- Mounting Features

- Installation and operation

- Quality ventilation

- Mounting options

- Horizontal installation of coaxial pipes

- Vertical installation of a two-channel pipe

- How to check and adjust the draft in the chimney of a gas boiler

- Why does the boiler blow out and how to fix it

- Video: how to check draft in a gas boiler

- 2 What steps should be present when installing a coaxial chimney and what is important not to forget?

- 2.1 Rules for laying a coaxial chimney to the boiler - video

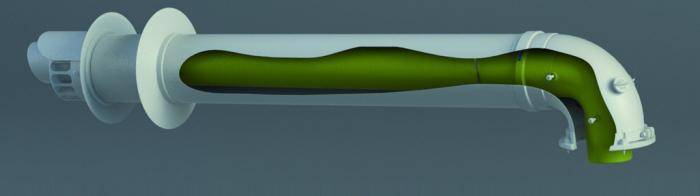

- Types of coaxial smoke exhaust pipes

- Aluminum

- stainless steel

- Plastic

- A little about the cons of the system

- Conclusions and useful video on the topic

Mounting Features

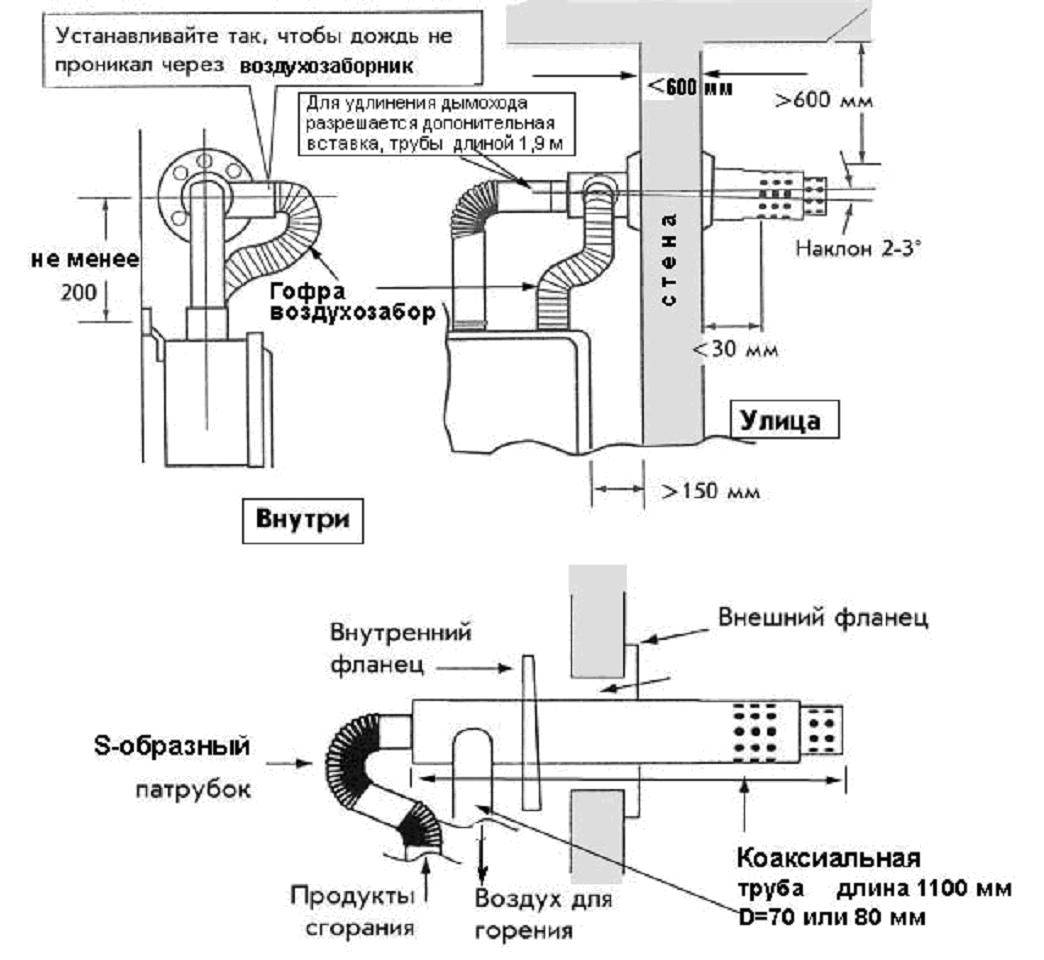

The horizontal type of chimney is quite easy to install, besides it takes up much less space. To obtain the highest quality work, you must follow a number of requirements:

- The outer pipe must be 2 meters from the ground.

- Distance from pipe to doors, windows, ventilation ducts, etc. vertically and horizontally should be at least 0.5 meters.

- If there is a window above the ventilation hole, the distance to its lower area must be at least a meter.

- Under the coaxial pipe, there must be a free space of at least 1.5 meters. At this distance there should be no obstacles, pillars, walls and fences.

- If there is no condensate collector, then the pipe must be placed with a slope to the ground. Its angle should be between 3° and 12°.

- It is forbidden to output the channel to any other space, except for the street.

- If gas pipes and chimney parts pass nearby, a distance of 20 cm should be maintained between them.

The chimney pipe can be placed under a canopy or balcony. The closer the chimney hole is to the balcony, the longer the length of the outer part of the pipe should be. There is an opinion that with a horizontal installation scheme, the length of the chimney should not be more than 3 meters. This is not always true. Some types of equipment have a length of 4-5 meters.

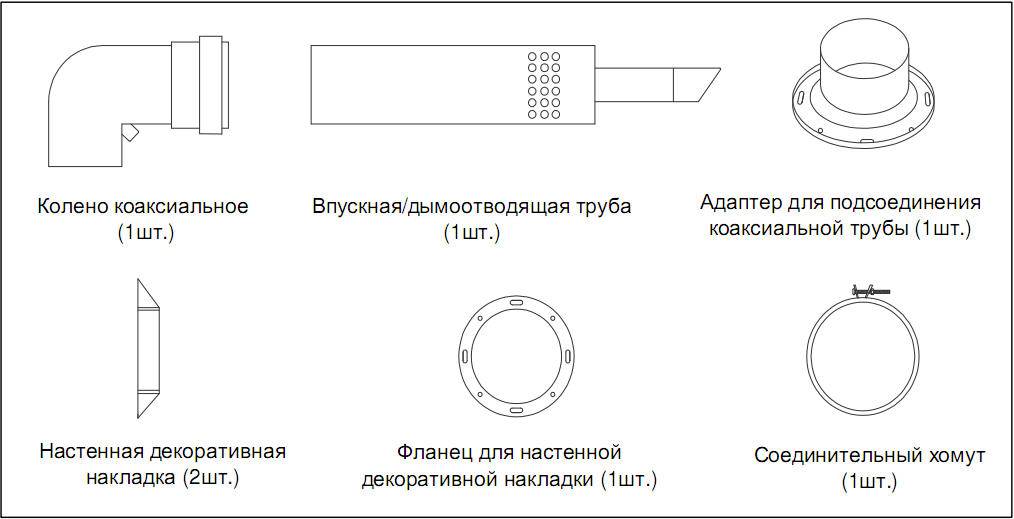

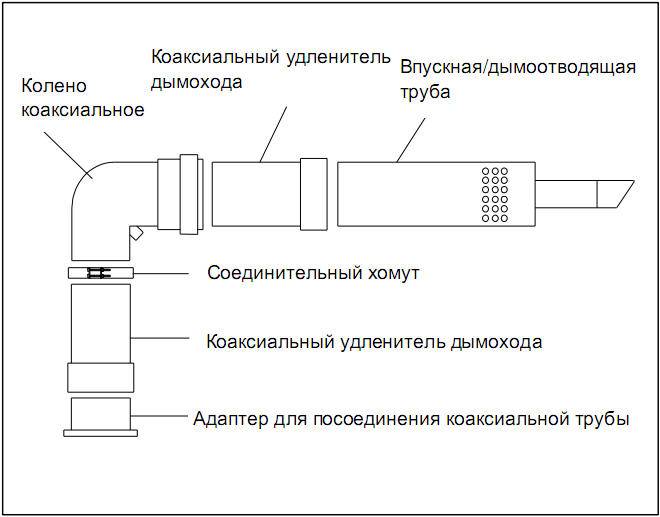

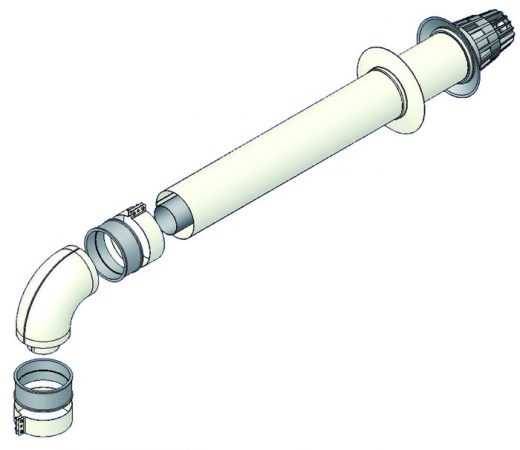

To install a coaxial chimney with your own hands, you need to stock up on the necessary materials. The list of tools may vary depending on the situation, but most often the following devices are required:

- the pipes themselves;

- an adapter connecting the chimney and the boiler;

- tee, elbow;

- crimping collars for effective fixing of details.

Installation and operation

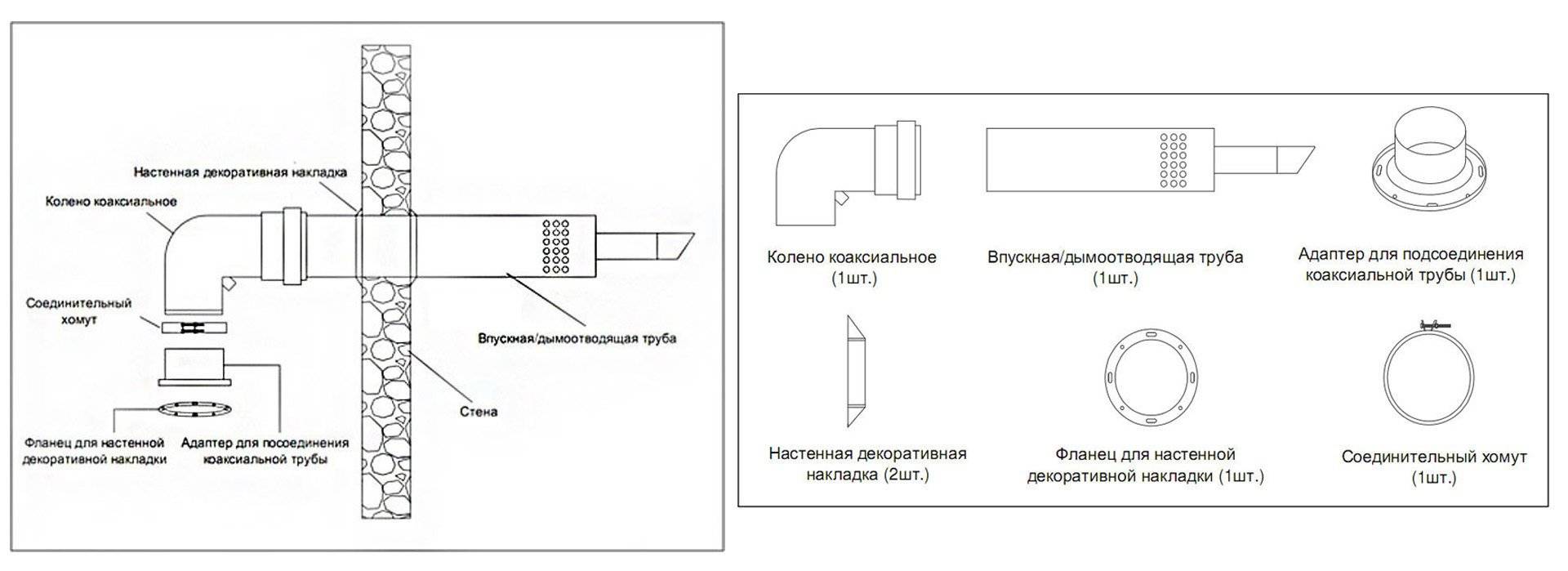

Installation and proper connection of the system to the boiler is a simple process. To install a horizontal chimney, you need to follow the step-by-step instructions:

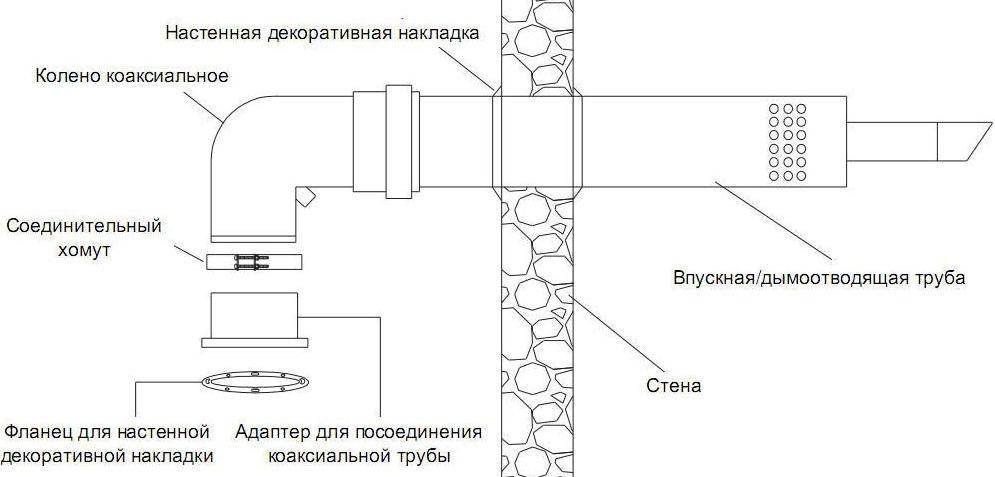

- First you need to place the gas boiler in its place, and on the wall of the building outside, mark the center of the intended outlet of the pipe.

- Now the boiler should be temporarily removed and, using a puncher and a cutting crown, drill a hole in the load-bearing wall. Its diameter should be 20 mm larger than the size of the outer pipe.

- An adapter must be connected to the outlet of the boiler. When connecting, use a sealing gasket.Then, using self-tapping screws or screws, attach the adapter flange to the surface of the boiler.

- The pipe must be connected to the outer fitting of the adapter. To create a secure fixation, you can not use any sealants.

- Be sure to check the tightness of the connections and the fixation of the fasteners. If everything is done correctly, the pipe is led into a hole in the wall.

- Now the boiler can be returned to its original place and fixed on the wall. The chimney must be installed with a slope of 3-5 degrees towards the street. It should be fixed in the wall with small pebbles.

- Holes between the outer casing and the wall must be sealed with polyurethane sealant.

Quality ventilation

Although the waste substances exit through a sealed channel, and the air enters from outside, care must be taken to ensure good ventilation of the room in which the boiler is placed. This will maintain ideal indoor humidity levels, which will positively affect the operation of the equipment and extend its service life.

No matter how high-quality the system is, it can fail after some time. If a small breakdown occurs in the boiler room, with good ventilation, carbon monoxide will naturally escape. In this case, the risk of gas poisoning is significantly reduced.

A coaxial chimney is reliable, efficient and easy to install equipment. In order for the system to work efficiently, it is necessary to comply with the installation requirements and follow the operating instructions.

Mounting options

Complete with a coaxial chimney, factory assembled, detailed installation instructions are required.Following and careful implementation of these recommendations affects the operation of the boiler and the efficiency of the smoke exhaust system. According to experts, the main reason for blowing out the boiler, the appearance of frost or ice, is associated with errors in the calculations and when connecting the chimney.

Horizontal installation of coaxial pipes

Horizontal installation is carried out taking into account the technical characteristics of the building. Initially, the place where the pipe exits the wall is selected. There are restrictions associated with the distance to the nearest window of a neighbor when a horizontal coaxial chimney is removed from the wall, which must be carefully observed.

Additionally, the following parameters are calculated:

- The height of the pipe is from the outlet pipe of the boiler to the passage hole in the wall; for floor-standing gas boilers, the height must be at least 1 m. The direct outlet of the pipe from the outlet pipe to the street is not allowed. For wall-mounted gas boilers, a height reduction of up to 0.5 m is allowed.

- The number of swivel couplings in the area should not exceed 2 pcs.

- The maximum length of the horizontal section is 3-5 m, depending on the boiler model. To extend the pipe, a coupling with heat-resistant sealing rubber is used. Do not use silicones or sealants.

A feature of using a two-channel chimney in winter is increased condensate production. The reason for the loss of moisture is that the system was originally designed for more favorable operating conditions. With increased formation of condensate, it will be necessary to insulate the pipe.

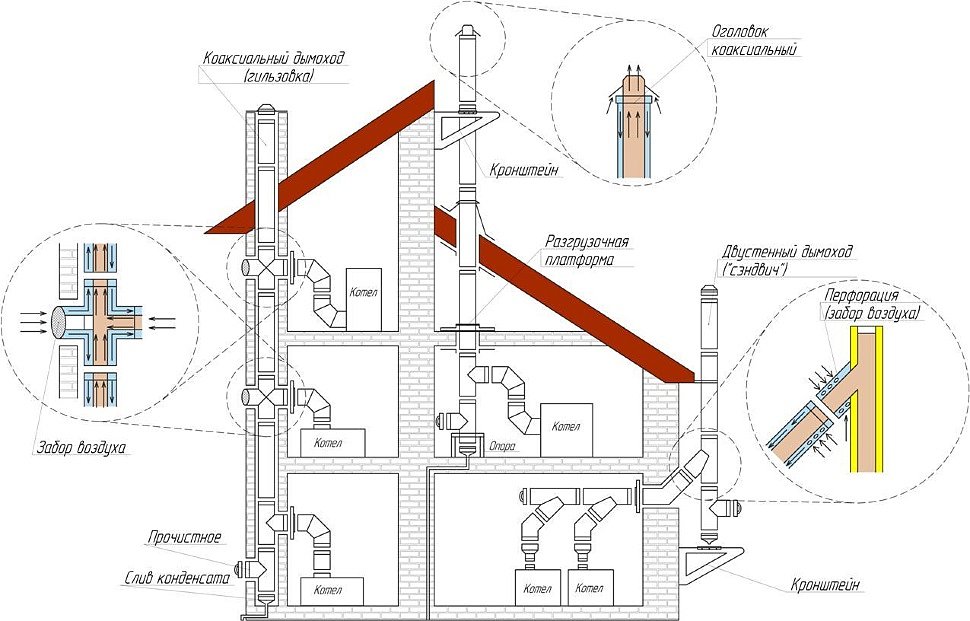

Vertical installation of a two-channel pipe

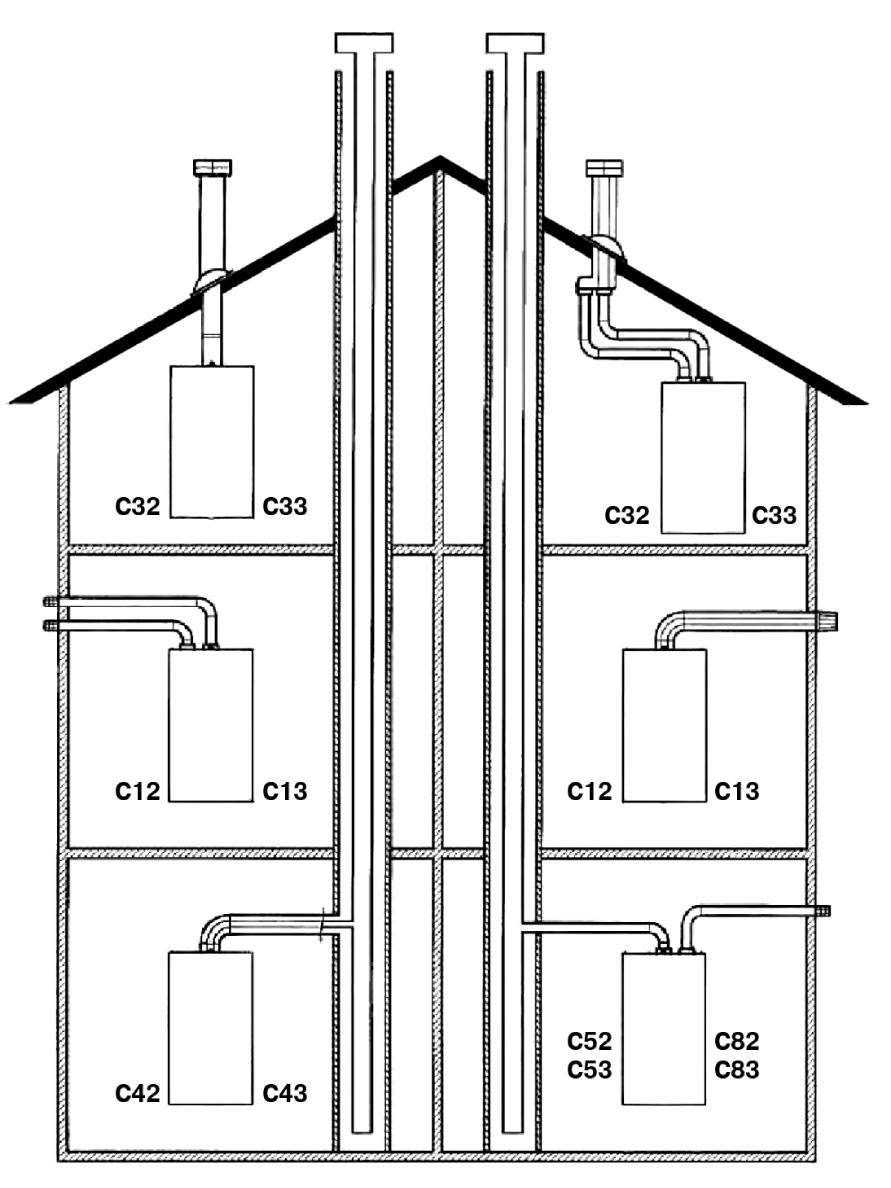

Vertical installation of the chimney provides two connection methods:

- Cascade scheme for connecting collective chimneys of condensing boilers. Several heating units are connected to one pipe at once. The cascade scheme is used in apartment buildings. The chimney is installed outside or inside the building.

Vertical installation of the pipe is carried out only after careful calculations and preparation of project documentation, taking into account the rules set forth in SP 60.13330 (SNiP 41-01-2003). - Individual connection - the maximum length of the vertical coaxial combustion products removal system is 7 m, which allows installation in a two-story building. In a house made of aerated concrete blocks, the pipe is installed exclusively inside the building. The walls of the building cannot withstand a large load on the walls.

In brick houses, a smoke exhaust system is installed inside and outside the building. In any case, a mandatory thermal insulation of the coaxial type chimney is carried out.

How to check and adjust the draft in the chimney of a gas boiler

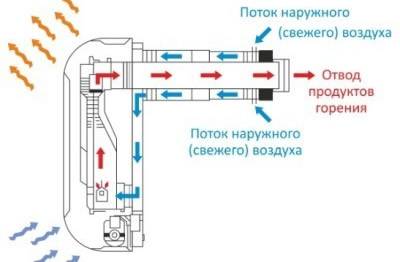

Thrust is a reduction in pressure at the place where the fuel is burned. The pressure reduction occurs due to the removal of combustion products through the smoke channel. Speaking within the framework of this article, the draft forces fresh air to enter the combustion chamber, where there is a reduced pressure that occurs due to the fact that the products of combustion of the gas are removed to the outside.

The presence of draft indicates that the chimney is designed and installed correctly, and the equipment is working properly. Lack of draft may be a direct or indirect confirmation of the need for preventive maintenance or repair of equipment and the smoke exhaust system.

To check the level of traction, the following methods are used:

- visual inspection - in the room where the heating equipment is located, there should be no smoke;

- use of improvised means, for example, a sheet of paper. It is brought to the viewing hole. If there is traction, then the sheet will deviate towards the hole;

- measurement with a special device - anemometer. It is used to control the air speed.

For traction control, it is better to use the latter method, since only it will show the exact value. When measuring natural draft, the flue gas velocity should be in the range of 6–10 m/s. The value is taken from SP 41-104-2000 "Design of autonomous heat supply sources".

If this does not help, then the only way out is to replace the chimney with a preliminary calculation of the cross section of the chimney. At the same time, it is desirable to minimize the number of rotary elements or even remove them altogether.

Why does the boiler blow out and how to fix it

The main reason why the burner blows out in the boiler is the backdraft effect that occurs due to problems with the chimney.

Before proceeding with any measures, you should check the height of the chimney above the level of the ridge and the presence of an installed deflector, which allows you to reduce the penetration of wind flows into the chimney. If the pipe device is not made according to the rules, then after the steps described below, you will need to build up the pipe and install a deflector.

In order to solve the problem with blowing the boiler, you will need to do the following:

- First of all, it is necessary to check the level of draft in the pipe. For better use an anemometer.If it was not possible to find it, then with the boiler running, you need to lean the paper against the outlet of the chimney. If the sheet is attracted to the chimney, then there should be no problems with draft.

- If it was found that the blowing is due to a loss of natural draft, then it will be necessary to check the chimney connection points. For this, a thermal imager is used. If the pipe passes air, then the device will show a strong temperature difference between the main pipe and the junction of the two modules.

- If the chimney is assembled correctly, then it is necessary to clean the smoke channel using a cable with a nozzle. The diameter of the nozzle is selected according to the section of the chimney pipe. An inspection hole at the bottom of the chimney is used to clean soot, tar and other combustion products.

- After performing these simple steps, you will need to check the level of traction again. If the natural draft has not improved, then it is necessary to carry out work to correct the height of the chimney and install a deflector. During installation, a heat-resistant sealant and crimp collars are used.

In cases where the work described above did not work, you should contact the gas service to check the gas equipment. Perhaps the problems with blowing are associated with ultra-sensitive automation.

Video: how to check draft in a gas boiler

Compliance with regulatory requirements is a guarantee that during the operation of the chimney there will be no emergency situations. This is especially true for vertical chimneys, when it will take a lot of time to correct the mistakes made during their installation.

2 What steps should be present when installing a coaxial chimney and what is important not to forget?

In order for the installation of a coaxial chimney with your own hands to be correct, it is important not to forget anything and exactly follow all the necessary steps, which you can learn about from our article

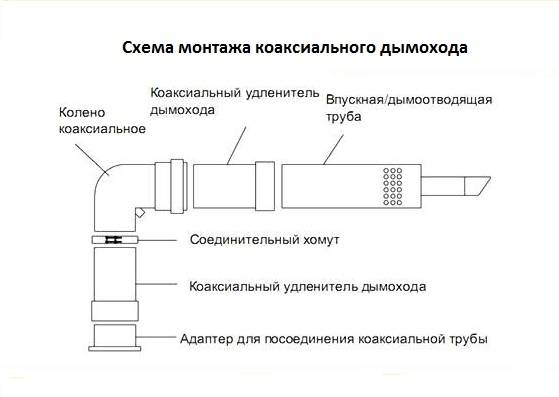

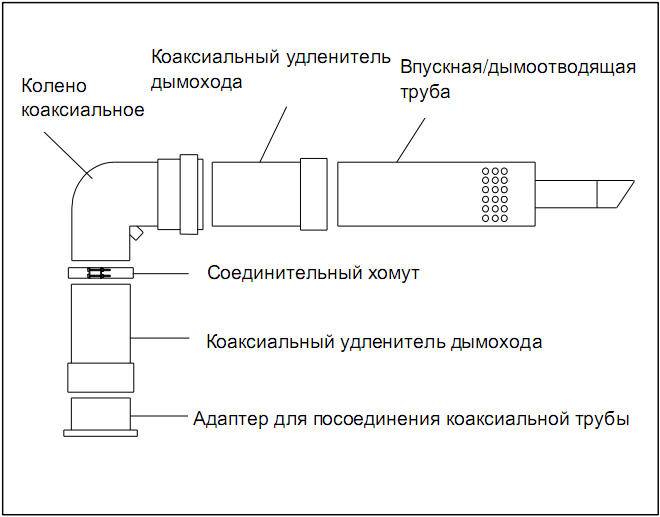

Coaxial chimney connection diagram

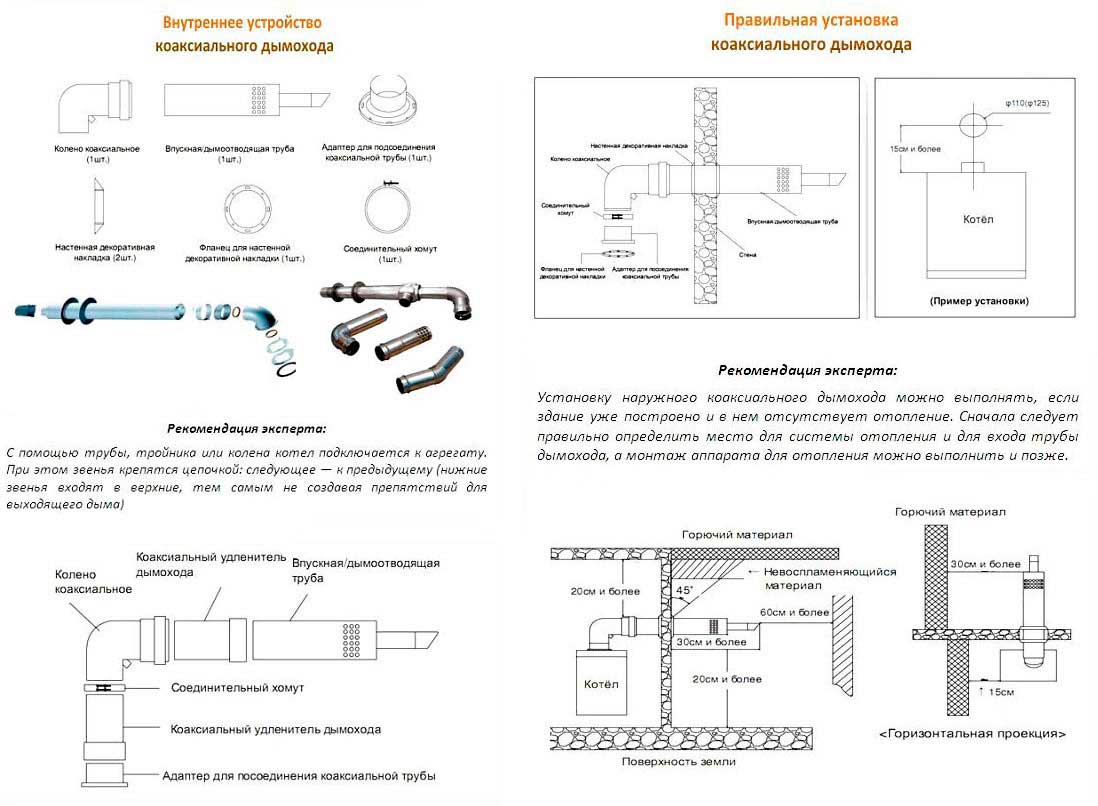

First, determine whether you will install the chimney horizontally or vertically. Vertical installation of a coaxial chimney is rarely done, since such a device is more overall.

In addition, to install this type of chimney, it is necessary to punch a hole in the roof, which is not always easy to do. But still, sometimes the installation of a baxi coaxial chimney of this type is necessary.

This happens in cases where, due to the layout of the room, horizontal installation is simply not possible. This may be hindered by protrusions of the wall, radiators, doors or windows.

Types of coaxial chimney connections

But if all these obstacles are not present, then feel free to install the coaxial chimney horizontally, since such an arrangement, in combination with a fan, is the most optimal.

Horizontal installation is mainly assumed by the rules for installing a coaxial chimney in an apartment building. This is also due to the fact that if the apartment is not located on the top floor, then vertical installation is not possible.

The rules for installing a coaxial chimney for a gas boiler provide that all adapters, tees and clamps, elbows must be selected in accordance with the diameter of the coaxial pipe.

Scheme of the passage of a coaxial chimney through the wall

It is important to ensure that the distance between the two pipes of such a chimney is always kept at the same level, including in the places where adapters and other auxiliary installation elements are used. All auxiliary elements that involve the installation of a coaxial chimney with your own hands must fit snugly together, ensuring the system is sealed. This is important to ensure good draft, which enhances the heating effect of the boiler.

This is important to ensure good draft, which enhances the heating effect of the boiler.

All auxiliary elements that involve the installation of a coaxial chimney with your own hands must fit snugly against each other, ensuring the system is sealed

This is important to ensure good draft, which enhances the heating effect of the boiler.

Also, the tightness of the system can guarantee that air with impurities of combustion products will not be mixed with fresh air, which is not a desirable phenomenon, as it can cause smoke in the room.

The rules for installing coaxial chimneys require that the structure be placed away from gas pipelines. Also, the installation of a coaxial chimney in an apartment building is done so that the exit is not located close to the window, and not very low above the boiler - these are safety requirements.

Air flows through a coaxial chimney

There must be at least 600 mm to the window, and at least 1.5 meters from the upper edge of the boiler.

Installing a coaxial chimney in a wooden house has its own rules. Wood is sensitive to moisture, so the walls of such a house must be protected from condensation, which can occur when the hot exhaust air is cooled.

To do this, the installation of a coaxial chimney in a wooden house is carried out using heat-insulating materials so that the temperature on the surface of the pipe is even.

Where the pipe faces wood flooring, upholstery steel sheets can be used to reduce the chance of spontaneous combustion.

Another type of coaxial chimney

The rules for installing a coaxial chimney for a gas boiler are well known by a specialist who will do everything faster and better than you, unless, of course, you have solid experience in this area.

In some new buildings, when laying communications, individual heating is already provided.

Therefore, a single system of coaxial chimneys has been laid there, which will save you from unnecessary trouble and give you confidence that all the requirements for installing a coaxial chimney of a gas boiler are met.

2.1 Rules for laying a coaxial chimney to the boiler - video

Types of coaxial smoke exhaust pipes

Installation of chimney channels is carried out in two ways - vertically and horizontally. In the first, the pipe is led through the roof, and in the second, the output is made through a window opening or wall. Most often, horizontal mounting of the device is used.

The technical characteristics of a coaxial chimney and its service life largely depend on the material from which the pipes are made.

Aluminum

The material is quite light. Its main advantage is resistance to temperature extremes and good anti-corrosion characteristics.

Due to the inability to withstand high temperatures, aluminum is rarely used in a coaxial chimney system.It is mainly used in combination with plastic.

stainless steel

Stainless steel pipes are the most popular. They do not deform under the influence of sharp temperature fluctuations and endure heating up to 550 degrees. The material is highly resistant to aggressive substances and can be used as a chimney for 30 years.

Two types of stainless steel pipes are used for the coaxial combustion gas exhaust system:

- Insulated. Mainly used for installation of vertical chimneys. Such a pipe greatly increases the aerodynamic qualities of the device and is installed during the construction of the building.

- Uninsulated. It is used for both domestic and industrial coaxial-type chimney structures. Differs in longevity

Coaxial chimneys for stainless steel boilers are the most popular

Coaxial chimneys for stainless steel boilers are the most popular

The disadvantages of using non-insulated pipes include high vapor condensation.

Plastic

Chimneys made of heat-resistant plastic are used for condensing gas boilers. In addition to light weight and the ability to withstand heating up to 205 degrees, the material has a relatively low cost.

Plastic coaxial pipes are easy to install. But still, unlike stainless steel products, the duration of their use is low. Such chimneys are used exclusively in gas exhaust systems with low temperature conditions.

Coaxial chimneys for plastic boilers

Coaxial chimneys for plastic boilers

When selecting pipes, you should pay attention to the manufacturer's recommendations for the type of heater

A little about the cons of the system

Of course, there is no ideal system that would not have flaws.In our case, although there are disadvantages, some of them can simply be ignored, since they are insignificant, while others will have to be put up with.

The main disadvantage of such structures is that their cost is ultimately 20-40% higher than the installation of separate systems. Another problem is the concentric arrangement of pipes with hot and cold air. You have probably noticed icing on such pipes more than once. It is formed due to the accumulation of condensate and its freezing at sub-zero temperatures. You can deal with this by installing an additional drain and insulation. But all this will further increase the price.

Well, the last drawback is the limited length of the coaxial pipe. It's about 4-5 meters. Therefore, if your boiler is not installed near a window or there is no way to remove the coaxial pipe for any reason, this option is not suitable for you.

Conclusions and useful video on the topic

Video #1 The device of a coaxial chimney, the principle of its operation and installation features are presented in the following video:

Video #2 The complete set of a coaxial chimney of industrial production is shown here in detail:

Video #3 Overview of coaxial anti-icing kit:

A coaxial chimney is a convenient and easy-to-install device that can significantly improve life in the house.

But in order for such a chimney to function effectively, it is important to comply with the norms and requirements when installing it.

Did you have any questions while reading the material, did you find any shortcomings or would you like to tell us about your own experience in assembling and using a coaxial chimney? Please post your comments in the block below the article.Leave posts with your opinion and photos on the topic.