- Proper operation of the boiler and heating system

- What threatens the boiler leak

- Getting rid of condensate

- Problems with solid fuel boiler

- Cause of condensation

- Dew point

- What is harmful condensate

- Why clean the column

- What is condensate?

- Why do windows fog up?

- Manufacturing defects

- Houseplants

- Windowsill

- Curtains

- How to remove scale from a column

- Fighting condensate in an atmospheric boiler

- What is condensate?

- Leaking through threaded connections?

- Condensation Prevention

- Chimney materials and the effect of condensate on them

- Chimney installation rules

- Influence of pipe material on the occurrence of excess moisture

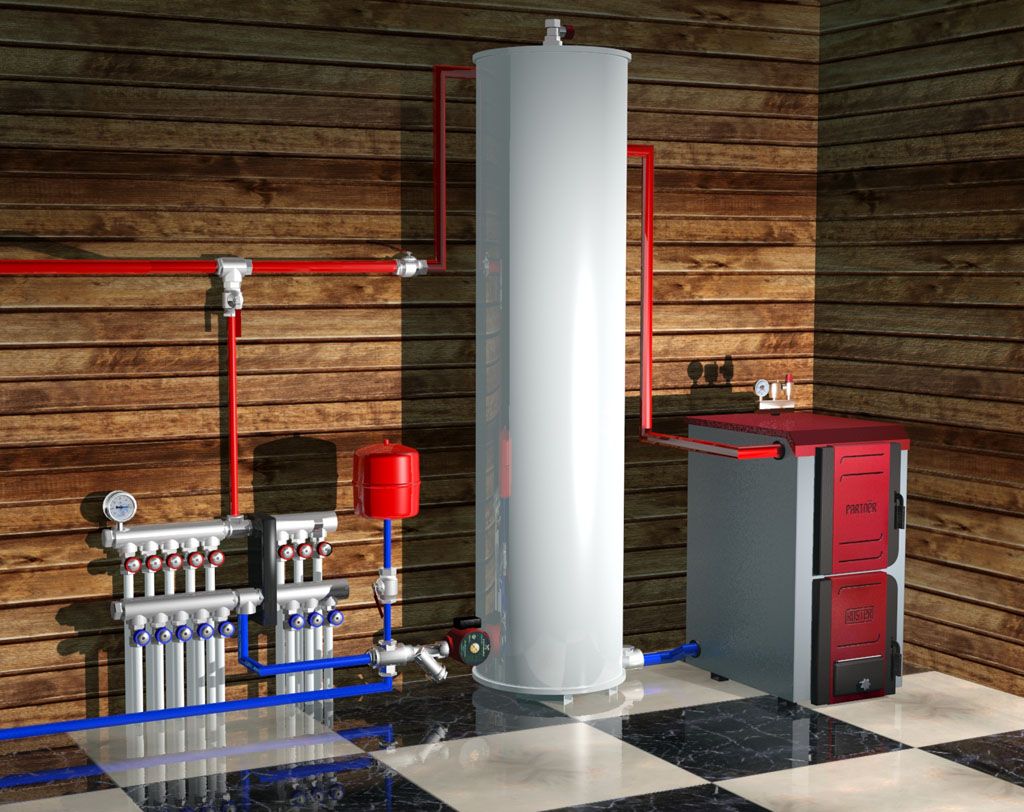

Proper operation of the boiler and heating system

Do not turn on the circulation pump of the heating system at a negative temperature in the heating system. It is advisable to turn on the pump after the boiler has warmed up to a temperature of at least 50-60 degrees. Otherwise, there is also a problem of condensate formation in the boiler furnace and heat exchanger. As the boiler operates and the heating system warms up, the condensate will, of course, evaporate, but this takes time and additional energy to evaporate moisture.

The question arises - how to control the inclusion of the pump?

The first option - free of charge - we stand next to the boiler and control the temperature with a thermometer at the outlet of the boiler.After the boiler has warmed up, it is necessary to turn on the pump at the minimum speed and observe the temperature change. If the temperature rises quickly enough, then it is necessary to increase the speed of the circulation pump. The optimal mode from the point of view of efficiency and durability of the boiler is the flow of coolant into the boiler with a temperature of 50-60 degrees.

The second option is to use an automation unit that controls the operation of the heating system pump. The control unit monitors the temperature at the outlet of the boiler and turns on the pump only when the temperature at the outlet of the boiler is above the set threshold value. In long-burning START boilers, as well as in pellet boilers, circulation pumps are connected to the automation unit, in which these pump switching algorithms are organized.

The third option is to organize a small circulation circuit through the boiler using a three-way valve and an additional circulation pump. This ensures the most correct mode of operation of the heating boiler. The boiler operates in the same mode and the possibility of condensate formation is almost completely excluded (only during the start-up period).

What threatens the boiler leak

In most cases, further operation of a leaking boiler is impossible. Even if it continues to heat water, you should not use it. The liquid contained in the heating system is able to extinguish the burner, which will lead to the filling of the dwelling with gas. And if electrical appliances are located in the immediate vicinity of the boiler, a short circuit may occur.

As a temporary solution to fix the leak before the arrival of the repair team, you can use cold welding or sealant.As a permanent solution, this option is not suitable: after a short time, the leak will reappear. Therefore, if you have a gall boiler dripping, call us urgently!

Getting rid of condensate

Elimination of condensate in the chimney is a common occurrence. Every owner of a fireplace or stove has to deal with this from time to time.

No matter what the system is made of, small or large amounts of condensate will still form. Most of all, non-standard devices suffer from such a scourge. If you are concerned about the question of how to get rid of condensate in the chimney, then there are many ways

You can purchase and install a special tap. This is a convenient way to clean the chimney. It will only be necessary to clean the collector from accumulated waste

If you are concerned about the question of how to get rid of condensate in the chimney, then there are many ways. You can purchase and install a special tap. This is a convenient way to clean the chimney. It will only be necessary to clean the collection from accumulated waste.

If an additional device is not installed, then other methods will have to be used.

- Use only proven firewood, well dried. Firewood is prepared in advance, chopped. Typically, the preparation of such fuel takes about two years.

- Eliminate air suction. The hole must be closed completely or completely eliminated. Sometimes cracks are used as suction, they should be covered up.

- Pipes should be insulated. This is a good way to protect your chimney from harmful deposits. The pipe will always be warm and, therefore, less condensate will settle.

- Try your best to balance the temperature. If the outgoing gases have a temperature of at least 100 degrees, then the amount of condensate will be minimal.Achieved by burning a large amount of firewood. Sometimes the system is equipped with a special channel.

Additionally, once again carefully study the entire structure, identify any flaws, understand why the chimney condenses. Also check any installed options. Perhaps they, while performing one function well, but at the same time act negatively on another. For example, they have a bad effect on the formation of condensate.

There is the best way to solve this problem. This is the installation of a special stainless acid-resistant steel channel. Mounting it is very easy. It will perfectly save the entire system, and improve its performance. You should also add a diverter in addition to the channel. This option will help to forget about the problem for a long time.

Don't forget to clean your pipes. It takes a little time for this work, and the chimney will last a long time and uninterruptedly.

Problems with solid fuel boiler

Sometimes the heater smokes due to the banal filling of the ash pan. Before looking for another possible source of problems, you should free the blower and check the condition of the grate.

The second most common problem with a solid fuel boiler is a clogged chimney. The reason is poor quality fuel. When using raw firewood or wood with a high resin content, not only soot is formed, which easily crumbles after tapping on the chimney casing. Resinous soot with a high moisture content adheres firmly to the walls, after which it hardens and narrows the diameter of the pipe.

Cause of condensation

Moisture and steam on windows

All the time and always there is steam in the air. The higher the temperature in the room, the more the air absorbs moisture.As soon as the moisture exceeds the maximum amount, the absorption of air into itself begins to condense.

An example, a similar result occurs when you pour boiling water into a cup at the moment puffs of steam arise.

Below is a description of climate moisture:

- Total humidity (g / m?) - the amount of steam in a cubic meter of air in grams.

- Peak humidity (g / m?) - the largest amount of vapor that, at a specific atmospheric temperature, can dissolve in one cubic meter of air.

- Conditional humidity (%) - an indicator of the percentage of the largest potential soluble amount of superheated steam contained in the air at that moment or time period:

Conditional humidity = (total humidity 100%) / highest humidity When the temperature decreases, the cooling increases, which means that when the temperature rises, it decreases

Dew point

The dew point is a specific indicator of the content of water vapor in the air.

Causes of mold from condensation

With an increase in the moisture mark, an increase in the dew point value also occurs (under the conditions of the presence of a specific temperature and pressure). The value of this physical quantity is expressed in degrees Celsius.

This is the temperature at which it is possible to achieve the greatest abundance of air with water vapor, provided that they are regularly contained in the atmosphere at the same temperature.The basis of the secondary occurrence of condensate on a variety of surfaces in the room is nothing more than a vapor pressure gradient, which occurs due to the cause of the temperature difference and different air humidity between the 2 sides of the element (outer and inner).

Always steam will move to the colder side of this structure; while at equal temperatures, the steam will move towards the side where the humidity is less. If cooling is done and the dew point is reached, then condensate will be formed already familiar to us.

Due to this, we can conclude that temperature plays an important role in the formation of condensate. When it is lowered into service. element to the mark of reaching the dew point of the outer third, the water quickly passes to the surface.

The farther the same dew point is, the longer the path of moisture to the surface will be. If the selected structure is isolated only inside, then the temperature will drop to the point where primitive moisture becomes condensate.

To avoid such a mistake, fix vapor barrier impregnations on the sides of the room itself.

Mold has formed

Mold fungi are also found on woody, damp surfaces. But the mold does not harm the tree, and during the drying period, mold fungi are easily removed with an ordinary brush.

This does not mean that more dangerous organisms cannot form on wooden surfaces.

To do this, use specialized antibacterial agents.

What is harmful condensate

At first glance, there is nothing wrong with the fact that a certain amount of water appears inside the boiler. Sooner or later, it will still evaporate under the influence of high flue gas temperatures.However, everything is not so simple here. In fact, the condensate contains not pure water, but a weak solution of acids. In addition, the complete evaporation of condensate may not happen if it appears in too large quantities.

Despite the low concentration, acids in the composition of the condensate can corrode the metal body of the boiler even in one season of active operation of the unit. In a properly configured heating system, this will never happen. But the piping of the heat generator, performed with errors, leads to the fact that condensate is formed during the entire time of operation of the boiler. As a result, it accumulates and continuously acts on metal surfaces, gradually destroying them.

The second problem associated with the appearance of condensate is that soot particles begin to stick to it. In the process of fuel combustion, a certain amount of soot is emitted into the flue gases, most of which exits the boiler through the chimney to the street. However, if there is any amount of condensate on the surface of the heat exchanger, then a small percentage of soot constantly sticks to these droplets.

As a result, over time, a fairly dense layer appears on the heat exchanger. If, in addition, wet firewood is used during the operation of the heat generator, this plaque also contains various combustible resins. The gradual thickening of such a crust leads to a drop in the efficiency of the boiler, since it isolates the metal body of the heat exchanger from the heat of the heated gases. The temperature from the furnace to the coolant is transferred worse and worse with each subsequent inclusion of the heat generator.

In the maintenance of the heat generator, there is one feature that is not so obvious at first glance, but becomes the main reason for the too infrequent cleaning of the boiler. We are talking about the fact that modern solid fuel units have a rather complex structure, which is specially calculated to increase the efficiency of the device.

As a result, a large number of intricate ornate passages inside the boiler greatly complicates the process of cleaning it. From which, over time, any desire to perform this procedure with the necessary regularity disappears. For the same reason, it is completely impossible to access some places of the structure, which once again confirms the need to solve the problem with condensate.

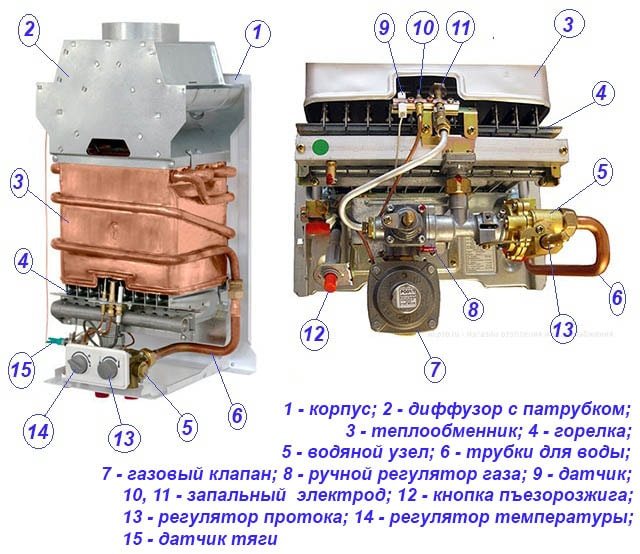

Why clean the column

The need to clean the column from dirt and, first of all, from scale, no one doubts for the following reasons:

- The deposition of salts on the inner walls of the heat exchanger reduces the efficiency of heat transfer - as a result, there is a significant waste of energy resources.

- Due to the longer heating time of water in a clogged system, the heat exchanger plates overheat and, accordingly, its service life is reduced.

- Scale clogs the passage channel of the heat exchange pipeline, while reducing the volume of outflowing hot water per unit time - this causes inconvenience when washing dishes, taking water procedures.

- The loose particles of insoluble oxides clog valves, aerators of mixing taps and other parts of the system, causing the need for frequent repairs to the equipment.

- The soot formed on the plates of the heat exchanger reduces the efficiency of its operation, preventing the exchange of heat with the burner flame.

What is condensate?

Condensate is the product of the conversion of vapor into a liquid state. This phenomenon looks like an accumulation of water droplets on the surface. In the case of window fogging, liquid usually settles on the glass surface in a fairly large amount. Drops of water gradually collect and flow down, forming a puddle or wet spot on the windowsill.

Condensation always leads to excess moisture, which, in turn, can cause fungus and mold to grow on slopes or windowsills. Most often, windows in a private house or apartment leak in winter. The accumulation of liquid on the glass surface can be explained using such a concept in physics as the “dew point”.

The "dew point" is measured in degrees and reflects the temperature to which the air must be cooled so that the vapor begins to transform into a liquid. In the kitchen, when cooking, it is often possible to observe condensation on cold surfaces.

Why do windows fog up?

First of all, the microclimate in the room itself affects the formation of condensate on the windows. There are certain standards of temperature and humidity, which are often violated due to some factors. The optimum temperature in a residential area should be about 18-23 degrees Celsius with an air humidity of no more than 50%. In this case, it is necessary to organize good ventilation.

Ventilation in apartments is mainly represented by an exhaust hood in the bathroom and in the kitchen, but in other rooms it is most often not. In living rooms and on the balcony, the gaps between the window frame and the wall play the role of ventilation ducts. However, this mainly applies to old wooden windows, since metal-plastic structures are distinguished by excellent tightness.

The problem of fogged windows does not have a universal solution, since there are quite a few reasons for the occurrence of condensate. This problem can be caused by a number of factors.

- Poor ventilation in the room.

- High levels of humidity in the room, which in the first place can be caused by everyday activities. For example, in the kitchen, the humidity rises due to cooking. Some rooms may have clothes dryers. Wet clothes also affect the level of humidity in the room.

- glass type. Single-chamber double-glazed windows do not provide the proper level of thermal insulation, and it is not recommended to install them in residential premises.

- Temporary causes of condensation include repair work. After finishing, some time should pass for the microclimate to normalize in the room.

- Incorrect installation of the window structure.

- Factory defect of the window structure itself.

- Temperature regime in the room.

- The presence on the windowsill of a large number of indoor plants.

Manufacturing defects

The quality of plastic windows depends on the manufacturer. Not all designs perform their functions equally well. If condensation is found on the glass, it is necessary to inspect the window structure for defects.

Marriage can be expressed as follows:

- gaps in window sashes;

- deformed frame;

- glass cracks;

- poorly attached fittings.

In case of damage to the double-glazed window, it must be completely replaced. Covering cracks with an adhesive will only give a temporary effect and, in addition, will spoil the appearance of the glass.This defect is most often caused by improper transportation of the window structure, and the supply company is also responsible for it.

Houseplants

Some types of flowers that are intended for growing at home in pots release moisture abundantly into the air. In the presence of a large number of such plants on the windowsill, the effect of a greenhouse is created, which contributes to the formation of condensate. It is quite simple to check whether the flowers really cause the windows to fog up - you need to free the window sill for a while and move the pots to another place. If the condensate has disappeared, then it is not necessary to return the plants to their original place.

Windowsill

Too large and dense window sill can prevent good heating of the window structure. The heat from the heating radiator will simply not flow to the double-glazed window. Replacing the window sill or a few holes in it will help solve this problem. The heat from the batteries will eliminate excess moisture and prevent it from settling on the glass.

Curtains

Thick long curtains, like a large window sill, can block the spread of heat from radiators. This problem is especially relevant in winter. In this case, it is recommended to open the battery, and for this it is not necessary to completely abandon the curtains. It will be enough to replace them with a shorter version so that the space below the windows remains free and does not overlap with fabric.

How to remove scale from a column

All internal components of the geyser

This problem occurs frequently. Its consequence is a weak pressure of warm water from the tap.

What to do in this case

: you need to clean the heat exchanger (its replacement is carried out in very neglected states).And if you yourself cannot carry out the replacement, then cleaning it is quite up to you.

First, let's look at the reasons why scale occurs. Everything is very simple - the water in our pipes flows very hard, with a lot of lime. When the water temperature reaches 80˚С, it settles on the walls of the heat exchanger. Conclusion - try to use very hot water as little as possible - above 80 ° C

. After all, even greasy dishes can be washed at 45 ° C.

If you still need to clean it, then you have to arm yourself the following equipment

- Open-end wrenches;

- Screwdrivers;

- rubber hose;

- Paronite gaskets;

- Descalers (e.g. acetic acid).

Step 1

. Shut off the water and open one hot water - at the point that is closest to the column.

Step 2

. Remove all fittings and cover from the column.

Step 3

. Disconnect the hot water hose from the radiator and lay it aside. Wait until all the water has drained.

Step 4

. Put a hose on the heat exchanger and very carefully start pouring an acid solution or other agent through it. Do not pour in a large amount at once, otherwise a very violent chemical reaction may begin. Leave for at least 2 hours.

Step 5

. Place a basin or other container under the tap and open it. If there is a lot of sludge in the water and the pressure is restored, then the problem is solved. If not, we recommend doing the procedure again.

For more information about cleaning the heat exchanger, you can watch the video:

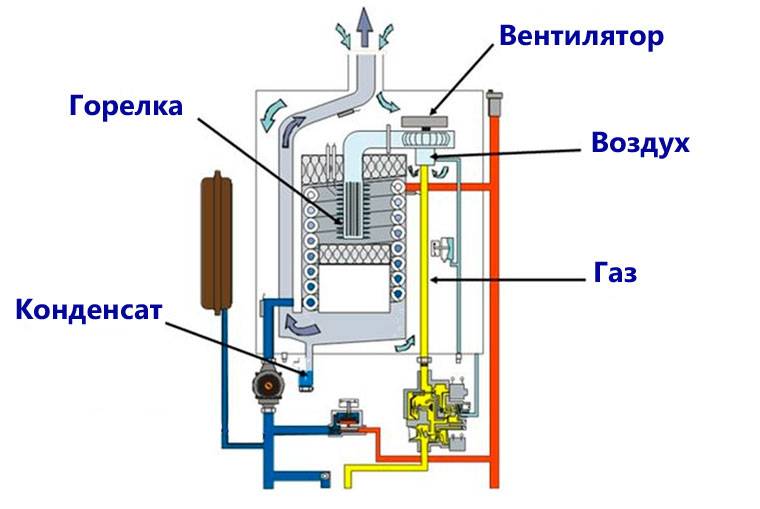

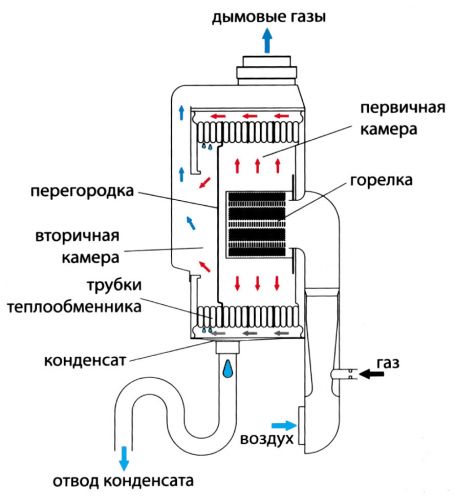

Fighting condensate in an atmospheric boiler

If an atmospheric wall or floor gas boiler is installed in the house, the combustion products are heated to 170-200 ° C. Water is also present in the gases formed during combustion.However, it does not condense, but turns into steam and is discharged through the smoke channel along with other smoke and flying soot particles.

When starting the floor gas appliance after a long period of inactivity, a small amount of condensate may appear, which will evaporate after the boiler has warmed up. In the cold season, the boiler operates non-stop, so the appearance of liquid is unlikely

In pipes made of stainless steel, the problem of condensate formation can be solved by installing a condensate neutralizer and supplementing with an element for removing condensation moisture deposited on the surface of the pipe.

When assembling ordinary metal chimneys and sandwich chimneys, it is imperative to follow the assembly and connection of elements, which provides for the spontaneous removal of condensate outside the chimney.

What is condensate?

Condensate is a liquid that settles on the walls of the chimney as a result of temperature changes. In modern gas equipment, the outgoing gases have a low temperature.

Causes of condensation:

- improperly insulated chimney;

- a sharp temperature drop;

- unheated pipes;

- clogging of the smoke channel;

- low exhaust gas temperature (ideally, the temperature should not be lower than 100 ° C);

- a very long chimney pipe, resulting in excessive cooling of the smoke;

- rough walls of the chimney (collect more water than smooth ones);

- design flaws;

- traction problems.

During the operation of a gas boiler, in addition to water, carbon dioxide and other chemical compounds (oxides) are also released.

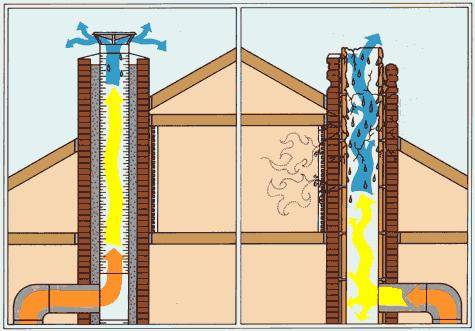

Since modern boilers are periodically turned off, the walls of the chimney are cooled from top to bottom.Condensation forms when the temperature of the gases drops to 40-60°C

Since modern boilers are periodically turned off, the walls of the chimney are cooled from top to bottom.Condensation forms when the temperature of the gases drops to 40-60°C

Under the influence of high temperature, oxides react with water and aggressive acids (nitric, hydrochloric, sulfuric, etc.) are formed. They settle on the surface of the equipment along with condensing vapors. Aggressive acidic environment leads to the rapid destruction of the chimney.

What is the danger of the resulting moisture:

- if condensate freezes in the deflector or at the mouth of the pipe, the cross section of the chimney is blocked, as a result, the draft decreases, which can lead to the formation of reverse draft and combustion products enter the house, causing poisoning of its inhabitants;

- large amounts of water can extinguish the flames, allowing carbon monoxide to enter the room.

In addition, if moisture enters the boiler furnace, its walls will collapse. As a result of destruction, toxic combustion products will partially enter the house.

Condensation leads to the destruction of the chimney. If the problem is not corrected, a complete restoration of the pipe will be required in the future.

Condensation leads to the destruction of the chimney. If the problem is not corrected, a complete restoration of the pipe will be required in the future.

The waste gases contain water in the form of steam. As the temperature of the gases decreases, the vapor becomes supersaturated and droplets form. In the case when the gases are hot, the formation of condensate occurs at the colder walls of the chimney, where drops of liquid settle.

Leaking through threaded connections?

The heating circuit of the boiler is closed. The heated coolant flows from the heat exchanger tube to the supply pipeline and then to the radiators. The coolant returns through the return pipeline, entering the heat exchanger again and then continuing to circulate in a circle.

The branch pipes of the heating circuit are connected to the supply and return pipelines using threaded (detachable) connections using fittings - spurs with union nuts, or otherwise American.

With the help of American women with union nuts, expansion tanks, stopcocks and other elements of the heating system are connected to the mains

Threaded connections are sealed with elastic heat-resistant seals in the form of rings. If they are worn out or improperly installed, water leakage occurs. Badly tightened nuts lead to the same consequences.

If you see that water is dripping at the threaded connection, you should first try to tighten the nut. Excessive zeal is useless here, since if the nut is tightened too much, it may break. If water continues to leak after tightening the nut, the seal must be replaced.

Turn off the gas and water supply in advance, drain the water from the heat exchanger. Unscrew the union nut, replace the seals and reinstall the nut.

Manufacturers of heating boilers seal detachable connections with gaskets made of rubber, silicone, paronite or other elastic materials. They are easy to use, durable and readily available. They often come with brackets. When choosing gaskets, take into account the size of the thread.

Also, sanitary flax can be used as a sealant. Regardless of the presence of leaks, seals are changed with each disassembly of water communications.

Condensation Prevention

To avoid problems associated with the operation of the chimney system, you should know how to avoid condensation in the chimney.There are several preventive measures that will extend the life of the system and make its operation not only as efficient as possible, but also safe. Among them:

- at the design stage of the system, all the rules and regulations related to the installation of the chimney and regulated by special documentation must be observed;

- installation of the system must be carried out without deviations from the project, which was drawn up by a specialist;

- making changes to the system configuration is possible only after agreement with the expert;

- in the installed chimney, it is necessary to provide increased draft: install smoke exhausters, deflectors, turbines, etc.;

- pipes must be cleaned regularly;

- It is better to use only dry fuels.

In addition, the heating system should be subjected to a scheduled inspection before each heating season. This will allow timely identification and elimination of faults.

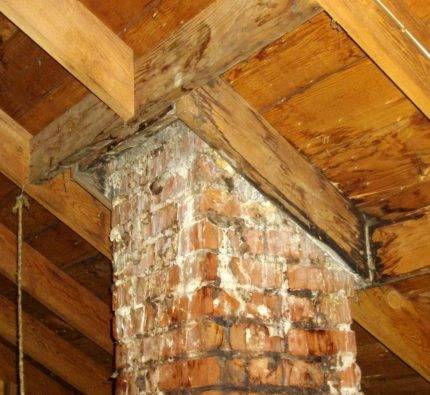

Chimney materials and the effect of condensate on them

If you use materials that do not absorb moisture, condensation problems will not disappear. If it is formed, it does not spoil the walls of the chimney, but as it accumulates, it flows down through the pipes. As a result, at the lower point it will accumulate in large quantities and in the end, the accumulation will lead to blockage of the chimney. Up to this point (depending on the type of connection of the boiler to the chimney), it penetrates into the boiler, disrupting its operation. Condensation creates malfunctions, which leads to a breakdown of the gas boiler.

Chimney materials that do not absorb liquid

Even if the condensate does not enter the boiler, but collects at the lowest point of the chimney (usually inside the house), it will cause an unpleasant smell in the room or throughout the house.

They also indicate such a moment - the junction point of the boiler and the chimney is a weak spot, and the acid formed as a result of mixing condensate with soot will eat through this area.

For brickwork, as already mentioned, condensate will be an effective destructive factor. Brick absorbs moisture, and when saturated, it becomes less durable. If the bricks cool down, the frozen moisture does more damage. The chimney is destroyed by this negative effect during one winter period.

In addition, the appearance of condensate does not occur immediately, but after several seasons. Before the first start of the boiler after the summer, and at the end of work in the spring, the owner is recommended to inspect the chimney without fail, clean it (professionals also perform similar work) and make sure that there is no condensate.

Chimney wall thickness

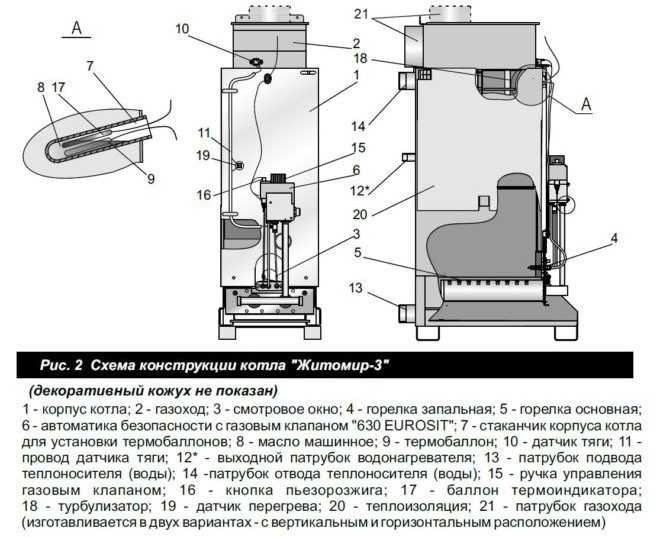

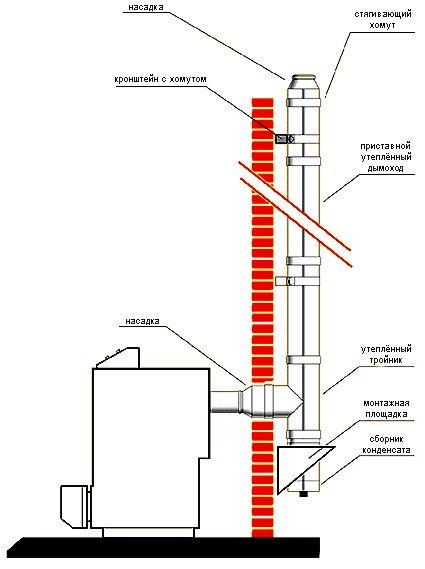

Chimney installation rules

The entire system must be insulated, waterproof and protected from aggressive materials.

The basic principles used during installation:

- the chimney should be collected according to the "condensate";

- each joint is treated with a sealing compound;

- it is better to retreat from the vertical by a maximum of 30%;

- the length of inclined sections constructed at an angle of no more than 30º to the horizon - up to one meter;

- along the entire length of the channel, components of the same section are used.

It is recommended to install ready-made chimney kits, which are available in specialized stores.

The placement of an acid-resistant sleeve and a condensate collector makes it possible to delay the dismantling of the old chimney and saves a significant amount. However, be prepared for the fact that traction will decrease

Recommended parameters of the chimney system for gas boilers:

- for the manufacture of the chimney, it is necessary to use stainless steel type AISI 321;

- minimum thermal insulation - 50 mm;

- the system must include: a tee with a condensate collector, as well as a protective cone above the upper section of the chimney.

When choosing a chimney, you should pay attention to these characteristics

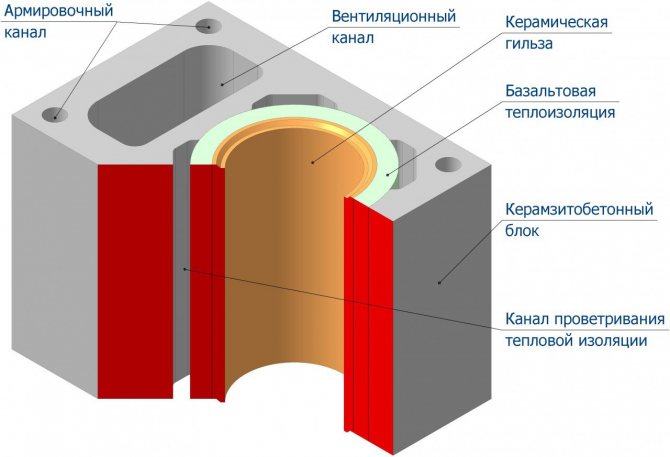

Influence of pipe material on the occurrence of excess moisture

In a gas boiler, unlike an electric or solid fuel one, condensate is constantly formed, therefore the material and thermal insulation of pipes for arranging a chimney are very important and are reflected in the safe and trouble-free operation of the device.

The optimal types of pipes for a gas boiler are:

- made of stainless steel, resistant to aggressive acids, smooth, assembled according to the "sandwich" principle - a pipe of a smaller diameter is in a pipe of a larger one;

- sandwich pipes, consist of internal and external contours, between which a thick layer of insulation (stone wool) is placed;

- ceramic, the most expensive, are distinguished by strength and durability, fireproof, heat up quickly and cool down slowly, resistant to chemical compounds, easy to maintain, insulated with mineral plates and expanded clay shell;

- coaxial, do not form condensate, built according to the “pipe in pipe” principle, where combustion products are discharged through one of them, and fresh air from outside the room enters through the other to ensure the process of maintaining the flame in the boiler, with high efficiency, safe.

The shape of pipes is allowed only oval or round. The square chimney contributes to increased soot accumulation.It is better not to use a brick or asbestos-cement channel for the removal of combustion products - they are destroyed by acidic compounds, are not sufficiently sealed and thermally insulated, and absorb moisture.

Brick chimney under the influence of condensate