- Types of collector nodes

- Selection of system components

- Pipes for systems of private cottages

- Pipes for apartment buildings

- What is it needed for

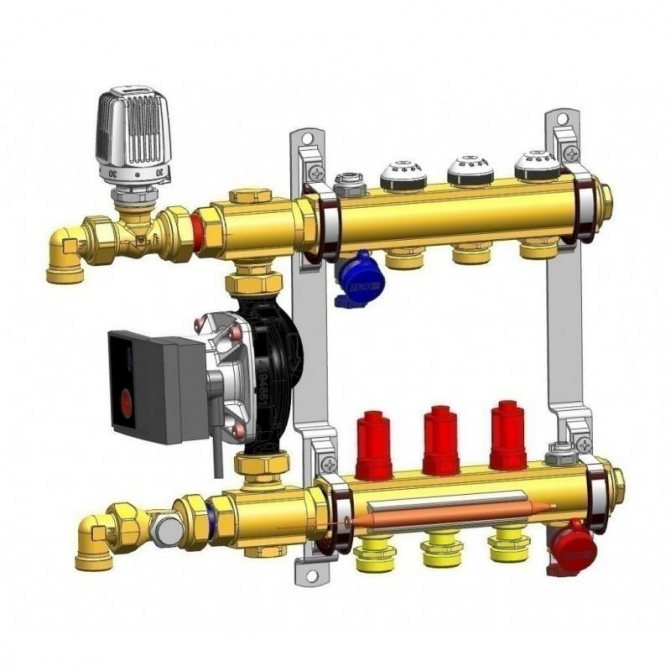

- Collector group for heating system assy

- Comb - manifold assembly

- General design principles

- Connection rules and installation features

- Option # 1 - without additional pumps and hydraulic arrows

- Option # 2 - with pumps on each branch and a hydraulic arrow

- Installation of a collector heating system

- Advantages of a collector heating system

- The principle of operation of the collector

- Positive and negative sides of the collector circuit

- Not without a circulation pump

- 4 The principle of drawing up wiring diagrams

- Advantages and disadvantages

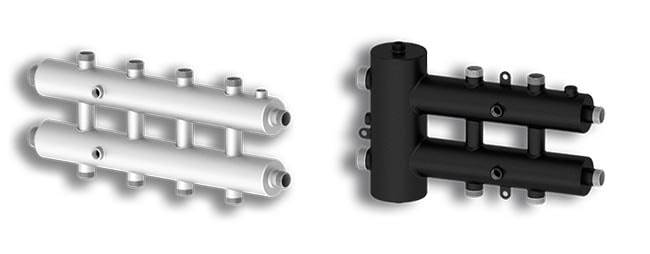

Types of collector nodes

Before considering the types of combs, we will indicate how they can be used in water heating systems for private houses and apartments:

- distribution and regulation of water temperature in the contours of underfloor heating, abbreviated as TP;

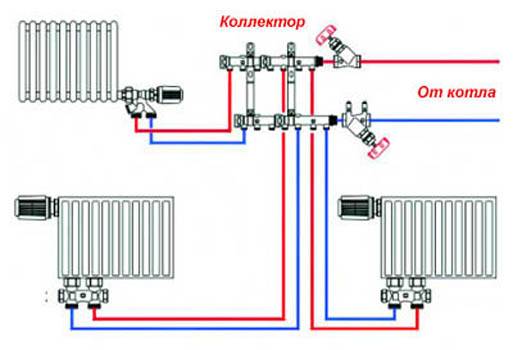

- distribution of coolant to radiators according to the beam (collector) scheme;

- overall heat distribution in a large residential building with a complex heat supply system.

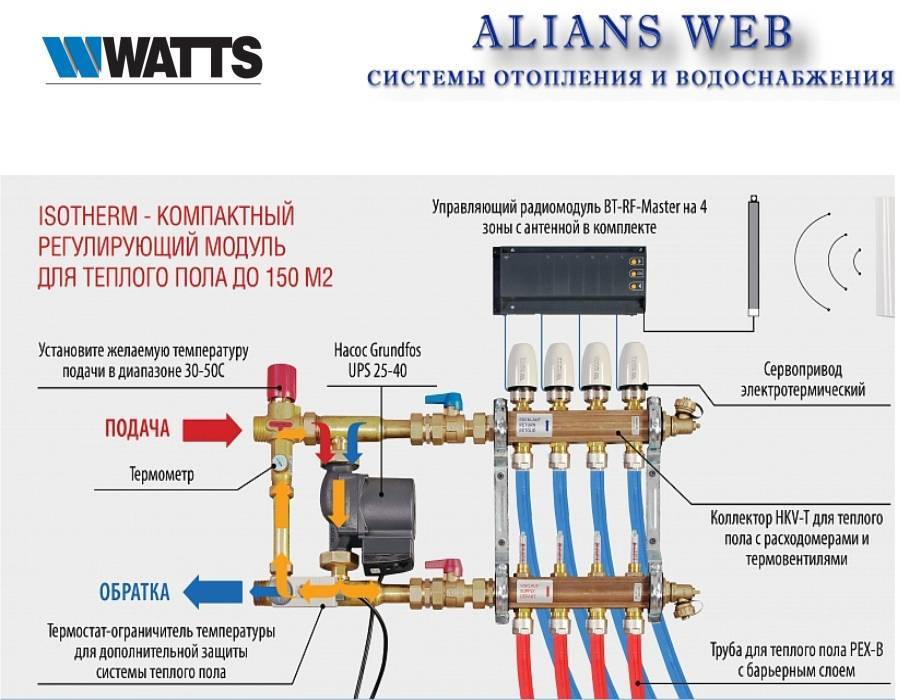

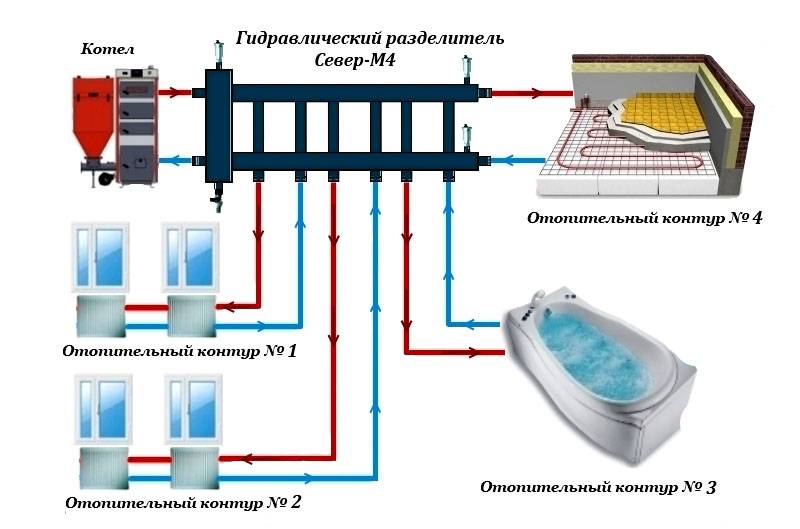

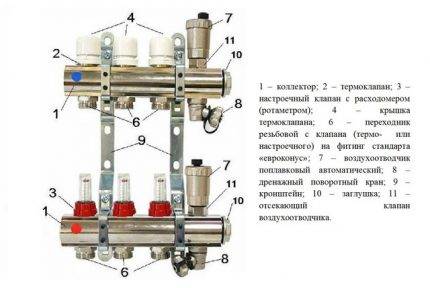

On the left in the photo - a coplanar collector for distributing the coolant along the branches, on the right - a finished collector module with a hydraulic arrow

In country cottages with branched heating, the collector group includes the so-called hydraulic arrow (in other words, a thermo-hydraulic separator). In fact, this is a vertical collector with 6 outlets: 2 - from the boiler, two - to the comb, one top to remove air, water is discharged from the bottom.

Now about the types of distribution combs:

- To limit the water temperature, regulate the flow and balance the contours of the warm floor, special collector blocks made of brass, stainless steel or plastic are used. The size of the connecting hole of the main heating main (at the end of the pipe) is ¾ or 1 inch (DN 20-25), branches - ½ or ¾, respectively (DN 15-20).

- In radiator beam schemes, the same combs of floor heating systems are used, but with reduced functionality. We will explain the difference below.

- Large-sized steel collectors are used for the general house distribution of the heat carrier, the connection diameter is over 1” (DN 25).

Factory collector groups are not cheap. For the sake of economy, homeowners often use combs soldered with their own hands from polypropylene, or take cheap distributors for water systems. Next, we will indicate the problems associated with the installation of homemade and plumbing collectors.

Combs for radiator and floor systems - stainless steel, brass and plastic

Selection of system components

When designing heating, it is best to purchase factory-made distribution units.

Due to the variety of the assortment, it will not be difficult to choose a comb for certain heating parameters, thereby ensuring the accuracy and reliability of the system.

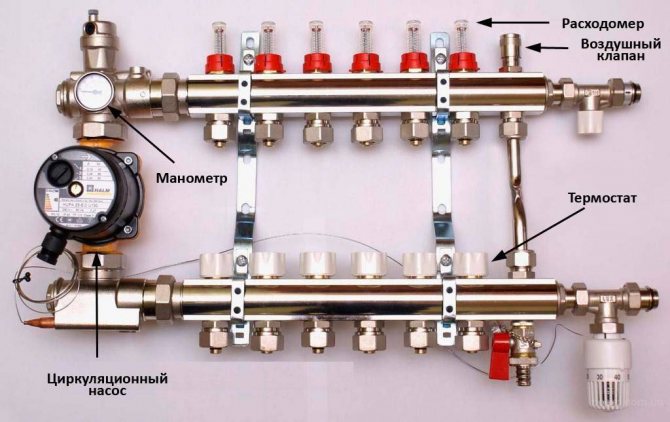

On sale you can find ready-made manifold blocks that combine the supply and return units, as well as thermostatic valves and automatic air vents

On sale you can find ready-made manifold blocks that combine the supply and return units, as well as thermostatic valves and automatic air vents

The key parameters when choosing pipes for heating circuits are corrosion resistance, heat resistance and high burst strength. In addition, pipes must have the necessary flexibility so that they can be laid at any angle.

When choosing products, preference should be given to pipes produced in bays. The use of one-piece products will avoid connections in the wiring, which is especially important for the closed method of installation inside the screed.

Pipes for systems of private cottages

When designing heating in private houses, it is worth focusing on the fact that the pressure in the system is about 1.5 atmospheres, and the coolant temperature can reach:

- for radiators - 50-70 degrees;

- for warm floors - 30-40 degrees.

For autonomous heating systems with their predictable parameters, it is not at all necessary to purchase stainless corrugated pipes. Many owners are limited to purchasing pipes made of cross-linked polyethylene marked "PEX".

Polyethylene pipes for heating circuits are commercially available in 200-meter coils; they are able to withstand pressure up to 10 kgf / kV.cm and operate at temperatures within 95 ° C

Such pipes are joined using tension fittings, so that inextricable connections can be obtained.

In addition to high performance parameters, the main advantage of cross-linked polyethylene is the mechanical memory of the material. Therefore, if you stretch the edge of the pipe with force, and insert a fitting into the gap formed, it will tightly cover it, providing a strong connection.

When using metal-plastic pipes, the connection is made by means of union fittings with compression nuts. And this already turns out to be a detachable connection, which, according to SNiP, cannot be “monolithized”.

You may also have information on which pipes are best for heating, discussed here.

Pipes for apartment buildings

If the collector system will be installed in an apartment building, then it should be borne in mind that the working pressure in it is 10-15 atmospheres, and the coolant temperature can reach about 100-120 ° C. It should be remembered that the collector heating device is possible only on the first floor.

The best option for installing the system in an apartment building is the use of corrugated pipes made of stainless steel.

A good example of this is the products of the Korean company Kofulso. Pipes of this brand are able to operate at an operating pressure of 15 atmospheres and withstand temperatures of the order of 110 ° C. The breaking pressure of Kofulso pipes reaches 210 kgf/sq.cm.

Due to the excellent flexibility of the pipe, in which the bending radius is equal to its diameter, it is convenient to use the products when laying a "warm floor"

Due to the excellent flexibility of the pipe, in which the bending radius is equal to its diameter, it is convenient to use the products when laying a "warm floor"

The assembly of pipeline connections using such elements is not difficult. The pipe is simply inserted into the fitting and secured by screwing on the nut, which compresses the corrugated metal surface with an elastic silicone seal.

What is it needed for

When installing water pressure systems, there is a rule: the total diameter of all branches should not exceed the diameter of the supply pipe.With regard to heating equipment, this rule looks like this: if the diameter of the boiler outlet fitting is 1 inch, then two circuits with a pipe diameter of ½ inch are allowed in the system. For a small house heated only with radiators, such a system will work effectively.

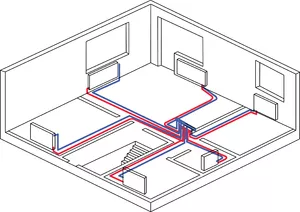

In fact, there are more heating circuits in a private house or cottage: underfloor heating, heating of several floors, utility rooms, and a garage. When they are connected through a tapping system, the pressure in each circuit will be insufficient to effectively heat the radiators, and the temperature in the house will not be comfortable.

Therefore, branched heating systems are performed by collectors, this technique allows you to adjust each circuit separately and set the desired temperature in each room. So, for a garage, plus 10-15ºС is enough, and for a nursery, a temperature of about plus 23-25ºС is required. In addition, warm floors should not heat up more than 35-37 degrees, otherwise it will be unpleasant to walk on them, and the floor covering may be deformed. With the help of a collector and a shut-off temperature, this problem can also be solved.

Video: using a collector system for heating a house.

Collector groups for heating systems are sold ready-made, while they may have different configurations and the number of taps. You can choose a suitable collector assembly and install it yourself or with the help of specialists.

However, most industrial models are universal and do not always fit the needs of a particular home. Their alteration or refinement can significantly increase costs.Therefore, in most cases it is easier to assemble it from separate blocks with your own hands, taking into account the features of a particular heating system.

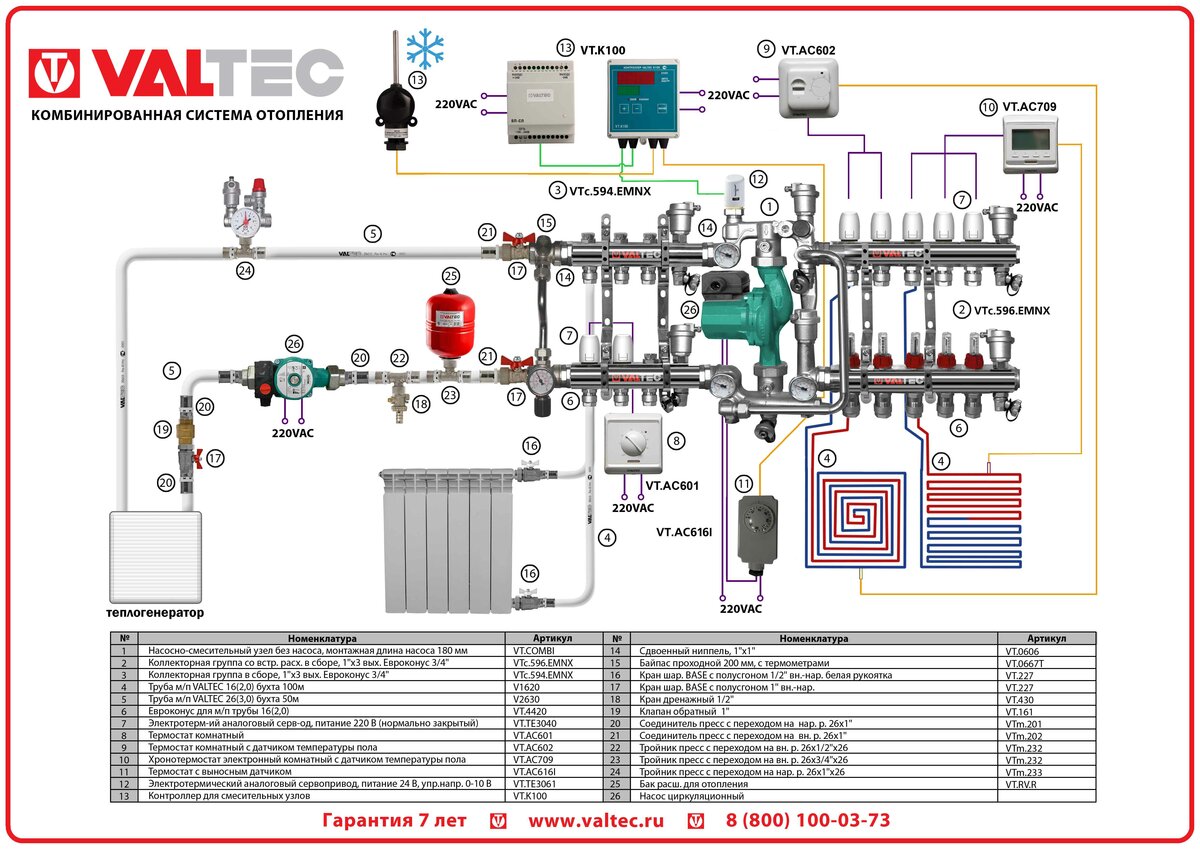

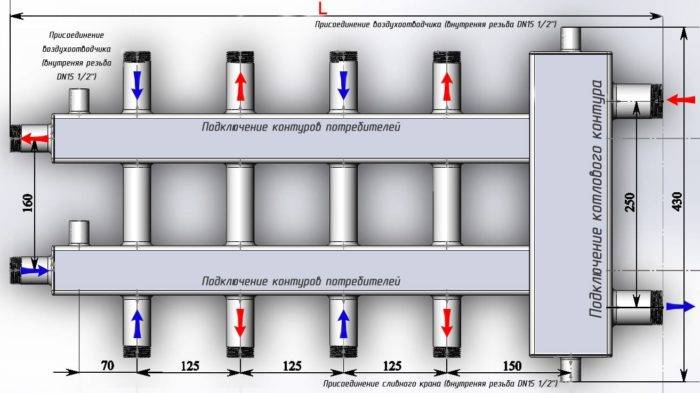

Collector group for heating system assy

The design of the universal manifold group is shown in the figure. It consists of two blocks for direct and reverse flow of the coolant, equipped with the required number of taps. Flowmeters are installed on the supply (direct) manifold, and thermal heads are located on the return manifold to control the temperature of the return water in each circuit. With their help, you can set the required flow rate of the coolant, which will determine the temperature in the heating radiators.

The manifold distribution unit is equipped with a pressure gauge, circulation pump and air valves. The supply and return manifolds are combined into one unit with brackets, which also serve to fix the unit to a wall or cabinet. The price of such a block is from 15 to 20 thousand rubles, and if some of the branches are not used, its installation will be clearly inappropriate.

The rules for mounting the finished block are shown in the video.

Comb - manifold assembly

The most expensive elements in the manifold distribution block are flow meters and thermal heads. To avoid overpaying for extra elements, you can buy a collector assembly, the so-called "comb", and install the necessary control devices with your own hands only where necessary.

The comb is a brass tube with a diameter of 1 or ¾ inches with a certain number of branches with a diameter for heating pipes ½ inch. They are also connected to each other by a bracket.The outlets on the return manifold are equipped with plugs that allow you to install thermal heads on all or part of the circuits.

Some models can be equipped with taps, with their help you can adjust the flow manually. Such combs have a cast body and are equipped with a fitting / nut thread at the ends, which allows you to quickly and easily assemble a manifold from the required number of taps.

In order to save money, the collector for heating systems can be assembled from individual elements on your own or completely done by yourself.

General design principles

Is there any general instruction for drawing up working designs for systems of this type?

In the general case, both equipment and heating devices are selected for specific tasks. However, some general advice can be given.

The use of collector circuits is not for city apartments. Categorically.

Why? Imagine a practical implementation. The apartment has several risers, each of which is connected to one or two heaters.

You disconnect from all risers, except for one; you mount a couple of combs on it and distribute heating throughout the apartment. As a result, on your tie-in, the drop in the drop and return temperature will be so significant that the neighbors on your riser will begin to freeze: in their apartments, the batteries will be barely warm.

The consequences are obvious: the visit of a housing representative, the drawing up of an act on unauthorized changes in the heating configuration and a forced costly alteration.

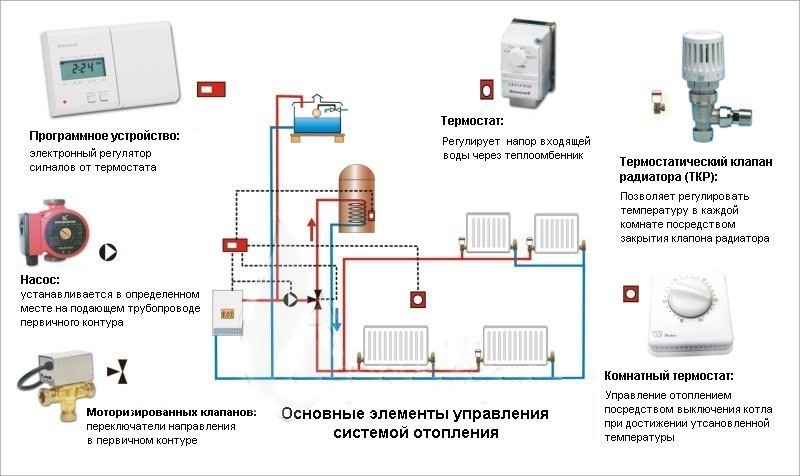

The automatic air vent is mounted directly on the supply and return manifolds. Sooner or later, all the air in the circuit will pass through them.

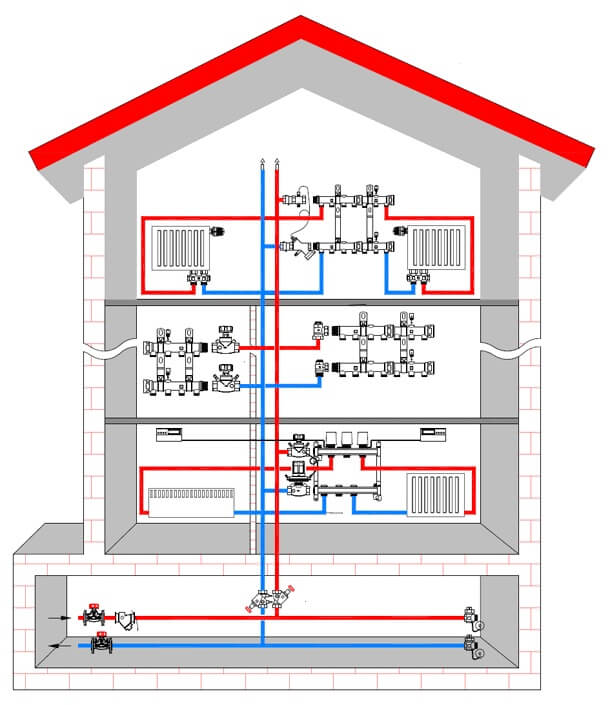

There are a number of features that are common not only to collector wiring, but also to other types of heating systems.

- The circuit must be equipped with an expansion tank, the volume of which must be at least 10 percent of the total volume of the coolant. More is possible: in this case, there will be no negative consequences. The price of expansion tanks is not so high as to save on these simple devices.

- The optimal placement of the expansion tank is on the return line, in front of the circulation pump along the water course. If a hydraulic arrow is used, the tank is placed in front of the main pump, which provides circulation in a small circuit. The reason for this arrangement is that, in order to avoid pressure fluctuations in the circuit, it is recommended to install membrane tanks where the water flow has a minimum of turbulences.

- Where to place the circulation pumps in each circuit is, in general, unprincipled; however, the resource of the device will be somewhat longer on the return line. Just because of the lower operating temperature. The pump is mounted in such a way that the shaft is located strictly horizontally - otherwise the first air bubble will leave the device without cooling and lubrication.

Connection rules and installation features

Installation of the comb begins with attaching it with brackets to the wall, where it will be located openly or in a closet. Then it will be necessary to attach the main pipes from the heat source to the ends and proceed to the piping.

Option # 1 - without additional pumps and hydraulic arrows

This simple option assumes that the comb will serve several circuits (for example, 4-5 radiator batteries), the temperature is assumed to be the same, its regulation is not provided.All circuits are connected directly to the comb, one pump is involved.

The characteristics of pumping equipment should be related to the performance of the heating system and the pressure created in it. So that you can choose the best pump that is ideal for its characteristics and cost, we recommend that you familiarize yourself with the rating of circulation pumps.

A master with experience in collector equipment knows how to correctly install a distribution manifold and hide it in a cabinet so as to hide all pipes

Since the resistance in the circuits is different (due to different lengths, etc.), it is necessary to ensure optimal consumption of the coolant by balancing.

To do this, not shut-off valves, but balancing valves are placed on the nozzles of the return manifold. They can regulate (although not exactly, but by eye) the coolant flow in each circuit.

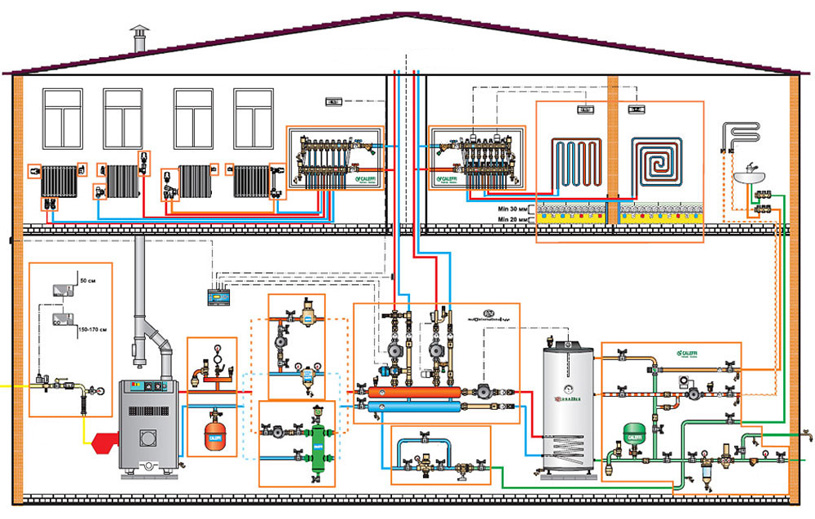

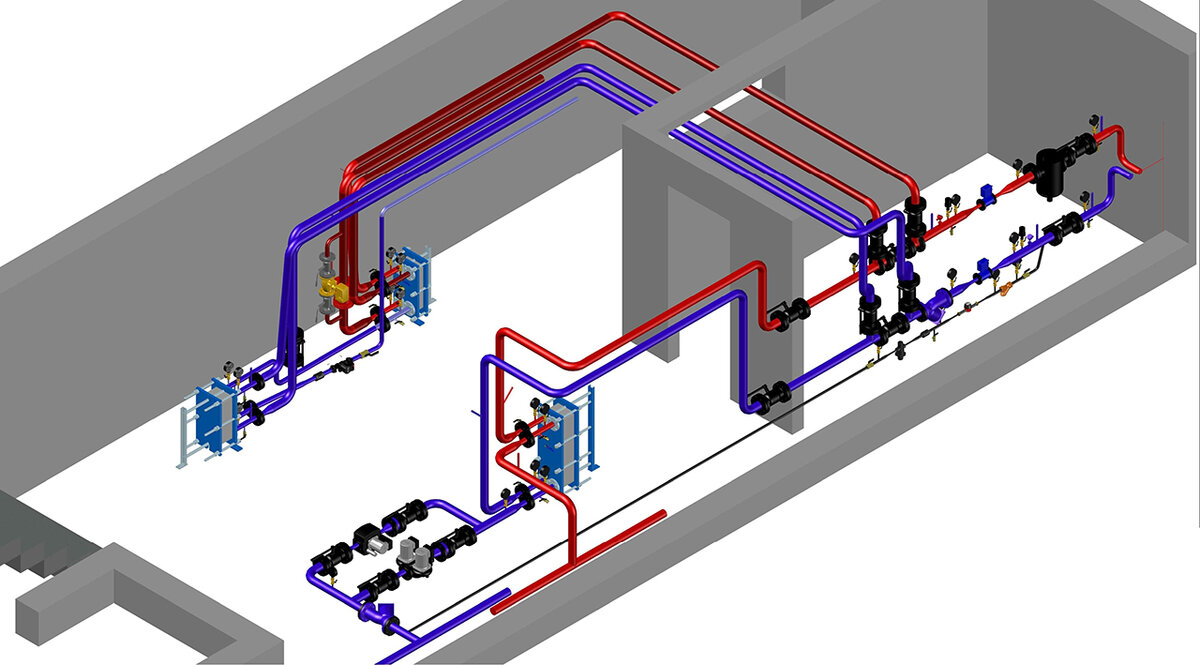

Option # 2 - with pumps on each branch and a hydraulic arrow

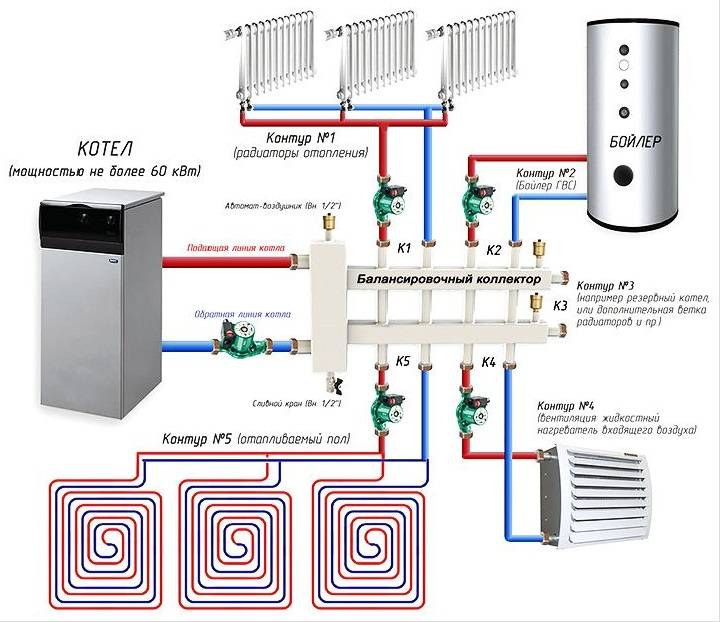

This is a more complex option, which, if necessary, will need to power consumption points with different temperature conditions.

So, for example, in radiator heating, water heating ranges from 40 to 70 ° C, a warm floor is enough in the range of 30-45 ° C, hot water for domestic needs must be heated to 85 ° C.

In the strapping, a hydraulic arrow will now play its special role - a piece of deaf from both ends of the pipe and two pairs of bends. The first pair is needed to connect the hydraulic arrow to the boiler, the distribution combs are joined to the second pair. It is a hydraulic barrier that creates a zone of zero resistance.

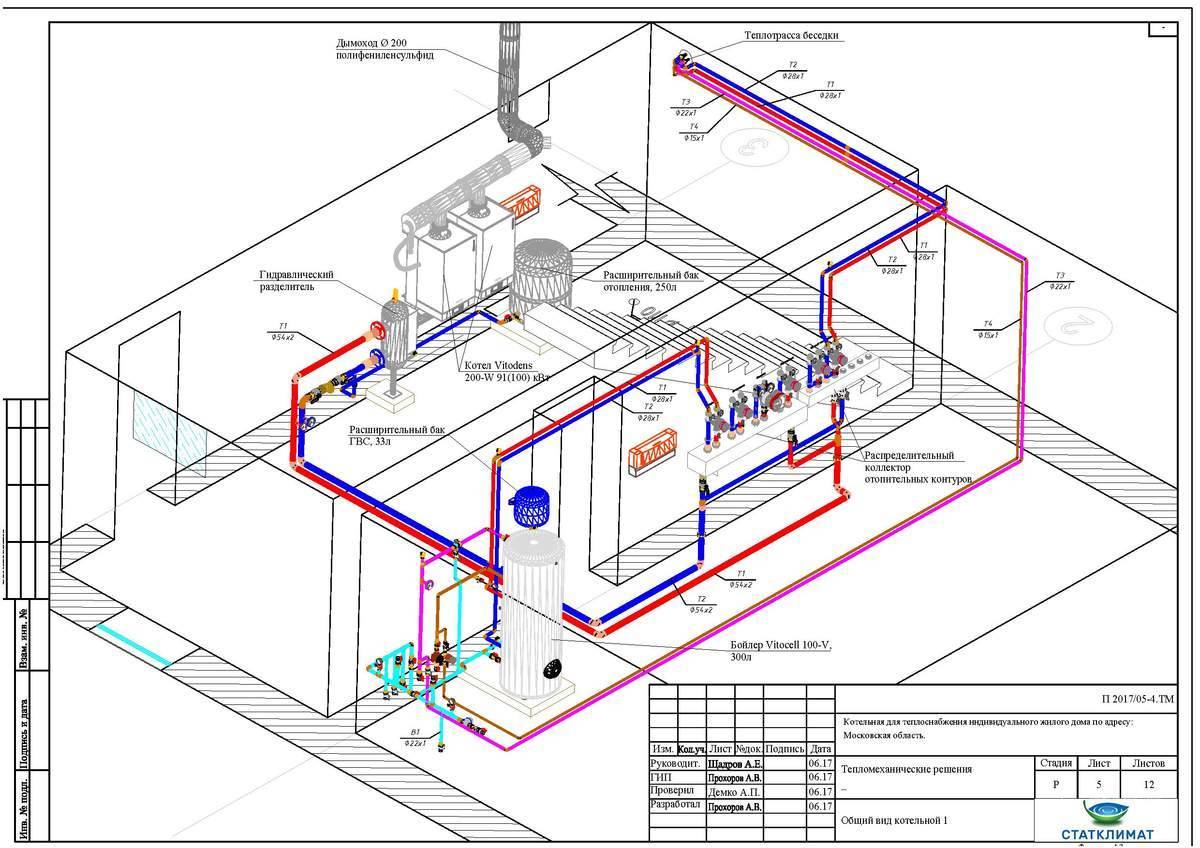

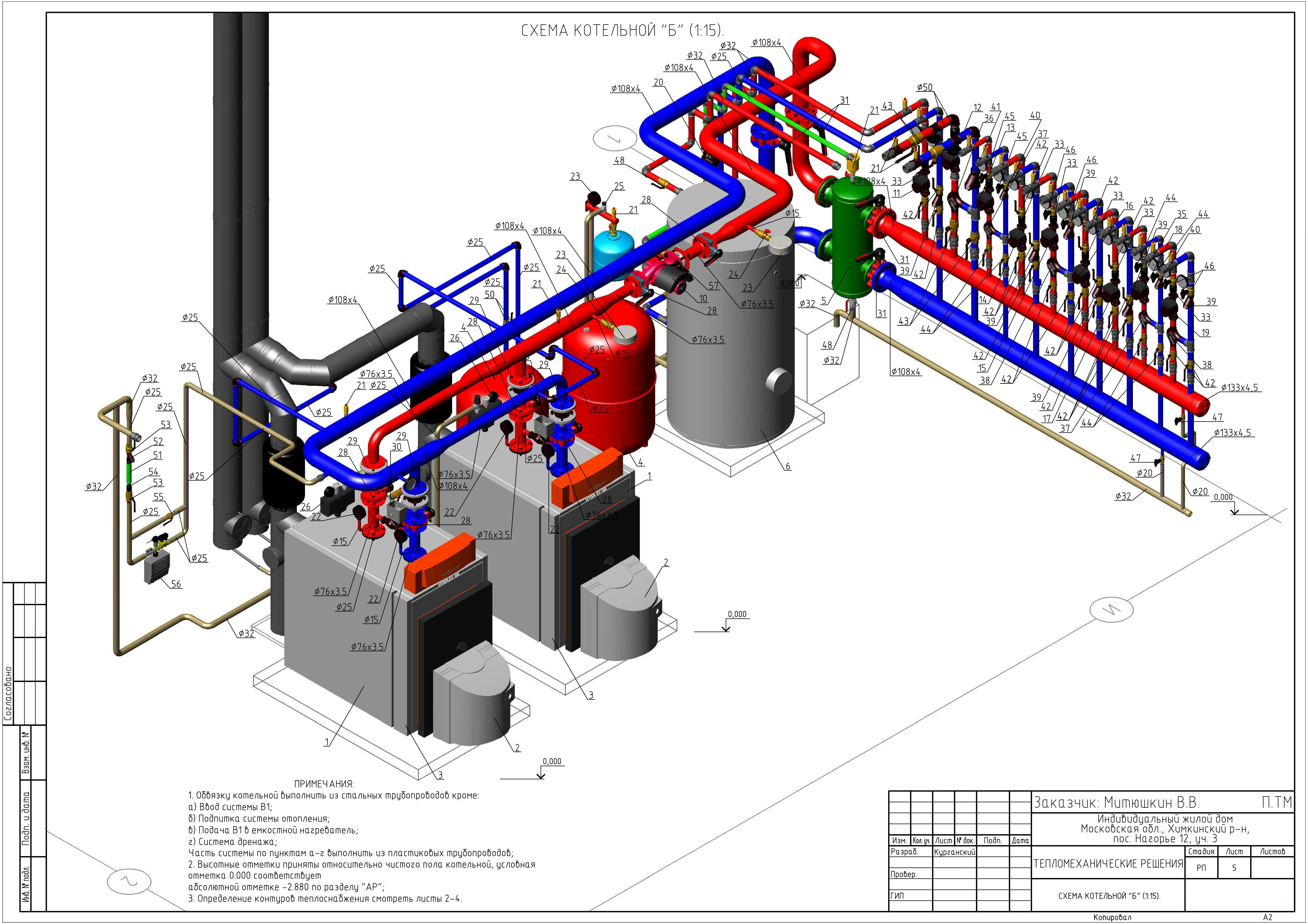

For boilers with a power of 50 kW and above, it is recommended to use a distribution manifold together with a hydraulic arrow without fail. It is mounted vertically on the wall with separate brackets to avoid excessive horizontal overload.

On the comb itself there are mixing units equipped with three-way valves - temperature control devices. Each outlet branch pipe has its own pump operating independently of the others, providing a specific circuit with the necessary amount of coolant.

The main thing is that these pumps do not exceed the total power of the main boiler pump.

Both considered options are used when installing distribution manifolds for boiler rooms. Everything you need is sold in specialized stores. There you can buy any unit assembled or element by element (based on savings due to self-assembly).

To further reduce future costs, you can make a heating distribution comb with your own hands.

The collector for the boiler room is located in close proximity to the heating equipment and is exposed to high temperatures that only metal can withstand.

Not so stringent requirements for thermal stability are imposed on a local distribution manifold; not only metal pipes, but also polypropylene, metal-plastic pipes are suitable for its manufacture.

For a local distribution manifold, it is easiest to select suitable scallops from those that are commercially available. In this case, one should take into account the material from which they are made - brass, steel, cast iron, plastic.

Cast scallops are more reliable, eliminating the possibility of leakage.There are no problems with connecting pipes to combs - even the most inexpensive models are threaded.

Distribution combs assembled from polypropylene parts impress with their cheapness. But in an emergency, the joints between the tees will not withstand overheating and will flow

Craftsmen can solder a collector made of polypropylene or metal-plastic, but you still have to buy threaded lugs, so the product will come out not much cheaper in terms of money than a finished one from a store.

Outwardly, it will be a set of tees interconnected by tubes. The weak point of such a collector is insufficient strength at high heating temperatures of the coolant.

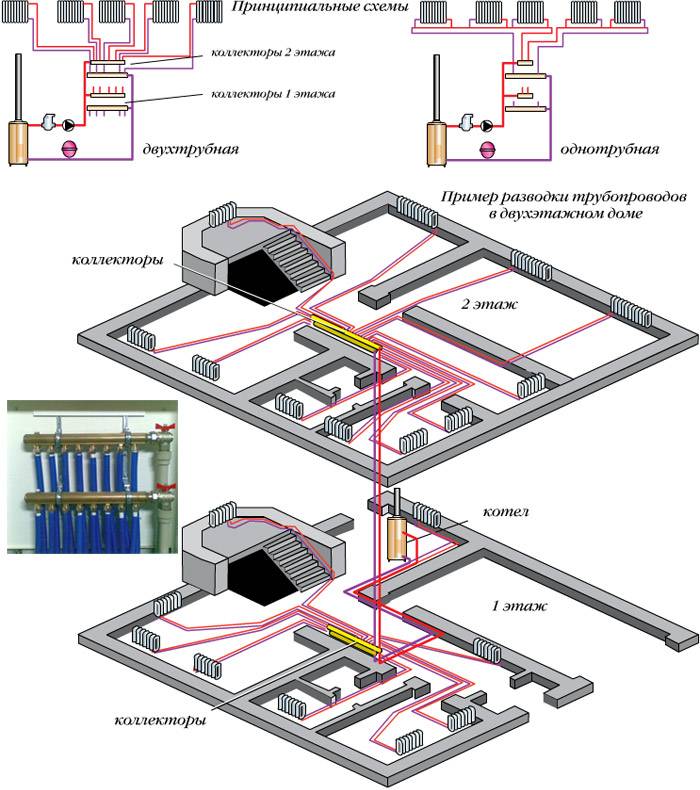

The comb can be round, rectangular or square in cross section. Here, the transverse area comes first, and not the shape of the section, although from the position of hydraulic laws, a rounded one is preferable. If the house has several floors, it is better to install local distribution collectors on each of them.

Installation of a collector heating system

Conventionally, the entire installation process can be divided into 3 stages: laying and fixing pipes on the floor of the room, installing a manifold cabinet and connecting pipes to the combs.

The work instructions look like this:

- the base is first prepared - the concrete is cleaned and leveled;

- then a layer of waterproofing is spread, and a tape is glued around the perimeter of the room, which will smooth out the expansion of the concrete screed;

- then follows a layer of waterproofing;

- an ordinary metal mesh is laid on top of it and pipes are attached to it with wire or special clips. When attaching pipes to the grid with wire, you need to leave a small gap;

All ready to pour concrete

followed by pouring the floor. With this method of laying pipes, when transporting the coolant to the radiator, they will partially work to heat the floor in the room.

Pipes are in the thickness of concrete

As for the manifold cabinet, for a private house, you can choose both wall-mounted or floor models, as well as options built into the wall. In principle, this does not affect the heating efficiency in any way, so you have to choose more based on the convenience of access to the collector combs.

An example of a wall cabinet model

Under the models of cabinets built into the wall, it is desirable to provide a niche even at the design stage of the house. Regardless of the type, the locker must additionally be fixed to the walls with anchors or self-tapping screws (in a wooden house), for this special eyelets are provided in the design of the locker.

You can do without a locker, but the interior of the room will suffer

Advantages of a collector heating system

The main advantages are the convenience of managing the structure, in particular:

- Each loop element can be controlled independently and centrally. This means that in the house the owner sets the temperature of each room, has the ability to turn off the radiator or a group of radiators from heating altogether.

- Cost reduction. Due to the supply of coolant to only one battery, pipes of smaller diameter are suitable for forming a pipeline. Plus, the ability to turn off the battery from the heat supply - together you get a good savings. The eyeliner is most often recessed into the screed with the calculation of the minimum distance from the boiler and radiator.

- It is possible to equip several circuits with different heating parameters, including those with temperature fluctuations, while using a hydraulic arrow.

Also, when installing a collector for a heating system, it is necessary to take into account the disadvantages:

- increased energy consumption;

- difficulties in equipping beam wiring and drowning devices in a screed;

- increased hydraulic resistance in the system.

When arranging an independent heat supply to different circuits, it becomes necessary to use circulation pumps for each circuit, which means that the system becomes energy-dependent.

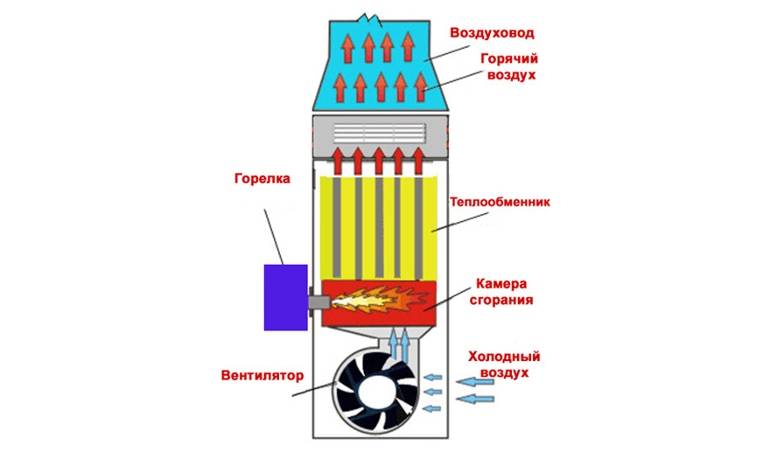

The principle of operation of the collector

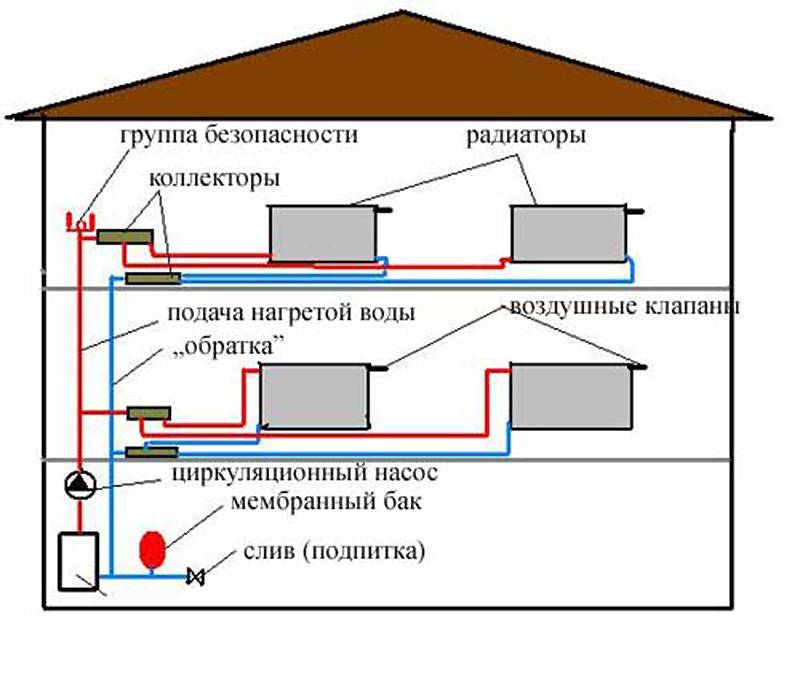

The main purpose of the device is the uniform supply of heat flows from the main line along the contours of the circuit and to the heating radiators, as well as the implementation of the return flow to the boiler. The device acts as an intermediate distribution unit and consists of a supply and return comb. In this case, the supply element is responsible for supplying the coolant to the circuit, the return element is responsible for returning the liquid to the boiler.

Leads depart from each comb for connecting circuits leading to heaters. The distribution manifold of the heating system with outlets can be supplemented with shutoff valves, which help regulate the pressure inside the circuits and, if necessary, repair or reduce the heating intensity, shut off the coolant supply to a separate branch.

The principle of operation is simple - a heat collector for heating a house transfers the coolant through the supply comb to the circuits, while inside the intermediate node the coolant circulation rate decreases due to the increased internal diameter of the structure, and this ensures uniform redistribution to all outlets.

The coolant is directed through the connecting pipes, enters separate circuits and is transported to heating radiators or to the underfloor heating grid. Then the structure warms up, and the liquid is redirected through another pipe to the intake header of the collector. From here, water flows to the heat generator.

Positive and negative sides of the collector circuit

When planning a heating installation with collector wiring, you should carefully study the technical side of the issue and determine all the positive and negative qualities of this system. Given these qualities when building a house, you will be able to achieve its greatest energy efficiency.

- direct control of each individual radiator of the system;

- a differentiated approach to the distribution of heat in each room, which makes it possible to effectively maintain the required temperature throughout the house, while saving;

- ease of operation, the ability to access each component of the system without interfering with the work of the others;

- aesthetic component, which consists in the possibility of installing the pipeline and auxiliary components of the system in the wall or in the floor;

- high payback associated with the efficient consumption of energy resources.

Negative qualities: high costs at the initial stage of design and installation, associated with the need to use pipes and additional components;

As you can see, there are not many minuses, they are not significant in comparison with the pluses of the system. Therefore, a collector heating system is rightfully considered the best solution today.

Not without a circulation pump

Scheme of the device of the collector heating system.

The layout of this heating system involves the circulation of fluid under duress. This function is assigned to the pump. It is this part of the beam system that distills the liquid with the indicated pressure and guarantees the best temperature readings that are comfortable for people.

The parameters of the pipes, the dimensions of the heat exchangers affect the type of circulation pump that will be in the organized heating system. It is preferable to purchase a pump that moves liquid through pipelines at high speed. It is more difficult to choose a pump for a radiant floor heating system. This will require devices large in their power, capable of pumping water.

The strength of such a pump and the power of a radiant heating system must have equivalent parameters. Anyone who ignores this warning will receive noise as a result of a stupid error.

The circulation pump should start functioning if the resulting heating system is completely filled with water. Otherwise, damage may occur.

The pump is allowed to start its operations only clean - it must first be thoroughly rinsed.

The system of created collector heating requires the placement of a pump for fluid circulation closer to the expansion tank. According to the plan, it is fixed on the return pipeline. There is not too high a temperature, and in this place it fulfills the conditions stipulated by the instructions.

When preparing a plan for radiant heating, it is necessary to think it over, double-check it several times. High-quality materials, tools, and the beam system assembly scheme itself will require time, money, and attention. But this will turn into comfort in terms of uniform heat generation in any of the rooms of the equipped dwelling.

4 The principle of drawing up wiring diagrams

There are no specific rules for drawing up the wiring of collector heating. You can and should arrange it depending on the individual characteristics of a particular room.

The connection is only permissible if, at the design stage of the multi-apartment building, valves were provided for connecting any distribution of the heating system.

Thus, the collector heating circuit allows you to heat the house as efficiently as possible, if necessary. That is, the rationality of the installation must be calculated, basically this solution is suitable for two- or three-story houses.

Advantages and disadvantages

Collector heating in an apartment or a private house has pros and cons. The advantages of this system include:

- Maintainability. If a breakdown is detected, you can easily turn off a single section of the pipeline without completely interrupting the operation of the system.

- Small pipes can be used. Since each branch leaving the distributor feeds only one radiator, it is possible to choose small-section pipes for its installation, while they can be easily placed in the screed.

- Ease of operation. Due to the fact that each device has autonomous control, the owner of the house has the opportunity to set the temperature in any particular room. And if necessary, turn off the heating devices in the room. And the temperature in the rest of the rooms will remain the same.

- You can install a collector heating system in a private house with your own hands.

The cost of the economic plan is one of the disadvantages of this heating

In order to create several branches that have different characteristics, for example, different coolant pressure, distribution wiring with a hydraulic compensator is used. A hydraulic arrow is a capacious pipe, where several independent branches are connected to the outlets.

See also: description and principle of operation of the hydraulic switch.

Due to the fact that heated water reaches the radiators with minimal losses, the efficiency of the system increases. This allows you to reduce the power of the boiler, saving fuel costs.

The heating system also has disadvantages. The main ones are:

- Pipe consumption. In contrast to the classical connection, the consumption of pipes during the arrangement of the collector circuit increases by 2-3 times. The difference in costs is due to the number of premises involved.

- The presence of circulation pumps is required, which will entail additional material investments.

If something happens to the pipes, you will have to open the floor

Also, the disadvantage is the dependence on electricity: even with the boiler running, during a power outage, the radiators will remain cold. Therefore, these systems are not recommended for use in areas where power outages are common.

When laying pipes in a screed, it must be remembered that any connection is a possible place for a leak, and if problems occur, the floor will need to be opened. And this is quite laborious and costly work. Therefore, the connection of the wiring of the circuits is made only above the floor level.