- Septic tank made of concrete rings: construction stages

- Preparatory stage

- Excavation

- Delivery and installation of reinforced concrete rings

- Waterproofing

- Ventilation

- Overlapping a septic tank

- Choosing a place for a septic tank, installing a filter well

- Video description

- Mounting Features

- Video description

- Conclusion

- Schemes of sewerage from concrete rings

- Features of the installation

- Cesspool made of other materials

- Cesspool made of bricks

- Cesspool of tires

- Cesspool made of plastic

- How to clean a cesspool

- Overview of popular schemes

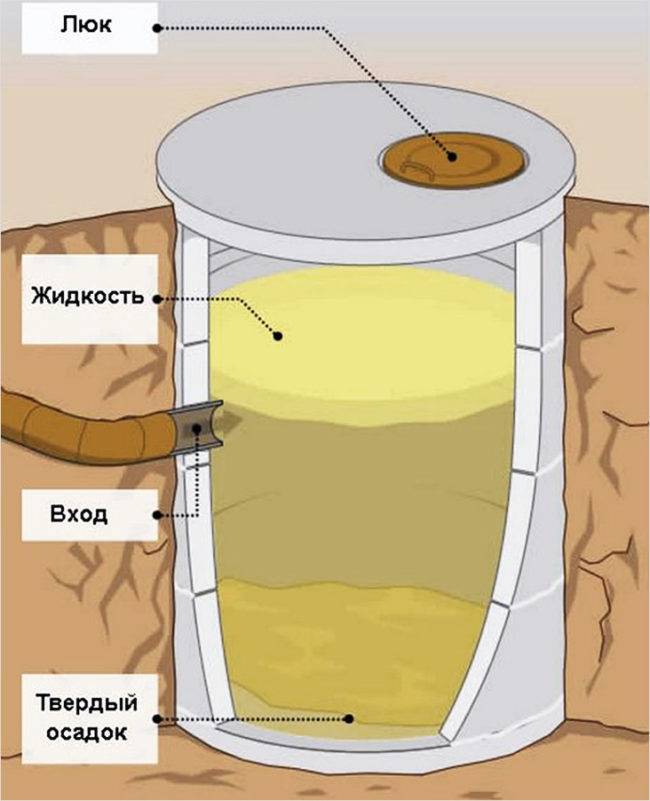

- Separate storage tank

- Drain hole without a bottom

- Two-chamber septic tank made of concrete rings

- Stages and features of installation work

- Pit arrangement

- Mounting

- Supply of sewer pipes

- Ventilation system device

- Sealing joints between rings and pipes

- Installation of floors and backfill

- How plastic rings are installed

- Why is a closed cesspool a part-time treatment plant?

- Installation of concrete rings

- Construction stages

- Video description

- How to choose the best place for a septic tank

- Pit preparation

- Installation of rings and sewer pipes

- Sealing and waterproofing

- Manhole installation and backfill

- How does the septic tank start up

- What rules must be observed when maintaining a septic tank

Septic tank made of concrete rings: construction stages

Sewerage with a septic tank made of concrete rings is distinguished by reliability, durability and a high level of cleaning of household sewage. The price of such a structure will be relatively low, and with excellent waterproofing and the correct scheme, it will not be necessary to pump out the tanks often. The difficulties of construction include the need to attract heavy equipment and the peculiarities of installing pipes between concrete sections.

Preparatory stage

Installation of a septic tank is carried out in compliance with all sanitary, building rules and regulations. They think over the design of the treatment plant, the location on a private site and coordinate the plan with the relevant authorities. They decide which septic tank is better to install so that the sewerage system in a private house is made as comfortable as possible. Correctly calculate the volume of the septic tank and proceed to construction.

Excavation

The pit for the sewage treatment plant in a private house should be so large that nothing interferes with the installation of the rings. The bottom of the cesspools, at the installation site of the sedimentation tanks, is concreted. This prevents the ingress of untreated water into the soil.

Pit for a septic tank

The base for the second or subsequent chambers is made in such a way that water can go into the soil. To do this, make a filtration pad up to 1 meter deep from gravel and sand.

Advice! If, during the installation of a septic tank, the pit under the filtration well reaches the sandy layer of soil, the water will leave it as quickly and easily as possible.

The shape of the pit does not have to be round, a standard, square one is also suitable, the main thing is that the rings go into it freely.In addition, a ready-made concrete slab can be laid on the bottom of a square pit, while only a cement screed can be made in a round pit. At this stage of work, it is also worth remembering that if each subsequent well is located 20-30 cm lower than the previous one, the septic tank and the sewage system itself will be more functional.

Delivery and installation of reinforced concrete rings

The rings are delivered and installed by freight transport, so it is worthwhile to provide access to the construction site in advance, take into account additional economic costs and the turning radius of the crane boom, gas, telephone or electrical communications should not interfere with it. Between themselves, the rings are usually connected with metal brackets, the joints are coated with a solution of cement and sand.

Installation of reinforced concrete rings

When all the wells are installed, holes are made in them and overflow pipes are installed, the external sewage system is connected to the treatment plant through a drain pipe entering the first tank. Pipe entry points must be sealed. The space between the installed rings and the walls of the pit is covered with soil and carefully compacted in layers. If the septic tank is installed above the freezing level of the soil, it is insulated, otherwise the sewage system will be non-functional during the cold season.

Waterproofing

Good waterproofing of a septic tank is fundamental to its proper operation. Each builder determines which sealant is best for this purpose. Usually, rubber-bitumen mastic is used to process seams, polymer mixtures are less common. For a longer operation of cesspool structures, internal waterproofing of the seams of the tank is also performed.

Waterproofing of well rings

If the sealing is done poorly, then the ingress of untreated drains into the ground will be the lesser of the evils. The septic tanks, especially during the spring thaw, will be filled with water, and all its contents will flow out through the plumbing in the house, repeated pumping will be required.

Ventilation

An exhaust pipe up to 4 meters high above the level of the septic tank must be installed on the first tank. It is necessary so that the gases formed as a result of the fermentation of effluents can escape, and there are no unpleasant odors on the site. If possible, ventilation pipes are installed on each well.

Septic tank ventilation

Overlapping a septic tank

The task of overlapping is not only to close the pit, it must ensure the tightness of the containers. As a rule, the chambers are covered with ready-made reinforced concrete slabs, on which there is a hole for a hatch made of cast iron or thick plastic. Then the structure is covered with a small layer of soil. Manholes on each of the wells will help monitor the condition and filling of the septic tank, and will also make it possible to periodically add a mixture of active bacteria for cesspools.

Choosing a place for a septic tank, installing a filter well

The choice of a place to place a septic tank is carried out taking into account regulatory requirements (5 m from the house, 30-50 meters from the water intake or reservoir). The second criterion is service. Although septic tanks do not require frequent pumping like cesspools, it is necessary to free the containers from solid sediments - otherwise they will form a large layer of “mineral” deposits at the bottom, and this will reduce the performance of the treatment system.

When biological post-treatment of wastewater in wells or fields, it must be borne in mind that they are arranged in soils with good filtering properties - sand and sandy loam.

Restrictions when installing septic tanks

For weakly filtering soils, after the septic tank, filtering trenches are arranged with the collection of water in storage tanks for irrigation or discharge into a nearby reservoir.

If, according to the geological features of the site, a scheme with trenches and filtration fields is chosen, then it must be borne in mind that only a lawn can be laid out on their area or small shrubs with a shallow root system can be planted.

Sewerage from the rings

The filter well does not have a sealed bottom - instead, a mixture of gravel (crushed stone) with screenings or coarse sand is backfilled. The height of the backfill is about 30 cm. They don’t do it anymore because of the difficulties in the subsequent replacement.

The rest of the load for filtering treated effluents is taken by the backfill around the "perforated" walls of the well. The recommended layer thickness is 30 cm. Perforation of the walls should start from below and end at the level of the pipe inlet from the overflow of the last septic tank chamber. For the walls, either ordinary well rings are used, in the walls of which holes with diameters of 3-6 cm are made before installation (with a total area of at least 10% of the total), or special perforated rings for drainage wells are installed.

Video description

Visually about the choice of a place for a septic tank and sewerage for a private house made of concrete rings, see the following video:

Mounting Features

Sewer rings are installed on the bottom slab, which acts as a slab foundation. The prefabricated reinforced concrete structure must have a stable and reliable foundation.Here, preparation of the bottom of the pit is also needed: leveling, tamping, backfilling with a layer of sand and gravel.

During installation, it is obligatory to seal the joints with cement mortar, followed by the treatment of the entire surface with waterproofing compounds.

The recommended height of wells is no more than three rings. If you make it higher, then the design will be "weaker".

The stage of installation of sewerage in a private house of concrete rings

The inlet to the first well is mounted at least 30 cm from the cover. And the overflow holes are made with a slight decrease. This leads to a decrease in the "working" volume of the septic tank, which must be taken into account when choosing the size of the rings.

Video description

An example of installing a septic tank from concrete rings, see the following video:

Conclusion

Calculation, design and construction of an autonomous sewage system of any type is a task for specialists. And if the use of factory septic tanks simplifies this task, then individual schemes using concrete rings require the involvement of professional builders who have experience working with precast concrete structures.

Schemes of sewerage from concrete rings

Sewerage from concrete rings is done according to different schemes. The specific type depends on the seasonality of residence, the intensity of operation, the financial possibilities for the purchase of additional equipment and the payment of operating costs.

The following options can be distinguished:

- Storage septic. Behind this name lies an ordinary cesspool with a waterproof bottom and walls. Tightness is a mandatory requirement, failure to comply with which, according to the administrative code of the Russian Federation, is regarded as damage to the land.When the drains fill the tank, they call a sewage truck.

A storage septic tank is simply a container into which wastewater is collected.

The smaller the capacity and the higher the intensity of operation of points connected to the sewer, the more often you need to call the car. Often this is how they arrange country sewage from concrete rings.

- Anaerobic septic tank. Two-, less often single-chamber, septic tanks, in sealed containers of which wastewater is cleaned by anaerobic bacteria (without oxygen). The number of chambers and their volume are chosen in such a way that the drains at the outlet of the septic tank are cleaned by 65-75%. Post-treatment takes place in filtration wells (“without a bottom”), trenches or fields with aerobic bacteria (it is called “biological treatment”). Only then can the effluent be discharged into the ground. The scheme is very popular among owners of country houses and cottages because of the simplicity of the device and energy independence. The disadvantage of the scheme is that it is necessary to periodically change the sand and gravel in the filtering facilities, while they have to be opened, and the used material to be disposed of (although this is done infrequently).

Scheme of an anaerobic septic tank from reinforced concrete rings

- Aerobic septic tanks and biological treatment plants. There is also a phase of primary accumulation and partial processing of faeces with the help of anaerobic bacteria. The principle of operation consists in clarifying wastewater in the absence of oxygen, and post-treatment in the last chamber with aerobic bacteria under conditions of forced air injection. The purity of the wastewater at the outlet is considered to be 95-98%, and they can be discharged into the ground or used for irrigation. The disadvantage is that aerobic bacteria die if the air supply compressor does not work.And this happens with a bad network due to power outages.

The principle of operation of aerobic septic tanks - electricity is required for operation

Features of the installation

If you are thinking about the question of how to make a sewer in the country with your own hands, then you should initially purchase the appropriate components. Thus, nine rings will be needed to carry out the work. In addition, you need to purchase three hatches, their number is determined by the number of trenches.

Do-it-yourself sewerage in the country can easily be done. To do this, at the first stage, it is necessary to deal with the arrangement of pits, they must be arranged in a row, their number is limited to three units, the depth is three meters, and the diameter is 2.8 m, which slightly exceeds this figure for reinforced concrete products. It will be quite problematic to dig holes on your own, so it is worth attracting assistants, some of whom will work on receiving the earth supplied from below. The bottoms of the first and second pits must be provided with concrete substrates. Next, you can proceed to the installation of concrete elements. Here you have to take care of the availability of lifting equipment, with which it will be possible to mount heavy elements.

In order for the do-it-yourself sewerage in the country to be made with high quality and perform all the functions, you need to take care of its tightness. To do this, the horizontal grooves between the rings must be eliminated using liquid glass. After installing the internal elements, some space will remain between the walls of the pit, which will have to be disposed of by backfilling with soil.

Do-it-yourself sewerage in the country should be equipped in such a way that sewage flows from one ring to another without hindrance. To guarantee this condition, it is necessary to follow some rules, among them the need to install a pipe leading to the starting well with a certain slope. But the pipe that mates the first and next wells must be mounted 20 cm lower, as well as the connecting element between the second and last tanks.

Cesspool made of other materials

In addition to the most common version of a cesspool made of concrete rings, there are many analogues. Some are cheaper but not suitable for permanent residences, some are more expensive but have restrictions on use in certain types of soil.

Cesspool made of bricks

To lay out the walls of the well with bricks, it is not necessary to be a bricklayer. It is enough to have minimal knowledge and acquire basic bricklaying skills. To complete the work you will need:

- shovel ordinary bayonet - for leveling the soil in the right places;

- shovel shovel - for collecting and removing excess earth;

- stairs - in order to go down and get out of the pit;

- tape measure - to measure the required dimensions;

- buckets - for carrying mortar and various materials;

- trowel - to apply the mortar to the masonry;

- level - allows you to control the strict verticality of the walls.

Of the materials you will need - brick, cement, sand and water.

If you are laying a hole with a sealed bottom, then first you need to prepare a concrete base. To do this, it is necessary to make a compacted sand cushion with a thickness of at least 20 cm.After installing the pillow, you can start pouring concrete. The thickness of the concrete bottom should be at least 5-7 cm, it is also possible to reinforce such a base to make it more rigid.

After the concrete has hardened, you can begin the construction of the masonry. At the same time, there are no special requirements for either the quality of the brick or the quality of the masonry itself, the main thing is to maintain the level and the absence of cracks in the masonry. The pit can be either square or round - it all depends on your imagination.

If you are building a sewer without a bottom, then as a brick sole, you need to make a pillow and pour concrete in the form of a ring so that water can escape into the inside.

Cesspool of tires

A cesspool made from waste car tires is distinguished by its low cost and ease of assembly. To install such a pit, you will need old tires of the desired diameter, tires from a passenger car are suitable for a small volume, and for a large one you can take from a truck or even a tractor.

To add usable area, the side parts of the tires must be cut in a circle. You can easily do this with a jigsaw or a grinder. But if they are not available, an ordinary, only very sharp, knife with a rigid blade will do.

The prepared tires are stacked one on top of the other in a pit dug in advance for the diameter of the blanks and fastened together with plastic ties, bolts with nuts, etc. If necessary, the joints between the tires can be sealed with bitumen or other adhesive.

This type of cesspool is often used to collect wastewater in a bathhouse or summer kitchen.

Cesspool made of plastic

The easiest way to make a drain hole is from a ready-made plastic container that you can buy at the store.You just need to dig a pit and install the container itself there.

The indisputable advantages of this method is that you will deprive yourself of an unpleasant smell and be one hundred percent sure that the drains will not fall into the soil and will not mix with groundwater. But as it fills up, you will have to call the sewage equipment for pumping out, which will undoubtedly entail spending money.

Also, restrictions for such containers are imposed by the level of groundwater, since at their high level, the container can be squeezed out of the ground.

How to clean a cesspool

You can pump out the contents of the cesspool by inviting specialists with equipment that should not be less than the volume of your cesspool in volume. The hose of such a sewage machine should be enough to completely lower into the pit, and the entrance to the pit should be convenient.

There are also special products for cleaning cesspools, which are bacteria that are completely safe for nature and process waste products. You can buy such funds at any store for home and garden. Such products remarkably clean even the walls and bottom of the pit, processing solid waste into sludge, gas and water.

Thus, a cesspool in a private house is an economical option for organizing sewage, requiring attention only a few times a year. The indisputable advantage of a cesspool made of concrete rings is its durability, low cost and the possibility of installing such a system with your own hands using minimal equipment.

Overview of popular schemes

Despite the material of manufacture, sewer structures can have a different design. The difference concerns, to a greater extent, the number of cameras - from one to three. Consider the schemes that are most suitable for providing private houses with autonomous sewage.

Separate storage tank

A cesspool from one sealed chamber is the simplest option. It does not pollute the environment, therefore, it is safe and environmentally friendly. Such a pit takes up a minimum of space, and since it is underground, it does not interfere with growing flowers or setting up beds nearby.

Restrictions apply to the planting of trees that, with their roots, can depressurize the sewer structure.

Scheme of the simplest single-chamber cesspool. It is necessary to ensure that wastewater does not rise above the level of the sewer pipe tie-in, and call the vacuum trucks in time

A single-chamber drive is relevant for those who rarely use the sewer system, that is, they rarely visit the country house. There is another option - if a single person lives in the house, and the sewer system consists of a minimum of active points of use (toilet, shower, sink).

When constructing a tank, it must be remembered that it is not filled to the very top, but to the level of the pipe inlet, therefore it is only used for 2/3 of the volume. A simple drive requires regular pumping, and for this it is necessary to prepare a convenient access road for vacuum trucks and it is better to conclude a contract for constant maintenance.

Drain hole without a bottom

A variant of a single storage tank is a pit with a filter bottom.The main purpose of the filter is to pass part of the effluent directly into the ground in order to reduce the load on the structure and reduce the number of calls for specialists to pump out waste.

The design of the lower part of the tank differs from the blind bottom of the sealed chamber. This may be a structure made of concrete blanks, a brick well or a plastic container.

Scheme of a cesspool with perforated walls and a filter bottom. A thick sand and gravel pad acts as a filter, which needs to be updated over time

In soils with low throughput, for example, in plastic sandy loams, it is advisable to arrange additional perforation of the walls. To do this, form small holes after about 10 - 15 cm.

They are arranged along the entire height of the soil filter in a checkerboard pattern. Such methods increase the filtration area, as a result, the recycling process is accelerated.

Two important conditions for a filtration device:

- sandy or sandy loam soil - loose, with a high degree of water permeability;

- low level of occurrence of water horizons.

Dense clay soils, hard sandy loams, loams of any consistency simply will not absorb water, so the perforation device is useless.

This scheme is more suitable for the construction of filter wells, which are the second or third compartment and are installed after the drive. The quality of post-treatment in the soil of partially clarified water is much higher than that of unsettled sewage from the first storage cesspool.

Pumping out waste from a pit without a bottom is carried out a little less often than from a conventional pit. If the filter is clogged, the pumping mode is the same.

Two-chamber septic tank made of concrete rings

A complicated version of the drain pit is a double tank.

It can have a different design:

- concrete container, divided into 2 parts by a partition;

- 2 wells connected by an overflow pipe.

Despite some differences in design, the goals of building two-chamber models are the same - to separate waste according to the degree of pollution. In the first section, which is a full-fledged accumulator, the processing of waste by anaerobes begins, as a result of which a solid precipitate and a cloudy liquid are formed.

In the second - wastewater is even more clarified, the sediment is much less.

A variant of the device of a two-chamber septic tank. The second tank is a filter well that receives wastewater from the first chamber and sends it to the ground for post-treatment (+)

If the second container is equipped with a compressor, then the cleaning will be more effective, since the processing will also be carried out by aerobic microorganisms. Two-chamber models, in fact, are no longer just storage tanks, but septic tanks that can partially clean sewage.

Briefly, the process of building a two-chamber septic tank from concrete rings is represented by the following photo selection:

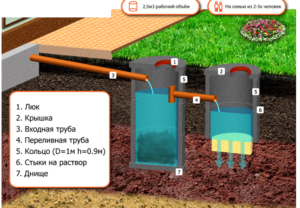

Stages and features of installation work

The main stages of installation work in the construction of a septic tank from concrete rings:

- arrangement of the pit;

- installation of concrete rings;

- supply of sewer pipes;

- device of the ventilation system;

- joint sealing;

- installation of ceilings and backfilling.

Pit arrangement

Excavation work can be carried out using special equipment or manually. When building a new house, it is better to dig a pit with an excavator.But at the same time, one nuance should be taken into account: when digging a pit with a bucket, a pit is obtained, the shape and dimensions of which are much larger than those required by a septic tank made of concrete rings. It will not be easy to lower products weighing 400 kg or more into such a pit on your own. Therefore, you will have to use the services of a crane. Digging by hand takes much more time, but allows you to make a foundation pit exactly in size.

Concrete rings with a bottom should be installed in the pit first, i.e. - bottom

The bottom of the pit must be concreted to prevent the penetration of untreated sewage into the soil. If the septic tank is made of concrete rings and its device involves the use of special products with a bottom, then the bottom of the pit does not need to be concreted.

If a three-chamber version is being constructed from concrete rings for a bathhouse or a house, then in the third filter well a pillow of gravel and sand 50 cm thick is made. At the stage of digging a pit, trenches are made for pipes connecting the tanks and leaving the house. A layer of sand 10 cm thick is covered at the bottom of the trenches.

Mounting

Since the concrete elements are quite heavy, a truck crane or a homemade winch is used to install them in the pit. You can use another method - the sequential installation of rings with digging, but this method is very labor-intensive. In addition, it is rather inconvenient to concrete the bottom of the septic tank, in which the rings are already installed.

After installation, the rings must be fastened together with a cement-sand mortar. Additionally, they can be fastened with metal brackets.

This precaution will prevent the formation of cracks in the rings during seasonal ground movements.

Supply of sewer pipes

Holes for pipes are punched in the mounted rings. The pipe transporting wastewater to the first well is placed at a slight angle. The pipe that connects the first and second wells should be 20 cm lower than the previous one, and the pipe supplying the treated effluents to the filter well should be installed another 20 cm lower.

Ventilation system device

To ensure ventilation of the septic tank, it is necessary to connect the sewer pipe to the ventilation riser, which goes to the roof of the building. The riser pipe in diameter must be no less than the pipe transporting domestic wastewater to the septic tank.

If the ventilation pipe is made smaller than the sewer pipe, then the drains will create a “piston” effect, and this leads to the disappearance of the water seal in the siphons of plumbing fixtures. As a result, sewage odors begin to penetrate into the room.

Therefore, it is very important to build a septic tank from concrete rings, the ventilation of which will perform two main tasks as efficiently as possible:

- to exclude rarefaction of air in sewer pipes;

- eliminate unpleasant odors from sewer lines and wells.

Sealing joints between rings and pipes

Ordinary concrete, contrary to popular belief, does not hold water. A septic tank made of concrete rings is no exception.

Waterproofing indoor and outdoor surfaces of the septic tank must be done very carefully. To do this, use a solution of liquid glass, bituminous mastic or well-proven polymer mastics. The best results when deciding how to properly make a septic tank from concrete rings with the best waterproofing are given by a concrete solution with special additives.

Installation of floors and backfill

Mounted sewer wells are covered with concrete slabs, in which holes are made for the installation of hatches. After installing the plates, the septic tank is backfilled. To do this, use the soil taken out of the pit. Upon completion of backfilling, the septic tank is completely ready for operation.

How plastic rings are installed

They are installed directly into the ground. The installation process consists of several stages:

- Preparing a place for a toilet.

- Digging a pit for a plastic container.

- Preparation of the bottom of the pit, which consists in laying alternately layers of gravel, sand and geotextiles.

- Now you can start installing polymer rings. They are lowered one by one into the hole.

Their order is:

- Bottom.

- One or two rings.

- with pipe hole.

- with lid.

To connect, a slight pressure is enough for each element to sit firmly in the grooves provided.

The cesspool equipped in the summer cottage should be pumped out periodically, so you need to monitor its filling. For these purposes, you can buy a special float that will signal the degree of filling of the pit.

Why is a closed cesspool a part-time treatment plant?

A cesspool is a kind of septic tank that recycles incoming water, but does not provide complete purification.

A closed cesspool is not just a sump for liquid waste: anaerobic bacteria process the contents in it, with the exception, perhaps, of the layer that is in direct contact with air.Anaerobic bacteria are known to perform the initial step of converting wastewater into cleaner water. After fermentation with their participation, the water does not lose, but it changes the smell - to a marsh. The water does not become transparent from this purification: turbidity remains at this stage. Also, solid particles of mechanical suspension can be deposited in the pit, and if there is a desire to separate them to obtain compost, then a chamber with overflow from the sump to the septic tank can be built. Naturally, such a septic tank provides far from complete water purification, and they are also subject to disposal by a sewage machine. The scheme of such a cesspool will be much more complicated, since this is, in fact, the simplest septic tank.

Let's get back to soil research. If it is found that the groundwater in your area is deep, then you can turn the cesspool into a filtration well. This scheme is called a cesspool without a bottom. It is possible to indirectly determine whether the water is deep by the following sign: if most of the neighbors have wells dug, and not wells, then they have found shallow aquifers in their plots. If everyone uses exclusively wells, then you need to ask how deep they are. But for the final decision, you need to make sure with the help of hydrological studies. If it is not possible to conduct them, then it is better to choose a sealed cesspool scheme, since it is universal.

Installation of concrete rings

To equip a cesspool with concrete products, it is necessary to prepare the following materials:

- Concrete rings (depending on the intended depth).

- cement mortar.

- Materials for a small foundation.

- Sand, based on the area to be filled, if its layer is 50 cm.

- Gravel, based on the area to be filled, if its layer is 20 cm.

- Cover with hatch.

Installation of such rings is carried out without waterproofing. The installation process consists of the following items:

- Preparation of a round pit with a small margin for the diameter of the rings.

- The bottom of the pit must be filled with concrete. Only after the solution has completely solidified, work can be continued, usually it takes about 5 days.

- Now it remains to install the rings. For this, it is recommended to use special equipment, since their weight is very large.

- The free space between the walls of the rings and the pit must be filled with gravel or crushed stone from granite.

- The inner surface must be plastered, having carried out internal and external waterproofing of the seams.

- It remains to install the cover and the ventilation duct.

Construction stages

Installation is carried out in the following order:

- A place is selected, an installation scheme is built, and the parameters of the septic tank are calculated.

- A hole is being dug.

- Rings are installed, pipes are connected.

- Sealing and waterproofing works are underway.

- Covers are installed.

- Backfilling is underway.

Video description

The order of work and the installation of a septic tank from concrete rings on the video:

How to choose the best place for a septic tank

The structure is mounted above the groundwater level. The best location is at the maximum distance from the house (at least 7 meters, but not more than 20, so as not to increase the cost of pipeline construction). It is logical to have a septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving the tanker-vacuum truck is affected by access to the system and the length of the hose.In addition, with the correct location, the sewage truck does not need to drive into the yard, and the hoses will not roll on the beds or paths (otherwise, when the hose is rolled up, the waste can get into the garden).

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of rings and their waterproofing. The bottom is covered with rubble and concreted.

Preparing a pit for a septic tank from concrete rings

Installation of rings and sewer pipes

Rings for a septic tank are installed using lifting equipment, which saves a lot of time (when compared with manual installation). Fixation of the seams is provided with cement mortar, metal ties (brackets, plates) are additionally placed.

The crucial moment is the process of installing rings

Sealing and waterproofing

Sealing the seams of the septic tank from concrete rings is carried out on both sides of the structure. For this, cement and coating protective solutions are used. Inside the well, you can install ready-made plastic cylinders. Such additional costs will make the system 100% hermetic.

In the process of waterproofing concrete rings for a septic tank, the joints are treated with liquid glass, mastic based on bitumen or polymer, concrete mix. To prevent freezing (and destruction) of the structure in winter, it is recommended to insulate it with a layer of polystyrene foam.

Sealing joints and waterproofing a septic tank from concrete rings

Manhole installation and backfill

The wells are covered with concrete slabs, with holes for manholes.In the first two wells, ventilation is necessary to remove methane (gas appears as a result of the vital activity of anaerobic bacteria). To backfill the installed floors, use the soil taken out of the pit (backfill).

Backfilling of finished wells

How does the septic tank start up

In order for the system to begin to function effectively, the erected septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- A new septic tank is filled with wastewater and defended for 10-14 days. Then it is loaded with sludge from an operating anaerobic septic tank (2 buckets per cubic meter).

- You can buy ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes that are intended for other treatment systems).

Ready to run septic tank from the rings

What rules must be observed when maintaining a septic tank

There are simple rules that support the quality of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (and preferably in 2-3 years), bottom heavy fats are cleaned. The volume of sludge must not exceed 25% of the volume of the tank. During cleaning, part of the sludge is left to restore the microflora.

- Quality of work. Effluent at the outlet of the system must be cleaned by 70%. Analysis of wastewater in the laboratory will determine the acidity index, which will allow you to know the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after enhanced ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (wet environment).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.