- Comparison by main parameters

- Comparison by main parameters

- What are polymer composite gas cylinders

- Can composite gas cylinders be used indoors

- The main technical characteristics of gas-balloon equipment for giving

- The size of the cylinder and the material of its manufacture

- Supply gas hoses

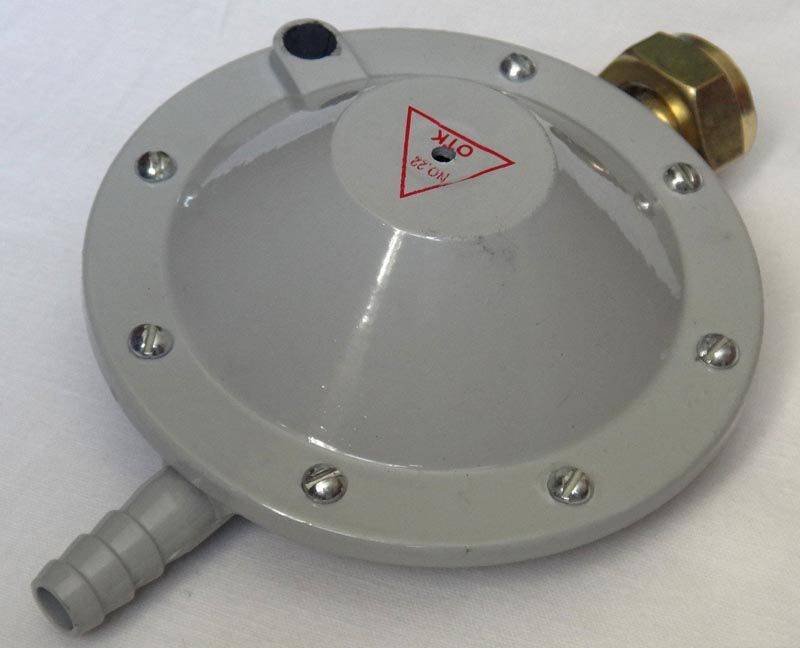

- Reducer for gas bottle

- Pros and cons of plastic containers

- Gas in a cylinder: safety in everyday life

- Service life of composite gas cylinder

- Advantages and disadvantages of composite cylinders

- LiteSafe Composite Gas Cylinders - India

- Pros and cons of plastic containers

- Scope of application

- Advantages and disadvantages of gas cylinders

- Advantages

- Flaws

- Conclusion: composite or metal?

- Let's summarize why a polymer-composite gas cylinder, and not a metal one

- Metal cylinders will be used on a par with polymer

- Finally

Comparison by main parameters

According to the manufacturers of eurocylinders, the rupture pressure of fiberglass flasks is almost twice as high as that for products made of metal. Although in this case it is more correct to be guided by GOST, according to which the case must withstand a load of 50 atmospheres.Propane tanks that have passed inspection, regardless of the type of material from which they are made, meet this criterion, therefore they can be operated in private households.

Working temperature

The lower temperature limit for metal and polymer-composite containers is the same - 40°C. The upper limit is higher for plastic - +60°C versus +45°C.

Here the advantage is on the side of plastic products. Firstly, such a container does not rust. Secondly, the process of destruction of the wall of the composite flask is much slower, so re-examination is carried out once every 10 years, while metal structures are routinely checked every 5 years.

The mass of an empty steel container with a volume of 12 liters is 6 kg. The polymer-composite tank with a volume of 12.5 liters weighs 3.4 kg. In addition to the almost twofold difference in weight, composite cylinders are equipped with special handles for convenience, which makes their transportation even easier.

Metal in its structure does not belong to transparent materials, unlike fiberglass. Due to this feature, the level of the propane-butane mixture cannot be determined visually. At the same time, transparent flasks of eurocylinders allow you to constantly monitor the level of propane and refuel in a timely manner.

Locking and safety devices

Since polymer-composite gas storage tanks are manufactured abroad, their valves comply with international standards. In addition, all flasks are equipped with a check safety valve and a fusible link. The safety valve is designed to release excess pressure, and the fusible link is triggered in the event of open combustion.Steel containers in our country are usually equipped with standard VB-2 valves without safety devices, which makes them less safe. Although, if desired, a modern reducer with a safety valve, such as GOK, can be installed on a metal vessel, and thereby ensure a similar level of safety. By the way, GOK, in addition to shut-off and control valves, produces group balloon plants, which you can read about in the article: GOK balloon plants - technical features and scope.

Comparison by main parameters

According to the manufacturers of eurocylinders, the rupture pressure of fiberglass flasks is almost twice as high as that for products made of metal. Although in this case it is more correct to be guided by GOST, according to which the case must withstand a load of 50 atmospheres. Propane tanks that have passed inspection, regardless of the type of material from which they are made, meet this criterion, therefore they can be operated in private households.

Working temperature

The lower temperature limit for metal and polymer-composite containers is the same - 40°C. The upper limit is higher for plastic - +60°C versus +45°C.

Durability

Here the advantage is on the side of plastic products. Firstly, such a container does not rust. Secondly, the process of destruction of the wall of the composite flask is much slower, so re-examination is carried out once every 10 years, while metal structures are routinely checked every 5 years.

The weight

The mass of an empty steel container with a volume of 12 liters is 6 kg. The polymer-composite tank with a volume of 12.5 liters weighs 3.4 kg.In addition to the almost twofold difference in weight, composite cylinders are equipped with special handles for convenience, which makes their transportation even easier.

Transparency

Metal in its structure does not belong to transparent materials, unlike fiberglass. Due to this feature, the level of the propane-butane mixture cannot be determined visually. At the same time, transparent flasks of eurocylinders allow you to constantly monitor the level of propane and refuel in a timely manner.

Locking and safety devices

Since polymer-composite gas storage tanks are manufactured abroad, their valves comply with international standards. In addition, all flasks are equipped with a check safety valve and a fusible link. The safety valve is designed to release excess pressure, and the fusible link is triggered in the event of open combustion. Steel containers in our country are usually equipped with standard VB-2 valves without safety devices, which makes them less safe. Although, if desired, a modern reducer with a safety valve, such as GOK, can be installed on a metal vessel, and thereby ensure a similar level of safety. By the way, GOK, in addition to shut-off and control valves, produces group balloon plants, which you can read about in the article: GOK balloon plants - technical features and scope.

What are polymer composite gas cylinders

Composite cylinders consist of two parts:

internal - partially transparent polymer container (flask);

external - lattice protective casing made of HDPE (high-density polyethylene), manufactured using overpressure molding technology.

The control fittings (valves, safety valves) are integrated into the finished polymer container before being installed into the casing.

In view of the raw material base and the peculiarities of the production technology, composite gas cylinders have a number of properties that are attractive to users.

Safety - unlike a metal one, a composite cylinder will not aggravate the situation under critical conditions.

Igsh1Member

The main advantage of composite cylinders is explosion safety. Steel can also be relatively secure with a protective valve. Melting of the case in composite - an additional degree of protection ...

Let us explain: at high temperatures in case of fire, the cylinder does not explode, hitting with fragments, but gradually melts, which allows the gas to be bled through the relief valve and prevent "pop".

- Lightweight - the largest tank at 33.5 liters weighs only 6.3 kg, not to mention the small one at 12.5 liters (3.4 kg). And although a small mass is mainly important for women and the older generation, this property of the composite can also be useful for men.

- Visual control - the gas level in the cylinder can be seen with the naked eye, due to the partial transparency of the flask, which is quite convenient.

Harold reg50Member

For cooking in the country, I have been using composite cylinders with a volume of 33 liters for two years now. The cylinders are light, you can visually control the remaining gas, the reducer is connected without an adjustable wrench (tightened by hand). Before that, there were several steel cylinders of 50 liters each.I had to buy composite cylinders, despite the price - my back hurt; and the wife could not lift a filled steel cylinder by 50 liters. The difference in volume is not critical, a 33-liter composite is enough for 2-3 months, a 50-liter steel cylinder was enough for 3-4 months.

- Lack of corrosion - it simply has nowhere to come from, since there are no metal elements either inside the cylinder or outside.

- Durability - the cylinder recertification period is ten years, and the service life, with proper operation, manufacturers call up to one hundred years, although users have doubts.

GuffychMember

Composite cylinders do not rust, but “fatigue” loads are more critical for them, won’t it just start to siphon over time?

Geir VeteHexagon Ragasco Technical Support Manager

The materials used to manufacture composite cylinders are identical to those used in the manufacture of fiberglass aircraft, underwater or underground pipelines. They have been used in various industries for over 50 years and are known for their resistance to external influences, pollution and corrosion. Rigorous testing did not reveal any significant material wear due to exposure to UV radiation, contact with gases (including propane-butane mixtures) or other substances as a result of testing. Over the 20-year history of the production and operation of composite gas cylinders, no cases of fatigue of the composite material have been identified, which excludes the occurrence of gas leaks for this reason.First of all, abrasions of the outer casing may appear on the cylinder, while the flask almost always remains safe and sound. What distinguishes a composite gas cylinder from a traditional metal one, in which the degree of damage to the flask itself is much higher during operation.

serjtMember

To the question of the reliability of composite cylinders. This afternoon I refueled two of my cylinders of 33.5 liters. The first filled normally, and in the second, as soon as they started to refuel, gas whistled from the bottom. It is not visible to the eyes, but it was clearly audible, a cylinder of the 14th year.

Geir Vete

The flask of the composite cylinder consists of an internal one-piece liner and winding with fiberglass threads. Due to the peculiarities of the composite material, small pores and micro-cavities invisible to the eye remain in the winding. When the cylinder is filled with gas, the liner expands and pushes the air out of these cavities, so a characteristic whistling sound is sometimes heard, especially when the cylinder is wet. This is an absolutely normal situation and is not an indicator of a leak or any mechanical damage to the cylinder.

Can composite gas cylinders be used indoors

Adherents of the usual metal cylinders, one of the arguments against composite ones, are the restrictions associated with the ban on their use indoors.

For lovers of beautiful composite cylinders, I recommend going to Gorgaz for a safety briefing. They are prohibited for indoor installation. There they will show, tell, photos of exploded cylinders and houses will be shown. In composites, there is a valve that releases gas when the pressure is exceeded.

What is characteristic - in principle, it is forbidden to use gas cylinders with a volume of more than five liters in the premises, regardless of what they are made of.

In accordance with the federal norms and rules in force on the territory of the Russian Federation regarding the use, operation and filling of domestic gas cylinders, there is no division into metal and composite cylinders. By Decree of the Government of the Russian Federation of April 25, 2012 N 390 “On the fire regime”, paragraphs 91-94, the installation of gas cylinders in residential premises, with the exception of one cylinder with a volume of not more than 5 liters, connected to a factory-made gas stove, is prohibited. Cylinders should be located outside buildings, in extensions made of non-combustible materials, near a blank wall pier, at a distance of at least 5 meters from the entrances to the building, basement and basement floors. As for the overpressure relief valve found on composite cylinders, its main purpose is to protect the user, so there are more and more companies that independently install this valve with an overpressure relief valve on metal cylinders.

In practice, both metal and composite are installed everywhere in kitchens and boiler rooms, despite existing standards. However, with equal inputs, in case of an emergency, whatever one may say, there will be much less harm from the composite.

But it is better, of course, not to create conditions for such situations and adhere to existing fire regulations. “Safety is written in blood” in almost every area of our life.

The main technical characteristics of gas-balloon equipment for giving

The choice of the gas stove itself for giving under bottled gas is still half the battle. It is also necessary to choose the right equipment for it. You will need to purchase:

- The gas cylinder itself;

- Hose for gas supply;

- Reducer.

When buying a gearbox, it is better to give preference to a domestic manufacturer

When buying a gearbox, it is better to give preference to a domestic manufacturer

Now let's figure out how to choose the right components of the system.

The size of the cylinder and the material of its manufacture

The size of the gas cylinder is selected depending on the frequency of use and the possibility of its placement. Now they can be purchased in various versions - from fairly large to compact. The most common are the following volumes:

- 12 l - metal (12.5 l - from composite materials);

- 27 l - regular (24.5 l - composite);

- 5 l - eurocylinder;

- 50 l - both metal and composite.

Such cylinders made of composite materials are very convenient.

Such cylinders made of composite materials are very convenient.

The advantage of eurocylinders made of composite materials is their lighter weight. But at the same time they are more overall, which is not always convenient.

Supply gas hoses

These parts can be both ordinary rubber and modern, protected by a metal corrugation. Although many believe that steel pipes are better suited for this purpose, it should be understood that in this case it will be necessary to perform a certain amount of installation work using welding. Yes, and this option is rather inconvenient to connect and use.

Such hoses are considered the most reliable

Such hoses are considered the most reliable

A protected corrugated hose is the most optimal - it easily bends in any direction and is not afraid of minor mechanical damage.In addition, it is already equipped with the necessary connecting nuts and gaskets, which allows you to connect it without having the skills of such work.

Reducer for gas bottle

This equipment limits the pressure of the gas supplied to the stove. The reducer is necessary due to the fact that blue fuel is in a liquefied state in cylinders and its supply pressure is much higher than in main networks.

Chinese gearboxes are very unreliable

Chinese gearboxes are very unreliable

When choosing, you should pay attention to the Russian and European manufacturers. Chinese products, even if they have been certified in Russia, have rather thin walls.

This greatly shortens their service life and may lead to leakage. You should also check with the seller what fuel the gearbox is designed for - it may not be suitable for liquefied gas, and the manufacturer does not provide for the possibility of self-tuning it.

Pros and cons of plastic containers

Polymer containers are very ergonomic in storage. These cylinders can be stacked on top of each other in horizontal and vertical positions. Composite products are connected to the same gas appliances that are designed for conventional liquefied gas supply units. Plastic cylinders can be safely transported for domestic use, long-term storage or outdoor activities.

The main advantages of composite devices:

- It is highly recommended to check polymer products once every ten years, and metal counterparts should be checked more often - once every five years.

- The walls of such a flask are transparent, so you can easily estimate the volume of the remaining gas at a glance. Over time, transparency is not lost, the amount of fuel inside also does not affect it.

- The composite shell does not spark in the event of impact or friction against each other, so the risk of an unexpected explosion is almost eliminated.

- The weight of products of this type is one third less than the mass of metal aggregates, however, they are no worse in strength. The weight of a conventional cylinder is 20 kg, and a composite one is only 7 kg.

- These containers have a very rich assortment in terms of volume and shape. Everyone can choose an attractive model suitable for a particular occasion.

- Composite coating tolerates heating up to a temperature of 100C.

- Consumers note that the handles on the case make the operation of the device very convenient when carrying and transporting.

- The service life of a polymer cylinder is 30 years, but proper and careful handling increases this period even more.

- The flask outside is reliably protected by a special plastic casing, which significantly increases the strength of the product. In the event of a fall or impact, the force impact will have on this shell, even if it is damaged, the flask and its explosive contents will remain completely intact.

- Static electricity is also not scary for a composite balloon. The occurrence of sparks, explosion and fire are practically excluded.

Eurocylinders also have significant drawbacks - a smaller volume than a metal counterpart, and a high cost. The price of vessels made of polypropylene is 3-4 times higher than the cost of a device made of metal. The only benefit in this regard is a high degree of safety, a beautiful appearance and ease of storage and operation.

Gas in a cylinder: safety in everyday life

Inside the domestic cylinder is natural hydrocarbon gas under high pressure.Excessive pressure transforms the gas into a liquid state of aggregation. When leaving the cylinder, liquefied gas returns to its previous state. If you delve into the understanding of this process, it turns out that:

Hydrocarbon gas is a mixture of butane, propane, ethane and methane. A complex composition is necessary to create certain properties of the gas mix. Inside the cylinder, not the entire volume of gas is in a liquid state. Rather, it can be called a two-phase content: a liquid, and above it a gas. The higher the pressure, the more fluid.

When leaving the cylinder, the liquid literally evaporates, acquiring the gaseous state necessary for domestic use. LPG composition in cylinders may vary slightly

At the same time, all hydrocarbon gases are explosive and easily ignite in case of any careless handling.

They have a specific recognizable smell so that you can spot a leak in time. According to the degree of toxicity, they are classified as hazard class IV (“low-hazardous substances”). It's true: even perfumes and deodorants use liquefied hydrocarbon gases.

So there is no need to do without a gas cylinder in everyday life. Moreover, according to the law, all manufactured gas cylinders undergo a mandatory technical check and receive supporting documents (the so-called “passport”).

You can (and should!) check for the seal when buying a cylinder. It is located near the neck and contains information about the date of manufacture of the cylinder, expiration date, nominal volume and weight.

Service life of composite gas cylinder

Each owner of a car with HBO installed must study the rules for operating a cylinder filled with gas.

The composite cylinder must have:

one.Passport - it indicates the period of service. For cylinders made of polymer material, it is up to 30 years. Sometimes the question is asked: is it possible to use the cylinder after the end of its service life? It is possible, but after expensive diagnostics. For this money it is easier to buy a new cylinder.

2. Mandatory examination is the control of the technical condition of the cylinder, as well as the preparation of a conclusion on the continuation of operation or disposal.

The certified cylinder is safe and is allowed to be used as part of LPG.

Examination of cylinders filled with gas includes a number of procedures:

- inspection of the surface of the flask for the absence of mechanical damage;

- control of compliance with GOST marking and coloring of the hull;

- hydraulic tests.

The results of the examination are recorded in the passport. The right to issue an opinion is granted to an organization with powers from supervisory authorities.

Safety Compliance Certificate. It is issued after testing and is required for registration. To register with the traffic police, you must accurately indicate the type and model of the cylinder. For the safe operation of HBO on a car, allocate a key and extend the service life by performing maintenance.

The main maintenance activities include:

1. Status check.

As a result of operation, scuffs, scratches, dents appear on the case. Checking helps to prevent gas leakage from the tank.

2. Checking the markings.

You can find out everything about the cylinder by the marking on the flask. When refueling, the brand of fuel must match the type of cylinder.

3. Check the condition of the valve.

Composite cylinders are equipped with shut-off valves made according to international standards.The valve must fit snugly against the flask.

Advantages and disadvantages of composite cylinders

Consider the advantages and disadvantages of new-style gas cylinders. Like all even modern products, they are also available, but there are much more advantages.

Modern containers for storing blue fuel have the following advantages over metal ones:

- Significantly less weight (about half);

- Functionality and comfort. The product is equipped with handles, any housewife will be able to easily transfer the medium-sized container;

- Balloon transparency. Now each consumer can determine the level of filling with blue fuel. Metal products were completely deprived of this quality, which served as a pretext for possible fraud among sellers and suppliers of natural resources;

- Convenient storage, operation and transportation. The valve and reducer are protected at the top by a ring handle. Branded vessels can be safely stacked on top of each other or folded in a lying position on their side;

- Significantly longer service life compared to metal specimens;

- Among the important technical characteristics of a composite cylinder, I would like to note a high degree of safety. It doesn't generate a spark. It is supplied with additional safety elements that minimize the possibility of an explosion (safety check valve and special insert).

The high price is the main disadvantage of practical products. If we rationally assess the situation, then the traditional copy is objectively inferior in all respects to gas cylinders made of composite materials.

LiteSafe Composite Gas Cylinders - India

Indian manufacturers offer the widest range of volumes - from 5 to 47 liters.They have not yet managed to gain a high reputation, like their European counterparts, since they have been on the market since 2016. The containers are produced in compliance with all quality standards required for gas vessels, but they look rustic due to low-cost materials. The protective cover is less durable and prone to scratches and abrasions.

Asian products are also inferior in weight - cylinders of equal volume are heavier by 7-10%

LiteSafe is an excellent choice for fishing or giving, because the price is 4-12% lower than that of Europeans.

Pros and cons of plastic containers

Polymer containers are very ergonomic in storage. These cylinders can be stacked on top of each other in horizontal and vertical positions. Composite products are connected to the same gas appliances that are designed for conventional liquefied gas supply units. Plastic cylinders can be safely transported for domestic use, long-term storage or outdoor activities.

The main advantages of composite devices:

- It is highly recommended to check polymer products once every ten years, and metal counterparts should be checked more often - once every five years.

- The walls of such a flask are transparent, so you can easily estimate the volume of the remaining gas at a glance. Over time, transparency is not lost, the amount of fuel inside also does not affect it.

- The composite shell does not spark in the event of impact or friction against each other, so the risk of an unexpected explosion is almost eliminated.

- The weight of products of this type is one third less than the mass of metal aggregates, however, they are no worse in strength. The weight of a conventional cylinder is 20 kg, and a composite one is only 7 kg.

- These containers have a very rich assortment in terms of volume and shape.Everyone can choose an attractive model suitable for a particular occasion.

- Composite coating tolerates heating up to a temperature of 100C.

- Consumers note that the handles on the case make the operation of the device very convenient when carrying and transporting.

- The service life of a polymer cylinder is 30 years, but proper and careful handling increases this period even more.

- The flask outside is reliably protected by a special plastic casing, which significantly increases the strength of the product. In the event of a fall or impact, the force impact will have on this shell, even if it is damaged, the flask and its explosive contents will remain completely intact.

- Static electricity is also not scary for a composite balloon. The occurrence of sparks, explosion and fire are practically excluded.

Eurocylinders also have significant drawbacks - a smaller volume than a metal counterpart, and a high cost. The price of vessels made of polypropylene is 3-4 times higher than the cost of a device made of metal. The only benefit in this regard is a high degree of safety, a beautiful appearance and ease of storage and operation.

Scope of application

The technical and operational characteristics of polymer-composite gas cylinders provide them with great potential and an almost unlimited scope. This is an autonomous source of one of the most demanded energy carriers in a variety of situations.

Cooking - both at a seasonal dacha or in a capital country house (gas stoves), and at a picnic or on a trip (gas grills and barbecues, mobile stoves).

In heating systems - a variety of home gas heaters, sauna stoves, outdoor heaters (trip to nature).

In construction and decoration - welding machines, heat guns.

In autonomous power supply systems - generators.

The convenience of using compact and presentable composite cylinders, in almost all conditions, is undeniable.

Advantages and disadvantages of gas cylinders

An autonomous gas cylinder is a useful thing both for permanent operation and “for every fireman”. Let's see what its pros and cons are.

Advantages

Among the main advantages use of bottled gas users highlight:

- Mobility, that is, the tank can be rearranged, transported, etc. without problems.

- If the cylinder is filled, then until the moment of operation it can be stored as much as necessary. What can not be said, for example, about the electric drive.

- A wide selection and the ability to easily purchase a cylinder of any size, purpose and material

Autonomous gas cylinder - a useful thing

Flaws

Now a few words about the most common disadvantages and risks that users rightly pay attention to:

Explosion and fire hazard. If a metal gas cylinder gets into the area of a fire or a sharp jump in temperature, it threatens the life and health of the owner, and can also severely damage the house.

If a metal gas cylinder gets into a fire zone or a sharp jump in temperature, it threatens the life and health of the owner

In old cylinders that have been used for a long time, sediment forms at the bottom. Such a cylinder must be cleaned before further work.

Old cylinders may release gas. To avoid this, you need to change the jet from time to time.

The cylinder is dangerous if it is turned over abruptly. In this case, a large pressure surge and a sharp ejection of the flame are possible (if the cylinder is with a burner). It is not always possible to extinguish this flame on your own.

There is a risk of inhaling gas. The cylinder passes gas, but no one knows about it. For example, if a faulty cylinder is located in a room where people sleep (or next to it), and works constantly (say, for a heating boiler), the likelihood of getting burned is high.

Conclusion: composite or metal?

Summing up, we will once again list the advantages of a composite vessel over a metal device:

- fire and explosion safety;

- light weight;

- transparency;

- resistance to corrosion processes;

- elimination of sparks.

But consumers are deterred by the high cost of such devices and a smaller maximum tank volume.

Thus, the composite gas cylinder is a relatively new device for storing liquefied gas, but polymer tanks are gradually pushing their metal counterparts out of the market. This is due to the convenience and safety of operation. With proper use and timely maintenance, a composite gas tank will serve flawlessly for many years.

Let's summarize why a polymer-composite gas cylinder, and not a metal one

Polymer-composite gas cylinders are produced in volumes from 5 liters to 47 liters. The practicality of the material allows you to use:

- leaving to rest in nature;

- in industrial and household purposes.

The absence of corrosion adds safety to the polymer cylinder. A sharp tangential blow will not cause a spark at the cylinder. These characteristics allow the cylinders to be transported safely.

Metal cylinders will be used on a par with polymer

With the advent of polymer gas cylinders on the market, a lot of controversy arose whether they would use metal cylinders or not.

The Ministry of Industry and Trade began to prepare amendments to GOST on the safety of using gas cylinders. Rumors spread that polymer-composite cylinders will completely replace metal ones. There is no official statement, because in many industries it is prescribed to use a metal cylinder. For example: in the Ministry of Defense or at industrial facilities.

As far as safety is concerned, with proper handling, a metal cylinder is almost as good as a polymer cylinder. Most of the explosions occur due to incorrect connections. Yes, the device of the metal cylinder is outdated and needs to be improved, therefore, measures will be taken to refine the gas distribution mechanism and the gas cylinder as a whole.

A metal cylinder has a significant advantage - it is several times cheaper than its polymer counterpart. Approximately 30 million gas metal cylinders are in circulation in Russia. For this reason, it will not be possible to replace all cylinders at once. For a gradual replacement, adjustments will be made to the rules for the use of gas cylinders.

It doesn't matter what the balloon is made of, what matters is how it is handled. Proper gas connection and proper storage of gas cylinders is important

Observing safety precautions, gas cylinders will last as long as the manufacturer claims.

Finally

Gas stoves with cylinders are quite convenient for use in summer cottages and do not require any permission.However, it should be understood that such equipment, if improperly connected and operated, can be life-threatening not only for the homeowner, but also for his neighbors. It is for this reason that it is worth carefully monitoring the leaks and malfunctions of the system and periodically auditing the equipment.

There are stoves with 5 burners, but they are not so popular.

There are stoves with 5 burners, but they are not so popular.

We hope that the information presented today was useful to the dear reader. If you still have questions on the topic, then our team will be happy to answer them in the discussion for this article. Ask questions, share your experience - because it can be useful to someone.

And finally, we suggest watching a short video on the topic of connecting such equipment:

Watch this video on YouTube

Watch this video on YouTube

Previous Household appliances100% success in the fight against viruses - quartz lamp for home

Next Household Appliances Why do you need an air purifier for an apartment: types, models and some characteristics