- The device and principle of operation of Termet boilers

- Traditional boilers

- Condensing boilers

- Instructions for connecting a room thermostat

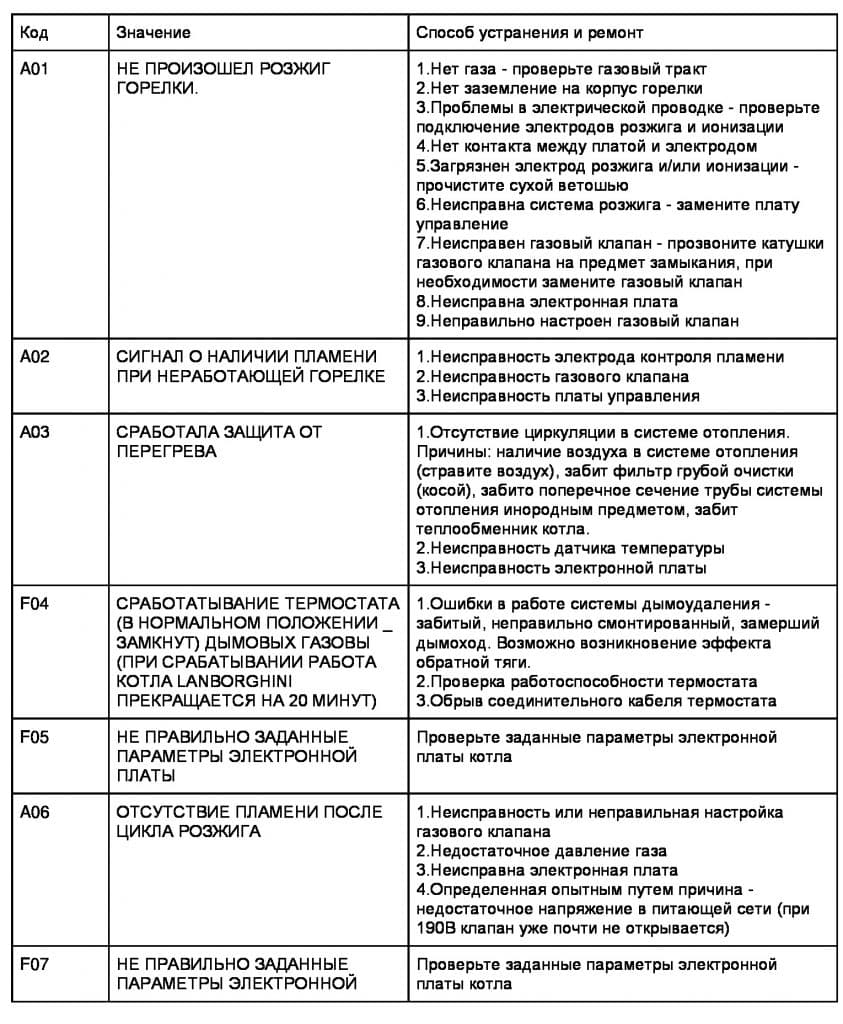

- How to repair boiler codes?

- Boiler overheat error

- Low system pressure

- There is no gas boiler draft

- The boiler does not ignite the flame when ignited

- The boiler is kindled, but the flame immediately goes out

- The panel gives incorrect errors

- A series of gas boilers Daewoo

- The boiler does not turn on - there is no indication

- Protective fuses

- The ingress of water (moisture) on the board

- Varistor and power supply

- Display board

- Code decryption

- Checking signal lines

- Checking the Temperature Sensor

- Sensor Test Method

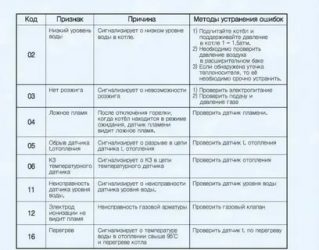

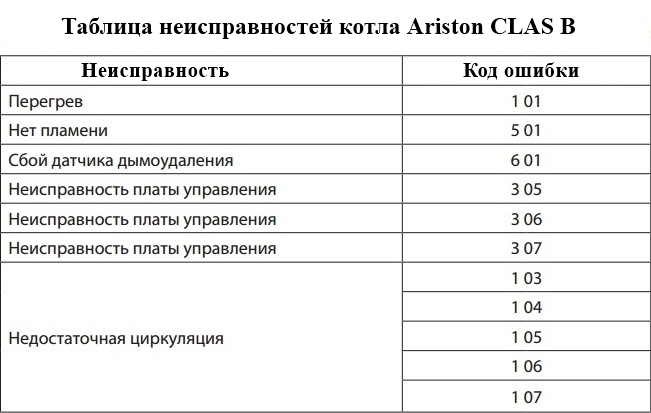

- Basic error codes

- 01

- 02

- 03

- 04

- 08

- 09

- l3

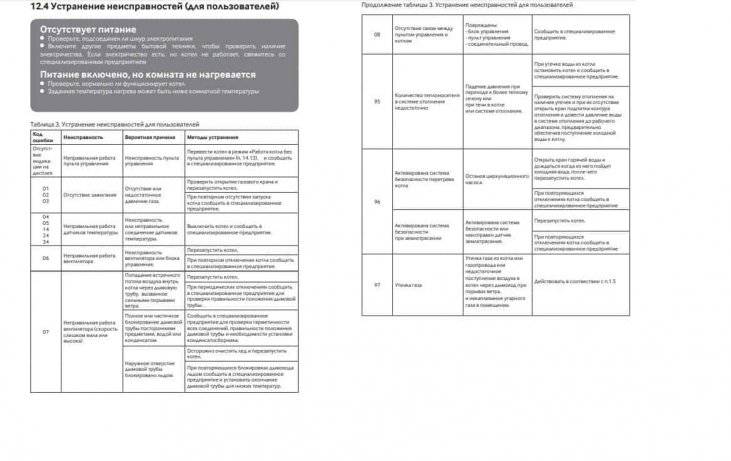

- Methods for self-diagnosis of faults

- Useful advice

- Possible causes of error f2

- heat exchanger

- Electronic board

- Malfunctions and error codes of Viessmann boilers

- Doesn't start

- Malfunctions and error codes of Viessmann boilers

- Failures in electronics (error 3**)

- Conclusions and useful video on the topic

- Conclusion

The device and principle of operation of Termet boilers

Traditional boilers

The Termet company produces single-circuit and double-circuit traditional gas boilers with an open and closed combustion chamber. The atmospheric burner is installed in the uniCO ELEGANCE EGO, ECO DP MINITERM ELEGANCE and ECO DP MAXITERM ELEGANCE series.All devices are wall-mounted.

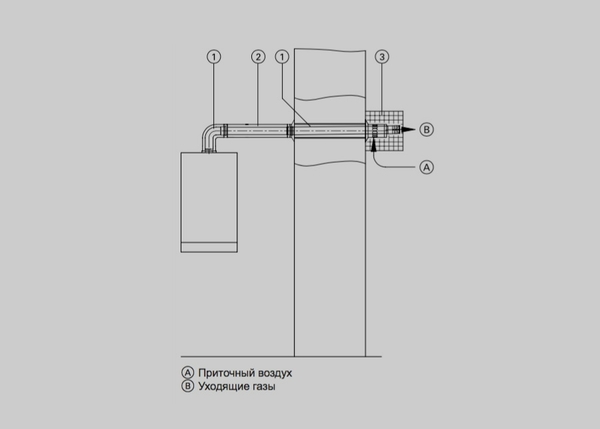

Air enters the open type combustion chamber from the room in which the boiler is installed. The output of combustion products occurs naturally through the chimney. In the center is a burner with ignition electrodes, above which there is a heat exchanger.

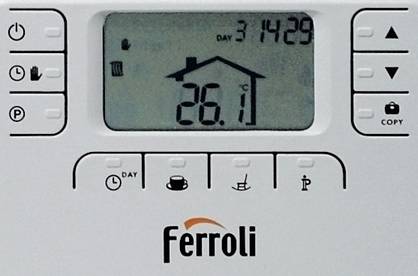

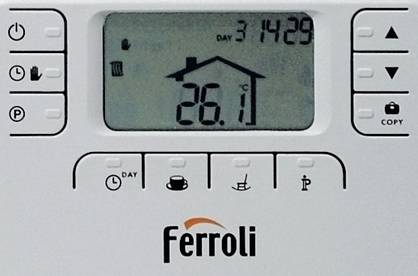

At the bottom of the housing there is a screen that displays the temperature of the coolant, domestic hot water, system pressure and error codes in case of a malfunction. On the sides of it are the buttons for turning on, selecting the operating mode and water temperature. Above the screen and buttons is the boiler control panel. The mains switch is located at the bottom of the boiler.

A turbocharged burner is installed in the MINIMAX turbo, MINITERM turbo and uniCO turbo ELEGANCE series. Devices with a closed type combustion chamber are equipped with a fan for the forced removal of combustion products and the delivery of oxygen from the street. This happens through a coaxial chimney.

Double-circuit boilers additionally have a plate heat exchanger to provide hot water. The devices have the possibility of electronic smooth modulation of the flame level in the burner and stabilization of the gas pressure at the inlet.

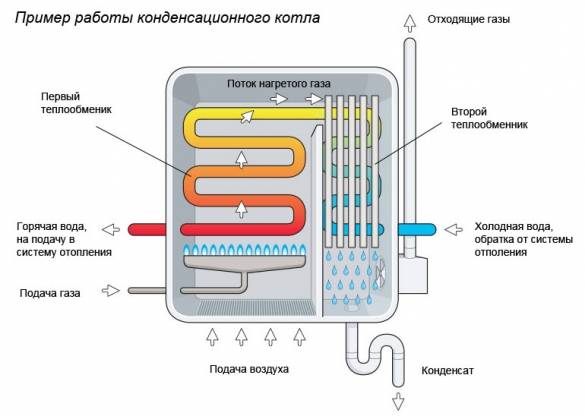

Condensing boilers

Condensing boilers are also available with one or two circuits. They allow to achieve additional fuel savings by using the heat of condensation of water vapor. In the first heat exchanger, heat is transferred from the combustion of gas, and in the second from volatile combustion products, which in the usual the boiler just exits through the chimney.

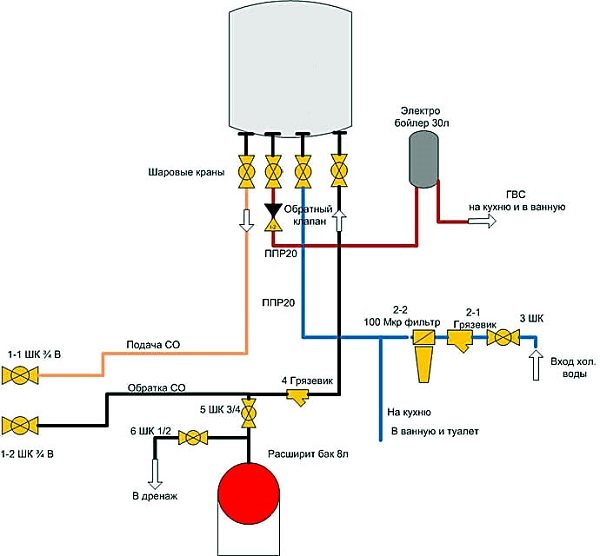

Instructions for connecting a room thermostat

Own sensors of gas boilers are able to control the temperature of the coolant, but they cannot determine the air temperature in the room.This causes inconvenience during warming, in the spring or during the first frosts.

It may be hot in the room, but according to the boiler system, everything is going fine - the specified mode of heating the coolant is maintained.

If you install a room thermostat that is based on the analysis of air temperature, the level of comfort will increase significantly, and excessive gas consumption will disappear.

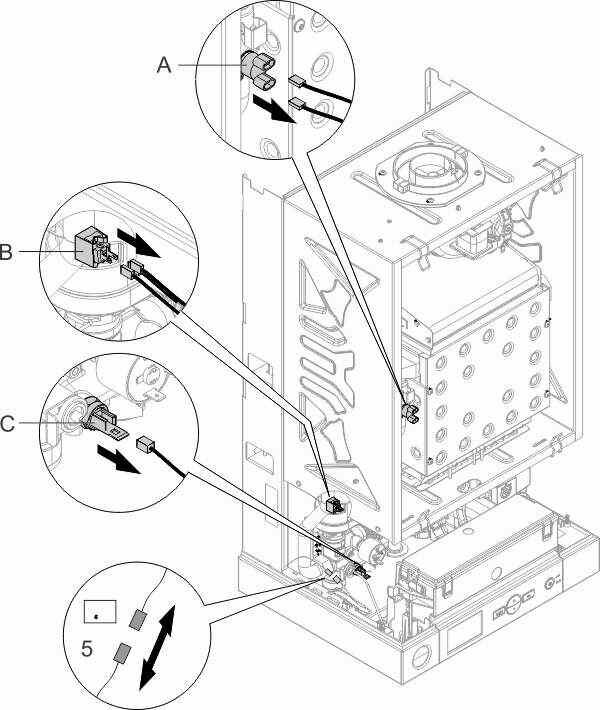

The room thermostat is connected to the corresponding contacts on the control board.

By default, they are closed by a jumper, which must be removed and a thermostat connected to the break in the circuit. In this case, the boiler's own thermostat is set to a maximum or to a certain value, above which the temperature should not rise.

IMPORTANT!

You can connect a room thermostat yourself, but it is best to entrust this task to a master from a service center.

How to repair boiler codes?

Boiler overheat error

A gas boiler malfunction in the form of overheating may occur due to lack of circulation. In this case, you need to check the pump and filter. Maybe the overheating thermostat is broken.

Low system pressure

If the pressure does not rise when the boiler is heated, then the tightness of the system may simply be broken and the connections must be tightened, after which a little pressure should be added. If this problem arose almost immediately after installing the boiler, then you just need to remove the air through the automatic air vent and add a little water.

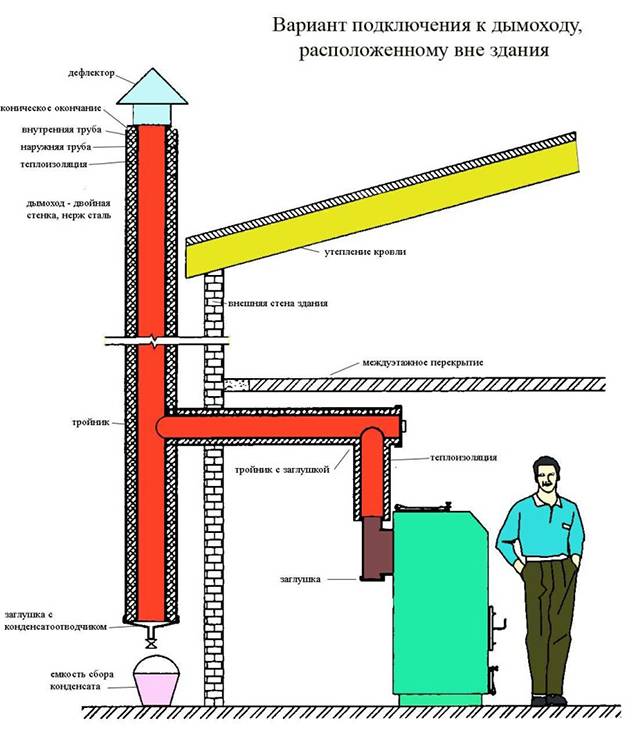

There is no gas boiler draft

If the boiler has an open combustion chamber, it is enough to see if it is clogged with something.If the combustion chamber is closed, then condensate drips from the outer pipe, getting into the inner one and freezing, in the winter season, it turns into an icicle, blocking the access of air to the boiler. To eliminate this problem, it is necessary to pour the formed icicle with hot water. Another foreign object can also get into the chimney.

The boiler does not ignite the flame when ignited

This indicates a malfunction of the gas valve in the boiler. To verify this, you can unscrew the hose and see if gas is supplied. If there is gas, then you should call a specialist who will replace this valve.

The boiler is kindled, but the flame immediately goes out

In this case, the panel may show a malfunction of the gas boiler in the form of a lack of ionization current. You need to check this by turning on the boiler again, turning the plug over, thereby changing the phases. If nothing has changed, then the operation of the ionization current may be disrupted due to any electrical work in the house. If the boiler periodically extinguishes the flame, then this is due to power surges and a stabilizer is needed.

The panel gives incorrect errors

Sometimes electronic board errors can occur. This happens from bad electricity and poor-quality power supply. From this, some parasitic charges arise on the boards, due to which such errors are observed. To eliminate this, you need to disconnect the boiler from the network and let it stand for about 30 minutes. The capacitors will discharge during this time and these unnecessary charges will disappear. After that, the boiler should work well.

In general, that's all. If the material was useful, do not forget to share it by clicking on the social media buttons below this text.

Also find out how to choose the right gas boiler so that there are no problems in the future:

Read also:

A series of gas boilers Daewoo

Daewoo is one of the most famous Korean conglomerates, which ceased to exist in 1999. Many divisions of the concern received independence or merged into the structure of other companies.

Now in South Korea there are two companies that were previously related to the corporation and produce gas boilers:

- Altoen Daewoo Co., Ltd (until 2017 - Daewoo Gasboiler Co., Ltd). Now production facilities are located in Dongtan.

- Daewoo Electronics Co., which produces gas equipment at the factories of KD Navien.

Components for the boilers of both companies are made in South Korea and Japan, and the assembly is carried out in an automated mode.

Company Altoen Daewoo Co.., Ltd did not transfer production facilities to Chinese industrial clusters in order not to lose the possibility of constant quality control of products

The following lines of gas boilers from Altoen Daewoo Co. are presented in Russia. Ltd:

- DGB MCF. Boilers with an open combustion chamber.

- DGBMSC. Boilers with a closed combustion chamber.

- DGBMES. Boilers of condensing type with a closed combustion chamber. The models of this line have a weekly work programmer, an autonomous control panel, and the connection of the chimney is also simplified.

All models of the listed lines are wall-mounted, double-circuit, that is, they are designed for heating and hot water supply.

Models of the DGB series are equipped with an informative display that shows an error code if a malfunction occurs or the built-in automatic diagnostic system is triggered.

Daewoo Electronics Co. There are two lines of gas boilers: wall-mounted "DWB" and floor-standing - "KDB".They have their own characteristics, including error codes that differ from competitor models. However, these boilers in Russia are not widely used.

Therefore, the article will only provide error codes for gas boilers from Altoen Daewoo Co., Ltd.

The boiler does not turn on - there is no indication

Almost all modern gas boilers are equipped with a control board and an information panel with a liquid crystal display or LED indicators. If there is no indication, first of all it is necessary to make sure that power is supplied to the boiler. Usually the electrical connection of the boiler is carried out through a separate “machine” - check whether it is turned on or not.

The surest way to make sure that power is being supplied to the boiler is to check with a multimeter in voltmeter mode the presence of 220V at the point of connection to the boiler board. If there is no voltage, it is necessary to localize and fix the problem. In real life, it happens that one of the household members simply pulled the plug from the outlet.

Protective fuses

You should also pay attention to the location of the fuses. In some boilers, depending on the model (for example, Ariston, Buderus, Vaillant), the fuses are located on the board itself, and in some before connecting to the board

If there are no problems with connecting electricity to the boiler, you should check the integrity of the fuses (with the same multitester in the “ringing” mode).

If the fuses are intact and there are 220 volts at the control points, but it is likely that the boiler does not turn on due to a malfunction in the control electronics.

If during the test it turned out that the fuses were blown, then there was at least a problem with the power supply.In this case, it would be correct to first examine the actuators (fan, pump, priority valve) and boiler wiring for short circuits. Nevertheless, in practice, even representatives of specialized organizations simply replace the fuses with serviceable ones and check the boiler in operation. If the fuses blow again, then the high-voltage parts of the boiler are sequentially turned off to identify the problem area (this is not a recommendation for action! This approach is not entirely correct).

Several spare fuses are usually supplied with the boiler.

If the fuses blow due to damage to any of the actuators, it must be replaced (or the cause of the short circuit eliminated). In the case when it is proved that the mechanisms (and wiring) are exactly in good order, the control board itself remains. Blown fuses indicate that there was an unacceptable load on the electronics (thunderstorm, pulse power surge in the network), so a short circuit on the board itself can also be the cause of the malfunction.

The ingress of water (moisture) on the board

Water ingress is one of the most annoying situations. Although the board is in a protective case, water can get inside due to leakage or condensation. Often it gets into the box through the wires. Water ingress almost always causes damage to the board, in most cases irreparable. On the board from water, characteristic stains and oxidation will be visible.

Varistor and power supply

Often, if the boiler board is damaged, burnt or charred elements can be visually detected on it. A varistor is a protective element of the board, which is installed at the input of the circuit.In most cases, this is a blue round part (but not necessarily). When the rated load is exceeded, the varistor is destroyed and opens the circuit. In some cases, if the varistor has helped prevent damage to the electronics, biting it out is sufficient to repair the break in the circuit.

Important! Although the circuit board will work without a varistor, remember that the varistor is a safety device and the correct solution is to replace it. The power supply is a microcircuit, which is also damaged primarily during power surges or during a thunderstorm.

If cracks or damage are visible on it, diagnostics and repair of the boiler board will probably be required.

Display board

For some boiler models (Vaillant, Ariston, Navien), the control unit consists of a main board and an information board (display board). The boiler may also not turn on if the display board breaks down. The display board, unlike the main one, is cheaper, but most often it is not repaired. In this case, the only way to detect a malfunction is to replace a known-good part.

If the gas boiler is working, there is an indication on the display, but it does not start or gives errors, further diagnostics are required.

Code decryption

The problem is common to all models. Error f59 indicates the absence of a signal from the DHW temperature sensor. Fault codes are often initiated by voltage instability - you need to restart the Vissmann boiler with the power switch on the front panel. If the result is negative, you should look for the cause of the error.

How to reset the Vitodens 100 W gas boiler

Checking signal lines

Error f59 is caused by an open, short circuit, unreliable contact. The defect is determined visually after removing the casing of the Vissmann boiler.

Checking viessmann vitopend 1 sensors

Checking the Temperature Sensor

It is a thermal resistance: a semiconductor device in a non-separable case. The only way to be sure that it works is to measure R (kΩ), given that as the temperature of the water rises, the resistance decreases.

Temperature sensor Viessmann Vitopend 100

Sensor Test Method

- Measure the resistance of the "cold" device. The multimeter should show 20 kΩ.

- Dip in hot water and soak for a few minutes. When you re-measure at a serviceable sensor, the resistance will drop to 5 kOhm.

There may be slight deviations of the readings from the indicated values, associated with the error of the multimeter. But if they are significant, the sensor is considered faulty and must be replaced.

If the measures taken cannot eliminate error f59, the reason is in the electronic board of the boiler. You need to contact the service center: you should not try to repair it yourself. Without appropriate schemes, guidelines, practical experience, a positive result cannot be achieved - in the end it will cost more.

Basic error codes

01

Error 01 is displayed during three ignition attempts (when using liquefied gas - 2 attempts) with an interval of 30 seconds for ventilation. If all attempts fail, RESET appears. In this case, it is necessary to check whether gas enters the boiler. If necessary, the valves are opened and the reset button is pressed.

02

Error 02 indicates the danger of boiling of the coolant. Appears when the water temperature in the heat exchanger reaches above 95 degrees. In this case, the device is blocked and turned off. You must wait until the temperature drops, press the RESET button and check the settings on the control panel.

03

Error 03 means too little draft in the chimney. It is necessary to clean the chimney from clogging, check the cleanliness of the heat exchanger fins.

04

Error 04 means that the NTC heating fluid temperature sensor is damaged. In this case, the burner switches off automatically. You should inspect the sensor and its wires.

08

Error 08 occurs when the water pressure transmitter of the heating circuit is damaged. The burner is switched off and the pump runs for another 180 seconds. It is not advised to fix this breakdown yourself, contact the service center.

09

Error 09 appears when the pressure value in the central heating installation is incorrect. If the pressure is too high, drain the water from the radiators. Check the operation of the expansion tank. If the pressure is too low, you need to find a leak.

l3

Error l3 does not mean any malfunctions. It is displayed during normal operation of the device and is displayed when the set temperature is reached or exceeded by 5 degrees. The number "3" indicates three minutes during which the system will cool down.

Methods for self-diagnosis of faults

Often the user is in a situation where he is not sure what exactly has broken in the gas boiler. In such cases, there is no need to rush to remove and repair something. This is risky and dangerous. Before work, it is necessary to diagnose the equipment and identify the exact causes of malfunctions.

If the boiler smokes, then usually the cause of this phenomenon is the consumption of low-quality gas or lack of air. You can check the cause of the malfunction yourself

Modern gas boilers are equipped with various sensors that reflect a number of important functional indicators of the unit. They track changes in temperature, pressure and other parameters. In the event of a malfunction, modern models of boilers provide for automatic shutdown of the device.

The source of the breakdown is identified by the consequences caused by it. For example, visually you can see burning, smudges, sparks. By smell, you can feel a gas leak or a short circuit. By the changed sound of the gas boiler, it becomes clear that the unit has failed.

The instructions that came with the purchase of the device describe the most common malfunctions in the boiler model being purchased and how to detect, diagnose, and eliminate them. It also indicates what a specific error code means and flashing lights on the dashboard.

So the light can flash in different modes: fast or slow. Or burn all the time. The color of the light bulb can be red, green or yellow.

The manufacturer's instructions indicate all possible error codes that may appear on the display. It also explains how to troubleshoot.

Do not throw away the instructions from the device, as it may be useful to the gasman called by you to fix the breakdown. It indicates the characteristic features of the gas boiler model, the dimensions and location of components and parts.

Useful advice

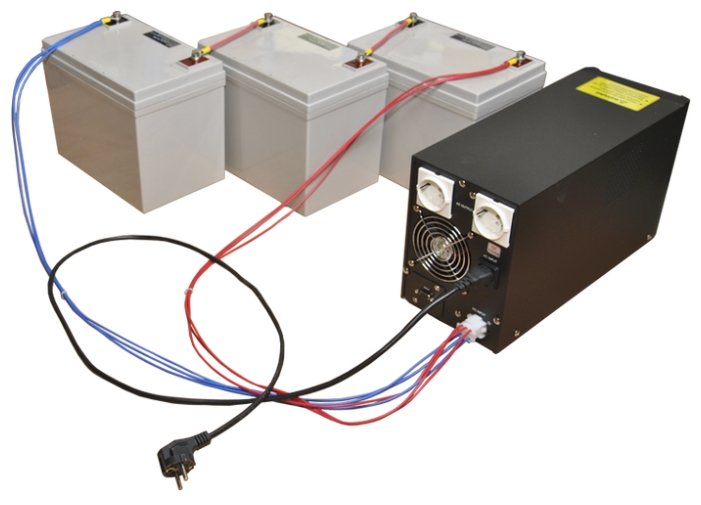

A UPS is a guarantee that the number of possible errors of the Vissmann boiler is reduced to a minimum. Stabilizers, heavily advertised by managers in the salons of heating equipment, do not completely solve the problem with the power supply of the facility. They just level the tension, nothing more.If the power line breaks, the boiler will stop, and if there is a problem with starting the backup generator, the house will cool down, the heating circuit will unfreeze. The UPS includes a stabilization circuit, a charger, a group of batteries. The unit will ensure the autonomous operation of the Vissmann boiler for several hours, until the accident on the line is eliminated.

The original article is posted on the site

All about Viessmann boiler errors:

Possible causes of error f2

- Lack of voltage at the terminals, unreliable contact, open circuit. It is easy to identify and eliminate.

- Impeller contamination. A common cause of the Wismann boiler f2 error. With a low quality of the coolant, salt deposits and dirt accumulate on the blades, which slow down the shaft. Cleaning is carried out mechanically under running water.

- Destruction of the bearing as a result of lack of lubrication - replace.

- Shaft distortion. The speed of rotation of the impeller decreases, error f2 is displayed. This spare part is not for sale - only replacement of the pump.

- Stator winding. Problems: breakage, short circuit (on the case, interturn). Testing is carried out with a multimeter in ringing mode. Wisman boilers are equipped with pumping devices from two manufacturers - to measure the resistance of the winding, you need to clarify the passport data. If, in fact, R is less, there is an internal closure (between the turns). To eliminate error f2, you will have to install another pump.

heat exchanger

The cavity of the device is gradually overgrown with deposits, deposits, the circulation channel narrows up to blocking. The primary heat exchanger of the Wiesmann boiler requires regular cleaning, otherwise the f2 error is inevitable; if the quality of the liquid is poor, it is carried out annually.

heat exchanger burnt vitopend 100

Washing at home gives a short-term effect.Professional maintenance involves the use of a special aggressive environment, exposure to time, removal of exfoliated fractions under pressure. In a service organization, the recovery of the heat exchanger will take 2–3 days: during this time, a backup heat source is used to heat the facility. This approach ensures that during the heating period there will be no problems with overheating of the Wiesmann boiler.

Electronic board

A malfunction in it causes an error f2. A specialist can detect and eliminate a defect - without experience, diagrams, devices, it is better not to try.

Malfunctions and error codes of Viessmann boilers

F2 error

1) Faulty component - burner

2) Control element - temperature limiter What to do:

— Check the filling level of the heating system (pressure).

— Check the pump and bleed if necessary.

- Check temperature limiter and connecting cables. Error F3 - Burner defective

It is necessary to check the ionization electrode and the connecting cables. Error F4 - The burner of the Viessmann boiler is faulty

There is no flame signal.

— It is necessary to check the ignition electrodes and the connecting cables.

— Check gas pressure and gas control valves, ignition and

ignition module. Error F5 - Malfunction of the gas burner

Wismann boiler.

The air pressure switch at burner start-up is not open or does not close when

reaching RPM under load during ignition.

— The LAS air-combustion system, hose and

air pressure switch, air pressure switch and connecting cables. Error F6 - Faulty burner

Thrust tipping device has tripped 10 times within 24

hours.

- It is necessary to check the system for removing combustion products. Error F8 - the burner of the Wiesmann boiler is faulty

The gas control valve closes with a delay.

- It is necessary to check the gas control valves and both control valves

cable. Error F9 - Faulty gas burner machine

The modulating valve control device is defective.

— The modulating flame control device must be checked.

__________________________________________________________________________

__________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

__________________________________________________________________________

OPERATION AND REPAIR OF BOILERSProterm Panthera

Proterm Skat

Proterm Bear

Proterm Cheetah

Evan Ariston Aegis

Teplodar Cooper

Atem Zhitomir

Neva Lux

Arderia

Nova Termona

Immergas

Electrolux

Conord

Lemax

Galan

mora

Aten

_______________________________________________________________________________

Boiler models

Boiler repair tipsError codes

Service instructions

_______________________________________________________________________________

Doesn't start

Turning on the boiler is often immediately blocked by automation that detects problems in the system.

Boiler failure at startup can occur for several reasons:

- No electricity or gas supply.

- The presence of air jams in the system, due to which the circulation pump cannot work.

- Failure of the control board or (more often) short circuit of one of the sensors, causing the boiler to block.

- Problems with the chimney, in particular - the ingress of foreign objects, icing or burnout of the pipe.

You can deal with the supply of gas or electricity on your own. Often they forget to open the gas valve, or when connecting the boiler to the network, they use a regular socket, which makes it possible to incorrectly connect the phase.

Bleeding air from the system also does not cause any problems. All other problems can only be solved by contacting the service center.

You should not try to solve the issue on your own, since most often a lot of others are added to one problem, which requires expenses and does not guarantee a favorable result.

Malfunctions and error codes of Viessmann boilers

F2 error

1) Faulty component - burner

2) Control element - temperature limiter What to do:

— Check the filling level of the heating system (pressure).

— Check the pump and bleed if necessary.

- Check temperature limiter and connecting cables. Error F3 - Burner defective

It is necessary to check the ionization electrode and the connecting cables. Error F4 - The burner of the Viessmann boiler is faulty

There is no flame signal.

— It is necessary to check the ignition electrodes and the connecting cables.

— Check gas pressure and gas control valves, ignition and

ignition module. Error F5 - Malfunction of the gas burner

Wismann boiler.

The air pressure switch at burner start-up is not open or does not close when

reaching RPM under load during ignition.

— The LAS air-combustion system, hose and

air pressure switch, air pressure switch and connecting cables. Error F6 - Faulty burner

Thrust tipping device has tripped 10 times within 24

hours.

- It is necessary to check the system for removing combustion products. Error F8 - the burner of the Wiesmann boiler is faulty

The gas control valve closes with a delay.

- It is necessary to check the gas control valves and both control valves

cable. Error F9 - Faulty gas burner machine

The modulating valve control device is defective.

— The modulating flame control device must be checked.

__________________________________________________________________________

__________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

__________________________________________________________________________

OPERATION AND REPAIR OF BOILERSProterm Panthera

Proterm Skat

Proterm Bear

Proterm Cheetah

Evan Ariston Aegis

Teplodar Cooper

Atem Zhitomir

Neva Lux

Arderia

Nova Termona

Immergas

Electrolux

Conord

Lemax

Galan

mora

Aten

_______________________________________________________________________________

Boiler models

Boiler repair tipsError codes

Service instructions

_______________________________________________________________________________

Failures in electronics (error 3**)

Such complex modern equipment as gas boilers is equipped with electronics for automatic operation and response to different situations. Control boards can fail as a result of aging, power surges, excessive moisture, or mechanical damage.

Error No. 301. Problems with the EEPROM board (non-volatile memory) of the display. If such a message occurs, you need to check the correct installation of the EEPROM key on the motherboard. This must be done as described in the user manual for the respective model.

If the key is working correctly, then you need to check the contacts of the cable from the motherboard to the display board. There may also be a problem with the LCD screen itself. Then it will have to be replaced.

The display is connected to the board with a cable. If the boiler is working, and the screen is off, then first of all you need to check the quality of the connection. Naturally, when the power is completely off

Error number 302 is a special case of the previous problem. Both boards pass the test, but the connection between them is unstable. Usually the problem is a broken cable that will have to be replaced. If it is in order, then the fault is on one of the boards. They can be removed and taken to a service center.

Error No. 303. Malfunction of the main board.Rebooting usually does not help, but sometimes it is enough to turn off the boiler from the network, wait and turn it on again (this is the first sign of aging capacitors). If such a problem becomes regular, then the board will have to be changed.

Error #304 - More than 5 reboots in the last 15 minutes. Talks about the frequency of problems that arise. You need to turn off the boiler, wait a while and turn it on again. It should be monitored for some time to identify the type of warnings if they reappear.

Error number 305. Crash in the program. It is necessary to let the boiler stand for some time off. If the problem persists, you will have to reflash the board. You need to do this at a service center.

Error No. 306. Problem with the EEPROM key. The boiler needs to be restarted. If the error persists, you will have to change the board.

Error number 307. Problem with the Hall sensor. Either the sensor itself is faulty, or there is a problem on the motherboard.

Error No. 308. The type of combustion chamber is set incorrectly. It is necessary to check the type of combustion chamber installed in the menu. If the problem persists, then the wrong EEPROM key is installed or the motherboard is faulty.

You can try to fix any electronic boards in computer repair shops. Especially if the problem is caused by loss of contact or aging capacitors.

Error No. 309. Flame registration after blocking the gas valve. In addition to a malfunction of the motherboard (it will have to be replaced), there may be a problem in the ignition unit - a loose closing of the gas valve or a malfunction of the ionization electrode. If the problem is in the electrode, then you can try to simply dry it.

Conclusions and useful video on the topic

Eliminating similar errors C4 and C6 and installing a filter to collect condensate:

A short video tutorial on how to fix the EA error:

What to do if the pressure drops in the heating system, setting up the expansion tank:

Determining the problem with the fan and its solution:

We examined the errors of various Bosch boilers sorted by the first letter, as well as other codes that sometimes pop up on the displays. Before correcting the problem by code, try reconnecting the device, look at the position of the taps and control knobs. It did not help - disassemble the device and proceed step by step as required by the instructions.

An old Bosch gas boiler may need professional repairs, despite the reliability of this technique in general. Only certified craftsmen and gas workers have the right to touch gas pipes.

Ask questions and leave comments on the topic of the article. Write what kind of gas boiler you use and whether you are satisfied with the operation of the device. Tell us about the breakdowns, if any, indicate your steps in solving the problem. The contact form is located below.

Conclusion

Any equipment is prone to failure.

The more complex the design, the more risk factors that can disrupt the operation and disable the installation.

Gas boilers are critical units, the failure of which creates a risk of gas leaks or defrosting of the heating system.

This was the reason for the creation of a self-diagnostic system that immediately notifies the user of problems with a particular unit of the unit.

If the error does not reset and occurs again and again, it is urgent to call the wizard for repairs.

Some problems are fixed on their own, mainly they are related to the supply of water or electricity.

The condition of gas boilers is a subject of constant concern for the owner, who must quickly respond to problems and seek help from specialists.