- How to calculate wall thickness

- Calculation of wall thickness, insulation thickness, finishing layers

- An example of calculating the thickness of the insulation

- 4.8 Rounding off calculated thermal conductivity values

- Annex A (mandatory)

- Need for wall insulation

- Thermal engineering calculation of walls from various materials

- Calculation of the required thickness of a single-layer wall

- Calculation of the heat transfer resistance of a wall

- Aerated concrete block wall

- Wall made of expanded clay concrete block

- Ceramic block wall

- Silicate brick wall

- Calculation of a sandwich structure

- What is thermal conductivity and thermal resistance

- We carry out calculations

- How to choose the right heater?

- Basic requirements for thermal insulation materials:

- Thermal conductivity of gypsum plaster

- Efficiency of sandwich structures

- Density and thermal conductivity

- Calculation of wall thickness and insulation

- Other selection criteria

- Bulk weight of insulation

- Dimensional stability

- Vapor permeability

- combustibility

- Soundproof properties

- Table of thermal conductivity of thermal insulation materials

- Sequencing

- Coefficient of thermal conductivity.

How to calculate wall thickness

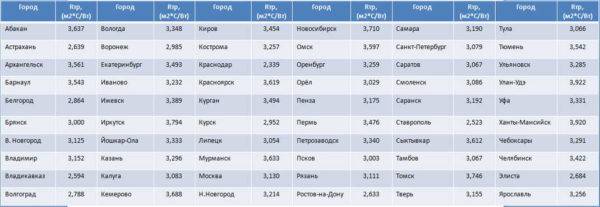

In order for the house to be warm in winter and cool in summer, it is necessary that the enclosing structures (walls, floor, ceiling / roof) must have a certain thermal resistance.This value is different for each region. It depends on the average temperature and humidity in a particular area.

Thermal resistance of enclosing structures for Russian regions

In order for the heating bills not to be too large, it is necessary to select building materials and their thickness so that their total thermal resistance is not less than that indicated in the table.

Calculation of wall thickness, insulation thickness, finishing layers

Modern construction is characterized by a situation where the wall has several layers. In addition to the supporting structure, there is insulation, finishing materials. Each layer has its own thickness. How to determine the thickness of the insulation? The calculation is easy. Based on the formula:

Formula for calculating thermal resistance

R is thermal resistance;

p is the layer thickness in meters;

k is the thermal conductivity coefficient.

First you need to decide on the materials that you will use in construction. Moreover, you need to know exactly what type of wall material, insulation, finish, etc. will be. After all, each of them contributes to thermal insulation, and the thermal conductivity of building materials is taken into account in the calculation.

First, the thermal resistance of the structural material is considered (from which the wall, ceiling, etc. will be built), then the thickness of the selected insulation is selected according to the "residual" principle. You can also take into account the thermal insulation characteristics of finishing materials, but usually they go "plus" to the main ones. So a certain reserve is laid "just in case". This reserve allows you to save on heating, which subsequently has a positive effect on the budget.

An example of calculating the thickness of the insulation

Let's take an example.We are going to build a brick wall - one and a half bricks, we will insulate with mineral wool. According to the table, the thermal resistance of the walls for the region should be at least 3.5. The calculation for this situation is given below.

- To begin with, we calculate the thermal resistance of a brick wall. One and a half bricks is 38 cm or 0.38 meters, the coefficient of thermal conductivity of brickwork is 0.56. We consider according to the above formula: 0.38 / 0.56 \u003d 0.68. Such thermal resistance has a wall of 1.5 bricks.

- This value is subtracted from the total thermal resistance for the region: 3.5-0.68 = 2.82. This value must be "recovered" with thermal insulation and finishing materials.

All enclosing structures will have to be calculated

If the budget is limited, you can take 10 cm of mineral wool, and the missing will be covered with finishing materials. They will be inside and outside. But, if you want the heating bills to be minimal, it is better to start the finish with a “plus” to the calculated value. This is your reserve for the time of the lowest temperatures, since the norms of thermal resistance for enclosing structures are calculated according to the average temperature for several years, and winters are abnormally cold

Because the thermal conductivity of building materials used for decoration is simply not taken into account.

4.8 Rounding off calculated thermal conductivity values

The calculated values of the thermal conductivity of the material are rounded off

according to the rules below:

for thermal conductivity l,

W/(m K):

— if l ≤

0.08, then the declared value is rounded up to the next higher number with an accuracy of

up to 0.001 W/(m K);

— if 0.08 < l ≤

0.20, then the declared value is rounded up to the next higher value with

accuracy up to 0.005 W/(m K);

— if 0.20 < l ≤

2.00, then the declared value is rounded up to the next higher number with an accuracy of

up to 0.01 W/(m K);

— if 2.00 < l,

then the declared value shall be rounded up to the next higher value to the nearest

0.1 W/(mK).

Annex A

(mandatory)

Table

A.1

| Materials (structures) | Operating Humidity | |

| BUT | B | |

| 1 Styrofoam | 2 | 10 |

| 2 Expanded polystyrene extrusion | 2 | 3 |

| 3 Polyurethane foam | 2 | 5 |

| 4 slabs of | 5 | 20 |

| 5 Perlitoplast concrete | 2 | 3 |

| 6 Thermal insulation products | 5 | 15 |

| 7 Thermal insulation products | ||

| 8 Mats and slabs from | 2 | 5 |

| 9 Foam glass or gas glass | 1 | 2 |

| 10 Wood fiber boards | 10 | 12 |

| 11 Fiberboard and | 10 | 15 |

| 12 Reed slabs | 10 | 15 |

| 13 Peat slabs | 15 | 20 |

| 14 Tow | 7 | 12 |

| 15 Gypsum boards | 4 | 6 |

| 16 Plaster sheets | 4 | 6 |

| 17 Expanded products | 1 | 2 |

| 18 Expanded clay gravel | 2 | 3 |

| 19 Shungizite gravel | 2 | 4 |

| 20 Crushed stone from blast-furnace | 2 | 3 |

| 21 Crushed slag-pumice stone and | 2 | 3 |

| 22 Rubble and sand from | 5 | 10 |

| 23 Expanded vermiculite | 1 | 3 |

| 24 Sand for construction | 1 | 2 |

| 25 Cement-slag | 2 | 4 |

| 26 Cement-perlite | 7 | 12 |

| 27 Gypsum perlite mortar | 10 | 15 |

| 28 Porous | 6 | 10 |

| 29 Tuff concrete | 7 | 10 |

| 30 Pumice stone | 4 | 6 |

| 31 Concrete on volcanic | 7 | 10 |

| 32 Expanded clay concrete on | 5 | 10 |

| 33 Expanded clay concrete on | 4 | 8 |

| 34 Expanded clay concrete on | 9 | 13 |

| 35 Shungizite concrete | 4 | 7 |

| 36 Perlite concrete | 10 | 15 |

| 37 Slag pumice concrete | 5 | 8 |

| 38 Slag pumice foam and slag pumice aerated concrete | 8 | 11 |

| 39 Blast-furnace Concrete | 5 | 8 |

| 40 Agloporite concrete and concrete | 5 | 8 |

| 41 Ash gravel concrete | 5 | 8 |

| 42 Vermiculite concrete | 8 | 13 |

| 43 Polystyrene concrete | 4 | 8 |

| 44 Gas and foam concrete, gas | 8 | 12 |

| 45 Gas and foam ash concrete | 15 | 22 |

| 46 Brick masonry from | 1 | 2 |

| 47 Solid masonry | 1,5 | 3 |

| 48 Brickwork from | 2 | 4 |

| 49 Solid masonry | 2 | 4 |

| 50 brickwork from | 2 | 4 |

| 51 Brickwork from | 1,5 | 3 |

| 52 Brickwork from | 1 | 2 |

| 53 Brickwork from | 2 | 4 |

| 54 Wood | 15 | 20 |

| 55 Plywood | 10 | 13 |

| 56 Cardboard facing | 5 | 10 |

| 57 Construction board | 6 | 12 |

| 58 Reinforced concrete | 2 | 3 |

| 59 Concrete on gravel or | 2 | 3 |

| 60 Mortar | 2 | 4 |

| 61 Complex solution (sand, | 2 | 4 |

| 62 Solution | 2 | 4 |

| 63 Granite, gneiss and basalt | ||

| 64 Marble | ||

| 65 Limestone | 2 | 3 |

| 66 Tuff | 3 | 5 |

| 67 Asbestos-cement sheets | 2 | 3 |

Keywords:

building materials and products, thermophysical characteristics, design

values, thermal conductivity, vapor permeability

Need for wall insulation

The justification for the use of thermal insulation is as follows:

- Preservation of heat in the premises during the cold period and coolness in the heat. In a multi-storey residential building, heat loss through the walls can reach up to 30% or 40%. To reduce heat loss, special heat-insulating materials will be needed. In winter, the use of electric air heaters can increase your electricity bills. This loss is much more profitable to compensate through the use of high quality heat-insulating material, which will help ensure a comfortable indoor climate in any season. It is worth noting that competent insulation will minimize the cost of using air conditioners.

- Extending the life of the building's load-bearing structures. In the case of industrial buildings that are built using a metal frame, the heat insulator acts as a reliable protection of the metal surface from corrosion processes, which can have a very detrimental effect on structures of this type. As for the service life of brick buildings, it is determined by the number of freeze-thaw cycles of the material. The influence of these cycles is also eliminated by the insulation, since in a thermally insulated building the dew point shifts towards the insulation, protecting the walls from destruction.

- Noise isolation. Protection against ever-increasing noise pollution is provided by materials with sound-absorbing properties. These can be thick mats or wall panels that can reflect sound.

- Preservation of usable floor space. The use of heat-insulating systems will reduce the thickness of the outer walls, while the internal area of buildings will increase.

Thermal engineering calculation of walls from various materials

Among the variety of materials for the construction of load-bearing walls, sometimes there is a difficult choice.

When comparing different options with each other, one of the important criteria that you need to pay attention to is the “warmth” of the material. The ability of the material not to release heat to the outside will affect the comfort in the rooms of the house and the cost of heating. The second becomes especially relevant in the absence of gas supplied to the house.

The second becomes especially relevant in the absence of gas supplied to the house.

The ability of the material not to release heat to the outside will affect the comfort in the rooms of the house and the cost of heating. The second becomes especially relevant in the absence of gas supplied to the house.

The heat-shielding properties of building structures are characterized by such a parameter as resistance to heat transfer (Ro, m² °C / W).

According to existing standards (SP 50.13330.2012 Thermal protection of buildings.

Updated version of SNiP 23-02-2003), during construction in the Samara region, the normalized value of heat transfer resistance for external walls is Ro.norm = 3.19 m² °C / W. However, provided that the design specific heat energy consumption for heating the building is below the standard, it is allowed to reduce the heat transfer resistance value, but not less than the allowable value Ro.tr =0.63 Ro.norm = 2.01 m² °C / W.

Depending on the material used, in order to achieve standard values, it is necessary to choose a certain thickness of a single-layer or multi-layer wall construction. Below are the heat transfer resistance calculations for the most popular exterior wall designs.

Calculation of the required thickness of a single-layer wall

The table below defines the thickness of a single-layer exterior wall of a house that meets the requirements of thermal protection standards.

The required wall thickness is determined with a heat transfer resistance value equal to the base value (3.19 m² °C/W).

Allowable - the minimum allowable wall thickness, with a heat transfer resistance value equal to the allowable one (2.01 m² °C / W).

| No. p / p | wall material | Thermal conductivity, W/m °C | Wall thickness, mm | |

| Required | Permissible | |||

| 1 | aerated concrete block | 0,14 | 444 | 270 |

| 2 | Expanded clay concrete block | 0,55 | 1745 | 1062 |

| 3 | ceramic block | 0,16 | 508 | 309 |

| 4 | Ceramic block (warm) | 0,12 | 381 | 232 |

| 5 | Brick (silicate) | 0,70 | 2221 | 1352 |

Conclusion: of the most popular building materials, a homogeneous wall construction is only possible from aerated concrete and ceramic blocks. A wall more than a meter thick, made of expanded clay concrete or brick, does not seem real.

Calculation of the heat transfer resistance of a wall

Below are the values of heat transfer resistance of the most popular options for the construction of external walls made of aerated concrete, expanded clay concrete, ceramic blocks, bricks, with plaster and facing bricks, with and without insulation. On the color bar you can compare these options with each other. A stripe of green means that the wall complies with the normative requirements for thermal protection, yellow - the wall meets the permissible requirements, red - the wall does not meet the requirements

Aerated concrete block wall

| 1 | Aerated concrete block D600 (400 mm) | 2.89 W/m °C |

| 2 | Aerated concrete block D600 (300 mm) + insulation (100 mm) | 4.59 W/m °C |

| 3 | Aerated concrete block D600 (400 mm) + insulation (100 mm) | 5.26 W/m °C |

| 4 | Aerated concrete block D600 (300 mm) + ventilated air gap (30 mm) + facing brick (120 mm) | 2.20 W/m °C |

| 5 | Aerated concrete block D600 (400 mm) + ventilated air gap (30 mm) + facing brick (120 mm) | 2.88 W/m °C |

Wall made of expanded clay concrete block

| 1 | Expanded clay block (400 mm) + insulation (100 mm) | 3.24 W/m °C |

| 2 | Expanded clay block (400 mm) + closed air gap (30 mm) + facing brick (120 mm) | 1.38 W/m °C |

| 3 | Expanded clay block (400 mm) + insulation (100 mm) + ventilated air gap (30 mm) + facing brick (120 mm) | 3.21 W/m °C |

Ceramic block wall

| 1 | Ceramic block (510 mm) | 3.20 W/m °C |

| 2 | Ceramic block warm (380 mm) | 3.18 W/m °C |

| 3 | Ceramic block (510 mm) + insulation (100 mm) | 4.81 W/m °C |

| 4 | Ceramic block (380 mm) + closed air gap (30 mm) + facing brick (120 mm) | 2.62 W/m °C |

Silicate brick wall

| 1 | Brick (380 mm) + insulation (100 mm) | 3.07 W/m °C |

| 2 | Brick (510 mm) + closed air gap (30 mm) + facing brick (120 mm) | 1.38 W/m °C |

| 3 | Brick (380 mm) + insulation (100 mm) + ventilated air gap (30 mm) + facing brick (120 mm) | 3.05 W/m °C |

Calculation of a sandwich structure

If we build a wall from different materials, for example, brick, mineral wool, plaster, the values \u200b\u200bmust be calculated for each individual material. Why sum up the resulting numbers.

In this case, it is worth working according to the formula:

In this case, it is worth working according to the formula:

Rtot= R1+ R2+…+ Rn+ Ra, where:

R1-Rn - thermal resistance of layers of different materials;

Ra.l - thermal resistance of a closed air gap. The values \u200b\u200bcan be found in table 7, clause 9 in SP 23-101-2004. A layer of air is not always provided for when building walls. For more information on calculations, see this video:

What is thermal conductivity and thermal resistance

When choosing building materials for construction, it is necessary to pay attention to the characteristics of the materials. One of the key positions is thermal conductivity

It is displayed by the coefficient of thermal conductivity. This is the amount of heat that a particular material can conduct per unit of time. That is, the smaller this coefficient, the worse the material conducts heat. Conversely, the higher the number, the better the heat is removed.

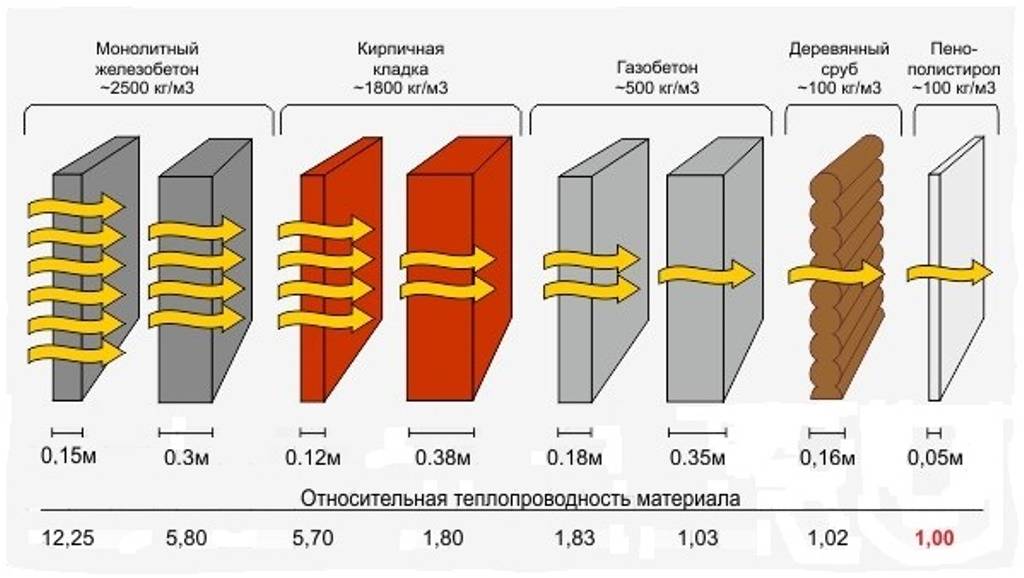

Diagram that illustrates the difference in thermal conductivity of materials

Materials with low thermal conductivity are used for insulation, with high - for heat transfer or removal. For example, radiators are made of aluminum, copper or steel, as they transfer heat well, that is, they have a high thermal conductivity. For insulation, materials with a low coefficient of thermal conductivity are used - they retain heat better. If an object consists of several layers of material, its thermal conductivity is determined as the sum of the coefficients of all materials. In the calculations, the thermal conductivity of each of the components of the "pie" is calculated, the found values are summarized. In general, we get the heat-insulating ability of the building envelope (walls, floor, ceiling).

The thermal conductivity of building materials shows the amount of heat that it passes per unit of time.

There is also such a thing as thermal resistance. It reflects the ability of the material to prevent the passage of heat through it. That is, it is the reciprocal of thermal conductivity. And, if you see a material with high thermal resistance, it can be used for thermal insulation. An example of thermal insulation materials can be popular mineral or basalt wool, polystyrene, etc.Materials with low thermal resistance are needed to remove or transfer heat. For example, aluminum or steel radiators are used for heating, as they give off heat well.

We carry out calculations

The calculation of wall thickness by thermal conductivity is an important factor in construction. When designing buildings, the architect calculates the thickness of the walls, but this costs extra money. To save money, you can figure out how to calculate the necessary indicators yourself.

The rate of heat transfer by the material depends on the components included in its composition. The heat transfer resistance must be greater than the minimum value specified in the regulation "Thermal insulation of buildings".

Consider how to calculate the thickness of the wall, depending on the materials used in construction.

Consider how to calculate the thickness of the wall, depending on the materials used in construction.

δ is the thickness of the material used to build the wall;

λ is an indicator of thermal conductivity, calculated in (m2 °C / W).

When you purchase building materials, the coefficient of thermal conductivity must be indicated in the passport for them.

How to choose the right heater?

When choosing a heater, you need to pay attention to: affordability, scope, expert opinion and technical characteristics, which are the most important criterion

Basic requirements for thermal insulation materials:

Thermal conductivity.

Thermal conductivity refers to the ability of a material to transfer heat. This property is characterized by the coefficient of thermal conductivity, on the basis of which the required thickness of the insulation is taken. Thermal insulation material with low thermal conductivity is the best choice.

Also, thermal conductivity is closely related to the concepts of density and thickness of the insulation, therefore, when choosing, it is necessary to pay attention to these factors. The thermal conductivity of the same material can vary depending on the density

Density is the mass of one cubic meter of thermal insulation material. By density, materials are divided into: extra light, light, medium, dense (hard). Lightweight materials include porous materials suitable for insulating walls, partitions, ceilings. Dense insulation is better suited for insulation outside.

The lower the density of the insulation, the lower the weight, and the higher the thermal conductivity. This is an indicator of the quality of insulation. And the light weight contributes to the ease of installation and installation. In the course of experimental studies, it was found that a heater having a density of 8 to 35 kg / m³ retains heat best of all and is suitable for insulating vertical structures indoors.

How does thermal conductivity depend on thickness? There is an erroneous opinion that thick insulation will better retain heat indoors. This leads to unjustified expenses. Too much thickness of the insulation can lead to a violation of natural ventilation and the room will be too stuffy.

And the insufficient thickness of the insulation leads to the fact that the cold will penetrate through the thickness of the wall and condensation will form on the plane of the wall, the wall will inevitably dampen, mold and fungus will appear.

The thickness of the insulation must be determined on the basis of a heat engineering calculation, taking into account the climatic features of the territory, the material of the wall and its minimum allowable value of heat transfer resistance.

If the calculation is ignored, a number of problems may appear, the solution of which will require large additional costs!

Thermal conductivity of gypsum plaster

The vapor permeability of gypsum plaster applied to the surface depends on the mixing. But if we compare it with the usual one, then the permeability of gypsum plaster is 0.23 W / m × ° C, and cement plaster reaches 0.6 ÷ 0.9 W / m × ° C. Such calculations allow us to say that the vapor permeability of gypsum plaster is much lower.

Due to the low permeability, the thermal conductivity of gypsum plaster decreases, which allows increasing the heat in the room. Gypsum plaster perfectly retains heat, unlike:

- lime-sand;

- concrete plaster.

Due to the low thermal conductivity of gypsum plaster, the walls remain warm even in severe frost outside.

Efficiency of sandwich structures

Density and thermal conductivity

Currently, there is no such building material, the high bearing capacity of which would be combined with low thermal conductivity. The construction of buildings based on the principle of multilayer structures allows:

- comply with the design norms of construction and energy saving;

- keep the dimensions of the enclosing structures within reasonable limits;

- reduce material costs for the construction of the facility and its maintenance;

- to achieve durability and maintainability (for example, when replacing one sheet of mineral wool).

The combination of structural material and thermal insulation material ensures strength and reduces the loss of thermal energy to an optimal level. Therefore, when designing walls, each layer of the future enclosing structure is taken into account in the calculations.

It is also important to take into account the density when building a house and when it is insulated. The density of a substance is a factor affecting its thermal conductivity, the ability to retain the main heat insulator - air

The density of a substance is a factor affecting its thermal conductivity, the ability to retain the main heat insulator - air.

Calculation of wall thickness and insulation

The calculation of the wall thickness depends on the following indicators:

- density;

- calculated thermal conductivity;

- heat transfer resistance coefficient.

According to the established norms, the value of the heat transfer resistance index of the outer walls must be at least 3.2λ W/m •°C.

The calculation of the thickness of walls made of reinforced concrete and other structural materials is presented in Table 2. Such building materials have high load-bearing characteristics, they are durable, but they are ineffective as thermal protection and require an irrational wall thickness.

table 2

| Index | Concrete, mortar-concrete mixes | |||

| Reinforced concrete | Cement-sand mortar | Complex mortar (cement-lime-sand) | Lime-sand mortar | |

| density, kg/cu.m. | 2500 | 1800 | 1700 | 1600 |

| thermal conductivity coefficient, W/(m•°С) | 2,04 | 0,93 | 0,87 | 0,81 |

| wall thickness, m | 6,53 | 2,98 | 2,78 | 2,59 |

Structural and heat-insulating materials are capable of being subjected to sufficiently high loads, while significantly increasing the thermal and acoustic properties of buildings in wall enclosing structures (tables 3.1, 3.2).

Table 3.1

| Index | Structural and heat-insulating materials | |||||

| pumice stone | Expanded clay concrete | Polystyrene concrete | Foam and aerated concrete (foam and gas silicate) | Clay brick | silicate brick | |

| density, kg/cu.m. | 800 | 800 | 600 | 400 | 1800 | 1800 |

| thermal conductivity coefficient, W/(m•°С) | 0,68 | 0,326 | 0,2 | 0,11 | 0,81 | 0,87 |

| wall thickness, m | 2,176 | 1,04 | 0,64 | 0,35 | 2,59 | 2,78 |

Table 3.2

| Index | Structural and heat-insulating materials | |||||

| Slag brick | Silicate brick 11-hollow | Silicate brick 14-hollow | Pine (cross grain) | Pine (longitudinal grain) | Plywood | |

| density, kg/cu.m. | 1500 | 1500 | 1400 | 500 | 500 | 600 |

| thermal conductivity coefficient, W/(m•°С) | 0,7 | 0,81 | 0,76 | 0,18 | 0,35 | 0,18 |

| wall thickness, m | 2,24 | 2,59 | 2,43 | 0,58 | 1,12 | 0,58 |

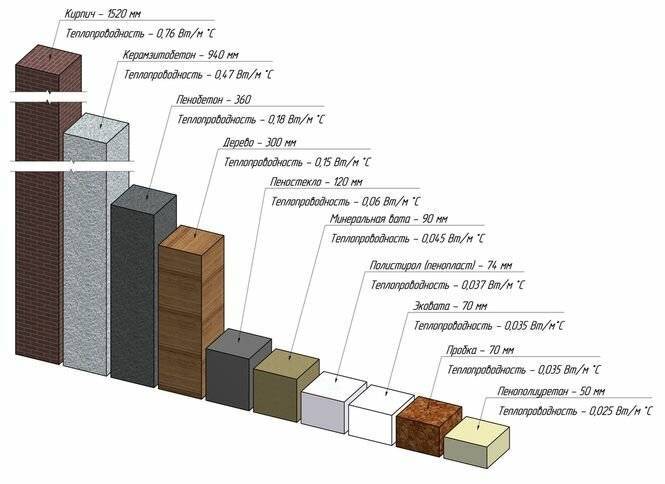

Heat-insulating building materials can significantly increase the thermal protection of buildings and structures. The data in Table 4 show that polymers, mineral wool, boards made from natural organic and inorganic materials have the lowest values of the thermal conductivity.

Table 4

| Index | Thermal insulation materials | ||||||

| PPT | PT polystyrene concrete | Mineral wool mats | Heat-insulating plates (PT) from mineral wool | Fiberboard (chipboard) | Tow | Gypsum sheets (dry plaster) | |

| density, kg/cu.m. | 35 | 300 | 1000 | 190 | 200 | 150 | 1050 |

| thermal conductivity coefficient, W/(m•°С) | 0,39 | 0,1 | 0,29 | 0,045 | 0,07 | 0,192 | 1,088 |

| wall thickness, m | 0,12 | 0,32 | 0,928 | 0,14 | 0,224 | 0,224 | 1,152 |

The values of the tables of thermal conductivity of building materials are used in the calculations:

- thermal insulation of facades;

- building insulation;

- insulating materials for roofing;

- technical isolation.

The task of choosing the optimal materials for construction, of course, implies a more integrated approach. However, even such simple calculations already at the first stages of design make it possible to determine the most suitable materials and their quantity.

Other selection criteria

When choosing a suitable product, not only the thermal conductivity and the price of the product should be taken into account.

You need to pay attention to other criteria:

- volumetric weight of the insulation;

- form stability of this material;

- vapor permeability;

- combustibility of thermal insulation;

- soundproof properties of the product.

Let's consider these characteristics in more detail. Let's start in order.

Bulk weight of insulation

Volumetric weight is the mass of 1 m² of the product.Moreover, depending on the density of the material, this value can be different - from 11 kg to 350 kg.

Such thermal insulation will have a significant volumetric weight.

The weight of thermal insulation must certainly be taken into account, especially when insulating the loggia. After all, the structure on which the insulation is attached must be designed for a given weight. Depending on the mass, the method of installing heat-insulating products will also differ.

For example, when insulating a roof, light heaters are installed in a frame of rafters and battens. Heavy specimens are mounted on top of the rafters, as required by the installation instructions.

Dimensional stability

This parameter means nothing more than the crease of the product used. In other words, it should not change its size during the entire service life.

Any deformation will result in heat loss

Otherwise, deformation of the insulation may occur. And this will already lead to a deterioration in its thermal insulation properties. Studies have shown that heat loss in this case can be up to 40%.

Vapor permeability

According to this criterion, all heaters can be divided into two types:

- "wool" - heat-insulating materials consisting of organic or mineral fibers. They are vapor-permeable because they easily pass moisture through them.

- "foams" - heat-insulating products made by hardening a special foam-like mass. They do not let in moisture.

Depending on the design features of the room, materials of the first or second type can be used in it.In addition, vapor-permeable products are often installed with their own hands along with a special vapor barrier film.

combustibility

It is highly desirable that the thermal insulation used be non-combustible. It is possible that it will be self-extinguishing.

But, unfortunately, in a real fire, even this will not help. At the epicenter of the fire, even that which does not light up under normal conditions will burn.

Soundproof properties

We have already mentioned two types of insulating materials: “wool” and “foam”. The first one is an excellent sound insulator.

The second, on the contrary, does not have such properties. But this can be corrected. To do this, when insulating "foam" must be installed together with "wool".

Table of thermal conductivity of thermal insulation materials

To make it easier for the house to keep warm in winter and cool in summer, the thermal conductivity of walls, floors and roofs must be at least a certain figure, which is calculated for each region. The composition of the "pie" of walls, floor and ceiling, the thickness of the materials are taken in such a way that the total figure is not less (or better - at least a little more) recommended for your region.

Heat transfer coefficient of materials of modern building materials for enclosing structures

When choosing materials, it must be taken into account that some of them (not all) conduct heat much better in conditions of high humidity. If during operation such a situation is likely to occur for a long time, the thermal conductivity for this state is used in the calculations. The thermal conductivity coefficients of the main materials used for insulation are shown in the table.

| Material name | Thermal conductivity W/(m °C) | ||

|---|---|---|---|

| Dry | Under normal humidity | With high humidity | |

| Woolen felt | 0,036-0,041 | 0,038-0,044 | 0,044-0,050 |

| Stone mineral wool 25-50 kg/m3 | 0,036 | 0,042 | 0,,045 |

| Stone mineral wool 40-60 kg/m3 | 0,035 | 0,041 | 0,044 |

| Stone mineral wool 80-125 kg/m3 | 0,036 | 0,042 | 0,045 |

| Stone mineral wool 140-175 kg/m3 | 0,037 | 0,043 | 0,0456 |

| Stone mineral wool 180 kg/m3 | 0,038 | 0,045 | 0,048 |

| Glass wool 15 kg/m3 | 0,046 | 0,049 | 0,055 |

| Glass wool 17 kg/m3 | 0,044 | 0,047 | 0,053 |

| Glass wool 20 kg/m3 | 0,04 | 0,043 | 0,048 |

| Glass wool 30 kg/m3 | 0,04 | 0,042 | 0,046 |

| Glass wool 35 kg/m3 | 0,039 | 0,041 | 0,046 |

| Glass wool 45 kg/m3 | 0,039 | 0,041 | 0,045 |

| Glass wool 60 kg/m3 | 0,038 | 0,040 | 0,045 |

| Glass wool 75 kg/m3 | 0,04 | 0,042 | 0,047 |

| Glass wool 85 kg/m3 | 0,044 | 0,046 | 0,050 |

| Expanded polystyrene (polyfoam, PPS) | 0,036-0,041 | 0,038-0,044 | 0,044-0,050 |

| Extruded polystyrene foam (EPS, XPS) | 0,029 | 0,030 | 0,031 |

| Foam concrete, aerated concrete on cement mortar, 600 kg/m3 | 0,14 | 0,22 | 0,26 |

| Foam concrete, aerated concrete on cement mortar, 400 kg/m3 | 0,11 | 0,14 | 0,15 |

| Foam concrete, aerated concrete on lime mortar, 600 kg/m3 | 0,15 | 0,28 | 0,34 |

| Foam concrete, aerated concrete on lime mortar, 400 kg/m3 | 0,13 | 0,22 | 0,28 |

| Foam glass, crumb, 100 - 150 kg/m3 | 0,043-0,06 | ||

| Foam glass, crumb, 151 - 200 kg/m3 | 0,06-0,063 | ||

| Foam glass, crumb, 201 - 250 kg/m3 | 0,066-0,073 | ||

| Foam glass, crumb, 251 - 400 kg/m3 | 0,085-0,1 | ||

| Foam block 100 - 120 kg/m3 | 0,043-0,045 | ||

| Foam block 121- 170 kg/m3 | 0,05-0,062 | ||

| Foam block 171 - 220 kg / m3 | 0,057-0,063 | ||

| Foam block 221 - 270 kg / m3 | 0,073 | ||

| Ecowool | 0,037-0,042 | ||

| Polyurethane foam (PPU) 40 kg/m3 | 0,029 | 0,031 | 0,05 |

| Polyurethane foam (PPU) 60 kg/m3 | 0,035 | 0,036 | 0,041 |

| Polyurethane foam (PPU) 80 kg/m3 | 0,041 | 0,042 | 0,04 |

| Cross-linked polyethylene foam | 0,031-0,038 | ||

| Vacuum | |||

| Air +27°C. 1 atm | 0,026 | ||

| Xenon | 0,0057 | ||

| Argon | 0,0177 | ||

| Airgel (Aspen aerogels) | 0,014-0,021 | ||

| slag wool | 0,05 | ||

| Vermiculite | 0,064-0,074 | ||

| foamed rubber | 0,033 | ||

| Cork sheets 220 kg/m3 | 0,035 | ||

| Cork sheets 260 kg/m3 | 0,05 | ||

| Basalt mats, canvases | 0,03-0,04 | ||

| Tow | 0,05 | ||

| Perlite, 200 kg/m3 | 0,05 | ||

| Expanded perlite, 100 kg/m3 | 0,06 | ||

| Linen insulating boards, 250 kg/m3 | 0,054 | ||

| Polystyrene concrete, 150-500 kg/m3 | 0,052-0,145 | ||

| Cork granulated, 45 kg/m3 | 0,038 | ||

| Mineral cork on a bitumen basis, 270-350 kg/m3 | 0,076-0,096 | ||

| Cork flooring, 540 kg/m3 | 0,078 | ||

| Technical cork, 50 kg/m3 | 0,037 |

Part of the information is taken from the standards that prescribe the characteristics of certain materials (SNiP 23-02-2003, SP 50.13330.2012, SNiP II-3-79 * (Appendix 2)).Those material that are not spelled out in the standards are found on the manufacturers' websites.

Since there are no standards, they can differ significantly from manufacturer to manufacturer, so when buying, pay attention to the characteristics of each material you buy.

Sequencing

First of all, you need to choose the building materials that you will use to build the house. After that, we calculate the thermal resistance of the wall according to the scheme described above. The obtained values should be compared with the data in the tables. If they match or are higher, good.

If the value is lower than in the table, then you need to increase the thickness of the insulation or wall, and perform the calculation again. If there is an air gap in the structure, which is ventilated by outside air, then the layers located between the air chamber and the street should not be taken into account.

Coefficient of thermal conductivity.

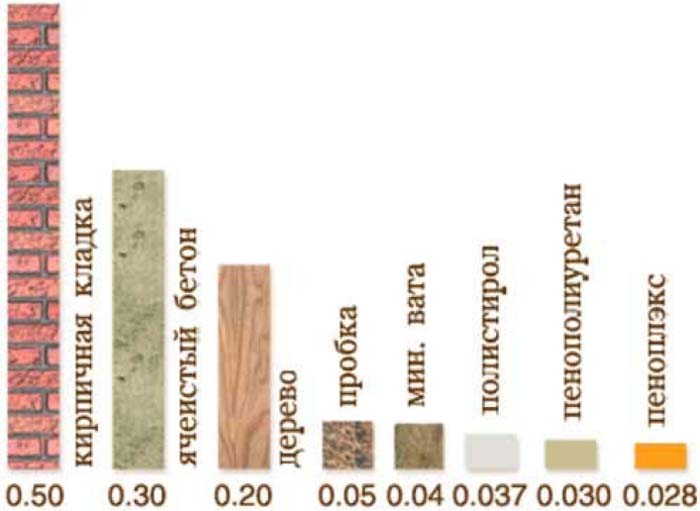

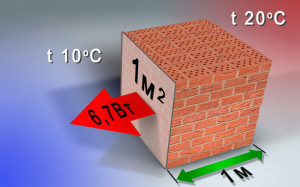

The amount of heat that passes through the walls (and scientifically - the intensity of heat transfer due to thermal conductivity) depends on the temperature difference (in the house and on the street), on the area of \u200b\u200bthe walls and the thermal conductivity of the material from which these walls are made.

To quantify thermal conductivity, there is a coefficient of thermal conductivity of materials. This coefficient reflects the property of a substance to conduct thermal energy. The higher the thermal conductivity of a material, the better it conducts heat. If we are going to insulate the house, then we need to choose materials with a small value of this coefficient. The smaller it is, the better. Now, as materials for building insulation, mineral wool insulation and various foam plastics are most widely used.A new material with improved thermal insulation qualities is gaining popularity - Neopor.

The coefficient of thermal conductivity of materials is indicated by the letter ? (lower case Greek letter lambda) and is expressed in W/(m2*K). This means that if we take a brick wall with a thermal conductivity of 0.67 W / (m2 * K), 1 meter thick and 1 m2 in area, then with a temperature difference of 1 degree, 0.67 watts of thermal energy will pass through the wall. energy. If the temperature difference is 10 degrees, then 6.7 watts will pass. And if, with such a temperature difference, the wall is made 10 cm, then the heat loss will already be 67 watts. More information about the method of calculating the heat loss of buildings can be found here.

It should be noted that the values of the thermal conductivity coefficient of materials are indicated for a material thickness of 1 meter. To determine the thermal conductivity of a material for any other thickness, the thermal conductivity coefficient must be divided by the desired thickness, expressed in meters.

In building codes and calculations, the concept of "thermal resistance of the material" is often used. This is the reciprocal of thermal conductivity. If, for example, the thermal conductivity of a 10 cm thick foam is 0.37 W / (m2 * K), then its thermal resistance will be 1 / 0.37 W / (m2 * K) \u003d 2.7 (m2 * K) / Tue