- Pros and cons of purchasing and installing

- Pros and cons

- The best known manufacturers and models: features and prices

- BAXI Duo-TEC Compact 1.24

- Protherm Lynx (Condence) 18/25 MKV

- Viessmann Vitodens 100-W B1HC042

- Vailliant ecoTEC pro VUW INT IV 236/5-3 H

- De Dietrich NANEO PMC-M 24

- Rating TOP-5 wall-mounted single-circuit boilers

- MORA-TOP Meteor Plus PK24SK

- BAXI ECO Four 1.14 F

- Viessmann Vitopend 100-W A1HB001

- Buderus Logamax U072-24

- Protherm Panther 25 KTO

- Gas and more

- Advantages and disadvantages

- Principle of operation

- Classification by installation site

- Floor type boilers

- Features of wall equipment

- The nuances of parapet devices

- Rating TOP-5 non-volatile gas boilers

- Lemax Premium-12.5

- Lemax Premium-20

- Lemax Patriot-12.5

- Siberia 11

- MORA-TOP SA 40G

Pros and cons of purchasing and installing

The list of advantages of these boilers is quite large, so there is no need to be surprised at the growth of their popularity:

- The boilers are quite small. This makes it possible to install them even in small apartments.

- They consume much less fuel than conventional ones.

- You can easily choose a boiler, the power of which corresponds to the size of the house.

- Condensing boilers emit approximately 70% less harmful combustion products into the atmosphere than conventional gas boilers.

- Such boilers do not need a separate room, they are simply mounted on the wall.

A condensing boiler has many advantages

But there is also the other side of the coin:

- For example, in the middle lane, the temperature often drops to very low temperatures in winter. In this case, in order to heat the house, you need to “add fire”, that is, to increase fuel consumption at times. In this case, the temperature of the process water in the return circuit will be above 60°C and wet vapors will not be able to condense. As a result, the condensing boiler starts to work like a normal one.

- A separate neutralization system must be provided for the disposal of condensate.

Despite some disadvantages, a condensing boiler can be attributed to ideal equipment that can make life in a country house as comfortable as possible.

Pros and cons

The advantages of non-volatile boilers include:

- there is no dependence on the availability and quality of power supply;

- simplicity of design, lack of minor details;

- guaranteed continuity of the process of heating the house;

- the cost of the boiler and repair work is much lower than that of volatile models;

- maintenance and cleaning can be done independently.

The disadvantages are considered to be:

- the protection system is limited to a few sensors;

- there is no possibility of remote control;

- The operation of the boiler depends on external factors that cannot be adjusted.

IMPORTANT!

Despite some drawbacks, non-volatile boilers are a practical and reliable solution. In some settlements, they have no competitors due to power outages.

The best known manufacturers and models: features and prices

BAXI Duo-TEC Compact 1.24

The small-sized single-circuit boiler of the Duo-TEC series is considered one of the smartest representatives of the budget segment. The introduction of Think technology allows it not only to adapt to various operating conditions (weather, gas composition, chimney parameters), but also to control different temperature zones.

Such an adaptation system optimizes fuel consumption as much as possible - with a power of 24.0 kW, no more than 2.61 m3 / h (LPG 1.92 kg / h). The safety of the boiler is ensured by a modern hydraulic unit, including a pump with a post-circulation function, an automatic bypass and a double pressure gauge (1 - warning, 2 - blocking). According to owner reviews and installation experience, the boilers have been operating without problems for more than 7 years and are known for their high reliability.

Cost: 50,860 - 55,380 rubles.

Producer: BAXI (BAKSI), Italy.

The best Italian gas boilersHigh efficiency, alloy quality and reliability at an affordable price

Protherm Lynx (Condence) 18/25 MKV

Also inexpensive, but already a double-circuit unit, designed specifically for operation with gas of inadequate quality and water of increased hardness: a well-thought-out design does not provide for the presence of thin winding tubes that could become clogged by blocking the ducts in the heating and hot water circuits.

Despite the low power of 18.1 kW, it is capable of producing up to 12.1 l / min of hot (30-60 ° C) water, while fuel consumption does not exceed 2.71 m3 / h (LPG 1.98 kg / h). Communicative automation with built-in eBus makes it possible to integrate the unit into complex systems, including cascade ones.

Cost: 61,240 - 67,180 rubles.

Producer: Protherm (Proterm), Slovakia.

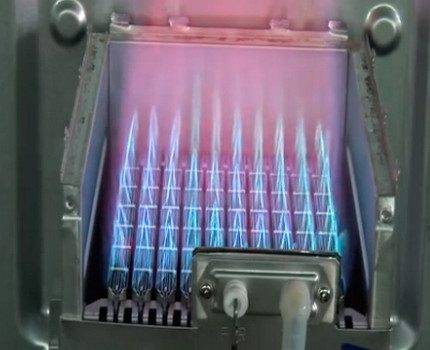

Viessmann Vitodens 100-W B1HC042

A classic single-circuit model with a laconic design, but at the same time a very interesting content: its Inox-Radial heat exchanger, made of thick stainless steel, has an unprecedented service life for a wall-mounted boiler (10 years warranty), the same applies to the MatriX cylindrical burner.

German models have always been known primarily for their reliability and quality materials. In convection counterparts, the actual service life of such heat exchangers is on average 14-15 years, which is an extremely worthy result.

The Lambda Pro Control Plus program is responsible for stable energy efficiency. In addition to constantly monitoring the state of the unit, it also adjusts itself to the consumption of a particular type of fuel, reducing its consumption to 2.57 m3 / h (SUG 1.86 kg / h) when operating at a maximum power of 26.0 kW.

Cost: 86,310 - 104,740 rubles.

Producer: Viessmann (Visman), Germany.

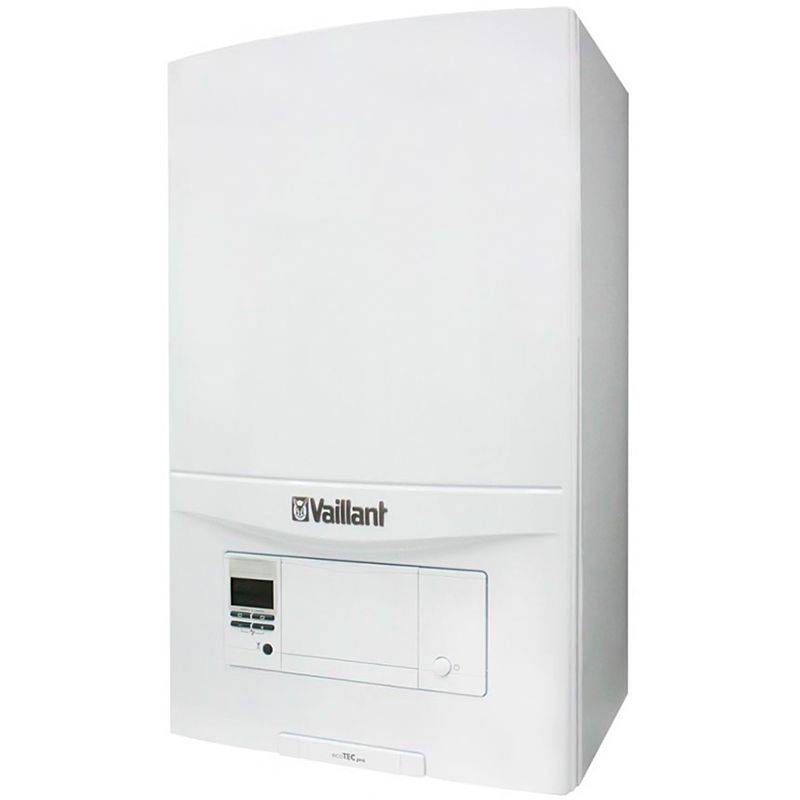

Vailliant ecoTEC pro VUW INT IV 236/5-3 H

Another reference German model. A double-circuit unit with a capacity of 23.0 kW is perhaps one of the best gas condensing boilers for heating a private house and apartment: its advantage is that, thanks to the Aqua-Kondens system, it uses the energy of the outgoing steam not only for heating, but also for hot water up to 11.0 l/min (25–65 °C).

By switching to economy mode, gas consumption even in winter is no more than 2.54 m3/h (LPG 1.80 kg/h). The built-in controller with a digital information and analytical module DIA-System is supplied in a single housing with the unit, which greatly simplifies its installation, operation and maintenance.

Cost: 76,120 - 91,860 rubles.

Producer: Vailliant (Vailant), Germany.

De Dietrich NANEO PMC-M 24

The truly innovative 24.8 kW single-circuit gas condensing boiler is the most compact (66.4 x 36.8 x 36.4 cm) and lightest (25 kg) model on the market. It was originally designed for the use of different types of gas, so it does not require additional equipment to work on LPG.

Its removable control panel, which can be installed under cauldron or hang on the wall, has the functions of cleaning pipes, resetting and adjusting the temperature of heating / hot water supply (DHW sensor for storage tank sold separately). Fuel consumption does not exceed 2.54 m3/h (LHG 1.96 kg/h).

Cost: 64,510 - 78,080 rubles.

Manufacturer: De Dietrich (De Dietrich), France.

Rating TOP-5 wall-mounted single-circuit boilers

Consider the most popular and popular models of wall-mounted single-circuit boilers:

MORA-TOP Meteor Plus PK24SK

Convection type gas boiler designed and manufactured by Czech engineers.

The power of the unit is 24 kW, which corresponds to 240 square meters. m. of serviced area. The boiler has electronic control, multi-stage protection against external influences or failures in the operation mode.

Main parameters:

- Efficiency - 90%;

- coolant temperature (max) - 80 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 2.6 m3/hour;

- dimensions - 400x750x380 mm;

- weight - 27.5 kg.

Models of this power are the most in demand, since they roughly correspond to the needs of medium-sized private houses.

BAXI ECO Four 1.14 F

Italian convection gas boiler. The power of the unit is 14 kW, which is suitable for premises up to 140 sq..m

It can be apartments, offices, small houses.The unit has a closed combustion chamber that allows you to install it in the kitchen.

Consider its characteristics:

- Efficiency - 92.5%;

- coolant temperature (max) - 85 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 1.7 m3 / hour;

- dimensions - 400x730x299 mm;

- weight - 31 kg.

Italian heating engineering is famous for its quality, but the prices cannot be called too affordable.

Viessmann Vitopend 100-W A1HB001

The quality of German technology has long been the benchmark for all manufacturers. The Vitopend 100-W A1HB001 boiler confirms the prevailing opinion.

Its power is 24 kW, the most demanded value for heating a house of 240 square meters. m. The turbocharged burner does not spread smoke odors, so installation in the kitchen or other interior areas of the house is possible.

Options:

- Efficiency - 91%;

- coolant temperature (max) - 80 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 2.77 m3/hour;

- dimensions - 400x725x340 mm;

- weight - 31 kg.

The unit can be switched to liquefied gas, for which you will have to change the set of nozzles and change the settings a little.

Buderus Logamax U072-24

High-quality heating boiler from a well-known German manufacturer.

The company is a "daughter" of the Bosh concern, which eloquently indicates the quality and capabilities of the unit. The power is 24 kW, the heated area is 240 square meters. m.

Main characteristics:

- Efficiency - 92%;

- coolant temperature (max) - 82 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 2.8 m3/hour;

- dimensions - 400x700x299 mm;

- weight - 31 kg.

The unit is equipped with a copper heat exchanger in the form of a coil. This increases heat transfer and makes the boiler more durable and stable.

Protherm Panther 25 KTO

There are two modifications of this model - from 2010 and 2015.

They differ little from each other. in a more recent design, some shortcomings have been eliminated and power has been slightly increased. It is 25 kW, allowing you to heat houses of 250 square meters. m.

Boiler parameters:

- Efficiency - 92.8%;

- coolant temperature (max) - 85 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 2.8 m3/hour;

- dimensions - 440x800x338 mm;

- weight - 41 kg.

Equipment from Slovakia enjoys well-deserved success with buyers.

A distinctive feature are the names of the series. For example, all series of wall-mounted boilers bear the names of animals from the cat family.

Gas and more

Despite the fact that methane is the most efficient type of fuel, gas condensing boilers can also be used with other gases, namely propane and butane, with a mixture of which gas tanks are filled. Since regular filling and maintenance of the gas tank requires constant expenses, the consumer subconsciously (or not) is always trying to save gas. A condensing boiler in this situation is convenient not only as a generator of albeit small, but additionally produced heat, but also as a device with a wide range of power modulation (regardless of the manufacturer). This saves gas because the consumer does not overheat the house. In addition, the reconfiguration of the burner to liquefied gas is carried out by switching the boiler settings without interfering with its design.

There are both liquid fuel and biofuel condensing boilers on the Russian market, which, unfortunately, are not widely used.

Advantages and disadvantages

The advantages of single-circuit boilers include:

- simplicity, reliability of the design;

- the absence of unnecessary components and parts;

- less risk of breakage, more stable operation of the device;

- the absence of additional nodes reduces the weight of the boiler;

- when using an external boiler, it becomes possible to supply hot water, moreover, this method is considered more efficient;

- the price of single-circuit models is lower.

The disadvantages can be considered:

- there is no possibility of independent preparation of hot water;

- the cost of external boilers is quite high, and installation requires space;

- in the summer, you have to spend fuel to heat water in an external boiler (if any);

- the use of external storage increases the load on the heat exchanger and increases fuel consumption.

IMPORTANT!

The disadvantages of single-circuit boilers do not pose a significant problem. Experienced people prefer to purchase just such units in order to get a more reliable heating system and a stable supply of hot water using a boiler.

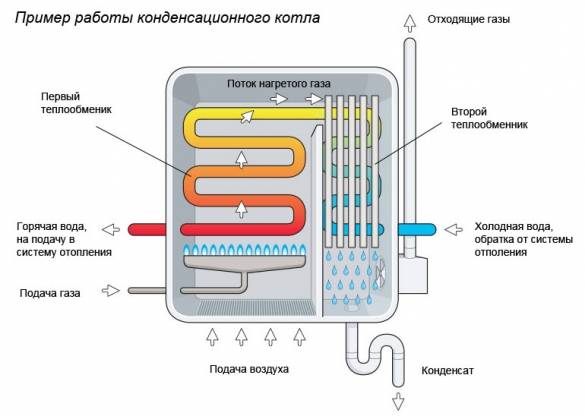

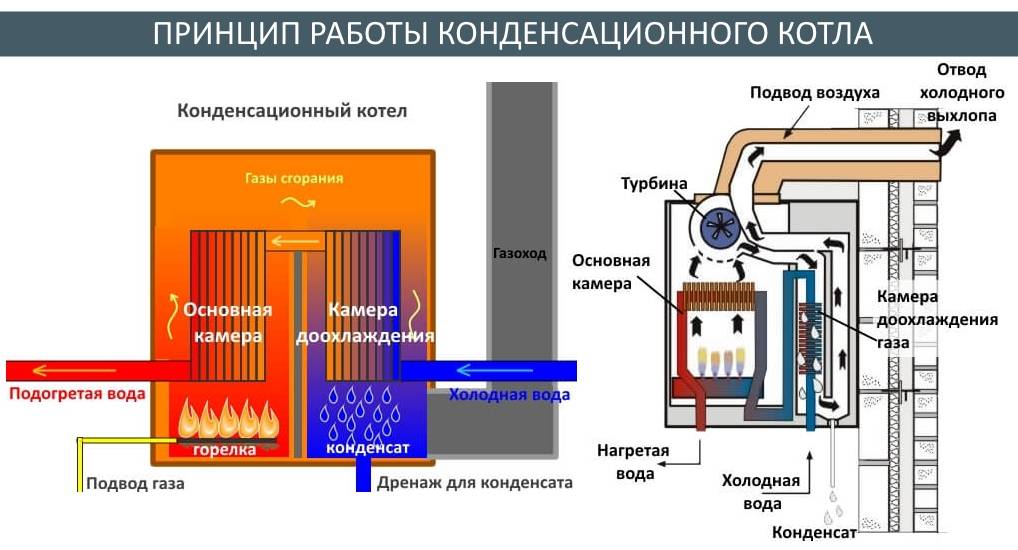

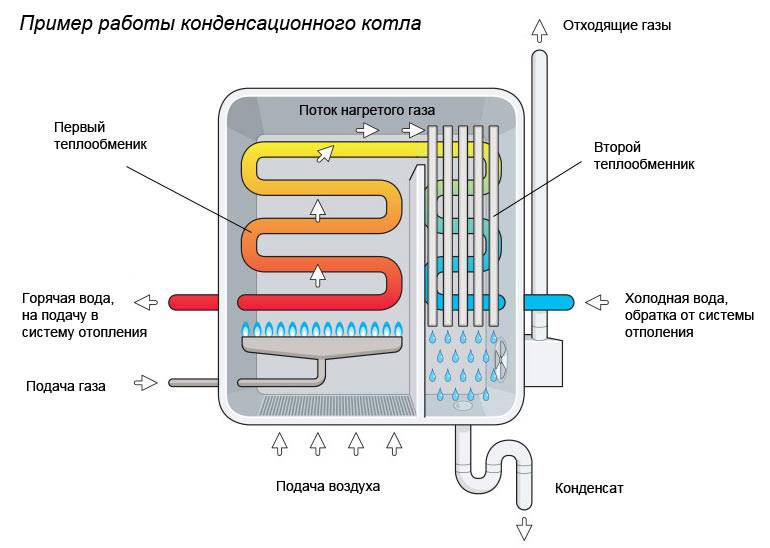

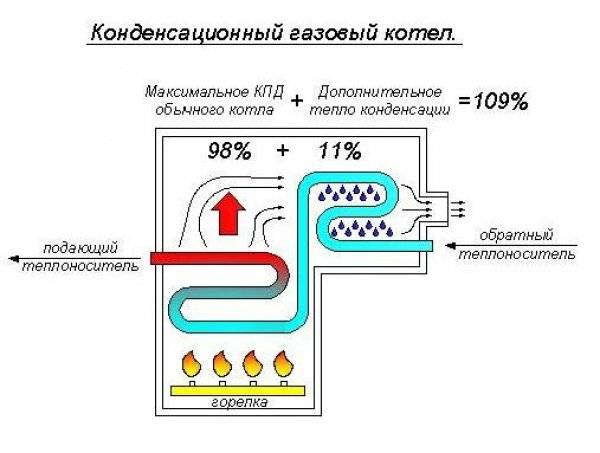

Principle of operation

The operation of the unit takes place in two stages:

- the return flow of the coolant enters the condensation chamber. It is a heat exchanger in which energy from the settling water vapor from the flue gases is transferred to the HW (heating water). From this, the temperature of the coolant rises slightly, which makes it possible to make the heating mode of the gas burner more economical and softer;

- from the condensation chamber, the RH enters the primary heat exchanger, and then the whole process takes place according to the usual traditional method. Receiving full heating, the liquid enters the secondary heat exchanger, giving part of the energy for the preparation of domestic hot water. Then it enters the heating circuit or floor heating system.

For the efficient operation of a radiator-type thermal circuit, it is necessary that the return temperature is not higher than the degree of heating of the condensation chamber heat exchanger, otherwise the operation of the first stage will become impossible.

IMPORTANT!

In the conditions of Russia, it is physically impossible to provide such conditions, so it remains only to use condensation models to power the underfloor heating circuits. Such a limitation calls into question the feasibility of using these units in inappropriate conditions, since the difference in cost destroys all the benefits of fuel economy.

Classification by installation site

According to the installation principle, boilers serving two communication circuits are floor, wall and parapet. Each option has its own special characteristics.

Focusing on them, the client can choose the most suitable installation method for himself, in which the equipment will be located conveniently, will not “eat up” the usable area and will not cause problems during operation.

Floor type boilers

Floor-standing units are high-power devices capable of heating and providing hot water not only to a standard apartment or residential building, but also to a large industrial premises, public building or structure.

If a double-circuit boiler is planned to be used not only for heating and supplying domestic hot water, but also for feeding warm water floors, the base unit is equipped with an additional circuit

Due to their large size and solid weight (up to 100 kg for some models), floor-standing gas boilers are not placed in the kitchen, but are placed in a separate room directly on the foundation or on the floor.

Features of wall equipment

The hinged appliance is a progressive type of household heating equipment. Due to its compact dimensions, the gas speakers can be produced in the kitchen or other small spaces. It is combined with the interior solution of any type and organically fits into the overall design.

The double-circuit mounted boiler can be located not only in the kitchenbut also in the pantry. It will take up a minimum of space and will not interfere with furniture or other household appliances.

Despite its small size, the wall-mounted boiler has the same functionality as the floor-standing device, but has less power. It consists of a burner, an expansion tank, a pump for the forced movement of the coolant, a pressure gauge and automatic sensors that make it possible to use the fuel resource with maximum efficiency.

All communication elements are "hidden" under a beautiful, modern body and do not spoil the appearance of the product.

The flow of gas to the burner is controlled by a built-in security system. In the event of an unexpected cessation of the resource supply, the unit will completely stop functioning. When the fuel begins to flow again, the automation automatically activates the equipment and the boiler continues to operate in standard mode.

The automatic control unit allows you to set the device to any operating parameters that are most suitable for the user. Possibility to set your own temperature for different times days, thus ensuring economical consumption of the fuel resource.

The nuances of parapet devices

The parapet boiler is a cross between a floor and wall unit.It has a closed combustion chamber and does not create harmful emissions. Does not require the arrangement of an additional chimney. The removal of combustion products is carried out through a coaxial chimney laid in the outer wall.

A parapet-type boiler is the best option for heating equipment for small rooms with a weak ventilation system. The device is designed in such a way that during operation it does not emit combustion products into the atmosphere of the room in which it is installed.

The device is mainly used to provide hot water and full heating for small houses and apartments in high-rise buildings, where it is not possible to mount a classic vertical chimney. The base power ranges from 7 to 15 kW, but despite such low performance, the unit successfully copes with the tasks.

The main advantage of parapet equipment is the ability to connect heating and water supply communications to the central gas system and pipelines from any side convenient for the user.

Rating TOP-5 non-volatile gas boilers

Consider the features of some models of non-volatile units:

Lemax Premium-12.5

Non-volatile floor boiler of domestic production. The power of the unit is 12.5 kW, so the area of \u200b\u200bthe room should not exceed 125 square meters. m.

The model is equipped with a steel heat exchanger, overheating protection and a gas supply controller.

Main performance characteristics:

- Efficiency - 90%;

- maximum heating water temperature - 90 °;

- pressure in the heating circuit (max) - up to 3 bar;

- natural gas consumption - 1.5 m3/hour;

- dimensions (W-H-D) - 416x744x491 mm;

- weight - 55 kg.

Lemax gives a long-term guarantee for its boilers - the user receives technical support for 3 years.

Lemax Premium-20

Another floor-standing non-volatile gas boiler made in Taganrog.

Its power is 20 kW, which is optimal for most private two-story houses. The maximum area for this unit is 200 sq. m.

Boiler parameters:

- Efficiency - 90%;

- maximum heating water temperature - 90 °;

- pressure in the heating circuit (max) - up to 3 bar;

- natural gas consumption - 2.4 m3/hour;

- dimensions (W-H-D) - 556x961x470 mm;

- weight - 78 kg.

The single-circuit design is designed for heating the coolant, but if necessary, you can connect external indirect heating boiler.

Lemax Patriot-12.5

Non-volatile parapet model from Taganrog. Boiler with specific features.

Non-volatile unit, but the combustion chamber is of a closed type. Boiler power 12.5 kW, suitable for heating 125 sq. m.

Main technical characteristics:

- Efficiency - 87%;

- maximum heating water temperature - 80 °;

- pressure in the heating circuit (max) - up to 2 Bar;

- natural gas consumption - 0.75 m3/hour;

- dimensions (W-H-D) - 595x740x360 mm;

- weight - 50 kg.

The main advantage of parapet boilers is low fuel consumption - almost half that of conventional models.

Siberia 11

Production of Rostov manufacturers of heat engineering. Units are available in single and double circuit versions, which expands the choice.

The power is 11.6 kW, allowing you to heat a house up to 125 square meters. m.

Main parameters:

- Efficiency - 90%;

- maximum heating water temperature - 90 °;

- pressure in the heating circuit (max) - up to Bar;

- natural gas consumption - 1.18 m3/hour;

- dimensions (W-H-D) - 280x850x560 mm;

- weight - 56 kg.

Rostov units are positively evaluated by specialists and ordinary users.

MORA-TOP SA 40G

The Czech gas non-volatile boiler with a capacity of 35 kW is designed for use in rooms up to 350 sq. m. The massive structure is equipped with a cast-iron heat exchanger.

Options:

- Efficiency - 92%;

- maximum heating water temperature - 85 °;

- pressure in the heating circuit (max) - up to Bar;

- natural gas consumption - 3.9 m3/hour;

- dimensions (W-H-D) - 630x845x525 mm;

- weight - 151 kg.

The cast iron heat exchanger has a sectional design of 5 departments. There are pressure and temperature sensors.