- Forced circulation system

- Varieties of combined boilers

- Recommendation for choosing a boiler for gas and wood

- The main manufacturers of wood-gas boilers

- How much does gas and wood burning equipment cost

- Universal heating: wood, gas and electricity boiler

- Types of combined heating boilers

- gas-electricity

- gas-wood

- wood-electricity

- Universal multi-fuel units

- Combined wood-electricity boiler

- pros

- Principle of operation

- Popular manufacturers and their offers

- In conclusion, a few video reviews

- Universal water heaters

- Internal organization

- Device advantages

- autonomy

Forced circulation system

Equipment of this type for two-story cottages is considered more preferable. In this case, the circulation pump is responsible for the uninterrupted movement of coolants along the mains. In such systems, it is allowed to use pipes of smaller diameter and a boiler of not too high power. That is, in this case, a much more efficient one-pipe heating system for a two-story house can be arranged. The pump circuit has only one serious drawback - dependence on electrical networks.Therefore, where the current is turned off very often, it is worth installing the equipment according to the calculations made for a system with a natural coolant current. By supplementing this design with a circulation pump, you can achieve the most efficient heating of the house.

A gas boiler without electricity is a traditional model of a floor appliance that does not require additional energy sources to operate. It is advisable to install devices of this type if there are regular power outages. For example, this is true in rural areas or summer cottages. Manufacturing companies produce modern models of double-circuit boilers.

Many popular manufacturers produce different models of non-volatile gas boilers, and they are quite efficient and of high quality. Recently, wall-mounted models of such devices have appeared. The design of the heating system must be such that the coolant circulates according to the principle of convection.

This means that the heated water rises and enters the system through the pipe. In order for the circulation not to stop, it is necessary to place the pipes at an angle, and they must also be large in diameter.

And, of course, it is very important that the gas boiler itself is located at the lowest point of the heating system.

It is possible to separately connect a pump to such heating equipment, which is powered by the mains. By connecting it to the heating system, it will pump the coolant, thereby improving the operation of the boiler. And if you turn off the pump, then the coolant will again begin to circulate by gravity.

Varieties of combined boilers

Separate universal heating equipment depending on the type of fuel used.

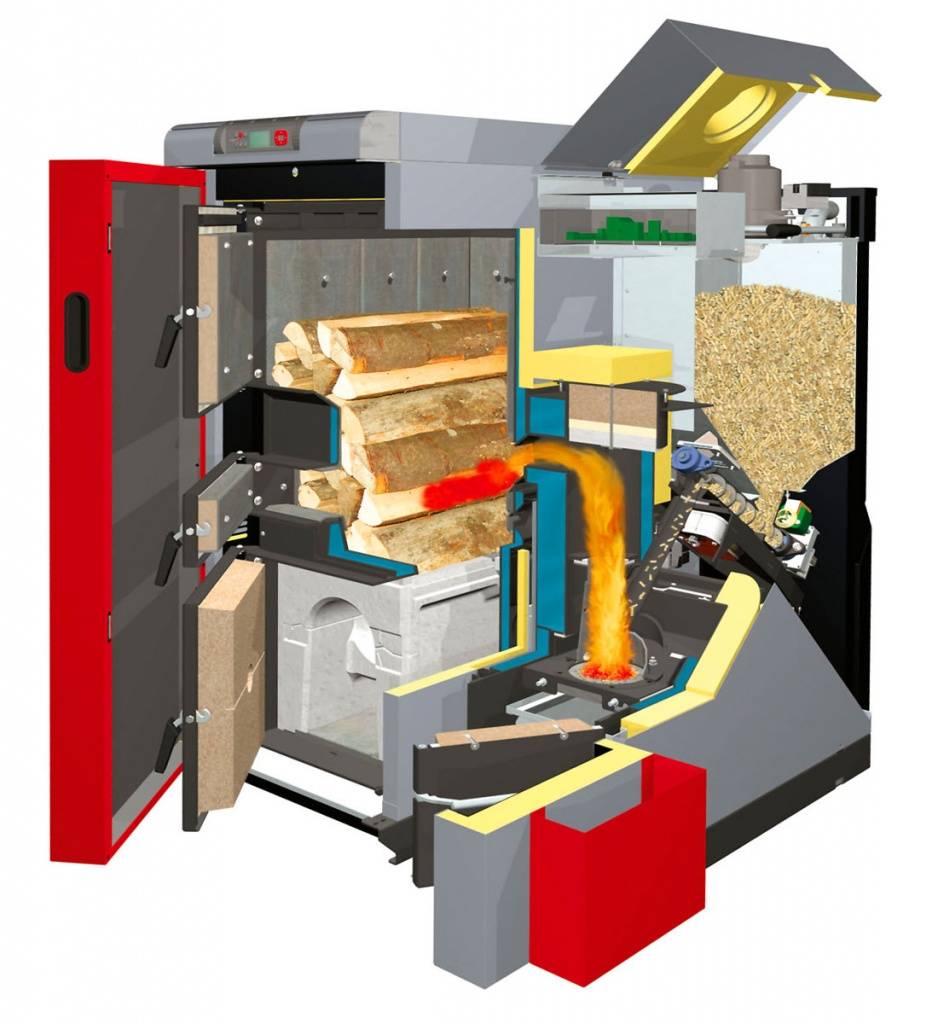

Rice.1 Internal construction of combi boilers

Rice.1 Internal construction of combi boilers

So, the following combined options are distinguished:

- Gas + Solid fuel. Allows you to quickly replace the main gas when it was turned off as a result, for example, of an accident on the line. A wood and gas boiler is one of the most popular solutions due to the good availability of wood.

- Gas + Liquid fuel. Such options are convenient in case of periodic failures in gas supply, but require the organization of storage of diesel fuel stocks.

- Gas + Electricity + Liquid fuel. A combined option for savings in the absence of a guarantee of timely supplies of gas and diesel fuel.

- Gas + Solid and liquid fuel. One of the most versatile models for heating cottages. Great replacement for wood burning stoves.

- Gas + Solid and liquid fuel + Electricity. This model makes the owner of a private house completely independent of tariffs and other factors that affect the change of energy carrier. For example, a wood-gas-electricity appliance.

There are universal boilers without connection to a gas main, for example, for coal and firewood with the ability to connect heating elements to be powered by electricity. Heating boilers combined gas firewood are often installed in conditions of interruptions in gas supply. Firewood for heating, including special granules (pellets), causes less inconvenience during storage than other types of fuel. Yes, and there is no smell, as, for example, from diesel fuel (and a gas boiler, sometimes, gives a slight smell).

Another option - a combined gas-firewood-electricity boiler - allows you to become completely autonomous with any changes in tariffs and in other situations.For a wood-gas-electricity device, you don’t have to worry about the same firewood stocks, power outages, etc.

Recommendation for choosing a boiler for gas and wood

The choice of combined heating boilers for wood and gas is influenced by the technical parameters of the heated building, the need to automate the combustion process

Pay attention to the presence or absence of additional functions in the device

The main selection criteria are:

- Productivity - one kilowatt of power is enough to heat 10 m² of a building. The boiler is selected in accordance with the need for thermal costs of the building. For a room of 100 m², you will need to install a 10 kW model, for 200 m² - 20 kW, etc.

- The presence of a hot water supply circuit - choosing a universal boiler with hot water is somewhat more difficult. During operation, a certain amount of power will be spent to heat domestic water. Therefore, the calculation of the required power of double-circuit boilers is carried out taking into account the reserve in thermal energy of 15-20%. For a typical building of 100 m², the minimum power of heating equipment will be 12 kW.

- Built-in heating element - the presence of an electric heater, significantly increases the functionality of the boiler. Automatic switching to heating with a heating element occurs thanks to the installed sensitive controller. In the settings of most models, there is a mode that allows you to maintain a minimum heating of the coolant (+ 5-10 ° C) and spend a minimum amount of electricity, which is convenient if you want to leave the building for some time in winter, without proper heating.

- Design features - as already noted, multi-fuel boilers can have one universal combustion chamber designed for the alternate use of gas and firewood, or separate furnaces for each type of fuel. The second option is preferable due to the fact that the transfer of the boiler from wood to gas is carried out automatically.

When connecting the boiler to the main gas, you will need to make a project and obtain all the necessary permits for commissioning. Installation rules are the same as for any other gas equipment.

The main manufacturers of wood-gas boilers

Another important aspect influencing the choice of a dual-fuel boiler is the country of origin and brand of the heating unit. High-quality equipment is manufactured in the EU, Russia and Ukraine:

- Ukrainian and Russian combined boilers are fully adapted to the realities of domestic operation, insensitive to fuel quality, voltage drops in the network. Heating boilers for wood and gas, Russian-made, are produced by several leading manufacturers: Kupper PRO (Teplodar company), Zota MIX, Karakan (Novosibirsk concern STEN), PARTNER (Novosibirsk manufacturer KOSTER), STS (Ukrainian manufacturer Steel Solid Fuel Systems) .

- European combined boilers - more than a dozen different companies offer products on the heating equipment market. The following brands are in constant demand: Wirbel (Austrian-German company of the same name), Jaspi (Finnish concern specializing in the production of solid fuel boilers).

As for build quality and reliability, European units are somewhat ahead of their domestic counterparts. Shortcomings are clearly visible in Russian boilers, especially with regard to the automation of the device and operation in the gas generation mode.

The quality of Russian equipment is constantly improving, the wishes of customers are taken into account. Over time, we can expect the release of competitive products.

How much does gas and wood burning equipment cost

Pricing policy depends on the location of the manufacturer and brand awareness. A multi-fuel boiler PARTNER, a Russian manufacturer, will cost 22-24 thousand rubles, depending on the power and configuration.

The Finnish analogue of Jaspi costs from 120 to 150 thousand rubles. Significant difference. True, the consumer, for this money, receives an almost completely autonomous station with a storage capacity and automation that fully controls the combustion process. In the case of a Russian boiler, all processes will have to be adjusted manually.

Self-conversion of a gas boiler for firewood often costs the approximate cost of a conventional domestic-made multi-fuel unit.

Universal heating: wood, gas and electricity boiler

When choosing a method of autonomous heating, owners of a private house often face a difficult choice. On the one hand, you should choose a model for the cheapest fuel so that heating costs are minimal. On the other hand, it is difficult to get full confidence in the possibility of a continuous supply of energy, which is especially true for centralized pipelines (gas, electricity).

Therefore, combined options are becoming increasingly popular, for example, a wood and gas boiler.This is the only way to guarantee that the heating season will run with a stable heat supply. Moreover, the choice is not limited to such modifications. Pellets are combined with electricity, coal with wood models, for example, as in combined boilers. Universal heaters easily allow you to bypass seasonal tariff increases, as well as, for example, use nightly price reductions, etc.

Combined modifications, for example, a wood-gas-electricity heater, are often installed to replace old wood-burning stoves or their coal-fired counterparts. firewood and coal are the most affordable in all regions of our country, while they have a relatively low price. The heating system itself is often not redone, limited to replacing a wood-burning boiler with a combined model.

Types of combined heating boilers

All hybrid boilers for heating country houses are divided into single and double circuit. The first type is responsible only for heating the house, and the second models are designed for heating the building and heating hot water for domestic needs. Some models automatically switch from using one type of fuel to another, others require a replacement burner.

gas-electricity

Electric gas heating boilers are considered the most efficient and economical.

They not only quickly heat up the coolant, but also have the following advantages:

- The device is small in size, because the heat exchanger with a heating element is built directly into the gas fuel combustion chamber.

- Most of the time, the boiler runs on gas, since this is the most inexpensive type of fuel. The start of the electric heater occurs when the pressure in the gas pipeline decreases or for the purpose of quickly heating the coolant at the first start.In the second case, the consumption level is much lower than that of conventional electric boilers.

- The heater has an acceptable cost, because it does not have separate combustion chambers. Single-circuit models have a special connector for connecting a boiler that will heat water for hot water supply.

- Since built-in heating elements are needed only to maintain the required temperature of the heat carrier, their power is small. This saves the most expensive energy resource - electricity.

This heating equipment is not suitable for regions without gasification. Despite the fact that electricity is the most expensive, most of the time the boiler runs on gas.

gas-wood

From the point of view of saving energy costs, a gas and solid fuel boiler is considered a more profitable option. However, the weight and dimensions are quite impressive, because it has two heat exchangers.

Gas-fired boilers come with one or two heat exchangers. In the first case, one heat exchanger is installed on two combustion chambers, while fuel is loaded into the wood-burning furnace manually. One portion of firewood completely burns out in 4 hours. For uninterrupted operation, the boiler has an automatic system that switches the unit to use gas in the absence of firewood in the furnace.

wood-electricity

It is advisable to use an electric wood-burning heating boiler in regions without gasification. This non-volatile powerful equipment, in terms of design, is a bit like gas-fired units. In principle, it is easy to make such a design with your own hands by installing a heating element inside the heat exchanger of a conventional solid fuel boiler.

The boiler for wood and electricity has some features:

- To remotely control the operation of the equipment, software and automatic units are connected to it.

- Such heaters are valued for their durability and reliability.

- Electric wood boilers are distinguished by good maintainability. If the heating element fails, it will not be difficult to replace it.

The main disadvantage is the slow adjustment of the power of the heating equipment, which does not allow you to accurately adjust the temperature of the air heating in the room. To solve the problem, the equipment is equipped with an electronic control unit.

Universal multi-fuel units

Also on sale there are multi-fuel boilers that operate on several types of fuel. For example, it can be gas-electricity-firewood. Typically, in such options, two combustion chambers and a heat exchanger with a built-in heating element are installed. With a removable burner, pellets and diesel fuel can be used.

To install a universal multi-fuel boiler, the following conditions must be met:

uninterrupted power supply in the house;

enough free space or even a separate room must be allocated for fuel storage;

it is important to take care of the organization of regular fuel supplies.

Combined wood-electricity boiler

Electric mode

Unlike traditional solid fuel boilers, an additional heating element is installed in the heat exchanger tank. In addition, this model of combined boiler has a built-in automation system that allows you to change the power and operating modes of the boiler. Also in such models automatic switching between types of fuel is provided, which ensures maximum safety of the unit.It can be concluded that this model of boilers is the most efficient and has a number of advantages over other types of combined boilers.

pros

- Low cost of the unit;

- Versatility;

- Availability;

- Availability of an automation system;

- High quality heating.

Principle of operation

This model works almost the same as a conventional solid fuel boiler. Firewood is loaded into the furnace, which is located below, and the heat that is released during the combustion of wood is heated by a heat exchanger with water that enters the heating system. An additional heating element maintains the required temperature, preventing the coolant from freezing. After burning firewood, it turns on automatically.

What to Look for When Buying an Electric Wood Boiler

A combined boiler that runs on wood and electricity is worth buying, given the main parameters:

- power;

- the presence of a coil for hot water - the second circuit;

- grate material for sifting ash, when using firewood, it is better to give preference to cast-iron grates, they are the most heat-resistant, ceramic grates are suitable for bulk materials - straw or wood chips;

- unit weight - some models can weigh more than a dozen kilograms, so additional floor reinforcement may be required before installation;

- furnace size;

- valve for silent operation of the boiler;

- the material of the heat exchanger, it can be steel or cast iron, the latter are heavier in weight and can crack from temperature extremes, but, unlike steel, they will save you from corrosion.

The use of combined heating systems will ensure reliability, high performance and efficiency heating your home.

Popular manufacturers and their offers

There are quite a few companies that produce solid fuel boilers, among them there are several of the most popular. Our rating of the best boilers of 2018.

Buderus Logano

Price: 100,000 -109,000 rubles.

| Advantages | Flaws |

| High quality construction, manufacturer's warranty up to 20 years | High price |

| Reliable automation | |

| Ease of installation |

Stropuva

This Baltic brand has been known in Russia since 2008, Stropuva units are reliable and an impressive volume of the fuel chamber, they are able to work on one tab for up to 5 days, if coal is used, for firewood this limit is limited to 30 hours.

This Baltic brand has been known in Russia since 2008, Stropuva units are reliable and an impressive volume of the fuel chamber, they are able to work on one tab for up to 5 days, if coal is used, for firewood this limit is limited to 30 hours.

Price: 52,000 - 65,000 rubles.

| Advantages | Flaws |

| High efficiency, at least 90% | Large unit weight |

| economical consumption | Lack of built-in automation |

Protherm

The Czech company Protherm has been present on the Russian market since 2011, during which time the company's products have gained wide popularity due to such qualities as reliability, ease of installation and maintenance, as well as the energy independence of heating devices of this brand.

The Czech company Protherm has been present on the Russian market since 2011, during which time the company's products have gained wide popularity due to such qualities as reliability, ease of installation and maintenance, as well as the energy independence of heating devices of this brand.

Price: 52,000 - 60,000 rubles.

| Advantages | Flaws |

| not expensive | Manual ignition |

| Efficiency up to 90% | small firebox |

| Built-in automation |

Zota

To whom, if not Siberians, to know what cold is, the Krasnoyarsk enterprise Zota is known for its combined models of boilers. The versatility of the equipment allows the use of various types of fuel - gas, firewood, coal or diesel fuel, with such a set of options it is impossible to be left without heat, even in hard-to-reach areas.

To whom, if not Siberians, to know what cold is, the Krasnoyarsk enterprise Zota is known for its combined models of boilers. The versatility of the equipment allows the use of various types of fuel - gas, firewood, coal or diesel fuel, with such a set of options it is impossible to be left without heat, even in hard-to-reach areas.

Price: 34,000 - 40,000 rubles.

| Advantages | Flaws |

| Built-in automation | Low efficiency, 70% |

| Low price | |

| Built-in electric heater |

Teplodar

A characteristic name for the products of a Russian company, which fully justifies it. Boilers Teplodar are versatile, there is always the opportunity to change wood or coal for pellets or gas, this does not require the replacement of the unit, it is enough to install the appropriate burner. Under this brand, many different models are produced, both expensive and budget.

A characteristic name for the products of a Russian company, which fully justifies it. Boilers Teplodar are versatile, there is always the opportunity to change wood or coal for pellets or gas, this does not require the replacement of the unit, it is enough to install the appropriate burner. Under this brand, many different models are produced, both expensive and budget.

Price: 30,000 - 90,000 rubles.

| Advantages | Flaws |

| Large selection of models by type and fuel | Additional equipment must be purchased separately |

| Built-in heater |

Teplodar Kupper

This product of the Teplodar plant allows the owner not to think about problems with the purchase of fuel - any one will do. The unique design of the Kupper brand is the basis for the efficient operation of the equipment, its efficiency is one of the highest among analogues.

Kupper Pro

Another successful development of the Teplodar company is the Kupper Pro long-burning boilers, the entire line of this series has an efficient heat exchanger and a water-cooled grate, the units are equipped with an additional door, there are three of them on the front side.

Don

Another Russian representative in the market of solid fuel boilers, Don heat generators are produced at the Rostov Concord plant. They have earned their popularity due to their versatility and reliability; the manufacturer uses high-quality boiler steel for the manufacture.

Siberia

The NMK plant from Novosibirsk specializes in the production of inexpensive budget models, but despite the reasonable price, Siberia brand units are very efficient, high efficiency is ensured by a grate made of pipes and beams at the outlet of flue gases, also filled with coolant.

In conclusion, a few video reviews

Indeed, solid fuel equipment can be installed without thinking about poor infrastructure or remoteness from large settlements. You can always choose a model that will provide heat and hot water to residential or industrial premises in the most adverse conditions.

Universal water heaters

Today, many consumers prefer to use powerful multifunctional equipment for space heating, so they install combined heating boilers at home. Such devices make it possible to use gas and electricity (or other combinations) as an energy carrier.

These are technological units that have the ability to switch to another type of fuel with minimal modifications. Some models combine solid propellant components, while others combine solid propellant with liquid or gaseous.

Internal organization

Particularly popular with combined devices for heating a private house was their versatility, thanks to which any type of fuel can be used. This effect is due to the special design of the device:

- two chambers for different types of fuel (solid, gas, electricity);

- integrated heater;

- several outputs for different heating circuits;

- inflatable burner.

Additional outputs for connecting the heating system make it possible to heat several rooms at the same time, besides, they reduce the main length of the radiator pipes.

Device advantages

Universal models have the following advantages:

- operate simultaneously on different fuels;

- reliable;

- operate offline;

- can serve as a backup heating option;

- comfortable to use.

autonomy

Experts note that combined boilers provide complete autonomy. So, you can use the main and bottled gas for heating until the system is connected to the central gas supply.

The universal design will allow you to maintain heat in the home if the electricity is turned off. Solid propellant units, having structural elements for switching to gas or liquid fuel, reduce the complexity of their maintenance process.

If you run out of liquid fuel, then with the help of a combined boiler you can heat the house with firewood. If, due to bad weather, it is not possible to prepare firewood, then using the built-in tubular electric heaters, you can heat the cottage using electricity. This will prevent the system from defrosting and keep the inhabitants of the house from freezing.