- Types of combined boilers

- Combined gas and liquid fuel boilers

- Combined boilers for gas, liquid and solid fuels

- Combined boilers with electric heater

- Combined heating stoves

- What should be guided

- gas boilers

- Electric boilers

- Solid fuel boilers

- Oil boilers

- How to choose the right boiler?

- Types of gas boilers

- With open combustion chamber

- With closed combustion chamber

- single circuit

- Dual circuit

- Disadvantages of combined boilers

- "Extra" energy consumption

- Decrease in efficiency

- Lack of automatic control

- High final cost

- Furnace equipment

- Combined dual-fuel heating boiler

- Combined heating boiler for gas and liquid fuel, GAS / Diesel

- Combined heating boiler SOLID FUEL (HF)/GAS

- Combined heating boiler Solid fuel/Electricity (TEN)

- Design features

- How the installation works

- Benefits of installations

- Materials for the manufacture of heating boilers

Types of combined boilers

Today, there are many types of combined boilers for heating private houses. Each of them is worth considering in more detail.

Combined gas and liquid fuel boilers

The design difference between the boilers operating on these energy carriers is minimal, which is why the rational decision of the developers was to combine them. Boilers can run on gas (natural and liquefied) and diesel fuel. The transition between fuel types is carried out by adjusting the burner settings (depending on modifications in manual or automatic modes). At the same time, the operating mode and the generated power remain unchanged.

When buying combined boilers for home heating, they prefer to use gas as the main type of fuel, for its relatively low price, safety of use and environmental friendliness. Diesel fuel is often used as a second energy carrier, for which it is necessary to separately prepare a container and a storage room. The removal of exhaust gases is carried out according to the same technology for gas and liquid fuels. It is advantageous to use these boilers for constant heating of private houses and industrial premises with a large area.

Combined boilers for gas, liquid and solid fuels

The main difference of this type from the boilers discussed earlier is the presence of a furnace for solid fuel: fuel pellets, briquettes, firewood and other materials. The huge advantages of boilers of this type are versatility and low cost, both of the boilers themselves and of the energy carriers used.

The disadvantages include: low efficiency, a weak level of automation, the construction of a gas exhaust chimney. These boilers are used most often in small private houses or in summer cottages; it is not economically feasible to heat large private houses.

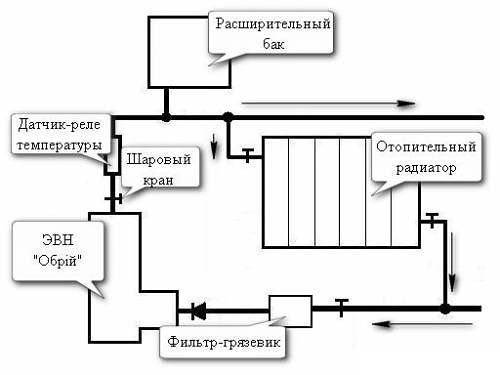

Combined boilers with electric heater

Unlike the above boilers, which use combustion energy to heat water, this boiler additionally uses electric heating. Due to the low power output, it will not be possible to heat a private house or a room with electricity alone, but in combination with gas, liquid or solid fuels, this is an excellent option.

The main advantages: a high level of automation and efficiency, the ability to use in regions with an unstable supply of the main type of fuel, reliability and multifunctionality. Thanks to automation, when the temperature in a private house drops below +5 degrees, the boiler turns on water heating in an economical mode, this function is implemented to prevent freezing of the heating system.

Combined heating stoves

For a long time, in private homes, traditional brick stoves were used for space heating. Modern technologies allow them to be re-equipped and, as a result, a furnace with a combined heating system is obtained, thereby significantly increasing efficiency, heat transfer and functionality. To do this, you can install several heat exchangers, a boiler for direct or indirect heating, and equip a coarse. These operations can be performed either completely or separately, depending on financial capabilities and the availability of free space in a private house.

Performed modifications of combined ovens:

- installation of the hob - in addition to heating a private house, it allows you to additionally cook food;

- installation of a burner for gas or solid fuel - increases the efficiency of combustion of the energy carrier, increasing the heat transfer from one unit of conventional fuel. The recommended option is a gas burner that does not create unpleasant odors in the house;

- installation of a heat exchanger for water heating - will allow heating a private house evenly around the entire perimeter. Minus - long-term heating of water in the pipes of a private house.

What should be guided

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we distinguish several types of boilers.

gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive, it is available to a wide range of consumers. What are the boilers gas heating? They differ from each other depending on what type of burner - atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products leave through a special pipe with the help of a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall mounted gas boiler

As for the method of placing the boilers, the choice of a heating boiler assumes the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to conduct hot water, then you can install modern wall-mounted heating boilers. So you will not need to install a boiler for heating water, and this is a financial savings. Also, in the case of wall-mounted models, combustion products can be removed directly to the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall models is their dependence on electrical energy.

Electric boilers

Next, consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. Such types of heating boilers are small in size, so they can be used in small houses, as well as in cottages from 100 sq.m. All combustion products will be harmless from an environmental point of view. And the installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and prices for it are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as spare appliances for heating.

Solid fuel boilers

Now it's time to consider what solid fuel heating boilers are. Such boilers are considered the most ancient, such a system has been used for space heating for a long time. And the reason for this is simple - fuel for such devices is available, it can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not able to work offline.

Gas generating solid fuel boiler

Modification of such boilers are gas generating devices. Such a boiler differs in that it is possible to control the combustion process, and the performance is regulated within 30-100 percent. When you think about how to choose a heating boiler, you should know that the fuel used by such boilers is firewood, their humidity should not be less than 30%.Gas-fired boilers depend on the supply of electrical energy. But they also have advantages in comparison with solid propellant ones. They have a high efficiency, which is twice as high as solid fuel appliances. And from the point of view of environmental pollution, they are environmentally friendly, since the combustion products will not enter the chimney, but will serve to form gas.

The rating of heating boilers shows that single-circuit gas-generating boilers cannot be used to heat water. And if we consider automation, then it is great. You can often find programmers on such devices - they regulate the temperature of the heat carrier and give signals if there is an emergency danger.

Gas-fired boilers in a private house are an expensive pleasure. After all, the cost of a heating boiler is high.

Oil boilers

Now let's look at liquid fuel boilers. As a working resource, such devices use diesel fuel. For the operation of such boilers, additional components will be needed - fuel tanks and a room specifically for the boiler. If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this, replaceable burners or special burners are used, which are capable of operating on two types of fuel.

Oil boiler

How to choose the right boiler?

The only objective criterion for choosing a combined boiler for your home is the required power to ensure the functioning of the heating system. Moreover, this indicator should not be affected by the number of connected circuits.

It makes no sense to pay more for a powerful boiler in the hope of adjusting its operation with automation. This approach contributes to the "idle" operation of the device, which leads to a faster failure. In addition, this mode of operation contributes to the acceleration of the condensation process.

As for the calculation of power, theoretically, to heat an area of 10 m2, it will be necessary to use 1 kW of heat energy.

But this is a rather conditional indicator, which is adjusted based on the following parameters:

- ceiling heights in the house;

- the number of floors;

- degree of building insulation.

Therefore, it is advisable to use a one-and-a-half coefficient in your calculations, i.e. in calculations, increase the margin by 0.5 kW. The power of a multi-circuit heating system is calculated with a surcharge of 25-30%.

So, in order to heat a building with an area of 100 m2, a power of 10-15 kW is required for single-circuit heating of the coolant and 15-20 kW for double-circuit heating.

To select a gas burner for a solid fuel boiler, you need to accurately measure the dimensions of the combustion chamber. It is these proportions that will correspond to the size of the gas burner

An equally important criterion when choosing a combined heating boiler is the price category. The price of the device depends on the power, the number of functions and the manufacturer.

For users, other characteristics are no less important:

- DHW;

- material of manufacture;

- ease of management;

- dimensions;

- accessories;

- weight and installation features;

- other.

The issue with hot water supply will immediately have to be resolved: a boiler will provide hot water or there is an electric boiler for this.

In the case of determining the first option, the preferred method is chosen - storage or flow, as well as the parameters of the water reservoir according to needs (calculated based on the number of residents).

As for the dimensions of the equipment, they only matter in the case of installation in a room with a small area.

According to the material of manufacture, a wide range of boilers is presented. But the most popular options are steel or cast iron. Also, such a boiler is able to withstand a high and prolonged temperature load, has a longer service life.

Judging by the intensity of sales and relying on consumer reviews, the following models are actively in demand:

Automation of control affects the usability, and the security system depends on how automated the process of combustion of energy carriers is. Most models can be controlled using convenient remote controls or panels.

Most models are optional. This includes the presence of a hob for cooking, injectors, draft regulators, burners, a soundproof casing, etc.

The choice of a boiler according to this parameter should be based on personal preferences and the allocated amount for the purchase.

When choosing a heating boiler with a combination of wood / electricity, it is necessary to calculate the required power of the heating element. It is recommended to choose models with an indicator of at least 60% of the required coefficient for home heating

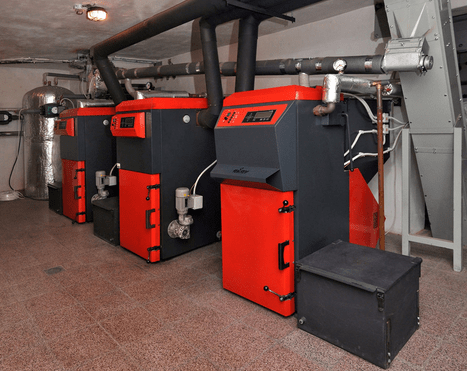

But the weight of the equipment and the complexity of its installation should immediately pay attention.Installation in a residential building of most floor models of combined boilers for heating, equipped with several combustion chambers, requires an additional concrete pedestal device, because a standard floor covering cannot withstand such a load

The best solution is to equip a separate boiler room

Installation in a residential building of most floor models of combined boilers for heating, equipped with several combustion chambers, requires an additional concrete pedestal device, because a standard floor covering cannot withstand such a load. The best solution is to equip a separate boiler room.

Knowing the main parameters that affect the choice of a combined boiler, you can choose the most suitable model.

Additional selection recommendations, as well as a comparative overview of different heating units for a private house, are given in.

Types of gas boilers

With open combustion chamber

Boilers with an open combustion chamber use air to maintain the fire, which comes directly from the room with the equipment located there. Removal is carried out using natural draft through the chimney.

Since a device of this type burns a lot of oxygen, it is installed in a non-residential specially adapted room with a 3-fold air exchange.

These devices are absolutely not suitable for apartments in multi-storey buildings, since ventilation wells cannot be used as chimneys.

Advantages:

- simplicity of design and, as a result, low cost of repair;

- no noise during operation;

- a wide range of;

- relatively low cost.

Flaws:

- the need for a separate room and chimney;

- unsuitable for apartments.

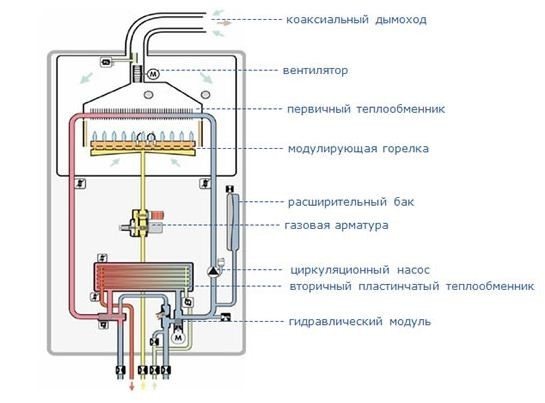

With closed combustion chamber

For units with a closed firebox, there is no need for a specially equipped room, since their chamber is sealed and does not come into direct contact with the internal air space.

Instead of a classic chimney, a horizontal coaxial chimney is used, which is a pipe in a pipe - one end of this product is attached to the appliance from above, the other goes out through the wall. Such a chimney works simply: air is supplied through the outer cavity of the two-pipe product, and exhaust gas is removed through the inner hole using an electric fan.

This device can be installed both in apartments and houses, and in any room convenient for operation.

Advantages:

- no need for a special room;

- operational safety;

- relatively high environmental friendliness;

- simple installation;

- ease of use.

Flaws:

- dependence on electricity;

- high noise level;

- High price.

single circuit

A single-circuit boiler is a classic heating device with a local purpose: preparation of a coolant for a heating system.

Its main feature is that in the design, among the many elements, only 2 tubes are provided: one for the entry of cold liquid, the other for the exit of the already heated one. The composition also includes 1 heat exchanger, which is natural, a burner and a pump that pumps the coolant - in the case of natural circulation, the latter may be absent.

When installing hot water, an indirect heating boiler is connected to the CO system - given the possibility of such a prospect, manufacturers produce boilers that are compatible with this drive.

Advantages:

- relatively low fuel consumption;

- simplicity in design, maintenance and repair;

- the possibility of creating hot water using an indirect heating boiler;

- acceptable price.

Flaws:

- used only for heating;

- for a set with a separate boiler, a special room is desirable.

Dual circuit

Double-circuit units are more complicated - one ring is intended for heating, the other for hot water supply. The design can have 2 separate heat exchangers (1 for each system) or 1 joint bithermic. The latter consists of a metal case, an outer tube for CO and an inner tube for hot water.

In the standard mode, water, heating up, is supplied to the radiators - when the mixer is turned on, for example, washing, the flow sensor is triggered, as a result of which the circulation pump turns off, the heating system stops working, and the hot water circuit starts to function. After closing the tap, the previous mode resumes.

Advantages:

- providing hot water to several systems at once;

- small dimensions;

- simple installation;

- affordable cost;

- the possibility of local shutdown of heating for the season "spring-autumn";

- a large selection, including design;

- ease of use.

Flaws:

- DHW flow diagram;

- accumulation of salt deposits in hard water.

Disadvantages of combined boilers

"Extra" energy consumption

This drawback comes to the fore in combined boilers, in which the main or auxiliary fuel is electricity.Each heating installation using liquid, solid or gaseous fuel for heating the coolant must be connected to a chimney. If the design of your universal heating boiler allows the use of solid fuel electricity, then in this case an increased consumption of electricity is inevitable. This is due to the fact that part of the heat from the water heated by the heating element in the heat exchanger will escape through the chimney.

Decrease in efficiency

Heating installations using solid fuel as the main one have the lowest efficiency, which is associated with the low heat capacity of this type of energy resource. Depending on the fuel used, the design of the chimney and the heating unit itself, the presence or absence of automatic control, climatic factors and a number of other parameters, the efficiency of the boiler will increase or decrease. But even in the most optimal conditions, the efficiency of such a device will rarely exceed 80%. The low cost of solid fuel and the possibility of using the boiler as a waste disposal plant offsets this disadvantage.

By launching the heating element to heat the coolant in the combined boiler, you “agree” in advance to an even greater decrease in the efficiency of the heating installation (although this figure is one of the highest for electric boilers). This is due to the reduced size of the tank used for heating the coolant, in which it is impossible to integrate many heating elements. In addition, the use of electricity as an auxiliary energy carrier causes the inclusion of low-power heating elements in the design of the installation for autonomous heating of premises.This feature of boilers using electricity as fuel is most typical for high-power models.

Lack of automatic control

Devices for autonomous space heating, using solid fuel as the main source of heat, have a high rate of inertia. In simple words, when loading coal, firewood, briquettes or other solid fuel into a universal heating installation, it will either be very hot or cool in your house. This makes it impossible to accurately adjust the thermostats that control the air temperature in the rooms. Therefore, manufacturing companies "save" on automatic control systems for combined boilers, using simpler automatic control systems.

The low control parameters of automation for the control of universal boilers further reduce the efficiency of combined apparatuses that use solid fuel as the main fuel.

If the combination boiler has a sufficiently high-level automatic control system, then you find yourself “tied” either to a certified service center that has a license to carry out repairs from the manufacturer, or to service centers that can repair such auto-control systems, whose services are also not cheap. .

High final cost

Regardless of the number and types of combined boilers used for heating a house with additional energy resources, its cost will be lower than buying each type of boiler separately. But the total operating costs will always be higher.

Furnace equipment

The use of combined heating boilers may require the equipment of a special room, which can be critical for houses with a relatively small area. This is related to the need securing your home and family, as well as ensuring an adequate supply of fuel, for example, if coal and electricity are needed to operate a heating installation for a private house.

What to do, give up trying to save money and put up with additional costs or a decrease in the comfort of your own home? No, you can install two boilers, each of which will use one of the energy resources at your disposal. It will be more expedient and it is such a solution that will save you money in the long run.

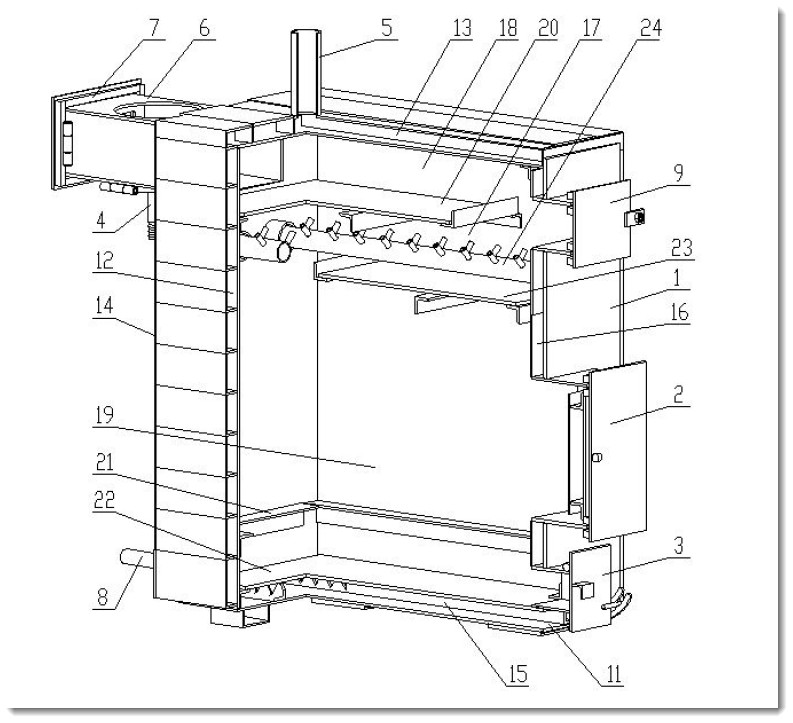

Combined dual-fuel heating boiler

Combined boilers with various fuel combinations are produced. In such boilers, one type of fuel is the main one, the second is additional. Usually, a purchased set of a dual-fuel boiler is designed for the main type of fuel. To operate on additional fuel, the purchase of additional equipment is required. True, there are also boilers that are fully equipped to work on all the prescribed types of fuel.

Combined heating boiler for gas and liquid fuel, GAS / Diesel

Dual fuel heating boiler with gas/diesel or diesel/gas fuel types are the most popular. Gas is popular because it is relatively cheap, liquid fuel is popular because of its availability. The transition from one fuel to another is made by replacing the burner, of course, if a combined burner is not used.As a rule, one burner is included in the purchase kit of a dual-fuel gas / liquid fuel boiler, the second will have to be purchased separately.

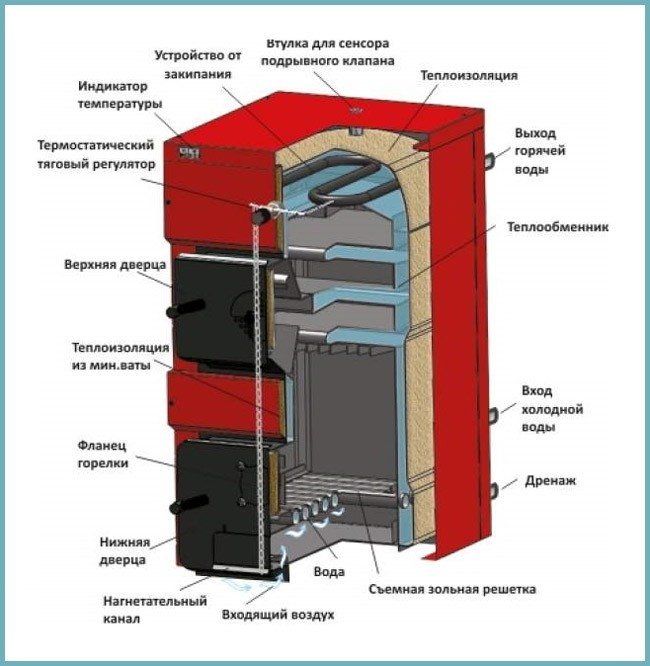

Combined heating boiler SOLID FUEL (HF)/GAS

Solid fuel boilers have been and most likely will be consistently popular. In a combined dual-fuel heating boiler, gas (natural or liquefied) can be the second fuel. The transition to gas is carried out by replacing or installing a gas burner.

Combined heating boiler Solid fuel/Electricity (TEN)

In addition to gas in combined boilers, together with solid fuel, an additional heating chamber is used, powered by electric heating elements. The power of heating elements is about 4 or 9 kW.

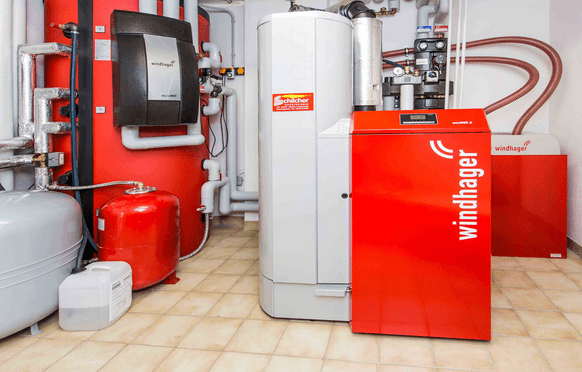

Design features

The range of heating boilers is represented by different models. Some operate on gas, others on electricity, and others on liquid fuel. Each variety has its own operational advantages and disadvantages. The disadvantages of using certain installations haunt designers and technicians. Therefore, they decided to combine some models, and combined heating devices were born. They can operate, for example, on solid fuel and gas at the same time.

Such a combination made it possible to minimize emergency risks and organize the operation of the same solid fuel boiler in an autonomous mode. How do such installations work, and where is their use more than justified? As a rule, universal boilers are always supplied with an additional number of nozzles. They can be used to connect underfloor heating, heating radiators, greenhouse control systems, heating water in a pool or heating a sauna.

The gas burner in such a boiler is located below the combustion chamber, where firewood, briquettes, sawdust or coal are laid. Therefore, if necessary and switching, it allows you to completely burn the remaining solid fuel. If the work is transferred to solid fuel, the gas burner automatically closes. For ease of use, a steel heat exchanger responsible for space heating runs through the entire body. All walls are thermally insulated with special mineral wool, so the efficiency of the unit is almost 92%. And this is a very high figure.

The DHW heat exchanger is made of copper and is located at the top of the unit. Copper is not afraid of corrosion, so the service life of the coil is equal to the service life of the entire device as a whole. Universal boilers have lever and air dampers, which ensure the supply of the necessary portion of air.

How the installation works

The principle of operation of the gas-firewood boiler is trivially simple. The design uses two autonomous cameras. The furnace is located above the gas. This feature allows you to use two types of fuel at the same time. Gas burners are capable of operating at low pressure. Therefore, you can often see models that are not connected to the central gas pipelines, but to liquefied gas cylinders.

Note! When disconnected electricity boiler gas-firewood can't run on gas. And all because the products of its combustion in this case will not be independently removed through the chimney to the outside, and condensate instantly accumulates on its walls, clogging the chimney. If there is no light in the house, the boiler is heated exclusively on wood

If there is no light in the house, the boiler is heated exclusively with wood.

Benefits of installations

There are quite a few advantages for gas-firewood boilers, so we will only indicate the most basic ones:

- The main factor is the ability to save money and use cheap firewood instead of expensive blue fuel. If the firewood runs out, you can switch to gas in automatic mode.

- The combined design allows the use of autonomous heating. Gas ensures the operation of the plant at night without additional fuel loading. It is also nice to come home after work to a well-heated house, knowing that the gas will maintain the right temperature when there is no one to throw firewood into the stove.

- Universal combined boilers can have one or two circuits, thanks to which the installation can be used not only for heating, but also for supplying hot water for technical needs. Today, universal gas-firewood boilers are understaffed with storage boilers, and there are models that can heat water to the desired temperature in a flow way. The choice is great, and it pleases.

But before deciding to purchase such installations, experts recommend studying features of their operation and disadvantages.

Materials for the manufacture of heating boilers

When choosing a heating boiler, it is necessary to take into account the material from which it is made. Most often, boilers are made of steel or cast iron. Steel boilers are lightweight, they are not afraid of temperature changes, since steel is ductile. But the body of the unit may be subject to corrosion.

Cast iron equipment is heavy, which makes it difficult to transport and install. In addition, cast iron can crack if cold water is poured into a hot boiler. But at the same time, corrosion of cast-iron units is not terrible.

Heat exchangers for boilers are also made of steel or cast iron, less often copper

When choosing a heat exchanger, it is important to pay attention to the protective coating on the internal surfaces. Thanks to him, soot does not accumulate on the walls, and this is a guarantee of uninterrupted heat transfer of equipment and a reduction in fuel consumption.

The service life of cast iron and steel boilers is different. Cast iron can be used for 20-50 years, and steel - only 15. But, as a rule, a steel unit is operated longer than the allotted time. If the owner monitors the boiler, cleans the internal walls of the heat exchanger in time and changes parts, then the equipment can last longer than the period set by the manufacturer.

When choosing a heating boiler for your home, look in the tables below to see how much this or that heating system will cost you, taking into account fuel consumption. It is clear that the gas boiler is the most economical. The complexity of the installation lies only in the installation of the chimney. If there is no gas on the site, then the solid fuel boiler is the second most economical. Of course, this is just an approximate selection of equipment for a boiler room in a house. When deciding which boiler is better to choose, the final decision remains with the owner, especially since new high-tech and economical models are constantly appearing on the market.