- Wiring diagram

- Homemade external thermostat for the boiler: instructions

- The principle of operation of a room thermostat

- Setting procedure

- Recommendations for selection and installation

- Types of thermostats

- Electric boilers

- How to connect a thermostat to a boiler

- How does a thermostat for a heating boiler work

- Thermostat for a heating boiler: temperature regulator or not only?

- Relays or triacs

- The best choice

- Wired or wireless

- Temperature setting accuracy

- Possibility to set the hysteresis value

- Programming capability

- WiFi or GSM

- Safety

- The practical use of a remote regulator - is it possible to do without it

- Where can you make combined systems?

- Where can you make combined systems?

- 4 Proven schemes for connecting a water-heated floor

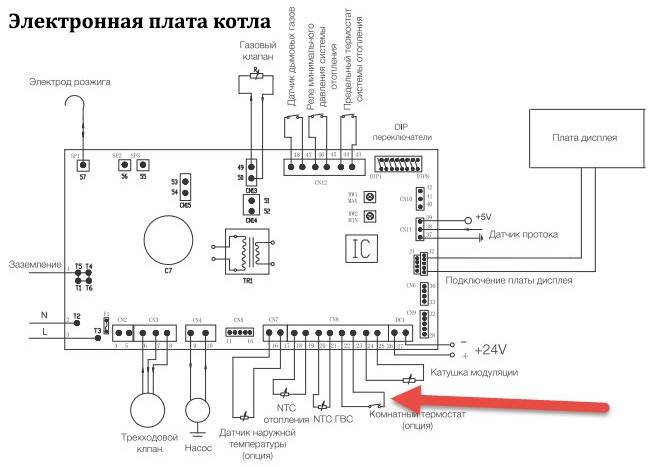

Wiring diagram

Almost all thermostats on the market today are relay. This means that they are powered by a relay that opens and closes contacts based on a user-defined temperature. As a theoretically connected thermostat, we will use an electric relay-type thermostat with dry contacts. Dry contacts is a term that means that in any state, closed or open, there is no voltage on the contacts.

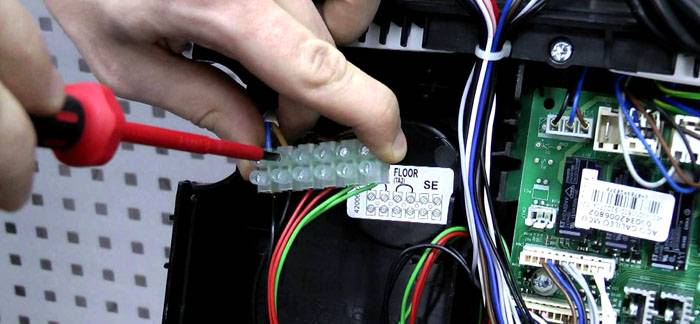

To connect to the boiler, there are terminals on the thermostat, you need to connect open and common ports. If they are not indicated in the manual for your particular model, you just need to ring the contacts with a tester. Next, we need to make sure that the thermostat can be connected to the boiler. Usually this is indicated directly in the technical documentation, if there is none, then the information is easy to find in any of the search engines.

On the found electronic diagram of the board, the location of the very jumper into which the thermostat will be connected to the boiler is indicated. Depending on the model of the boiler, you will have to unscrew a few bolts to get to the required part. The block can be installed both on the control board and taken out separately. Connecting a thermostat for any of these options will not differ in anything.

Next, you need to pull out the jumper, and put the cable that comes with the thermostat (or purchased separately) in its place. This is a two-core wire with a cross section of at least 0.75 square millimeters. Polarity when connecting does not matter. To the thermostat control unit, the cable is connected to the normal open and common ports, as described above. The ports are located on one side of the control unit, on the other, there are ports for connecting the power supply cable. You can either purchase a new cable of the desired section, or use the complete one.

This completes the connection of the thermostat to the gas boiler. It remains only to check the performance of the system. On the thermostat, we set the required air temperature in the room, the signal is transmitted to the control unit and, depending on the set temperature, the relay contacts close or open.When setting a temperature that is lower than the current one, the burner turns on to heat the water in the system, when the temperature is set higher, the burner, on the contrary, starts to work.

Homemade external thermostat for the boiler: instructions

Below is a diagram of a home-made thermostat for a boiler, which is assembled on Atmega-8 and 566 series microcircuits, a liquid crystal display, a photocell and several temperature sensors. The programmable Atmega-8 chip is responsible for compliance with the set parameters of the thermostat settings.

In fact, this circuit turns the boiler on or off when the outside temperature drops (rises) (sensor U2), and also performs these actions when the temperature in the room changes (sensor U1). Adjustment of the work of two timers is provided, which allow you to adjust the time of these processes. A piece of circuit with a photoresistor affects the process of turning on the boiler according to the time of day.

Sensor U1 is located directly in the room, and sensor U2 is outside. It is connected to the boiler and installed next to it. If necessary, you can add the electrical part of the circuit, which allows you to turn on and off high-power units:

Another thermostat circuit with one control parameter based on the K561LA7 chip:

The assembled thermostat based on the K651LA7 chip is simple and easy to adjust. Our thermostat is a special thermistor that significantly reduces resistance when heated. This resistor is connected to the electricity voltage divider network. This circuit also has a resistor R2, with which we can set the required temperature.Based on such a scheme, you can make a thermostat for any boiler: Baksi, Ariston, Evp, Don.

Another circuit for a thermostat based on a microcontroller:

The device is assembled on the basis of the PIC16F84A microcontroller. The role of the sensor is performed by a digital thermometer DS18B20. A small relay controls the load. Microswitches set the temperature that is displayed on the indicators. Before assembly, you will need to program the microcontroller. First, erase everything from the chip and then reprogram, and then assemble and use it to your health. The device is not capricious and works fine.

The cost of parts is 300-400 rubles. A similar regulator model costs five times more.

A few last tips:

- although different versions of thermostats are suitable for most models, it is still desirable that the thermostat for the boiler and the boiler itself be produced by the same manufacturer, this will greatly simplify the installation and the operation process itself;

- before buying such equipment, you need to calculate the area of \u200b\u200bthe room and the required temperature in order to avoid “downtime” of equipment, and changing wiring due to the connection of devices of higher power;

- before installing the equipment, you need to take care of the thermal insulation of the room, otherwise high heat losses will be inevitable, and this is an additional expense item;

- if you are unsure that you need to purchase expensive equipment, then you can conduct a consumer experiment. Get a cheaper mechanical thermostat, adjust it and see the result.

Modern technologies allow you to equip a warm floor in several ways, depending on which connection you plan to use.Underfloor heating water systems have proven themselves to be highly reliable and economical. Easy to install are electric heating floors, the wide popularity of which is due to the possibility of placement under any coating. Of course, all the positive aspects take place only when using high-quality equipment and its proper installation.

Since part of the work on energy saving and convenience is assigned to the thermostat, special attention should be paid to its installation and connection.

A modern thermostat can be programmed to change the temperature not only by the hour, but also by the days of the week

The use of a thermostat allows you to use any heating device without the risk of overheating and failure. That is why thermostats are built into electric irons, kettles and water heaters. Cable, rod and film underfloor heating were no exception. Thanks to the installation of an adjusting device, you can not only change the temperature under your feet, but also program the operation of additional heating to save energy.

All existing thermostats can be divided into two types:

The sensor of the electronic thermostat is installed in the controlled area, and the control unit is mounted separately

The principle of operation of a room thermostat

The air thermostat for a gas boiler has a temperature sensitive element inside. This temperature sensor contains a gas that expands when heated and contracts when cooled. As a result of these processes, the contacts of the gas equipment power circuit are closed / opened.

Depending on the model, the thermostat may have:

-

One or more temperature sensors;

-

Digital timer for programming the operating modes of the boiler;

-

Mechanical regulator for setting the required temperature;

-

Display with software control unit.

Wireless thermostat TEPLOCOM TS-2AA/3A-RF, price about 6000 rubles

The simplest is a device with a mechanical switch, with which the parameters of the modes for turning on and off the boiler equipment are set. The most advanced are thermostats with a programmable control unit that allows you to set the operation settings separately for day and night. It's like a pumping station and a simple pump for a well - in general, they perform the same functions, but their capabilities differ.

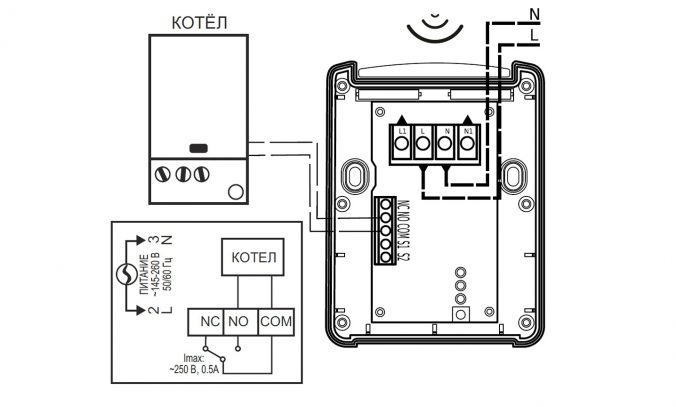

Installation diagram TEPLOCOM TS-2AA/3A-RF

Setting procedure

To set up the system and select a comfortable temperature, do the following:

- Set the remote controller to the maximum temperature.

- Start the boiler and bring it to the optimal operating mode, in which the unit reaches the highest efficiency.

- When all rooms are comfortably warm, take an electronic thermometer and measure the temperature near your regulator.

- Select the measured value on the thermostat as the heater cut-off threshold. Enter the required settings in the programmer.

Let us explain the purpose of these manipulations. Due to different areas and heat losses, the temperature in the rooms may differ by 1-3 degrees, so it is better to navigate by the degree of air heating near the sensor itself.

If the temperature at the point where the controller is installed is very different from the rest of the rooms, the adjustment must be adjusted for this difference. In some models, for example, Baxi Magic Plus, a function of such an adjustment (called a temperature shift) is provided. Then it remains only to enter the desired value, which is from 1 to 5 degrees, into the memory of the device.

Recommendations for selection and installation

When choosing a model of a room thermostat for a gas boiler, one should be guided by the temperature limits available for the device, the size of the room and the characteristics of the heating water heater.

If the repair in the rooms has already been done, then it is worth picking up a wireless device. You don't have to run wires for it. If at the forefront is the desire to optimize the functioning of the entire heating system as much as possible, then there is no better option than a programmable thermostat. It allows you to more carefully control the temperature parameters of the air and the operating modes of the boiler.

When installing the regulator in question, it is necessary to ensure that the temperature sensors:

-

They were located at a height of about 1.5 meters and on the inner walls;

-

They were not closed with curtains, curtains and furniture;

-

They were at least a meter away from windows, doors and heating radiators.

Room installation

The air around the temperature sensors must circulate freely. Putting them in a closet or behind the decor is unacceptable. Also, these sensors should not be mounted on walls facing the street and near doors. This will result in incorrect readings due to drafts and greater cooling of the outer building envelope compared to the inner partitions.

Ideally, room thermostats should be purchased from the same manufacturer that made the existing boiler. So they are easier to connect and configure, and they will work together with fewer failures and last longer.

To install such a regulator, you do not need to have special skills in electrical engineering and thermal power engineering. Remote sensors are mounted on the walls. And the connection of wires is carried out by means of terminals on the case. You just have to not mix up the strands. In the instructions for the boilers and these devices, the connection diagrams are described in as much detail as possible. Such a device in a programmable version is not cheap, but it pays off in just a couple of heating seasons.

Types of thermostats

Basically, these devices can be divided into 2 groups:

- remote temperature controllers connected with wires;

- wireless room thermostats for gas boilers.

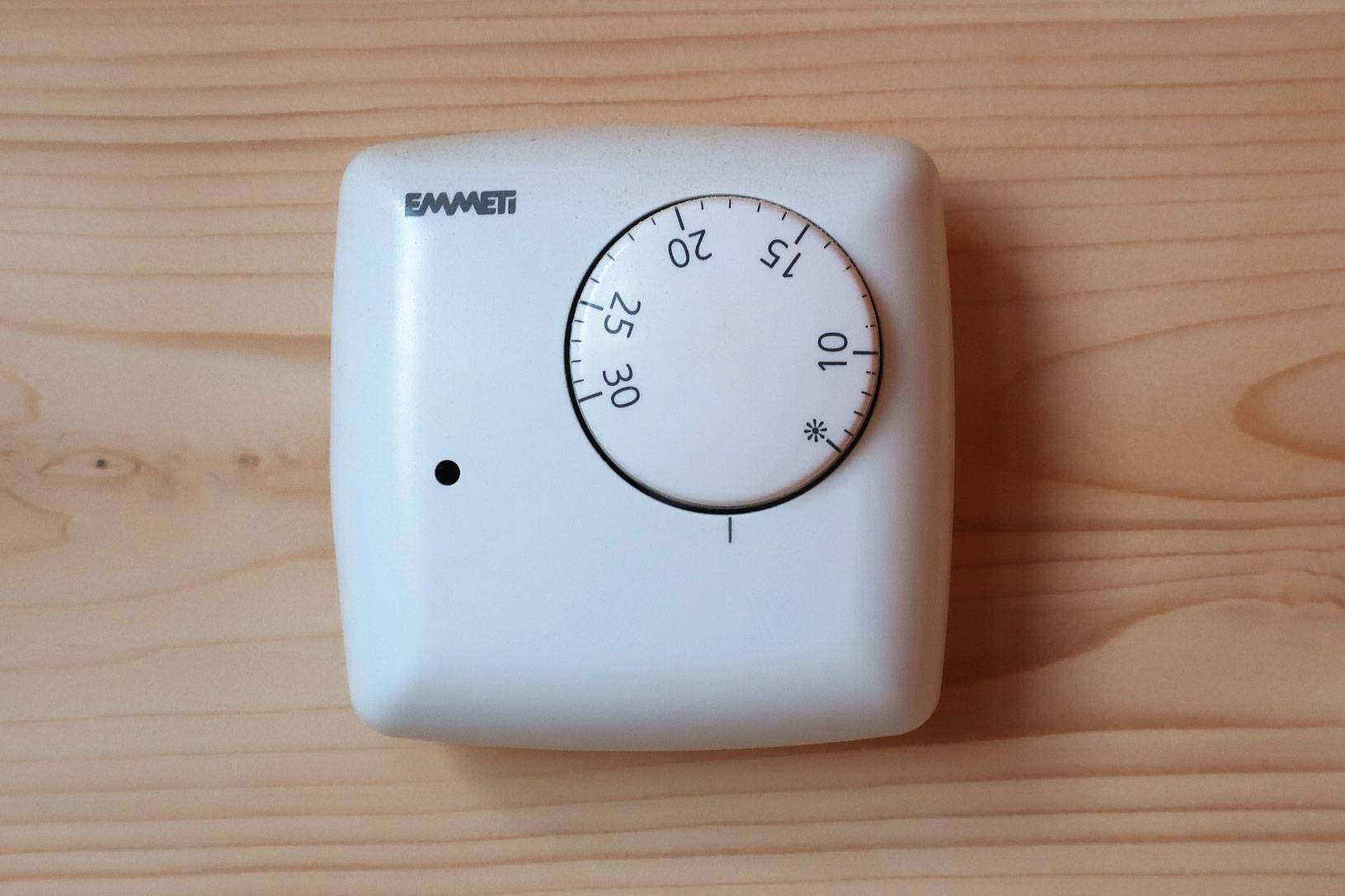

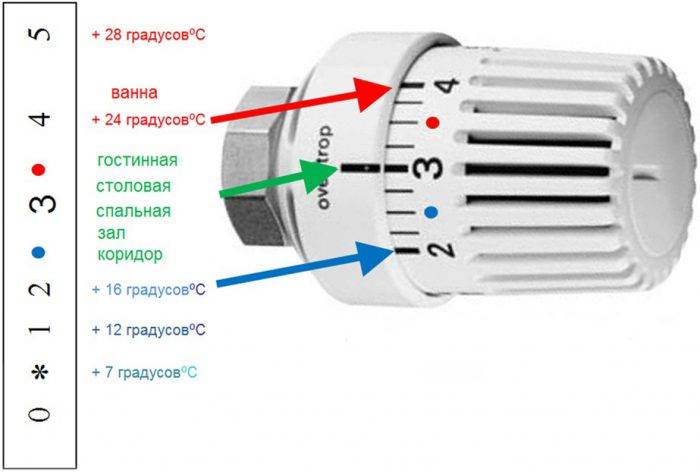

Devices of the first type are distinguished by their simplicity and reliability, as well as low cost. The design provides for constant maintenance of one temperature, set by the handle on the front side of the product. As a rule, the control range is from 10 to 30 ºС.

Devices of the first type are distinguished by their simplicity and reliability, as well as low cost. The design provides for constant maintenance of one temperature, set by the handle on the front side of the product. As a rule, the control range is from 10 to 30 ºС.

Various manufacturers offer models powered from an external electrical network, powered by batteries or directly from the controller of the boiler plant. The main disadvantage of this type of thermostats is that only one air temperature can be set. If you need to change it, then you need to go “turn the knob” again. In addition, some inconvenience is associated with laying wires, so it is better to install such devices during new construction and installation of a heating system.

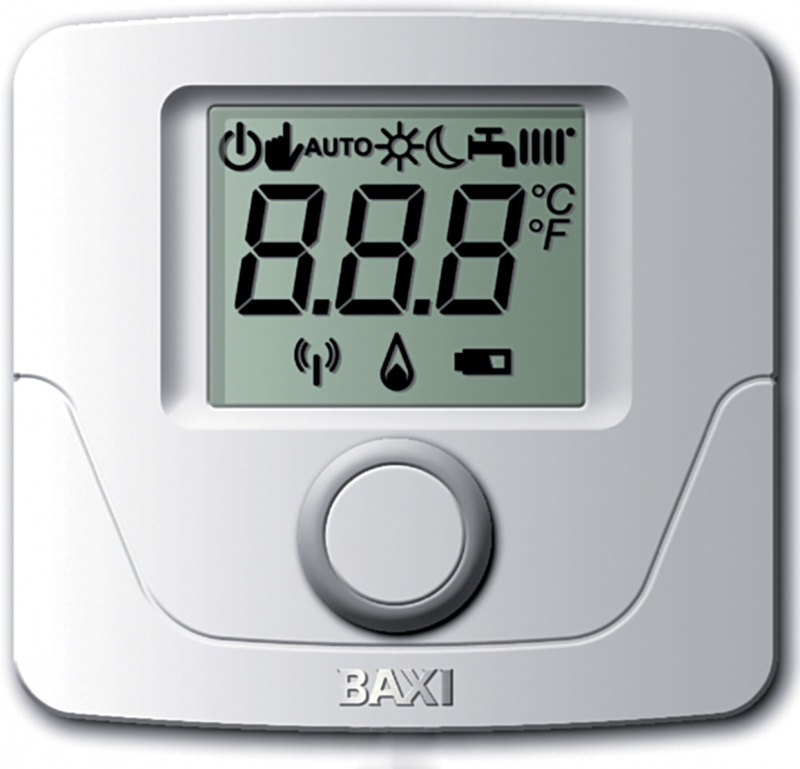

You can set several air temperatures, which must be observed at different times of the day, on the display of the programmable controller. Moreover, it is possible to set a program for a week in advance and in this way fully automate the control of a gas boiler. In conditions where the heating system is already in operation, it is more convenient to install a programmable wireless thermostat, then the interior details will not be disturbed by the wiring.

Such devices have one drawback that deserves attention, this is the battery life, which must be monitored and changed on time. Otherwise, the device will turn off and the gas boiler will focus only on the readings of the internal sensor, heating the coolant to a high temperature.

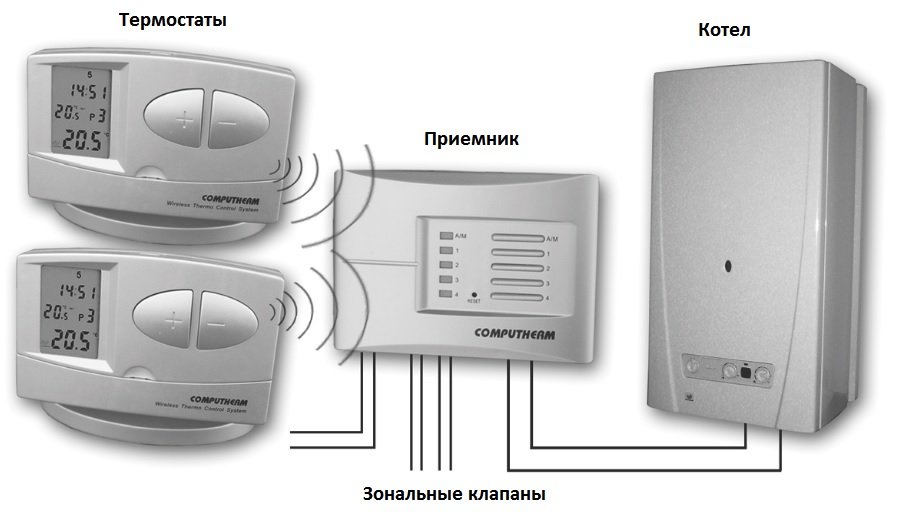

When installing wireless appliances, connecting the thermostat to a gas boiler consists in installing a combustion unit in the room - a signal receiver and connecting it to the controller or the gas valve of the heater. That is, the installation of devices will not take you much time and money, although the product itself will cost significantly more than a simple wired thermostat.

Electric boilers

A fairly common alternative to gas and solid fuel boilers. A lot of advantages, high efficiency, but a long payback period. The connection is simple, like with gas boilers, but without a cold water supply. Temperature control and overheating protection are provided.

Boiler mechanical timer

With a simple mechanical timer for an electric boiler, there are three options for starting the central heating system:

- The boiler is off;

- The boiler supplies hot water;

- The boiler turns on and off at the set time.

Mechanical timers usually have a large round dial with a 24-hour scale in the center. By turning the dial, you can set the desired time and then leave it at that position. The boiler will turn on at the right time. The outer part consists of a set of tabs with a 15-minute period, which are inserted for the convenience of adjusting the operation and setting modes. An emergency reconfiguration is possible, which is performed when the boiler is connected to the network.

Mechanical timers are easy to set, but the boiler always turns on and off at the same time every day, and this may not satisfy the owners if the family is large and bath procedures are performed several times a day at different times.

How to connect a thermostat to a boiler

To choose a high-quality model of a mechanical thermostat for a heating boiler, you also need to know the prices. The cost of individual models can be seen in the table.

| Image | Models | Cost, rub. |

|---|---|---|

| Viessmann 7817531 | 3670 |

| TR 12 for boilers Bosh Gaz 6000 W for gas boilers | 2100 | |

| Galan Comfort | 3500 |

| Galan MRI 15 | 4500 |

| Terneo rk 30 for electric boilers | 2870 |

| BeeRT regulator for electric boilers | 3300 |

| Thermostat for solid fuel boiler Auraton S 14 | 5990 |

Scheme of connecting the thermostat to the boiler

The following recommendations will help in the installation of such devices:

- it is desirable that the control device and the heating unit be made in the same production, which will facilitate the installation process;

- before purchasing, calculate the area of the heated room and the optimal temperature indicator, which will avoid equipment downtime;

- before installation, consider the thermal insulation of the room.this will prevent significant heat loss.

Connecting the mechanical regulator to the heating unit

Experts advise mounting regulators in living rooms. If they are placed in utility rooms, this will lead to problems in the system. It is also better to choose a colder room. There should be no sources of heat and electrical appliances near such equipment.

The boiler is switched on using a relay. In modern gas boilers, a special place is provided for connecting a thermostat. You can connect the device using the terminal located on the boiler. The method of connection is indicated in the passport to the boiler.

After installation, the equipment must be configured. On the front panel there are buttons with which the device is configured. The switches allow you to control the cooling and heating of the air, as well as temperature fluctuations and the delay time of the sensors.

Using the buttons, the optimum temperature is maintained, which is maintained during the day. And at night, this indicator will decrease in order to save fuel resources and prevent their overrun.

Thermostat in a system with an AOGV boiler

The thermostat is an important part of the autonomous heating system. It ensures high-quality operation of the system, and also avoids unnecessary fuel consumption. This device, despite its simplicity, ensures the long-term operation of the boiler and the entire system.

How does a thermostat for a heating boiler work

In order to understand the features of the thermostat, it is necessary to find out the principle of its operation in combination with a hot water heating system using the example of a gas boiler:

- Using the buttons (handles), the operator lights the boiler, sets the required temperature.

- The device has a sensor that indicates the temperature of the coolant. If the water temperature reaches the set value, then the fuel supply is shut off (closed by a gas valve). The pump circulates water through the heating system.

- When the water cools to the lower limit value (cooling the air by 1-2 degrees), the gas supply to the burner is restored, it ignites and heats the water again.

The thermostat for a gas boiler with an external temperature sensor increases the time interval between switching on and off in a gas boiler, based on the temperature of the slowly cooling air. The installation of a room thermostat for a gas boiler is carried out by breaking the electrical circuit between the gas valve and the built-in pump.

Advantages of installing an automatic thermostat for boilers:

- reduce the use of electricity;

- convenient control of heating equipment;

- increases the operating time of the boiler.

There are two features to be noted:

- The use of a room thermostat for the boiler does not cancel the operation of the temperature sensor for the heating boiler, which will stop heating the water when it reaches the limit.

- When the boiler burner stops working on a signal from the automation, the mains pump continues to work. When the remote thermostat is triggered, both the burner and the pumping equipment stop working.

In addition to the above functions, there are so-called limit thermostats, which are one of the safety elements. The sensors are triggered if the coolant temperature rises to 104°C.

After triggering, the sensor is set to working condition by pressing the button. This design is made in order not to panic immediately and continue to operate the boiler, since a one-time operation is not a sign of emergency operation, but a reason to monitor the further situation. Often, overheating of the coolant is a consequence of poor flow, blocked shutoff valves or unstable operation of pumping equipment.

Thermostat for a heating boiler: temperature regulator or not only?

There are several types of boilers. These are gas, solid fuel, as well as electric models. The material for the manufacture of such equipment is cast iron or steel. Temperature control and adjustment is carried out using a special thermoelement. This equipment is a metal structure. As a result of thermal expansion, the position of the lever that moves the damper changes. In order for the combustion to grow, the damper opens slightly. Newer designs mount controllers that can regulate airflow.

Thermostatic draft regulator for solid fuel boiler

The most commonly used gas models, which are single-circuit and with two circuits. Some models have separate room thermostats for a gas boiler for a hot water circuit and a heating circuit.

Electric devices are characterized by high efficiency and simple connection.In such designs, there is protection against overheating and temperature control. With the use of a mechanical timer, various methods of temperature control are produced. More often, the unit simply turns on / off when the temperature drops / rises. But it is also possible to set a specific switch-on time.

The design of the electrical unit

Relays or triacs

To control an electric boiler or convector, powerful relays are most often used, the contacts of which are rated for current up to 16 A. Such a relay can switch loads up to 2.5 kW.

It is best to use triacs in your design, which can switch significant currents of hundreds of amperes.

There are enough circuits for temperature controllers and circuits for controlling thyristors and triacs in the network. If there is a desire, then it is better to use the experience and experience of people who have already made thermostats. In most cases, the technical data of such “home-made products” exceeds industrial designs.

The best choice

The selection of a thermostat for a heating boiler is based on the personal preferences of the owners of the premises. When choosing, you should consider what characteristics are required when using a particular boiler.

Wired or wireless

The communication of the control unit with sensors and the boiler for different models is carried out by wire or wireless. In the first case, a wire laying is required. The cable length reaches 20 m. This allows you to mount the control unit at a great distance from the room in which the boiler room is equipped.

Wireless thermostats for a heating boiler are designed as a receiver and transmitter. A distinctive feature of products of this type is the absence of the need for wiring.The transmitter signal can reach a distance of 20-30 m. This allows you to install the control panel in any room.

Temperature setting accuracy

Depending on the design of the room thermostat, the setting of the room temperature differs. Inexpensive models have mechanical control. The disadvantage of cheap thermostats is the error, reaching 4 degrees. In this case, the temperature adjustment step is one degree.

Products with electronic control have an error of 0.5 - 0.8 degrees and an adjustment step of 0.5o. This design allows you to accurately set the required power of boiler equipment and maintain the temperature in the room within a certain range.

Possibility to set the hysteresis value

The room thermostat for a gas boiler has a difference between the on and off temperatures. It is necessary to maintain optimal heat in the room.

Hysteresis principle

For mechanical products, the hysteresis value does not change and is one degree. This means that after switching off the boiler unit will start working after the air temperature in the room drops by one degree.

Electromechanical and electronic models have the ability to set a hysteresis. Adjustment allows you to change the value up to 0.1 degrees. Thanks to this design, it is possible to constantly maintain the temperature of the room in the desired range.

Programming capability

The function is only available for electronic or electromechanical thermostats. It is possible to program the control unit to set the temperature by the hour.Depending on the model, the thermostats are programmable for up to 7 days.

So it is possible to make the heating system with the gas boiler turned on autonomous. At a certain time, the thermostat connects, disconnects the boiler or changes the intensity of its work. With weekly programming, gas consumption can be reduced by up to 30 percent.

WiFi or GSM

Thermostats with built-in wi-fi and gsm module are connected to the Internet. To control the heating, gadgets with installed applications are used. This is how remote shutdown, connection of the boiler and adjustment of the temperature indicators in the heated room are carried out.

Using the gsm standard, the room thermostat transmits information about the occurrence of malfunctions in the heating system to the owner's phone. It is possible to remotely turn on or off the gas boiler.

Safety

When choosing a thermostat for gas boiler equipment, you should pay attention to the presence of security systems. Functions are available to prevent the stop of the circulation pump, protection against freezing or exceeding the maximum temperature in the heating system, etc.

The presence of such options allows you to safely use boiler equipment offline.

The practical use of a remote regulator - is it possible to do without it

Many private homeowners and people living in apartments with individual heating are familiar with the situation when they have to adjust the intensity of the boiler to constantly changing weather conditions. It is easier to maintain a heat-generating gas appliance in an apartment, at least in terms of the compactness of living quarters.The owners of private houses, who part-time have to be operators of boiler equipment, sometimes have to run short distances if the boiler house is not in the main building.

All modern gas units are equipped with automation that regulates the intensity of the gas burner or the frequency of its on / off. The automatic control system clearly responds to changes in the temperature of the circulating fluid, maintaining the thermal regime in a certain corridor set by the owner. But the temperature sensor that sends signals to the electronic "brains" is installed in the boiler's heat exchanger, so it cannot respond to weather changes. As a result, we have the following situation:

- it has become sharply cold outside, and the household is beginning to freeze slightly;

- there is a sudden thaw outside the window, and the windows are wide open, because in rooms with temperature pluses there is a clear bust.

It is useful to ventilate the premises intensively, but along with kilojoules, savings fly away through the window, which will have to be paid on bills for the consumed energy carrier. Shaking with unusual coolness is also good for the body, but still a constant comfortable air temperature is more pleasant and natural for housing that claims to be called modern.

To maintain the temperature regime within comfortable limits, it is not necessary to hire a stoker or run to the boiler every hour. It is enough to install a thermostat for the boiler, which would read information about the actual temperature within the living space and transfer the data to the control system that regulates the operational activity of the heating equipment. Such a move will allow you to "kill a few birds with one stone":

- maintaining a constant comfortable temperature within the housing;

- significant energy savings (gas);

- reduced load on the boiler and circulation pump (they work optimally, without overloads), which prolongs their service life.

And these are not miracles, but the result of the work of a room temperature sensor - an inexpensive, but very useful device, which in European houses and apartments (and they know how to save on a "communal apartment") is a must-have addition to heating equipment. Even the most expensive remote thermostat with a liquid crystal touch display and many functionalities easily pays for itself during the heating season.

Gas boilers, as a rule, are equipped with the simplest system for regulating the heating of the coolant. The user sets the temperature parameters using a mechanical, less often an electronic controller.

Sensors that control the heating of the liquid in the heating system, giving a signal to the automation, turning off and on the gas supply. Such a device is ineffective, since it does not take into account the heating temperature of heated rooms.

Room thermostat for gas boiler, designed for precise adjustment. Installing the sensor reduces fuel costs by 15-20%.

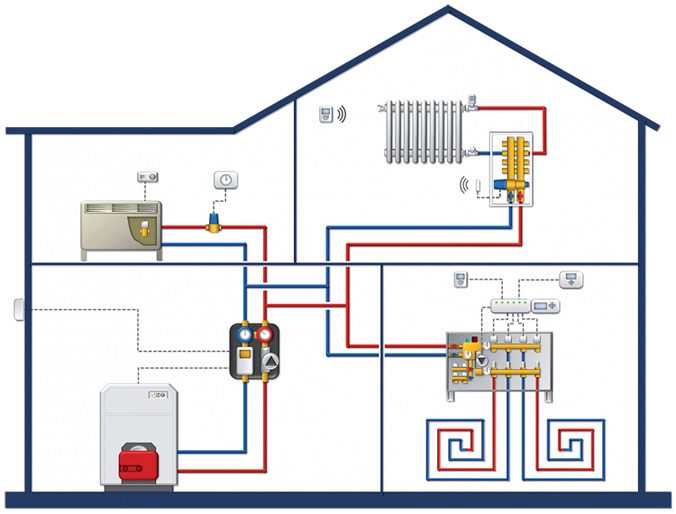

Where can you make combined systems?

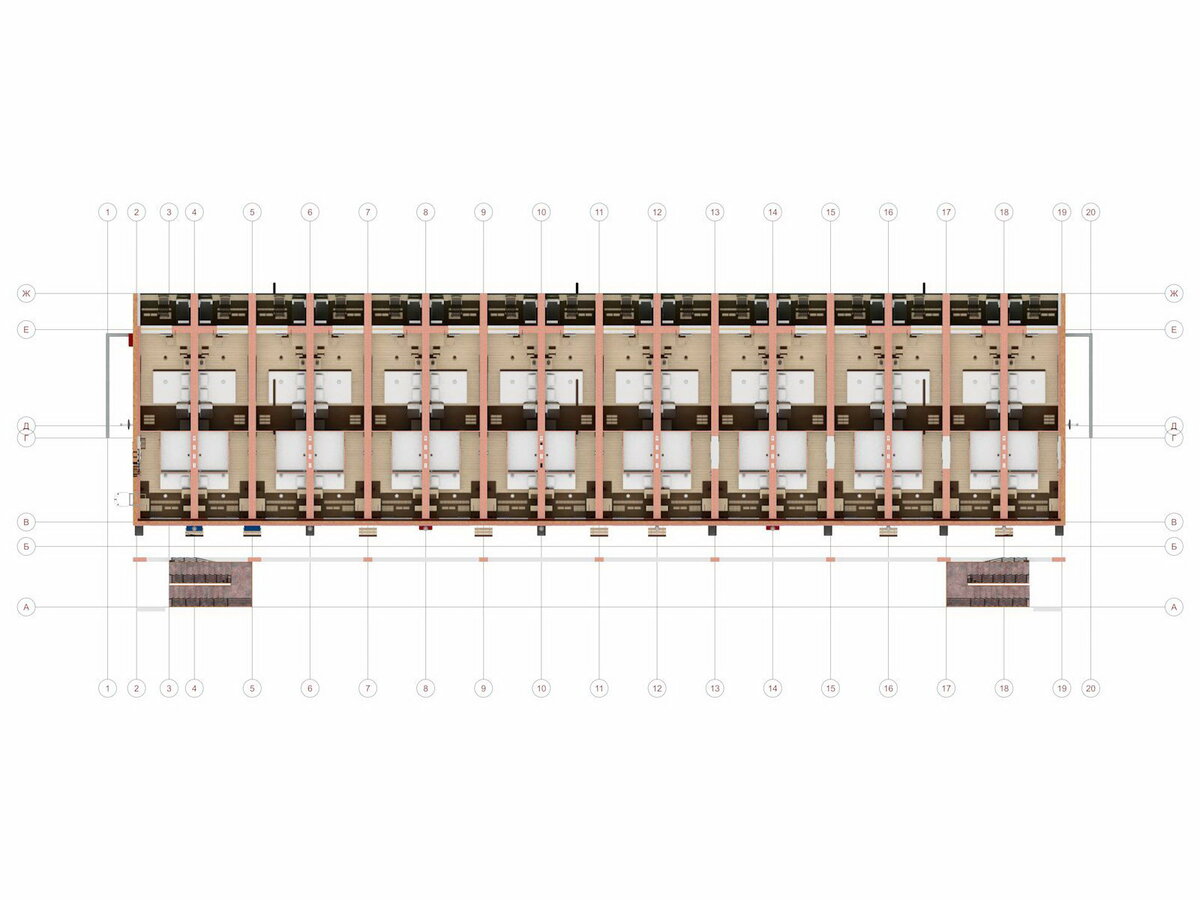

The area and number of floors in our example are very conditional. It is also necessary to coordinate their modes of operation.

It is one thing: to connect the radiator heating system to the boiler, when all the functionality for this is already installed in the boiler. They propose to carry out supply and return polypropylene pipes in a layer of sand under the screed along the foundation. It can be single pipe or double pipe.

In some situations, when all radiators are closed, and the underfloor heating is running, the boiler pump and the underfloor heating pump work in series, interfering with each other. Installation of combined heating in a system with a gas boiler The most difficult moment in the process of installing combined heating is the need to supply heat carrier from the collector for underfloor heating and radiators with different temperatures through two pipes. Depending on the temperature at the outlet of the underfloor circuit, the mixing valve opens or closes, increasing or decreasing the amount of hot coolant from the supply in the recirculation circuit.

This is necessary to ensure the tightness of all joints made. Air source heat pump main source of heat Air source heat pump Before considering the positive and negative aspects of existing heating units, let's talk a little about the air.

Where can you make combined systems?

The collector is mounted in a special box material - galvanized steel, which corresponds to its size. It does not matter the type of coolant or heat source.

Designation of the main elements of the scheme: wall-mounted gas boiler with built-in circulation pump and expansion tank; hydraulic separator thermo-hydraulic separator or hydraulic switch; collector collector beam for connecting heating circuits; circulation unit of the radiator heating circuit; mixing unit of the kennel of the water theople of the floor; safety thermostat. The three-way thermostatic valve of the second type is different in that it provides regulation of the flow rate of only the hot flow.In more complex systems, the controller is also guided by a weather sensor, carrying out a preventive change in heating power.

4 Proven schemes for connecting a water-heated floor

As a result, the heat carriers are mixed in the following way: the liquid from the return pipe is supplied continuously, and the hot liquid is supplied only when necessary. In this case, floor structures will be durable, reliable and durable.

A special temperature-sensitive device is used. Heating with a solid fuel boiler Combined heating with a solid fuel boiler is a closed gravity system with a heat storage device.

We combine heating. Underfloor heating + radiators. A simple solution