- Gree: Error and Fault Codes | Easy Repair

- GREE Air conditioners for semi-industrial, industrial use, - error codes

- How to respond to error codes

- How to start troubleshooting?

- What are the most common faults

- Brief repair instruction

- Causes and Troubleshooting for Simple Problems

- Features of diagnosing the operation of the heating element

- The most common Gree air conditioners

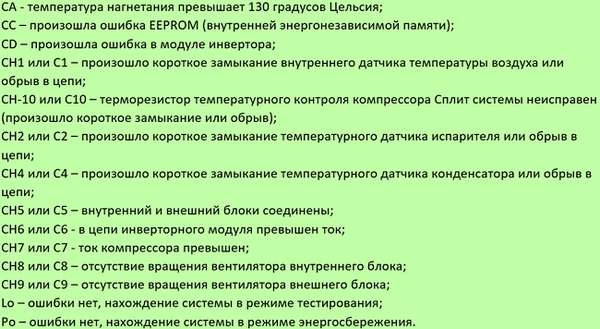

- Atypical values on the display

- Error codes for the refrigerator "ElGee"

- Errors on the air conditioner heat indicator (H)

- Error reporting principle

- Errors on the indicator of the air conditioner (E)

- What is an error code?

- Self-diagnosis system of modern air conditioners

- Conclusions and useful videos on the topic

Gree: Error and Fault Codes | Easy Repair

With Gree air conditioners and split systems, repairs are easier than with hi-fay series models.

Self-diagnosis of Gree air conditioners

What explains this, the layman asks?

The explanation is simple Gree: codes. On Gree air conditioners and split systems, there are not many protection system sensors. Those. everything is simplified.

The internal self-diagnosis of Gree air conditioners is unified and almost identical in error positions to inexpensive air conditioners, such as Pioneer, General Climate, Lessar and others.

You will laugh, but for example, the catalog of Supra air conditioners did not even change the name of the outdoor unit, perhaps there are not enough skills in Photoshop, perhaps they did not consider it necessary.

In a word, how were Supra air conditioners certified in Russia? It's a mystery to me. Supra Catalog!! In faith. Heh...

Self-diagnosis of Gree air conditioners is, -

- high pressure protection

- protected from freezing of the evaporator,

- Compressor overload protection,

- Errors in switching the air conditioner during installation, confusing wires,

- And errors of temperature sensors of the evaporator and condenser.

Everything, agree not much. Gree, like an air conditioner, is functionally simple, so there are not many error codes. There are drawbacks to this simplification, these are weak control board varistors, insufficient smoothing

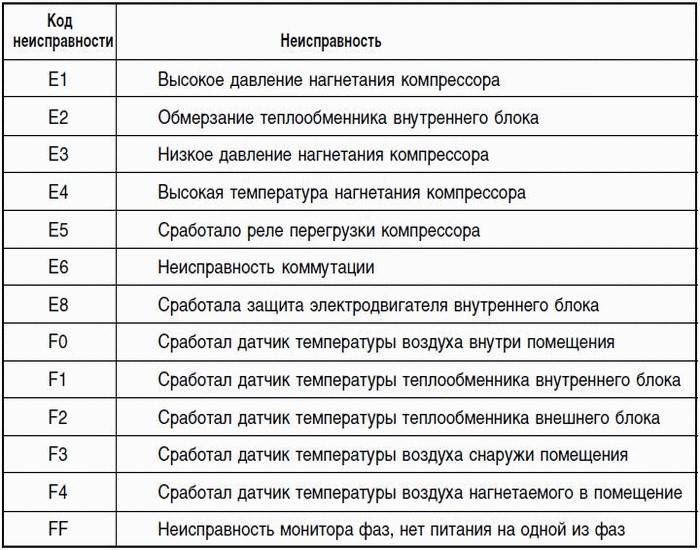

Error codes table, continued.

currents during voltage surges. A trifle, but this must be borne in mind when repairing Gree air conditioners and their analogues.

Example: country house. The owners, leaving the dacha, usually de-energize the building with a common switch. extinguished and everything, calmed down. We arrived ... They turned on the light with the same switch, but the air conditioner, refrigerator, or other household appliances did not work. Why? The answer is simple.

When the power is turned on with a load, current and voltage surges occur.

There are “specialists” who use wire when a fuse burns out. Can you do that? It is possible, but then, in addition to the varistors, the control board, the fan motor of the indoor unit will also burn out, and ... it rushed up to the compressor windings of the outdoor unit of the air conditioner.

Fireworks at the cottage. - Expensive repairs.

- malfunctions of the refrigeration circuit,

Error map, mapping. Primary diagnostics of the system.

GREE Air conditioners for semi-industrial, industrial use, - error codes

Error code = E1 Compressor, pressure surges (beep).

Error code = E2 Faulty coil

Error code = E3 Low pressure air conditioning compressor (beep)

Error code = F0 Faulty room temperature sensor.

Error Code = F1 Wrong sensor resistance.

Error code = F2

The temperature sensor of the outdoor unit of the air conditioner has tripped.

Error code = F3 Temperature sensor circuit open.

GREE Split Air Conditioners Error Code…

Cause of malfunction, - high protection system refrigerant, - pressure.code = E1

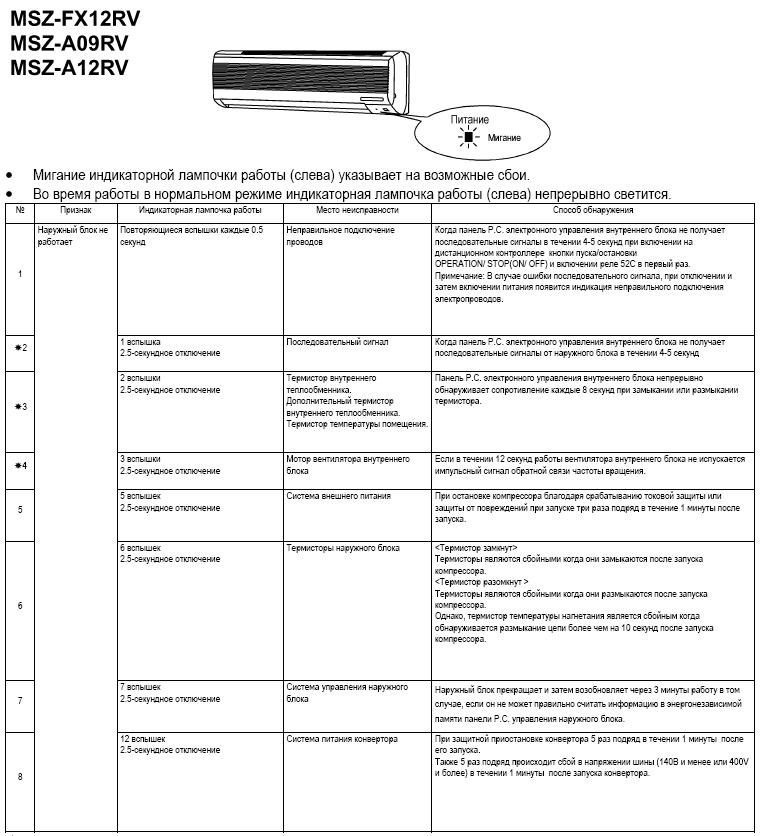

Air conditioner start LED = Gree LED blinks 1 time. Indicator, - cooling =

Heating indicator =

Gree Fault Cause - Frost Protection Code = E2

Air conditioning start LED = LED blinks 2 times. Indicator, - cooling =

Heating indicator =

LED start air conditioner = flashes 4 times Indicator, - cooling =

Heating indicator =

Cause of malfunction, - AC overcurrent protectionCode = E5

LED start air conditioner = LED flashes 5 times Indicator, - cooling =

Heating indicator =

The cause of the malfunction is a communication failure between the indoor unit of the air conditioner and the outdoor unit of the split system. code = E6

Gree air conditioner start LED = blinks 6 times Indicator, - cooling =

Heating indicator =

Cause of malfunction, - Anti-high temperature protection code = E8

LED start air conditioner = flashes 8 times Indicator, - cooling =

Heating indicator =

Cause of the malfunction, - No feedback from the internal fan motor Code = H6

LED start air conditioner = flashes 11 times Indicator, - cooling =

Heating indicator =

The cause of the malfunction, - Jumper cap is defective. protection code = C5

LED start air conditioner = flashes 15 times Indicator, - cooling =

Heating indicator =

Cause of malfunction, - Closed ambient sensor open, no contact or short circuit code = F1

Indicator, - cooling = LED flashes 1 time Heating indicator =

How to respond to error codes

Theoretically, codes can be displayed on any models that have a digital display. But in practice, not all models have this functionality. For example, for ordinary Kentatsu air conditioners, the digital display located on the indoor unit serves only to show the air temperature inside the room or the selected operating mode.

But for columnar models, in addition to the general rules of action in case of detection of malfunctions, a small table with codes is usually placed in the instructions.

E01 - temperature sensors have ceased to function correctly or are out of order.

E03 - the compressor cannot work due to low current.

E04 - blocking of the outdoor module is turned on

P02 - compressor overloaded

If you see one of these codes on the display - according to the manufacturer's recommendations, you need to contact the service center. Without fixing the breakdown, the equipment most likely will not return to operating mode.

Many try to solve the problem on their own. This is possible if the unit is already out of warranty and if you have sufficient knowledge and skills

E02 - a power overload of the compressor has occurred. It is recommended to turn off the split system for a while, and then press the “On” key again. If the device does not start working or behaves unusually - it makes uncharacteristic sounds, smokes - you need to call a technician.

P03 - when the indoor module is operating in cooling mode, the evaporator temperature has dropped below normal.

P04 - when the indoor module is operating in heating mode, the evaporator temperature has risen above normal.

P05 - the indoor module supplies superheated air to the room.

Most often, these 3 problems arise for a banal reason: due to a clogged air filter. You need to lift the front panel, remove visible dirt and vacuum the filter.

If heavily soiled, remove it, rinse, dry and reinsert. Most often, the operation of the air conditioner is getting better, and if not, the help of a master certified by the manufacturer is required.

For Kentatsu duct and cassette air conditioners, error codes can be displayed in two ways:

- alphanumeric characters on the electronic display of the control panel;

- indication - a combination of flashing LEDs.

A table with detailed explanations is given in the instructions:

The LED signals in the table are indicated by two types of symbols: a “cross” (x) indicates that the LED is off, and an “asterisk” indicates that it flashes at a frequency of 5 Hz

The manufacturer prohibits cardinally intervening in the operation of the air conditioner, removing or reinstalling important components on its own. But before calling the technical service, he recommends re-checking the power supply and the correctness of the selected mode.

Often, the operation of climate technology stops due to a sharp change in external conditions - for example, due to overheating. It is possible if an additional heat source appears in the room.

You also need to monitor the sealing of the room: with open doors or windows, the split system will run idle.

How to start troubleshooting?

Modern air conditioners are intelligent electronic devices, the operation of which is controlled by an embedded processor. It is he who analyzes the information coming from a variety of sensors, recognizes faults and displays their codes.

Errors that occur are one-time, for example, power surges in the network, and there are long-term ones, for example, a short circuit of the fan windings. In order to understand what the nature of the fault is, the first thing to do is to restart the power supply. It will reset the air conditioning control systems and reset the signals from the sensors.

To reset the errors, turn off the unit, then unplug the AC power cord from the outlet. If the split system is connected via a separate line, then turn off the corresponding machine in the shield

To reset the errors, turn off the unit, then unplug the AC power cord from the outlet. If the split system is connected via a separate line, then turn off the corresponding machine in the shield

To restart, unplug the device for 30 seconds and then plug it back in. If the error was a one-time operation, then its code will disappear from the screen or indicators and the device will start working again. If the malfunction is serious, then the error will be displayed again and it will be necessary to eliminate its root cause.

What are the most common faults

ionization system E-Ion

The automatic control that controls the indoor unit can give a signal and block the operation of the Panasonic air conditioner not only when it needs repair. If the unit does not turn on and the warning light is on or flashing, it may mean that the panasonic air conditioner needs to be cleaned. This situation occurs quite often because:

- The indoor unit of some models (depending on the marking) is equipped with an E-Ion cleaning system.Its sensors monitor the state of the air, when contaminated, a generator of charged ions is turned on, which kills mold and fungal spores. When the sensor indicates an acceptable air quality, the E-Ion system will turn off and the timer will indicate the problem. It is easy to understand that an alert can indicate both that a sensor or generator needs repair, or that it’s just time to clean the filters;

- the Air Purifying filtration system is also constantly monitored and any malfunctions in this structure that fights pathogenic bacteria, viruses and allergens cause the air conditioner to turn off. Often, you just need to disassemble, clean the filters, after which the device turns on again and works without failures.

Brief repair instruction

The LG machine is a reliable device, so when the first problems appear, you should try to eliminate the cause of the problem without opening the device. For example, if the washing machine does not work, then most often this is due to an elementary lack of electricity in the power supply.

Causes and Troubleshooting for Simple Problems

Rattles, thumps in the drum and vibrations often occur due to the unstable position of the legs. If the machine is rearranged, then the problem will resolve itself.

Also, periodic knocking during washing may indicate wear on the bearings and the seal that seals the drum. You can replace them yourself.

To be sure of the cause of the noise, you should independently turn the machine drum left and right with your hands. If there is noise, crackling or rumble, then the reason is definitely faulty bearings.

A properly installed washing machine will not “snort”! Over time, the balance set during installation may be disturbed due to the movement of the case during the spin cycle.

If the machine jumps or jumps, then this malfunction is due to violations in the structure of the counterweight attachment.

Water leaks occur due to worn hoses or improper connection. In this case, you can simply tighten the couplings in problem areas.

It often happens that even after cleaning the drain pump filter, the machine “refuses” to drain the water. It is possible that the cause is a clogged drain hose, which you just need to clean

If water does not drain from the washing machine drum, you need to repair the drain system: clean the filter, check the drain hose and pump.

Features of diagnosing the operation of the heating element

If the machine began to heat the water poorly, then you need to diagnose the heating element. The fact is that during long-term operation, scale forms on the heating element, which prevents its normal operation. The heating element can be easily cleaned even at home, for example, with acetic and citric acid.

Cleaning the heater with citric acid:

- the washing mode is set without linen (temperature 60-90 degrees);

- instead of powder, citric acid should be poured (about 100 grams, but it all depends on the degree of contamination of the device).

This procedure can also be used for preventive purposes - once every six months or a quarter, depending on the intensity of washing. For detailed instructions on cleaning the washing machine with citric acid, read this material.

Vinegar cleaning:

- also sets the wash mode without linen;

- 2 cups of vinegar are poured into the powder receiver;

- run the wash for the longest program;

- 5-10 minutes after starting work, pause the machine and hold it in this position for about an hour;

- after an hour, you should resume washing and rinse the tank well to completely rinse off the vinegar solution;

- after that, wipe the hatch doors with a piece of cloth soaked in acetic acid.

But it will be more effective to prevent the formation of scale. Prevention of pollution can be carried out by installing specific magnetic water softeners (filter softeners), which purify the incoming water from calcium and magnesium salts.

Not everyone can afford magnetic softeners, so you can install a conventional chemical mechanical cleaning filter on the pipe leading to the machine, which does not let rust and sand into the washing machine

To increase the service life of the heating element, certain rules should be followed: do not wash clothes in boiling water (if possible) and do not bring things to a state of deterioration and a very dirty look, because. particles will enter the heating element and form scale.

It is also recommended not to use cheap counterfeit detergents, but to be more selective in choosing washing powders and gels.

The most common Gree air conditioners

The question is not idle, since in most cases the layman is rather poorly aware of the types of air conditioners. In addition, air conditioners of the same type often have several different names.

When talking about household air conditioners, in most cases they mean two-block wall-mounted inverter split systems. Air conditioners without an inverter are already yesterday, in the world they are beginning to be banned for sale.

Gree inverter air conditioners are the most popular air conditioner model in the world.Climatic equipment without an inverter is a thing of the past

To put it simply, split systems are such air conditioners, one “box” of which hangs outside the window, the other in the room. Gree also produces multi-split systems. Multi-split systems are when there is only one “box” outside the window, and several “boxes” inside the house and all literally create “weather in the house”.

Have a closer look? Did you see a box outside the window? Great, that's enough, let's continue the diagnostics.

Griya air conditioners can use refrigerants for operation:

- freon R22;

- freon R410a.

The chemical formula of the first substance is difluorochloromethane, the second is a mixture of pentafluoroethane and difluoromethane. It is not necessary to memorize the names, the main thing to remember is that the errors of two- and multi-block air conditioners of the Grii brand, operating on different refrigerants, are displayed in the same way.

Atypical values on the display

If, when the “Heating” mode is turned on, the device starts to work, but after a while it stops blowing air, the indicator sun blinks and the inscription H1 lights up, this means that the device has switched to the defrost mode.

It is necessary to turn off the device from the remote control, hold down X-FAN and MODE at the same time. After half an hour, the air conditioner should work in a normal rhythm.

Sometimes an incomprehensible code may appear on the display, the decoding of which is not in the instructions and on the manufacturer's website. For example, a flashing sun and the value of H7

In case of error H7, diagnostics of the control and indication module of the device are needed. It can only be performed by a specialist.

The value of H6 stands for the operation of the compressor blocking sensor. This happens in two cases: when the sensor itself is broken and needs to be replaced, or when there is insufficient freon charging.

Also, with such an error, a variant with incorrect power connection of the impeller of the indoor unit is possible, which was not taken into account during assembly. Here you need to disassemble the board to clarify the cause and eliminate it.

Error codes for the refrigerator "ElGee"

The control board is equipped with a self-diagnosis system. It is she who displays the error code. Sometimes it can be a system failure, which can be eliminated by rebooting:

- Unplug the refrigerator.

- Connect after 10-15 minutes.

If during this time the code disappeared from the screen, then the problem is solved. If it lights up again, it's broken. To determine exactly which node is broken, take a look at the instructions or our table:

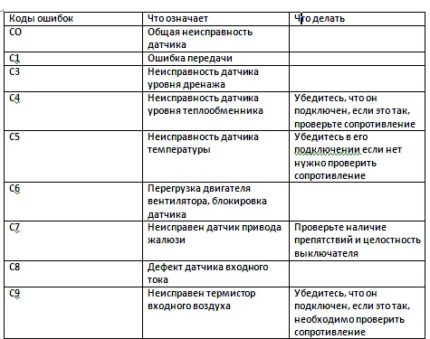

| Error code | What does | How to fix the problem yourself |

| FS | The temperature sensor in the freezer does not work. | There was probably a short circuit. Check sensor contacts and wiring. Replace the defective part. To prevent such problems, it is recommended to install a voltage stabilizer. |

| rs | Closed refrigerator compartment sensor. | The sensor is beyond repair. The element is being diagnosed and replaced. |

| dS | Freezer compartment sensor 2 does not give a signal. | No communication with sensor and control board. Contacts and connections are examined. Replacement is in progress. |

| dH | The evaporator sensor has failed. | Temperature rises in the department. You need to check the sensor and install a new part. |

| FF | The freezer fan is not working. | The fan accelerates cold air through the chamber in the No Frost system. If it is not working, then the temperature will begin to rise.The blades are checked for icing, defrosting is carried out. The engine is diagnosed, it is replaced with a serviceable one. |

| CF | The refrigerator fan is broken. | It is necessary to check, find out the cause of the failure and install serviceable elements. |

| CO | Faulty wiring between control board and information display. | The display may malfunction. Inspection of the wiring at the time of burns and insulation violations. Loop replacement. |

| dP | Throttle motor does not work. | You need to inspect, find out the cause of the problem and fix it. Probably the motor is not working. Then it is replaced. |

| Er | The freezer evaporator does not work. | There was a breakdown of one of the parts of the evaporator: sensor, timer, heater. Diagnostics, ringing of parts and assemblies are carried out. The defective element is replaced. |

Similar codes can be seen in any models, but most often in LG GR-389SQF, LG R-S392QVC, LG GR-P227ZCAW, LG GA-B489 ZVCK.

Certain indicators may also flash and light up. As soon as you notice such symbols on the display, do not delay the inspection, call the wizard or do it yourself.

Errors on the air conditioner heat indicator (H)

The most common trouble is the H1 code. She's also the easiest to fix.

The air conditioner stopped supplying heat because it turned on the defrost mode of the external unit. The control sensor of the heat exchanger of the outdoor unit worked and the automation turned off the heat injection. It is fed to the outdoor unit, defrosting it. Unfreeze - everything will work. If not, then you need to check the health of the sensor and the heat exchanger.

Errors on the heat indicator can indicate a malfunction of the air conditioner circuit, as well as other problems of the outdoor unit from the control board to a clogged drainage system

Error H2 means that the electrostatic filter is at risk, the one that collects dust and other particles circulating in the air. This filter can be cleaned. Or replace with a new one. According to reviews, Gree air conditioner filters are one of the weakest points. So it would be better to learn how to clean them in advance.

To do this, simply remove the filter from the air conditioner, rinse in a detergent solution, rinse well under running water and dry thoroughly. And then put it back in.

An air conditioner with a dirty filter runs louder, and noticeable sparking is also possible. So you can take action without waiting for the H2 error.

The electrostatic filter must be cleaned regularly. You can simply wash it under running water. This will help you avoid big problems.

Error H3 protects the compressor from overheating. Overheating, as well as compressor overload, can occur due to leakage of oil, freon or freon and oil. First of all, you need to check the roller connections. Or maybe due to a malfunctioning fan or condenser.

If there are no traces of oil on the connections, the fan is working normally, and the external unit itself is clean, then it is necessary to calibrate the circuit using the same pressure valve, thermostatic valve and pressure gauge.

Error H4 means a malfunction. If the air conditioner does not work after restarting, the problem is either in the control board or in improper installation.

Code H5 means the outdoor unit's IPM board is defective. If the board fails, it must be replaced.

The letter H7 means that the compressor fault is indicated by the energy saving inverter (DC Inverter). It is he who is responsible for turning the compressor on and off in inverter split systems. Constant switching on and off sooner or later will affect the operation of the compressor. Error H7 rarely happens for reasons that you can fix yourself.

Error H8 means that the automation considers the drainage system to be overflowing with condensate. We need to check the external drainage system. If it is clogged, clean it.

The condensate drainage system is one of the simplest and most understandable air conditioning systems. You can clean it yourself

H9 - a problem in the electric heater. First you need to check if it works. If it does not work, then the reason is probably an open circuit. Or the heater is burned out.

Problems H0 and FH clearly indicate the operation of the temperature sensor on the evaporator (H0) or on the evaporator and condenser at low speed. It is necessary to check the refrigeration circuit and the refrigerant level in the circuit as with errors E7 and E8. The reasons are exactly the same, only the inverter sensors pointed to them.

A circuit with a thermostatic expansion valve is one of the basic systems that ensure the operation of an air conditioner. The performance and long-term service of climate equipment depend on its action.

An error under the letter FH means that the evaporator may freeze. A good air conditioner can solve the problem on its own. If necessary, it must be cleaned. Also, the evaporator may freeze due to freon leakage or failure of the valve and circuit valve settings.

Error reporting principle

To improve the reliability of the device and prevent serious damage, Samsung air conditioners are equipped with a self-diagnosis system that continuously checks several parameters of the device.

If at least one of the specified parameters is out of the norm, the device reports this in two ways:

- On the display of the indoor unit, a combination of the letter E and three numbers, for example, E101;

- On the LED board of the outdoor unit, by glowing yellow, green and red diodes in various combinations.

The indoor units of some models of air conditioners are not equipped with a display. They report their problems in the same way as outdoor units, by flashing buttons of different colors.

The display of the indoor unit of the air conditioner in normal mode shows the air temperature, and in case of a malfunction it displays an error code

Below we will talk about the codes displayed by Samsung air conditioners in the event of a malfunction on the display or indicator board. Knowing the decoding of these alphanumeric combinations will allow you to understand what problems have arisen in the split system.

Errors on the indicator of the air conditioner (E)

Error E0 air conditioner Gree means insufficiently high starting voltage. That is, most likely, “in the socket” there is simply insufficient voltage. For an air conditioner, this is potentially dangerous, since prolonged exposure to inrush currents on its electrical network can cause overheating, which will “burn” the wiring insulation, and then the electrical appliance itself.

If the matter is “in the socket”, then the problem is solved by purchasing a voltage stabilizer, which will bring the voltage to the required 220V.

But it is possible that the matter is in the wiring of the air conditioner itself. Therefore, if the mains voltage is 220V, but the air conditioner still gives an E0 error, then you need to check it.

Connecting both units of the split system to the power line is not so simple. Incorrect connection will almost certainly cause errors and malfunctions.

Error E1 is a shutdown to protect the compressor from too high pressure. Error E3 means that too low pressure is applied to the compressor.

Sometimes, to eliminate E1, it is enough to wash the air conditioner air condenser well. If it is not blown enough, then this leads to an increase in freon pressure. If the air conditioner has a water condenser, the water supply must be checked. Another possible reason is an excess of freon itself or an unadjusted thermostatic valve.

Just in case, you should immediately check the valve. It should at least be open. If visually everything is normal, then you will have to call the master to adjust the contour. On your own, besides, without skills and a pressure gauge, it is unlikely that you can adjust the valve (you may also have to adjust the discharge valve) and refill freon according to the scales.

Most errors on the indicator of work are associated with the protection of the compressor - one of the most important components of the air conditioner

Too low pressure in the circuit can occur if the evaporator, fan or filter is dirty. That is, the algorithm of actions is exactly the same. First, dirt is removed, and then the contour is adjusted. It is also necessary to check the tightness of the rolling joints. If traces of oil are visible on them, then the mixture is leaking.

Error E2 means that the indoor unit of the air conditioner may start to freeze or is already frosting over.

Using this error as an example, we can explain the general principle of diagnosing problems associated with the compressor (E1-E5):

- Some kind of sensor is triggered, warning of a problem.

- We remove contaminants that can cause temperature extremes. Check the fan impeller. Is the console still giving an error?

- Most likely, the problem is in the level of freon, loosely rolled copper pipes are leaking, the thermostatic valve or pressure valve is incorrectly adjusted.

If so, then most likely you will have to call the wizard. Since we are talking about either an initially incorrect installation of the air conditioner (you will have to turn the pipes and refill the air conditioner with freon), or more serious problems that require replacement of components.

The same principle solves problems E5 (activation of the compressor overload protection sensor) and E4 (activation of the compressor discharge tube protection sensor from overheating).

Error E6 indicates that there is no phase, that is, it is necessary to reconnect the switching. It is also necessary to check the commutations with an error H6. By acting consistently and slowly, you can find a problem in the electrical circuit.

Error E7 - a contradiction in the specified modes, typical for multi-split systems. One block of the multi-split system is set to a mode that contradicts another block of the same system. The air conditioner, to put it simply, is confused.

Error E8 means that the indoor unit motor sensor indicates evaporator overheating. Again, it is necessary to check the thermostatic valve and the pressure valve. If they are in order, then it is possible that the freon simply ends in the evaporator. Or maybe the evaporator tubes are clogged.

Adjusting the circuit with a thermostatic expansion valve and a pressure valve is a delicate job that requires care and accuracy. Read the pressure gauge carefully.

E8 error shutdown protects against too cold air in heating mode. Cold air can cause liquid to build up which, if it enters the compressor, will almost certainly damage it.

And finally, the F0 error means that the pressure sensor is broken. Most likely, they are.

What is an error code?

Panasonic air conditioners have a good set of functions and many automatically controlled systems. This can be fine air purification, ionization of the atmosphere, the destruction of dangerous microorganisms, etc.

Automation turns off the air conditioner when it needs repair or cleaning. New models of Panasonic air conditioners have an advanced self-diagnosis system. Based on its results, the control system detects a malfunction and reports its cause on the control panel.

The error code is a flashing number-letter designation on the panel of the air conditioner or the module of the multi-split system. If an error code lights up on the display of the air conditioner, you need to find out what it means

The error code is a flashing number-letter designation on the panel of the air conditioner or the module of the multi-split system. If an error code lights up on the display of the air conditioner, you need to find out what it means

In the event of a serious breakdown, all operation of the equipment may be blocked. If the failure does not affect the operation of the system, the error message will continue to flash during operation. If the air conditioner or split system detects two or more breakdowns, the fault with the highest priority is displayed first, then all the others.

When a flashing signal appears, you need to immediately deal with the causes of the failure. There may be several violations in the work, but the most serious one will be displayed most actively.

When a flashing signal appears, you need to immediately deal with the causes of the failure. There may be several violations in the work, but the most serious one will be displayed most actively.

However, a working air conditioner in the presence of a flashing error is not a reason to continue the operation of the system.Ignoring the sensor signal will exacerbate the problem and, as a result, more serious repairs, entailing high costs.

Therefore, when a flashing signal appears, you need to deal with the causes of the failure as soon as possible and call the master for repair or, if you have the necessary experience and skills, solve the problem yourself.

If an emergency occurs, the air conditioner self-diagnosis system will stop the operation of the equipment and display an error code on the display. If an error code appears, you must immediately take measures to clean or repair the device

If an emergency occurs, the air conditioner self-diagnosis system will stop the operation of the equipment and display an error code on the display. If an error code appears, you must immediately take measures to clean or repair the device

Also, under the cover that hides the air conditioner buttons, there is a Check key, with which you can see all the errors in the system by scrolling through the “Up” and “Down” arrows. To reset critical errors, you must eliminate them, after which they will disappear from the display on their own. Errors are also reset after a power reset.

Self-diagnosis system of modern air conditioners

New generation household appliances are usually equipped with a self-diagnostic system designed to detect malfunctions and errors in operation at their first occurrence. The self-diagnosis system is a single network of sensors that monitor the state of one or another working unit of the unit.

When the air conditioner is turned on, the sensors automatically start working and continue to perform their functions in continuous mode until the device is disconnected from the power supply. Sometimes, to eliminate failures and errors, it is enough for the owner of the air conditioner to perform simple actions with his own hands, sometimes you have to invite masters from the authorized General Climate service.

Consider possible errors and their codes in various models of air conditioners and split systems GC, their causes and ways to eliminate them.We will try to figure out in which cases hand-made actions are appropriate, and in which cases an experienced master should be invited.

GC air conditioners are equipped with a modern self-diagnosis system that sends signals in case of failures and errors in operation to the control module

When the operating parameters of the node on which the sensor is installed are changed, an error signal is immediately sent to the control module, which is displayed on the device display. If necessary, the control module also blocks the equipment in order to avoid incorrect operation of the air conditioner and its final breakdown.

Fault codes for different models of General Climate air conditioners may differ from each other. We will try to consider in detail the codes of each model.

Conclusions and useful videos on the topic

The video tells that the cause of the E101 error was the appearance of a microcrack on the printed circuit board in the street block:

The video shows the cleaning of the outdoor unit of the air conditioner with its dismantling:

As you can see, thanks to the advanced diagnostics and fault indication system, you can independently determine the cause of the failure of the Samsung air conditioner. The first thing to do is to disconnect the split system from the electrical network for 30 seconds to reset the errors.

Also, before turning on the device again, it is better to make sure that the outdoor unit has no mechanical damage. To identify and eliminate more serious malfunctions, you will need to have at hand the decoding of error codes and the necessary tool. And some errors require a mandatory call to the service.

Want to talk about your own experience in identifying the failure of your own split system? Do you have any technological nuances that are worth sharing with site visitors? Please write comments in the block form below, post pictures and ask questions on the topic of the article.