1 Device, technical characteristics of the universal convector

The convector heating wagon has a fairly good design, which allows this device to easily achieve the goals set by the owner.

It is impossible not to say about the modern design of the convector, which not only allows you to use it in combination with the thinnest interior, but also guarantees the safety of children and pets interacting with it, thanks to a well-thought-out safety design.

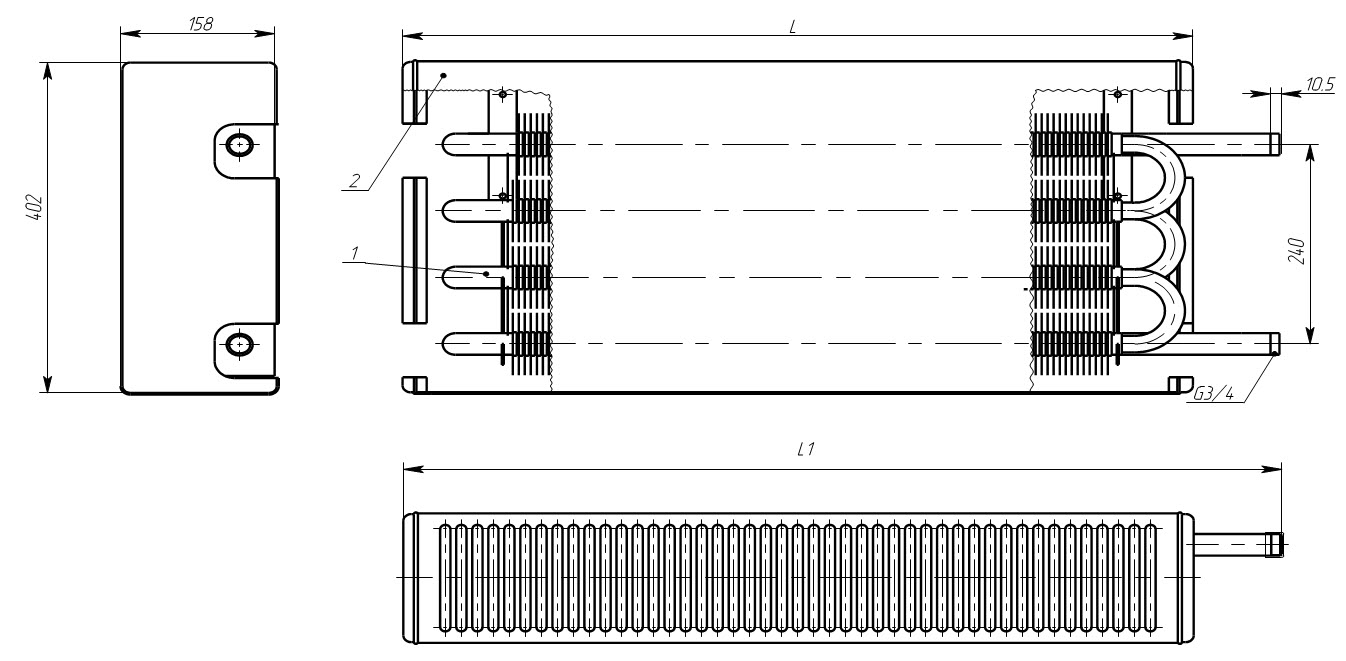

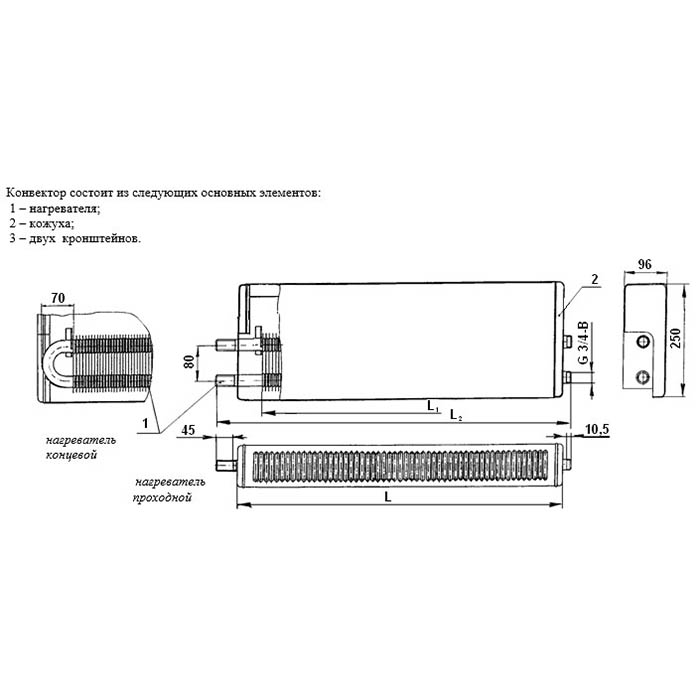

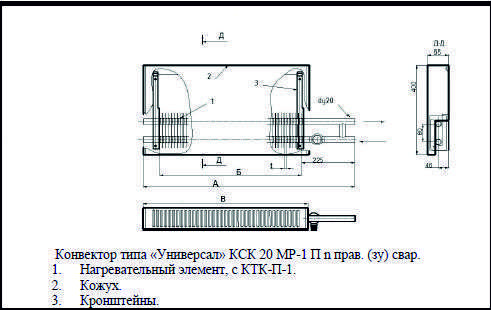

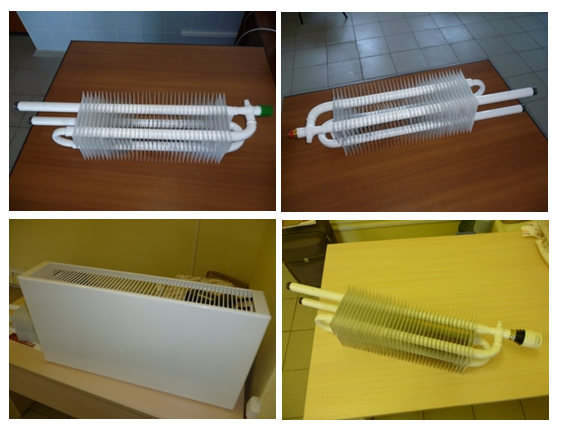

The TZPO universal convector consists of the following elements:

- Protective housing (casing) which is made of sheet steel, usually with a smooth front panel and with walls that do not have sharp corners (to avoid injury);

- Air outlet grille, paired with a special frame, which guarantee excellent exhaust potential;

- Heat exchanger, which is a heating element, consisting of special sealed pipes and plates, for air circulation;

- Valve for bleeding air from the system;

- Holes for water circulation (inlet, outlet).

The universal heating convector has the following principle of operation: cold air entering from the bottom of the device circulates through the heat exchanger, and exiting through the grill rises up, evenly distributed throughout the room. Then, when some of the air cools again, it enters the system again. Thus, the conventional principle provides the room with constant heat.

The characteristics of the station wagon convector are best considered on a specific model, for a better understanding of the device. For example, the technical characteristics of the convector station wagon KSK 20:

The power of the device starts from 0.4 kW and reaches 1.96 kW;

The convector KSK 20 wagon TB has a different mass, depending on the power of the device. The initial model weighs only 8 kg, the mass of the average power convector is 14-15 kg, while the most powerful representatives have a mass equal to 21 kg;

The universal convector KSK 20 has another important characteristic that is directly related to power, namely the step size between the heat exchanger plates. The greater this distance (12 mm for the base model), the lower the power, and vice versa (6 mm for the most powerful convector);

The length of the convector body. An important indicator, since it is it that demonstrates whether the KNU KSK 20 universal convector is suitable specifically for your room

This indicator is also important in that it corresponds to the level of warm power. The initial convectors are about 65 cm long, while the most powerful ones are 160 cm.

Types of convectors Universal

2 Advantages and disadvantages of the universal convector, their prices

Convector station wagon TB, made in Russia. This equipment is of high quality and affordable price.In addition, the KSK universal convector has a number of advantages that allow the device to be one of the leaders in the segment, including:

- Operational safety. The fast-heating heat exchanger is installed in such a way that the protective casing is practically not heated. This factor, combined with the absence of sharp corners on the convector, allows you to use it with confidence, even if there are children or pets in the room;

- The universal steel convector complies with domestic requirements and standards, which will allow you to install such equipment in your home without installing additional adapters and other devices;

- Manufacturer's warranty. A weighty argument in favor of the universal convector is the fact that the manufacturing plant provides a 5-year warranty for its products. That will allow you to safely use domestic equipment. And the whole service life of such convectors is 25 years;

- A wide range of products, among which you can always choose the most suitable for your home.

At the same time, the universal M convector has practically no drawbacks. The only one nuance when choosing this device - the absence of fasteners in the kit, which obliges you to buy the latter for a fee. Also, the disadvantages include the possibility of the convector only from the heating main.

Convector Universal

The price of a station wagon convector can also be considered its advantage. The price of a station wagon convector KSK 20 (the most common model) starts at 1200 rubles. For that kind of money you get one convector of minimum power.

As a rule, the system needs two or more heating convectors, adding the cost of fasteners of 200 rubles, we get a minimum cost of 2600 rubles. Medium power models are priced at 2400 rubles / piece, and the most powerful units reach a price of 5000 rubles.

Before you buy a station wagon convector, you should choose the type of device for yourself, as well as decide on some selection criteria.

- First of all, you need to understand how many convectors you need for your home. In one situation, only one end device is enough to heat a small room. Whereas in other situations, for the efficiency of the heating process, several through convectors and one or more end convectors should be purchased;

- An important step is the choice of heat exchanger material. Recently, the manufacturer has been using one material, but there are still models, for example, with a brass heat exchanger;

- Depending on the parameters of the case, you can purchase a convector with a small depth universal TB, a medium depth convector and a convector with a large depth. This factor affects the convenience of the location of the device, as well as the appearance against the background of the interior;

- When the above factors are established, you should decide on the power, as well as choose the most affordable convector in terms of length and cost.

Convector wagon in the room

Reviews about convectors station wagon:

Alexey Goncharov, 25 years old, Nizhny Novgorod

Victor Zotov, 36 years old, Smolensk

Water heating convectors

wall-mounted floor convector BRIZKSK-20floor convectorsfloor convector

Water heating convector KSK 20

| KSK-20 shallow depth KSK-20 medium depth KSK-20 specifications KSK-20 price list |

1.1 The rated heat flux is determined under normal (standard conditions):

- temperature difference (the difference between the arithmetic mean temperature of the coolant in the convector and the air temperature in the room) taken equal to 70?

- coolant flow rate - 0.1 kg / s when it moves according to the "top - down" scheme

- atmospheric pressure 1013.3 hPa (760 mm Hg)

1.2 The main parameters and dimensions of the KSK-20 convectors comply with the interstate standard GOST-20849-94: height 400mm, depth 96mm, linear density of the nominal heat flux not more than 1.5 kW/m, nomenclature range from 0.4 to 2.941 kW.

1.3 Connection of KSK-20 convectors to the heating system is carried out using G 3 /4-B thread and welding.

1.4 The diameter of the connecting pipes is D 20mm.

1.5 Pipe thread on the parts of KSK-20 convectors is made in accordance with GOST 6357, accuracy class B metric in accordance with GOST 9150-2002 and GOST 24705-2004 with tolerances in accordance with GOST 16093-2004.

1.6 Symbol of the convector: "Convector KSK 20 - 0.655 K (P) GOST 20849-94,

where KSK is a convector with a casing;

20 - conditional passage of the connecting pipe in millimeters

0.655 - nominal heat flow in kilowatts

K (P) - execution (K - end, P - through passage).

Convector KSK-20 technical requirements

1 KSK-20 convectors are single-row in depth and height.

1 KSK-20 convectors are single-row in depth and height.

2 When developing design and technological documentation, the following indicators were used:

2.1 Type of heat carrier - water, maximum operating overpressure 1.0 MPa, maximum temperature of the heat carrier 150C.

2.2 Trial overpressure 1.5 MPa.

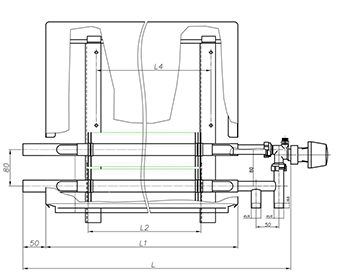

2.3 Height 400mm.

2.4 Powder coating of KSK-20 convectors.

2.5 The distance between the axes of the pipes is 80mm.

2.6 Thread at the ends of pipes G 3/4B.

3. KSK-20 convectors are airtight and durable, they withstand test water pressure of 1.5 MPa (15 kgf/m2).

4. Deviations from the nominal value of the heat flux from +5 - 4°С.

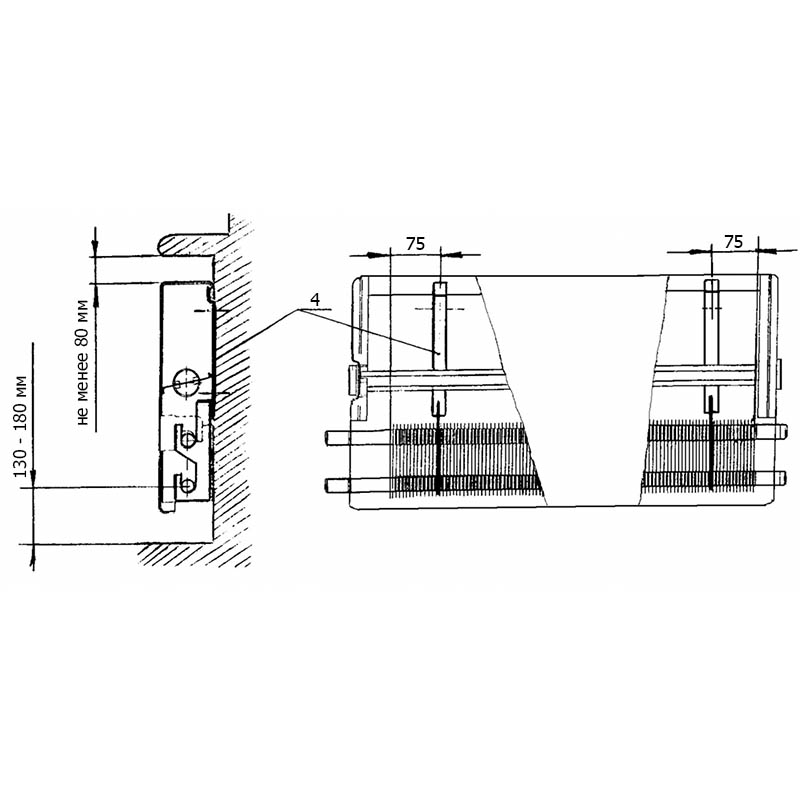

5. The design of the KSK-20 convector provides access to the heating elements for their cleaning during operation.

6. KSK-20 convectors with air valves for heat flow regulation provide heat flow regulation up to 50% of the nominal value.

7. Tube fins are tightly fitted. The tension of the plates on the pipe is 0.4 mm.

8. The ovality of bent heating elements made of pipes does not exceed 5mm.

9. The surfaces of the KSK-20 convector, visible under operating conditions, do not have sharp edges and burrs.

10. Climatic version of KSK-20 convectors - UHL, location category - 4.2 according to GOST 15150-69.

11. The casing of the KSK-20 convector is made of steel ST3 SP 0.8 mm thick, the finning plates are made of steel ST3 SP 0.4 mm thick, the heating element pipe is non-galvanized water and gas pipe GOST 3262-75.

12. Metal parts of KSK-20 convectors are coated with:

corrosion protection – convector heating elements,

protective and decorative against corrosion - convector casings,

heat resistant.

Coating of casing and finning plates is powder coated. .

Coating thickness 100 microns.

The quality of the coating of the surfaces of the KSK-20 convectors and casings visible under operating conditions corresponds to class IV according to GOST 9.032-74.

13. KSK-20 convectors are supplied as a set according to the customer's specification.

14. Each convector is equipped with brackets for attaching them to the wall in the amount of 2 pieces.

15. A passport is attached to each batch of convectors, which indicates

- name of the product and address of the manufacturer,

- manufacturer's warranty,

- stamp and date of acceptance by technical control.

Upon delivery to the distribution network, the documentation is attached to each KSK-20 convector.

16. Each KSK-20 convector is marked with the name of the manufacturer, type of convector, nominal heat flow in kilowatts, the last two digits of the year of manufacture, and the stamp of the technical control department.

The marking is applied on the side panel of the casing from the inside, on the heating element - on the finning plate with glue and remains during the service life.