- Why are wells dug in winter?

- What is a bottom well filter

- How to dig a well with your own hands

- Shutdown

- Technology and performance features

- Well digging process

- First option

- Second option

- How to dig wells in winter

- Seam sealing

- Well Digging Seasons Review - Pros and Cons

- Spring

- Summer

- Autumn

- Winter

- Expert advice + video

- We protect the structure from surface water

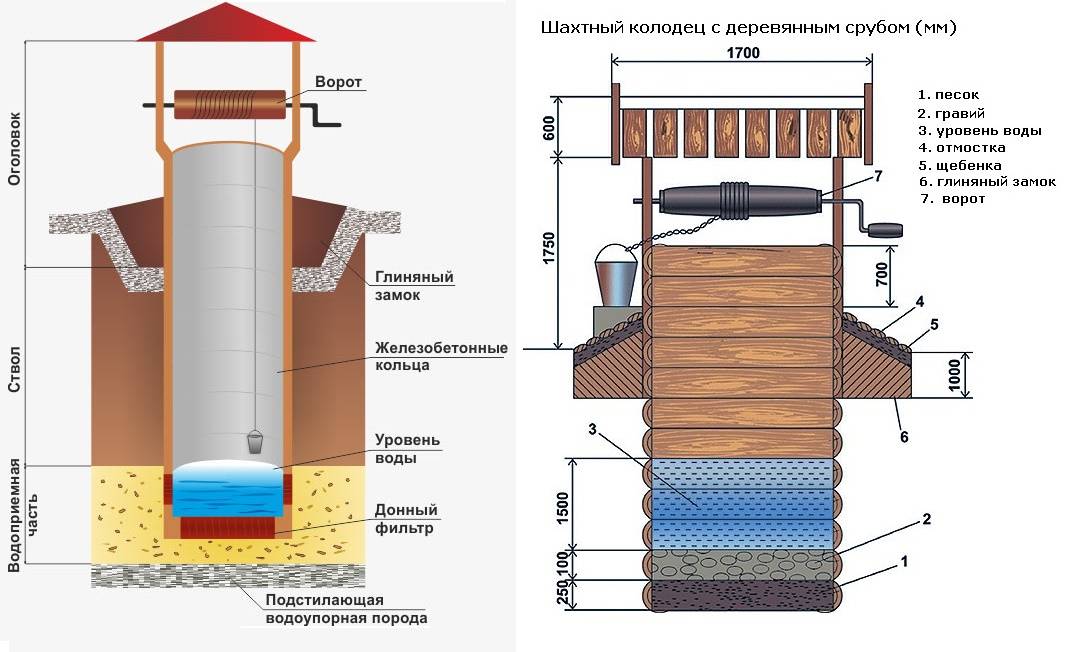

- Types of wells

- Drilling well in the country

- Mine well in the country

- Wooden frame

- Do-it-yourself well decor in the country

- How to properly dig a well in the country: a bottom filter and sealing casing rings

- How to choose when to dig a well

- Digging with an excavator

- Digging methods

- Alternate installation of rings

- Installation of rings after reaching the aquifer

Why are wells dug in winter?

It is incorrect to say that you can dig a well at a certain time of the year. It can be arranged at any time

Only each season has its drawbacks, which should be paid attention to. And if we compare all the periods, it turns out that digging in winter is the most correct

Reasons for digging wells in winter:

- The first and main reason is the depth of water. In winter, the water decreases and is at its greatest depth. Wells dug to this level in winter will be full of water in other periods and will never dry up.

- Freezing perch water facilitates the process of digging.

- In winter, the site is freed from greenhouses and water intake tanks, which facilitates the access of equipment and the transport of materials.

The complexity of digging in winter does not differ from summer time. The main reasons for digging wells in winter clearly characterize this time as the most successful for such work.

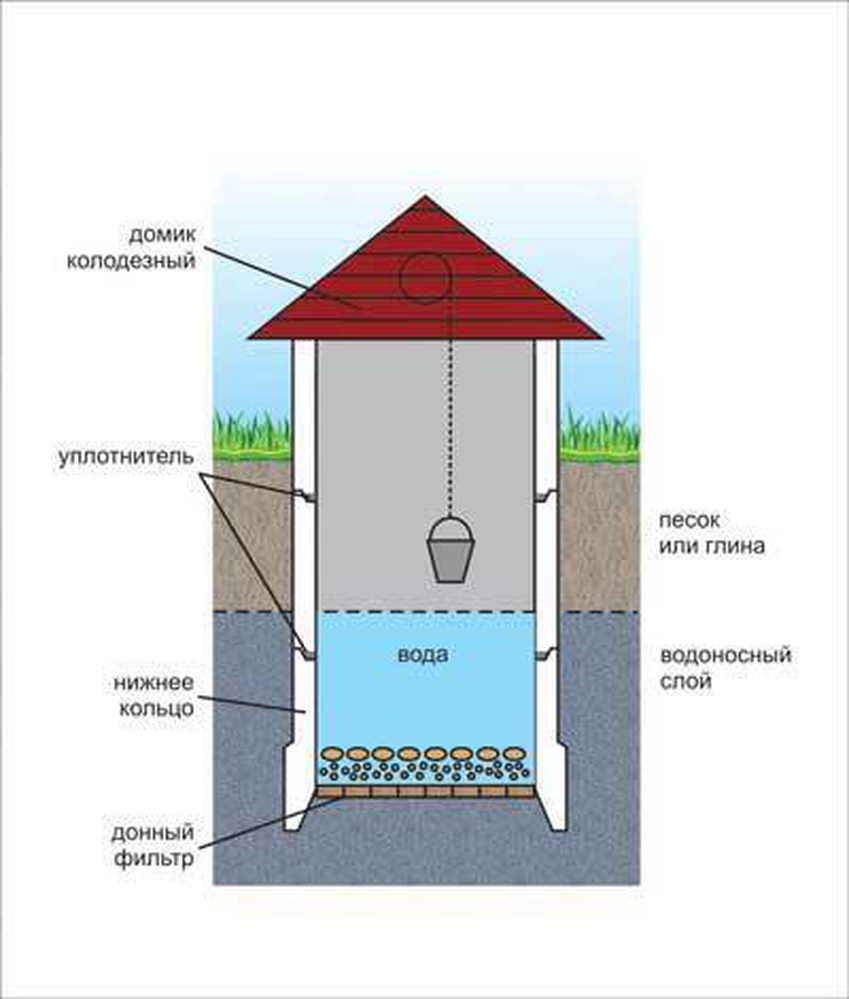

What is a bottom well filter

Upon reaching the aquifer, a pump should be installed to remove the water entering the mine, and the rings should be deepened by another 1-2m. Excessive deepening at this moment should not be due to the danger of passing through the aquifer and deepening into a layer of soil that does not contain water.

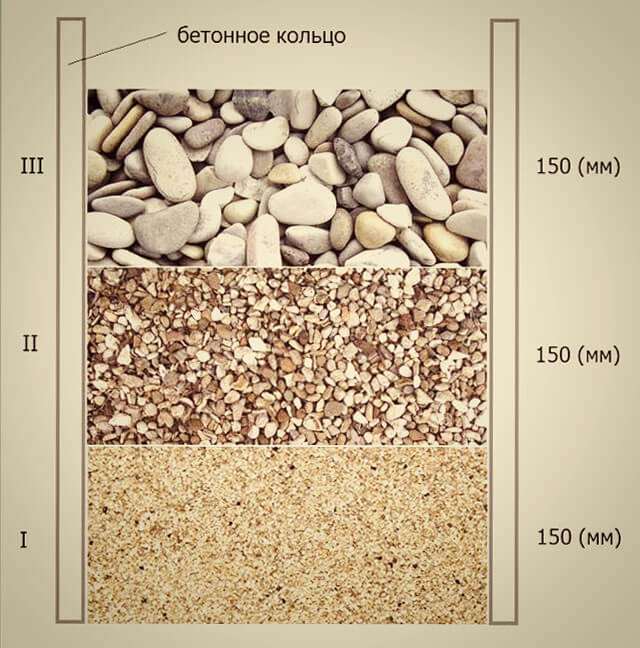

After that, a filter should be equipped at the bottom of the well for natural purification of the water entering the mine. Without this, it will be cloudy, with impurities of suspended sand and clay.

The bottom filter is made by filling stones or large gravel into the well. The thickness of this layer should reach 20cm. The second layer is filled with gravel of medium fraction (1-3 cm in diameter) with the same layer.

And on top of these two layers, the final layer of river pebbles and coarse-grained clean sand is poured. Water, rising from the bottom of the well, passes through this multi-layered filter and is purified in a natural way.

How to dig a well with your own hands

Before you start digging a well, you need to prepare the necessary equipment.

For work you will need:

shovels, crowbar, buckets, a pump for pumping water, a rope, a chain, a lifting device (such as a hand hoist), and, of course, concrete rings.To begin with, consider the option of digging a well manually with the installation of concrete rings.

We begin to dig a hole, the diameter of which is equal to the ring, about two meters deep.Then, having installed the ring, we begin to select the earth inside the ring, while taking into account the viscosity of the earth.

If the earth is dense, we dig under the ring, if it is loose, we start from the middle of the circle. In the process of digging, the ring lowers under its own weight.

If the earth is dense, we dig under the ring, if it is loose, we start from the middle of the circle. In the process of digging, the ring lowers under its own weight.

When the ring is deep enough, put the next one on it.

The whole process is repeated. When doing work, it is imperative to watch that the rings fall evenly, otherwise not only distortion, but also clamping may appear, the elimination of such problems is quite laborious.

We seal the seams between the rings with a cement-sand mortar, having previously laid a tarred hemp rope, and we fasten the rings themselves together with iron plates, screwing them with bolts using special metal eyes.

The depth of the well is usually about 10 meters, but this value can vary up or down depending on the topography of the site.

The depth of the mine is determined by the following parameters:

the soil moisture increases, the clay layer is passed, the air temperature decreases.

If water appears in the well, work does not stop, and the water is pumped out using. If there is a rapid set of water, we stop digging. Now you should pump out the water and leave the well for 8-12 hours, then pump out the water again and select more soil until we see aquifers.

We make a clay castle.

Outside, we dig our well to a depth of about a meter, ram it with clay at ground level, and then make a blind area.

Everything, the digging of the well is completed.

Now we arrange a bottom filter for water purification. It is done like this, at the bottom of the well we lay small and large gravel of about 20 centimeters.If the soil at the bottom of the well is very viscous, then first you need to make it from boards with holes for water, and then lay the bottom filter on top.

Shutdown

We complete the work by installing a water-lifting mechanism, or a pump. Close the well with a lid.

The design of the ground part of the well, the head, everyone chooses to their taste and financial capabilities. Many options are offered.

You can also dig a well without rings. For the device, we need a wooden one, chopped into a paw.

But this method is more time-consuming and it is chosen by lovers of ecological construction.

Own source of water in your favorite suburban area will significantly increase the level of comfort. Eliminates the need to carry water in buckets to care for reverently grown plants, to fill containers in a bath or shower.

The construction of a water intake structure can be entrusted to a team of workers specializing in this field. But it's better to dig and equip well in the country with your own hands, investing in it a minimum of funds. We will tell you how to choose a place for a water source, how to drill and equip a working.

Any enterprise requires careful preliminary preparation from the future contractor. Especially as laborious as digging a well.

Errors in planning, distribution of forces and work stages will certainly affect the result. In the best case, the construction will stretch for a long, but unknown period, in the worst case, it will end with the construction of a useless tunnel "to nowhere".

Image gallery

Image gallery

Technology and performance features

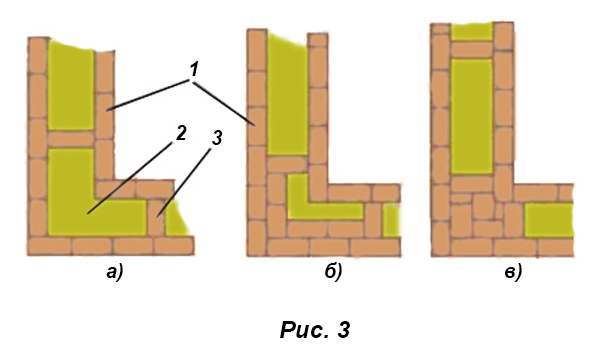

a)-c) Three options for laying the corner of the building 1. External and internal walls of the well. 2. Opening filled with insulation. 3. Vertical jumpers (diaphragms).Horizontal jumper (reinforcing mesh or reinforcement).

As already noted, the complexity of well masonry is somewhat higher than usual, but it is not difficult to master it with experience as a bricklayer. With little experience, it is advisable to arm yourself with a detailed ordering drawing

This is especially important at the initial stage. An example of fragments of such a drawing is shown in fig. 2

2.

Here in fig. 2a shows a diagram of odd, and in Fig. 2b - even rows of masonry. To ensure a reliable connection between the walls, a horizontal jumper is laid after every sixth row. For this purpose, a reinforcing mesh is usually used (see Fig. 2c).

In the same figure, they are indicated by numbers:

- The outer and inner walls of the well.

- Opening filled with insulation.

- Vertical bridges (diaphragms).

- Horizontal jumper (reinforcing mesh or reinforcement).

The laying of vertical lintels must be securely tied with the longitudinal walls. Their thickness can be 1-3 horizontal rows. The greater the thickness of the jumpers, the stronger the structure, but the thermal insulation worsens. Instead of brick, it is possible to select jumpers from reinforcing pins with a thickness of 6-8 mm. For reliability, their ends are bent.

Corners can also be laid out in different ways. The device of several of its variants is shown in Fig. 3. Numerical designations here are the same as in fig. 2. Brief characteristics of these options:

- the option with only two parallel walls (a), the most economical, but also the least durable;

- the option with a thickening of the outer walls (b) requires more building materials, but the strength of the masonry increases;

- the option with a continuous layout of the corner (c) is the most durable, but also the least economical.

At least two rows of bricks under window openings should be solid. In addition, in these cases, it is desirable to reinforce the brick walls with a reinforcing mesh. When the laying of the outer walls is completed, a reinforced concrete reinforcing belt is usually poured over the last row.

This is especially important when it is planned to build a brick pediment.

As already noted, for all its merits, the well structure is not its most durable option. Therefore, in order to hold a fairly heavy brick gable, the presence of a reinforcing belt is highly desirable.

And one more important note. Like any brickwork in winter conditions, a well should be done with a doubling of the number of reinforced joints that provide reinforcement of the brickwork, and using the appropriate mortar. The backfill inside the wells must be absolutely dry, not containing frozen inclusions.

It is also desirable to use additional liners from dry cinder blocks.

The backfill inside the wells must be absolutely dry, not containing frozen inclusions. It is also desirable to use additional liners from dry cinder blocks.

Well digging process

Let's get down to the actual construction work. All work is done entirely by hand, while not forgetting about safety.

The video in this article will show the entire process of doing the work.

First option

This is how you can do the work if your soil wakes up and you cannot immediately make holes in full size.

So:

- At the location of the future well, we mark up in such a way that the diameter of the well exceeds by 10 cm the diameter of the concrete rings used. The hole is dug to a depth that allows the first ring not to sink completely. 8-10 cm should remain above the ground;

- On a trolley, the height of which is also 8-10 cm, the concrete ring is brought to the shaft and lowered vertically. Do not distort the ring, as this will affect the quality of the entire structure. Then we place the next concrete ring, fastening with three brackets;

- In the center we make a hole deeper by 80 cm. Then the hole needs to be dug round so that the concrete ring sinks into the ground through its gravity. If the earth is soft, then it is removed first in the center of the ring, if the earth is hard, then it is removed first under the ring itself, so that nothing prevents it from lowering. Then, when the ring descends and settles, they take out the earth in the center;

- Docking of concrete rings is ensured by tightness by laying a pitched hemp rope, which is then treated with a solution based on cement and sand. We lower the rings into the shaft until water appears at the bottom of the well. The appeared water with sand is taken out from the well mine. The well will be filled with water within 12 hours;

- The next day it is necessary to remove the water from the well again. Cleaning is carried out until the water is completely purified. Then the well is covered and not touched during the day;

- After that, water with sand is pumped out again, filtering gravel or crushed stone is placed on the bottom of the well. First, 10-15 cm of fine fraction, then 30-40 cm of larger gravel. The allowable level of well water is 1.5 meters. It's more than one concrete ring;

- The distance between the walls of the pit and the well shaft must be covered with a mixture of gravel and sand, fixed on the surface of the earth with clay and covered with sand. Clay will not allow rainwater to enter the well, as well as thawed snow in the winter.

Second option

This kind of work is perfect for soil that does not wake up and you can do the work with an open method:

First, we make a hole in the ground. It should be larger than the ring by about 50 cm in diameter;

Now you should bring the second ring and lower it into the pit. For this, it is best to use a crane. This is the least secure. Although some make block structures and use them to do this work

But in their manufacture, special attention should be paid to quiet reliability. After all, the ring does not weigh so little;

Application of blocks for lowering the ring

- Now you need to put a sealing tape along the contour and then install the second ring. So we do to the very top;

- The fastening of the rings is done using metal brackets for the well.

How to dig wells in winter

Digging a well in winter

The instruction indicates that sometimes, for a number of reasons, it is better to dig a well in winter.

Reasons for this may be:

- The lowest level of groundwater means that it will not dry out in summer.

- In winter, it is easier to find labor.

- The cost of building materials and the rings themselves is much lower.

The disadvantages of this may be:

- Clearing the road from snow for the delivery of goods.

- Providing builders with warm housing.

It is known that in winter the ground freezes by about one meter, which is not very difficult to warm up or beat off with hammers.

The subsequent actions are the same as in other seasons.The shaft can be deepened three rings lower, which will make it possible to use water all year round, and a newly dug well can be used already in the spring.

Seam sealing

After installing the rings, it is necessary to seal the seams. This is necessary so that the upper sewage does not penetrate into the well.

Making seam seals

So:

- We make cement mortar. It consists of sand and cement. For M300 we use the proportion 1/3;

- We cover the seam from the inside of the ring with a spatula;

- After complete solidification, some recommend treating the coating with liquid glass.

Now you see that the price of drinking water in the house is not so big. The most important thing is to follow the rules for doing the job.

Well Digging Seasons Review - Pros and Cons

When determining the best time of the year for digging a well, soil properties are taken into account. For sand, it is more convenient to start work at any time except summer. Clay is difficult to develop in the cold. In summer it dries up, which is also an unfavorable factor. Loam behaves in a similar way, and in the heat and in the cold it will not work to dig a well without mechanization.

Specialists do not see much difference, since their experience, knowledge and material and technical base allow them to perform work in any conditions. But still, if someone decides to dig on his own, he will have to take into account all the pros and cons that each season has.

Spring

The difficulty lies in the fact that spring floods and raising the level of the perch water do not make it possible to determine exactly how deep the pit should be. At this time, digging a well is recommended only if the soil consists of sand. But it can collapse or move if it rains and a floater forms.

Summer

If there is a lot of rainfall, you won’t have to dig much to get water, but next year, when there may not be very little rain, the water will leave and the well will dry up. Therefore, you need to build on the weather conditions in the region.

Autumn

If there is a lot of rainfall, then at this time of the year they do not dig wells. Digging is recommended only if the depth of the aquifers is known. For clay, this is also not the best option, since if it rains, the water will fill the hole and have to be pumped out. The optimal time is the second half of August and the beginning of September.

Winter

The lack of demand for the service leads to a decrease in the cost due to seasonal discounts. But this is only if the work is performed by special equipment. It will not work to dig a well manually, as the soil will be frozen. And it will be a monolith that cannot be crushed even with a jackhammer, especially if you have to dig clay or loam.

Expert advice + video

There are several recommendations regarding the digging process in various conditions:

Since ancient times, people digging wells began to work according to the lunar calendar. Watchmen say that this should be done when the moon passes the constellation Pisces. You can buy a lunar calendar in almost any store that sells printed materials. The exact start and end dates of work can be found on specialized websites or in applications for smartphones. Before you start digging, it makes sense to talk with your neighbors. If they have a well on the site, they will be able to provide reliable information. The level of groundwater occurrence even in adjacent areas may differ, but the neighbors will tell you exactly the seasonal level differences.And so you can navigate to what depth you need to go deep. Some use the agricultural calendar as a guide. It can be spied on by those who are seriously engaged in the garden or grow various crops in the garden. Greenhouses and greenhouses are a different matter, and such people may not have it. As a rule, wells are dug before the start of the sowing season, and immediately after the harvest.

It is important not to leave the dig halfway. Work must be carried out without interruption

If the summer resident is employed, this must be done over the weekend. Even better to play it safe and take a couple of days off or vacation. The fact is that the end date of digging can be delayed, and the reason for this is solid ground plates. They will take extra time to complete.

The convenience of contacting specialists is obvious, especially if they have the necessary specialized equipment and tools at their disposal. In this case, nothing will prevent you from digging a well at any time of the year.

HelpfulUseless

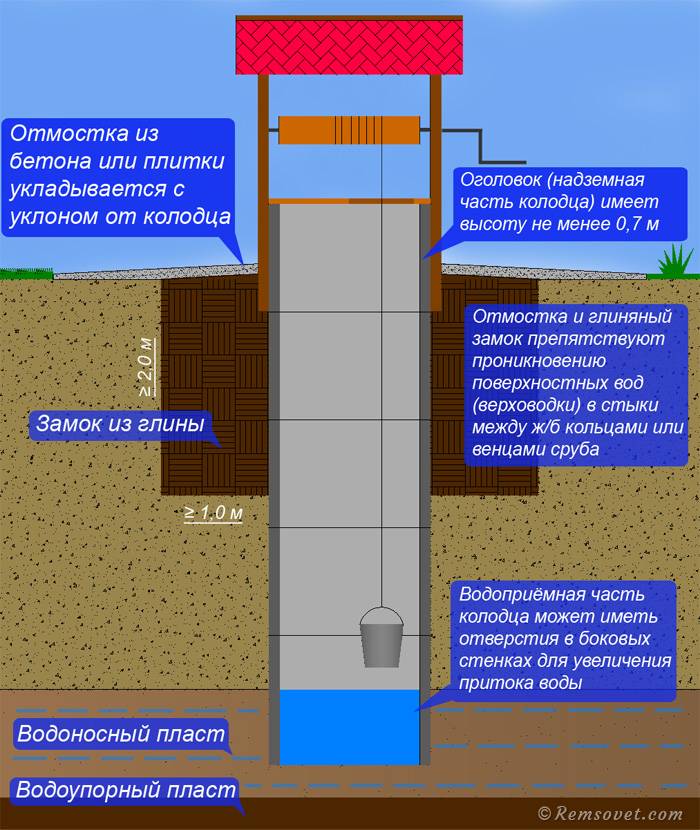

We protect the structure from surface water

To keep the well clean, it must be properly protected. Water should enter the shaft only from below, and therefore the walls must be reliably insulated. To do this, we firmly connect the rings to each other, resorting to one of two possible methods.

- We drill the walls of the rings and fix them with metal brackets mounted on bolts.

- We twist the rings with steel wire, catching it on the loading eyes. To twist the wire, we use a metal rod, for example, a crowbar.

External and internal sealing of concrete rings with traditional bituminous materials

We strengthen the seams according to the following scheme.

Step 1. We put pieces of linen rope in the voids between the rings (an excellent material - natural and environmentally friendly).

Step 2. We cover the ropes with a solution of sand, cement and liquid glass. In this way, we will achieve reliable waterproofing, which, moreover, will be completely neutral when in contact with water.

Step 3. On top of the upper rings, we dig a pit of a meter depth.

Step 4 We waterproof the outer surface of the rings using liquid bituminous mastic.

Step 5. We lay a thermal insulation layer around the upper rings (we can use any foamed polymer, for example, foam).

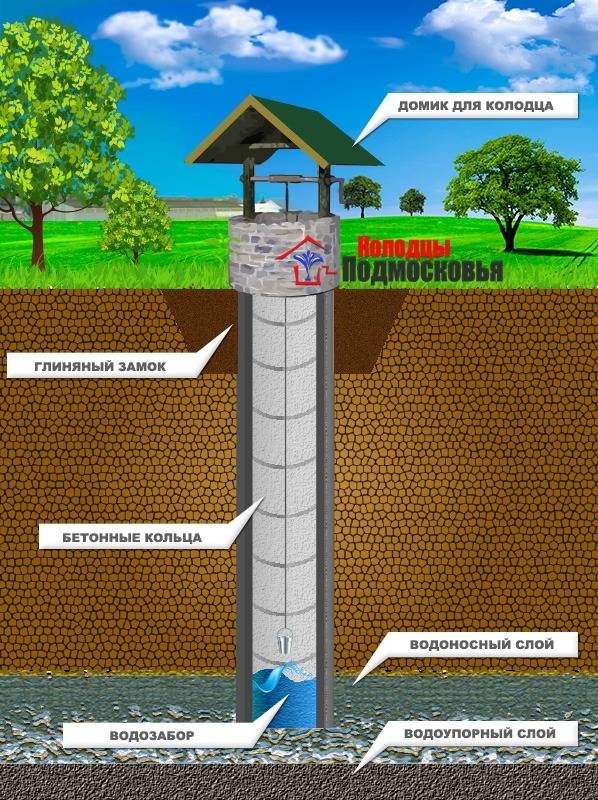

Step 6. We fill the pit around the well with clay. This is called "clay castle".

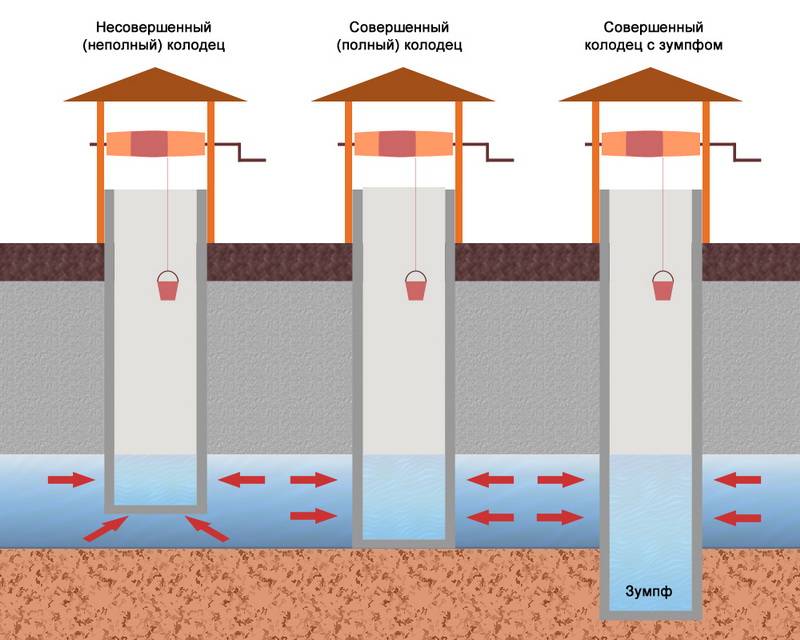

Types of wells

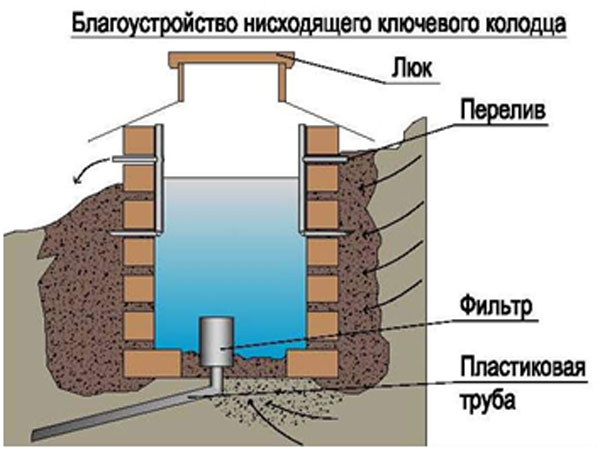

A well is a shaft that reaches the water horizon with water suitable for consumption. Depending on the depth at which the water layer lies, experts divide these hydraulic structures into two types:

- Key or superficial. This is when there is a key in the suburban area, from which the purest drinking water beats. Convenient, inexpensive option.

- Mine. This is when it is necessary to dig up the soil to the water layer, constructing a mine with a round or square section. The depth of the structure can reach up to 10 m.

Key well at their summer cottage

Drilling well in the country

Bored wells are more durable than mine wells (especially those made in the old "grandfather" ways), and much safer in environmental terms. Drilling wells are usually built in areas where groundwater is close to the surface. As the name suggests, drill wells are created by drilling a well.A special drill bit, the so-called drill spoon, is turned until it is filled with earth, after which it is lifted, emptied and drilling continues. Thanks to this method, the borehole can be made very narrow.

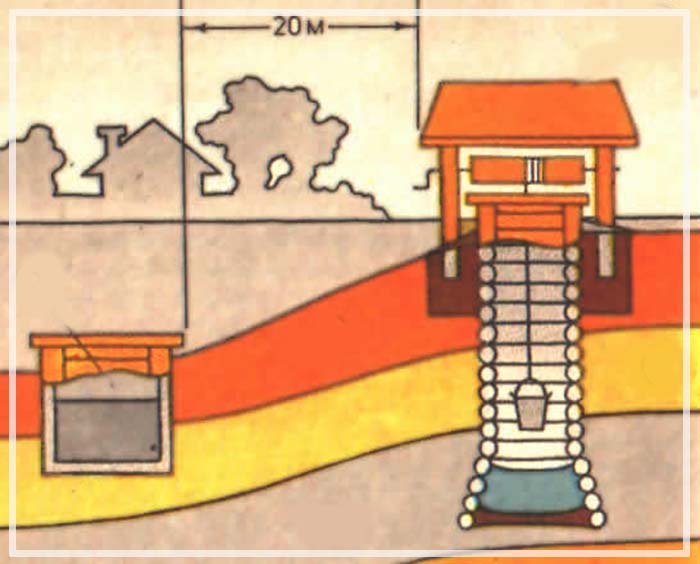

Metal or asbestos-cement pipes with a diameter of at least 15 cm are strengthened in the well, and a protective device against debris, a mechanism for lifting water and a canopy (can be decorative) are installed on top. Such wells are not deeper than 20 m.

Mine well in the country

If there are rocky rocks above the aquifer that make drilling difficult, you will have to make a shaft well. The shaft well is dug by conventional methods, the earth is removed from it with buckets or buckets on a rope, so the shaft is quite wide, 80-120 cm. The maximum depth for it is 20-25 m, and the deeper it is, the less likely it is to pollute the well water. You can dig a shallow shaft well yourself using simple improvised tools: bayonet shovels, crowbars and special containers for excavation (buckets or tubs). But to deepen the well to a decent distance, special equipment is required. A layer of pebbles and crushed stone 30-50 cm high is covered at the bottom of the well to filter the water.

Wooden frame

The ancient grandfather way. For the construction of a well log house made of wood, logs with a diameter of 10-15 cm or thick boards are best suited. The technology for strengthening the walls of the mine is as follows: first, a shallow well is dug to the height of a log or board, then a finished log house is installed in it. Then they dig up the soil under the log house, gradually deepening it and making room for the next crown, then the second, third, etc. are installed on the first log house.- until the finished structure reaches the groundwater layer. And so that the log crowns do not crumble, they are firmly fastened with vertical boards.

Do-it-yourself well decor in the country

Wooden structures are often decorated with carvings. This is appropriate on a site with a log house, decorated in the Slavic style. If this decor seems too elegant to you, limit yourself to carving.

Stone and brick base does not require additional decoration

Usually the masonry itself attracts attention. And sometimes it is complemented by wooden or forged parts.

You can ennoble any small structure on the site with the help of plants. Subject to building technologies, it should not be damp here, but only a little damp. For planting, climbing flowers are suitable, for example, clematis, wisteria or decorative sweet peas. Below you can build a flower bed of squat flowers: phlox, aster, iris and ampelous, which are hung in pots: for example, petunia and verbena. You can experiment with viburnum or hydrangea bushes near the structure.

What is important to consider

- Provide a working and wet area around the source of drinking water: there will most likely be a table or even a bench.

- Do not plant tall and deciduous trees - in autumn the foliage will fall into the mine. Not even a wide closed roof will save.

- Do not plant plants that will be often treated with chemistry. The area with clean water is sanitary, so it is better to choose unpretentious flowers.

Well, if the creation of a real well is not included in your plans, then take a closer look at the decorative one. This is a structure that is as similar as possible to the present, but serves to decorate the site and is often used as a flower bed.

Instagram @boheme_provincial

How to properly dig a well in the country: a bottom filter and sealing casing rings

These are two, almost final stages of work, which provide an answer to the question of how properly dig a well at the cottage with their own hands. They are not difficult, but you can not do without them. Let's start in order.

-

Seal of casing rings. This is a kind of waterproofing of the well, which helps to prevent the penetration of rain and melt water into the well, which together with them carry a lot of harmful substances and dirt to the source. This seal is made as follows - first, the space between the ring and the ground needs to be expanded. It must be at least 300mm around the entire perimeter of the ring. The depth of such excavations should be 20 centimeters below the level of the first junction of the rings. All this space is covered with clay, which is carefully rammed and spilled with water. From the same clay, around the well, an embankment is made in the form of a tubercle - from the edge of the well, this embankment should end at a distance of at least one meter. This is the whole shutter, which will prevent the penetration of rain and melt water into the well. Among other things, all joints between the rings inside the well will need to be sealed with a solution, with the addition of liquid glass.

- Bottom filter. It is needed in order to avoid stirring up the water when lowering the bucket into the well, in addition, it separates the soil from the used part of the well and purifies the water - if of course you do it right. And it is done simply. At the bottom of the well, you need to lay a round shield of their boards, according to the size of the well itself, or rather the inside of the casing rings. On top of this shield, a layer of natural stone with a thickness of 100 - 200 mm is laid.The ideal option would be gravel of medium fraction mixed with a natural mineral called shungite - this is a natural filter and a mineralizer in one person.

In principle, everything - as you can see, digging a well in the country yourself is not so difficult. Yes, this is a laborious and dangerous process, but not difficult at all.

Well, in conclusion, the topic of how to dig a well in the country with your own hands, it remains to add not much - in particular, to say a few words about the aerial part of the well. The so-called house with a roof, which is made for a reason - first of all, it is protection from rain and snow. Such a house may have a different design - by and large, it may not exist at all. What the well, or rather its upper part, really needs is a cover - its presence just determines the protection of water from debris.

How to choose when to dig a well

Determining the time of well digging is an important task, and its correct solution allows:

- Avoid unnecessary spending.

- Save yourself from doing wasted work.

- Get everything done quickly and efficiently.

- Have an excellent water source on the site.

Experienced teams recommend digging a water intake at the end of summer or early autumn. This period has many advantages and practically no disadvantages. When is the best time to dig a well? When drilling a well, it is much easier to stumble upon an excellent aquifer (provided that the summer is dry and warm). In this case, the liquid must seep into the drilled shaft perfectly and constantly. Due to this, even with the use of huge volumes of moisture, its amount in the well will not decrease.It is not recommended to dig wells after heavy rain or during floods. In this case, even sandy soils will become supersaturated with water, and this signals the end of the digging process. During a period of drought, such a source will quickly dry up, because it is deprived of an excellent aquifer. It is because of this that it is not required to deal with this matter when the soil is saturated with moisture.

Digging a well shaft is a time-consuming and responsible event that is important to carry out at a certain period of the year. Because of this, people will not work "in vain", and the result will delight all home owners for decades.

Naturally, the finished structure needs to be cleaned from time to time, which will positively affect the quality of the water!

Digging with an excavator

Usually manual digging is carried out by a group of workers of 2-3 people with the help of special mechanisms that take out the ground and lower the worker. Sometimes a crane is used to move the concrete rings that reinforce the walls.

Before starting, it is important to determine which of the places in the summer cottage has the best water supply. There are some popular methods for this.

For example, you can use silica gel and brick chips.

For digging wells, special equipment is used, which significantly speeds up the process.

To get silica gel, you can break a brick of ceramic and grind it into a fine powder. Then it must be left in the oven to dry. Next, pour the powder into a jar and wrap it in a rag. Weigh and memorize the mass. In a place where there is approximately water, put the jar in a shallow hole about 1 m. Leave for a day. Carry out the weight measurement again.If the mass has increased significantly, there is definitely water in this place.

When digging a well with an excavator, it is important to consider some features:

- The excavator must be powerful enough, and its driver must be experienced.

- At the bottom of the pit, it is better to install restrictive rings using a mechanical manipulator. Next, they need to be pressed down a little with a bucket so that the ring sinks deeper.

- The direction must be controlled from below by one of the workers.

- In order for the well to turn out to be even, you need to use a building level and a plumb line.

- Rings must be clean.

- It is easier to move the rings if special loops are attached to them.

- It is better to immediately install a water filter at the bottom.

- The excavator usually digs to 5.5 m, while the depth of the well should be about 7 m. To do this, the driver must “besiege” his cab by at least 1.5 m.

Before starting work with an excavator, it will be useful to contact the geological center to accurately determine the coordinates of the location and depth of local waters.

As a rule, water is located between the clay and lime layer. The layer with the presence of water is most often represented by sand. There may be 2 or 3 of them. If sand begins to appear during digging, this indicates that the water is not far away. After the first flow of water, you need to dig a little more and pump the detected amount of water a little. At the first stages of excavation, you should not get carried away too much, otherwise you will have to dig up another layer in search of moisture. This can be difficult when working with an excavator, as it captures several layers at the same time.

Digging methods

There are two technologies for digging a well. Both methods are used, just at different depths. And both have flaws.

Alternate installation of rings

The first ring is placed on the ground, which is gradually removed from the inside and under the side. Gradually the ring descends. Here is a very important point: it is necessary to ensure that it falls straight down, without distortions. Otherwise, the mine will turn out to be inclined and, sooner or later, the sedimentation of the rings will stop.

To avoid distortion, it is necessary to control the verticality of the walls. They do this by tying a plumb line to the bar and laying it on the ring. Additionally, you can control the top level.

Tools needed for digging a well

When the upper edge of the ring is level with the ground, the next one is rolled. It is placed strictly on top. The work continues. If on the first ring the soil can be thrown over the side with a shovel with a shortened handle, then on the next one you have to take it out with the help of a gate or a tripod and a block. Thus, at least two people must work, and at least three, or even four, are needed to turn the rings. So it is impossible to dig a well on your own, in one hand. Unless to adapt the winch.

So, gradually, the depth of the well increases. When the ring drops to the level with the ground, a new one is placed on it. For descent, use driven brackets or ladders (more correctly, brackets).

The advantages of this method of digging a well:

- You can control how tight and even the ring has become.

- You can lay the same rubber gaskets that will ensure tightness or put them on the solution.

- The walls do not crumble.

These are all pluses. Now for the cons. Working inside the ring is inconvenient and difficult physically. Therefore, according to this method, they dig mainly to a shallow depth - 7-8 meters. And in the mine they work in turn.

The structure of the "knife" for easier penetration of soil when digging wells

Another point: when digging a deck with rings, you can speed up the process of settling and facilitate the passage of soil, you can use a knife. It is made of concrete, it is poured into the ground at the very beginning. To form it, they dig a groove in a circle. In cross section, it has a triangular shape (see figure). Its inner diameter coincides with the inner diameter of the rings used, the outer one is slightly larger. After the concrete has gained strength, a “regular” ring is placed on this ring and work begins.

Installation of rings after reaching the aquifer

First, a mine is dug without rings. At the same time, keep an eye on the walls. At the first sign of shedding, they put the rings inside and continue to deepen according to the first method.

If the soil does not crumble throughout the entire length, having reached the aquifer, they stop. Using a crane or manipulator, rings are placed in the shaft. Then, they deepen another couple of rings according to the first method, increasing the debit.

First, they dig a mine to the aquifer, then they put rings in it

The excavation technique is the same here: as long as the depth allows, it is simply thrown out with a shovel. Then they put a tripod and a gate and raise it in buckets. After installing the rings, the gap between the walls of the shaft and the ring is filled and rammed. In this case, the upper several rings can be sealed from the outside (with bituminous impregnation, for example, or with other coating waterproofing).

When working, it is also necessary to control the verticality of the walls, but it can be adjusted within certain limits. The control method is similar - a plumb line tied to a bar and lowered into the mine.

Advantages of this method:

- The shaft is wider, it is more convenient to work in it, which allows you to make deeper wells.

- It is possible to make external sealing of several upper rings, which minimizes the possibility of ingress of the most polluted waters.

More disadvantages:

- It is difficult to control the tightness of the junction of the rings: it is forbidden to be in the shaft during installation. It is impossible to move an already installed ring in it. It weighs hundreds of kilograms.

- You can miss the moment, and the mine will crumble.

- The backfill density of the gap between the shaft wall and the rings remains less than the "native" soil. As a result, melt and rain water will seep inward, where it will get inside through the cracks. To avoid this, a protective circle of waterproof material (waterproofing membrane) is made around the well with a slope from the walls of the well.