- What you need to know about remote condensing units

- How is a condensing unit selected?

- Calculation of power according to the formula

- Simple Calculations

- Varieties of compressor and condenser units

- KKB operation

- 6 How to choose a thermostatic expansion valve

- Safety when using capacitor units

- 8 Operational features of KKB

- Remote condenser unit device

- Specifications

- Components of the unit

- The principle of operation of the air-cooled condensing unit

- 4 Recommendations for choosing a filter drier

- Varieties of capacitor units and their scope

- Installation of KKB

- 1 Scope of use of KKB

- Selection of a condensing unit

- Areas of application of KKB

- Single stage air coolers

- Features of installation of KKB

- Features of using the chiller

- Operating principle

- Types of condensing units

- Air cooling procedure

What you need to know about remote condensing units

Given the rules by which the application and the principle of operation of remote condenser units, you can choose the right unit. To do this, you need to know about the following parameters:

- Boiling temperature in the evaporator;

- Condensing temperature indicator;

- Type of refrigerant;

- How many circuits are available;

- Block load.

In order for the specialists supplying equipment, the company to be able to choose the best option for you, which will meet your needs to the maximum, you need to tell them these indicators.

Only firms with employees with special knowledge and skills are required to install remote condensing units. This personnel undergoes the appropriate kind of training and at the end of it they receive certificates allowing the installation of this type of structure.

Capacitors are connected using special equipment and tools. If the remote mechanism has a large capacity, additional or full refilling with freon may be required.

Thus, we figured out how the application and the principle of operation of remote condenser units take place. Using this equipment, you provide yourself and others with comfort and convenience.

How is a condensing unit selected?

The main criterion for any unit is its power. To a greater extent, the required performance is affected by the operation of the ventilation system. In addition, when choosing a model, the following indicators are important:

- temperature of supply air masses;

- air humidity, seasonal fluctuations must be taken into account;

- temperature outside the building (climatic conditions in the region).

Some of the necessary data must be indicated in the equipment passport, others can be found in the SNiP tables. They are substituted into the diagram, and then the required (optimal) block power is selected.

Calculation of power according to the formula

When choosing a KKB, it is required to calculate the power of the air cooler (QX). For this, the formula is used:

QX = 0.44 L ΔT where L is the air flow (m3/h) and ΔT is the temperature difference. To make it clearer, it is necessary to give an example. If the air flow rate of the air cooler in the air handling unit is 2000 m3/h, and the air needs to be cooled from 28° to 18°, then the following KKB capacity is required:

QX \u003d 0.44 2000 (28-18) \u003d 8800 W \u003d 8.8 kW

In this case, a KKB with a capacity of 9 kW will be enough, however, it is recommended to add at least 10% of the margin to this figure. For a more accurate calculation, which is highly dependent on indoor humidity, room and outdoor temperatures, it is advised to use the equipment manufacturer's software.

Simple Calculations

Another way to define a characteristic is much simpler. Someone has already determined that with a room height of 3 meters, 1 kW of cold is needed for every 10 m2, so you need to divide the area of \u200b\u200bthe room by 10. However, this method is elementary, but not ideal, since the accuracy of the result is lower.

The minimum outside air temperature is always used in calculations. In this case, it is possible to guarantee the nominal operation mode, reduce the risk of equipment overloads. If you make a calculation, where the indicator will be the maximum temperature, then the unit, if it is significantly lowered, may simply fail. The boiling of the refrigerant in the evaporator will be partial, so a certain amount of freon will enter the compressor in a liquid state. The result will be jamming of the unit.

Since not all blocks have connection kits, when choosing a separate kit, it must be taken into account that the evaporator performance should be slightly higher. In accordance with this, the elements included in this node are selected.

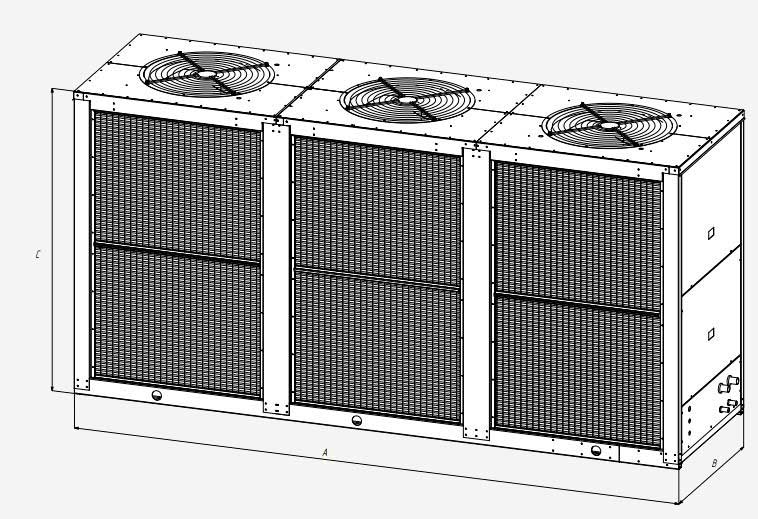

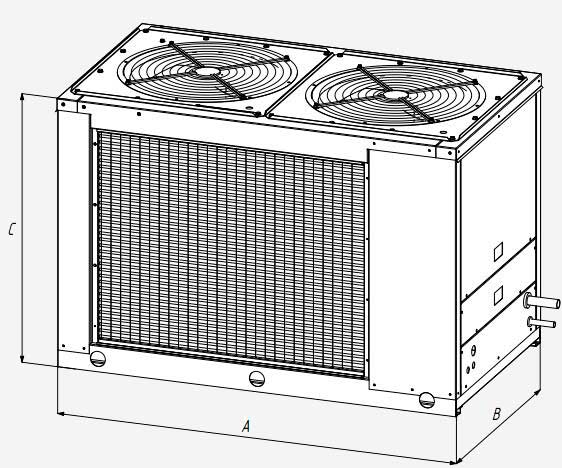

Varieties of compressor and condenser units

The type of KKB is determined by the type of its own cooling. It can be carried out with the help of air, water, external cooler. Units of the first type have a built-in fan that forms the air flow.

If an axial fan is included in the design, then the unit is mounted outside the building. In the presence of a centrifugal fan, the installation of the unit is carried out directly in the room.

The power of the air-cooled KKB can be very large - up to 45 kW per hour. In everyday life, a unit with a maximum power of 8 kW is usually sufficient.

The condensing unit, in which the condenser is cooled with water, is more powerful. It does not require a large volume of air for its operation, therefore it is compact and designed for indoor installation. Its installation is possible at a considerable distance.

KKB with a remote-type capacitor is used less frequently, mainly when there is a lack of space in the room. In this case, the block itself is installed inside the room. The heat exchanger is placed outside.

KKB operation

Instructions for use of KKB have a number of requirements for the operation and selection of the necessary model of the device:

- To ensure uninterrupted operation during the established period of operation, the KKB should undergo preventive inspection and repair once a year with the participation of service center specialists.

- The calculation of the installation must be made in accordance with the conditions of its placement.

- The equipment is connected to the mains, designed for the power consumed by it.

A separate section of the requirements also includes recommendations for ensuring the safe use of KKB:

- Free air access must be provided.

- Devices of this type are not installed in places with high humidity.

- The unit must not be placed in fire and explosion hazardous areas.

- The device must be grounded and installed in accordance with electrical safety rules.

For more detailed information on the operation of the cooling unit, see the instructions for use of a specific sample of the device. With a competent and responsible approach to organizing the conditions for the operation of the KKB, this unit will last a long time and will not require large expenses for repairs and maintenance.

6 How to choose a thermostatic expansion valve

Everything can be calculated more easily. For ten square meters of area, one kilowatt is needed to generate cold. That is, for a room of one hundred square meters, ten kilowatts are needed.

The necessary calculations must be made, focusing not on the maximum possible temperature on the street, but on the very minimum provided for by the technical characteristics of the apparatus.

Normal operation is ensured by the compressor having less capacity than the maximum possible capacity given by the evaporator.

Such a device regulates the flow of freon into the evaporator. It must be selected according to the following criteria:

- performance declared in the technical documentation;

- boiling point;

- the temperature at which condensation occurs;

- temperature maximum and minimum of the workplace where the KKB is installed.

The way the valve is installed will also affect.

Safety when using capacitor units

Any of the master electricians who take part in the installation, operation or testing of a remote capacitor device must observe safety precautions.In addition, the specialist must be fully aware of the technical nuances of the installed unit.

A prerequisite for obtaining access to work on the installation of the air conditioning system is the presence of a medical examination. He will determine the suitability of a person to work in conditions with electrical installations, the voltage of which reaches over 1000 volts.

The entire team must be able to provide first aid in case of an accident and use fire extinguishing equipment.

All installation work must be carried out in accordance with safety rules:

- It is necessary to punch furrows, holes or openings in structures made of concrete or stone only with glasses with protection;

- Mounting guns should be used during installation only by a scientific specialist;

- Work in a room where there is no excessive danger, you can use electrified tools with a voltage size of 220 volts, if there is a reliable kind of grounding of the body part;

- The work area should be equipped with a sturdy parts table and a rubber mat;

- Equip the place where the unit will be installed with a circuit breaker with a fuse. Through it, power will be supplied to the test circuit;

- Work is carried out in rubber gloves and dielectric boots.

These and other precautions will help you properly install and use your air conditioning system.

8 Operational features of KKB

There are a number of requirements that must be met unquestioningly to ensure reliable and long-term operation.

- 1. Annual preventive check in the service center.

- 2.Installation is carried out taking into account the conditions of the location.

- 3. The equipment must be connected to adequate mains power.

- 4. As elsewhere, a separate section is devoted to safety precautions that must be followed.

- 5. Organization of free access to airspace.

- 6. There are no humidifiers nearby.

- 7. The same applies to fire hazardous places.

- 8. Grounding is carried out in accordance with all the rules.

Never be too lazy to look at the instructions. Proper observance of the requirements will ensure the durability of the KKB and the preservation of its quality characteristics.

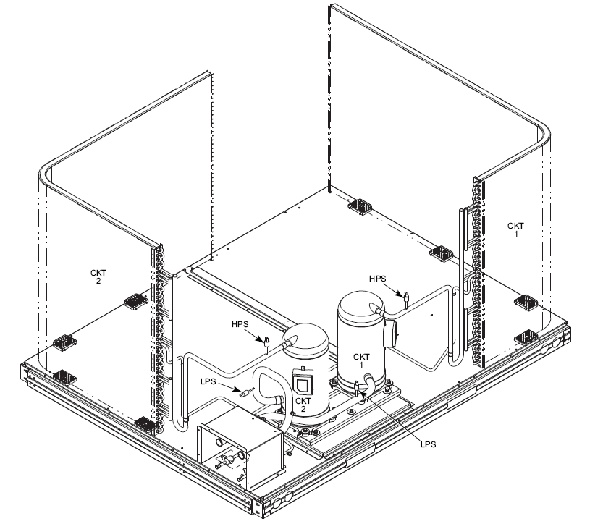

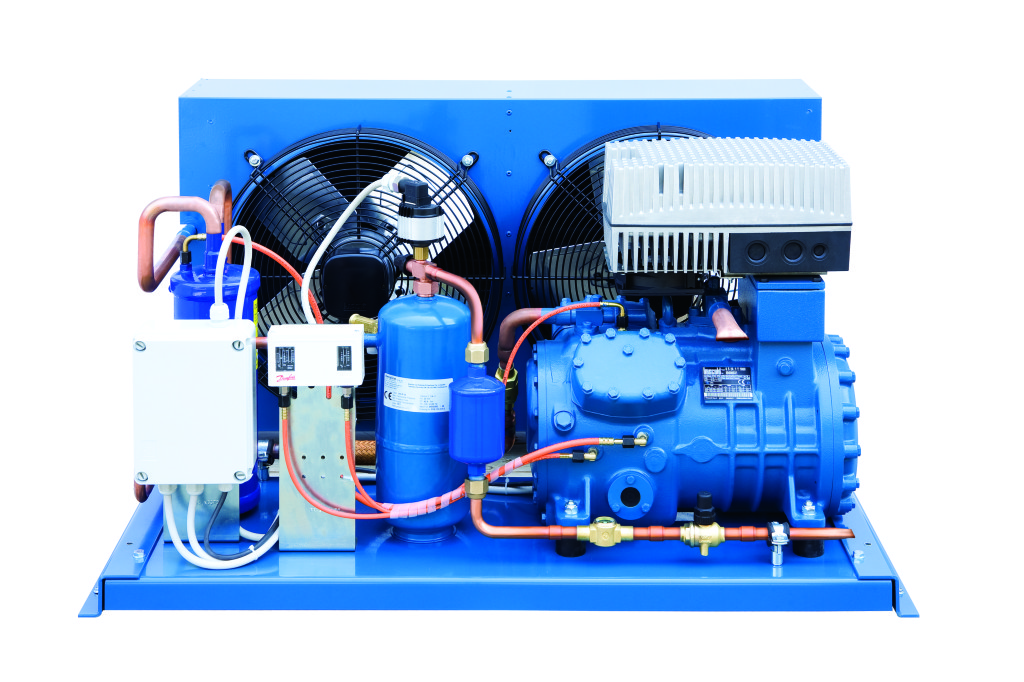

Remote condenser unit device

The most common the condenser block consists of such details:

- One compressor or more;

- A control system that helps to monitor the speed of rotation of the fans;

- Electrical power system;

- Heat exchanger;

- Centrifugal or axial fan equipment, which is designed to circulate the air flow coming from the outside through the heat exchanger.

In addition to these main components, in order for the cold supply system to function, this technique is equipped with a connecting kit consisting of:

- Thermal expansion valve;

- filter drier;

- sight glass;

- solenoid valve.

Of all the above parts, the most basic is the heat exchange plate, since it is in it that the entire ventilation process takes place.

Specifications

For small shops, gas stations and other low-budget businesses, relatively “quiet” condensing units are used. They emit noise and vibration vibrations that are acceptable when used in the residential sector.

The purpose of these devices is to create an artificial lowering of the operating temperature in small commercial and air conditioning equipment.

The units operate on explosion-proof refrigerants (R22, R404A, R407C, R507). In addition, these liquids do not ignite and do not destroy the planet's ozone layer.

Low temperature performance ranges from 3.8 to 17.7 kW, depending on the selected fluid.

The control is performed by starting and stopping according to the signals of external devices and sensors (for example, a thermostat). When the required level of cold is reached, the compressor automatically turns off, and when the set temperature rises, it turns on.

The condensing unit has comprehensive protection: against overheating of windings, fans, high pressure, unsuitable voltage in the network.

Components of the unit

The main part of any refrigeration unit comes ready-made from the manufacturing plant. Pipes and fittings that are under high pressure are tested before assembly. The electrical circuits and the control panel are also tested. Upon receipt of the device, you should check the integrity of the package, case. If all the characteristics are normal, you can connect the condensing unit to the refrigeration unit.

The basic composition of the device:

- High pressure switch. The purpose is to control the cooling system (fans).

- Control Panel. The latter consists of a thermostat (responsible for the automatic start / stop of the compressor), a fan speed controller. The operation of the motor is responsible for turning the heater on and off.

- Double relay (high and low pressure).Such a device works in emergency situations.

- Compressor. This unit is filled with oil, as well as a heater for heating it. Pressure sensors are installed on the suction and discharge lines of the refrigerant.

- Vibration and noise isolation.

The principle of operation of the air-cooled condensing unit

The compressor block, consisting of the motor and the compressor itself, must interact effectively with the condenser. So, a heat exchanger with a fan, performing its function in the air conditioning system, helps to set the air temperature necessary for a person in the room. The very principle of operation is based on the physical law of energy transfer, in which freon is converted from one state of aggregation to another.

The same is true for space heating. Freon, transforming into a liquid state, absorbs cold air.

The compressor block is used to change the pressure inside the system. It is in it that the gaseous freon is compressed. In this state, in the heat exchanger, the processes of heat loss and condensation occur more intensively due to a sharp pressure jump. After the freon has cooled, it enters the evaporator with a fan. Blowing warm air, the refrigerant quickly boils, forming a gas. It is in this chamber that freon changes with the evaporator with air flows of different temperatures. After that, the gas again enters the compressor. With constant circulation of freon in the KKB, the room is continuously cooled. And familiar to all users of air conditioners, adjusting the power of the air flow, as well as turning the device on and off, occurs using the control system.Such a device is connected using special sensors and tires to the KKB.

The compressor block regulates the pressure inside the system

4 Recommendations for choosing a filter drier

Such an element is necessary for moisture absorption from the line with freon. Its choice is based on the brand of freon charged into the device. There is also a direct dependence on the form of its connection. The size of the connections depends on this procedure.

It is important to determine in advance whether the gas will work for heating or cooling. Such glass is necessary for monitoring the degree of presence of freon, assessing the technical condition of the filter and the presence of moisture. The choice is made on the brand of gas, external temperatures, glass installation method and degree of humidity

The choice is made on the brand of gas, external temperatures, glass installation method and degree of humidity

Such glass is necessary for monitoring the degree of presence of freon, assessing the technical condition of the filter and the presence of moisture. The choice is made on the brand of gas, external temperatures, glass installation method and degree of humidity.

Changing the color of the glass informs about the various states of the unit.

Varieties of capacitor units and their scope

Due to various configurations and operating principles, capacitor devices are divided into:

- Units with axial fans and air cooling. In the configuration of such equipment there is a fan with an axial mechanism. This type of device is acquired when the block is planned to be placed at the building. This option is considered the cheapest.At the same time, it requires a sufficient amount of space outside, for the uninterrupted supply of the units with the necessary amount of air flow to cool the condenser;

- Device with centrifugal fan and air cooling. This unit is installed on the inside of technical structures and connected to air ducts, through which air will be supplied and removed to the outside in order to continuously reduce the temperature of the condenser. This option is most suitable in those conditions where there is no platform for mounting the unit on or near the building;

-

Water cooled mechanisms. They are used to mount devices inside the room, and also use heat exchangers to provide water cooling for condensers. This kind of technique will make it possible to make the size of the capacitor structure much smaller and place it in a room with a minimum loss in area. This installation has the advantage of being able to install the cooling tower and the device itself at a great distance from one another;

- Takeaway condenser unit. It is usually used when the unit needs to be installed in technical rooms, and the heat exchange plate needs to be taken out into the yard. This placement allows you to occupy the minimum area in the building.

In order to choose the right device, you must carefully study all their technical characteristics.

Installation of KKB

Before starting the installation of the compressor and condenser, a place for its placement is carefully selected, which must meet all the conditions for maintaining such equipment.

This is important when installing the system in a closed room - there must be a fairly large area to ensure a constant supply of fresh air.

For outdoor installations, several types of installation are distinguished:

- On the ground (with the preparation of the foundation and frame).

- On the wall (on brackets).

- On the roof of the building (using platforms and frames).

And it is also necessary to accurately calculate the location and length of the pipes for the supply of refrigerant, as well as the removal of condensate and melt water. Freon pipes are most often made of copper. To install them, it is necessary to calculate the maximum length of the pipeline and the number of its bends, since the efficiency of the equipment depends on these factors.

KKB strapping scheme

KKB strapping scheme

In this case, it is especially important to choose the most suitable strapping parts in order to create the most tight connection.

1 Scope of use of KKB

The principle of operation of KKB refers it to climatic equipment. With the help of a modern set of elements, the functions of cooling the room or heating it are provided. This product is used in industrial or domestic air conditioning systems.

In principle, it is suitable and used for central cooling system in a public or industrial building.

Scope of application:

- private residential building;

- educational institution;

- office center;

- enterprise with established production.

Such a unit is usually installed in an air handling unit or ducted air conditioner, if it is not possible to install a larger cooler.

Consider the device of such a device:

- the key element is the compressor;

- electric motor.

- fan (varies by manufacturer);

- a heat exchanger used as a condenser;

- the desired power supply scheme;

- control.

There are various additional parts that improve the performance of the unit. Freon is the most commonly used refrigerant.

Selection of a condensing unit

When choosing a cooling unit for a building, you should pay attention to the following parameters:

- Type of KKB - air or water cooling, the choice of which depends on the dimensions of the room, the availability of free space for the installation of equipment and the planned budget.

- Heating temperature in the evaporators of the device.

- Condensing temperature (temperature of the air cooling the unit).

- Power and energy consumption of the installation.

- A kind of freon for refueling.

- The number of contours.

These wishes must be transferred to the jurisdiction of the supplier company, where the equipment for compressor and condensing purposes will be ordered. In this case, the specialists themselves will be able to choose a design option that is ideally suited to the conditions of the object.

Areas of application of KKB

They are used quite widely, since monoblocks are capable of performing different tasks. Usually they are chosen for those rooms where there is no need for an accurate temperature regime. KKB are intended for:

- air cooling in ventilation systems;

- ventilation of warehouses, various catering establishments;

- cooling showcases, counters, utility rooms of shops;

- technological equipment, including for automated lines.

The widespread use of KKB is explained by the fact that these devices perform the most important, difficult part of the work, since it is necessary not only to supply liquid refrigerant to the heat exchanger, but also to ensure circulation, re-entry of compressed gas into the condenser. The installation is as convenient as possible: it is compact, does not emit excessive noise, can be located anywhere: both inside and outside the building, on the roof.

If we talk about the advantages of such equipment, then first of all it should be noted its high efficiency, reliability, compactness, and almost complete absence of noise. Now manufacturers have managed to significantly reduce the energy consumption of KKB, so cost savings are added to the list. Minus - a relatively rough adjustment of the cooling capacity. The error can be 2-4°.

Single stage air coolers

Compact and streamlined designs that run on a safe, certified fluid and have improved performance are popular in many countries.

Among them, Bitzer condensing units are distinguished. The main characteristics and advantages of this type of apparatus include:

- Wide range of cooling capacities.

- Design reliability.

- Compactness.

- Wide spectrum cooling (normal, low temperature).

- Large area of heat exchangers.

- Increased protection of electrical control and boards.

- Engine regulation.

- It is possible to charge with essential oil (for some types of refrigerants).

Having correctly determined the required cooling capacity, it becomes possible to choose the most economical and most reliable device that will ensure uninterrupted operation over a long period.

Features of installation of KKB

The installation of the condensing unit must be preceded by careful preparation. First of all, they check the compliance of such unit data as phase connection, voltage, current frequency with the corresponding characteristics of the power supply line.

There should be no dust in the place where the KKB is planned to be installed, otherwise it can get into the heat exchanger. The air flow leaving the condenser must not be returned to it.

The process of installing a ventilation system begins with the installation of a floor-mounted KKB, an evaporator, and laying an inter-unit line. The most difficult moment is the installation of expansion valves, drying filters, receivers, sight glasses, and other elements

If the unit is installed on the ground, it must be positioned so that rainwater and snow do not get into it. The space around the unit must be free, without obstruction for air movement and maintenance. It is not possible to connect air ducts supplying and extracting air from the unit.

The assembly and installation of compressor and condenser units is carried out by specialized companies, whose employees have the appropriate qualifications and certificates. To connect the unit you need to have a special tool and equipment. It also happens that the unit has to be refueled or completely refueled.

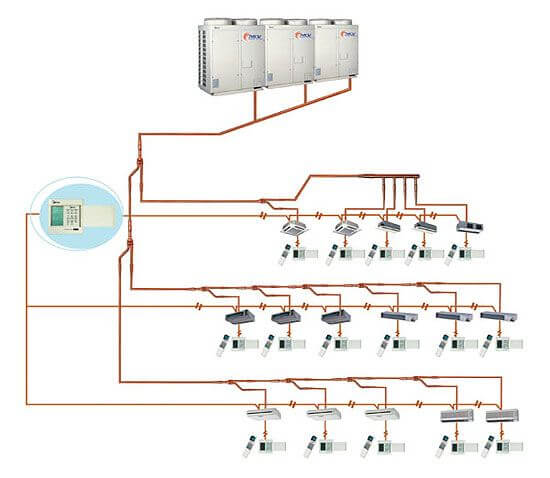

Features of using the chiller

The use of centralized supply and exhaust ventilation and air conditioning systems is advisable at large facilities (shopping malls, large office buildings, entertainment centers, etc.). The design of such systems poses the main question for developers: what to choose as a source of cold - a water-cooling unit or a direct-evaporation condensing unit. Let's consider both options. The use of a water-cooling unit (chiller) removes restrictions on the location of the refrigeration machine itself. The chiller can be located in any place convenient for installation and maintenance, since the hydraulic module supplied with it or selected individually can supply the coolant to any required distance. The limitation here can only be a significant distance between the refrigeration machine and the internal consumers of cold in height. The main advantage of a water-cooled refrigeration machine is its high reliability and the constancy of the coolant temperature. In this case, the “cold” accumulator is the coolant in the hydraulic system and the accumulator tank mounted if necessary. A large number of internal cold consumers can be connected to one water-cooling unit, both cooling sections of centralized ventilation and air conditioning units, and internal air conditioning units - “fan coils”.

The disadvantages of the “chiller-fan coil” system are the high capital costs for its installation, the need to use non-freezing liquids as a coolant, and the presence of permanent maintenance personnel for servicing and monitoring the system. For the climatic conditions of Kyiv, the use of a 40% ethylene glycol solution as an intermediate coolant reduces the effective capacity of the chiller by 17 - 30%. The use of air-cooled chillers in a high-density city may also require additional noise abatement measures, which increase the initial capital cost. A direct expansion condensing unit is much cheaper than a chiller with a similar cooling capacity, it is easier to maintain and does not require permanent maintenance personnel. It is enough to invite specialists for service maintenance 1-2 times a year. The disadvantages of using direct evaporation units are their relatively low power (up to 100 kW.), Restriction in distance and height difference between the refrigeration machine and internal cold consumers, the impossibility of using simple “non-inverter” compressor-condensing units together with direct evaporation cooling sections in supply air ventilation units without air recirculation. With significant cooling capacity requirements at the facilities, the use of a large number of condensing units can offset the difference in capital costs for systems with a water-cooling unit and direct expansion condensing units with comparable total cooling capacity.The admixture of fresh air in centralized ventilation and air conditioning systems in this case should not exceed 20-30% of the air capacity of the centralized ventilation unit. The accumulator of "cold" in this case will be the air itself in the volume of serviced premises. If these parameters are observed, the system will work correctly and efficiently. Recently, it has become possible to use units with "inverter" control as a source of cold for compressor-condensing units of direct evaporation, which allows you to smoothly change the power of the outdoor unit and the performance of the system as a whole. This allows you to integrate these blocks into the supply air system ventilation without mandatory air recirculation. However, this leads to an increase in the cost of the main equipment and does not remove the problem of removing all excess heat from the serviced premises. Indeed, in order to maintain comfortable conditions in working areas, the supplied air can only be cooled to a certain temperature. Therefore, to remove a large amount of excess heat, a significant amount of air is needed, much more than the necessary sanitary norm of fresh air, usually supplied to the facility.

The disadvantages of the “chiller-fan coil” system are the high capital costs for its installation, the need to use non-freezing liquids as a coolant, and the presence of permanent maintenance personnel for servicing and monitoring the system. For the climatic conditions of Kyiv, the use of a 40% ethylene glycol solution as an intermediate coolant reduces the effective capacity of the chiller by 17 - 30%. The use of air-cooled chillers in a high-density city may also require additional noise abatement measures, which increase the initial capital cost. A direct expansion condensing unit is much cheaper than a chiller with a similar cooling capacity, it is easier to maintain and does not require permanent maintenance personnel. It is enough to invite specialists for service maintenance 1-2 times a year. The disadvantages of using direct evaporation units are their relatively low power (up to 100 kW.), Restriction in distance and height difference between the refrigeration machine and internal cold consumers, the impossibility of using simple “non-inverter” compressor-condensing units together with direct evaporation cooling sections in supply air ventilation units without air recirculation. With significant cooling capacity requirements at the facilities, the use of a large number of condensing units can offset the difference in capital costs for systems with a water-cooling unit and direct expansion condensing units with comparable total cooling capacity.The admixture of fresh air in centralized ventilation and air conditioning systems in this case should not exceed 20-30% of the air capacity of the centralized ventilation unit. The accumulator of "cold" in this case will be the air itself in the volume of serviced premises. If these parameters are observed, the system will work correctly and efficiently. Recently, it has become possible to use units with "inverter" control as a source of cold for compressor-condensing units of direct evaporation, which allows you to smoothly change the power of the outdoor unit and the performance of the system as a whole. This allows you to integrate these blocks into the supply air system ventilation without mandatory air recirculation. However, this leads to an increase in the cost of the main equipment and does not remove the problem of removing all excess heat from the serviced premises. Indeed, in order to maintain comfortable conditions in working areas, the supplied air can only be cooled to a certain temperature. Therefore, to remove a large amount of excess heat, a significant amount of air is needed, much more than the necessary sanitary norm of fresh air, usually supplied to the facility.

We install KKB and chillers at reasonable prices.

Operating principle

To understand how these devices work, we must remember that all substances can absorb heat during the evaporation process. Conversely, heat is released during condensation processes. The physical processes of any climatic and refrigeration equipment are built on this.

The principle of operation is based on changes in the state of aggregation, in this case freon, depending on the temperature and pressure in the system.

Climate technology does not make cold. Warm air is transferred from indoors to outdoors. In order for the air in the room to cool, it is necessary to remove the warm air that is obtained in the process. Heat is energy, and, as you know, it never disappears anywhere.

As in refrigeration, freon is used as a refrigerant in air conditioning. When it evaporates, it takes away heat. You can do a simple experiment. If you rub your hand with alcohol, then you can feel the cold. Alcohol absorbs heat as it evaporates. So here.

When substances change from gas to liquid, then they give off heat. For example, in a bath, when moving, you can feel the heat from the steam that condenses.

If the KKB operates in cooling modes, freon evaporates in the heat exchanger and then condenses. If heating work is performed, then the opposite is true.

Cooling the air in the room with the use of compressor and condenser complexes consists in the entry of freon into the compressor. Then the process of compressing the gas to high pressure takes place. As a result, it heats up. The warm gas then enters the heat exchanger. After this stage, freon under pressure in liquid form is supplied to the tube. Here, the fluid parameters are reduced.

After entering the heat exchanger, freon begins to evaporate. At this time, air is absorbed, and with it heat. Then the freon again enters the compressor unit, and all these steps are repeated again.

Types of condensing units

Depending on the required power, the KKB kit may include not one, but several compressors at once. According to the number of circuits (compressors), condensing equipment is divided into:

- single-loop

- double-circuit

- three-circuit

Often, the KKB is directly connected to the indoor unit located in the room. It is possible to connect several indoor units to one KKB at once. However, in this situation, there is a possibility of uneven distribution of the refrigerant between the indoor units. Therefore, only one indoor unit is connected to a single-circuit KKB; to the double-circuit - two and so on. That is, for each circuit of the KKB, there is equal to one internal block. The number of connection kits is equal to the number of compressors in the unit.

Air cooling procedure

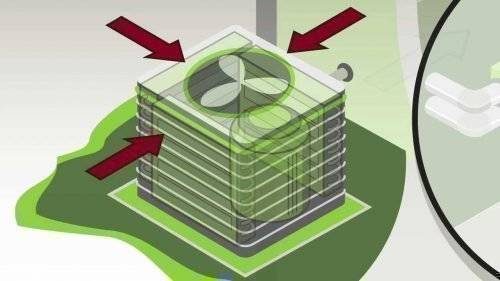

Since the main task of a remote-type condenser is to move the heat generated at the time of condensation into the air space located outside the structure, it is necessary to dwell on how this procedure is performed.

Initially heated to a state of gas, the refrigerant, being under high pressure, moves from the compressor chamber to the heat exchanger. The condensation processes taking place at this time contribute to the release of heat, which in turn heats the condenser heat exchanger from the back. Axial fans drive air through the condenser heat exchanger and cool it. So the heat is released outside, and the refrigerant absorbs the cold.