- Wire connection process

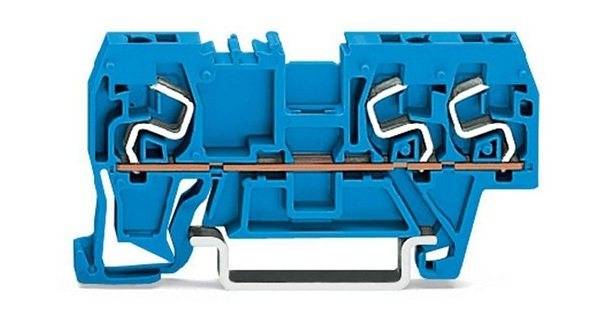

- Options for types of terminal blocks Vago

- Flat Spring Connectors

- cage clamp

- Fit Clamp

- Rules for choosing self-clamping terminals

- Twisting

- Benefits of twists:

- Cons of twists:

- General installation requirements

- Service terminal

- Advantages of terminal blocks

- Advantages and disadvantages of using

- Main types of terminals

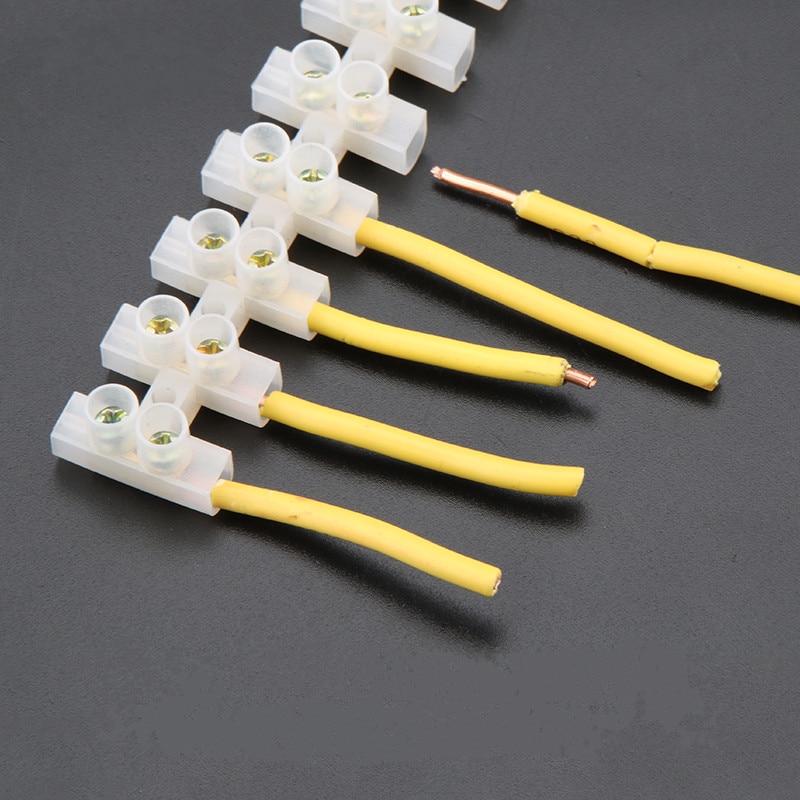

- Screw (construction, barrier)

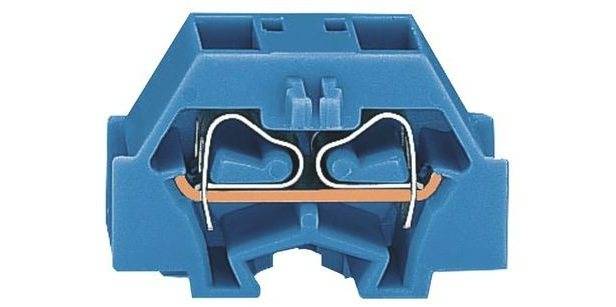

- Clamp (spring, self-clamping): wire clamps

- Junction box terminals

- Fused terminals

- Terminal blocks

- Knife terminal blocks

- Terminals for connecting wires

- Knife

- Forklifts

- Ring

- Pin

- Top Producers

- Top quality Legrand products

- Legrand Terminal block blue 21x1.5-16mm2

- Legrand blue 1x6-25+12x1.5-16mm2

- Universal terminal block 8×1.5-16 mm2, 75 mm

- Rating of the best Wago terminals

- WAGO for 4 wires with contact paste

- WAGO 3x(0.08-4.0)

- WAGO 2 221-412

- Rating of quality models of the STEKKER company

- STEKKER LD294-4002

- STEKKER LD294-4003

Wire connection process

In order to independently connect the wires at home, you must purchase the following equipment:

- terminals.

- wire, or as experts call it, twisted pair, which has 8 cores and differs in colors: emerald, brown, azure, carrot;

- a sharp knife for stripping the wire;

- cable crimping tool;

- curly screwdriver;

- drill;

- installation box;

In order to properly connect the outlet, you must perform certain steps in stages:

- Trim the ends of the wire with a sharp knife.

- We clean the wire with a blade.

- We add all the wiring parallel to each other.

- Fix the wires with a ferrule so that the wires protrude by about 1 centimeter.

- Insert the lug into the terminal and fix with the screw.

- Run the wire along the floor (if there is a need, you can hide it in a box or ready-made gates);

- If the cable is hidden, a mounting box should be installed (using a drill, make a small hole in the wall into which the box should be installed using self-tapping screws and dowels);

- With an open wiring method, the cable is mounted to the wall using brackets, or using a plastic box.

- After the above steps, we connect the electricity and check the correct connection of all elements.

If the work is completed, but the connection to the electrical network has not taken place, the quality of the work performed should be checked. To avoid this problem, you should work with a special cable tester.

After a positive result of checking the connection to electricity, you can proceed to fixing the outlet. Be sure to carefully place the cable in the box, and then attach the socket with screws. At the end of the work, you can decorate the outlet with a decorative overlay.

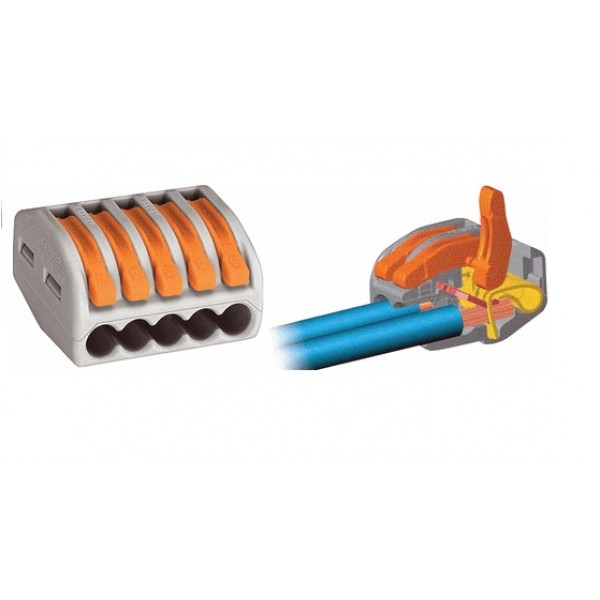

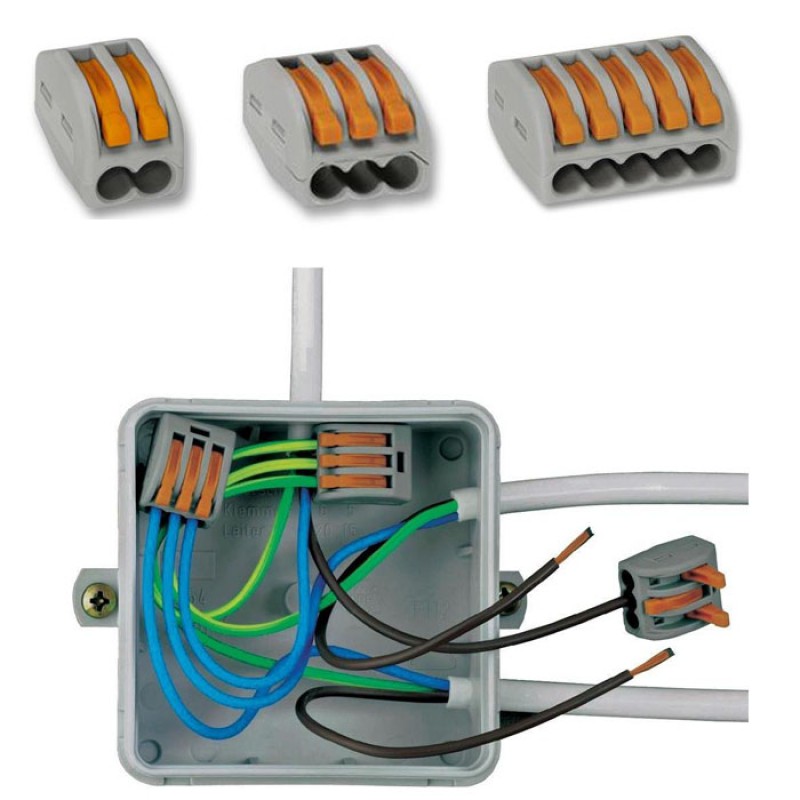

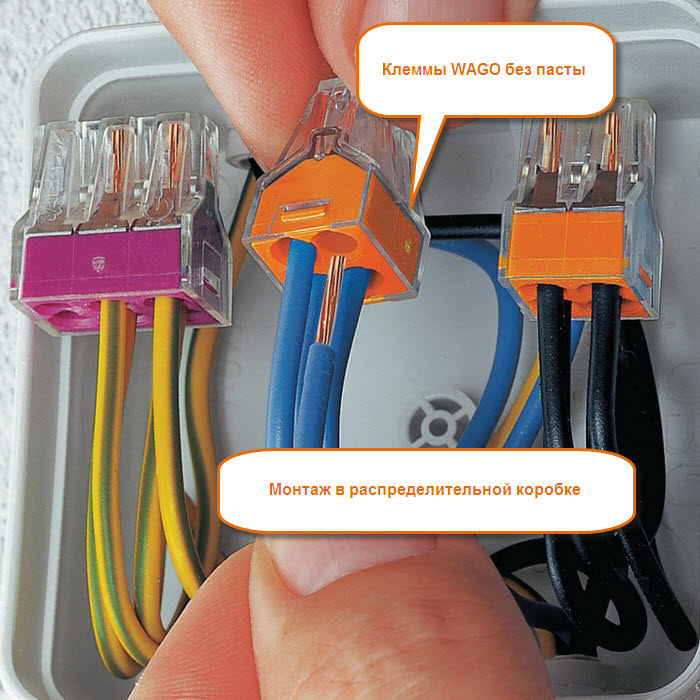

Options for types of terminal blocks Vago

WAGO clamps are divided into the three most popular types, the main difference between which is the type of spring used in the mechanism:

- flat spring;

- cage clamp;

- Fit Clamp.

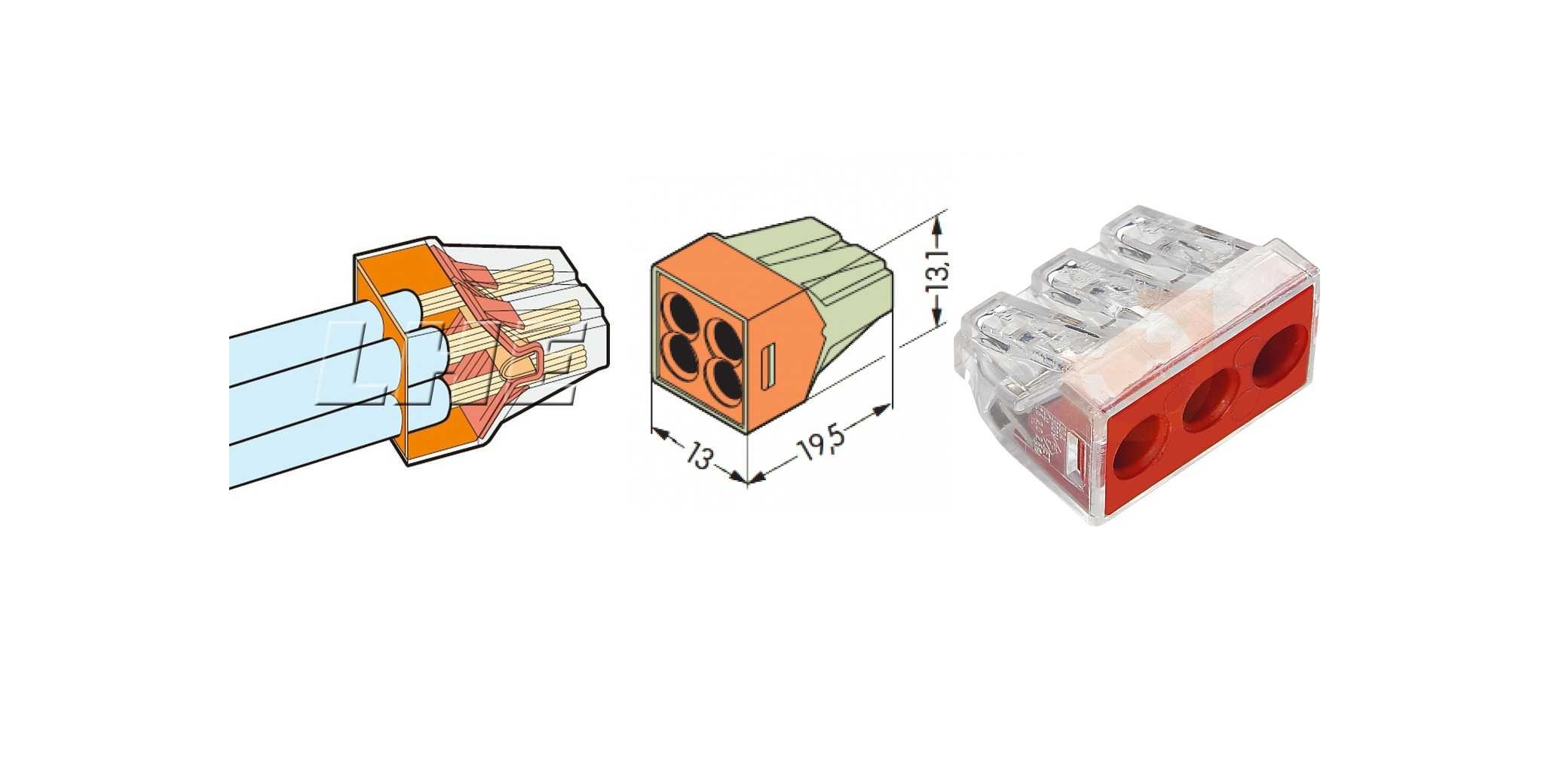

Flat Spring Connectors

The most convenient option for quick installation. Such clamps are not reused. They are recommended to fasten single conductors with a cross section of 0.5 to 4 mm².

Flat spring terminal block

Important! If you need to connect flexible multi-core cables, then they are pressed before installation

cage clamp

Used by professionals to connect lamps and other lighting fixtures. It can also be used for inductive motion sensors, motors, pumps, underfloor heating, heating installations and junction boxes. They allow you to create a contact of flexible and stranded conductors without their preliminary pressing.

You will be interested Description of installed and calculated capacity

cage clamp

Fit Clamp

Terminal blocks with mortise contacts. This means that you do not have to pre-stripping the wires before inserting them. This makes the connection process even easier and safer.

Fit Clamp

Rules for choosing self-clamping terminals

The main rule of a potential buyer of self-clamping terminal blocks, perhaps, is the mandatory verification of the goods for authenticity. On the commercial market, there are a lot of fake goods marked with a German mark - the manufacturer Wago itself warns about this.

The cost of such products is reduced, which naturally attracts the buyer. However, this kind of savings can turn into trouble when operating the assembled circuits.

Meanwhile, without unnecessary warnings, it should be obvious that a counterfeit product is a significant reduction in quality. How to choose the right wire connectors without fear of getting a fake? In principle, everything is quite simple.You just need to be more careful when choosing self-clamping terminals for installation.

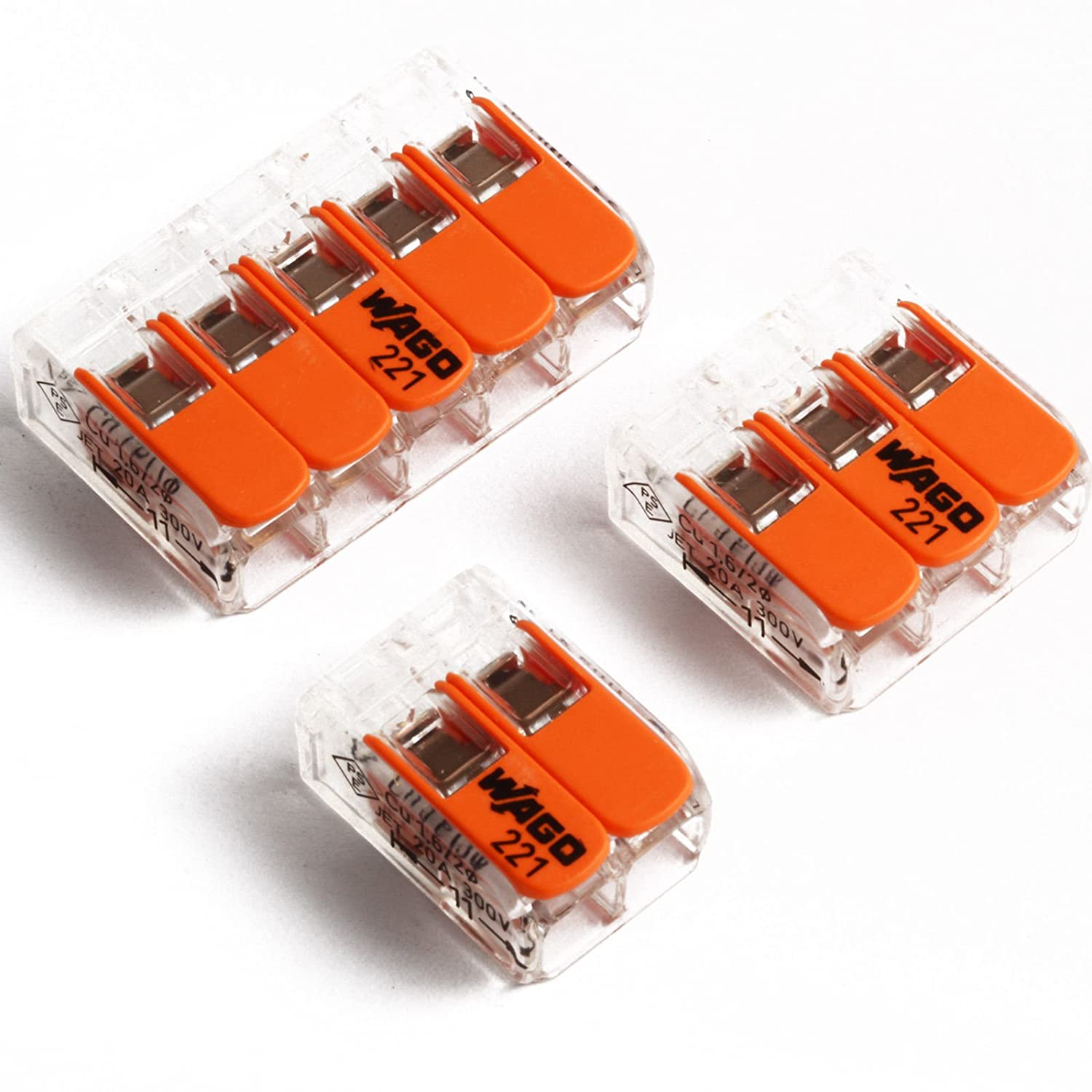

A branded product traditionally has the Wago logo printed in clear type, usually on the top or side of the case. Also, the main parameters are applied on the side - voltage and current.

This is what a branded product released under the Wago brand looks like. Fake terminal blocks, as a rule, do not contain such a seal, or they contain partially, applied with low quality

This is what a branded product released under the Wago brand looks like. Fake terminal blocks, as a rule, do not contain such a seal, or they contain partially, applied with low quality

The color color of the insulating material of branded products is distinguished by a single, clear color. On the back/side of the terminal block there is a mini-instruction for connection.

When compared with Chinese counterfeit goods, terminal blocks, as a rule, do not have any of the differences noted above. In addition, a fake is immediately distinguished by a blurry color of the insulator, often of different colors.

Of course, the main points of choice are the purely technical parameters of the self-clamping terminal blocks. In particular, the operating voltage and the permissible conducted current.

If the mounted circuits are designed for operating voltages that exceed the capabilities of the terminal blocks, respectively, the use becomes impractical and, moreover, dangerous.

You will learn about the color of the connected wires from the following article, the contents of which we advise you to read.

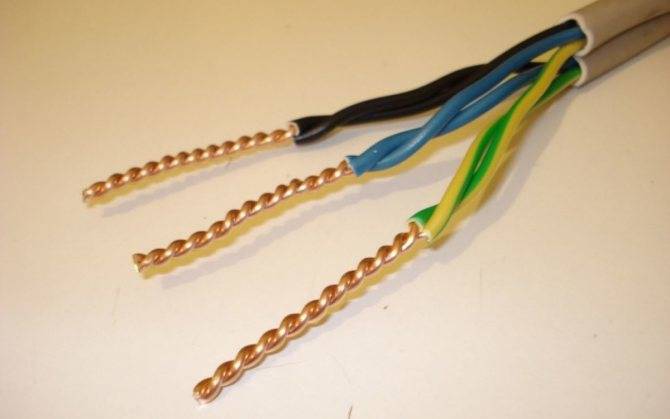

Twisting

This is the most common type of connection that can be made without special tools and even with fingers (not recommended). Since ordinary twisting is characterized by a rather unreliable connection, soldering or welding of an already twisted connector is additionally used.

Benefits of twists:

- Cheap connection.For twisting, two wires and insulating material (duct tape or cambric) are enough.

- Large contact area. The larger the area of the contacted conductors, the more power (current load) they are able to conduct. Twists can be made of any size, so the contact area will always be sufficient.

- Does not require maintenance.

- It is possible to connect single-wire and multi-wire conductors.

Cons of twists:

- Low moisture resistance. It is not recommended to use in damp rooms, as well as in wooden cottages.

- Additional insulation required. Unlike various terminal connections, stranding requires additional insulation.

- Do not combine aluminum and copper.

- High duration of the technological process. Soldering and welding contacts takes a lot of time.

- Requires additional hardware. To weld the contacts, you will need a welding machine with a small current. For example, the inexpensive Wert SWI model with argon-arc welding mode is suitable for high-quality welded strands.

Twisting without soldering and welding is usually used when installing temporary buildings, which then have to be removed.

General installation requirements

The quality of connections and branches during installation is of paramount importance. When troubleshooting an electrical circuit, most often the problem occurs due to a lack of contact. Poor contact can lead not only to a circuit break, but also to overheating of the wires. Often this is the cause of a fire.

Therefore, they are subject to stringent requirements.

Regardless of which terminals are installed, the following rules must be observed:

- During installation, it is necessary to leave a margin of wires in front of all connections (for reconnection).

- All connections must be located in accessible places.

- The location of the connecting elements must be protected from vibration and any other mechanical influences.

- The insulation of the connecting elements must match the insulation of the conductors.

- All connections must be made in junction boxes, cabinets and control panels, special niches in building structures.

There are many varieties of terminal blocks for their intended purpose:

- plug-in;

- hybrid;

- mini and micro terminals;

- fuse terminals;

- terminals with breakers;

- multi-output;

- multi-tiered;

- checkpoints and others;

For all types of installation rules are united.

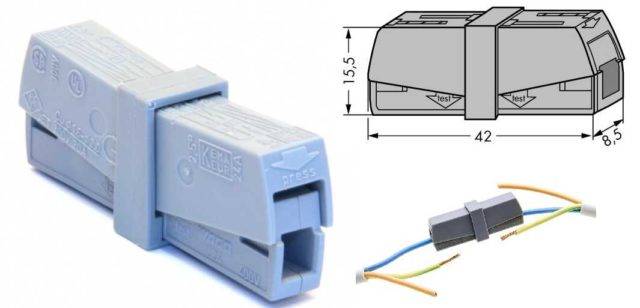

Service terminal

Connecting stranded wires is still a pleasure. It is difficult to achieve normal contact, since the wiring does not bend well. You can splice two wires using the WAGO service terminal (marking 224-201). It consists of two identical parts with buttons. When you click on them, a sufficiently large window opens, into which a stripped conductor is inserted. When the button is released, the spring presses the wire against the pad.

Vago service terminal - for connecting stranded wires

A similar operation is carried out on the other side. With this method of connection, the contact plate has a large area of contact with the conductors - it clamps a lot of wires. It really gives good results.

Advantages of terminal blocks

Wago terminal blocks have an impressive number of advantages:

- During operation, they do not require any maintenance.

- There is a separate terminal clamp for each of the connected wires.

- The connection does not require additional insulation.

- During operation, self-clamping terminal blocks of this type are absolutely safe, since they completely exclude the possibility of a person touching live parts.

- At the point of contact, the connection is gas-tight, which excludes any possibility of oxidation of bare cores.

- To connect wires using such terminal blocks, an electrician does not need to make any additional efforts or have special knowledge and skills. Installation is fast and accurate, you do not even need to use an elementary screwdriver. This is a huge advantage in cases where wiring has to be mounted in hard-to-reach places and large volumes, or work in poor lighting conditions.

- The connecting clamp Vago has a compact size.

- If necessary, the connection can be easily redone.

- Due to the springs, Vago terminal blocks have shock resistance and high vibration resistance.

- They withstand excessive humidity, exposure to aggressive environments (for example, fuels and lubricants) and high temperatures (as they are made of materials of the hardly flammable category).

- Since the spring terminals are adapted to a specific conductor cross-section, the applied clamping force is optimal. This eliminates the possibility of thermal deformation or damage to the wires. Thus, Wago terminals provide a reliable contact connection for the entire period of operation.

- In a junction box with such connectors, order and aesthetic appearance are always guaranteed.

- And, of course, the plus that all terminal blocks have is the ability to connect wires from different metals (for example, copper + aluminum).

The only disadvantage is that the connectors must be located in places accessible for inspection and work at any time. But not only the VAG terminals have such a disadvantage, it is inherent in absolutely all detachable connections.

Advantages and disadvantages of using

The main positive qualities of the terminals are the following provisions:

- Secure connection. The appearance of a spark is practically excluded.

- Reliability and durability in the process.

- High level of rigidity, which allows you to more firmly fix the terminals.

- Ease during installation. This allows you to use the terminals at home and fix them yourself.

- During the installation process, you can do with a simple screwdriver. No other tool is required.

A significant disadvantage is the size range of the connector. During installation work, it is worth considering the laying of wires and the installation of a junction box.

Main types of terminals

Screw (construction, barrier)

Screw terminals are the most popular option, which are characterized by simplicity and excellent reliability. Such terminal blocks are suitable for connecting sockets and for laying electrical wiring.

In this case, the connection of wires using screw-type clamps is used. This allows for a firm hold. Do not use screw terminals for aluminum wires.

Screw connectors

Clamp (spring, self-clamping): wire clamps

Such products are also called crimp terminals for wires. The cables in them are clamped with a spring. This does not require a special tool.The stripped wire is installed all the way into the block and fastened with a spring. In modern models, a self-clamping function is provided.

Spring terminals are popular because of the reliable connection. To remove the core, you need to pull the lever back. When choosing this option, the terminal block must be selected taking into account the number of connections. Spring products are made from different polymeric materials. The contact element is made of two brass plates.

Clamping products

Junction box terminals

To carry out the connection of wires in the junction box, a terminal made of a plastic case with holes for conductors, a spring element and a current-carrying busbar is used. For connection, the conductor must be inserted into the terminal as far as it will go. In this case, the spring element firmly presses the conductor.

Terminals inside the box

Fused terminals

Fused terminals are used for selective protection of secondary circuits. Both flexible and rigid conductors are used.

Terminal blocks

The terminal block is a device for switching all kinds of circuits with pairwise connected clamps. Products contain nests of large diameter. The pads have threadless and threaded outlets. Metal screws are used to tighten the wires. The types of pads are different, but the principle of their device is the same.

Vago pads are often used to quickly connect wires. They are of two types:

- with a flat-spring mechanism;

- universal with lever mechanism.

Compact terminal blocks

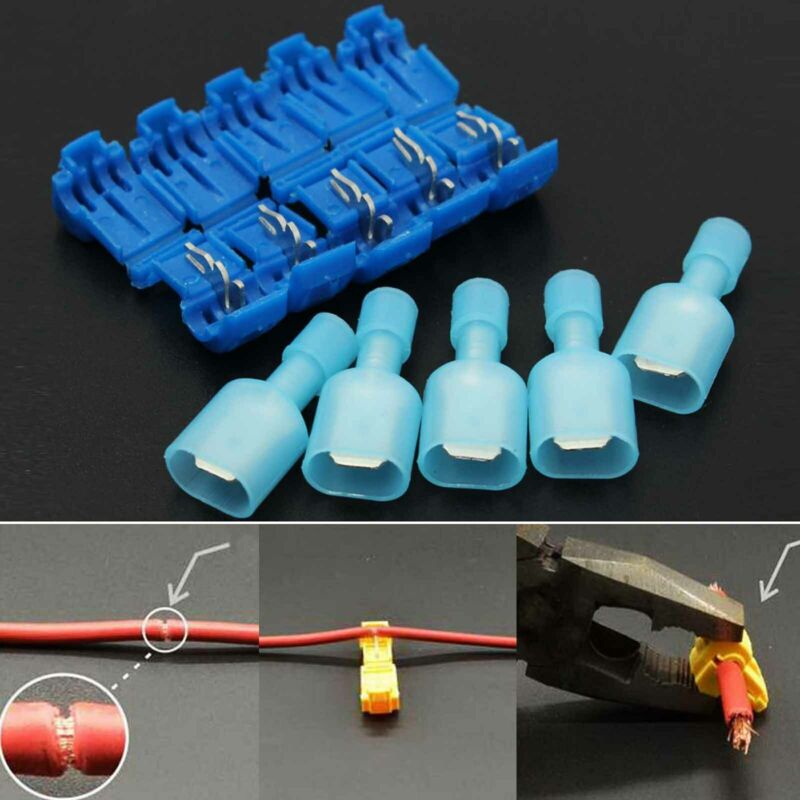

Knife terminal blocks

Such options are used for grounding and for grounding circuits. They are also used for cutting branches into the conductor. Knife connections are often used for audio equipment.Their feature is that the installation does not require stripping the conductor. The wire is simply installed in the terminal block and crimped.

The advantage of such terminal blocks is considered to be time saving for installation, reliability and safe connection due to a special lever. In addition, no special tools are required for installation.

Knife models

Terminals for connecting wires

Considering all the connecting terminals for wires produced by the industry, you should immediately make a reservation and divide the products into two types: electrical and electrical.

In fact, the difference (in terms of current load) between the types is often small, but still it exists. This point should be borne in mind when selecting electrical terminals for installation, repair or other actions.

- Faced with the need to select electrical terminals for wires, it is better to start with the simplest designs of domestic production - reliable, durable, proven in practice more than once:

- knife;

- forklifts;

- ring;

- pin;

- coupling.

Connections in the construction of electrical circuits can be performed in different ways, and terminals are just one of the options. However, it is this option that seems to be the simplest, most convenient and even economical in comparison, for example, with soldering, welding, including cold welding.

Knife

These are perhaps the most common design options for products. They can often be found in the electrical circuits of many household appliances: irons, refrigerators, heating devices, etc.

It is permissible to install this type of electrical products on conductors (stranded) with a cross section of 0.26-6.0 mm2 by force crimping the shank. There are two types of such products: insulated and non-insulated.

The insulation is usually painted in different colors (red, blue, yellow) depending on the rated power of the terminal block. Products are used in pairs in a bunch of "father-mother".

Forklifts

Fork-type terminals are designed for switching power and secondary circuits. Such ferrules are designed for subsequent fastening with screws directly to the equipment or to the busbars. The instruction advises using them as a temporary or requiring frequent reconnection of a contact.

The design of the fork tips is a two-pronged fork, hence the name. This design makes it quite easy to switch without completely unscrewing the screw clamp. At the same time, in the connected state, it provides a fairly tight contact.

Fork lugs are available for wires up to 6 mm2. The wires are attached to the terminals by crimping. This place in various variations may or may not have an insulating coating.

Ring

A more reliable contact is provided by the so-called ring terminals. Like their fork counterparts, they are designed for subsequent screw clamping. But due to the round shape of the contact part, they provide a large contact area and reduce the risk of “popping out” of the tips.

Ring terminals for wires are such a good solution that they are used not only in low-voltage networks, but are also a mandatory attribute of power cables of any section. At the same time, the method of attaching a wire or cable to lugs of this type can vary from welding and soldering to crimping.

Ring terminals are available in copper, aluminium, brass and copper-aluminum.Their cross section can vary greatly, ranging from small terminals for a triple screw and ending with bolts of 27 or more. At the same time, terminals for low-voltage networks can be supplied with insulation of the crimp part.

Pin

This group of connecting terminals for electrical wires is made according to the principle of a detachable part, consisting of two separate elements - a plug and a socket. The plug is marked with the symbol "A", for example, F2A.

The socket is marked with the symbol "B", for example, F2B. Mounting on conductors with a cross section of 1.25-6.64 mm is supported. The main purpose of the pin terminals is to ensure the connection of electrical conductors.

This group of mounting fittings belongs to insulated products. The tail end of the terminals is covered with insulating material. Depending on the rated power of the terminal block for connecting wires, the insulator has an appropriate color.

Insulators of electrical terminals for conductors with a cross section of up to 2 mm2 are painted blue, the rest (from 2 to 6.64 mm2) are yellow.

Top Producers

Top quality Legrand products

Great company that puts quality first. The main element of the connection is brass, which is covered with a thin layer of nickel on top. Thanks to this solution, tight contact between the wires is ensured. The insulation is made of polypropylene, which can withstand temperatures up to 100 degrees Celsius. The maximum cross section with which their products can operate is 25 mm2. Also a positive point is that the terminals can be used at a voltage of 380 V and at a current load of 100 A.

Legrand Terminal block blue 21x1.5-16mm2

A great option that is suitable for connecting most types of wires.It guarantees a person a tight connection and reliability for the entire period of operation. Sold in all specialized stores.

The average price is 470 rubles.

Legrand Terminal block blue 21x1.5-16mm2

Advantages:

- Quality connection;

- Reliability;

- Durability.

Flaws:

Legrand blue 1x6-25+12x1.5-16mm2

A good block designed for dense switching of cores. Suitable for home use. The case is made of high-quality plastic, which does not deteriorate over time and can withstand heavy loads.

The average price is 450 rubles.

connector Legrand blue 1x6-25+12x1.5-16mm2

Advantages:

- Connection density;

- High-quality case;

- Price.

Flaws:

Universal terminal block 8×1.5-16 mm2, 75 mm

A good model, which will be suitable for installation in many homes and businesses, guarantees a tight connection for the entire period. Can fix almost any wire.

terminal block Universal terminal block 8×1.5-16 mm2, 75 mm

Advantages:

- Good build;

- Tight connection;

- Durability.

Flaws:

Rating of the best Wago terminals

The products of this company are among the most in demand for 2020. This is made possible by the tight connection of the contacts in all circumstances. In addition, even an inexperienced user can make a connection, just look at the instructions and that's it.

Products are available in two variations: disposable and reusable, each user decides which one to choose. The maximum current load is 32 A, but in some cases the value does not rise above 25 A, this should also be taken into account.

The company produces products that are designed to connect single-core elements with stranded ones, which is a great advantage.At the same time, their cost is not much different from standard models.

WAGO for 4 wires with contact paste

An excellent product, which is made in a classic style and is able to securely fasten almost any element. The body is made of durable plastic.

The average price is 15 rubles apiece.

WAGO 4-wire connector with contact paste

Advantages:

- Low price;

- Good quality;

- Tight fixation.

Flaws:

WAGO 3x(0.08-4.0)

The model is designed for quick installation. With this terminal block, you can fix almost any wire, which is a big advantage.

WAGO 3x connector (0.08-4.0)

Advantages:

- Fast installation;

- Affordable cost;

- Quality case.

Flaws:

WAGO 2 221-412

A popular product that is in demand among electricians. The body is made of durable material that is durable.

connector WAGO 2 221-412

Advantages:

- Price;

- Reliability;

- Universal application.

Flaws:

Rating of quality models of the STEKKER company

The products of this company are suitable for installation at home or in a factory. The company produces screwless terminals that will provide a person with quality and reliability. With this element, it is possible to fasten cables of any type. Some models are made half open, while others are produced in a closed shell.

STEKKER LD294-4002

The model is suitable for fixing solid and stranded conductors. The case is made of high-quality plastic, which does not deteriorate from long-term use. Fastening is fast and high quality.

The cost is 30 rubles.

connector STEKKER LD294-4002

Advantages:

- Durability;

- Fire resistance;

- Maximum current - 16 A;

- Price.

Flaws:

STEKKER LD294-4003

This option is designed to capture more elements. At the same time, it guarantees fastening density and trouble-free operation for ten years.

The average price is 40 rubles.

connector STEKKER LD294-4003

Advantages:

- High service life;

- Reliability;

- Quality performance.

Flaws: