- Pros and cons of core drilling

- Related video: Well drilling technology

- Choice: with or without filter?

- Technological features of core drilling

- Technology features

- Varieties of drilling tools

- Features of auger drilling

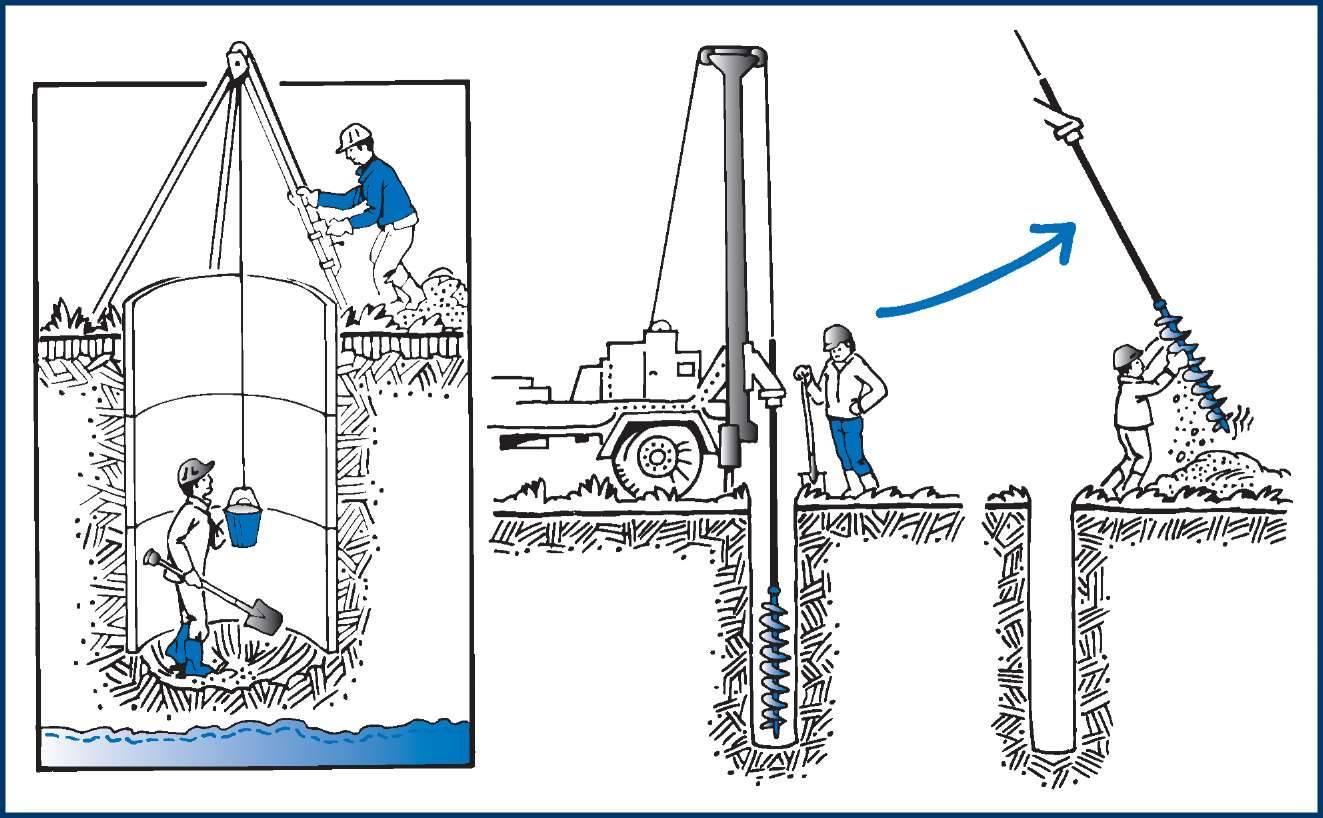

- Mechanical methods of well construction

- Mechanical methods of drilling aquifers

- Features of the column method

- Features of the mechanical rotary method

- Features of the screw method

- A source outside the perimeter or a well in the house?

- How to make a well in the country

- Principle and technology of work

- Features of core drilling at the exhibition

Pros and cons of core drilling

The positive aspects of the process include:

- The point action of the crown, which cuts the rock along its radius, unlike the rotary bit, destroys the soil during the passage.

- High performance method.

- Possibility by means of core drilling to study the underground structure of soils in the work area.

- Using this method, raise, multilateral, deviated wells are passed; in any layers, including basalt and granite.

- The rotational speed of the drill is adjustable: on soft ground, rather small revolutions, hard rocks require higher ones.

- Relatively high rate of penetration, which reduces the cost of the object, with a reduced energy intensity of the process.

As with any process, core drilling has some disadvantages:

- In those processes where slurry is used, there is a risk of siltation of the aquifer by the washing products.

- Rapid tool wear.

- Dry drilling is too costly.

When working with deep formations, these factors remain decisive. The cost of equipment, together with the price of ground work, is a solid figure.

The core drilling process takes place in several stages, the equipment is subject to regular inspection for damage and chips.

Masters undergo regular safety training, this precaution significantly reduces the percentage of damage

Related video: Well drilling technology

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

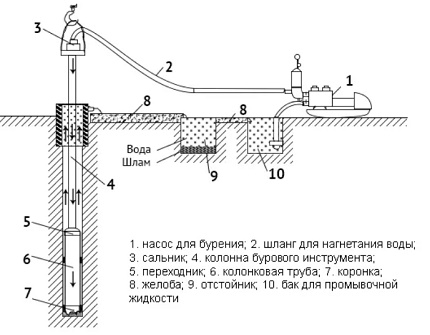

Choice: with or without filter?

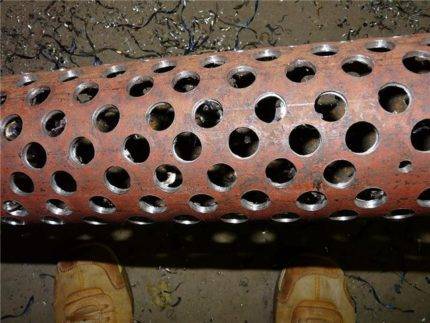

To prevent contamination from entering the well, a second pipe with a well filter is installed inside the wellbore. It is made from a long piece of pipe, the diameter of which must be less than the diameter of the casing. The upper part of the pipe is used for the stuffing box, and many holes are made in the middle part.

On the section of the pipe from which the filter for the well is made, a number of frequent and sufficiently large holes should be made. Such perforation will ensure the rapid flow of filtered water into the well.

The perforated section is covered with a lace weave mesh, but in extreme cases, a regular fine-mesh mesh, for example, with parameters 0.2X0.13, is also suitable. The mesh can be fixed with wire.

The lower part of the filter is a sump, where perforation is not needed. If it is possible to lower the filter into the well, arranged by the auger method, using interconnected rods, then when percussion-rope drilling is performed, the filter is delivered using a metal cable.

The perforated filter for the well should be covered with a metal mesh of galloon weaving and fixed with stainless steel wire. Instead of a network of galloon weaving, you can take a regular, fairly fine mesh

This does not allow pressing the filter with force to ensure the tightness of the structure when connected to the stuffing box. In this case, you can effectively use PSUL - pre-compressed sealing tape. This material is widely used in the installation of PVC windows.

Such a tape should be wound around the edge of the filter and immediately lowered into the shaft, since the PSUL expands rather quickly. If the filter is lowered immediately after winding the tape, it will expand at the bottom and provide a good filter seal. After the filter is lowered down, the casing pipe is carefully lifted up.

PSUL - pre-compressed self-expanding sealing tape is used when installing PVC windows, but is suitable for creating a borehole filter gland.It is necessary to wind the PSUL about 30 cm in the upper part of the filter and immediately lower it into the well

In this case, most of the filter should be below the level of the edge of the casing. Two five-ton jacks can be used to lift the pipe. The part of the pipe that is brought to the surface is cut off or unscrewed. To prevent the clamp from slipping, pieces of reinforcement are welded to the protruding piece of pipe.

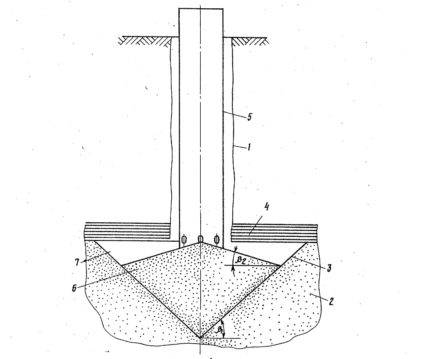

The shock-rope method of drilling allows you to create a filterless well. To equip it in this way, it is necessary to lower the casing pipe below the aquifer by about 0.5 meters. With “wet” auger or core drilling, it is difficult to extract a core from a well. The bailer easily removes loose, water-saturated clastic rocks.

Scheme of the device of a filterless well: 1 - well; 2 - aquifer - horizon; 3 - water intake funnel; 4 - roof; 5 – casing string; 6 - sand; 7 - a cavity formed in the process of pumping sand with an airlift

After the casing is firmly installed, two hoses are lowered into the well. On one of them, a stream of water is supplied to the well, and on the second, air is injected with the help of a compressor. Thus, the so-called airlift is obtained, and the flow of water prevents the formation of a sand plug.

As a result, a mixture of water, sand and air will go through the casing pipe, which must be drained into a separate container. When the mixture settles, the volume of sand washed up from the well should be measured. According to reference books, each cubic meter of such sand is equal to approximately 4.5 cubic meters of debit.

Another article, which we advise you to read, will introduce the core and auger method of drilling a water well.

Technological features of core drilling

If the hole diameter is within 1m, the penetration angle can be adjusted. Core pipes 40-60 cm long are reused for their intended purpose. During operation, the drill bit is subject to wear and requires replacement.

Features of core drilling of a well for water.

Before starting a new diamond crown, the bottom of the well is treated with a chisel. This measure extends the life of the tool. The drilling rig must be on a horizontal platform.

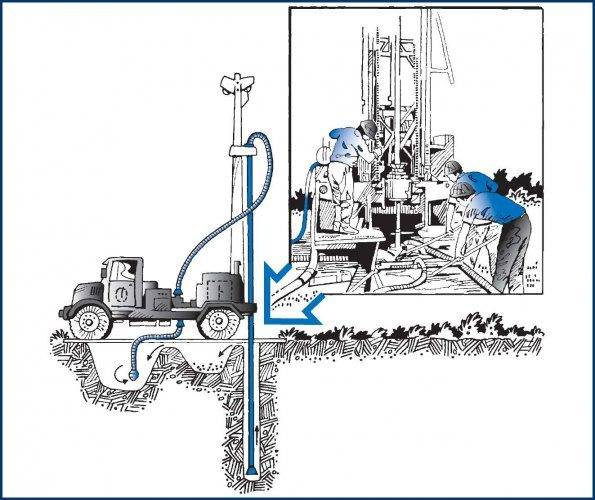

The system is mounted on the chassis of vehicles with a large load capacity. Caterpillar special equipment is used to work in difficult terrain. Drilling of wells for water is carried out using mobile equipment.

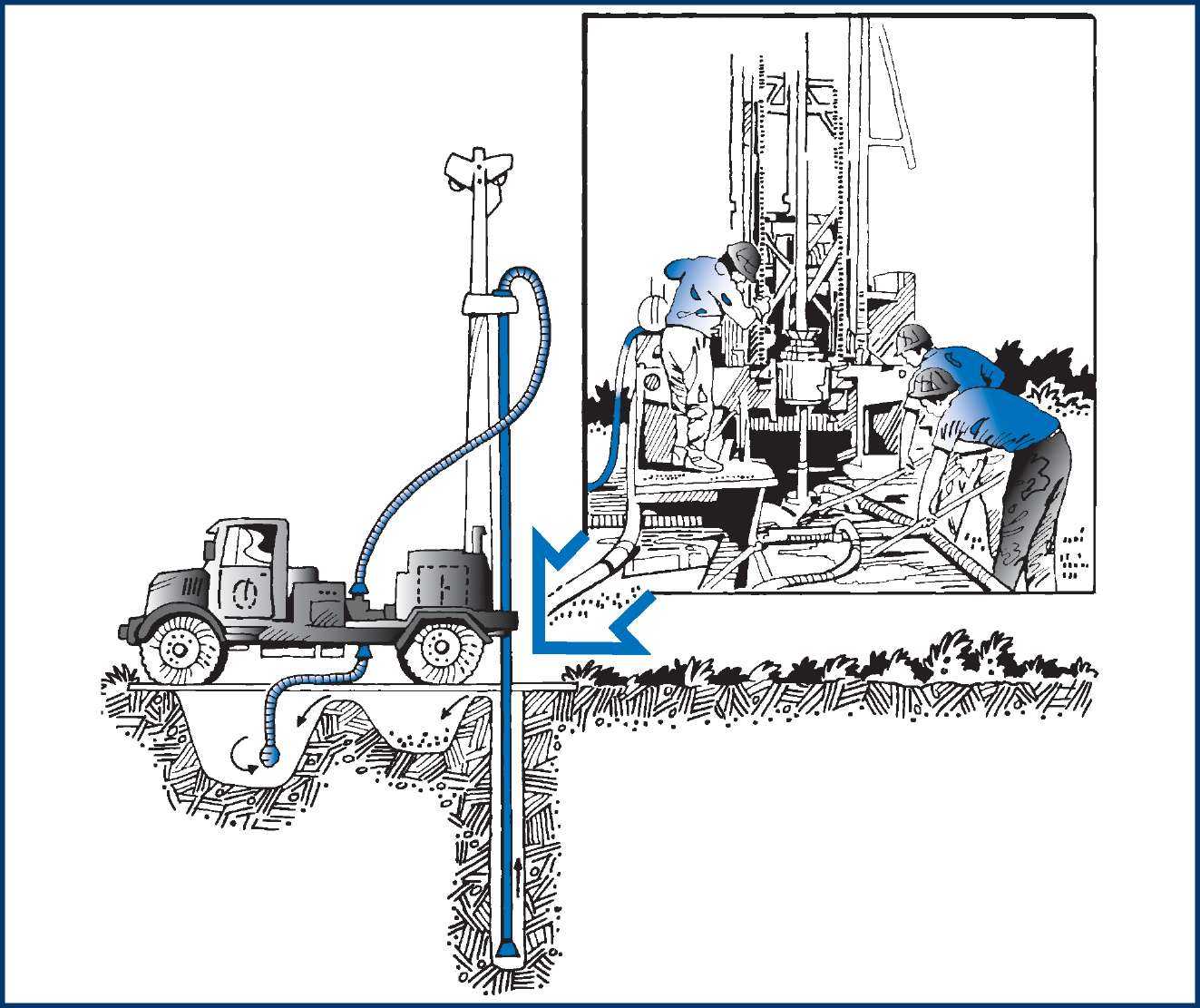

Technology features

With the core method, the pressure on the soil is carried out by special crowns in the form of hollow cylinders with cutters on one side. The cutters are able to drill soils of various hardness, thanks to the work at high speeds. In order for the tool to last longer, the rock is processed in advance with a drill bit. When working with hard rocks, strict observance of the alignment of the component elements of the tool is required, for which calibration is carried out using a carbide expander.

Core drilling can be carried out at any angle of inclination to the surface. The wells worked out at the same time are distinguished by a small diameter with sufficient depth. The machine itself weighs a little, so it is quite maneuverable.Diametric processing allows you to extract an integral part of the soil and analyze it, taking into account the natural sequence of layers.

A prerequisite is the presence of a flushing procedure, in which the machine is washed with water or clay solutions that protect the well from collapses. The final stage is excavation with a screw machine.

Varieties of drilling tools

The main working tool for drilling a well and lifting soil is a drill. For various drilling methods are used:

- An auger, or coil, is used for a rotary drilling rig when passing medium-density soils - loam, sandy loam, clay and earth. It is equipped with a metal nozzle with sharpened edges that perform soil drilling.

- A glass, or Schitz projectile, is used for viscous and dense soils in cable-percussion drilling rigs.

- The spoon is used for loose and moving soils - sandy, gravel. The drilling method is rotary and percussion-rotary.

- The bailer is used to clean the borehole channel from semi-liquid and loose soil mixtures remaining after the passage of the bit. Intended for cable-drilling installation.

- The chisel is used for passing hard and stony rocks. It is a special plate with rounded edges with a caliber equal to the inner diameter of the casing string minus 5 mm. Designed for cable-percussion drilling method.

The cutting elements of the drills are made of hardened steel sheets with a thickness of 3–5 mm.

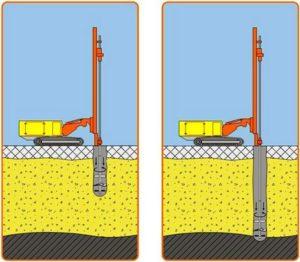

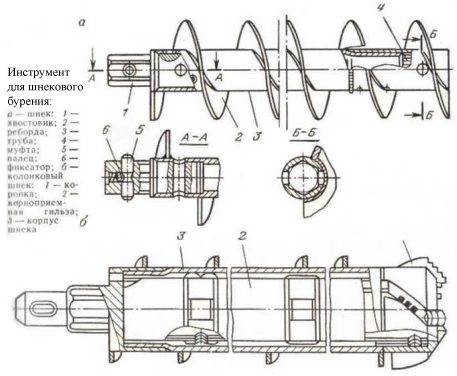

Features of auger drilling

This type of drilling is most often used today in the construction of aquifers in private households.A feature of auger drilling is that the developed rock is completely removed from the alignment. wells without additional equipment. The method resembles screwing, allows you to drill to a depth and at the same time remove unnecessary soil.

The tool used for drilling is called an auger. It is a metal rod with blades. Screwing into the ground, the auger destroys the rock that lingers on its blades. Due to the specific design of the auger, it is impossible to completely free the face from the dump. Therefore, it is mainly used for sinking the upper layers.

Drilling using an auger does not require much effort and financial costs, so the scope of this method is quite wide: exploration wells, laying communications, arranging bored wells and partially drilling for water. It is now actively used for the construction of Abyssinian wells, so as not to completely clog the needle-hole into dense soil, but to slightly facilitate the process of immersing the trunk into pre-destroyed rock.

The method is suitable for the development of aquifers up to 30 m deep on soft and loose soils and up to 20 m on medium-dense ones. After auger driving and casing installation, the wellbore must be cleaned with a bailer from unextracted rock.

The auger is categorically not suitable for working in rocks! It is used for partial drilling of wells up to 120 m, while this method is combined with others: rotary, shock-rope, core.

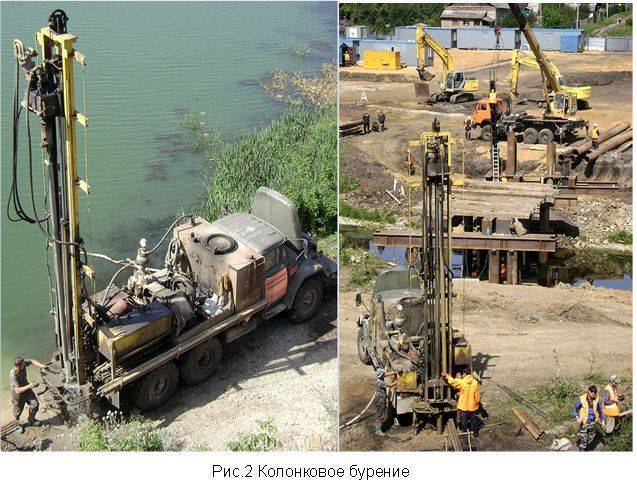

Core drilling is used to perform exploratory wells with great depth, sinking into rocky horizons, laying artesian wells.The method has a number of advantages, which are the mobility of the installations, the possibility of sampling rocks. Extraction of core material to the surface makes it possible to study the geology of the site and substantiate the prospects for further research and development.

Drilling of a well on water kolonkovy.

Mechanical methods of well construction

The most effective mechanical method is the core method of drilling wells. With it, you can get a well of considerable depth (up to 1000 m). More often this method is applicable in rocks. The process consists in the rotation of a drill string equipped with a strong nozzle. Choose a method because of the speed of penetration. In the process, it will be necessary to use small and maneuverable installations that provide a high level of efficiency, which is due to the destruction of the soil not by continuous, but by the annular slaughter.

Well drilling can also be carried out in a rotary way. The technology requires the use of a bit fixed on a rotating projectile. The method is successfully used in extremely hard soils. The method has earned the title of the most productive method.

Advantages of mechanical drilling:

- the ability to drill a well for water to a considerable depth;

- excellent water pressure, due to the fact that it is possible to use a submersible pump;

- high pass speed.

Cons of mechanical drilling:

- the inability to carry out work on their own without the involvement of specialists;

- the need to rent expensive machinery and equipment;

- big costs.

Mechanical methods of drilling aquifers

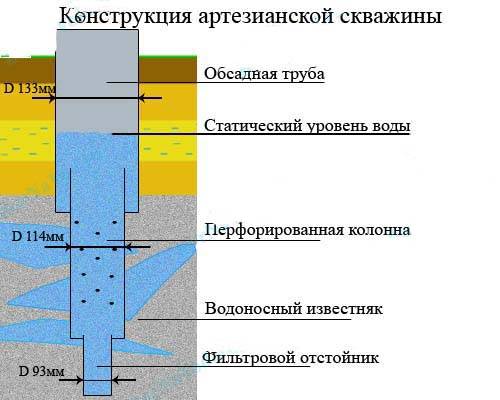

Artesian well device.

Mechanical drilling is performed using nozzles made of hard alloys. They are located on the drilling projectile. It also requires heavy equipment.

Wells made in this way are characterized by high productivity and excellent water quality. This category of method of drilling sources for the extraction of water, in turn, is divided into subtypes.

Thus, the following main 3 types that are used in modern engineering hydrogeology can be attributed to mechanical methods:

- mechanical rotary subtype;

- columnar subtype;

- screw subtype.

Features of the column method

Photo of a diamond crown.

Core drilling of wells is considered a good effective option from the category of mechanical method, in which the worked out soil is an integral rod called a "core". It is expedient to use this method for bottomhole wells with a large depth indicator (up to 1000 m) in areas dominated by rocks.

Core drilling technology is performed by rotating the drill string, which has a high-strength nozzle that looks like a diamond crown.

In addition to these advantages, this method has several other important advantages:

- excellent drilling speed;

- core drilling rigs are characterized by compactness and good maneuverability;

- due to the fact that the destruction of the rock occurs not by a continuous method of slaughter, but by an annular method, the efficiency of drilling increases.

The disadvantages of this method include the fact that with the help of it it is possible to make wells only with a small (up to 15-16 cm) diameter. Also, when they are formed in this way, the wear of drill bits occurs quite quickly.

Features of the mechanical rotary method

Photo of the mechanical rotary method.

The technology of rotary drilling of wells includes the use of a bit, which is fixed on a drill string capable of performing rotation. It, in turn, is driven by a specially built-in device called a "rotor".

This drilling method is considered one of the most productive, as it allows you to reach deep aquifers, where the purest water is located without various compounds, including iron. Also, drilling wells using a rotary method makes it possible to achieve a high stable flow rate of the source on almost any soil.

Perhaps, the disadvantages of this method include the high consumption of both clay and water, which are needed for the manufacture of the flushing mixture, as well as the fact that during the flushing of the trunk itself, clay elements enter the aquifer. All this, of course, makes this method of well formation more laborious.

The chisel in the mechanical rotary method must be cooled with water.

In addition, in winter, certain difficulties arise when choosing this method. This is explained by the fact that in this case it will be necessary to heat the flushing mixture, which is not at all easy to do in such volumes.

Features of the screw method

Device tool for auger drilling.

This method is considered the most optimal for creating shallow sources in areas where loose soils are located. Using the auger drilling option, work on the formation of a well for the extraction of drinking water is carried out quite quickly.

Moreover, this method does not require the employment of highly skilled workers and the use of heavy special equipment. That is why it is often chosen to create aquifers in private land ownership.

All work with this type of drilling is performed using an auger. This device is a rod with blades and cutters. With the help of these elements, rocks are removed from the borehole channel.

Drilling rig for auger method.

The auger method has the following additional advantages:

- providing high mechanical speed;

- in the process of work, the cleaning of the bottom hole occurs continuously, that is, in parallel with the process of rock destruction;

- it is possible, simultaneously with drilling, to make and lay the walls of the well from concrete or steel, which are necessary to hold the rock in order to prevent its collapse.

A source outside the perimeter or a well in the house?

Homeowners who are still undecided about the best option for themselves should consider accommodation options from all angles.

- Residential building: is there or is it just planned? In the first case, it is better to prefer a street structure, since work and construction are not limited by anything: neither the area that is needed for equipment, nor the depth of the well.

- Selection of the type of source. The minimum deep Abyssinian needle remains ideal for the home, which can be relatively easily arranged for “permanent residence” in the basement. More serious wells are still better to build on the street.

- Expenses. If a residential building has not yet been built, then internal work will cost half as much as external work. When it is already completely ready, the situation is the opposite: the construction in the house will be 2 times more expensive than outside it.

- The possibility of using special equipment: both “now”, and in the future, for maintenance. The best place is at the gate, next to the road. In this case, it is possible to provide a removable section in the fence.

Service life is another important criterion. It is believed that street wells are more durable than those that are protected at home. There is another option - a well located under the building, but not under the residential (workshop, garage, separate cellar, greenhouse). It is better if it is possible to partially dismantle the structure in order to provide the water source with trouble-free scheduled maintenance or repairs.

How to make a well in the country

Almost every owner of a country house, and even a villager, wants to have a well on his site. Such a source of water from which it would be possible to constantly obtain high-quality water.

It is worth noting that if the water is at a depth of up to ten meters, then such a well can be drilled independently. This is not such a laborious process as it might seem at first glance. We need a standard pump. It will pump out water and at the same time, in a sense, drill a well.

Video-how to drill a well in the country

Let's move on to the drilling process itself. It should be noted that the pipe that we will lower into the well must be located vertically. Water will be pumped into this pipe using a pump. The teeth should be located at the bottom end of the pipe. Such teeth can be made by hand. Water, which is under pressure from the lower end, erodes the soil.Since the pipe is heavy, it sinks lower and lower, and soon reaches the aquifer.

Video-how to drill a well under water

In order to really get drilling, we need only a steel pipe. The radius of such a pipe must be at least 60 mm (preferably more). Such a pipe will serve as a casing pipe. The length of such a steel pipe must not be less than the depth of groundwater. The end of the pipe, which we close at the top with a flange and a special fitting.

To do this, we use a pass-through fitting. Through this element, water will pump through the hose. We also need to use a welding machine. With it, we will weld four "ears" with special holes. These holes should fit the M10 bolts.

As a water tank, we will take a barrel with a volume of 200 liters. In order for us to somewhat speed up the drilling process, we need to shake the pipe and turn it a little either clockwise or counterclockwise. Thus, we will wash out a large amount of soil. For the convenience of pipe rotation, we can use a gate. To do this, take two metal tubes and attach them to the pipe. For these purposes, we can use special clamps.

For drilling, several people are needed (two are possible). In the place allotted for the well, a hole is dug. The depth of such a pit must be at least 100 cm. A pipe is lowered into this pit. And the jagged end down. Next, using the collar, deepen the pipe. It is worth noting that the pipe must be in a vertical position. Next, we turn on the pump. The hole will fill with water. We scoop it out. Then it can be spilled through a sieve and poured back into the barrel.It is quite possible to drill six meters in a few hours.

Here you can read:

how to drill a well for water, how to drill a well for water video, how to drill a well, how to make a well for water, how to make a well for water on the site video

Principle and technology of work

In the basic configuration, core drilling equipment is placed on the chassis of a truck; in working condition, it is able to take a vertical position, as well as tilt at the required angle. However, for more complex work, there are specially designed crawler platforms. This indicates the wide application of this method in different climatic conditions.

The technology of work is as follows:

the drilling mechanism is installed at the site of the upcoming drilling and is firmly fixed on the surface of the earth;

it is possible to use different nozzles, which allows you to work with different soils, including rocks;

this method allows you to raise the soil without mixing it, this is especially important for the subsequent study of the soil;

it is widely used in construction when drilling foundation pits for supporting piles;

will allow you to quickly produce water by creating a domestic well;

designed for the construction of deep wells reaching a depth of several thousand meters.

It is possible to change the speed of rotation of the drilling rig, due to which the process of its heating is controlled and the efficiency of drilling operations increases.

Features of core drilling at the exhibition

Features of core drilling of wells, the technology of its application is covered on the largest industry exhibition "Neftegaz", which takes place annually at the Expocentre Fairgrounds.

This is an international event, which is attended by companies from all areas related to the oil and gas industry.

Well drilling is one of the most topical topics that receive special attention at the Neftegaz exhibition. Among the topics discussed: the development and improvement of equipment, the use of new technologies, as well as drilling methods

Blowout prevention equipment used in drilling