- Design features and varieties

- Chimney insulation

- The main types of chimneys and the rules for their installation

- Coaxial chimney and its installation rule

- Stainless steel chimney, its composition, properties and installation

- Chimneys for gas boilers

- Varieties of coaxial type chimneys

- External and internal systems

- Uninsulated and insulated devices

- Horizontal or vertical output

- Collective and individual designs

- The installation of a chimney can be considered using the example of a double-circuit design

- How to connect a two-channel coaxial chimney to the boiler

- Assembly without errors

- Installation of an external chimney

- Checking the functionality of the structure

- Flaws

- High price

- Condensation

- Features of the design, operation and installation of outdoor chimneyless gas boilers

- The design and principle of operation of chimney-free boiler equipment.

- Features of the installation of gas boilers with a coaxial chimney.

- Chimneyless boilers - their pros and cons of operation.

Design features and varieties

The single-circuit chimney system is made in the form of an air channel through which flue gases are discharged into the atmosphere. Chimney ducts must be durable, resistant to the aggressive effects of flue gases and all kinds of weather conditions.Condensate with acids that occurs on the walls of the pipe from flue gases should not cause corrosion on the walls.

The inner surface should be as even as possible so that soot deposits do not form along the length of the pipe. Boilers burn various types of fuel, depending on this, as well as on the design of the furnace space, the flue gas temperature ranges from 70 to 400 C, and in case of poor heat transfer - 1000 C. Therefore, the design of the chimney must withstand such elevated temperature conditions.

In order to safely remove flue gases into the atmosphere, the following types of flues are installed:

- made of bricks;

- using ceramic materials;

- metal/stainless steel pipes;

- asbestos-cement pipes;

- heat-resistant plastic;

- combined type, for example, brick and stainless steel.

The developer, if necessary, will be able to modify the typical design of the installation with additional parts, which are in sufficient quantity and assortment in the distribution network. Typically, stores sell pipes 0.5/1 m long with a diameter of 110/200 mm.

Chimney insulation

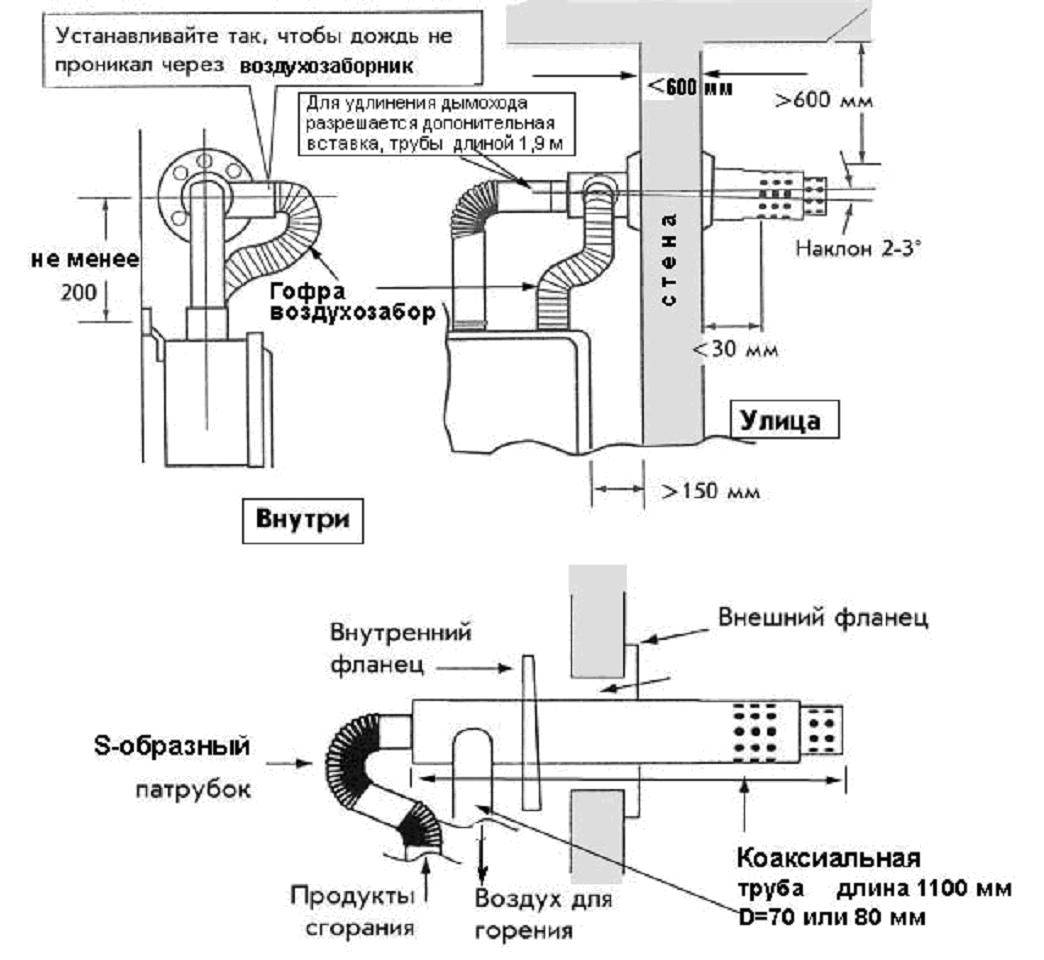

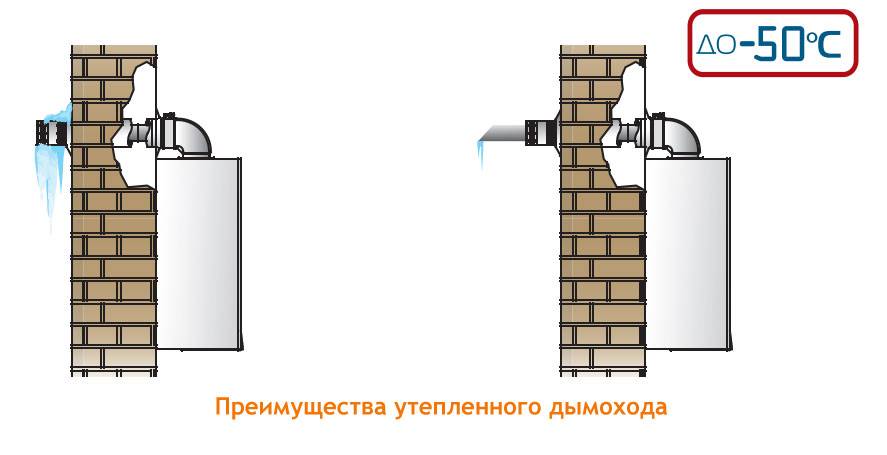

Freezing and icing of the head of the coaxial chimney is associated with the ingress of condensate into the air intake duct. To prevent moisture ingress, check the slope of the coaxial pipe relative to the combustion chamber. If the slope angle is at least 3°, then the freezing of the head will occur only at temperatures below -15°C.

The main errors during the installation of the chimney are associated with the incorrect slope of the horizontal sections.

Additionally, a special element can be installed on the head, which extends the inner channel by 10–40 cm relative to a larger diameter pipe.In addition, several holes can be drilled in the bottom of the outer pipe. This will allow air intake even with partial freezing of the head.

If the slope is insufficient, freezing cannot be eliminated, since the condensate will not drain towards the combustion chamber, but vice versa - towards the outlet, which will lead to the formation of icing and icicles at the end of the pipe. Warming by sheathing with heat-insulating material on the outside of the pipe will not help.

The main types of chimneys and the rules for their installation

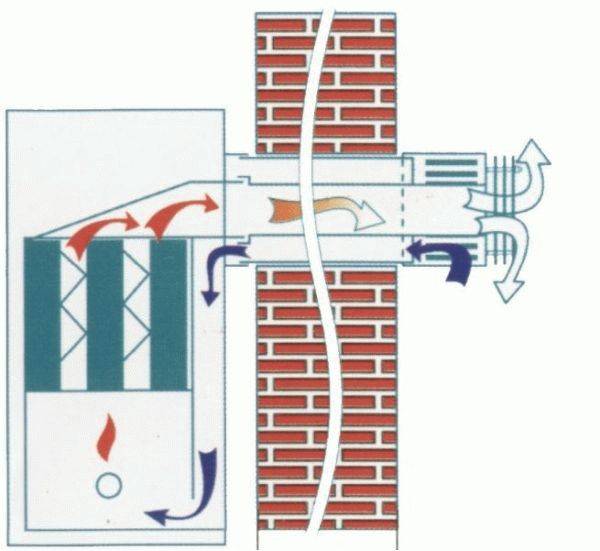

To date, various types of chimneys for a gas boiler are known, one of which is a coaxial chimney, which is led outside through the wall. With the help of it, air is taken from the outside so that extinction does not occur in the combustion chamber of the boiler. The coaxial chimney also removes exhaust gases from the premises to the street.

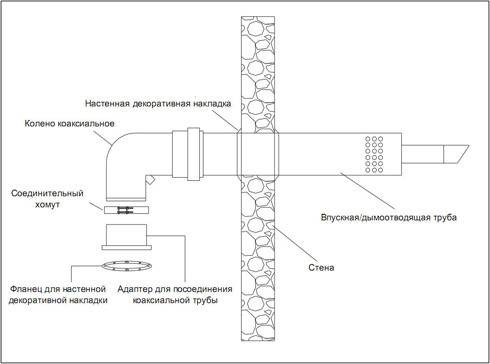

Coaxial chimney and its installation rule

coaxial chimney

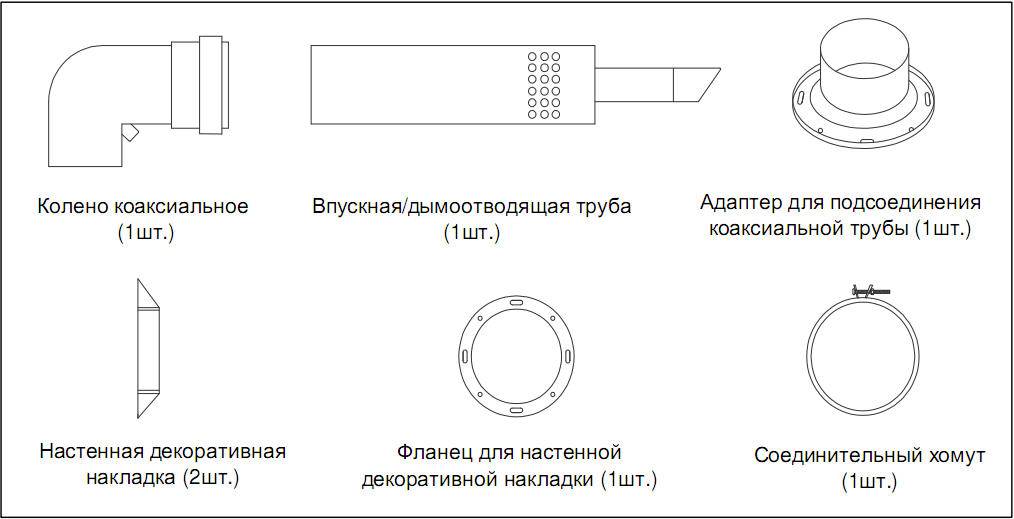

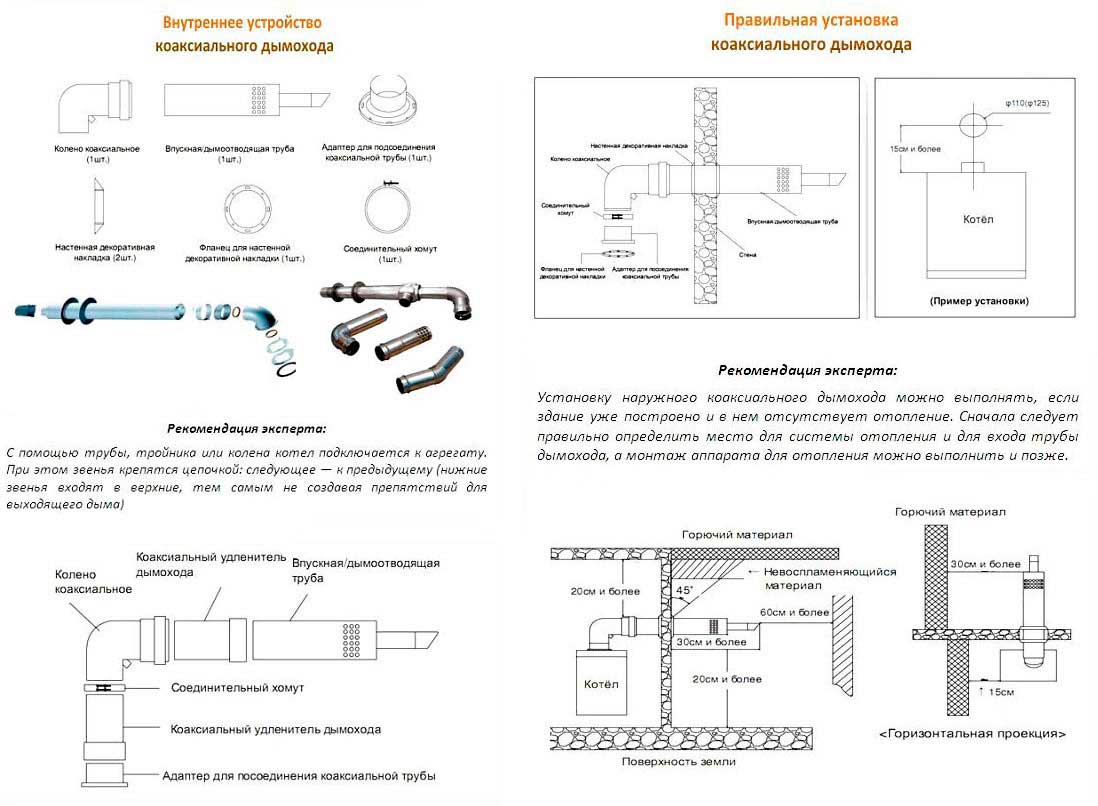

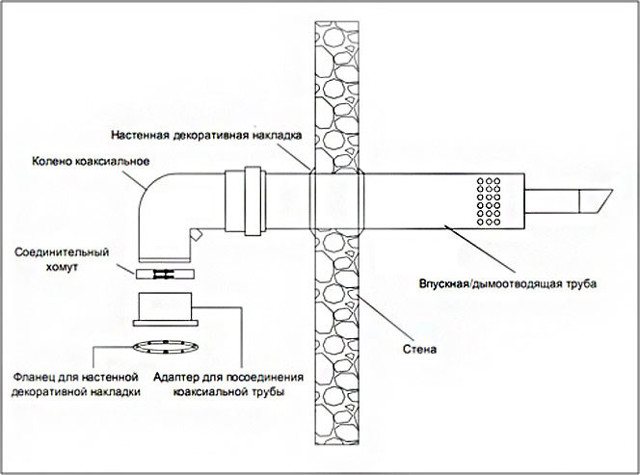

Installing a coaxial chimney for a gas boiler requires various materials and elements:

- flue pipe;

- flange;

- adapter through which the chimney is connected to the boiler;

- decorative overlays on the wall;

- chimney bend and connecting crimp collar.

The chimney is most often installed, given the shortest distance from the gas boiler to the near wall of the house outside. All substances and objects that can cause ignition or are damaged by high temperature are removed from the chimney zone.

Let's figure out how to properly install a chimney?

First of all, it is necessary to observe safety precautions and work to be done within the limits of personal protective equipment.Therefore, people working with chimneys must wear protective gloves made of very dense material or have synthetic caps on their palms.

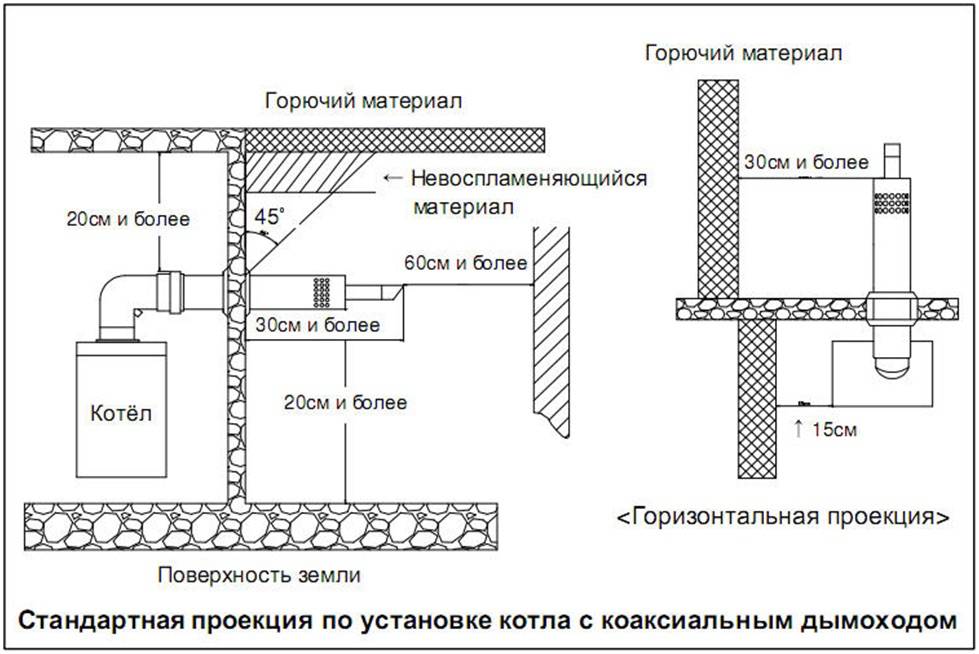

Installation of a boiler for a coaxial chimney

Observing the rules for installing a coaxial chimney for a gas boiler, it should be brought out in the opening into the walls and covered with a visor so that moisture does not penetrate. It is necessary to choose the place of the puncture of the wall. This will be the area in which the pipe is brought out of the premises to the street. It is desirable that this place exceeds the level of the chimney outlet by 1.5 meters.

In the event of an incorrect location of the gas boiler, at a large distance from the outer wall, this type of chimney can be significantly extended, but not more than three meters. For this, two connecting knees are used. The areas where the chimney is built up are stretched with a crimp collar.

How to install a coaxial chimney in areas of high humidity?

If a coaxial chimney for a gas boiler is installed in regions with high rainfall, in this case, the chimney is located at a certain level from the ground so that clogging or clogging of pipes does not occur.

A slight slope must be taken into account. This is necessary for the condensate to drain by gravity to reduce the risk of waterlogging the chimney.

After the chimney has been installed, the wall holes are closed with decorative overlays, in accordance with the diameter of the pipe itself. Most often, in order to avoid the formation of cracks, the holes around the chimney are foamed. The rules for installing a chimney for a gas boiler are observed in accordance with safety regulations.

The most common and popular chimney is the stainless steel chimney.The characteristic features of this type include a beautiful aesthetic appearance, which can harmoniously fit into any interior of the room.

The main task of such a chimney is to remove combustion waste from various rooms and ensure the functioning of equipment with heating.

Stainless steel chimney, its composition, properties and installation

Stainless steel chimneys

Installing stainless steel chimneys does not require a reinforced foundation, unlike brick chimneys.

Such chimneys are resistant to corrosion and are very durable. Chimneys made of stainless steel are suitable for almost all combustion devices and require a small installation area.

They are used not only at a temperature of 600 degrees, but also in heating systems together with condensate boilers. These products are manufactured using high quality stainless steel.

Coaxial chimney ESR 100/75 for boilers

Chimneys for gas boilers

Installing a chimney for a boiler requires knowledge of building codes and requirements for exhaust ducts.

The chimney for boilers must not only be airtight, but also resistant to condensate. The composition must include a channel: allowable connection of two devices to one channel. The distance must be at least 750 mm.

The chimney should go out into the sky and not have covers and visors. These standards must be observed during the stages of construction or repair, since defects during operation are difficult to correct.

Varieties of coaxial type chimneys

There are several types of "pipe in pipe" design. Let's take a closer look at each of them.

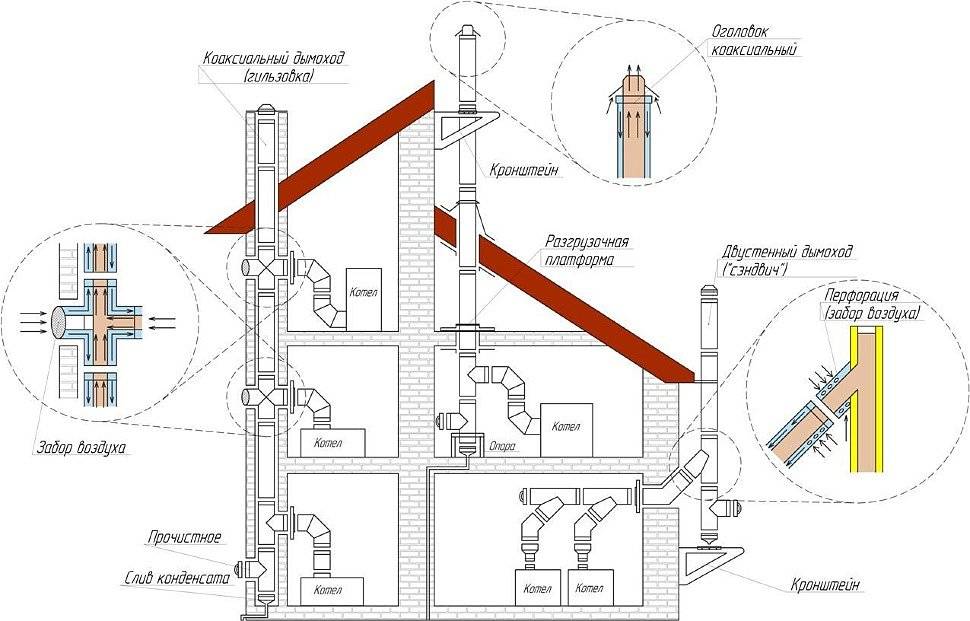

External and internal systems

All coaxial chimneys, depending on their location, are divided into external and internal. The first are located on the outside of the building and are fixed directly on the facade.

Given that such structures somewhat spoil the appearance of the building, they are trying to be placed on the inner sides of the building. A distinctive feature of the outdoor type chimney is ease of maintenance and installation.

Internal structures are mounted in specially laid shafts that run inside the building and are separated from the living quarters. In some cases, traditional chimneys can be used as such shafts.

It is important that their design and dimensions fully comply with modern fire safety requirements. Internal systems are quite difficult to maintain and install.

Uninsulated and insulated devices

In cold weather, especially in severe frosts, the channel supplying air to the system may freeze. In this case, the amount of oxygen entering the combustion chamber decreases sharply, which leads to a deterioration in the operation of the heater.

In some cases, and to stop it. Therefore, where low temperatures last for a rather long period of time, as well as where severe frosts are not uncommon in winter, it is recommended to install insulated systems.

Insulated coaxial chimneys are distinguished by the presence of another pipe. Between it and the outer part, a layer of non-combustible heat insulator is laid, which prevents the structure from freezing.

The coaxial chimney of the insulated type differs from the standard one by the presence of another pipe. The system looks like three nested parts.

The free space between the two extreme elements is insulated. For this purpose, it is filled with any suitable insulation. This reliably protects the air duct from icing and freezing.

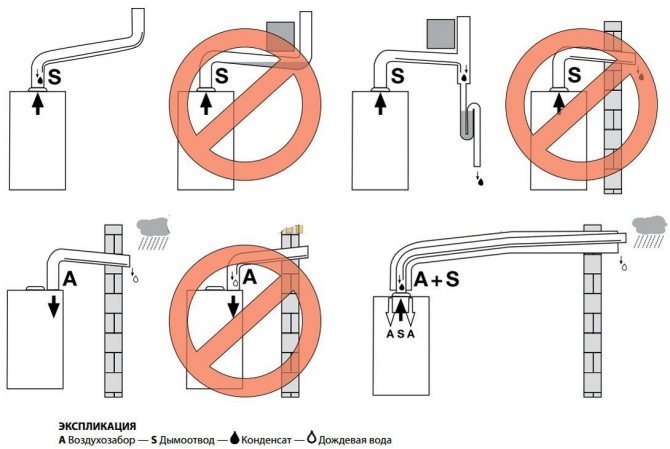

Horizontal or vertical output

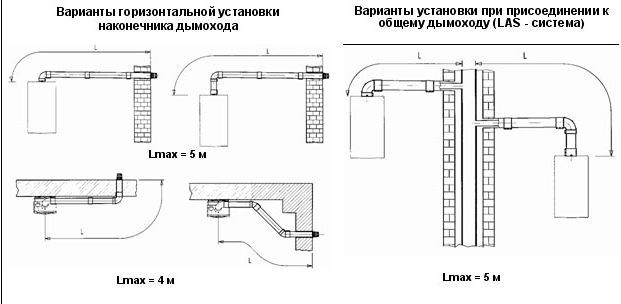

Initially, coaxial chimneys were designed as horizontally oriented systems, but in practice this arrangement is not always possible. Most chimneys of this type are mixed designs.

They may contain both vertically oriented and horizontal sections. This is due to the location of the heater in the building. In some cases, it is possible to use vertical chimneys, but only for boilers without forced draft.

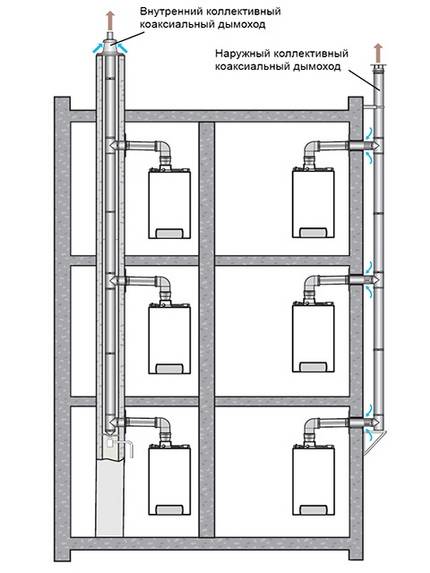

Collective and individual designs

To service one heater, individual coaxial chimneys are used. These are simple systems without branching, which can have a different configuration.

To work with several boilers, a collective chimney is mounted. This is a mine system with several branches. In this case, each of the branches goes to one of the heat generators. Such a design can only be vertical.

A collective coaxial chimney is characterized by the presence of several heat generators connected to one mine. Can be both external and internal

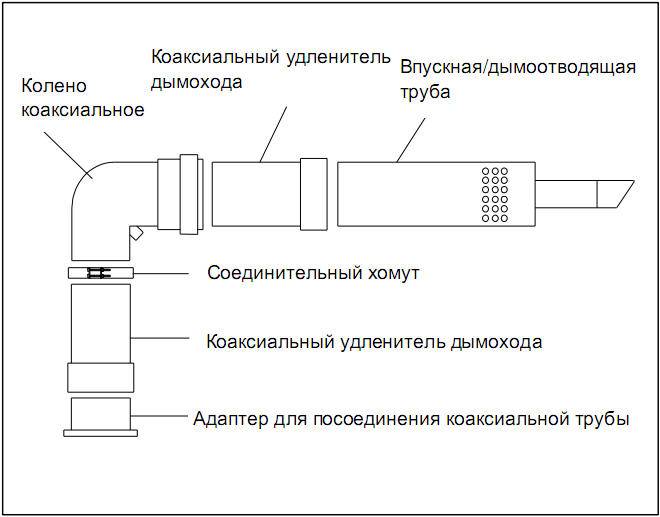

The installation of a chimney can be considered using the example of a double-circuit design

Chimneys for a gas boiler are being installed in the direction of the structure from the bottom up, that is, from the heating objects of the room towards the chimney. With this installation, the inner tube is put on the previous one, and the outer tube is inserted on the previous one.

All pipes are fastened to each other with clamps, and along the entire laying line, every 1.5–2 meters, brackets are installed to fix the pipe to a wall or other building element. A clamp is a special fastening element, with the help of which not only the parts are connected to each other, but also the tightness of the joints is ensured.

The laid sections of the structure in the horizontal direction up to 1 meter should not come into contact with elements that pass close to the communications. The working channels of the chimney are placed along the walls of buildings.

Be sure to install a bracket on the wall every 2 meters of the chimney, and the tee is attached using a support bracket. If it is necessary to fix the channel on a wooden wall, then the pipe is lined with non-combustible material, for example, asbestos.

When attaching to a concrete or brick wall, special aprons are used. Then we bring the end of the horizontal pipe through the wall and mount the tee necessary for the vertical pipe there. It is necessary to install the brackets on the wall after 2.5 m.

The next step is to mount, lift the vertical pipe and bring it out through the roof. The pipe is usually assembled on the ground and the mount for the brackets is prepared. The fully assembled volumetric pipe is difficult to install on the elbow.

To simplify, a hinge is used, which is made by welding pieces of sheet iron or cutting a pin. Typically, the vertical pipe is inserted into the tee pipe and secured with a pipe clamp. The hinge is attached to the knee in a similar way.

After raising the pipe in a vertical position, the pipe joints should be bolted where possible. Then you should unscrew the nuts of the bolts on which the hinge was fastened.Then we cut or knock out the bolts themselves.

Having selected the hinge, we attach the remaining bolts in the connection. After that, we stretch the remaining brackets. We first adjust the tension manually, then we fix the cable and adjust it with screws.

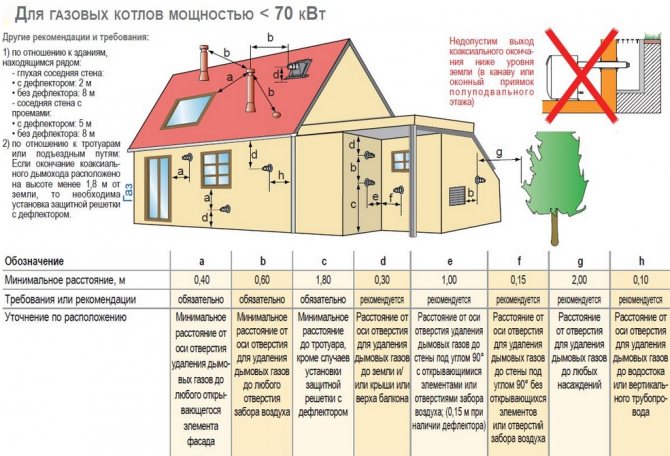

Necessary distances to be observed when the chimney is located outside

The installation is completed by checking the chimney draft. To do this, bring a burning piece of paper to the fireplace or stove. Draft is present when the flame is deflected towards the chimney.

The figure below shows the distances that must be observed in various options for the location of the chimney from the outside:

- when installed on a flat roof, the distance must not be less than 500 mm;

- if the pipe is removed from the roof ridge to a distance that is less than 1.5 meters, the height of the pipe must be at least 500 mm in relation to the ridge;

- if the chimney outlet installation is located at a distance of more than 3 meters from the roof ridge, then the height should not be more than the expected straight line.

The setting depends on the type of duct directions required for the combustion of the fuel. In the interior of the room, there are several types of directions for the chimney channel:

Support bracket for chimney

- direction with a rotation of 90 or 45 degrees;

- vertical direction;

- horizontal direction;

- direction with a slope (at an angle).

It is necessary to install support brackets for fixing the tees every 2 meters of the smoke channel, it is necessary to provide additional wall mounting. In no case, when installing a chimney, horizontal sections higher than 1 meter should not be created.

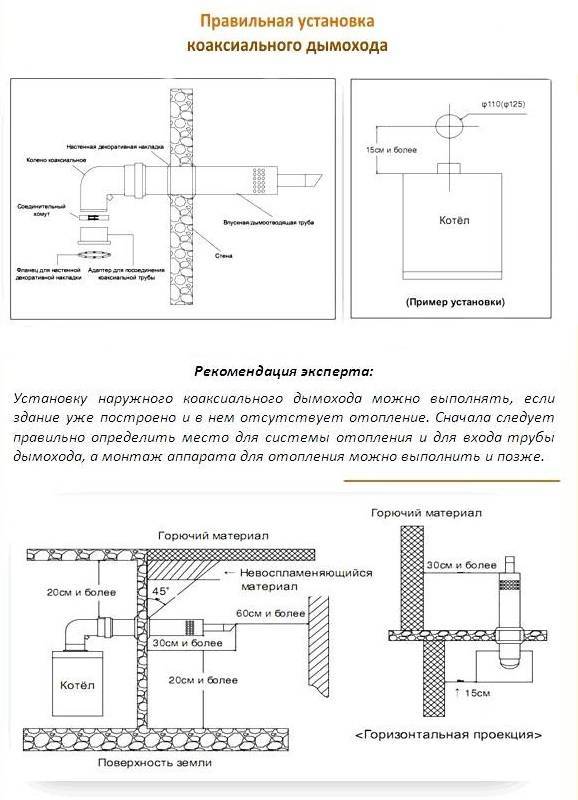

When installing chimneys, consider:

- the distance from metal and reinforced concrete beams to the inner surface of the chimney walls, which should not exceed 130 mm;

- the distance to many flammable structures is at least 380 mm;

- cuttings for non-combustible metals are made for the passage of smoke channels through the ceiling to the roof or through the wall;

- the distance from combustible structures to an uninsulated metal chimney must be at least 1 meter.

The connection of the chimney of a gas boiler is carried out on the basis of building codes and the manufacturer's instructions. The chimney requires cleaning up to four times a year (see How to Clean a Chimney).

In order to optimally calculate the height of the chimney, it is necessary to take into account the type of roof and the height of the building:

- the elevation of the chimney pipe must be at least 1 meter when installed on a flat roof and at least 0.5 meters above a non-flat one;

- the location of the chimney on the roof must be made at a distance of 1.5 meters from the ridge;

- the height of an ideal chimney has a height of at least 5 meters.

How to connect a two-channel coaxial chimney to the boiler

One of the common mistakes when connecting a coaxial smoke exhaust system is the use of improvised means, which is a gross violation of safety and operation. Standards prescribe the use of a special adapter for connection. It is forbidden to install a self-made branch pipe from a piece of stainless pipe.

Immediately after the outlet pipe, a tee with a condensate collector is mounted, after which the pipe is lifted up by 0.5-1 m, the angle is set and the chimney is led through the wall. Before commissioning, check the quality of traction.

Assembly without errors

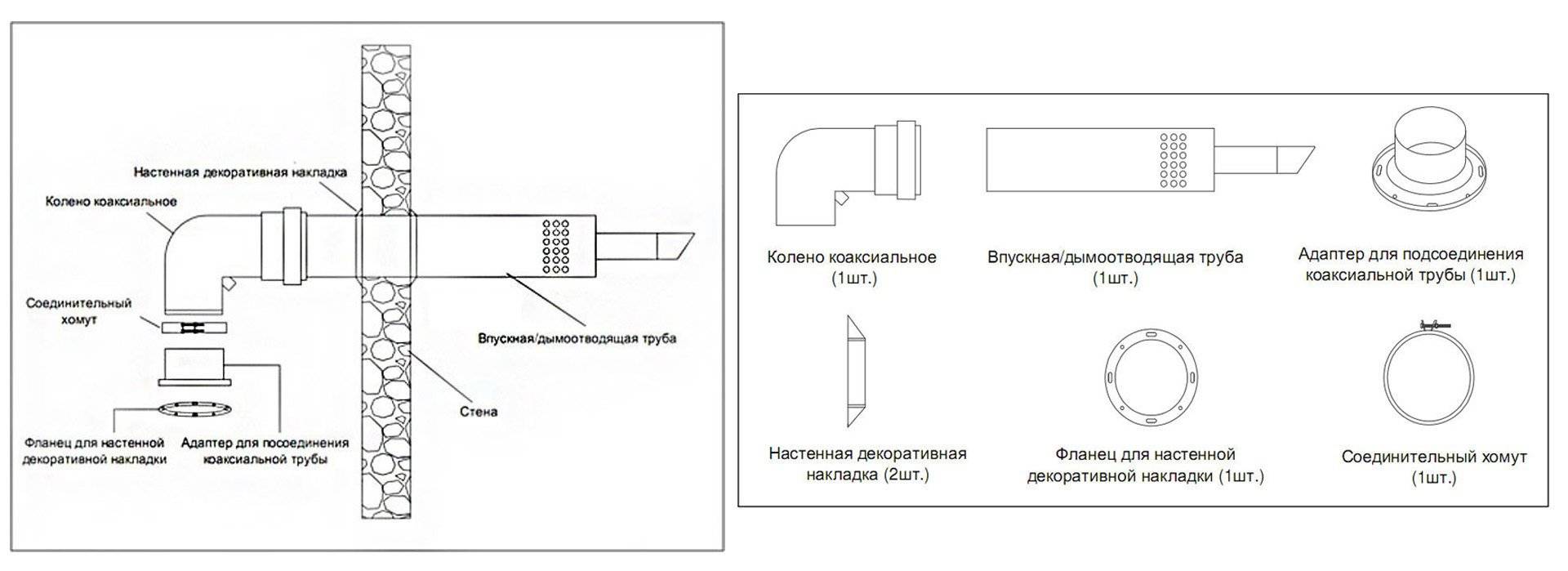

The first step in installing the chimney is to prepare the hole in the wall. Its diameter must correspond to the pipe that is brought out.

Then the chimney is connected to the outlet neck of the boiler, using a clamp to fix it. The assembled structure is bolted on both sides. Next, proceed to the assembly of the chimney itself. Its parts are connected to each other with clamps, in order to ensure their reliability. On top of them put on decorative lining. Their function is to preserve the design of the room.

No matter how simple the installation and arrangement of a coaxial chimney may seem, certain knowledge is needed to complete it. After all, with incorrect calculations of the system for removing combustion products, smoke, carbon monoxide can enter the room.

Installation of an external chimney

Installation of this design can be performed in two versions:

- outdoor

- internal

The first is used if the building has already been built. Before proceeding with the installation, determine the place for the location of the system and for the chimney inlet.

On the outer wall mark where the exit will be located. When performing it, fire safety rules should be followed. After the hole of the required diameter is ready, proceed to the installation of the chimney.

To do this, all internal work is preliminarily carried out: connecting the pipe to the boiler using a sectional single-circuit elbow and a double-circuit tee. The latter is necessary to secure the system in a vertical position. Next, the chimney is reinforced with brackets on the wall surface.

The installation of the internal system begins with the correct selection of the pipe diameter. Usually its diameter is indicated in the product passport.The main thing is that it matches in size with the outlet of the boiler.

The connection of the unit and the chimney is carried out using a tee. In this case, the links are fastened by a chain (the lower ones must go into the upper ones). This design allows the smoke to escape unhindered.

Double-circuit pipes are connected using a transition node. The joints are fastened using clamps.

Checking the functionality of the structure

After all the installation steps have been successfully completed, you need to check:

- Reliability of fastening of the connecting parts of the chimney

- The correct position of the flue pipe (it should be slightly inclined)

- The absence of barriers at the exit point of the structure to the outside

Only after making sure that the equipment is correctly installed, the hole in the wall is closed with decorative overlays. Their fastening is carried out on building glue or liquid nails. It is recommended to foam the hole around the chimney, this will prevent cold air from entering the room and the accumulation of condensate.

Flaws

Coaxial chimneys also have some disadvantages.

High price

It is due to increased requirements for the quality of materials and the performance of butt joints. This drawback is leveled by the fact that there is no need to build a main chimney, an isolated boiler room and special ventilation. Such a boiler can be installed in an ordinary kitchen with standard ventilation.

Condensation

Water vapor contained in the exhaust gases inevitably enters the air intake. In severe frosts, they can freeze, condense and drip in the off-season.When freezing occurs, the air supply decreases, the boiler may go out.

Photo 3. Coaxial chimney with condensate frozen on it. There are many tools available to fix the problem.

To prevent this from happening, there are a number of recommendations.

The dew point (condensing vapor) must be outside. The inner tube can be extended to prevent hot vapors from entering the air intake.

You can insulate the chimney to reduce the air temperature.

On sale there are additional modules that eliminate the problem of icicles and dripping condensate. They consist of an insulated nozzle: an extension cord and fasteners.

The disadvantages of a coaxial chimney are easily and inexpensively solved.

Features of the design, operation and installation of outdoor chimneyless gas boilers

If it is impossible to install a classic vertical chimney, chimneyless gas boilers are used for heating. For such heating equipment, a ventilated separate room for natural draft is not equipped.

Despite the name "chimneyless", there is a chimney in such boilers. Its role is played by a compact coaxial pipe, which provides traction and removal of smoke masses from the combustion chamber.

External outlet of the coaxial chimney

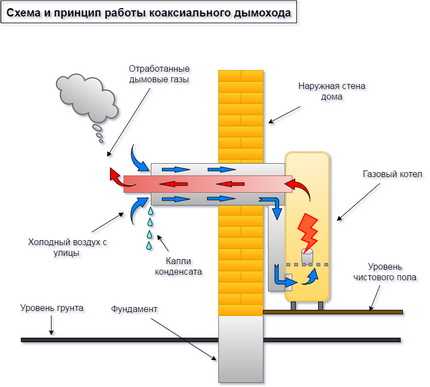

The design and principle of operation of chimney-free boiler equipment.

Chimneyless, like classic gas boilers, operate in heating mode - single-circuit, and even like water heaters (DHW) - double-circuit.

A distinctive design feature is the closed combustion chamber. The burner, through which the gas heats the water in the system, is located in a sealed chamber. Thus, carbon monoxide, soot and smoke from the combustion of fuel do not penetrate into the room, and the efficiency of the boiler increases.

Oxygenated air for combustion enters the closed chamber through the external chimney block. The air heated by the burner element heats the copper circuit through which the coolant flows. Then the "exhaust" air, together with the combustion products of the fuel, exits through the internal block of the coaxial pipe.

Scheme of operation of a floor coaxial boiler

Coaxial chimney is simple to implement. These are two coaxial pipes of different diameters, fastened together. Thus, the heated gas waste is cooled by the air entering the chamber, making the boiler fireproof and environmentally friendly for the residents of the house. Cooling the products of combustion, the air enters the combustion chamber already heated, which saves energy.

High-power gas boilers are equipped with deflectors to prevent insufficient draft, which increase the air flow by one and a half times. If there is a possibility of wind blowing, a special wind protection block is installed at the pipe outlet.

Features of the installation of gas boilers with a coaxial chimney.

Floor-standing chimneyless boilers for autonomous heating systems are installed in small buildings and in many apartment buildings or industrial premises.

Chimneyless gas boilers are installed on a special stand. If the boiler is controlled by an electronic board, then it is connected to electricity according to the rules for installing electric and gas equipment by specialists.

They are included in the heating system and gas mains in the same way as chimney gas boilers. The difference is the installation of a coaxial chimney.

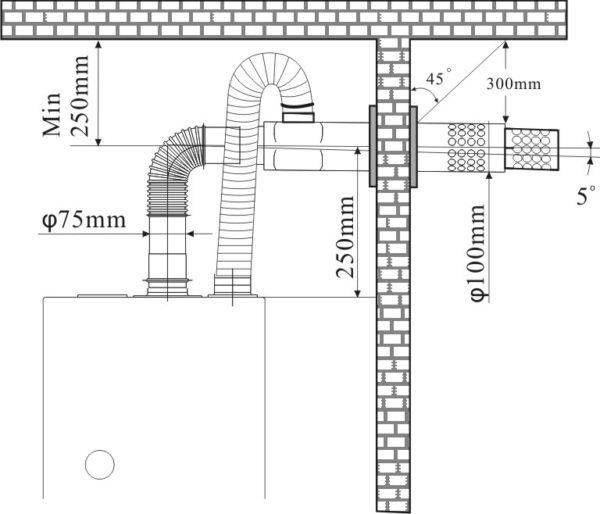

Installation diagram of a horizontal coaxial chimney

Requirements for installing a coaxial pipe as a chimney:

- The outlet of the chimney to the street passes through the wall horizontally.The length of this pipe section is no more than 1 meter.

- The chimney is horizontal, but if horizontal chimney is not possible, a vertical chimney is used. The length of the vertical part of such a chimney is about 3 meters.

- The outer part of the pipe is located no lower than 2 meters from the ground.

- The distance from the pipe to window or door openings is at least half a meter.

- You can not place the outlet of the pipe under the window.

- To prevent the accumulation of condensate liquid, it is installed at an angle of 3-5 degrees.

- Observe the diameters of the pipes of the coaxial chimney and their ratio for fire safety.

- The hole drilled in the wall for the pipe is lined with insulation made of non-flammable material.

Compliance with these requirements will make the operation of the boiler safe and efficient.

Chimneyless boilers - their pros and cons of operation.

The advantage of underfloor heaters equipped with a coaxial pipe is installation in the living room. To fit the boilers into the interior, the decoration of the walls and the junction of the chimney with the wall is selected.

You can learn more about coaxial chimneys and their use for gas boilers in the video below.

Coaxial boiler in the interior of the apartment

In addition, other advantages:

- simplicity and low cost of installation;

- there is no need to install supply and exhaust ventilation;

- high power units of such a design that they heat large areas;

- some gas models are equipped with convection holes, which makes it possible to heat a room without a radiator;

- long service life.

The disadvantages of coaxial boilers are in the smoke extraction system. The length of the smoke exhaust pipe is not more than 5 meters.During frosts, chimneyless boilers operate at high power, due to which more condensate forms in the coaxial pipe, which freezes and blocks the air supply and smoke removal. The blowing out of the chimney occurs if it is not equipped with a wind protection.