DAIKIN OUTDOOR UNIT ERROR CODES

E0 - the protective device has tripped (general).

E1 - malfunction of the printed circuit board of the outdoor unit.

EZ - worked high pressure sensor (HPS).

E4 - the low pressure sensor (LPZ) has tripped.

E5 - compressor motor overload, overheating relay.

Eb - blocking of the compressor motor due to excess current.

E7 - fan motor blocking due to overcurrent.

E8 - total current overload.

E9 - malfunction of the electronic expansion valve.

AN - current blocking of the pump.

EC - abnormal water temperature.

EJ - an additional protective device has tripped.

EE - abnormal water level in the drainage system.

EF - Faulty heat storage unit.

H0 - sensor malfunction (general).

H1 - the air temperature sensor is faulty.

H2 - malfunction of the system power supply sensor.

NC - malfunction of the high pressure sensor.

H4 - malfunction of the low pressure sensor.

H5 - the compressor does not work. The overload sensor has tripped.

H6 - the blocking sensor has worked. Compressor overload.

H7 - the blocking sensor has worked. Fan overload.

H8 - the input voltage sensor has tripped.

H9 - the outdoor temperature sensor has tripped.

ON - the outlet air sensor has tripped.

HH - the water pump blocking sensor has tripped.

HC - the hot water sensor has tripped.

NOT - the drainage level sensor has tripped.

HF - failure of the heat storage unit.

F0 - protective devices 1 and 2 have tripped.

F1 - the protective device of system 1 has tripped.

F2 - System 2 safety device tripped.

F3 - high temperature of the discharge pipe.

F6 - abnormal temperature of the heat exchanger.

FA - unacceptable discharge pressure.

FH - high oil temperature.

FC - impermissible suction pressure.

FE - unacceptable oil pressure.

FF - unacceptable oil level.

J0 - thermistor malfunction.

J1 - pressure sensor malfunction (general).

J2 - current sensor is faulty.

J3 - malfunction of the discharge pipe temperature sensor.

J4 - sensor malfunction at the low pressure saturation point.

J5 - malfunction of the thermistor on the suction pipe.

J6 - malfunction of the thermistor on the heat exchanger (1).

J7 - malfunction of the thermistor on the heat exchanger (2).

J8 - Malfunction of the thermistor on the liquid pipe.

malfunction J9 - malfunction of the thermistor on the gas pipe.

JA - Discharge sensor malfunction.

malfunction JH - malfunction of the oil temperature sensor.

JC - malfunction of the suction pressure sensor.

JE - malfunction of the oil pressure sensor.

JF - malfunction of the oil level sensor.

L0 - malfunctions in the inverter system.

L3 - temperature increase inside the control box.

L4 - increase in the temperature of the heat sink of the power transistor.

L5 - DC overload at the output (short-term).

L6 - overload on alternating current at the output (short-term).

L7 - high input current (multi-system), (common)

L8 - electronic thermal relay (delay).

L9 - warning stop (delay).

LA - the power transistor is faulty.

LC - communication with the inverter of the outdoor unit is faulty.

P0 - lack of gas (icing of heat storage equipment).

P1 - lack of phase, power supply imbalance.

РЗ - temperature increase inside the control unit.

P4 - malfunction of the radiator temperature sensor (power transistor).

P5 - malfunction of the DC sensor.

P6 - malfunction of the sensor on the output alternating / direct current.

P7 - high input current (in a multisystem).

PJ - incorrect capacity setting (outdoor unit).

LG

In LG air conditioning systems, when a problem is detected, the microprocessor blocks the start of the unit, after which it gives signals by flashing an LED that reports an error code.

If the system has detected several problems, then the breakdown that has the smallest sequence number is induced first. After that, there is an indication of faults in ascending order. The table below shows the error codes for LG air conditioners and explains what each of them means.

You should know: the occurrence of similar errors can be triggered by unsatisfactory parameters of the electrical network, or an accidental failure that occurred in the electronics of the unit. Therefore, do not rush to immediately contact the service, but simply turn off the power to the device and check the electrical voltage. You also need to make sure that the correct mode of operation of the device is selected. After these checks, you can turn on the machine.Most often, this method helps in solving this problem, and it no longer appears.

Evaporator unit faults:

Capacitor block defect designations:

Designations in LG Art Cool units:

Caring for your Beko air conditioner

So, as you can see, many problems in the operation of the air conditioner arise due to its untimely cleaning. Wherever an air conditioner is installed, urban or rural dust, not even visible to the eye, will quickly clog the pores of the filters, and the operation of the air conditioner will be disrupted.

How to clean the air conditioner to extend its life?

You need to clean the unit 2 times a year - in early spring or autumn. To cope with stubborn dirt, it is recommended to use cleaning products.

Or when signs appear that indicate a blockage of the equipment: noise or smell during operation, water leaks, icing of the evaporator coils.

For cleaning you need:

- open the cover of the outdoor unit;

- pull out the dirty filter;

- rinse the filter and dry naturally;

- turn on fan mode;

- spray all air conditioner cleaner in the work area;

- similarly process to clean the filter;

- wipe dusty blinds with a napkin or rinse under running water;

- install the filter in place;

- close the lid.

To service a split system, you can call a master from a service workshop accredited by the manufacturer to carry out all types of work with its air conditioners. He will do everything from installation to simple cleaning. But it is better to read the manual and do some of the work yourself if you do not want to spend too much money on the maintenance of climate technology.

General principles of diagnosis

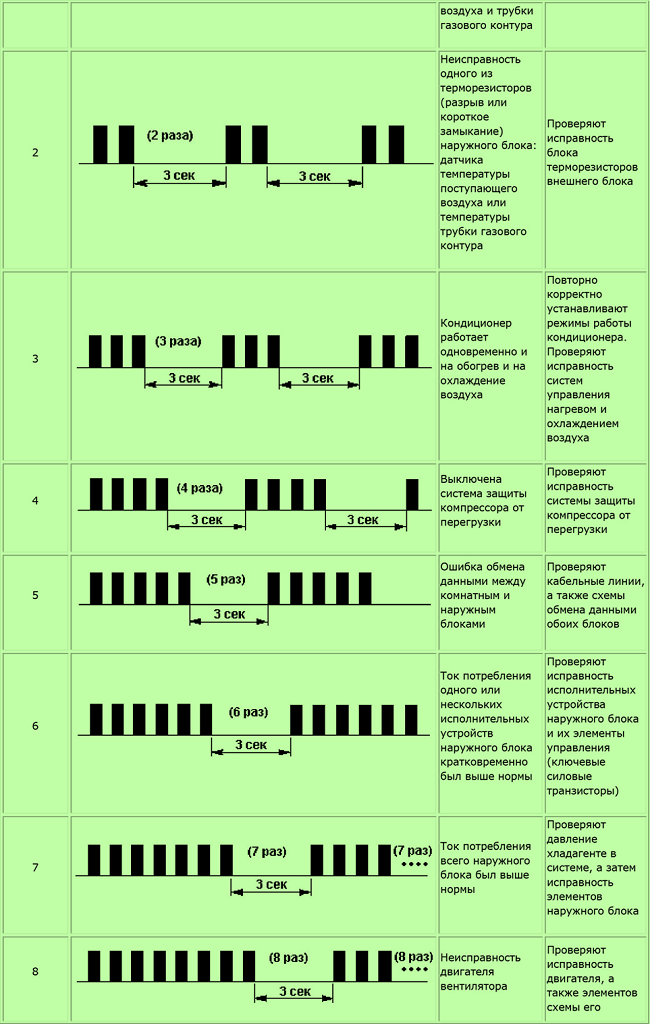

The indicators of the sensors of the outdoor unit are displayed on the control panel and the indoor unit. Errors are displayed on the remote control, which are duplicated by flashing indicator lights. Their location and purpose is easy to remember, there are only three of them.

Or you don’t have to remember, on a number of models they are signed and their names are definitely in the instructions:

- The indicator of work (Running), its blinking is responsible for errors with the letters E and H6.

- Heat indicator (Heating mode), it “winks” if Griya’s air conditioner generated errors with the letters H0-H9, FA, FH.

- Cold indicator (Cooling mode), errors F0-F9, FF.

The lights flash in a certain sequence, thereby “giving out” one or another error. Also, errors are duplicated on the block itself and on the remote control. So counting the number of winks that repeat every 3 seconds is optional. Moreover, there may be 9 or 11 of them.

A number of Gree air conditioner models have an uninformative display or none at all. Therefore, it is easiest to use the remote control for diagnostics, on which everything you need to know to determine the malfunction is written. Diagnostics is based on the data of numerous sensors of the air conditioner.

OTHER

31 - defect of the circulating air humidity sensor.

32 - a defect in the outdoor air humidity sensor.

33 - supply air sensor defect.

34 - defect of the circulating air temperature sensor.

35 - a defect in the outdoor temperature sensor.

36 - a defect in the temperature sensor of the control panel.

ZA - defective water leakage sensor 1.

ZN - defect of the water leakage sensor 2.

ЗС – defect of the dew condensation sensor.

40 - humidifier valve defect.

41 - defective cold water valve.

41 - hot water valve defect.

43 - defect of the cold water heat exchanger.

44 - defect of the hot water heat exchanger.

51 - overload of the supply air fan motor.

52 - overload of the circulating air fan motor.

53 - poor inverter air supply.

54 - poor air circulation of the inverter.

60 is a common error.

61 - PCB malfunction.

62 - anomalous concentration of ozone.

63 - malfunction of the pollution sensor.

64 - defective sensor of the room air temperature system.

65 - defective sensor of the outdoor temperature system.

68 - high voltage system malfunction.

6A - defect damper damper system.

6H - the door switch is open.

6C - Replace humidifier element.

6J - Replace high efficiency filter.

6E - Replace the odor removal catalyst.

6F - a malfunction of the simplified control panel.

| Do not delay, call +7 (495) 920 98 00 order an air conditioner repair now and your air conditioner will last longer! |

Daikin Air Conditioner Error Codes

| Deciphering Daikin Air Conditioner Error | ||

| Literal meaning | Numerical value | |

| BUT | Equipment breakdown prevention | |

| BUT | 1 | Indoor module board failure |

| BUT | 2 | Fan motor not working |

| BUT | 3 | Increased amount of condensate in the collection tank |

| A Daikin air conditioner error | 4 | Broken heat exchanger |

| BUT | 5 | Heat exchanger temperature too high or too low |

| BUT | 6 | Fan motor overheating |

| BUT | 7 | No power to blinds |

| BUT | 8 | Mains voltage too high |

| A | 9 | Expansion valve board failure |

| AA | Heating element temperature exceeded | |

| AH Daikin air conditioner error | Filters should be cleaned | |

| AC | No cooling/heating | |

| AJ | The control function of the indoor unit is broken | |

| AE | Not enough water in the installation | |

| AF | Moisturizing function impaired | |

| C | The function of the temperature sensor is broken | |

| C | 3 | The function of the sensor that measures the amount of condensate in the tank is broken |

| C | 4 | Malfunction of the temperature sensor of the internal heat exchanger |

| C | 5 | External heat exchanger temperature sensor failure |

| C | 6 | The sensor stopped the fan due to motor overheating |

| C | 7 | Blind motion sensor failure |

| C | 8 | No control over incoming mains voltage |

| C | 9 | Broken input thermistor |

| CA | Broken output thermistor | |

| CH error code Daikin air conditioner | Clean the indoor module from dust | |

| CC | Broken sensor that detects humidity inside the air conditioner | |

| CJ | Breakdown of the temperature sensor on the remote control | |

| CE | No communication between remote control and indoor unit | |

| CF | High pressure sensor failure |

Daikin

Errors of the air conditioner of this manufacturer may relate to various nodes.

According to the instructions, the codes look like this:

- A0: fuse tripped;

- A1: control board problems;

- A2: fan drum motor stop;

- A3: the amount of condensate in the drain has exceeded the set value;

- A4: the heat exchanger does not function;

- A5: Heat exchanger temperature is displayed incorrectly;

- A6: The fan motor has been overloaded.

The list of error codes is not limited to this.

The manufacturer uses numerical, alphabetic and mixed designations:

- AA: wire overheating;

- AC: presence of idling;

- AH: air filter dirty, pump blocked;

- AJ: the system does not have sufficient performance;

- C3: failure of the sensor that controls the level of condensate;

- C4, C5: temperature sensors 1 and 2 are faulty, respectively;

- C6: outdoor unit motor overload;

- C7: failure of the sensor that controls the operation of the blinds;

- CE: failure of the element that controls the level of radiation;

- CC, CF, CJ: malfunction of the humidity sensor, the overpressure control element, the thermistor on the control panel, respectively;

- CH: Increasing pollution level.

- E0: protection operation;

- E3, E4: activation of high and low pressure control elements;

- E5: relay overload, controlling and motor of outdoor unit;

- E6, E7: blocking the motor of the outdoor module, fan;

- E8: exceeding the allowable current value;

- EE: excess water volume in the drain above the set value;

- EF: failure of the heat storage unit;

- EJ: actuation of the additional protection system;

- F0, F1, F2: activation of protection elements;

- H0 - H9, operation of sensors that control the temperature of the air inside and outside, power supply, pressure, compressor performance;

- HA, HE, HC: activation of the sensor that controls the outlet air, drainage system, hot water.