- Table of thermal conductivity of building materials: features of indicators

- How to use the table of thermal conductivity of materials and heaters?

- Values of heat transfer coefficients of materials in the table

- The use of thermal conductivity in construction

- What building material is the warmest?

- Other selection criteria

- Bulk weight of insulation

- Dimensional stability

- Vapor permeability

- combustibility

- Soundproof properties

- How to calculate wall thickness

- Calculation of wall thickness, insulation thickness, finishing layers

- An example of calculating the thickness of the insulation

- Table of thermal conductivity of materials

- Efficiency of sandwich structures

- Density and thermal conductivity

- Calculation of wall thickness and insulation

- 4.8 Rounding off calculated thermal conductivity values

- Annex A (mandatory)

- The thermal conductivity of foam from 50 mm to 150 mm is considered thermal insulation

- Comparison of heaters by thermal conductivity

- Expanded polystyrene (styrofoam)

- Extruded polystyrene foam

- Mineral wool

- Basalt wool

- Penofol, isolon (foamed polyethylene)

Table of thermal conductivity of building materials: features of indicators

Table thermal conductivity of building materials contains indicators of various types of raw materials that are used in construction.Using this information, you can easily calculate the thickness of the walls and the amount of insulation.

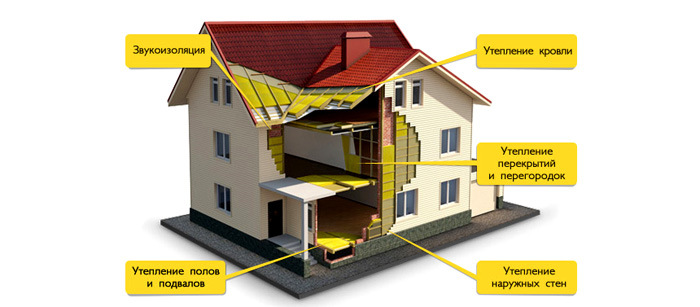

Warming is carried out in certain places

How to use the table of thermal conductivity of materials and heaters?

The heat transfer resistance table of materials shows the most popular materials

When choosing a particular thermal insulation option, it is important to take into account not only physical properties, but also such characteristics as durability, price and ease of installation.

Did you know that the easiest way is to install penooizol and polyurethane foam. They are distributed over the surface in the form of foam. Such materials easily fill the cavities of structures. When comparing solid and foam options, it should be noted that the foam does not form joints.

Ratio of Diverse Types of Raw Materials

Values of heat transfer coefficients of materials in the table

When making calculations, you should know the coefficient of resistance to heat transfer. This value is the ratio of temperatures on both sides to the amount of heat flow. In order to find the thermal resistance of certain walls, a thermal conductivity table is used.

Density and thermal conductivity values

You can do all the calculations yourself. For this, the thickness of the heat insulator layer is divided by the thermal conductivity coefficient. This value is often indicated on the packaging if it is insulation. Household materials are self-measured. This applies to thickness, and the coefficients can be found in special tables.

Thermal conductivity of some structures

The resistance coefficient helps to choose a certain type of thermal insulation and the thickness of the material layer. Information on vapor permeability and density can be found in the table.

With the correct use of tabular data, you can choose high-quality material to create a favorable microclimate in the room.

The use of thermal conductivity in construction

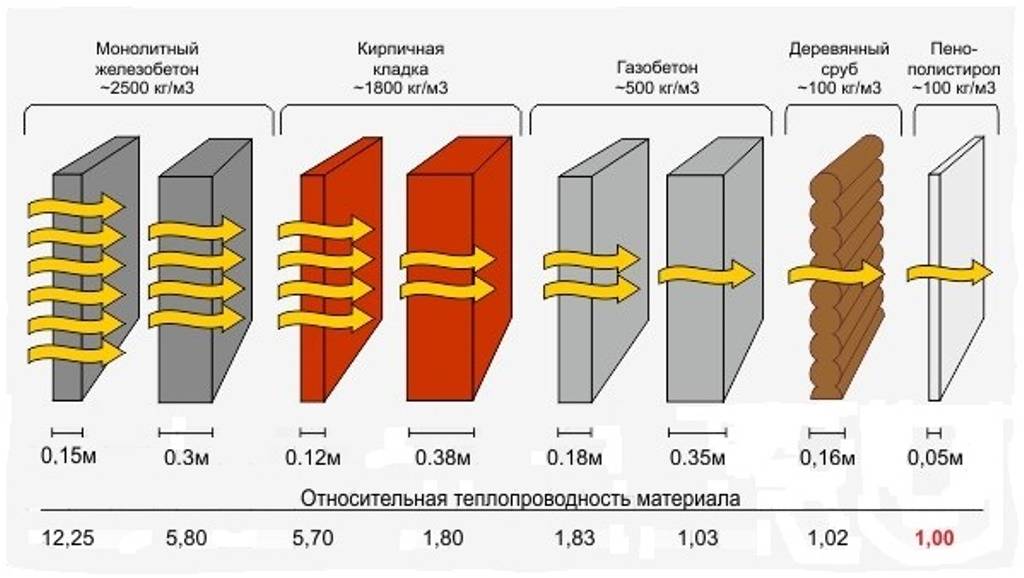

In construction, one simple rule applies - the thermal conductivity of insulating materials should be as low as possible. This is because the smaller the value of λ (lambda), the smaller the thickness of the insulating layer can be made in order to provide a specific value of the heat transfer coefficient through walls or partitions.

Currently, manufacturers of thermal insulation materials (polystyrene foam, graphite boards or mineral wool) are trying to minimize the thickness of the product by reducing the λ (lambda) coefficient, for example, for polystyrene it is 0.032-0.045 compared to 0.15-1.31 for bricks.

As far as building materials are concerned, thermal conductivity is not so important in their production, but in recent years there has been a trend towards the production of building materials with a low λ value (for example, ceramic blocks, structural insulating panels, cellular concrete blocks). Such materials make it possible to build a single-layer wall (without insulation) or with the minimum possible thickness of the insulation layer.

What building material is the warmest?

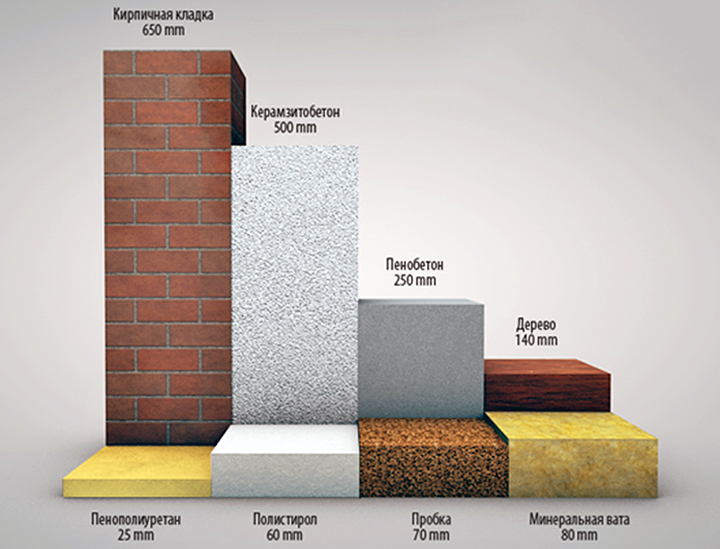

Currently, these are polyurethane foam (PPU) and its derivatives, as well as mineral (basalt, stone) wool. They have already proven themselves as effective heat insulators and are widely used today in the insulation of houses.

To illustrate how effective these materials are, we will show you the following illustration. It shows how thick the material is enough to keep heat in the wall of the house:

But what about air and gaseous substances? - you ask. After all, they have a Lambda coefficient even less? This is true, but if we are dealing with gases and liquids, in addition to thermal conductivity, here we must also take into account the movement of heat inside them - that is, convection (the continuous movement of air when warmer air rises and colder air falls).

A similar phenomenon occurs in porous materials, so they have higher thermal conductivity values than solid materials. The thing is that small particles of gas (air, carbon dioxide) are hidden in the voids of such materials. Although this can happen with other materials - if the air pores in them are too large, convection can also begin to occur in them.

Other selection criteria

When choosing a suitable product, not only the thermal conductivity and the price of the product should be taken into account.

You need to pay attention to other criteria:

- volumetric weight of the insulation;

- form stability of this material;

- vapor permeability;

- combustibility of thermal insulation;

- soundproof properties of the product.

Let's consider these characteristics in more detail. Let's start in order.

Bulk weight of insulation

Volumetric weight is the mass of 1 m² of the product. Moreover, depending on the density of the material, this value can be different - from 11 kg to 350 kg.

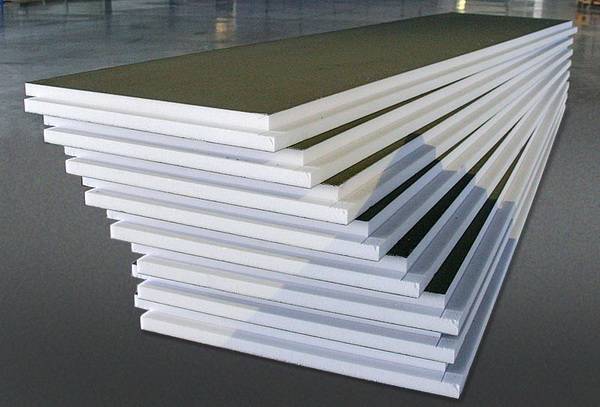

Such thermal insulation will have a significant volumetric weight.

The weight of thermal insulation must certainly be taken into account, especially when insulating the loggia. After all, the structure on which the insulation is attached must be designed for a given weight. Depending on the mass, the method of installing heat-insulating products will also differ.

For example, when insulating a roof, light heaters are installed in a frame of rafters and battens.Heavy specimens are mounted on top of the rafters, as required by the installation instructions.

Dimensional stability

This parameter means nothing more than the crease of the product used. In other words, it should not change its size during the entire service life.

Any deformation will result in heat loss

Otherwise, deformation of the insulation may occur. And this will already lead to a deterioration in its thermal insulation properties. Studies have shown that heat loss in this case can be up to 40%.

Vapor permeability

According to this criterion, all heaters can be divided into two types:

- "wool" - heat-insulating materials consisting of organic or mineral fibers. They are vapor-permeable because they easily pass moisture through them.

- "foams" - heat-insulating products made by hardening a special foam-like mass. They do not let in moisture.

Depending on the design features of the room, materials of the first or second type can be used in it. In addition, vapor-permeable products are often installed with their own hands along with a special vapor barrier film.

combustibility

It is highly desirable that the thermal insulation used be non-combustible. It is possible that it will be self-extinguishing.

But, unfortunately, in a real fire, even this will not help. At the epicenter of the fire, even that which does not light up under normal conditions will burn.

Soundproof properties

We have already mentioned two types of insulating materials: “wool” and “foam”. The first one is an excellent sound insulator.

The second, on the contrary, does not have such properties.But this can be corrected. To do this, when insulating "foam" must be installed together with "wool".

How to calculate wall thickness

In order for the house to be warm in winter and cool in summer, it is necessary that the enclosing structures (walls, floor, ceiling / roof) must have a certain thermal resistance. This value is different for each region. It depends on the average temperature and humidity in a particular area.

Thermal resistance of enclosing structures for Russian regions

In order for the heating bills not to be too large, it is necessary to select building materials and their thickness so that their total thermal resistance is not less than that indicated in the table.

Calculation of wall thickness, insulation thickness, finishing layers

Modern construction is characterized by a situation where the wall has several layers. In addition to the supporting structure, there is insulation, finishing materials. Each layer has its own thickness. How to determine the thickness of the insulation? The calculation is easy. Based on the formula:

Formula for calculating thermal resistance

R is thermal resistance;

p is the layer thickness in meters;

k is the thermal conductivity coefficient.

First you need to decide on the materials that you will use in construction. Moreover, you need to know exactly what type of wall material, insulation, finish, etc. will be. After all, each of them contributes to thermal insulation, and the thermal conductivity of building materials is taken into account in the calculation.

An example of calculating the thickness of the insulation

Let's take an example. We are going to build a brick wall - one and a half bricks, we will insulate with mineral wool. According to the table, the thermal resistance of the walls for the region should be at least 3.5. The calculation for this situation is given below.

- To begin with, we calculate the thermal resistance of a brick wall. One and a half bricks is 38 cm or 0.38 meters, the coefficient of thermal conductivity of brickwork is 0.56. We consider according to the above formula: 0.38 / 0.56 \u003d 0.68. Such thermal resistance has a wall of 1.5 bricks.

-

This value is subtracted from the total thermal resistance for the region: 3.5-0.68 = 2.82. This value must be "recovered" with thermal insulation and finishing materials.

All enclosing structures will have to be calculated

- We consider the thickness of mineral wool. Its thermal conductivity coefficient is 0.045. The thickness of the layer will be: 2.82 * 0.045 = 0.1269 m or 12.7 cm. That is, in order to provide the required level of insulation, the thickness of the mineral wool layer must be at least 13 cm.

Table of thermal conductivity of materials

| Material | Thermal conductivity of materials, W/m*⸰С | Density, kg/m³ |

| polyurethane foam | 0,020 | 30 |

| 0,029 | 40 | |

| 0,035 | 60 | |

| 0,041 | 80 | |

| Styrofoam | 0,037 | 10-11 |

| 0,035 | 15-16 | |

| 0,037 | 16-17 | |

| 0,033 | 25-27 | |

| 0,041 | 35-37 | |

| Expanded polystyrene (extruded) | 0,028-0,034 | 28-45 |

| Basalt wool | 0,039 | 30-35 |

| 0,036 | 34-38 | |

| 0,035 | 38-45 | |

| 0,035 | 40-50 | |

| 0,036 | 80-90 | |

| 0,038 | 145 | |

| 0,038 | 120-190 | |

| Ecowool | 0,032 | 35 |

| 0,038 | 50 | |

| 0,04 | 65 | |

| 0,041 | 70 | |

| Izolon | 0,031 | 33 |

| 0,033 | 50 | |

| 0,036 | 66 | |

| 0,039 | 100 | |

| Penofol | 0,037-0,051 | 45 |

| 0,038-0,052 | 54 | |

| 0,038-0,052 | 74 |

Environmental friendliness.

This factor is significant, especially in the case of insulation of a residential building, since many materials emit formaldehyde, which affects the growth of cancerous tumors. Therefore, it is necessary to make a choice towards non-toxic and biologically neutral materials. From the point of view of environmental friendliness, stone wool is considered the best heat-insulating material.

Fire safety.

The material must be non-flammable and safe. Any material can burn, the difference lies in the temperature at which it ignites. It is important that the insulation is self-extinguishing.

Steam and waterproof.

Those materials that are waterproof have an advantage, since moisture absorption leads to the fact that the effectiveness of the material becomes low and the useful characteristics of the insulation after a year of use are reduced by 50% or more.

Durability.

On average, the service life of insulating materials is from 5 to 10-15 years. Thermal insulation materials containing wool in the first years of service significantly reduce their effectiveness. But polyurethane foam has a service life of over 50 years.

Efficiency of sandwich structures

Density and thermal conductivity

Currently, there is no such building material, the high bearing capacity of which would be combined with low thermal conductivity. The construction of buildings based on the principle of multilayer structures allows:

- comply with the design norms of construction and energy saving;

- keep the dimensions of the enclosing structures within reasonable limits;

- reduce material costs for the construction of the facility and its maintenance;

- to achieve durability and maintainability (for example, when replacing one sheet of mineral wool).

The combination of structural material and thermal insulation material ensures strength and reduces the loss of thermal energy to an optimal level. Therefore, when designing walls, each layer of the future enclosing structure is taken into account in the calculations.

It is also important to take into account the density when building a house and when it is insulated. The density of a substance is a factor affecting its thermal conductivity, the ability to retain the main heat insulator - air

The density of a substance is a factor affecting its thermal conductivity, the ability to retain the main heat insulator - air.

Calculation of wall thickness and insulation

The calculation of the wall thickness depends on the following indicators:

- density;

- calculated thermal conductivity;

- heat transfer resistance coefficient.

According to the established norms, the value of the heat transfer resistance index of the outer walls must be at least 3.2λ W/m •°C.

The calculation of the thickness of walls made of reinforced concrete and other structural materials is presented in Table 2. Such building materials have high load-bearing characteristics, they are durable, but they are ineffective as thermal protection and require an irrational wall thickness.

table 2

| Index | Concrete, mortar-concrete mixes | |||

| Reinforced concrete | Cement-sand mortar | Complex mortar (cement-lime-sand) | Lime-sand mortar | |

| density, kg/cu.m. | 2500 | 1800 | 1700 | 1600 |

| thermal conductivity coefficient, W/(m•°С) | 2,04 | 0,93 | 0,87 | 0,81 |

| wall thickness, m | 6,53 | 2,98 | 2,78 | 2,59 |

Structural and heat-insulating materials are capable of being subjected to sufficiently high loads, while significantly increasing the thermal and acoustic properties of buildings in wall enclosing structures (tables 3.1, 3.2).

Table 3.1

| Index | Structural and heat-insulating materials | |||||

| pumice stone | Expanded clay concrete | Polystyrene concrete | Foam and aerated concrete (foam and gas silicate) | Clay brick | silicate brick | |

| density, kg/cu.m. | 800 | 800 | 600 | 400 | 1800 | 1800 |

| thermal conductivity coefficient, W/(m•°С) | 0,68 | 0,326 | 0,2 | 0,11 | 0,81 | 0,87 |

| wall thickness, m | 2,176 | 1,04 | 0,64 | 0,35 | 2,59 | 2,78 |

Table 3.2

| Index | Structural and heat-insulating materials | |||||

| Slag brick | Silicate brick 11-hollow | Silicate brick 14-hollow | Pine (cross grain) | Pine (longitudinal grain) | Plywood | |

| density, kg/cu.m. | 1500 | 1500 | 1400 | 500 | 500 | 600 |

| thermal conductivity coefficient, W/(m•°С) | 0,7 | 0,81 | 0,76 | 0,18 | 0,35 | 0,18 |

| wall thickness, m | 2,24 | 2,59 | 2,43 | 0,58 | 1,12 | 0,58 |

Heat-insulating building materials can significantly increase the thermal protection of buildings and structures. The data in Table 4 show that polymers, mineral wool, boards made from natural organic and inorganic materials have the lowest values of the thermal conductivity.

Table 4

| Index | Thermal insulation materials | ||||||

| PPT | PT polystyrene concrete | Mineral wool mats | Heat-insulating plates (PT) from mineral wool | Fiberboard (chipboard) | Tow | Gypsum sheets (dry plaster) | |

| density, kg/cu.m. | 35 | 300 | 1000 | 190 | 200 | 150 | 1050 |

| thermal conductivity coefficient, W/(m•°С) | 0,39 | 0,1 | 0,29 | 0,045 | 0,07 | 0,192 | 1,088 |

| wall thickness, m | 0,12 | 0,32 | 0,928 | 0,14 | 0,224 | 0,224 | 1,152 |

The values of the tables of thermal conductivity of building materials are used in the calculations:

- thermal insulation of facades;

- building insulation;

- insulating materials for roofing;

- technical isolation.

The task of choosing the optimal materials for construction, of course, implies a more integrated approach. However, even such simple calculations already at the first stages of design make it possible to determine the most suitable materials and their quantity.

4.8 Rounding off calculated thermal conductivity values

The calculated values of the thermal conductivity of the material are rounded off

according to the rules below:

for thermal conductivity l,

W/(m K):

— if l ≤

0.08, then the declared value is rounded up to the next higher number with an accuracy of

up to 0.001 W/(m K);

— if 0.08 < l ≤

0.20, then the declared value is rounded up to the next higher value with

accuracy up to 0.005 W/(m K);

— if 0.20 < l ≤

2.00, then the declared value is rounded up to the next higher number with an accuracy of

up to 0.01 W/(m K);

— if 2.00 < l,

then the declared value shall be rounded up to the next higher value to the nearest

0.1 W/(mK).

Annex A

(mandatory)

Table

A.1

| Materials (structures) | Operating Humidity | |

| BUT | B | |

| 1 Styrofoam | 2 | 10 |

| 2 Expanded polystyrene extrusion | 2 | 3 |

| 3 Polyurethane foam | 2 | 5 |

| 4 slabs of | 5 | 20 |

| 5 Perlitoplast concrete | 2 | 3 |

| 6 Thermal insulation products | 5 | 15 |

| 7 Thermal insulation products | ||

| 8 Mats and slabs from | 2 | 5 |

| 9 Foam glass or gas glass | 1 | 2 |

| 10 Wood fiber boards | 10 | 12 |

| 11 Fiberboard and | 10 | 15 |

| 12 Reed slabs | 10 | 15 |

| 13 Peat slabs | 15 | 20 |

| 14 Tow | 7 | 12 |

| 15 Gypsum boards | 4 | 6 |

| 16 Plaster sheets | 4 | 6 |

| 17 Expanded products | 1 | 2 |

| 18 Expanded clay gravel | 2 | 3 |

| 19 Shungizite gravel | 2 | 4 |

| 20 Crushed stone from blast-furnace | 2 | 3 |

| 21 Crushed slag-pumice stone and | 2 | 3 |

| 22 Rubble and sand from | 5 | 10 |

| 23 Expanded vermiculite | 1 | 3 |

| 24 Sand for construction | 1 | 2 |

| 25 Cement-slag | 2 | 4 |

| 26 Cement-perlite | 7 | 12 |

| 27 Gypsum perlite mortar | 10 | 15 |

| 28 Porous | 6 | 10 |

| 29 Tuff concrete | 7 | 10 |

| 30 Pumice stone | 4 | 6 |

| 31 Concrete on volcanic | 7 | 10 |

| 32 Expanded clay concrete on | 5 | 10 |

| 33 Expanded clay concrete on | 4 | 8 |

| 34 Expanded clay concrete on | 9 | 13 |

| 35 Shungizite concrete | 4 | 7 |

| 36 Perlite concrete | 10 | 15 |

| 37 Slag pumice concrete | 5 | 8 |

| 38 Slag pumice foam and slag pumice aerated concrete | 8 | 11 |

| 39 Blast-furnace Concrete | 5 | 8 |

| 40 Agloporite concrete and concrete | 5 | 8 |

| 41 Ash gravel concrete | 5 | 8 |

| 42 Vermiculite concrete | 8 | 13 |

| 43 Polystyrene concrete | 4 | 8 |

| 44 Gas and foam concrete, gas | 8 | 12 |

| 45 Gas and foam ash concrete | 15 | 22 |

| 46 Brickwork from | 1 | 2 |

| 47 Solid masonry | 1,5 | 3 |

| 48 Brickwork from | 2 | 4 |

| 49 Solid masonry | 2 | 4 |

| 50 brickwork from | 2 | 4 |

| 51 Brickwork from | 1,5 | 3 |

| 52 Brickwork from | 1 | 2 |

| 53 Brickwork from | 2 | 4 |

| 54 Wood | 15 | 20 |

| 55 Plywood | 10 | 13 |

| 56 Cardboard facing | 5 | 10 |

| 57 Construction board | 6 | 12 |

| 58 Reinforced concrete | 2 | 3 |

| 59 Concrete on gravel or | 2 | 3 |

| 60 Mortar | 2 | 4 |

| 61 Complex solution (sand, | 2 | 4 |

| 62 Solution | 2 | 4 |

| 63 Granite, gneiss and basalt | ||

| 64 Marble | ||

| 65 Limestone | 2 | 3 |

| 66 Tuff | 3 | 5 |

| 67 Asbestos-cement sheets | 2 | 3 |

Keywords:

building materials and products, thermophysical characteristics, design

values, thermal conductivity, vapor permeability

The thermal conductivity of foam from 50 mm to 150 mm is considered thermal insulation

Styrofoam boards, colloquially referred to as polystyrene foam, are an insulating material, usually white. It is made from thermal expansion polystyrene.In appearance, the foam is presented in the form of small moisture-resistant granules; in the process of melting at high temperature, it is melted into one piece, a plate. The dimensions of the parts of the granules are considered from 5 to 15 mm. The outstanding thermal conductivity of 150 mm thick foam is achieved through a unique structure - granules.

Each granule has a huge number of thin-walled micro-cells, which in turn increase the area of contact with air many times over. It is safe to say that almost all foam plastic consists of atmospheric air, approximately 98%, in turn, this fact is their purpose - thermal insulation of buildings both outside and inside.

Everyone knows, even from physics courses, atmospheric air is the main heat insulator in all heat-insulating materials, it is in a normal and rarefied state, in the thickness of the material. Heat-saving, the main quality of the foam.

As mentioned earlier, the foam is almost 100% air, and this, in turn, determines the high ability of the foam to retain heat. And this is due to the fact that air has the lowest thermal conductivity. If we look at the numbers, we will see that the thermal conductivity of the foam is expressed in the range of values from 0.037W/mK to 0.043W/mK. This can be compared with the thermal conductivity of air - 0.027 W / mK.

While the thermal conductivity of popular materials such as wood (0.12W / mK), red brick (0.7W / mK), expanded clay (0.12 W / mK) and others used for construction, is much higher.

Therefore, the most effective material of the few for thermal insulation of the outer and inner walls of a building is considered to be polystyrene. The cost of heating and cooling residential premises is significantly reduced due to the use of foam in construction.

The excellent qualities of polystyrene foam boards have found their application in other types of protection, for example: polystyrene foam also serves to protect underground and external communications from freezing, due to which their service life is increased significantly. Polyfoam is also used in industrial equipment (refrigerators, cold rooms) and in warehouses.

Comparison of heaters by thermal conductivity

Expanded polystyrene (styrofoam)

Expanded polystyrene (polystyrene) boards

This is the most popular heat-insulating material in Russia due to its low thermal conductivity, low cost and ease of installation. Styrofoam is made in plates with a thickness of 20 to 150 mm by foaming polystyrene and consists of 99% air. The material has a different density, has low thermal conductivity and is resistant to moisture.

Due to its low cost, expanded polystyrene is in great demand among companies and private developers for the insulation of various premises. But the material is quite fragile and quickly ignites, releasing toxic substances during combustion. Because of this, it is preferable to use foam plastic in non-residential premises and for thermal insulation of non-loaded structures - insulation of the facade for plaster, basement walls, etc.

Extruded polystyrene foam

Penoplex (extruded polystyrene foam)

Extrusion (technoplex, penoplex, etc.) is not exposed to moisture and decay.This is a very durable and easy-to-use material that can be easily cut with a knife to the desired dimensions. Low water absorption ensures minimal change in properties at high humidity, the boards have a high density and resistance to compression. Extruded polystyrene foam is fireproof, durable and easy to use.

All these characteristics, along with low thermal conductivity in comparison with other heaters, make Technoplex, URSA XPS or Penoplex slabs an ideal material for insulating strip foundations of houses and blind areas. According to manufacturers, an extrusion sheet with a thickness of 50 millimeters replaces 60 mm foam block in terms of thermal conductivity, while the material does not allow moisture to pass through and additional waterproofing can be dispensed with.

Mineral wool

Izover mineral wool slabs in a package

Mineral wool (for example, Izover, URSA, Technoruf, etc.) is made from natural materials - slag, rocks and dolomite using a special technology. Mineral wool has a low thermal conductivity and is absolutely fireproof. The material is produced in plates and rolls of various stiffness. For horizontal planes, less dense mats are used; for vertical structures, rigid and semi-rigid slabs are used.

However, one of the significant disadvantages of this insulation, as well as basalt wool, is low moisture resistance, which requires additional moisture and vapor barrier when installing mineral wool. Experts do not recommend using mineral wool for warming wet rooms - basements of houses and cellars, for thermal insulation of the steam room from the inside in baths and dressing rooms. But even here it can be used with proper waterproofing.

Basalt wool

Rockwool basalt wool slabs in a package

This material is produced by melting basalt rocks and blowing the molten mass with the addition of various components to obtain a fibrous structure with water-repellent properties. The material is non-flammable, safe for human health, has good performance in terms of thermal insulation and sound insulation of rooms. Used for both internal and external thermal insulation.

When installing basalt wool, protective equipment (gloves, a respirator and goggles) should be used to protect the mucous membranes from cotton wool microparticles. The most famous brand of basalt wool in Russia is materials under the Rockwool brand. During operation, the thermal insulation slabs do not compact and do not cake, which means that the excellent properties of low thermal conductivity of basalt wool remain unchanged over time.

Penofol, isolon (foamed polyethylene)

Penofol and isolon are rolled heaters with a thickness of 2 to 10 mm, consisting of foamed polyethylene. The material is also available with a layer of foil on one side for a reflective effect. The insulation has a thickness several times thinner than previously presented heaters, but at the same time retains and reflects up to 97% of thermal energy. Foamed polyethylene has a long service life and is environmentally friendly.

Izolon and foil penofol are light, thin and very easy-to-use heat-insulating material. Roll insulation is used for thermal insulation of wet rooms, for example, when insulating balconies and loggias in apartments. Also, the use of this insulation will help you save usable space in the room, while warming inside.Read more about these materials in the Organic Thermal Insulation section.