteners for installation (feet and special bolts). It is with their help that the battery is located and fixed in the floor. Installation of the product is simple:

- the legs of the radiator are fixed to the floor;

- height is regulated by special bolts;

- the box is filled with cement-based materials.

Professionals advise to retreat from windows at a distance of 10 to 25 mm, depending on the need. 10-20 mm also recede from the surface of the walls.

Convector connection. Main connection types:

The first type of communication connection makes it easy to clean the convector, and also makes it possible to carry out the connection of communications from the side. It is usually used for those radiators in which the heat exchanger can be raised to clean dust and debris underneath.

The second type of connection is the most reliable. However, cleaning will be difficult.

When connecting models with tangential fans to the network, you must additionally purchase a transformer, since standard fans in radiators have a power of 12 volts, and 220 volts in the network.

Installation of built-in radiators under the window sill can be done independently only if the latter comes with a convector. In other cases, it is better to entrust the installation to professionals.

Built-in heating radiators are a great alternative to classic batteries. They are invisible, but at the same time they perform their functions of heating the room. And therefore, they will remain popular for a long time as non-standard solutions for apartments and private houses.

For information on what built-in convectors are, see the following video.

Design features

Built-in radiators are heated by convection. The heating elements heat up the air masses around them, and then their warm part rises, while the cold part remains below and is again heated by convectors. Thus, a comfortable temperature is quickly reached in the room, and due to the continuous movement, the air in the room is constantly mixed.

Built-in convectors have a simple and clear design. Models for installation in the floor and under the window sill have only one difference - floor radiators are much larger in size.

The design of all built-in convectors includes the following components:

- metal case (it is not visible due to the hidden installation);

- tangential fan, which provide the passage of air masses;

- heating elements made of steel and various non-ferrous metals;

- thermostat that allows you to set and maintain the selected temperature.

By the way, thermostats and transformers for tangential fans are usually sold separately, but in some models of built-in convectors they are included in the basic delivery.

Often, models of radiators for installation in a window sill come with the latter. This is very convenient in cases where the distance under the windows has standard dimensions.

In all non-standard cases, it is better to embed the radiator in an existing window sill.