- What are compressors for?

- Air compressor for aeration of a septic tank: principle of operation, characteristics and selection criteria

- How to choose an aerator for a septic tank: tips and tricks

- Which compressor to choose for aeration of a septic tank

- Device Installation Procedure

- Popular brands

- Compressor installation

- Common breakdowns and repairs

- Pumps for septic tanks

- Submersible

- Semi-submersible

- outdoor

- Drainage

- For forced pumping of wastewater

- Classification and design features

- A brief overview of the best brands

- Eurolos BIO 4+

- Common breakdowns and repairs

- How to choose a compressor for a septic tank

- Purpose of the compressor

- Device types

- Design features

- Compressor installation

- Device Selection Tips

- Features of the functioning of homemade septic tanks

What are compressors for?

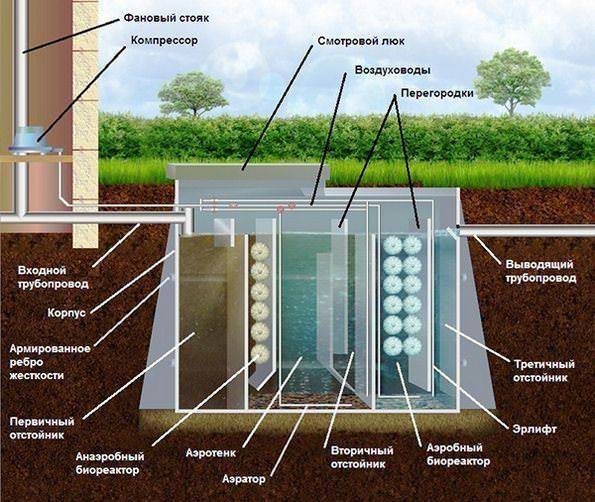

To give an exhaustive answer to this question, you must first understand the principle of operation of the septic tank. This device is designed to collect and process domestic wastewater. It consists of a container in which are:

- Pumps

- Compressor

- Pipe system

And if everything is clear with the purpose of the pumps, they are designed to move fluid in the system, then not everyone knows what compressor equipment is for. It is necessary to supply air into the septic tank.This contributes to an increase in the activity of microorganisms involved in the process of waste decomposition. Air injection speeds up this process.

Air compressor for aeration of a septic tank: principle of operation, characteristics and selection criteria

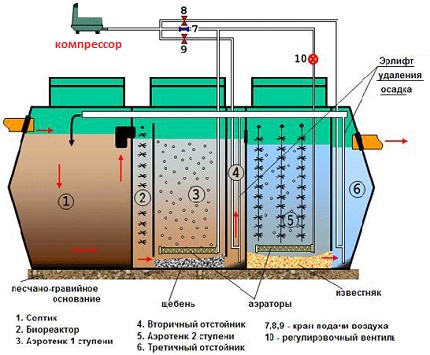

Any self-built septic tank can be made to process wastewater as efficiently as possible. Two types of bacteria take part in the process of decomposition of fractions and clarification of liquids: anaerobic and aerobic.

The vital activity of the first is completely independent and does not need human participation. For the operation of aerobic microorganisms, air is needed, the delivery of which is carried out by a compressor (aerator) for a septic tank.

How to choose an aerator for a septic tank: tips and tricks

The joint activity of anaerobic and aerobic bacteria provides multi-stage wastewater treatment, after which the liquid becomes safe and can be used for technical needs (for example, irrigation). Therefore, the correct choice of a compressor that maintains the optimal amount of air in the septic tank is so important.

A compressor is a device designed to compress and supply gases under pressure. Air is pumped into a chamber specially designed for this purpose and held in it, after which it is supplied to external devices (in our case, to a sealed chamber for wastewater treatment).

There are aerator installations consisting of a compressor, a drive and auxiliary devices (air dryer, intercooler). To modernize septic tanks, these more complex devices are not needed: for this purpose, the simplest unit is enough

But even among them there are devices that are different in terms of the principle of operation and performance, therefore it is important to know exactly how to choose a compressor for sewerage

Types of compressors

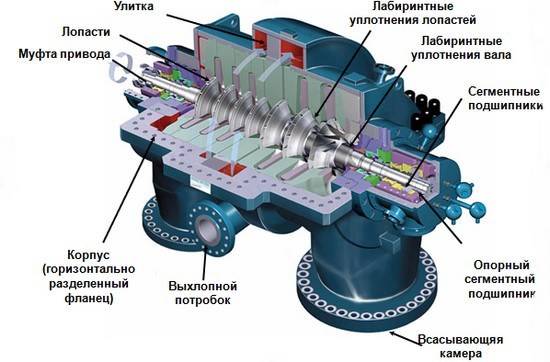

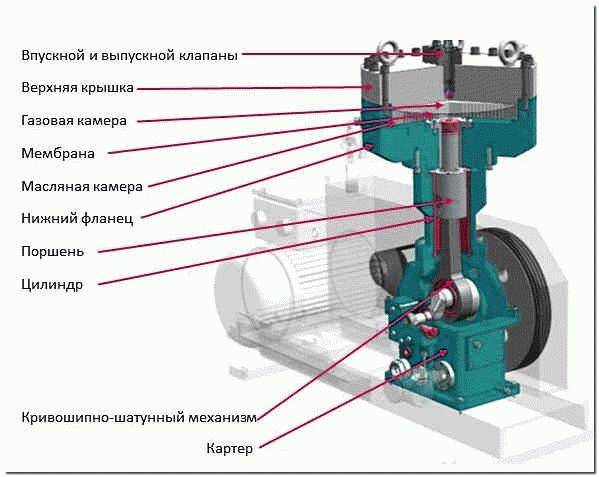

Units that increase the pressure of a gas by reducing its volume are called volumetric. Among them are piston and screw (rotary) installations. They differ in the principle of gas injection into the working chamber. Piston types provide pressure through the movement of pistons, screw - using a screw block. The latter are more compact, have a low level of vibration and are more durable.

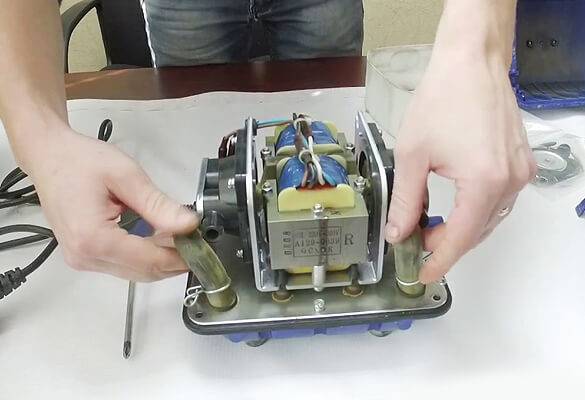

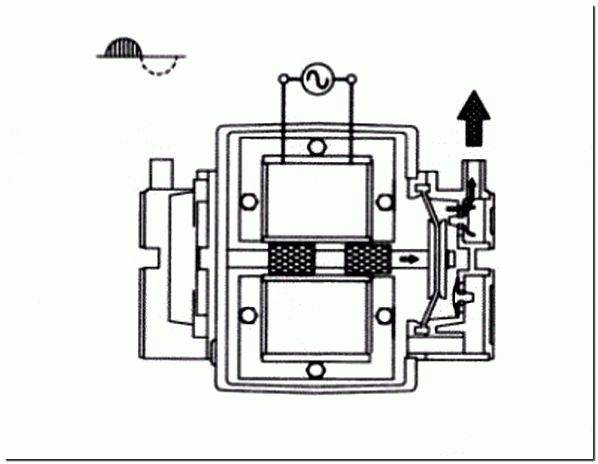

A variety of piston is an electromagnetic membrane (diaphragm) compressor for local sewage. The main advantage of this device is the ability to pump excess pressure at low performance characteristics.

The principle of operation of the compressor is as follows: the magnetic core moves back and forth in an alternating electromagnetic field and actuates the diaphragms that pump air.

The second type of compressors is dynamic. These units provide air injection by initially increasing its speed and converting it into increased outlet pressure. Among the dynamic devices are mainly centrifugal, which are radial and axial. All these units are more bulky, noisy, and expensive. Therefore, they are not considered as an aerator for a septic tank.

Which compressor to choose for aeration of a septic tank

To ensure autonomous treatment and post-treatment of wastewater, the best choice is a membrane-type apparatus. The distribution network presents a number of models, including mini compressors, which are widely used for autonomous sewers.

For aeration of local septic tanks, you can use screw compressors designed to operate around the clock.Many manufacturers of sewage treatment plants equip them with these units. When choosing on your own, it is not recommended to buy dry compression screw apparatuses, as they are large in size and require professional maintenance.

About performance

Companies producing compressor equipment indicate two characteristics of their performance: input and output power. Depending on the type of unit, these figures may be almost the same value or differ significantly.

The optimal compressor performance for aerating a septic tank is as follows:

- for chambers with a volume of 2-3 m3 - 60 l / min;

- for septic tanks with a volume of 4 m3 - 80 l / min;

- for a volume of 6 m3 - 120 l / min.

Device Installation Procedure

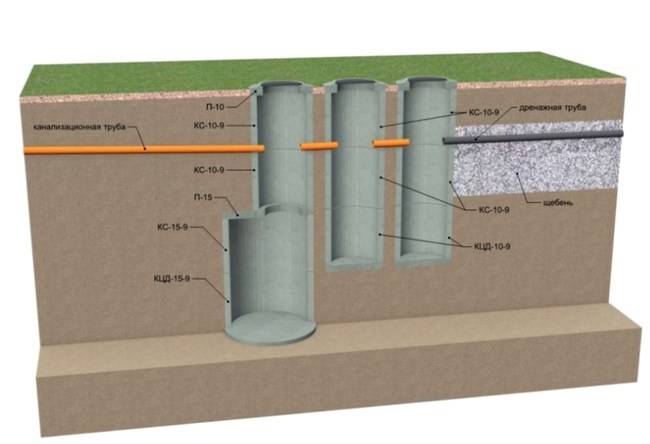

It is not difficult to supplement the design of a septic tank with a compressor, but you still have to work hard. If the septic tank includes only two compartments, it is better to add a third to it, designed to aerate the drains and called the aeration tank. It is here that the effluent will be saturated with air and cleaned with the help of aerobic microorganisms.

To do this, you will have to go through all the stages of creating a septic tank: dig a pit, install a sealed container made of plastic, concrete or other suitable material in it, connect it to the sewer pipe leading from the house, connect it with an overflow to other sections of the septic tank, install a cover, etc.

It is better to mount the compressor at the top of the tank, and not outside, so that the device is reliably protected from the weather. To do this, inside, at the lid itself, a special shelf is made, on which the compressor is subsequently placed.It will even be safer to make a more insulated compartment to protect the device from accidental wetness and other damage.

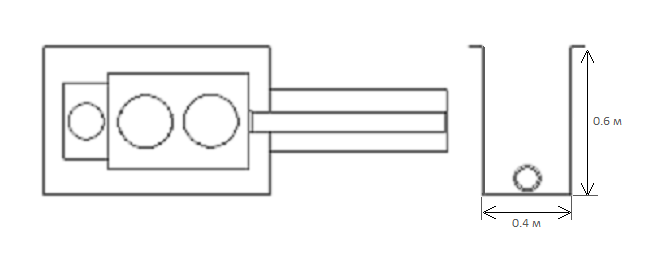

There must be a hole in the cover for the compressor electrical cable. You will also need another hole through which air will enter the compressor. Inside the aeration tank you need to install a plastic pipe. Its lower end should be hermetically sealed, and the walls should be perforated. Usually it is enough to make about three hundred holes or a little less.

It is better to do this with a drill with a two-millimeter drill. Through these openings, compressed air will enter the wastewater column, saturating them with oxygen and crushing large solid waste. The holes should be roughly evenly spaced so that the air is evenly distributed. The upper part of the pipe is connected to the compressor with a hose.

When all the elements are prepared, the following steps should be performed:

Lower the aerator into the aeration tank.

Install the compressor in the place provided for it.

Connect the aerator with a hose to the compressor outlet.

Connect the device to the power supply.

Turn on the compressor.

Close the lid of the septic tank.

Now it remains only to regularly inspect the device and periodically, about twice a year, clean the air filter. It is not difficult to perform this operation. The location of the filter is indicated on the device diagram in the manufacturer's instructions. It is necessary to unscrew the protective cover, usually it is held by mounting bolts

Then carefully remove the filter, rinse it and dry it. After that, the cartridge is put in its original place and closed with a lid.

If, upon inspection of the septic tank, it is found that the operating compressor is noisier than usual or some extraneous noise is detected, this is a cause for concern. If you leave everything as it is, the compressor will soon break down. Sometimes the standard cleaning of the air filter helps. But if the noise does not decrease, you should invite a specialist to diagnose the problem or apply for warranty service.

Popular brands

Biological treatment plants of many domestic manufacturers are equipped with an installed air compressor. With rare exceptions, these are membrane-type models of the Japanese brands Secoh and Hiblow. The specialization of both companies is the production of power plants and units using innovative technologies. Thanks to the constant updating and improvement of the design, branded products are distinguished by stable quality, reliability, and reasonable price.

Secoh models feature:

- Low power consumption.

- Minimum pulsation with continuous air supply.

- Designed silencer chamber.

- Light weight.

- Compact.

- Waterproof body.

- No overheating during long uninterrupted operation.

- Easy maintenance without professional training.

Characteristics of the well-known model EL-60: air flow - 60 l / min, maximum pressure - 2.5 atm, power consumption - 42 W, noise level - 33 dB, dimensions - 268.5x201x216 mm, weight - 8.5 kg. Options for higher power, without a significant increase in size, are obtained by integrating two compressors into a single housing.

The Hiblow HP-60 model of the same performance is characterized by the following parameters: pressure - 1.47 atm, power - 51 W, noise - 35 dB, dimensions - 280x190x171 mm, weight - 7 kg.

Compressor equipment from the following manufacturers also deserves attention: Friess and Thomas (Germany), Faggiolati and Doseuro (Italy), Matala (Taiwan), Hydrig (Russia).

Compressor installation

You can install and connect the compressor with your own hands. The installation of the compressor unit is carried out in the following way:

- choose a place to install the device. The compressor is recommended to be installed inside (in the upper part) of the septic tank, and not on the outside of the treatment plant. This will avoid the negative impact of weather conditions on the installation. If there is no separate chamber for biological treatment in the septic tank, then it is advisable to first install a partition or install an additional container next to the existing septic tank;

- the compressor is installed on a special shelf, which can be made with your own hands from improvised materials or purchased in specialized stores;

The correct location of the compressor in the septic tank

- any type of compressor will require the installation of additional equipment - an aerator, through which air will flow into a container with drains. You can make your own aerator. This will require a small piece of metal pipe, in which holes are drilled at equal distances from each other, with a diameter of 1 - 2 mm. The average number of holes is 300 pieces. The end of the pipe is closed with a plug;

Do-it-yourself additional equipment for a compressor

If the holes are unevenly distributed over the surface of the pipe, then the effluents will be saturated with oxygen unevenly, which will lead to a decrease in the efficiency of bacteria in certain places of the tank.

- the aerator is connected to the compressor outlet with a hose. The connection must be as tight as possible so that there is no loss of oxygen;

Compressor connection with a factory-made aerator

- the aerator descends into the tank;

- the compressor is installed on a shelf and connected to electricity. If the outlet is located next to the septic tank, then it should be protected as much as possible from the action of precipitation;

- the container with the compressor is closed with a lid to protect bacteria and installed equipment.

The compressor can be connected via an automatic relay that will turn the device off and on if necessary, as well as protect it from overheating.

The compressor is replaced in the same way.

The compressor requires periodic maintenance, which consists in replacing the filters installed on the outlet pipes (at least once a year). If the compressor began to work incorrectly or consume excessive amounts of electricity, then it is recommended to contact specialists to fix the problem.

Common breakdowns and repairs

Compressor failure can be caused by a number of reasons:

- Frequent and sudden voltage drops in the mains.

- Overflow or flooding of the septic tank.

- Natural wear and tear of individual elements.

Often, devices become unusable due to mechanical damage: inaccurate removal from the septic tank before the system is stored for the winter, falls, etc.

Eliminating the negative impact of power surges is relatively easy. To do this, just install a stabilizer.

Owners of diaphragm compressors are forced to replace the diaphragm approximately once every five years, which fails due to natural wear and tear. It is quite possible to carry out such repairs yourself by following these steps:

- Disconnect the compressor from the power supply and from the aerator.

- Unscrew the fixing bolts and remove the cover of the device housing.

- Remove the soundproof cover.

- Remove elements blocking access to the membrane.

- Unscrew the fastener holding the membrane cover.

- Remove cover.

- Loosen the central nut.

- Take out the membrane block and disassemble it.

- Replace worn diaphragms with new elements.

- Assemble the membrane block and install it in its original place.

- Assemble compressor in reverse order.

Detailed repair recommendations and a description of the nuances can be found in the instructions and technical data sheet of the product. For many models, special repair kits are sold containing a set of new diaphragms. From the tool for replacing the membrane, a regular or Phillips screwdriver is usually sufficient.

Pumps for septic tanks

For the equipment of a septic tank, not only an air compressor is needed, but also a pump. The role of pumping equipment is to pump wastewater, while the requirements for pumps for a septic tank are somewhat different from conventional models for pumping water.

The fact is that the drains contain a large amount of solid inclusions, which will lead to clogging and shutdown of a conventional pump, and it will require urgent repairs. Therefore, a fecal pump for a septic tank is used for local sewage, which is capable of pumping even highly contaminated liquids.The type of installation is divided into:

- Submersible;

- Surface;

- Semi-submersible.

Submersible

The main purpose of such pumps is to pump liquid from storage tanks. The equipment is adapted to work in an aggressive environment, that is, it is made of materials that are chemically resistant.

Semi-submersible

Semi-submersible pumps are distinguished by the presence of a special float holding part of the pump above the water surface. The engine is located in this float, and the pumping part of the unit itself is immersed in water. This equipment, as well as submersible pumps for septic tanks, is used to pump out the tanks of treatment plants.

outdoor

Outdoor or surface pumps are the cheapest type of septic tank equipment. However, such pumping equipment has lower technical characteristics than submersible models, so repairs to such pumps are required more often.

Drainage

Equipment such as a septic tank drain pump is suitable for pumping liquids that do not contain large inclusions. As a rule, this type of pumping equipment is used to work in storm sewers or to pump water when basements are flooded.

For forced pumping of wastewater

If the sump is located far from the sewer outlet from the house or it is higher in level, forced pumping of wastewater is necessary. For this, a fecal pump with a grinder for a septic tank is used. This equipment allows you to pump liquids that contain large and solid particles.

To ensure a full cycle of wastewater treatment, you can independently improve the treatment plant by repairing and upgrading an already operating septic tank. The repair consists in the installation of aeration equipment.

This equipment, like pumps, is important to select taking into account the fact that they will be operated in difficult conditions, so the units must be made of corrosion-resistant materials, otherwise, the equipment will often fail. The modernization carried out will significantly improve the quality of wastewater treatment

Thanks to this, the water withdrawn from the installation can be immediately sent for discharge. Thus, the modernization of the septic tank will save on the construction and maintenance of post-treatment plants

The modernization carried out will significantly improve the quality of wastewater treatment. Thanks to this, the water withdrawn from the installation can be immediately sent for discharge. Thus, the modernization of the septic tank will save on the construction and maintenance of post-treatment plants.

Classification and design features

The purpose of all types and models of compressors for aerating a septic tank is the same: they must take in, pump and eject air under pressure. However, the principles for creating pressure are different. Depending on this, the devices are divided into several types:

- Membrane (the second name is diaphragm). These devices pump air through a flexible membrane that moves under the influence of electromagnetic vibrations and thus pumps air. Pros - the models are easy to install, easy to maintain, economical. However, for the southern regions, this is not the best choice, because. the membrane material dries up.

- Screw (they are also called rotary). The air pressure is generated by the rotation of two rotors. The main advantages of models of this type are silent operation, compactness and low power consumption. Minus - for their maintenance and repair will have to invite specialists.

- Piston. A piston is located in the body of the device, which moves up and down, drawing in air and throwing it out through the outlet. For domestic wastewater treatment plants, such models are used infrequently, but they are well suited for sewer systems of industrial enterprises.

- Centrifugal. These models are not particularly popular with owners of septic tanks. The reason is low work efficiency, so any advantages of centrifugal devices lose all meaning.

Membrane models

A brief overview of the best brands

Industrial aerobic septic tanks are usually equipped with membrane compressors. The models of the best brands "Topas", "Tver", "Unilos" are equipped with imported devices, most often Japanese.

Buyers rarely make claims to the equipment of these brands. Compressors run smoothly, almost silently. They do not require special maintenance, rarely break down, and consume electricity economically. Prices depend on the manufacturer and the power of the models.

Table: compressor prices

Among the best it is worth noting the following brands:

- Hiblow. Market leader. Models of this brand are universal, suitable for local treatment plants of all types. The marking with numbers indicates the volume of air that the compressor is able to pump in 1 minute, for example, HP 60, 80, 100, etc.

Hiblow brand model

- Secoh. Another trusted brand. These are high quality compressors.Productivity can reach 200 l/min. Secoh brand devices are installed in Astra septic tanks.

- AirMac. The Korean brand AirMac is practically not inferior to its Japanese counterparts. The manufacturer uses wear-resistant membranes, thanks to which the compressors work for a long time and uninterruptedly.

Korean compressor brand AirMac

- Thomas. Classic German quality. Models of this brand consume electricity economically, are reliable, durable, and perfectly waterproofed. They rarely have problems. The AP-60 and AP-80 models are especially popular.

Eurolos BIO 4+

Add to cart Compare Add to favorites Go to catalog Then proceed to the next step:

- the aerator is lowered into the aeration tank

- compressor is installed

- aerator and unit are connected

- connects to the mains

- turn on the compressor.

This equipment should be inspected regularly. The filter should be cleaned approximately once every six months. To do this, the protective cover is unscrewed, the filter is removed, washed and dried. Then he returns to his place. The composition of the air sent to the septic tank does not matter. The main condition is the content of oxygen in it.

The pressure of the air stream, called the compression ratio, is important, as it has to overcome the resistance of water. The deeper the septic tank is, the stronger it is.

Usually the equipment is installed to a depth of less than two meters. Therefore, a coefficient of 2 atmospheres is quite enough.

Productivity is the amount of air produced by the compressor per unit of time. This indicator characterizes the power of the engine, and hence the need for electricity.

All of the above works are quite simple.But not everyone manages to do it on their own, following all the rules. In order to avoid possible errors that may have a negative impact on the operation of the sewer system, it is advisable to entrust such work to specialists who know all its features.

Common breakdowns and repairs

Compressor failure can be caused by a number of reasons:

- Frequent and sudden voltage drops in the mains.

- Overflow or flooding of the septic tank.

- Natural wear and tear of individual elements.

Often, devices become unusable due to mechanical damage: inaccurate removal from the septic tank before the system is stored for the winter, falls, etc.

The cause of damage to the compressor can be hitting the lid of the septic tank with heavy machinery. In such a situation, the body of the device, as well as other elements of the VOC, may be damaged.

Eliminating the negative impact of power surges is relatively easy. To do this, just install a stabilizer.

Owners of diaphragm compressors are forced to replace the diaphragm approximately once every five years, which fails due to natural wear and tear.

It is quite possible to carry out such repairs yourself by following these steps:

- Disconnect the compressor from the power supply and from the aerator.

- Unscrew the fixing bolts and remove the cover of the device housing.

- Remove the soundproof cover.

- Remove elements blocking access to the membrane.

- Unscrew the fastener holding the membrane cover.

- Remove cover.

- Loosen the central nut.

- Take out the membrane block and disassemble it.

- Replace worn diaphragms with new elements.

- Assemble the membrane block and install it in its original place.

- Assemble compressor in reverse order.

Detailed repair recommendations and a description of the nuances can be found in the instructions and technical data sheet of the product. For many models, special repair kits are sold containing a set of new diaphragms. From the tool for replacing the membrane, a regular or Phillips screwdriver is usually sufficient.

To replace the membrane in the compressor, it is necessary to disassemble the body of the device, remove the old membranes and replace them with new ones, and then reassemble

How to choose a compressor for a septic tank

Septic tanks installed in private estates and cottages play an important role in the comfortable living of a person. On sale there is a huge number of models of septic tanks, both domestic and imported. Each homeowner can choose a suitable model for himself and install it on his suburban area. But do not think that just by installing a septic tank, the system will work perfectly. The fact is that for the complete decomposition of waste, it is necessary to equip the septic tank with additional equipment. One such addition is the compressor. To understand this device, let's consider its need, principle of operation, installation, and how to choose a compressor for a septic tank installed on your site.

Purpose of the compressor

To fully understand the purpose of a compressor, let's briefly review the operation of a septic tank. The operation of the device is to collect and process sewage. The equipment includes:

- capacity,

- pipe system,

- set of pumps and compressor.

Pumps handle the liquid waste in the system, and they are indispensable, and some people save money on the compressor. And this is wrong.Thanks to the compressor, air is supplied to the septic tank. When interacting with air, the activity of bacteria increases, which are involved in the decomposition of sewage.

Device types

Compressors for septic tanks are of two types: screw and membrane.

- Screw compressors have two rotors. Rotating, they capture air and force it into the container. Due to their compactness, such models are installed in septic tanks with a small capacity. They are very economical and almost silent in operation.

- Diaphragm compressors are widely popular for septic tanks installed in cottages. Their feature is simple operation and ease of maintenance. The operation of this model consists in the coordinated operation of the membrane and valves, due to which pressure is created in the chamber. Directly from the chamber, oxygen enters the septic tank.

Note! Installation of reciprocating compressors in septic tanks is not practiced due to their high noise level.

Design features

All types of compressors for septic tanks are powered by electricity and are designed to force air into containers with sewage. Based on the fact that the capacities of septic tanks are different in volume, therefore, the compressor must be suitable in terms of power to supply the required amount of air. For large-capacity septic tanks, several compressors are installed. This allows for more complete wastewater treatment. Basically, the compressor is not mounted in the septic tank on its own, but together with pumping equipment that ensures its proper operation.

Compressor installation

If you study the manufacturer's instructions, then installing the compressor will not cause unnecessary questions.Installation is easy, and almost anyone can do it on their own:

- A compressor ready for operation is installed above the septic tank.

- An outlet pipe is connected to the aerator.

- The compressor is connected to the power supply, and the device is ready for operation.

Connectivity issue resolved!

Device Selection Tips

To complete the processing of sewage, they must settle and ferment in an airtight container, and air is not required for this process. But for aerobic decomposition, air supply is indispensable. For this purpose, you can install a biological treatment plant, which is quite an expensive pleasure.

Not every device model can fit your septic tank model

When purchasing a compressor, you need to pay attention to some parameters:

- Don't buy a cheap device. This will quickly affect the quality of work, and maybe even fail. It is better to buy a compressor from a company that has proven itself in the market for its quality and reliability.

- All parts of the compressor must be resistant to corrosion.

- Branded compressors, as a rule, have a long service life.

- Quiet operation of the device. No one will like the constant noise of a running compressor in their summer cottage.

- Compressor size should match your system model. Compressor power mismatch can lead to mismatch in the amount of oxygen supplied to the septic tank. Such an imbalance will affect the vital activity of microorganisms living in the septic tank, which entails a deterioration in the quality of sewage processing.

Popular device models

How to choose a compressor for a septic tank Find out how to choose a compressor for a septic tank.The article discusses the various types of compressors that need to be selected in accordance with the capacity of the septic tank.

Features of the functioning of homemade septic tanks

Two types of bacteria are involved in the processing of wastewater produced by local treatment plants: aerobic and anaerobic.

The first species can live and act only in an environment saturated with oxygen, while the second one perfectly exists and performs vital functions in an oxygen-free space.

The treated effluents from the septic tank, in which anaerobes are involved, are diverted to the filtration field for post-treatment. The presence of a compressor in biological processing stations makes it possible to do without such additional filtration, because. aerobes purify wastewater up to 95%

To protect the soil from contamination by unprocessed sewage, the septic tank compartments are sealed. Their walls not only prevent the penetration of bacteria and sewage into the ground, but also block the access of oxygen into the system.

Under such conditions, only anaerobes can exist, and aerobes need to ensure the supply of vital gas.

A septic tank for the needs of a small family consists of two or three sections. In the first section, sewage is settled, fermented under the action of anaerobes and mechanical filtration of the settled mass.

In the following compartments, the process is repeated, but the result of multi-stage separation in rare cases reaches 65 - 70%. Therefore, the sewer system with settling tanks is supplemented with ground purification devices - infiltrators, absorption wells, filtration fields.

To increase the degree of processing and ensure the possibility of free discharge of water from the septic tank to the relief, anaerobic microorganisms and their ability to digest organic matter are needed, cleaning the waste mass by 95-97%. And aerobic organisms need a regular supply of O2. Read more about bacteria for septic tanks.

Septic treatment plants, in which aerobes are involved, have an extremely high degree of purification, especially against the background of septic tanks operating on the principle of settling tanks and anaerobic digestion

Septic treatment plants, in which aerobes are involved, have an extremely high degree of purification, especially against the background of septic tanks operating on the principle of settling tanks and anaerobic digestion