- Compressor malfunction: symptoms

- Causes of breakdowns and failure of the compressor

- Refrigerator electrical equipment

- Refrigerator compressor ringing

- How much will the repair cost?

- Fulfilled orders for the repair of refrigerators in Moscow

- The compressor in the refrigerator broke down - what to do

- Step-by-step instructions for connecting the compressor

- Helpful Tips for Soldering Joints

- Why is the compressor hot

- Recommendations for use and care

- How long should the refrigerator run without shutting down?

- What does Artalis-Group offer?

- When do you need to replace the compressor in the refrigerator?

- Diagnostics

- Checking the operation of the connected compressor, starting the engine

- Conclusions and useful video on the topic

Compressor malfunction: symptoms

Quite often, breakdowns of refrigeration equipment occur due to a malfunction of the compressor. Most often, this problem can be recognized by the following signs:

- noticeable blocks of ice freeze on the walls of the refrigerator (often this happens in the absence of the No Frost system);

- when the compressor is running, a loud sound is heard, but the refrigerator does not freeze;

- when you turn on the refrigerator, there is a strong vibration;

- the compressor does not turn off;

- refrigerator freezes food.

No frost system

In order to deal with the problem, it is necessary to consider the signs of a breakdown in more detail.

Table 2.Compressor failure symptoms

| Breaking | The reasons |

|---|---|

| Compressor running but not freezing | The cause of the problem is often refrigerant leakage due to improper transportation of the unit. In addition, this happens in the event of a malfunction of the heating element. |

| Compressor won't stop running | This problem occurs for the following reasons: refrigerant leakage; depressurization of the capillary pipeline, due to which a blockage occurred in the system; the rubber seal has dried out, the temperature inside the unit has risen, due to which the motor starts to work without stopping. If there is an inverter-type compressor in the refrigerator, then after reaching the desired temperature, it still functions, but only at minimum speed. |

| Compressor hums but does not function | Extraneous noise during compressor operation often occurs due to the presence of bolts that must be dismantled after transportation. However, this only applies to new devices. There are other reasons for the malfunction: nozzle deformation; thermostat failure. |

| Refrigerator compressor turns on and then immediately turns off | The following causes of malfunctions are distinguished: breakdown of the starting relay, which is responsible for starting the motor; breakage of the internal winding; The start relay winding has broken and the compressor is overheating. |

Causes of breakdowns and failure of the compressor

The refrigerator cooling system, as mentioned above, is a complex closed circuit. Most modern manufacturers guarantee its proper operation for a long time. In addition, almost all such systems are equipped with protection systems against the most common violations of the rules of operation arising from the fault of the consumer.

The most common compressor failure is due to:

- increased or decreased voltage in the electrical network;

- peak voltage drops;

- violations of the operating modes of the refrigerator (for example, they forget to turn off the temporary “quick freeze” mode);

- additional heating of parts of the refrigerator (for example, if the refrigerator is near the radiator);

- attempts by consumers to independently change and repair parts of the refrigerator.

- damage (case, condenser) during transportation or movement of the refrigerator.

Refrigerator electrical equipment

The unit consists of many elements, the interconnection of which contributes to the cooling of the chambers located in the inner part. We will describe the key nodes in more detail in the table below.

Table 1. Components that include the electrical circuit of the refrigerator

| Components | Purpose |

|---|---|

| Electric heaters | Responsible for the supply of heat to the generator in the presence of absorption refrigeration equipment, which has a specific purpose. In addition, these devices are required in the presence of an automatic deicing system by heating the evaporative element. Sometimes the device is used to prevent the formation of water droplets on the opening of the unit. |

| Engine | This device sets the compressor to work. |

| wires | Connect the motor, compressor and other components together. |

| Paws | Required to illuminate the refrigerator. |

| Fans | Installed in some models in the presence of a forced air circulation system. |

Diagram of refrigeration equipment components

Refrigeration equipment does not operate in manual mode, and in order to ensure autonomous uninterrupted operation of the unit, automation is required.It is thanks to the auxiliary equipment that we can change the parameters due to which the temperature remains in a certain mode. Such equipment includes the following components:

- Thermoregulation relay. Devices help maintain the optimum temperature in the chambers of the unit.

- Start relay. Helps start the electric motor.

- Protection relay. Prevents damage to the compressor elements as a result of a high load on the electrical network.

- Devices for automatic removal of ice deposits.

Relay location

Refrigerator compressor ringing

You can call it like this:

- Using a tester, with the relay disconnected, attach probes to the contacts.

- The normal value should be 30 ohms. The right one gives a resistance of 15 ohms, while the left value is 20 ohms.

- Keep in mind that depending on the model, the tester can change its readings with a tolerance of 5 ohms, both up and down.

Three contact terminals are removed from the casing. One of the terminals is the output of the starting winding, the other is the working winding, and the third is the common bus.

Three contact terminals are removed from the casing. One of the terminals is the output of the starting winding, the other is the working winding, and the third is the common bus.

All these steps are needed in order to know how to check the refrigerator compressor with a multimeter. But this does not mean that such actions unambiguously solve the problem.

Successive exclusion of each of the possible faults will allow you to determine the true one and proceed to repair or replace the part.

Successive exclusion of each of the possible faults will allow you to determine the true one and proceed to repair or replace the part.

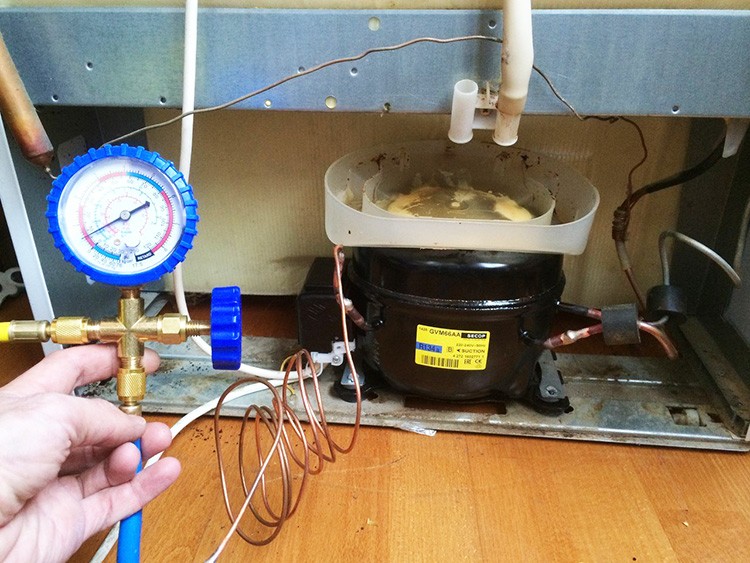

If the resistance of the refrigerator compressor windings on the device gives normal numbers, but with all this, household appliances do not start working, then it is necessary to carry out the check further. But use no longer a tester, but a device for measuring pressure. In this case, a manometer is used.

It is important to know the functional affiliation of each of the terminals and not to confuse the power supply line with the ground bus.

How much will the repair cost?

How much it costs to replace a compressor in a refrigerator will depend on several factors:

- the price of the motor itself or its equivalent;

- the difficulty of removing a failed device and installing a new one.

If you diagnose a malfunction in time, you can save a lot. For example, replacing the compressor of the Atlant refrigerator costs from 7,400 to 11,500 rubles. It turns out that restoration work can cost almost half the cost of a new device.

According to experienced craftsmen, costly refrigerator repairs and compressor replacements can in most cases be avoided by contacting professionals at the first sign of a breakdown. Often, a harbinger of a major malfunction is minor causes (freon leakage, thermostat failure, rubber seal wear), which are much cheaper to fix than a complete replacement.

Fulfilled orders for the repair of refrigerators in Moscow

| Damage reported by the client | Repair status |

|---|---|

| Refrigerator / Stinol / Refueling and sealing (Metro Orekhovo - on 4.03) Southern Administrative District | Executor: Murtazinov Nail Muradinovich |

| Refrigerator / Liebherr / does not turn on (compressor replacement) Southern Administrative District | Executor: Umnov Konstantin Vladimirovich |

| Refrigerator / — / Not cold (Italian frost metro Buninskaya alley) Southwestern Administrative Okrug | Executor: Kharisov Ruslan Rustamovich |

| Refrigerator / Stinol / not turns on (Kolomenskoye metro station) Southern Administrative District | Executor: Avagzhanyan Gurgen Zakharovich |

| Refrigerator / Indesit / Not cold (Metro Medvedkovo) Northern administrative district | Executor: Barinov Rostislav Olegovich |

| Refrigerator / Atlant / Not cold (nekrasovka metro station) Southeastern Administrative Okrug | Executor: Umnov Konstantin Vladimirovich |

| Refrigerator / Ariston / Not cold (Nogatinsky metro station) Southern Administrative District | Executor: Karyaev Denis Sergeevich |

| Refrigerator / Beko / Does not turn off (Sevastopol metro station) Southwestern Administrative Okrug | Executor: Kharisov Ruslan Rustamovich |

| Refrigerator / Whirlpool / Not cold (beeps) Northeastern Administrative Okrug | Executor: Rostokin Artem Alexandrovich |

| Refrigerator / — / does not turn on (svityaz) Northeastern Administrative Okrug | Executor: Barinov Rostislav Olegovich |

| Refrigerator / Beko / — (TO) Southern Administrative District | Executor: Protasevich Sergey Alexandrovich |

| Refrigerator / — / Not cold (large in the store) Northern administrative district | Executor: Kokarev Alexander Viktorovich |

| Refrigerator / — / — (fan) | Executor: Maslikov Vladislav Nikolaevich |

| Refrigerator / — / — (freezing showcase does not cool) Western administrative district | Executor: Razanov Zamirbek Suyunbaevich |

| Refrigerator / — / Does not cool (display compress replacement) Southern Administrative District | Executor: Khakimov Bahadir Ergashalievich |

The compressor in the refrigerator broke down - what to do

Compressor replacement is one of the most complex and expensive services in service centers. In addition, the spare part itself is expensive.The experience of the masters and long-term observations show that if the device has a worn-out node, there is a large output, it is better to immediately replace it with a new one. But in some cases, for example, if gaskets, rings or individual parts of the engine are worn out, the part can be repaired. The final decision is made by the master, based on the appropriateness of the procedure.

Diode KD 203A

You can try to wedge a stuck compressor. For this, a specialized device is used, consisting of 2 diodes with a permissible reverse voltage of at least 400V and a maximum forward current of 10 Amperes. For example, KD 203 A, D 232 A, D 246-247.

To eliminate the wedge using this design, voltage is applied to the motor windings for 3–5 seconds. The action is repeated after 30 seconds. The device can be connected through the sockets of the starting relays P1, P2 or P3 or using insulated clamps. The principle of operation of the design is based on the useful torque that occurs on the motor shaft when current flows through the diodes. The motor rotor begins to vibrate, the vibration is transmitted to the jammed nodes and releases them.

Electrical circuit diagram of compressor wedging device

Step-by-step instructions for connecting the compressor

Replacing a compressor is a complex process that requires certain skills from the master. However, if you decide to do it yourself, then you must follow the steps of the instructions.

Step one: you need to prepare the devices that will be needed for work. This includes the following:

- oxygen-propane burner;

- pliers;

- freon storage;

- valve;

- portable refueling devices;

- pipe cutting device;

- clamps;

- cylindrical device for high-quality connection of the device with the nozzle during refueling;

- copper tube;

- filter for installation in the pipeline;

- refrigerant bottle.

Step two: next, you need to release the refrigerant. You can do this in the following way:

- Using pliers, pinch the pipes that connect to the cooling system. At the same time, such work should be done carefully, because if you saw off the tubes with effort, dust is formed that can get into the condenser and ruin the elements.

- Then turn on the refrigerator for five minutes. This time is enough for the freon to condense.

- Then the hose that comes from the cylinder should be connected to the filling line.

- Then you should open the valve on the cylinder to collect the refrigerant. Typically, this takes less than 60 seconds.

- Next, you need to disconnect the relay unit with wiring (dark box).

- Leave the markup in order to install it correctly.

- After that, with the help of wire cutters, it is necessary to remove the clamps.

- Next, you need to disconnect the wiring that goes to the plug.

- After that, it will turn out to unscrew the device.

- The tubes must now be cleaned before installing another device.

Step three: now you should check the degree of resistance again. This will require an ohmmeter. As in the previous case, it is necessary to alternately apply the terminals of the device to the contacts. The resulting values must be checked with the nominal values \u200b\u200bfor a particular device. If the measurement is performed by a charging device, then the following manipulations must be performed:

- Fix the negative terminals on the lamp body with a power of 5 V.

- Fasten the positive terminals to the winding from above.

- To the ends of the winding, in turn, touch the base.

- Step Four: Now you need to measure the current. First, using the device, the start relay connected to the engine is checked. After that, the terminal must be connected to the device. The values obtained must correspond to the power of the motor. If its power is 130 V, then the current will be 1.3 A.

- Step Five: Install the new compressor. The first step is to fix the new device on the transverse bar of the refrigeration unit. You will have to remove the plugs from the tubes to complete the installation. The next step is to measure the pressure. At the same time, it should be remembered that the tightness (remove the tube plugs) of the device should not be earlier than five minutes before installation. Then you need to dock the tubes with a burner. At the time of soldering, you should observe the direction of the fire from the burner - it must be directed to the inside of the tubes. Otherwise, it will lead to melting of plastic parts. First, the filling pipe is connected, then to remove the refrigerant, and lastly, the discharge pipe.

- Step six: upon completion of installation, it is necessary to charge the equipment with refrigerant. First you need to connect the device to the filling line using a locking sleeve. Then it remains to connect the contacts and install the protection relay. After turning on the unit, it is necessary to fill the system with refrigerant by 45%. Then you should check the reliability of the connections and disconnect from the network. Next, you need to achieve an optimal pressure of 10 Ra, turn on the refrigerator again and fill it with freon. At the end, it remains to remove the coupling and solder the pipe.

Helpful Tips for Soldering Joints

The soldering of two branch pipes made of copper is carried out by an alloy of copper and phosphorus (4-9%). Docked elements are placed between the burner and the screen, heating it to a cherry color.

The heated solder is dipped into the flux and melted by pressing the rod against the heated joint area.

The control inspection of the solder joints is carried out from all sides using a mirror. They must be complete, without gaps.

For soldering pipes made of steel or its alloy with copper, solder containing silver is used. The soldering element is heated to red.

After the seam has hardened, it is wiped with a damp cloth to remove flux residues.

Why is the compressor hot

If we do not consider the “regular” overheating of the unit under normal operating conditions, then a very strong heating of the compressor (to a temperature above 90 degrees) may indicate the following reasons:

- continuous operation of the unit without shutting down when the desired temperature is reached;

- continuous work in extreme heat;

- heat exchanger malfunctions;

- freon leak from the system;

- cells overflowing with products;

- work in the mode of intensive freezing;

- unscrewed to the "maximum" thermostat;

- incorrect operating conditions.

In addition, the compressor may overheat slightly after the refrigerator has been defrosted. Excessively frequent opening of the doors of the chambers also leads to a quick failure of the unit (often this happens to those who try to limit food intake, but regularly look into the refrigerator in order to "snack" with something low-calorie).

It is important to note that even the highest quality refrigeration units have their own service life, and after 10–15 years of service, they begin to require major repairs. However, even these 10–15 years the device will serve only if all operational standards are observed and the condition of the main components is regularly monitored.

As in the case of a car engine, even one minor breakdown that is not fixed in time can lead to serious problems in the cooling system, up to its complete replacement.

Recommendations for use and care

There is nothing complicated in the operation of the equipment: it operates in automatic mode around the clock. The only thing that needs to be done the first time you turn it on and periodically adjust it during operation is to set the temperature regime that is optimal in specific circumstances.

The desired temperature is set by the thermostat. In an electromechanical system, the values are set by eye or taking into account the recommendations specified in the manufacturer's instructions.

When doing this, take into account the type and amount of food stored in the refrigerator.

The regulator knob, as a rule, is a round mechanism with several divisions, or, in more modern and more expensive models, control can be carried out using a touch panel.

In order to assess the degree of freezing, experts advise first putting the regulator in the middle position, and after a while, if necessary, twist it to the right or left.

Each mark on such a pen corresponds to a certain temperature regime: the larger the division, the lower the temperature. The electronic unit allows you to set the temperature with a maximum accuracy of 1 degree using a rotary knob or buttons.

For example, set the freezer compartment to -14 degrees. All entered parameters will be displayed on the digital display.

To maximize the life of your home refrigerator, you should not only understand its device, but also properly care for it. Lack of proper service and improper operation can lead to rapid wear of important parts and defective functioning.

You can avoid undesirable consequences by adhering to a number of rules:

- Regularly clean the condenser from dirt, dust and cobwebs in models with an open metal grill on the back wall. To do this, you need to use an ordinary, slightly damp cloth or a vacuum cleaner with a small nozzle.

- Install equipment correctly. Make sure that the distance between the condenser and the wall of the room is at least 10 cm. This measure will help ensure unhindered circulation of air masses.

- Defrost in time, avoiding the formation of an excessive layer of snow on the walls of the chambers. At the same time, to remove ice crusts, it is forbidden to use knives and other sharp objects that can easily damage and disable the evaporator.

It should also be borne in mind that the refrigerator should not be placed next to heating devices and in places where direct contact with sunlight is possible. Excessive influence of external heat has a bad effect on the operation of the main components and the overall performance of the device.

For cleaning parts of the product made of stainless steel, only special products recommended by the manufacturer in the instructions for the device are suitable.

If you plan to move from place to place, it is best to transport the equipment in a truck with a high van, fixing it in a strictly upright position.

Thus, it is possible to prevent breakdowns, leakage of oil from the compressor, which enters directly into the refrigerant circuit.

How long should the refrigerator run without shutting down?

There is no specific amount of time for non-stop operation of the refrigerator. It is affected not only by the model of the device, but also by the temperature in the kitchen, the level of wear of the compressor, the number of chambers, the settings set, etc.

But do not worry if the household appliance periodically makes noise longer than usual. After all, the thermostat and the sensor constantly analyze the state inside the refrigeration chambers. If the food placed inside is warm or the refrigerator has not been operated for a long time, the compressor operation time will increase.

But still, there are a number of alarming signs, which, combined with the long operation of the device, indicate possible defects:

- The sound of "rumbling" becomes too loud, rattling appears;

- From household appliances comes an unpleasant smell of burning;

- The noise rises and falls sharply in a short time.

In this case, the compressor or another part of the refrigerator fails and the wizard should be called.

In this video, master Dmitry Kondrashev will tell you how to understand if your refrigerator is working correctly at the moment:

What does Artalis-Group offer?

- We will return your refrigerator to a fully functional condition, and it will be able to serve you faithfully again! To do this, you just need to call us and leave a request for repair - then we will provide all the necessary assistance to your refrigerator.

- For the repair of refrigerators, we take only modern and reliable spare parts - if you use high-quality parts, then the quality of the repair will be good!

- We provide a guarantee for the replacement of the motor-compressor and other repairs.

- To properly replace the compressor, the master must be highly qualified. Only professional employees work for us - they have extensive experience in repairing refrigerators, in particular, in replacing the motor-compressor.

- We offer a refrigerator motor-compressor repair price that will be not only affordable, but also one of the lowest in the city.

- Our specialists go to the customer's house to repair the refrigerator, and to all districts of Moscow and the region, even the most remote ones, without cheating the price for it. In this case, the repair will have the same cost, regardless of the area of the city. Departure is already included in the price of the service.

- We not only promptly repair refrigerators, but also quickly come to the call - if it is convenient for you, our specialist can go for repairs immediately after the application.

| № | NAME OF WORKS | COST OF WORK |

| 1 | Refrigerant charge | from 1500 rub. |

| 2 | Installing the motor-compressor | from 3500 rub. |

| 3 | Evaporator repair | from 2000 rub. |

| 4 | Repair of the "NO FROST" evaporator | from 2500 rub. |

| 5 | Freezer Evaporator Replacement | from 2500 rub. |

| 6 | Installing the refrigerator evaporator | from 2500 rub. |

| 7 | Refrigeration unit condenser installation | from 1999 rub. |

| 8 | Clear blockage or replace capillary tubing | from 2100 rub. |

| 9 | Replacing the dryer filter | from 1000 rub. |

| 10 | Pipeline repair | from 1500 rub. |

| 11 | Removing the refrigerator from the furniture | from 1000 rub. |

| 12 | Thermostat replacement | from 1200 rub. |

| 13 | Replacing the start relay | from 1200 rub. |

| 14 | Heater Replacement | from 1900 rub. |

| 15 | Fan Replacement | from 1500 rub. |

| 16 | Replacing the defrost timer | from 1500 rub. |

| 17 | Replacing the fuse | from 1400 rub. |

| 18 | Restoration of the thermal insulation of the refrigerator | from 2400 rub. |

| 19 | Replacing sealing rubber on one door | from 2000 rub. |

| 20 | Door repair (door panel) | from 1500 rub. |

| 21 | Cleaning the drainage system | from 1200 rub. |

| 22 | Diagnostics | 500 rub. -household and 1500 rubles. - trading |

When do you need to replace the compressor in the refrigerator?

Replacing the compressor on the refrigerator, the price of which depends on the brand of the refrigerator, is necessary when it makes a strange noise, does not work, and buzzes a lot. If the motor does not work and does not make any sounds, then most likely it burned out. In this case, the only way to solve the problem is to replace the compressor with a new one. Burnt motors cannot be repaired.

Replacing the refrigerator compressor, the cost of which is affordable and not overpriced in our service center, is a complex procedure. It includes not only the replacement of the node itself, but also the search for the cause that provoked the failure of the compressor. If the real cause of the motor failure is not identified, subsequently the new motor will require replacement.

If the motor does not burn out, then it can be repaired. But for this it is necessary to carry out diagnostics in order to find out the cause of its failure. Turning to us, you can be sure that the repaired motor will serve you uninterruptedly for many more years.We repair refrigeration equipment of any brands, imported and Russian, including Atlant, Liebherr, Samsung, Indesit and others.

Very often people ask why the refrigerator compressor is hot. If you are faced with a similar problem, then you should know that the strong heating of the motor is the result of its intensive work. This suggests that the motor is working in enhanced mode and without stopping. In addition, this may also indicate that the compressor burned out.

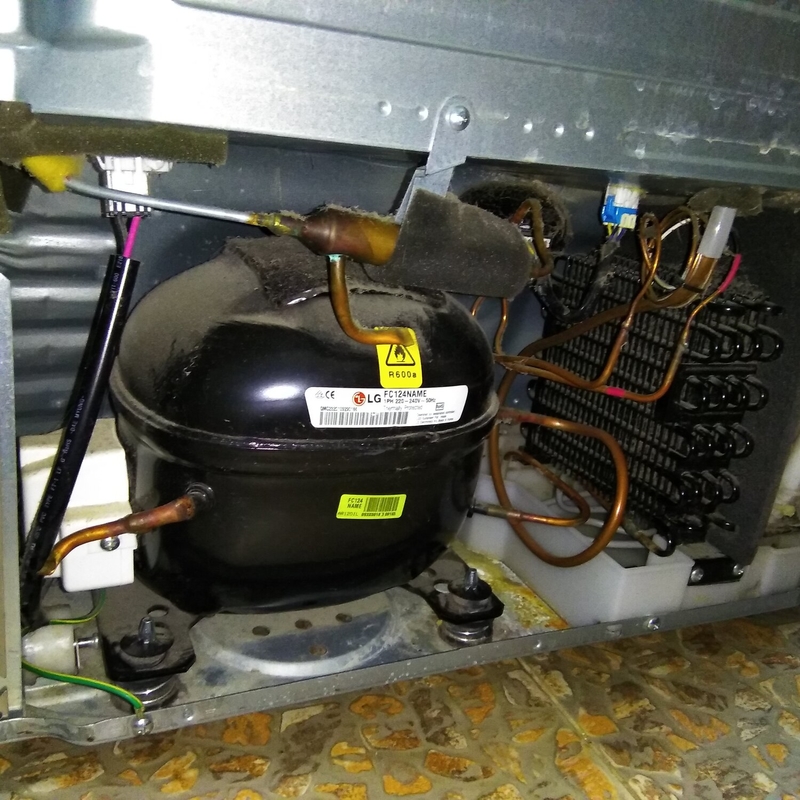

Diagnostics

When diagnosing a problem with your refrigerator, you should pay attention to the temperature of the refrigerator compartment. If it is increased, or the chamber is completely defrosted, the compressor unit may have failed.

It doesn't matter if you have Minsk or Atlant, this node is arranged in the same way. It is located at the bottom of the refrigerator, hermetically sealed in an oil casing.

If the motor is silent when the relay is activated, the compressor may not be working due to a motor breakdown, and it needs to be replaced.

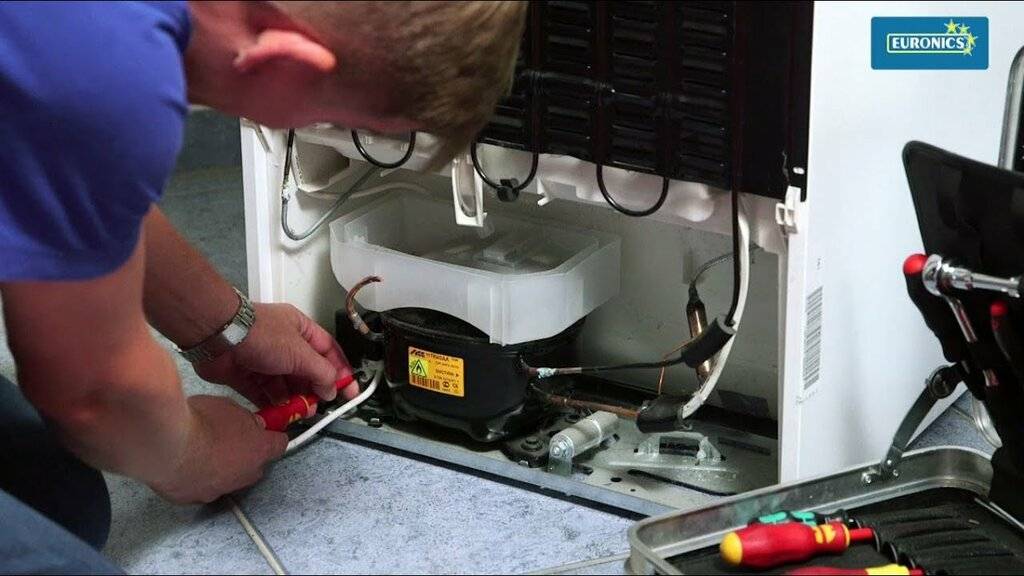

Removing the compressor

Before you start repairing the installation with the proposed replacement of the vacuum motor with your own hands, stock up on a multimeter to check the current and resistance. If there is a normal cable break, complex repairs will not be required. Replacing the cable is a banal procedure. The multimeter is applied to the contact and the case, on which the paint is preliminarily peeled off. The device should not respond. Otherwise, do-it-yourself repairs become unsafe.

Next, you can start working with the motor and the starting relay. The multimeter leans against the contacts, the current should be equal to 1.3 amperes, and the motor power is 140 watts. Look at the photo how the multimeter is correctly applied.

To determine the parts to be replaced, you need to touch the capacitor, it must be hot. If refrigerant leaks out, the unit will be at room temperature. Perhaps the thermostat has broken, the refrigerator needs to be replaced. Repair is not a quick matter, please be patient.

Motor failure occurs quite rarely, according to statistics - in 20% of cases. It is better to entrust the repair of the refrigerator compressor motor to a specialist

When repairing a refrigerator compressor, pay attention to checking such important elements as a temperature sensor and a relay. If they are not damaged, then the compressor itself needs repair.

Checking the operation of the connected compressor, starting the engine

The health of the compressor is determined by a multimeter. But before doing this, you need to make sure that the engine housing does not break through. If everything is fine, then the multimeter probes are alternately applied to each contact. If numbers appear on the screen, it means that the winding is faulty, the compressor performance can be judged by highlighting the “∞” sign.

To continue the test, remove the casing from the compressor. Disconnect the wiring from the contacts. They bite the tubes of the electric motor that connect it and other mechanisms. Tighten the mounting bolts and remove the compressor from the casing. Then unscrew the screws and measure the resistance between the contacts. To do this, apply tester probes to the output contacts. A resistance of 25 to 35 ohms is considered normal. It depends on the model of the refrigerator and the electric motor. If the reading is lower or higher, the compressor needs to be replaced. Then check the performance with a manometer.

A hose with a branch is connected to the discharge fitting, the engine is started and the pressure in the compressor is measured.If it is working, then the pressure gauge will show 6 atm. The device should be turned off immediately, because the pressure will rise quickly and the mechanism may break. In a compressor unsuitable for operation, the pressure gauge will show no more than 4 atm. It will have to be removed and a new one installed. In order to replace a failed compressor, certain skills are required, since this process is quite complicated. It is best to entrust this work to a professional.

If the pressure turned out to be normal, and the device does not turn on, there may be a problem in the start relay. It may happen that after connecting it does not turn on. Most often, the cause is jamming. You can fix it yourself using a special device with two diodes. It is connected to the motor windings and voltage is applied for a few seconds. Then, after half a minute, the procedure is repeated. Thanks to wedging, the motor can be shaken.

Not in all cases, it is possible to determine the cause of a refrigerator malfunction by testing the electrical circuits of the compressor. To start the electric motor when using inverter devices, you will need an electronic unit installed inside the device. If such a motor is tried to be forced to start, then a short circuit may occur, and then it will finally fail. It is more correct in these cases to seek help from specialized service centers where experienced craftsmen work and have the appropriate equipment.

Top 10 Best Inverter Compressor Refrigerators

Conclusions and useful video on the topic

The tools and materials that will be required to replace the compressor, as well as all the stages of work, are available in the video on the example of the Atlant refrigerator:

The service life of the compressor declared by manufacturers is 10 years. However, its breakdown is inevitable.

In the event of a blower malfunction, you can replace the broken compressor yourself, having previously familiarized yourself with all the safety rules and the stages of the work ahead. Also for these purposes it is necessary to stock up with the necessary equipment.

Do you professionally repair refrigerators and want to add to the above list of causes of compressor failure? Or share useful repair tips with beginners? Write your comments and recommendations at the bottom of this article.