- Why error 104 may occur - Insufficient circulation. Troubleshooting

- Briefly about the device and functional systems

- Basic error codes

- a01

- a02

- a03

- a08

- f05

- f11

- f37

- f41

- f50

- Installation and piping scheme of the boiler Kiturami

- Operating principle

- Other malfunctions

- Advantages and disadvantages

- Decoding errors Ariston

- First group of codes

- Likely causes:

- Likely cause:

- Second group of codes

- Likely causes:

- Fifth group of codes

- Likely causes:

- Sixth group of codes

- Likely causes:

- Possible causes of the error:

- Errors of individual modifications of Ariston

- Insufficient circulation, error 104. How I searched for the cause

Why error 104 may occur - Insufficient circulation. Troubleshooting

The circulation pump of the boiler has two speeds of rotation in the manual, they are designated as V2 (55 W) and V3 (80 W). The ECU naturally controls the speed of the pump.

In domestic hot water (DHW) mode The pump runs at speed V3 for better heat transfer.

In central heating (CH) mode, the control unit switches the pump speed depending on the temperature difference at the inlet and outlet of the heating system.

Therefore, the pump is controlled by not one, but two relays. One supplies 220V power and the other controls the speed.

To check these power circuits of the pump, it will have to be turned on.But for this you don’t need to light the cauldron, we don’t want to rape him! There is a simple and quick way to turn on the pump without lighting the burner.

It is necessary to transfer the boiler to the “Purge” mode. To do this, press the ESC button on the boiler panel and hold it pressed for more than 5 seconds. Purge mode is activated - During this mode, the circulation pump starts and runs in cycles of 60 seconds. incl. 30 sec off and so on for 6 minutes. and at the same time without ignition of the burner. And we need it!

This mode is designed to remove air from the heat exchanger and circuit, but we use it to control the operation of the pump. It turns on for 6 minutes, or you can turn it off forcibly by pressing ESC again.

So, we start the "Purge" mode and measure the alternating voltage at the terminals. Let's look at the drawing.

Addition: The voltage is 220 volts, with the relay RL 04 (the relay supplying power to the pump) it is possible and easier to measure at the control points on the board, see the photo below, (there are no two relays on the board, they are on the wires to the side) and the points where the probes indicate and there are needed. If they receive 220 volts, relay 04 is working.

Contacts on the board for voltage measurement with relay RL04

In my case, this was the case, 220 V was supplied to contacts 3 and 4 from the RL 04 relay. but the pump did not turn.

Relay contacts RL03 (pump speed control relay type JQX 118F) when the boiler was turned off, the multimeter rang shortly, which is the norm for a lower rotation speed, but under load the relay behaved incomprehensibly as the pump motor did not spin at all. As soon as pins 5 and 6 were closed with tweezers, the pump started to work. The output of the relay controlling the speed of the pump is faulty.

Therefore, until the time I pick up a relay for replacement, I just soldered the jumper, i.e.jumped from the installation side 5 and 6 conclusions. In fact, a working relay does almost the same job, closes this circuit or switches it to another contact, this is how the pump speed switches. Below are photos that will help you not to make a mistake.

Scheme and numbering of the location of the relay on the board

Photo of the board with explanations for installing a jumper on the RL03 relay - pump speed control.

So, these closed contacts, directly on the relay (Points A and B) or on the chip below, which are essentially the same, forcibly turn on the low speed of the pump.

But still, finally I found a great option to replace this relay, and now, in February 2018. my boiler has found its usefulness.

Briefly about the device and functional systems

Based in the Republic of Kazakhstan, Daesung Celtic Enersys Co. Ltd." offers the Russian consumer a line of wall-mounted gas boilers serving objects ranging from 110 to 210 m². Double-circuit units from South Korea with the Master Gas Seoul logo followed by the letter designation from 11 to 21 are adapted to domestic operating conditions.

In fact, they are a thoroughly thought out and carefully stocked mini-boiler room. It has its own protection systems, stimulation of the movement of the heated medium, removal of air pockets and combustion products, and other devices.

Despite the high build quality, as well as the scrupulous selection of components and parts, from time to time one of them becomes unusable. Violations in work happen due to banal wear and tear, the end of the working resource, etc. Unfortunately, the list of common reasons also includes the incorrect attitude of owners to complex technical equipment.

In addition, the units process gas in order to produce heat.And this type of fuel is extremely toxic, therefore, breakdowns should be taken seriously. Any violation can lead to undesirable threatening consequences, which are best prevented at the initial stages.

Before proceeding with the decoding of codes that signal malfunctions, you should carefully familiarize yourself with the design features, device and components of the gas boiler

The important components responsible for the operation of the boiler wall model include:

- Burner block. Located in the combustion chamber. It consists of a burner and a manifold with gas supply nozzles. Responsible for the preparation of the gas-air mixture, more precisely, for mixing the blue fuel with air in the proportions required for normal combustion.

- Lighting candle. Located to the left of the burner. When activated, it generates a spark that ignites the gas-air mixture.

- Circulation pump. Stimulates the movement of the coolant along the circuits located inside the boiler and "pushes" after heating to the outlet to the heating system and the hot water supply pipe.

- Expansion tank. It takes in the volume of the coolant formed when the water is heated. Eliminates thereby excess pressure, which could lead to depressurization of the circuits.

- Air vent. Device for automatic release of air pockets from closed pipeline systems contributes to the creation of a stable pressure without pressure excesses and pressure drops.

- Temperature and DHW flow sensors. Used to automate the process. The first fixes the upper and lower heating limits in order to send a command to turn on / off the burner.The second gives a signal about the transition to the supply of sanitary water at the moment the tap is opened.

- Heating temperature sensor. Responds to changes in the temperature of the coolant. Automates the heating process.

- Gas valve. Regulates the supply of gas to the combustion chamber through the gas manifold nozzles. Blocks the supply of fuel to the burner in the event of a threatening situation.

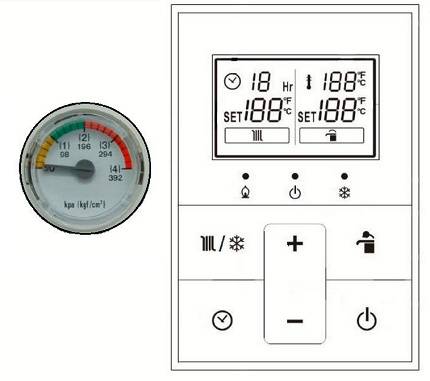

- Pressure meter. Controls the water pressure, gives commands to turn off the unit in case of pressure drop or excess.

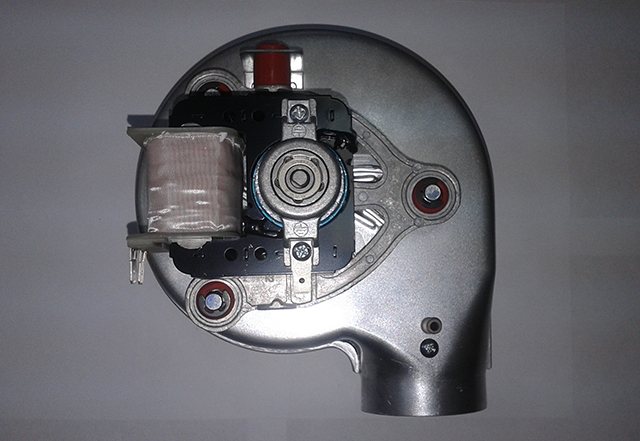

- Fan. Stimulates the output of products of gaseous fuel processing into the chimney. The air pressure switch is responsible for the operation of the fan itself, which, in the absence of traction, stops the boiler.

- Ionization candle. Detects the presence of a flame when the burner is running. If the fire goes out for any reason, this device will give a command to stop the gas supply.

Each of these devices performs its front of work. In addition to them, there is still an important group that prevents the occurrence of dangerous situations. These include a safety valve, a thermal relay that prevents overheating of heat exchangers, and other equally important parts and system components.

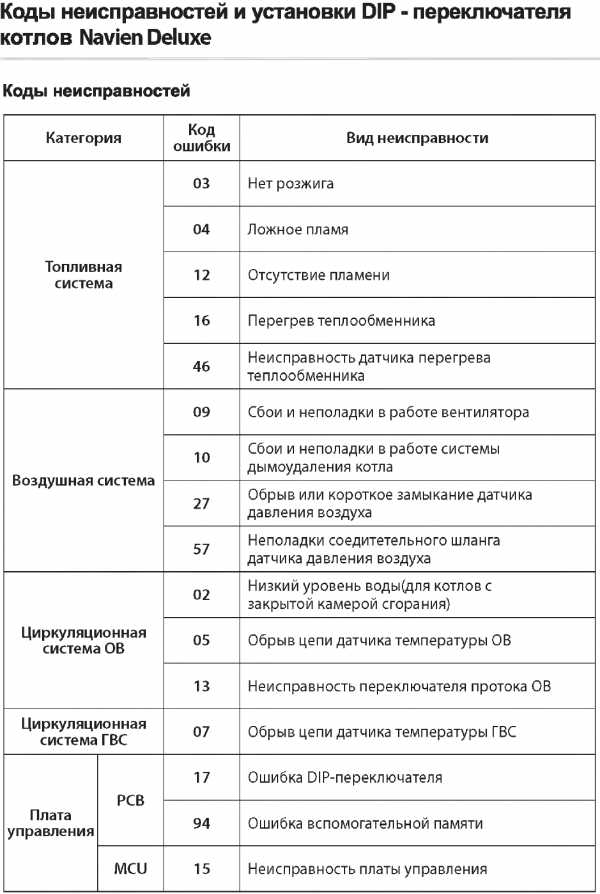

Basic error codes

a01

Error a01 - there is no signal about the presence of a flame. Gas does not flow or the gas valve or the ionization ignition electrode is faulty. The control board may not be working properly.

It is necessary to check all stopcocks and, if necessary, bleed air from the water supply. Check the gas pressure on the valve - it should be 20 mbar (2 kPa), as well as the gas valve itself (replace if necessary).

Check the electrode for contamination, as well as the gap between it and the burner. It should be 3 mm ± 0.5 mm.

a02

Error a02 - the signal about the presence of a flame is false. Control board or ignition electrode defective. Check for mechanical damage on the electrode itself, it is possible that it touches the burner. Also set the required gap between the burner and ignition / ionization - 3.5 ± 0.5 mm. Replace the control board if it fails.

Coreastar boiler ignition electrode

a03

Error a03 - the boiler is overheating. The bimetallic overheating sensor blocks the operation (or it is also called an emergency thermostat) - the threshold temperature is about 90 degrees. Air has entered the heating system and / or insufficient circulation in the heating water.

It is necessary to cool down the boiler and restart it. Replace sensor if necessary. Remove air from the circuit. Check the pump - open all shut-off valves, check the pump blades for contamination and supply voltage to its contacts. Replace pump if necessary. If a03 reappears, the control / board should be replaced.

a08

Error a08 - the OB overheating sensor is faulty. The temperature limiter gives an erroneous value. Check it for an "open" or short circuit and replace if necessary.

f05

Error f05 - a failure has occurred in the smoke exhaust system. The fan or air relay is not working properly or is defective. Chimney clogged.

Boiler fan Coreastar

Check the correct connection of the connectors to the contacts of the air relay and make sure that the air diaphragm has not stuck. Replace relay if necessary.

f11

Error f11 - RH temperature NTC sensor out of order. Open circuit or short circuit of the device. Check the resistance of the semiconductor - it should be 10 kOhm.It is possible that there is no signal between the control board and the temperature sensor. Disconnect the sensor and then reconnect it. Replace if it is defective.

f37

Error f37 - NTC DHW temperature sensor. Open circuit or short circuit of the corresponding device. With such an error, the burner will not be able to light up only in DHW mode. The boiler itself will be able to continue its work. Check the resistance of the sensor and the quality of the connection of the connectors. Replace parts if necessary.

The same code reports low pressure in the heating system. The extract air pressure sensor is defective or the circuit pressure has fallen below 0.8 bar. Check the sensor, replace if necessary, and find the leak. Fix the problem and replenish with water.

f41

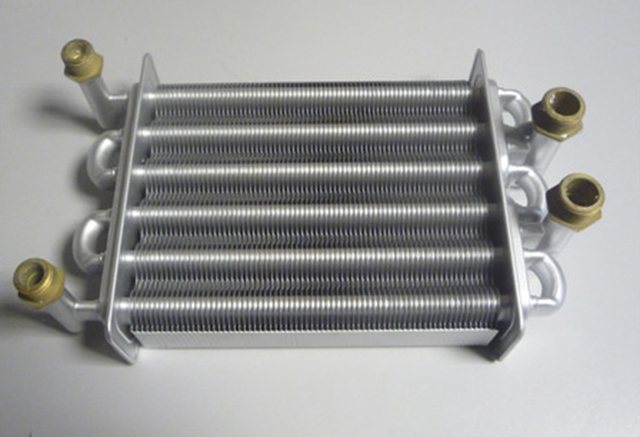

Error f41 - the heat exchanger is overheated. Poor heat exchanger circulation or air trapped. Remove air and check the pump, according to the method described in the instructions, with the valves open. If necessary, replace the circulation pump.

Heat exchanger for Koreastar boiler

f50

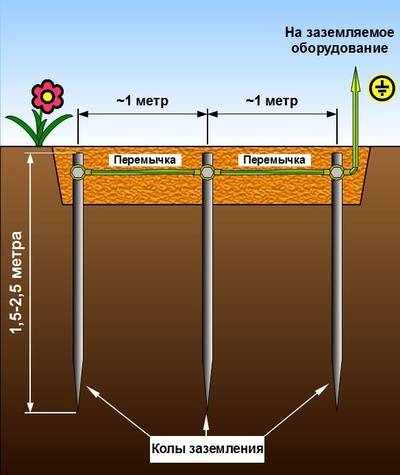

Error f50 - the operation of the control board has failed. Control board failure. Check the absence of a "breakdown" on the case, grounding, and in case of failure, replace the board.

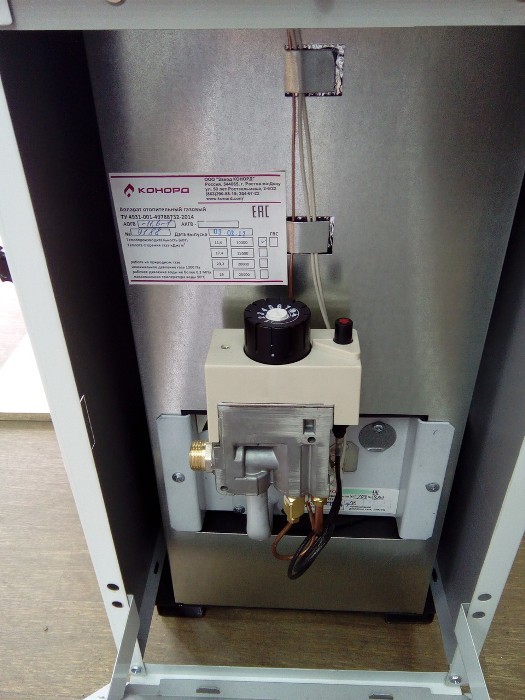

Installation and piping scheme of the boiler Kiturami

Since I have 3 sources of thermal energy (Kiturami pellet boiler, Waltek electric boiler, Laminox pellet aqua fireplace) and two consumers (indirect heating boiler and heating radiators), the piping scheme suggested itself:

All three boilers are connected in parallel and through the hydraulic arrow they give off thermal energy to consumers through the distribution manifold.

Implemented by a compact hydraulic gun from the Italian manufacturer Stout (SDG-0015-004001), manifold SDG-0017-004023, pump groups SDG-0001-002501. Circulation pumps Grundfos ALPHA1 L 25-60 180.

The first circulation pump of the small circle is controlled by the Kiturami boiler. The boiler loading pump is controlled by the Tech. The radiator loading pump is controlled by the Auraton 1106 controller.

Stainless steel sandwich chimney 125, height 6m. Two angles are 90 degrees, but since there is a smoke exhauster in the Kiturami boiler, this is enough.

The supply ventilation is 80, since the exit from the smoke exhauster is also 80. In case of lack of air, in the opposite part of the boiler room, in the pellet warehouse there is a window that can be opened for ventilation.

The boiler control thermostat is located in the living room. The control is simple: there is a temperature in the house and there is a temperature threshold below which the boiler turns on. The threshold is set to 23 degrees.

You can also set the temperature of the coolant from 60 to 80 degrees. Trusting the instructions, I set 60 for the summer. In winter, 80 is recommended.

There is a timer and Departure mode, when the temperature is maintained at 8. But in case of departure, I have an electric boiler that maintains a coolant temperature of 35 degrees constantly, and with thermal heads on radiators I maintain the temperature in vital areas where there is water: bathrooms, boiler room, kitchen.

Operating principle

Gas heating boiler Arderia has two varieties: it can have one bithermic heat exchanger or two radiators. The first type is distinguished by the fact that water is simultaneously heated for both water supply and heating.

The second type consists of two nodes. They heat up individually. One radiator is made of copper, the second is made of stainless steel.Water is circulated by a pump. The removal of combustion products is also forced. It happens with the help of a special fan.

All Arderia gas heating boilers have a number of features, which include:

- this equipment is fully suitable for Russian heating systems;

- boilers have a special voltage stabilizer that helps the device work smoothly even with power surges;

- boilers have a gearbox that stabilizes operation when the gas pressure drops;

- Arderia gas heating boilers are practical, stylish and of high quality.

The scheme of the principle of operation of these boilers is as follows:

- the first step is to set the required temperature using the remote control;

- the boiler turns on automatically using a temperature sensor and works until it reaches the set parameters;

- after that, the sensor turns off the boiler;

- as soon as the temperature drops by 15 degrees Celsius, the sensor turns on the boiler again.

Other malfunctions

CO code appears if:

- at a low temperature in the room, the anti-freeze mode is not set - turn on the anti-freeze mode with the button on the control panel;

- the water in the hot water tap does not match the one set in the settings - the tap may be unscrewed too much, screw it on a little until the desired temperature is reached. The second reason is low gas pressure or poor quality, you should contact the gas industry.

The hs code indicates a malfunction of the sensor on the return, check the reliability of its connections, if the sensor itself is faulty, install a new one.

The code ls means a malfunction of the hot water inlet controller, check the mechanical connection, the sensor for short and open, replace the sensor if necessary.

Clapping when turned on can be due to incorrectly set minimum and maximum pressure on the burner nozzles, when the electrode position is shifted relative to the nozzles, when the burner and jets are clogged with soot. Only a specialist can adjust the gas and electrode, clean the burner and jets yourself with a brush and blow.

The device makes noise and hum due to the heat exchanger clogged with scale, remove and clean it as described in your instructions, for this you can use special chemicals, you can use citric acid, dissolving it in water and immersing the heat exchanger in it.

Advantages and disadvantages

The equipment prevents smoke in the room

When choosing a Koreastar boiler, buyers are attracted by the reasonable cost of these devices and the price-quality ratio: few can afford to buy a German-made unit. Well-coordinated work in the conditions of cold winters, inherent in a significant part of the territory of Russia, is also of interest to the owners of private houses.

Other advantages of these devices are:

- low noise level from a running pump;

- high-quality automatic control unit;

- climate control option;

- optimization of gas supply (initiation - when the burner ignites, termination - when it goes out), which saves fuel;

- the use of a device that prevents smoke in the room;

- mechanism to prevent freezing of the coolant.

The downside is that sometimes power surges still cause malfunctions of the microprocessor board, despite the manufacturer's instructions for stable operation with drops within 15% on both sides of the nominal value. You can prevent such incidents by installing an uninterruptible power supply.

Decoding errors Ariston

First group of codes

Likely causes:

• The error indicates an insufficient coolant level. Before filling the circuit, check the system for leaks. Visually, it is easy to determine by the puddles on the floor. • Airing. The error is typical for lines with heating radiators without an automatic air vent. • The filter or heat exchanger of the Ariston boiler is clogged. Reducing the flow rate causes error 101. • Problem with the circulation pump. Built-in pumping devices are not repaired - only replaced. For a pump installed separately, on a pipe, there are options. • Excessive gas supply to the Ariston burner. If "screwing" the valve does not work, you need to adjust the valve.

103–

Likely cause:

The result of the accumulation of air in the system. Recommendations for Ariston models are somewhat different. • Egis Plus 24 series boiler. Press and hold the MODE button for at least 10 seconds. • Ariston UNO or Mathis. Likewise for the RESET button. Short-term operation of the pump in the absence of ignition allows you to remove air from the system - the error disappears.

108. Critical pressure drop

Probable cause: leakage. It may appear in the expansion tank (connection point), heat exchanger, at pipe joints, in heating appliances.The error disappears after the defect is eliminated and the system is filled with liquid.

. Overpressure

Probable cause: the destruction of its internal partition (crack, fistula) leads to the flow of fluid from the water supply into the OV circuit. You need to start by bleeding the air in the system, and drain some water as well. If over time the pressure rises and error 109 appears again, you will have to change the heat exchanger.

114–115

. Appears on the display of the Ariston boiler of the CARES X 24 series. Ariston CARES control panel

Ariston CARES control panel

Probable cause: low medium circulation. It is necessary to press and hold the reset button (REZET) for about 10 seconds.

Second group of codes

Likely causes:

• Open circuit. The oxidized contacts are cleaned, the departed wire is soldered. • Sensor failure - replace.

.

,

Recommendation: turn off the power to the boiler, and after a while turn on the power.

308

Fifth group of codes

. No ignition of the boiler. Displaying error 501 in the Ariston boiler

Displaying error 501 in the Ariston boiler

Likely causes:

• The gas path is blocked. Check the position of the stop valve (valve) handle on the pipe. • Incorrect position of the ionization sensor. The recommended interval between it and the burner comb is 8 mm. • Loose connection of the wire to the electrode. • Oxidized contacts. • Violation of the rules of binding Ariston. Initially, the boiler nozzles are “plugged” with plugs (plastic, sometimes paper). Novice installers, without checking this, connect the water pipe. The error appears on the display due to the lack of flow - the valve does not work, and the automation gives a signal that Ariston is not allowed to work.

Sixth group of codes

Likely causes:

• Change in direction and increase in wind speed. This happens when you choose the wrong place to take the chimney out of the house. In fact, the boiler "blows out."• The flue duct is clogged. Garbage, foreign objects, even small birds falling into the pipe are the cause of the error. • Non-compliance with the manufacturer's recommendations for the chimney layout. In this case, the 601st error appears already during the initial start-up of the Ariston boiler. • Traction sensor failure - replacement only.

604

Possible causes of the error:

• Relay failures. As a rule, it is associated with sticking contacts - replacement. • Malfunction of the boiler fan - similar.

608.  Placement of the pressure switch in the Ariston boiler

Placement of the pressure switch in the Ariston boiler

Errors of individual modifications of Ariston

a01

Probable causes: instability of the supply voltage, incorrect operation (or failure) of the boiler ionization sensor.

e34. sp2.

Probable causes: the gas main is blocked, a sharp drop in pressure in it, a weak pressure in the water supply.

H4554

When stopping the Ariston boiler, you do not need to immediately call the master and waste precious time. It is enough to look at the code that appears on the display. Repair statistics show that in 85% of cases the user can solve the problem on his own. But resorting to the help of "all-knowing and experienced" is not worth it. Some Ariston models have significant design differences, which are taken into account during the repair process. The main adviser is the manufacturer's instructions. The document must have a section with explanations for each error code.

Insufficient circulation, error 104. How I searched for the cause

According to the manual, I determined that 104 is “Insufficient circulation” I argue: What can interfere with normal circulation? After all, a clogged filter in the heating system or slag that has accumulated in the primary heat exchanger can interfere with the desired flow of the coolant.Could it be the circulation pump? Has the pump gone? To check it, unscrew the bleed screw on it, this will allow you to see whether the shaft is rotating or not.

There is a slot on the shaft for a wide, flat screwdriver, I tried to turn the shaft with a screwdriver ... it didn’t jam, it rotates. I try to start the boiler and see if the shaft rotates. The cauldron plays its terrible sounds and again goes into defense. The shaft does not rotate. At the time of launch, I tried to turn it with a screwdriver .... I thought, but suddenly a “dead point” appeared ... .. no, the shaft did not rotate.

Decided to check the pump supply voltage. When the presence of 220 volts was detected on the chip, the conclusion was unequivocal .... Replacement pump. Eeeh, I think, again, unforeseen expenses.

However, the conclusion was hasty, when I was looking for wires coming from the board to the circulation pump motor, I noticed that there were more than two of them. For what? Started looking into it and here's what I found out

![How to fix error 501 on ariston gas boiler [ariston]](https://fix.housecope.com/wp-content/uploads/e/d/5/ed5fecb9a051bd4c9bab227108126c07.jpg)