- Types of wells

- Well types

- Types of well houses and their tasks

- Which is better: open or closed options for houses

- What materials can be made

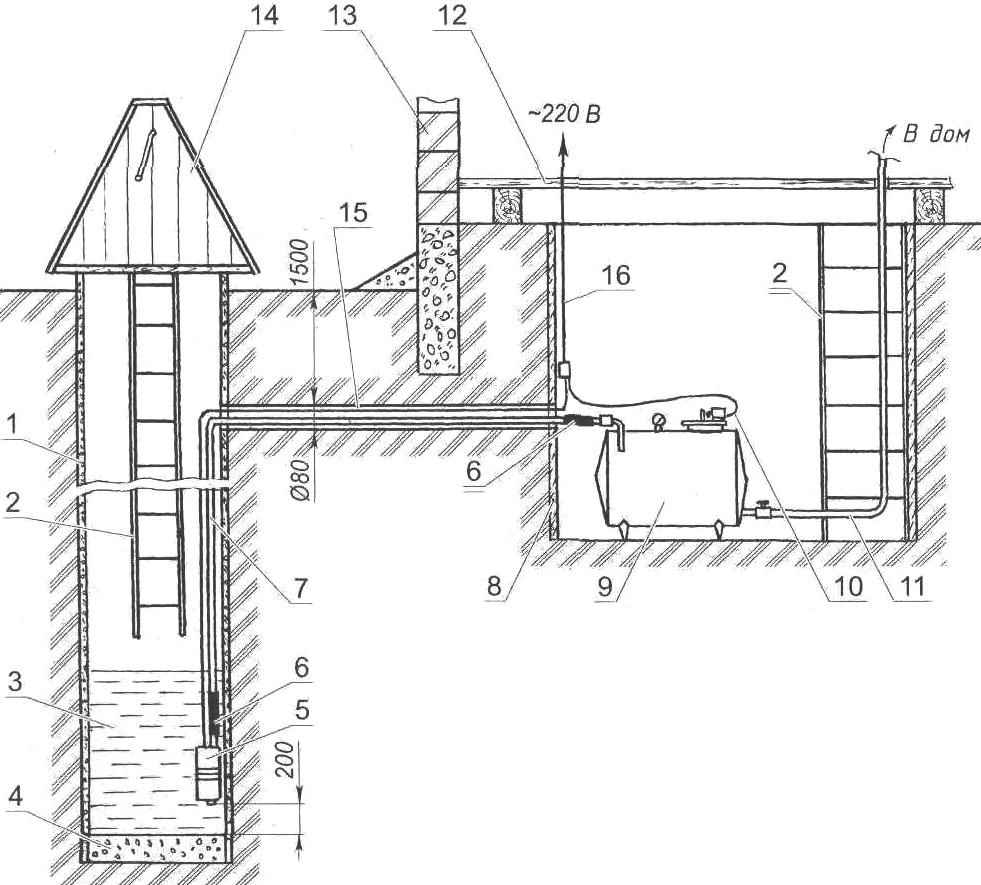

- How to organize an autonomous water supply from a well

- Video description

- Conclusion on the topic

- Two main ways to dig a mine

- Method #1 - Open Digging Technique

- Method #2 - private method features

- Arrangement of a clay castle

- Well digging options

- Closed way

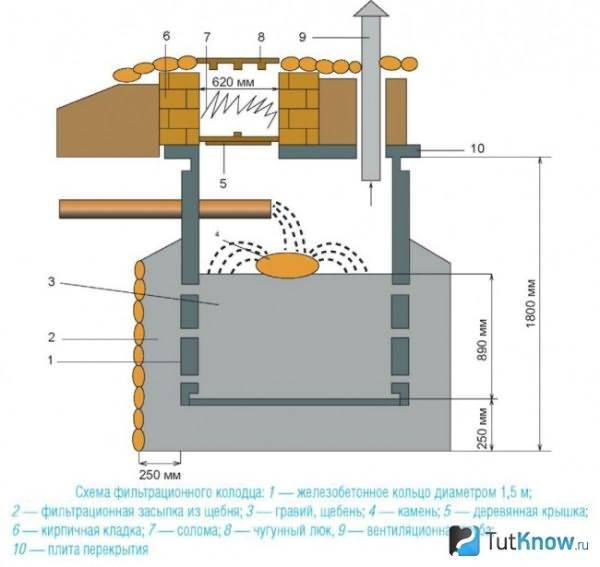

- The place of the sewer in the sewer system

- log house

- Manufacturing technology

- Digging methods

- Alternate installation of rings

- Installation of rings after reaching the aquifer

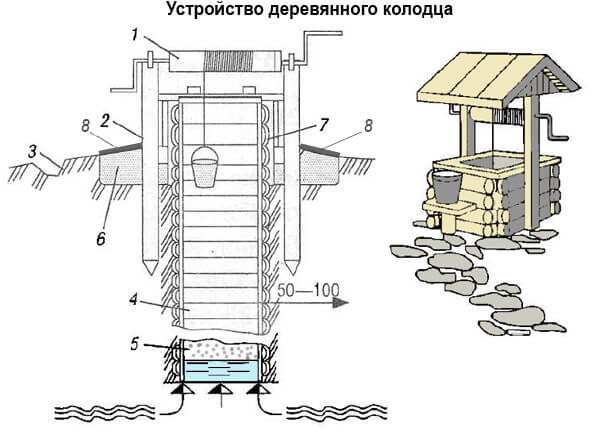

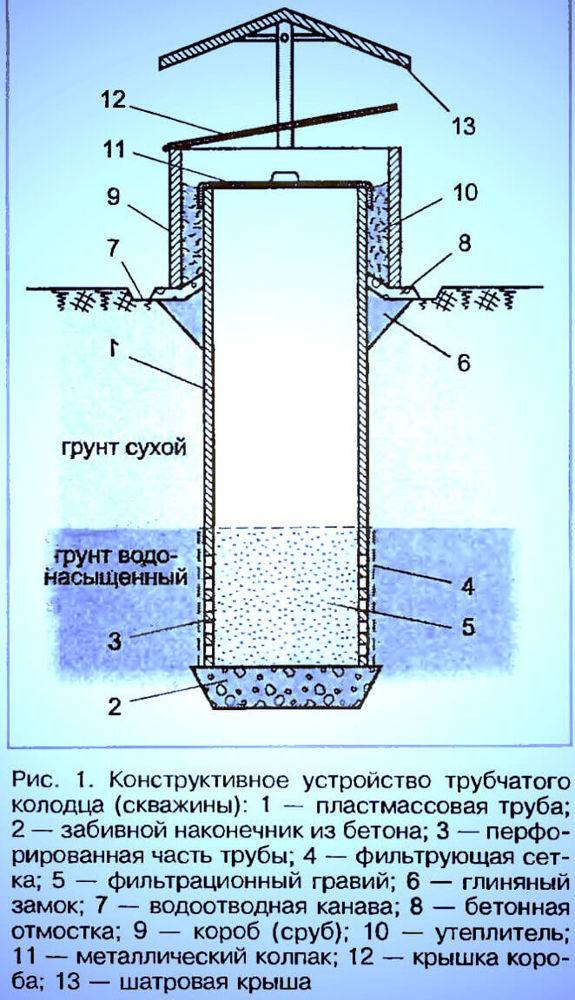

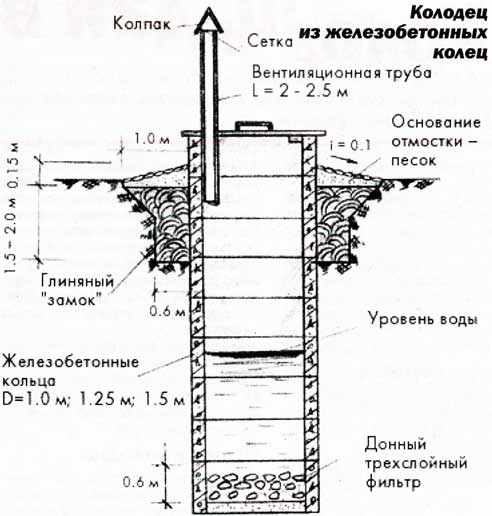

Types of wells

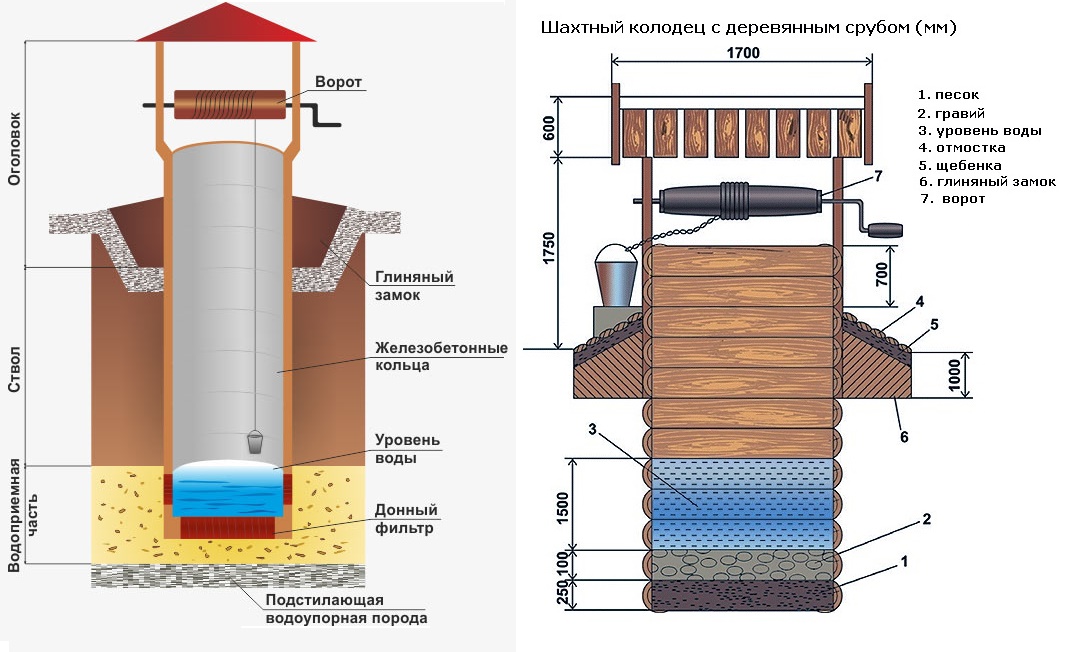

A well is a shaft that reaches the water horizon with water suitable for consumption. Depending on the depth at which the water layer lies, experts divide these hydraulic structures into two types:

- Key or superficial. This is when there is a key in the suburban area, from which the purest drinking water beats. Convenient, inexpensive option.

- Mine. This is when it is necessary to dig up the soil to the water layer, constructing a mine with a round or square section. The depth of the structure can reach up to 10 m.

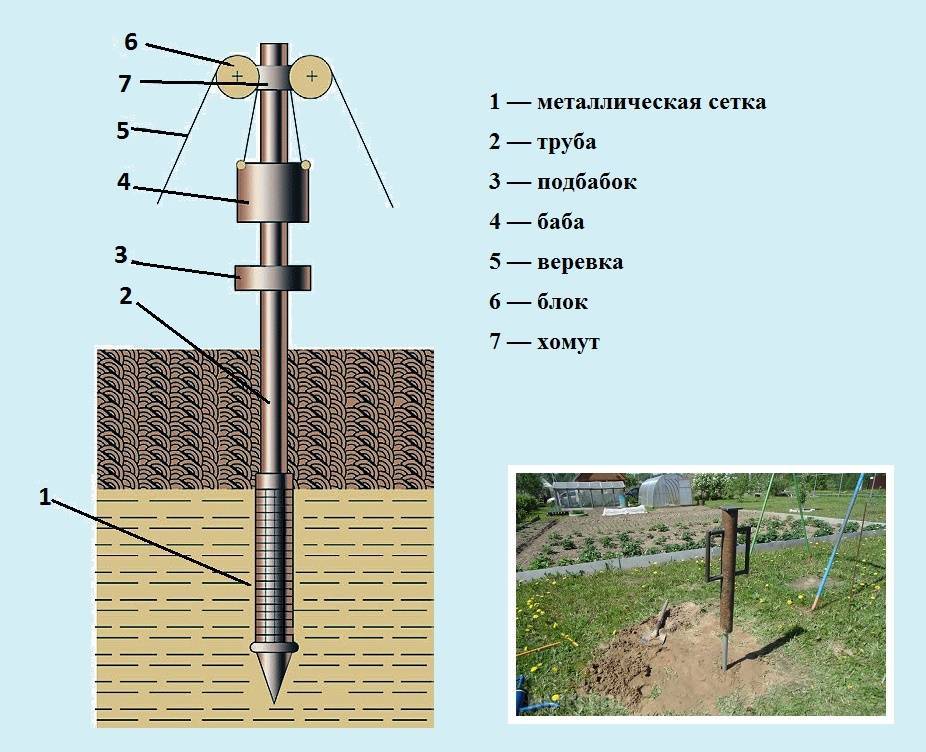

There is such a term - the Abyssinian well. In the form in which we are all accustomed to seeing wells, this structure is not.This is a well formed by a steel pipe that is driven into the ground. To raise the water, either an electric pump or a hand rocker is required. The depth of well formation is up to 30 m.

Key well at their summer cottage

Well types

There are three types that determine the operational supply of water inside the hydraulic structure and the method of its supply to the shaft.

- Imperfect wells. This variety is constructed so that the mine does not rest against solid rock. That is, the walls are formed so that the trunk of the structure is immersed in the aquifer by about 70%. That is, water is taken into the well both through the walls of the building and through the bottom.

- Perfect type. This is when the shaft of the mine rests on solid rock. In this case, water enters the well only through the walls.

- Perfect look with sumpf. The latter is a water collector, which is laid in the lower durable layer. And water enters the structure through the walls of the mine.

Three types of water wells

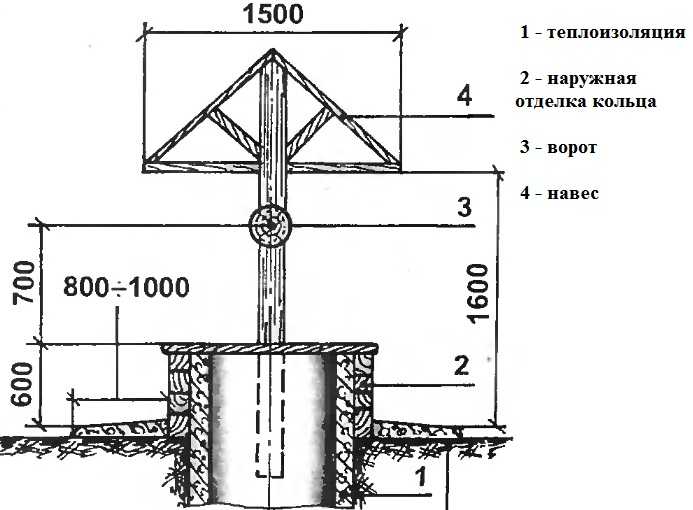

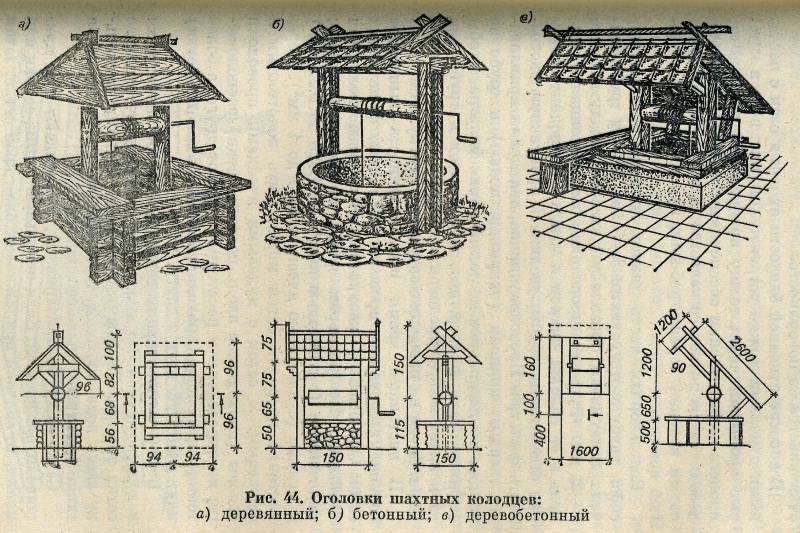

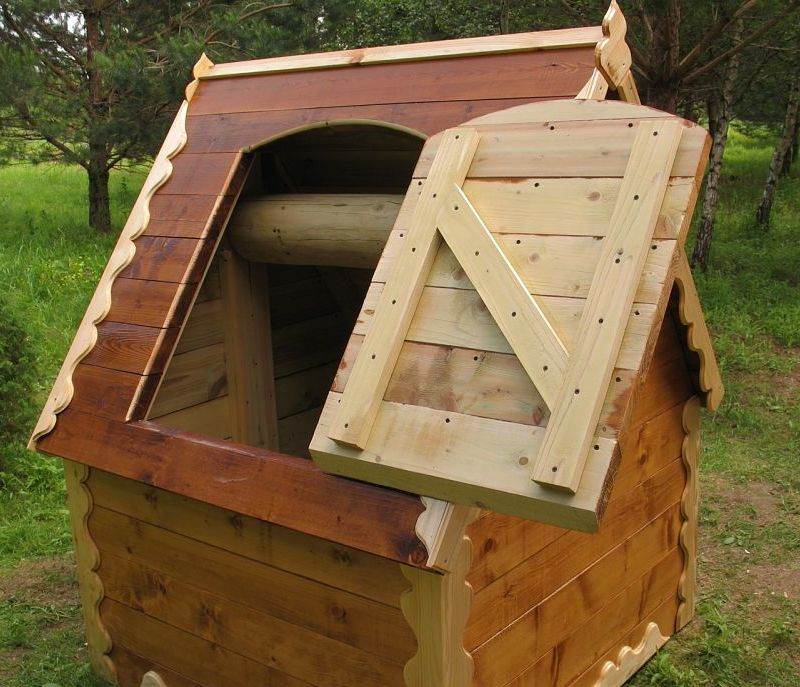

Types of well houses and their tasks

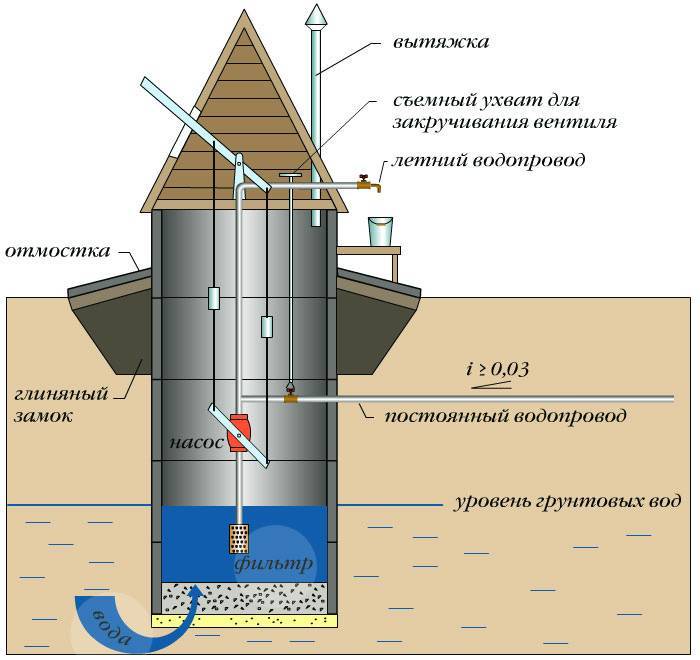

Open well houses provide free access to the mine and are used only to provide technical water. It cannot be used for drinking, cooking and washing dishes.

It has a lot of sewage. In addition, such structures pose a danger to the people around them, children or pets can get into them. Closed wells are more advanced, they are subject to additional requirements:

The main function of this design is to protect the shaft from the penetration of foreign objects, direct sunlight, dirt and dust. To do this, it is enough to install a flat cover that will fit snugly against the upper ring.Protection of the contained water from natural precipitation and various harmful impurities contained in them. To do this, it is enough to make a canopy, provide for low tides

It is important to prevent children and pets from entering the mine. To ensure safety, you will need to install locks and use them constantly

To increase the convenience of raising water, a special lifting device is installed in the form of a gate, with which it will be possible to use this water intake in the absence of electricity.

Compliance with the above measures will contribute to the safety requirements and ease of operation of the water source. Only in this form you can enjoy clean drinking water at any time convenient for you.

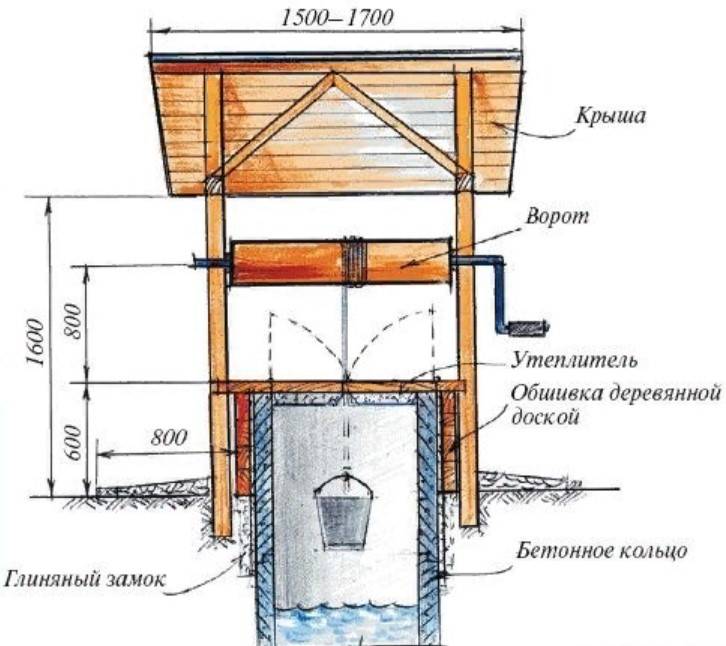

Which is better: open or closed options for houses

From the above, it can be seen that in order to ensure the convenience of using such a source, it is necessary to install a house on a well. It can be open or closed type:

- It will be cheaper to install an open house equipped with a canopy, a lid and a gate to raise water. There will be a minimum of materials for such a design, but in winter it will be inconvenient to use, and sometimes impossible. After all, the water will constantly freeze over.

- For year-round use, you will need to consider options for how to make a closed-type house, which has protection from piercing wind, rain and snow on all sides. The bottom line is that a full-fledged house with walls, a roof and doors is installed on the outside of the ring. As a material, you can use wood, a metal profile, modern thermal insulation.This will significantly add comfort, allow for additional protection of the water supply source from negative factors, and restrict access by unauthorized persons.

The quality of the produced water and the ease of use of the entire structure will depend on this choice.

What materials can be made

When choosing a material, special attention should be paid to the intended appearance of the structure. After all, it should harmoniously fit into the overall design of the courtyard, match its landscape and other buildings.

As always, making a decision comes easy enough:

- Such a structure can be made from a material similar to that used in the construction of a house or other buildings.

- It is possible, on the contrary, to highlight this building with another material, thereby visually separating a part of the landscape with a different design style.

- In any case, the well house should be easily accessible and in harmony with the overall landscape design.

Wood is often used, it is easily processed and allows you to make beautiful decorative designs. However, this material is not distinguished by its durability and requires annual treatment with paints and varnishes. The use of metal, especially stainless steel, looks good. But this material does not always harmoniously fit into the general view of the courtyard.

A modern solution is the use of durable plastic, which can be matched to the color scheme of interest. It is easy to process, does not require annual maintenance. There are many options, in each case it is selected based on the taste of the owners and the desired type of design.

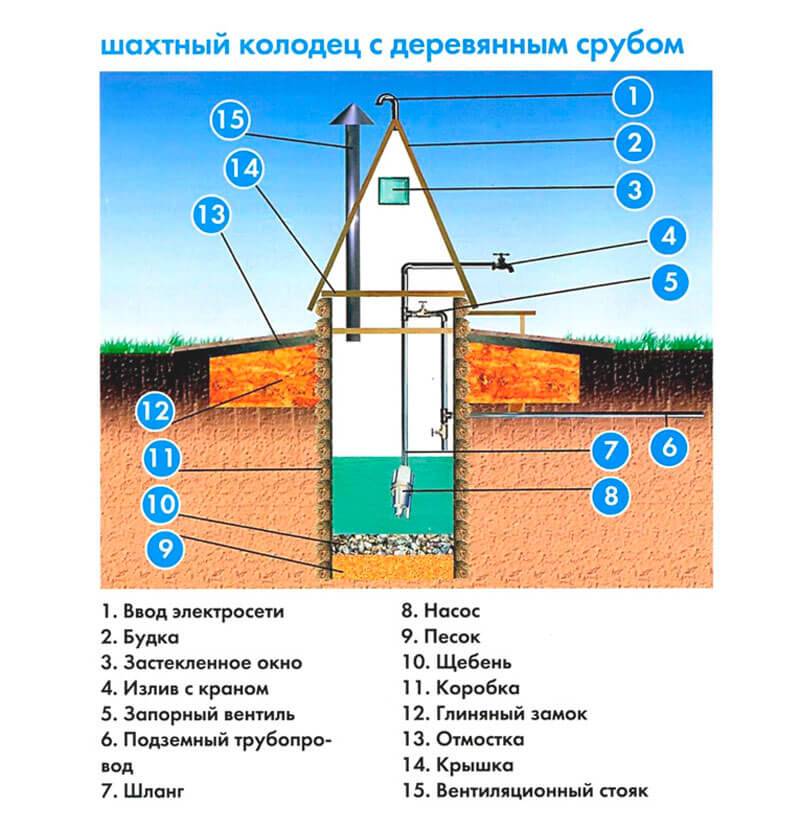

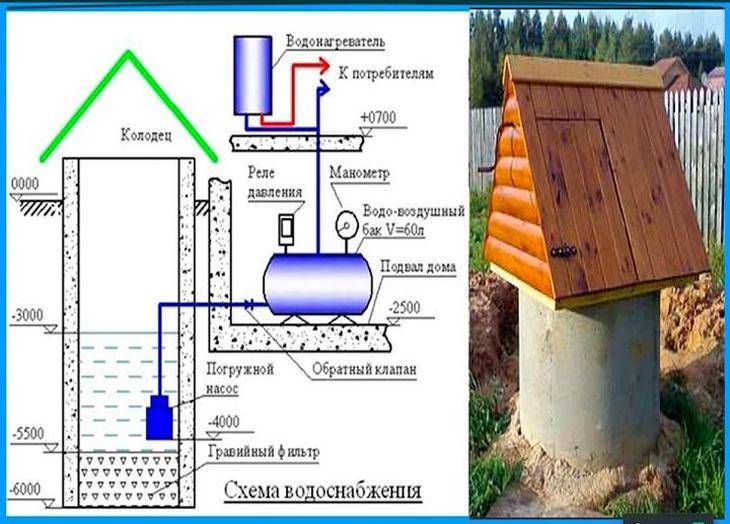

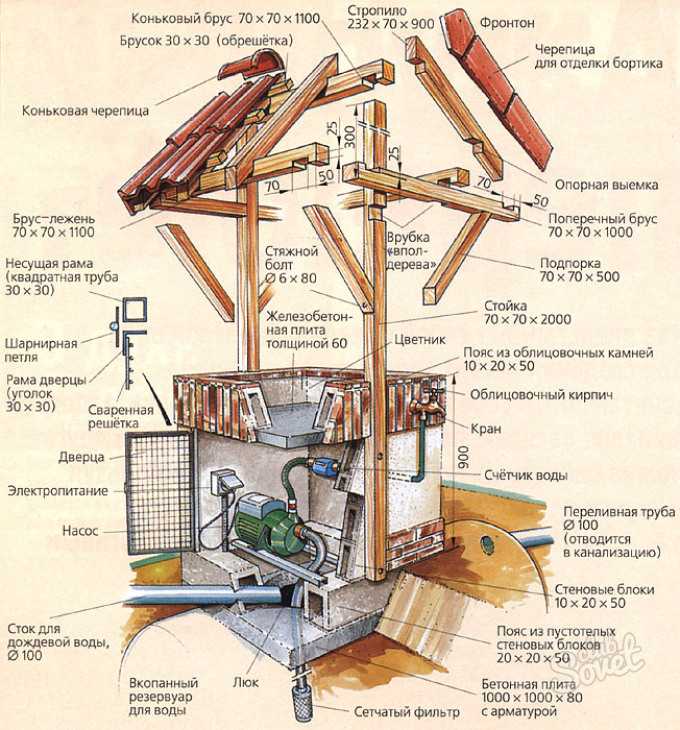

How to organize an autonomous water supply from a well

So, the country well is ready.But do not carry buckets of water from it into the house. If there is enough water in it, then you can organize a small water supply network with a plant right in the house. To do this, you need to choose an electric pump and a plastic pipe.

As for the pump, either a submersible version or a surface one is suitable here. The second one is better because it is always in sight. And if it is necessary to carry out its repair or routine inspection, then there is no need to pull it out of the mine, as a submersible option.

The pump itself is selected by power (capacity - m³ / h or l / s) and pressure. The first characteristic is selected taking into account the required amount of water that is used in the country. For example, the productivity of a standard kitchen sink is 0.1 l / s, a toilet bowl is 0.3 l / s, a valve for watering a garden is 0.3 l / s.

That is, it is necessary to calculate the number of plumbing fixtures that are used in a suburban area, determine the performance of each and add up these indicators. This will be the overall performance of the pump. As for the pressure, it is determined by the depth of the aquifer, that is, the depth of the well.

Installing a submersible pump in a well

If a submersible pump is selected, then it is installed directly in the well shaft, lowering it into the water. It is suspended on a steel cable. A plastic flexible pipe is carried out from the device inside the house. If a surface pump is mounted, then it is installed next to the well: either near the head, or inside the shaft on a special metal stand, or inside the house in a heated room. From it, a pipe is lowered into the well, at the end of which a strainer is installed.And a pipe is also drawn from the device inside the house.

If the cottage is operated only in the warm season, then the pump is dismantled in the fall, the hoses are twisted into a bay. And all this is stored in a dry place. In the spring, the equipment is reinstalled.

Video description

The video shows how easy it is to organize water supply for a country house. houses from the well:

Conclusion on the topic

The arrangement of a well in a summer cottage is a difficult, serious and responsible process. It is impossible not to take into account the rules and regulations for the location of this hydraulic structure

It is important to conduct construction correctly, where the option with a pit drill is the fastest, easiest and safest

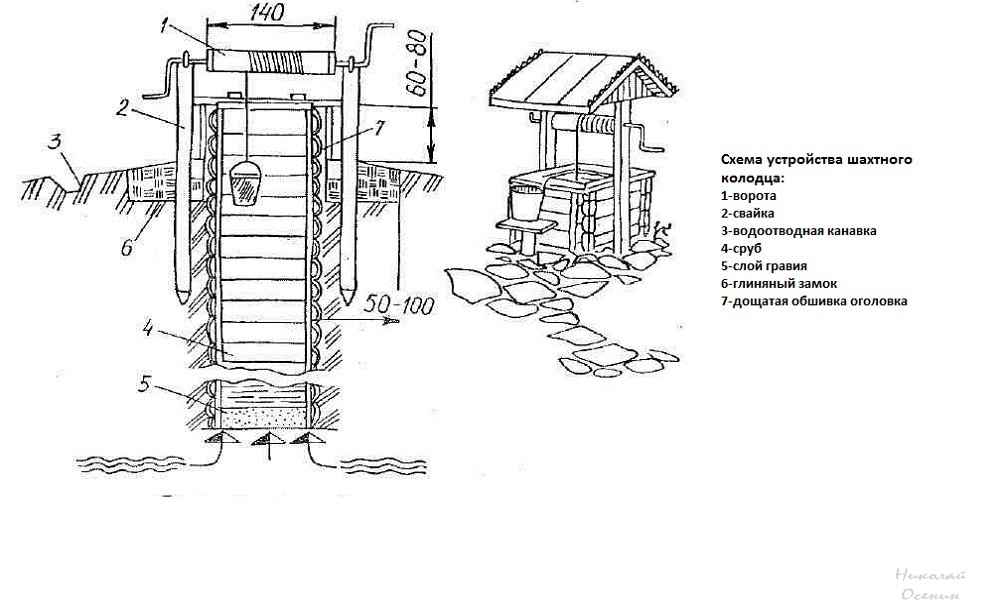

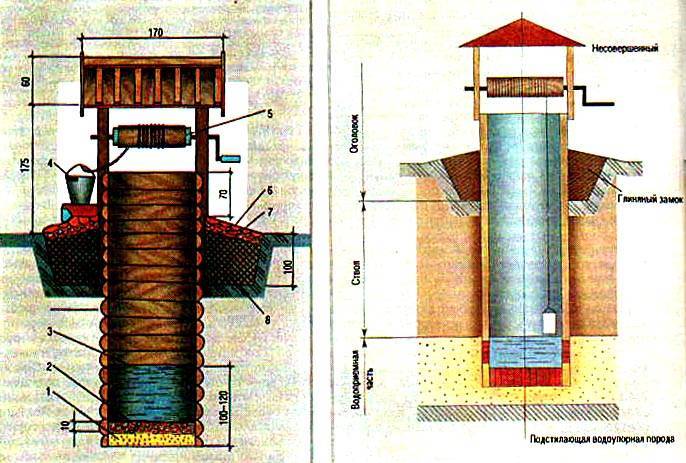

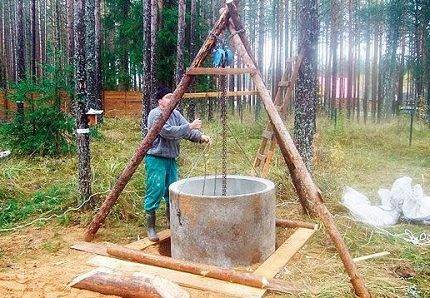

Two main ways to dig a mine

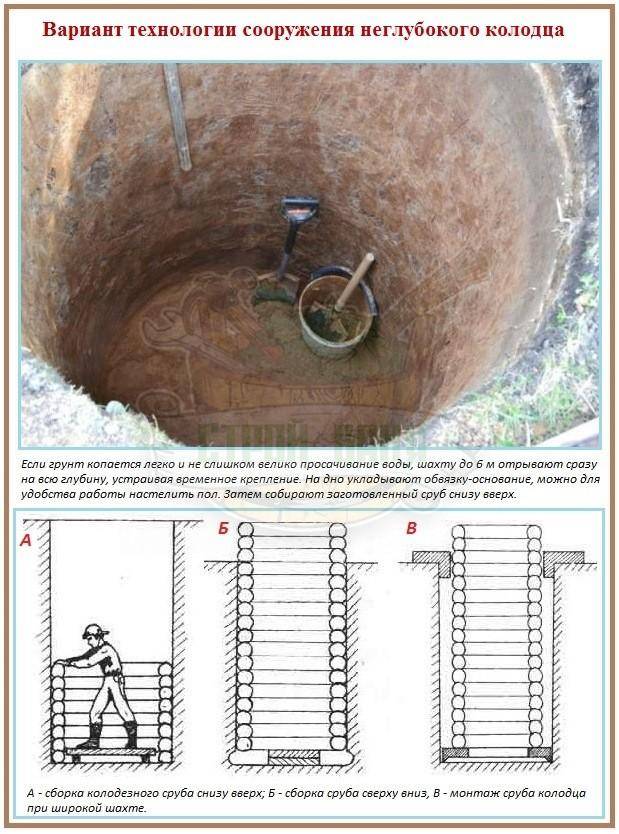

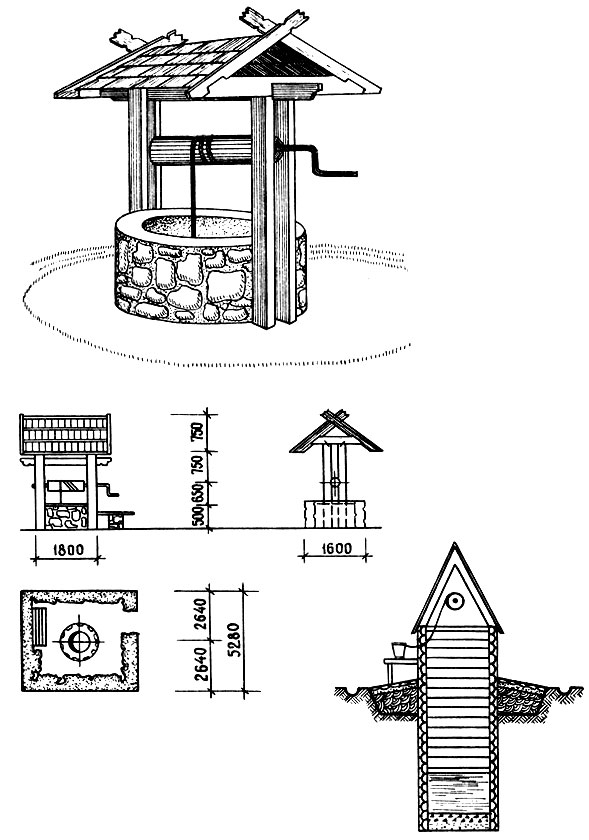

Before digging a well at home or in the country, you should decide on the type of soil and choose the appropriate method for building a mine. There are only two methods - open and closed. They differ significantly, each of them has its own characteristics.

The technology of open well digging is applicable on clay and loamy soils. For sandy and sandy soils, a closed method is more suitable.

Method #1 - Open Digging Technique

The open method of digging a well is convenient and simple. Its essence lies in the fact that you first need to dig a shaft to the desired depth, and then install concrete rings. This method is suitable for areas with dense soil that is not prone to shedding.

The mine is dug to the aquifer. If necessary, the walls are strengthened as they go deeper into the ground. The diameter of the pit should be slightly larger than the calculated dimensions of the finished structure. When the shaft is dug, its walls and bottom are equipped, and the remaining gap is covered with a layer of sand or gravel.

In order for the joints between the rings to be airtight, they are installed on a cement mortar. A good option is to use lock rings, the design of which immediately provides for the possibility of connection. A well of them will be stronger and more reliable

Method #2 - private method features

If the soil on the site is sandy, then the open digging method is not suitable, because. the risk of shedding the walls of the mine is too great. This makes work difficult and can be potentially dangerous for builders. Then use the method of digging a well "in the ring". The technology itself is more complicated than the open method, but safer.

Choosing a place for the well, you should dig a shallow hole for the first ring. The recess can be from 20 cm to 2 m. The diameter must correspond to the size of the rings. Having installed the first ring, they begin to select the soil from the inside of the structure. The heavy concrete ring will sink under its own weight.

Gradually, the first ring will lower so that it will be possible to install the second. It is placed exactly on the previous one, fastened with metal staples and mortar

It is important to avoid distortions, otherwise in the future this will lead to a loss of tightness of seams and joints. So gradually install all the rings

When the walls of the shaft are ready, it remains to waterproof them, equip the bottom and upper part. These steps are the same no matter which digging method is chosen.

The disadvantages of digging technology “in the ring” include the cramped space in which you have to work. It can be extremely uncomfortable for a person, and if the mine is very deep, then psychological discomfort is also possible.

When choosing a digging method, you need to take into account that many nuances arise during earthworks.Sometimes you need to get a large boulder that prevents you from going deep into the ground, or you can stumble upon a quicksand. It is much easier to deal with these problems if the open digging technique is chosen.

The disadvantage of the closed method can be considered the fact that a top water appears in the well. It contains more unnecessary impurities than groundwater, and can pollute the well. It is not always possible to get rid of the top water.

The open method of digging is also not ideal. You have to dig a hole bigger than the well itself. This involves a lot of labor.

Regardless of the chosen method of digging a well, it is best to work with three people. Then one worker can take out the soil, the second one can lift it to the surface. At this time, the third is resting, and if necessary, replaces one of the workers

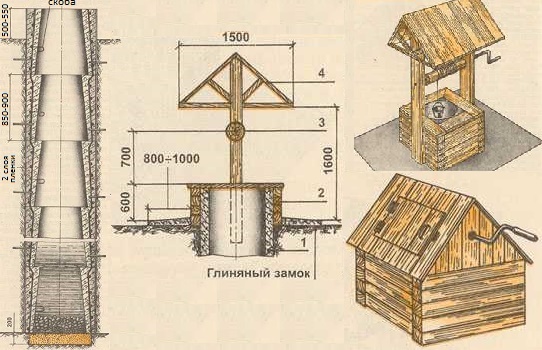

Arrangement of a clay castle

In order for the water in the well to be always clean in the future, it must, among other things, be protected from surface water. To do this, you should equip a clay castle. They make it using this technology:

- clay is diluted with a small amount of water and infused for several days;

- add to the resulting plastic mass of 20% lime;

- around the log house or the upper concrete ring of the well, they dig a pit with a depth of 180 cm;

- lay the clay mass in the pit in layers of 5-10 cm;

- from above they equip a clay blind area;

- crushed stone is poured over the clay, and then earth.

It is advisable to additionally wrap the concrete ring with roofing felt or plastic wrap before arranging the castle.

Well digging options

Experts say that there are two methods of digging wells: open and closed. The latter is sometimes called "in the ring".Both technologies are very different from each other, so it is worth considering each and understanding these very differences.

This digging option is usually used in areas with clay soil. That is, conditions are necessary under which the walls of the excavated mine were dense and strong and did not succumb to destruction in the process of digging the soil.

Control of the dimensions of the well shaft when digging

Here is the algorithm of the operations.

In place of the future well, the size of the future trunk is indicated, which is drawn on the ground with some object, for example, the tip of a bayonet shovel.

Then soil is dug to the entire depth of the well.

In this case, it is very important to accurately observe the dimensions of the pit, not to make the diameter smaller or larger. Moreover, you can’t make it more in one area, less in another

The trunk should be even and vertical, its walls without curvature.

The soil is selected with shovels, better with sappers. He rises to the surface with the help of a bucket and a rope. You can install a winch (manual or electric), which will simplify the lifting process.

It is necessary to dig in this way to the aquifer. As soon as the bottom of the mine becomes wet, then the water is close. It is necessary to dig until at least three keys begin to beat from the ground.

After that, the bottom of the well is cleaned of soil and dirt.

open-cut technology

This is where the digging of the well ends, you can proceed to the construction of the water intake itself

It is very important to strengthen the walls of the well shaft. What different materials can be used for: brick, blocks, stone, logs

Today, reinforced concrete rings are increasingly being installed for these purposes, since the size range allows you to make a well of different diameters. With them, the construction process itself is simplified to a minimum.In addition, concrete rings are durable and reliable products that will last as long in the country as the well itself.

Closed way

The technology "in the ring" is produced in a completely different way. Firstly, it is used both on clay soils and on loose soils. More often the latter. Secondly, only reinforced concrete rings are used to strengthen the walls of the mine. Previously, a structure was assembled in the form of a log house, which grew as the lower parts of the structure decreased. Today it makes no sense to use wood when there is an easier and more reliable option - concrete rings.

Closed digging technology

What is the peculiarity of this version of digging a well with your own hands. The thing is that the ring is first installed at the place of the future well, and then the soil is selected from inside it. In this case, the ring sits in a dug hole. And the deeper you dig, the deeper the reinforced concrete product shrinks. But there are other nuances, this is how the well is constructed in a closed way.

- First of all, a shaft is dug with a depth of 70-80 cm. Its diameter is 15-20 cm larger than the diameter of the ring.

- A concrete ring is installed in it. Since the standard height of this product is 90 cm, the edge will stick out above the ground by 10-20 cm.

- The second is placed on top of the first ring. They must be fastened together with metal brackets or mounting plates. The latter are attached to the rings with dowels (metal) or anchors. A prerequisite is the sealing of the joint between the two rings, for which only natural materials can be used. More often, a hemp rope is installed.

- In this way, all the soil is dug up to the aquifer.Everything else, and this is bottom cleaning and the formation of a water collector, is done in exactly the same way as with open technology.

Supply of soil from the mine

Digging soil from inside the ring is also a kind of technology that can be carried out in two ways. If the well is dug manually on loose soils, then the central part is first selected, then under the walls of the concrete ring. If the soil is hard or clayey, then everything is done the other way around: first under the walls, then in the center.

And one more nuance of the closed technology. The upper last ring does not dig deep into the ground. Its part sticking out above the ground will form the head of the structure.

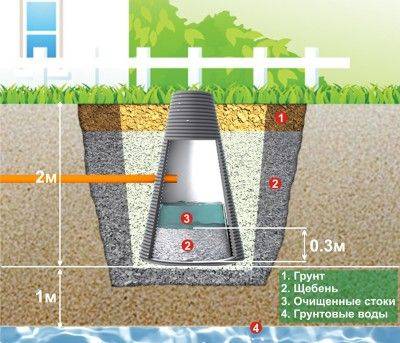

The place of the sewer in the sewer system

Often, there is simply no centralized sewerage system in the private sector with low-rise buildings. And household waste must be disposed of, not poured onto the ground. For this purpose, an autonomous sewage system is being built, including the inner and outer parts.

The internal sewerage system collects effluents from plumbing fixtures, and its outer part is intended for their disposal or accumulation for the purpose of subsequent pumping out by sewers. The effluent-receiving well on the street is the end point of the export local treatment system.

If there is no general sewerage network in the village, then one cannot do without a cesspool or sewage storage near a private house

Fecal effluents in the sewer well are clarified, resulting in the formation of partially purified water and suspensions. In the case of a cesspool, the first is drained into the ground, and the second is decomposed by microorganisms to a state of biologically safe sludge.

If the option with a storage tank is chosen, then sewage is simply collected in an airtight container, and as it is filled, they are pumped out with the involvement of a sewage machine.

Of course, you can install a full-fledged septic tank with several cleaning chambers, but it costs a lot. For a small cottage or dacha, where a family of three or four people lives, a storage tank or cesspool of several hundred liters in volume is quite enough. There are not so many drains, such a disposal system will cope with sewage without problems.

Fermentation and clarification of wastewater can be carried out in one or more tanks connected in series. However, in the second case, the installation of sewer wells is greatly complicated.

It is easier to equip one well structure, and to speed up the purification processes, pour chemical or biological reagents into it.

Most often, on the adjacent plot, the owners of private houses make a cesspool on their own. But if the groundwater level is high, then the cesspool option is not suitable, you have to install a storage tank. Moreover, its volume is selected large enough to reduce the number of calls for sewers.

The decomposition of the biological component of sewage in the cesspool occurs due to anaerobic microbes. They do not require oxygen replenishment for life, therefore, additional aerobic installations will not be required to be installed in the well. The entire cleaning system turns out to be non-volatile, not requiring connection to the mains.

All decay processes inside the sewer well occur naturally, thanks to bacteria living in the soil. In this matter, they are quite successful, but anaerobes “work” rather slowly. Therefore, in order to speed up the processes, bioactivators are occasionally added to the pit.

The distance between the draining bottom of the cesspool and the groundwater layer must be at least a meter, otherwise the purified water will have nowhere to go

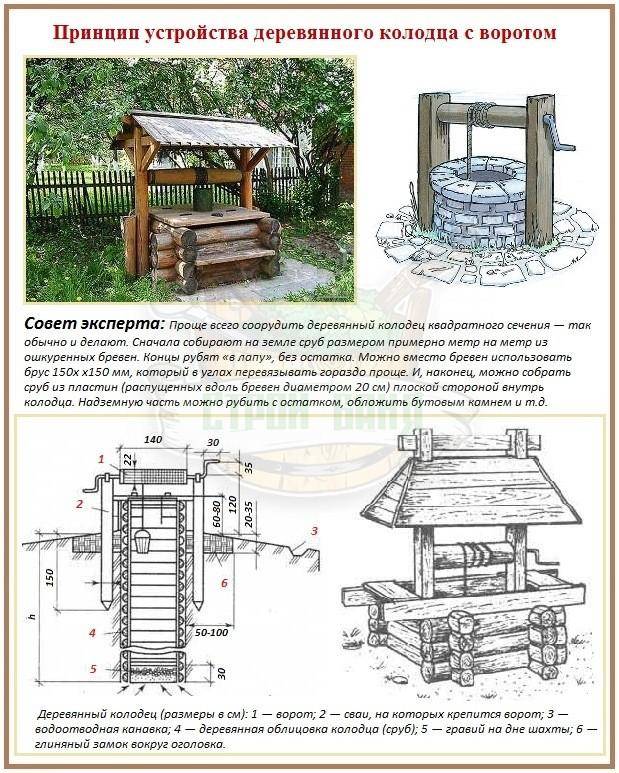

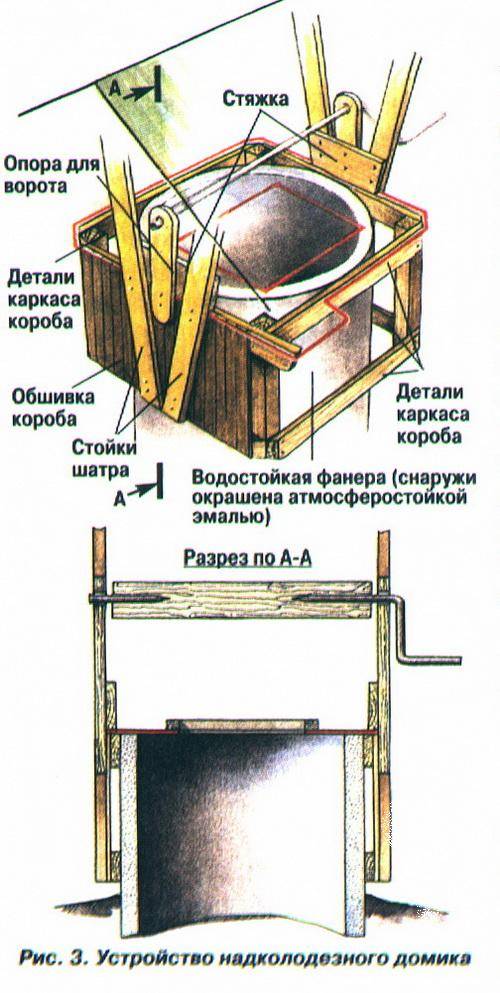

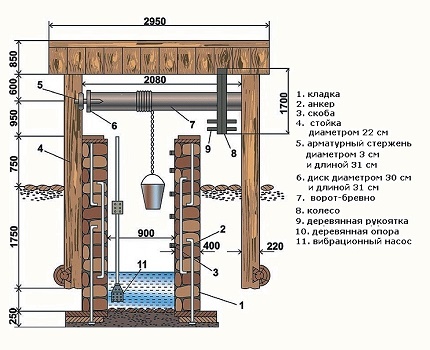

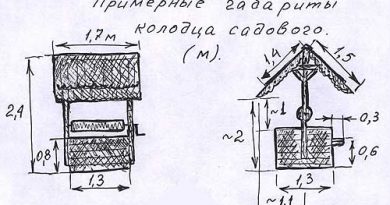

log house

Such a well house will have an original and very interesting design. To build such a structure, you will need the following:

log house

- rounded logs;

- boards for arranging roofs and supports;

- roofing finish;

- material for arranging the gate with a comfortable handle.

Similar well houses are often found in villages. Racks of the structure, gates and the frame itself are made from rounded timber.

log house

Manufacturing technology

Fold the rounded timber into a log house according to the dimensions of the well. Connect the timber by any suitable and convenient method. Install two massive wooden beam supports. For additional rigidity, equip the racks of the house with props. Arrange a wide roof structure on top of the support posts. Construction guide roofing was given in the previous section of the instructions - do everything in the same order.

Well house made of logs

The edges of the roof should extend beyond the base of the well house. This will prevent rainfall from entering the well shaft.

Lock the gate securely. You can decorate the protruding ends of the timber with a variety of curly cutouts.

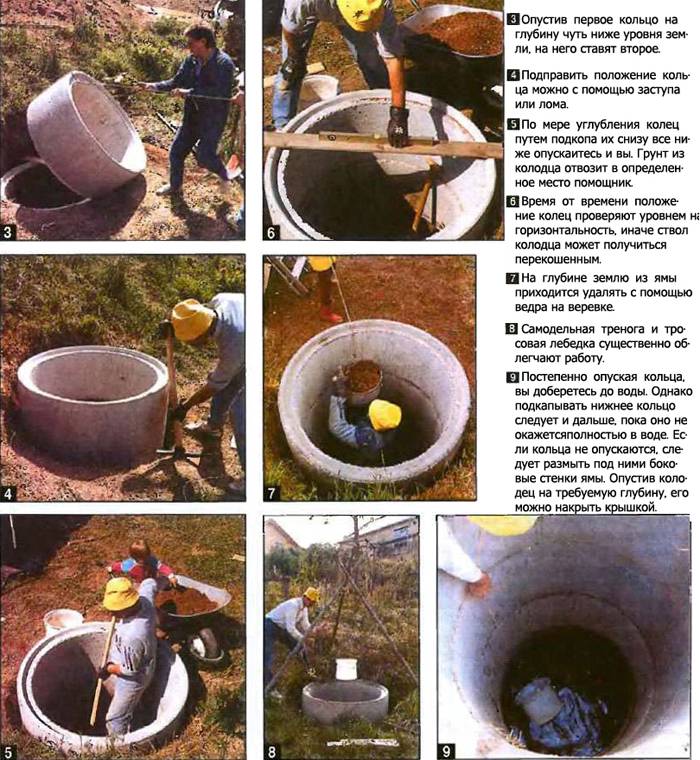

Digging methods

There are two technologies for digging a well.Both methods are used, just at different depths. And both have flaws.

Alternate installation of rings

The first ring is placed on the ground, which is gradually removed from the inside and under the side. Gradually the ring descends. Here is a very important point: it is necessary to ensure that it falls straight down, without distortions. Otherwise, the mine will turn out to be inclined and, sooner or later, the sedimentation of the rings will stop.

To avoid distortion, it is necessary to control the verticality of the walls. They do this by tying a plumb line to the bar and laying it on the ring. Additionally, you can control the top level.

Tools needed for digging a well

When the upper edge of the ring is level with the ground, the next one is rolled. It is placed strictly on top. The work continues. If on the first ring the soil can be thrown over the side with a shovel with a shortened handle, then on the next one you have to take it out with the help of a gate or a tripod and a block. Thus, at least two people must work, and at least three, or even four, are needed to turn the rings. So it is impossible to dig a well on your own, in one hand. Unless to adapt the winch.

So, gradually, the depth of the well increases. When the ring drops to the level with the ground, a new one is placed on it. For descent, use driven brackets or ladders (more correctly, brackets).

The advantages of this method of digging a well:

- You can control how tight and even the ring has become.

- You can lay the same rubber gaskets that will ensure tightness or put them on the solution.

- The walls do not crumble.

These are all pluses. Now for the cons. Working inside the ring is inconvenient and difficult physically.Therefore, according to this method, they dig mainly to a shallow depth - 7-8 meters. And in the mine they work in turn.

The structure of the "knife" for easier penetration of soil when digging wells

Another point: when digging a deck with rings, you can speed up the process of settling and facilitate the passage of soil, you can use a knife. It is made of concrete, it is poured into the ground at the very beginning. To form it, they dig a groove in a circle. In cross section, it has a triangular shape (see figure). Her inner diameter matches with the inner diameter of the rings used, the outer one is slightly larger. After the concrete has gained strength, a “regular” ring is placed on this ring and work begins.

Installation of rings after reaching the aquifer

First, a mine is dug without rings. At the same time, keep an eye on the walls. At the first sign of shedding, they put the rings inside and continue to deepen according to the first method.

If the soil does not crumble throughout the entire length, having reached the aquifer, they stop. Using a crane or manipulator, rings are placed in the shaft. Then, they deepen another couple of rings according to the first method, increasing the debit.

First, they dig a mine to the aquifer, then they put rings in it

The excavation technique is the same here: as long as the depth allows, it is simply thrown out with a shovel. Then they put a tripod and a gate and raise it in buckets. After installing the rings, the gap between the walls of the shaft and the ring is filled and rammed. In this case, the upper several rings can be sealed from the outside (with bituminous impregnation, for example, or with other coating waterproofing).

When working, it is also necessary to control the verticality of the walls, but it can be adjusted within certain limits. The control method is similar - a plumb line tied to a bar and lowered into the mine.

Advantages of this method:

- The shaft is wider, it is more convenient to work in it, which allows you to make deeper wells.

- It is possible to make external sealing of several upper rings, which minimizes the possibility of ingress of the most polluted waters.

More disadvantages:

- It is difficult to control the tightness of the junction of the rings: it is forbidden to be in the shaft during installation. It is impossible to move an already installed ring in it. It weighs hundreds of kilograms.

- You can miss the moment, and the mine will crumble.

- The backfill density of the gap between the shaft wall and the rings remains less than the "native" soil. As a result, melt and rain water will seep inward, where it will get inside through the cracks. To avoid this, a protective circle of waterproof material (waterproofing membrane) is made around the well with a slope from the walls of the well.