- What is a charge controller for a wind turbine

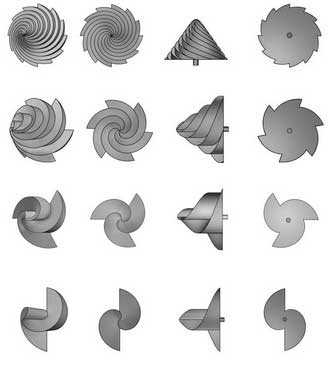

- Rotor drawings

- Schemes of operation of wind turbines

- Savonius rotor generators

- Dimensions

- Specifications

- Pros and cons

- The legality of installing a wind turbine

- Cable twist protection

- About homemade windmills for home

- Installation

- Parts and Consumables

- Conclusions and useful video on the topic

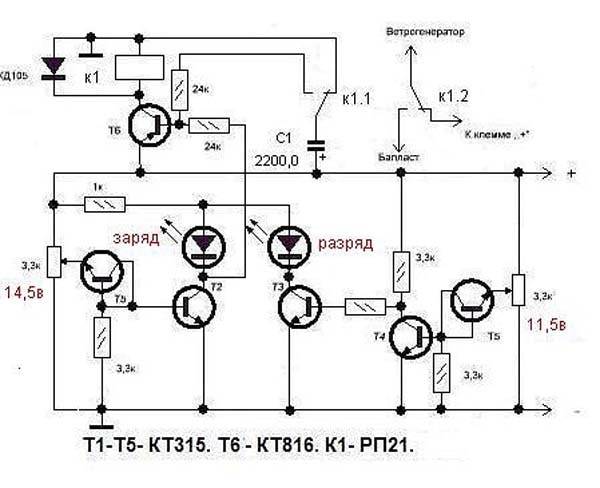

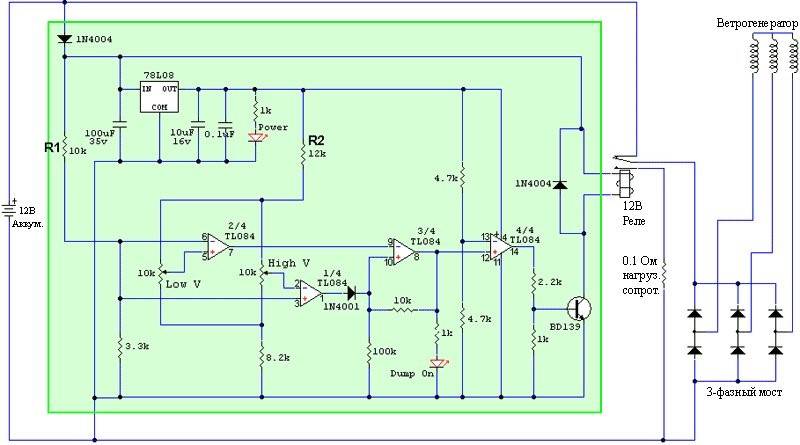

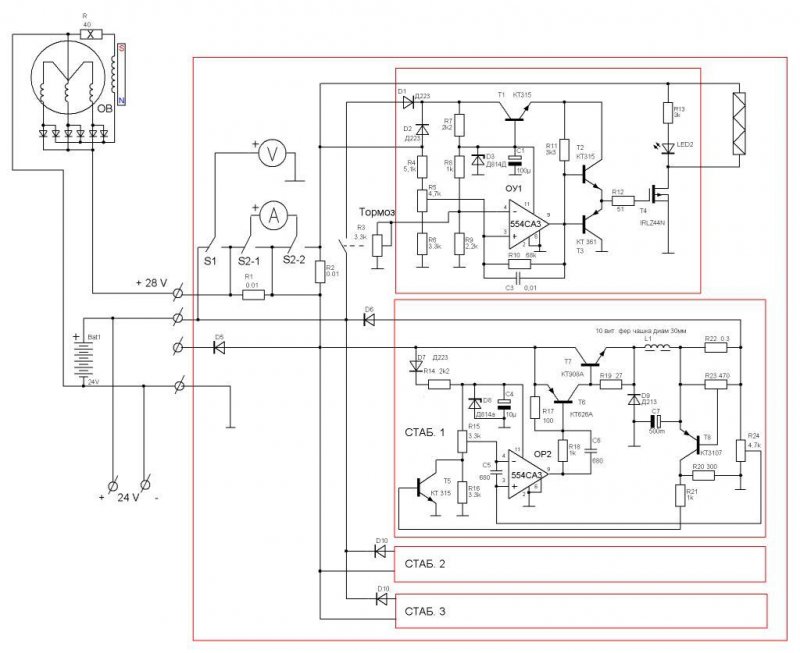

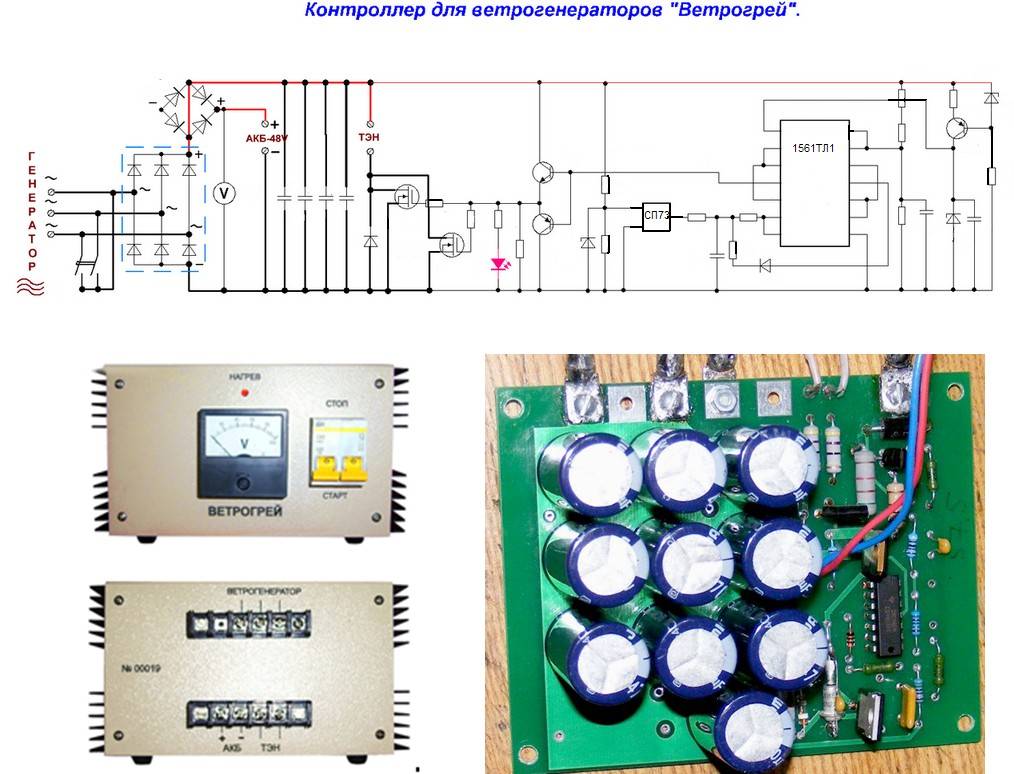

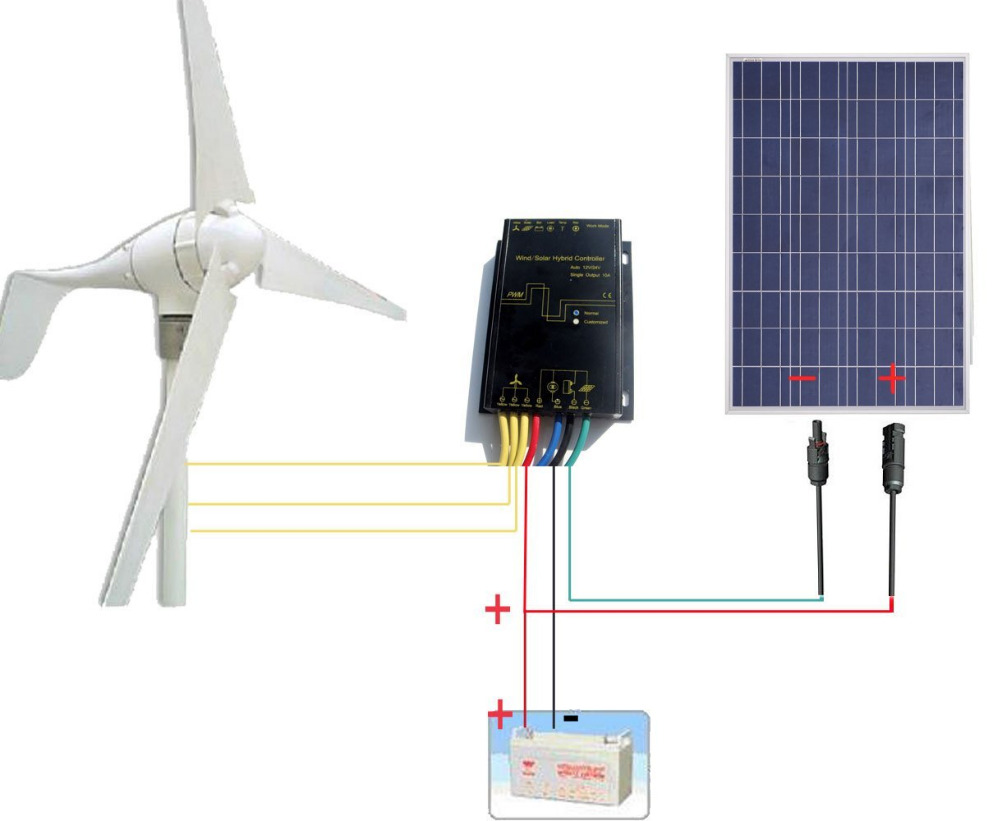

What is a charge controller for a wind turbine

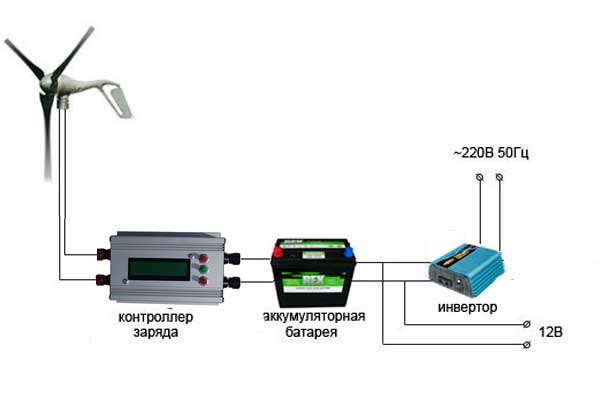

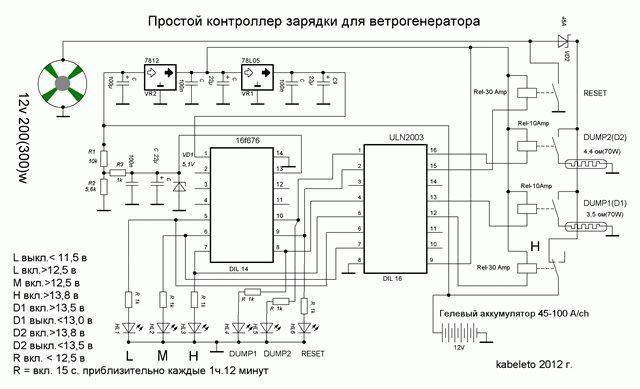

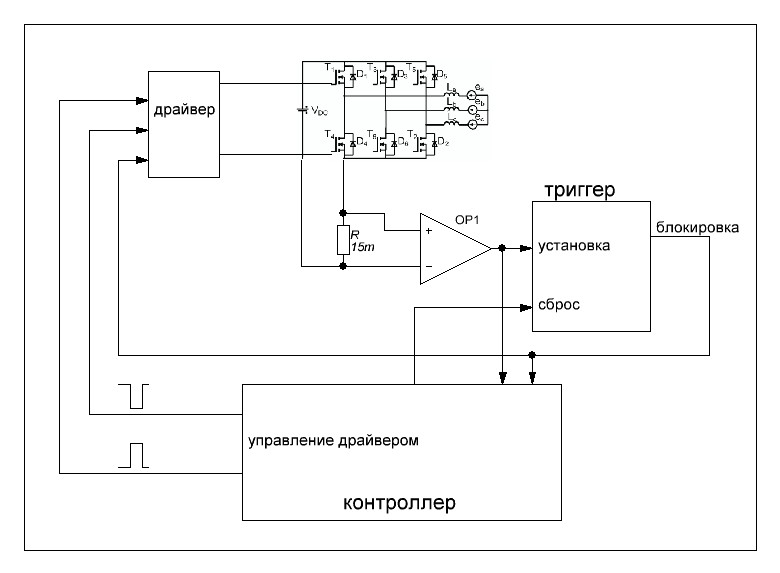

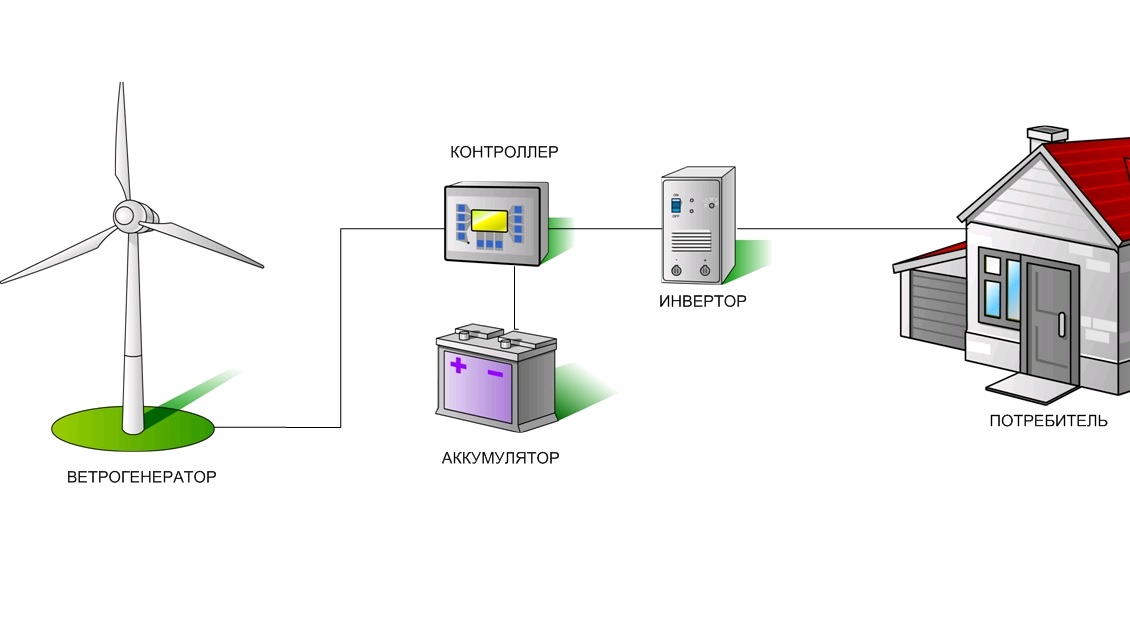

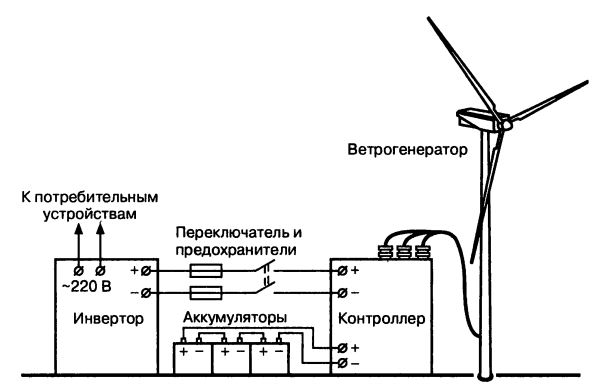

The controller is an electronic device responsible for converting the alternating voltage generated by the generator into a constant one and controlling the charge of the batteries. The presence of a controller in the scheme of operation of the wind turbine allows the operation of the wind generator in automatic mode, regardless of external factors (wind speed, weather conditions, etc.).

The function of controlling the amount of charge is performed by a ballast regulator, or controller. This is an electronic device that turns off the battery when the voltage rises, or dumps excess energy on the consumer - a heater, lamp or other simple and undemanding device for some power changes. When the charge drops, the controller switches the battery into charge mode, helping to replenish the energy reserve.

The first designs of controllers were simple and only allowed turning on the shaft braking.Subsequently, the functions of the device were revised, and the excess energy began to be used more rationally. And with the beginning of the use of wind turbines as the main power source for summer cottages or private houses, the problem of using excess energy disappeared by itself, since at present there is always something to connect in any house.

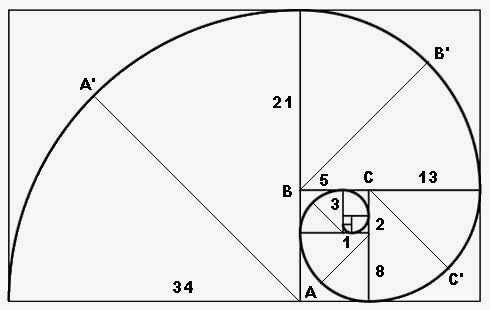

Rotor drawings

The inventor does not provide detailed drawings of his developments, but the principle of a mathematical spiral is used as a model for constructing the blades:

It is along this curve that each of the three blades of the impeller is built, in total forming a continuous surface, close in outline when viewed from the side to the shape of a cone. The spiral is built on the basis of the golden ratio, three blades form an angle between the axes of 120 °. Designers consider it possible to use a variety of options for manufacturing blades, considering the use of an Archimedean screw as the basis as the main condition.

Such an abundance of possibilities increases the chances of amateur windmill manufacturers who need to create a device for their needs.

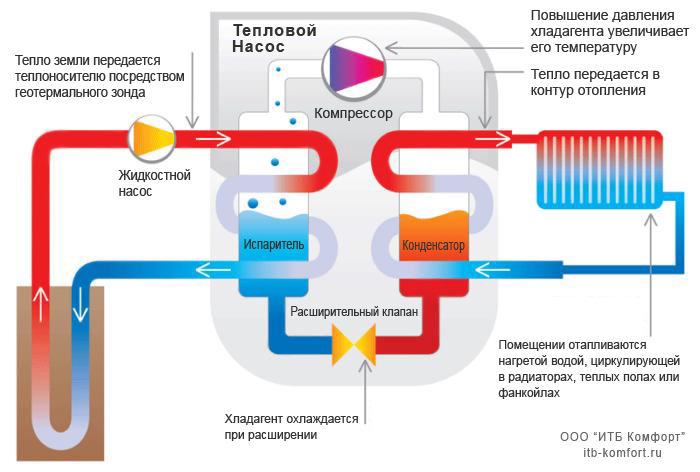

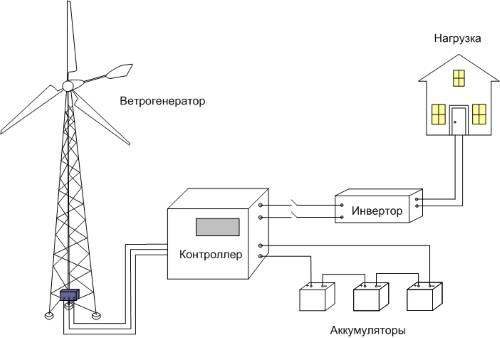

Schemes of operation of wind turbines

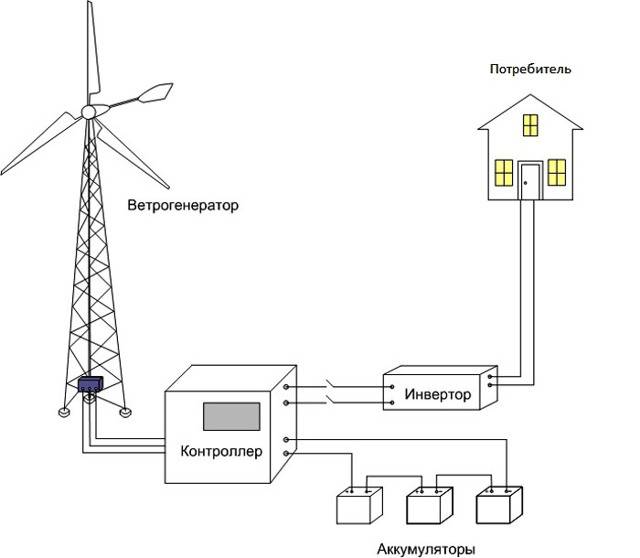

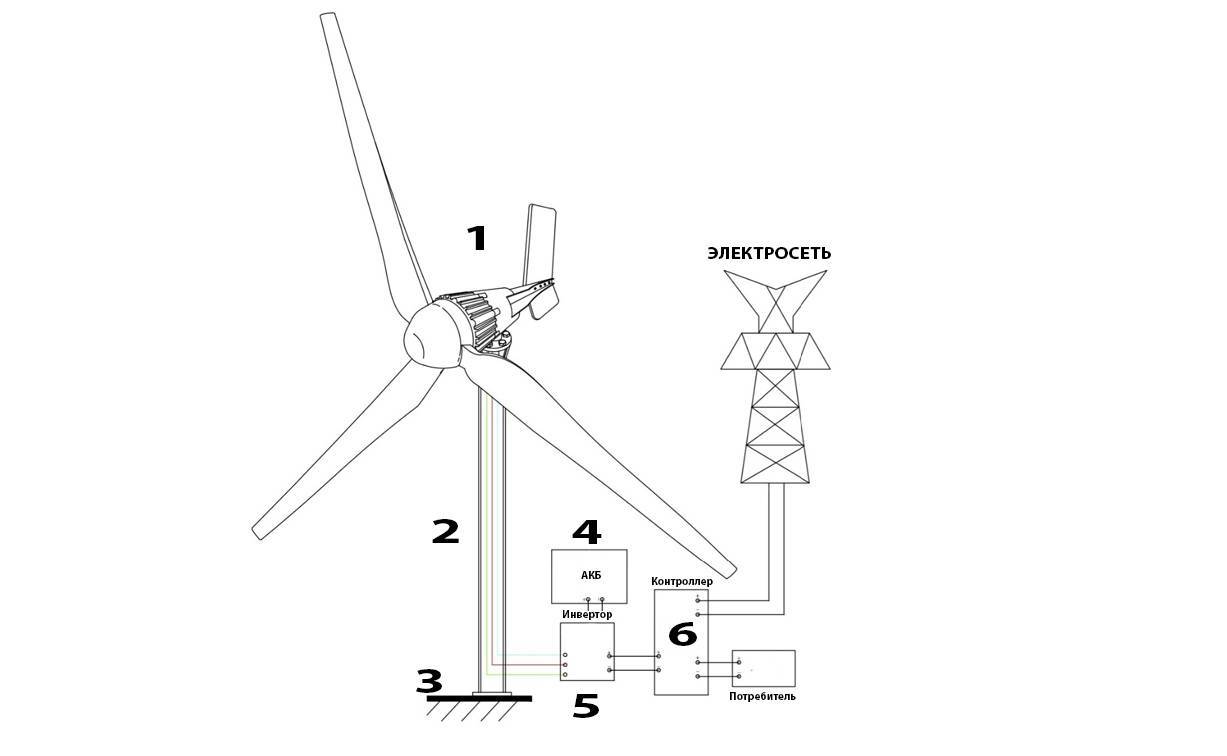

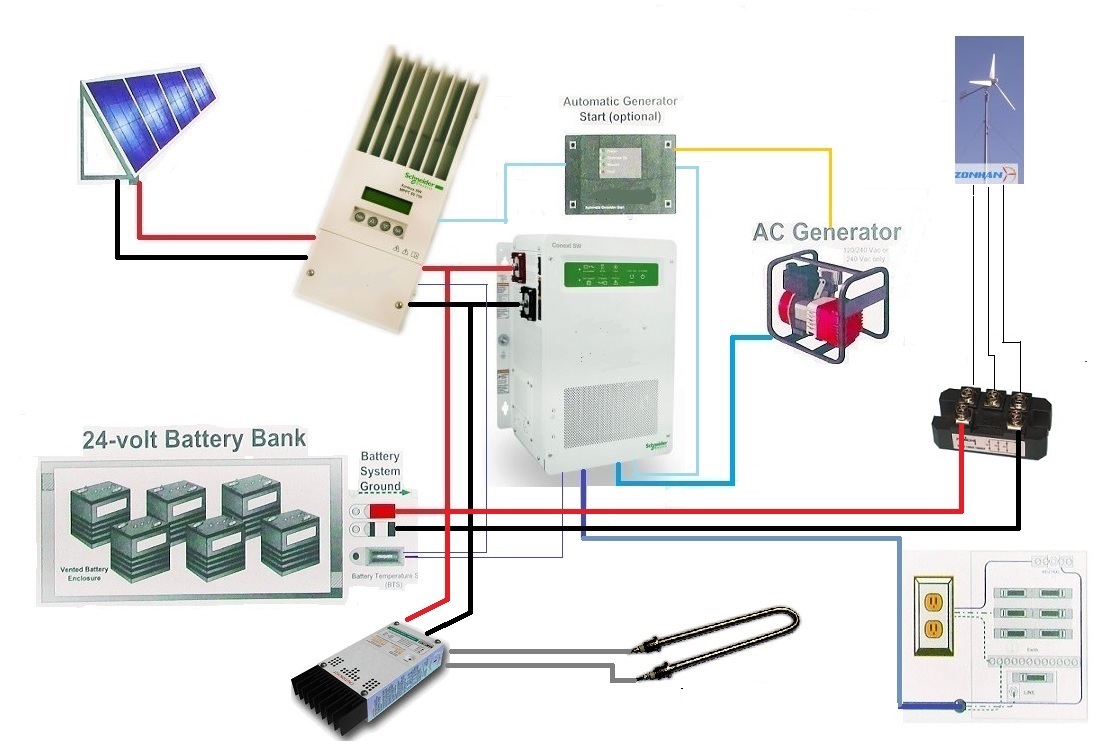

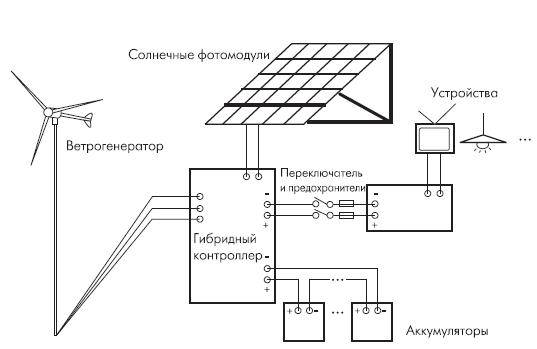

There are several options for the operation of a wind generator:

- Autonomous operation of the wind generator.

Autonomous operation of the wind generator

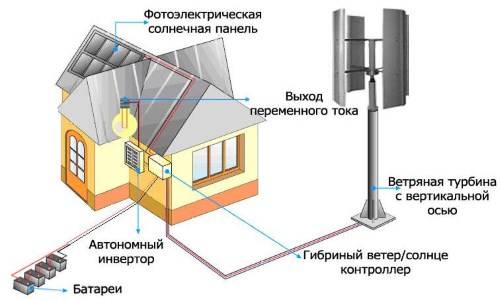

- Such joint work is considered a very reliable and efficient way of autonomous power supply. In the absence of wind, solar panels work. At night, when the solar panels are not working, the battery is charged by the wind turbine.

Parallel operation of a wind turbine with solar panels

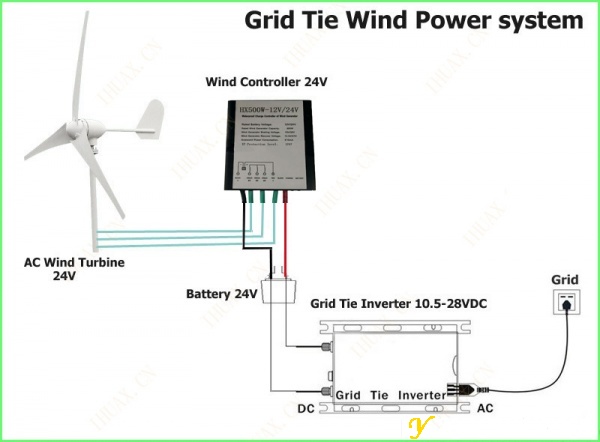

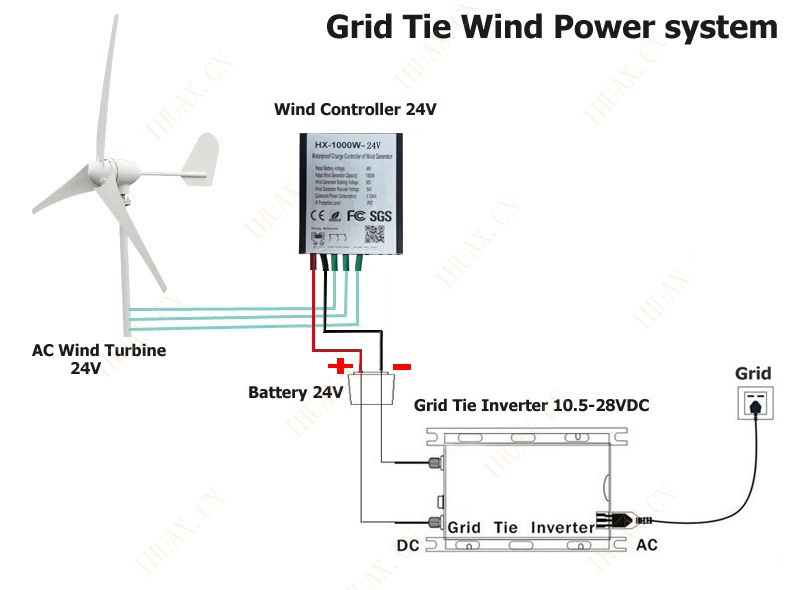

- The wind generator can also work in parallel with the mains.With an excess of electricity, it enters the general network, and with a lack of it, consumers of electricity operate from the general electrical network.

Parallel operation of the wind turbine with the power grid

Wind generators can work perfectly with any kind of autonomous power supply and a common power grid. At the same time creating a unified power supply system.

Savonius rotor generators

This rotary wind generator is also popular as a domestic wind farm. The basis of the design is in several half-cylinders - two or three, less often more, fixed on a vertical axis of rotation. Sometimes, to increase the power of a windmill with a Savonius rotor, blocks of half-cylinders are built in two rows - one above the other.

Industrially produced Savonius rotor generators often have an unusual high-tech look, reminiscent of the spread sails of yachts. Due to the simplicity of the design, they are often made independently. But only because of the simplicity of the design, since the power of vertical windmills of this type - with the Darrieus rotor, with the Savonius rotor and others, is three times lower than that of horizontal structures.

Dimensions

Devices for generating energy from wind can be of different sizes. Their power depends on the dimensions of the wind wheel, the height of the mast and the wind speed. The largest unit has a column length of 135 m, while the diameter of its rotor is 127 m. Thus, its total height reaches 198 meters. Large wind turbines with high height and long blades are suitable for providing energy to small industrial enterprises, farms. More compact models can be installed at home or in the country.

Currently, they produce a marching type of windmill with blades in diameter from 0.75 and 60 meters.According to experts, the dimensions of the generator should not be grandiose, since a small portable unit is suitable for generating a small amount of energy. The smallest model of the unit is 0.4 meters high and weighs less than 2 kilograms.

Specifications

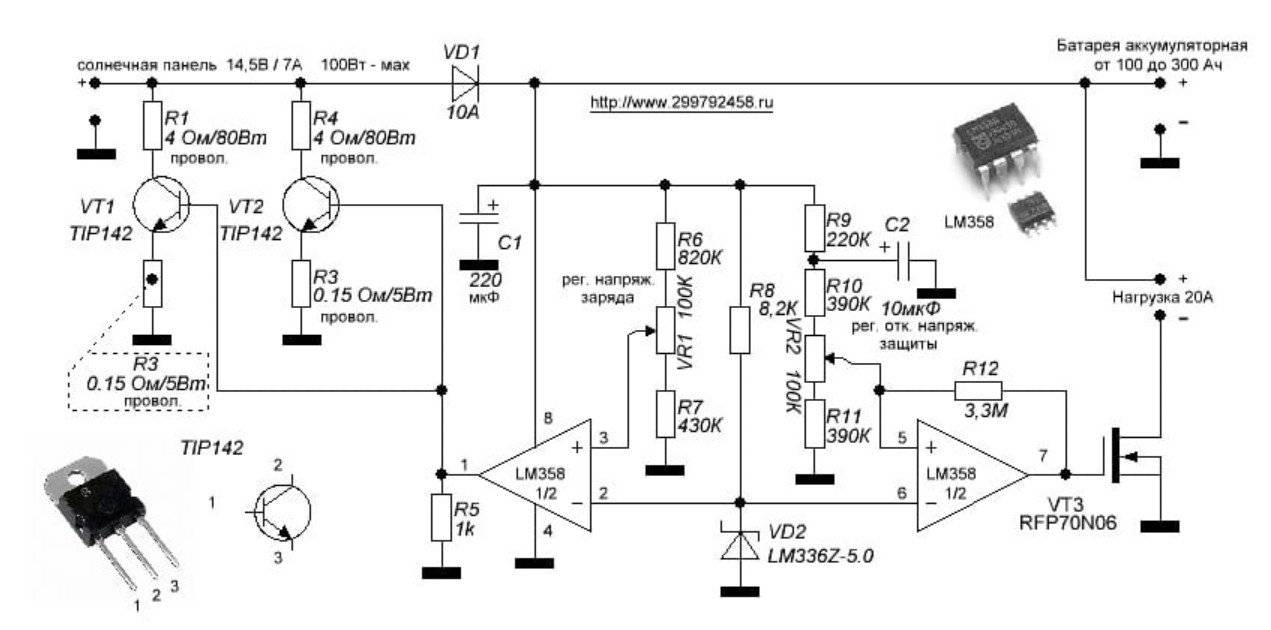

When buying a charge controller for a wind generator, you must carefully study its data sheet. When choosing, the characteristics are important:

- power - must correspond to the power of the wind turbine;

- voltage - must correspond to the voltage of the batteries installed on the windmill;

- Max. power - indicates the maximum allowable power for the controller model;

- Max. current - indicates with what maximum powers of the wind generator the controller can work;

- voltage range - indicators max. and min. battery voltage for adequate operation of the device;

- display capabilities - what data about the device and its operation are displayed on the display of a particular model;

- operating conditions - at what temperatures, humidity level the selected device can operate.

If you cannot choose a charge control device yourself, contact a consultant and show him the data sheet of your windmill. The device is selected in accordance with the capabilities of the wind installation. Incorrect operating conditions and deviations from the voltage range will adversely affect the operation of the entire wind system.

Pros and cons

The presence of additional devices in the scheme of operation of wind turbines makes it possible to improve the parameters of the received electrical energy.

The controller, as an element of such a scheme, has the following advantages:

- Allows you to operate the wind turbine in automatic mode.

- The use of a controller prolongs the life of the batteries, providing, for them, safe operating modes.

- The ability of the most complete use of the energy generated by the wind generator is the heating of heating elements, or other loads, at the moments when the batteries are fully charged.

- The operating conditions of the wind turbine are improved (easy start in light wind, etc.).

The disadvantages of the controller installed in the wind generator operation scheme include an increase in the cost of a set of equipment, as well as the likelihood of a wind turbine breaking down, operating in automatic mode, in the event of failure of this element of the control circuit.

You might also like the following content:Homemade Wind Turbine

Thank you for reading to the end! Don't forget if you liked the article!

Share with friends, leave your comments

Join our VK group:

ALTER220 Alternative energy portal

and suggest topics for discussion, together it will be more interesting!!!

The legality of installing a wind turbine

Alternative energy sources are the dream of any summer resident or homeowner whose site is located far from the central networks. However, when we receive bills for electricity consumed in a city apartment, and looking at the increased tariffs, we realize that a wind generator created for domestic needs would not hurt us.

After reading this article, perhaps you will make your dream come true.

A wind generator is an excellent solution for providing a suburban facility with electricity.Moreover, in some cases, its installation is the only possible way out.

In order not to waste money, effort and time, let's decide: are there any external circumstances that will create obstacles for us in the process of operating a wind turbine?

To provide electricity to a dacha or a small cottage, a small wind power plant is sufficient, the power of which will not exceed 1 kW. Such devices in Russia are equated to household products. Their installation does not require certificates, permits or any additional approvals.

In order to determine the feasibility of installing a wind generator, it is necessary to find out the wind energy potential of a particular area (click to enlarge)

However, just in case, you should ask if there are any local regulations regarding individual power supply that could create obstacles in the installation and operation of this device.

Claims may arise from your neighbors if they experience inconvenience associated with the operation of the windmill. Remember that our rights end where other people's rights begin.

Therefore, when buying or self-manufacturing a wind turbine for a home, you need to pay serious attention to the following parameters:

Mast height. When assembling a wind turbine, it is necessary to take into account the restrictions on the height of individual buildings that exist in a number of countries of the world, as well as the location of your own site. Be aware that near bridges, airports and tunnels, buildings that are more than 15 meters high are prohibited.

Noise from gearbox and blades.The parameters of the generated noise can be set using a special device, after which the measurement results can be documented

It is important that they do not exceed the established noise standards.

Ether interference. Ideally, when creating a windmill, protection against tele-interference should be provided where your device can provide such trouble.

environmental claims. This organization can prevent you from operating the facility only if it interferes with the migration of migratory birds. But this is unlikely.

When creating and installing the device yourself, learn these points, and when buying a finished product, pay attention to the parameters that are in its passport. It is better to protect yourself in advance than to be upset later.

- The expediency of a windmill is justified primarily by a sufficiently high and stable wind pressure in the area;

- It is necessary to have a sufficiently large area, the useful area of \u200b\u200bwhich will not be significantly reduced due to the installation of the system;

- Due to the noise accompanying the work of the windmill, it is desirable that there be at least 200 m between the neighbors' housing and the installation;

- The steadily increasing cost of electricity convincingly argues in favor of a wind generator;

- The installation of a wind generator is possible only in areas whose authorities do not interfere, but rather encourage the use of green types of energy;

- If there are frequent interruptions in the construction area of the mini wind power plant, the installation minimizes the inconvenience;

- The owner of the system must be prepared for the fact that the funds invested in the finished product will not pay off immediately.The economic effect may become tangible in 10-15 years;

- If the payback of the system is not the last moment, you should think about building a mini power plant with your own hands.

Cable twist protection

As you know, the wind does not have a constant direction. And if your wind generator rotates around its axis like a weather vane, then without additional protection measures, the cable going from the wind generator to other elements of the system will quickly twist and become unusable within a few days. We offer you several ways to protect yourself from such troubles.

Method one: detachable connection

The simplest, but completely impractical way to protect is to install a detachable cable connection. The connector allows you to untangle the twisted cable manually by disconnecting the wind generator from the system.

w00w00 User

I know that some people put something like a plug with a socket downstairs. Twisted the cable - disconnected from the outlet. Then - untwisted and stuck the plug back. And the mast does not need to be lowered, and current collectors are not needed. I read this on a forum on homemade windmills. Judging by the words of the author, everything works and does not twist the cable too often.

Method two: using a hard cable

Some users advise connecting thick, elastic and rigid cables (for example, welding cables) to the generator. The method, at first glance, is unreliable, but has the right to life.

user343 User

Found on one site: our method of protection is to use a welding cable with a hard rubber coating.The problem of twisted wires in the design of small wind turbines is greatly overestimated, and welding cable #4 ... # 6 has special qualities: hard rubber prevents the cable from twisting and prevents the windmill from turning in the same direction.

Method three: installing slip rings

In our opinion, only the installation of special slip rings will help to completely protect the cable from twisting. It is this method of protection that user Mikhail 26 implemented in the design of his wind generator.

About homemade windmills for home

Particular interest in wind energy is manifested at the level of the domestic sphere. This is understandable if you look at the next bill for consumed energy from the corner of your eye. Therefore, all kinds of craftsmen are activated, using all the possibilities of obtaining electricity inexpensively.

One of these possibilities, quite real, is closely related to windmill from a car generator. A ready-made device - a car generator - just needs to be equipped with correctly made blades in order to be able to remove some value of electrical energy from the generator terminals.

True, it will work effectively only if there is windy weather.

An example from the practice of domestic use of wind generators. A well-designed and quite effective practical design of a windmill. A three-bladed propeller is installed, which is rare for household appliances

The use of virtually any automotive generator is acceptable for windmill construction. But they usually try to pick up a powerful model for business, capable of delivering large currents. Here, at the peak of popularity, the design of generators from trucks, large passenger buses, tractors, etc.

In addition to the generator for the manufacture of a windmill, a number of components will be required:

- propeller two- or three-bladed;

- car battery;

- electrical cable;

- mast, support elements, fasteners.

The propeller design with two or three blades is considered the most optimal for a classic wind generator. But a household project is often far from engineering classics. Therefore, most often they try to pick up ready-made screws for home construction.

An impeller from a car fan that will be used as a propeller for a home wind turbine. Lightness and a large usable area for air force allow the use of such options

Such, for example, can be an impeller from an external unit of a split air conditioning system or from a fan of the same car. But when there is a desire to follow the traditions of designing wind turbines, you will have to build a windmill propeller from start to finish with your own hands.

Before deciding on the assembly and installation of a wind turbine, it is worth evaluating the climatic data of the site and calculating the payback. Significant assistance in this will be provided by the information of a very interesting article, which we recommend for review.

Installation

Installing a windmill is a very complicated procedure. First of all, you should buy mortgages in the foundation, fastening details. Then, you should pour a concrete base that will hold your unit. When pouring the foundation, you must immediately install the previously purchased elements for fastening. After the foundation is poured, it must stand for 21 days before the mast can be installed.

Installing a windmill is a very complicated procedure. First of all, you should buy mortgages in the foundation, fastening details. Then, you should pour a concrete base that will hold your unit. When pouring the foundation, you must immediately install the previously purchased elements for fastening. After the foundation is poured, it must stand for 21 days before the mast can be installed.

Further, the work is more difficult.You can’t do it yourself, you need specially trained personnel and heavy equipment (a crane is a must). Assembling one wind turbine for a home will take at least one full day.

All work related to the assembly and installation of equipment (this includes connecting to the network, connecting all wiring, assembling the entire unit, and so on) must be carried out exclusively by qualified workers.

Self-activity in this complex matter is not welcome. Installation of all equipment is carried out in a dry room with a temperature of 10 to 30 degrees Celsius. Special workers who mounted and installed the equipment must provide a package of services, according to which they will be required to repair the wind generator during operation.

Advantages of using a wind turbine at home:

- The biggest benefit is free electricity. Once you have paid for all the equipment and installation of this unit, you will no longer have to pay for electricity. Now you are making your own.

- It is a very common occurrence when, during difficult times of the year, power outages occur. This often happens due to a broken line, or some kind of problem with the transformer. By installing a wind generator at home, your electrical appliances will no longer be affected by the weather. In difficult weather conditions, the windmill will work even faster than normal.

- These units are environmentally friendly and produce virtually no noise during operation. This is a much better energy option than the one that destroys the planet's ecosystem.

- The windmill is very good in technical terms.After all, it can work in combination with several energy sources, for example: a diesel power plant, solar panels and so on. This is convenient if some source of electricity at full strength cannot provide energy to your home.

Cons of wind generators:

- The first significant disadvantage is, of course, the dependence on weather conditions. The windmill will not work where the wind is weak. It is reasonable to install it only on the coast of the sea and in places where windiness is increased. By installing a wind generator at home, in an area where wind flows are below average, you will never achieve that this type of electricity production is the main one.

- The price is also not very pleasant. Such pleasure is very, very expensive. This unit can pay off, at best, after only 10 years. The generator itself, the mast and the windmill are only 30 percent of the cost of the entire structure, the rest is taken by the batteries and the inverter. In addition, the batteries themselves are not durable today, and you will have to replace them very often, which will also hit your pocket with strong blows.

- The safety of this alternative energy generator is not the most advanced. Blades with heavy wear can simply come off and cause significant damage to property, or even worse, human life.

Wind turbine installation video:

Parts and Consumables

For the manufacture of a low-power (not higher than 1.5 kW) rotary wind generator, the following components will be required:

- 12 volt car alternator;

- 12-volt battery;

- converter from 12 V to 220 V, designed for power from 700 W to 1500 W;

- metal cylindrical container.You can use a regular bucket or a fairly large pot;

- a relay for charging batteries from a car and a light for charge control;

- pushbutton switch for 12 V;

- voltmeter;

- details for threaded connections;

- wires with a cross section of 2.5 and 4 squares;

- clamps for fastening the wind generator to the mast.

You will also need the following tools:

- shears for sheet metal processing (can be replaced with angle grinders);

- roulette;

- marker;

- screwdriver;

- different wrenches;

- drill with drills;

- pliers and side cutters.

Conclusions and useful video on the topic

The desire to make equipment for home use with your own hands is sometimes stronger than a simpler solution - buying an inexpensive device. What came of it, see the video:

Assessing the prospects for manufacturing electronics on our own, regardless of its purpose, one has to face the idea that the age of "homemade" is ending. The market is oversaturated with ready-made electronic devices and modular components for almost every household product. Now the only thing left for amateur electronics engineers is to assemble home kits.