- How to use

- Device

- Wago 773

- Wago 222

- Advantages and disadvantages

- Pros and cons of application

- The device and principle of operation of the block

- Varieties, their advantages and disadvantages

- For lighting equipment

- For electrical work

- For base mounting

- Advantages of Vago terminal blocks

- What are WAGO terminal blocks for?

- Terminal blocks Vaga, characteristics

- Internal construction of the WAGO terminal

- Wago and aluminum wires

- Scope of use of Wago terminal blocks

- Example 4. Wago terminal blocks: how to use when installing a new junction box

- Wago and aluminum wires

- HF device

- Vago installation recommendations

- Advantages and disadvantages of Vago clamps

- A few words for opponents of Wago terminal blocks

- Types of clips "Vago"

- Types of terminal blocks

- How to use Vago terminal blocks correctly

- Advantages of Wago connecting terminals

- Advantages and disadvantages

- Areas of use

How to use

The connection of terminal blocks is more reliable than traditional twisting with soldering, thanks to this, the wiring lasts much longer, withstanding high voltage and high current. All modern Vago clamps, which will be used below, have earned respect and recognition from many experts.

So, as an example, let's take the most popular type of Wago terminal block from the 222 series, to use which we perform the following steps:

- Remove the insulation from the end of the wire about 5 mm.

- Raise the orange clamp in the terminal.

- Insert the end of the bare electrical wire until it stops.

- Lower the clamp until it clicks.

After that, the wire is securely fixed in the socket, the master connects all other wires in the same way. There is nothing complicated about how to use Wago terminals, so many professional craftsmen actively use these pads to connect wires.

If you ask an experienced electrician if it is possible to twist the strands of the wire, he will answer that it is not possible, since the load during the operation of modern household appliances is not small. In this case, the twists may not withstand a large current and overheat, which can lead to a fire. Therefore, it is best to use Vago terminals when installing, allowing you to connect cables safely.

Giving preference to reliable contacts - Wago terminal blocks, as well as using a copper cable of the desired flow section, the master ensures the reliability of the wiring. In some cases, you can use an aluminum core, but over time they oxidize, and this leads to poor contact. The active use of Vago terminals in practice confirms the high quality of such connections, so the cost of the products is fully justified.

Watch this video on YouTube

Watch this video on YouTube

Device

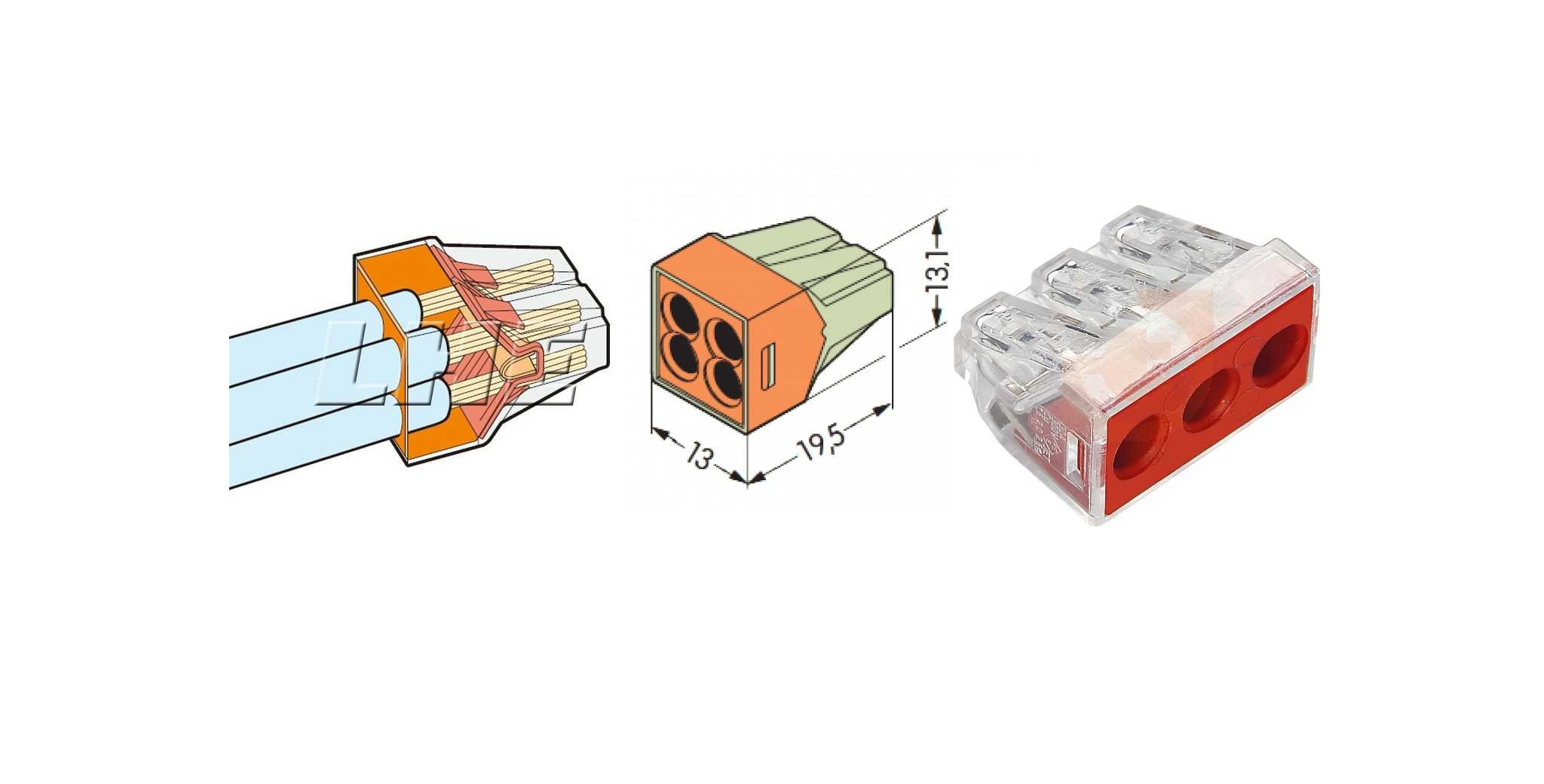

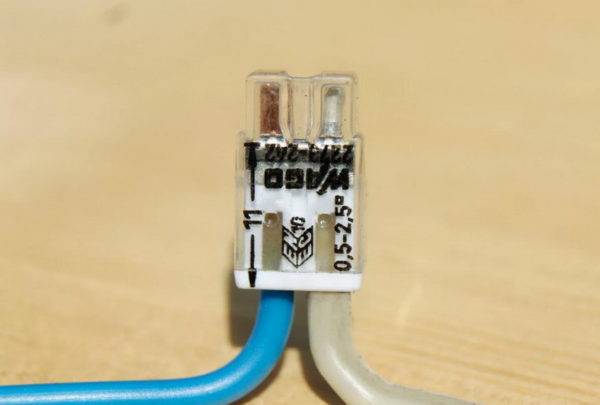

The wago terminal block has a plastic insulated housing, which makes it safe both during installation and during operation. It can be either transparent (mainly for terminal blocks of the 773 series) or made of matte gray plastic (series 222). Flags are made of orange plastic.

Inside the plastic case are the contacts themselves, made of copper tinned with tin. The difference between the 222 and 773 series is only in the design of these terminal contacts.

Wago 773

Terminal block vago 773, which is disposable, operates as follows. The wire, entering between the petals of the plate, unclenches them. When you try to pull it back, these petals are compressed. And the more force is applied, the stronger the end is clamped. Of course, it is possible to remove it if you apply a little effort to pull it out while twisting it. But, as already mentioned, you shouldn’t do this, it’s better to change the terminal block after that. But for saving length, this method is quite acceptable.

In addition, the cost of the contactor of this series is not too high to risk the safety of property and health for this. Although many people believe that the mounting spring terminal does not clamp the wire tightly enough and does not create the necessary contact, the long-term unreduced demand for such products and the durability of the connections made with its help indicate the opposite.

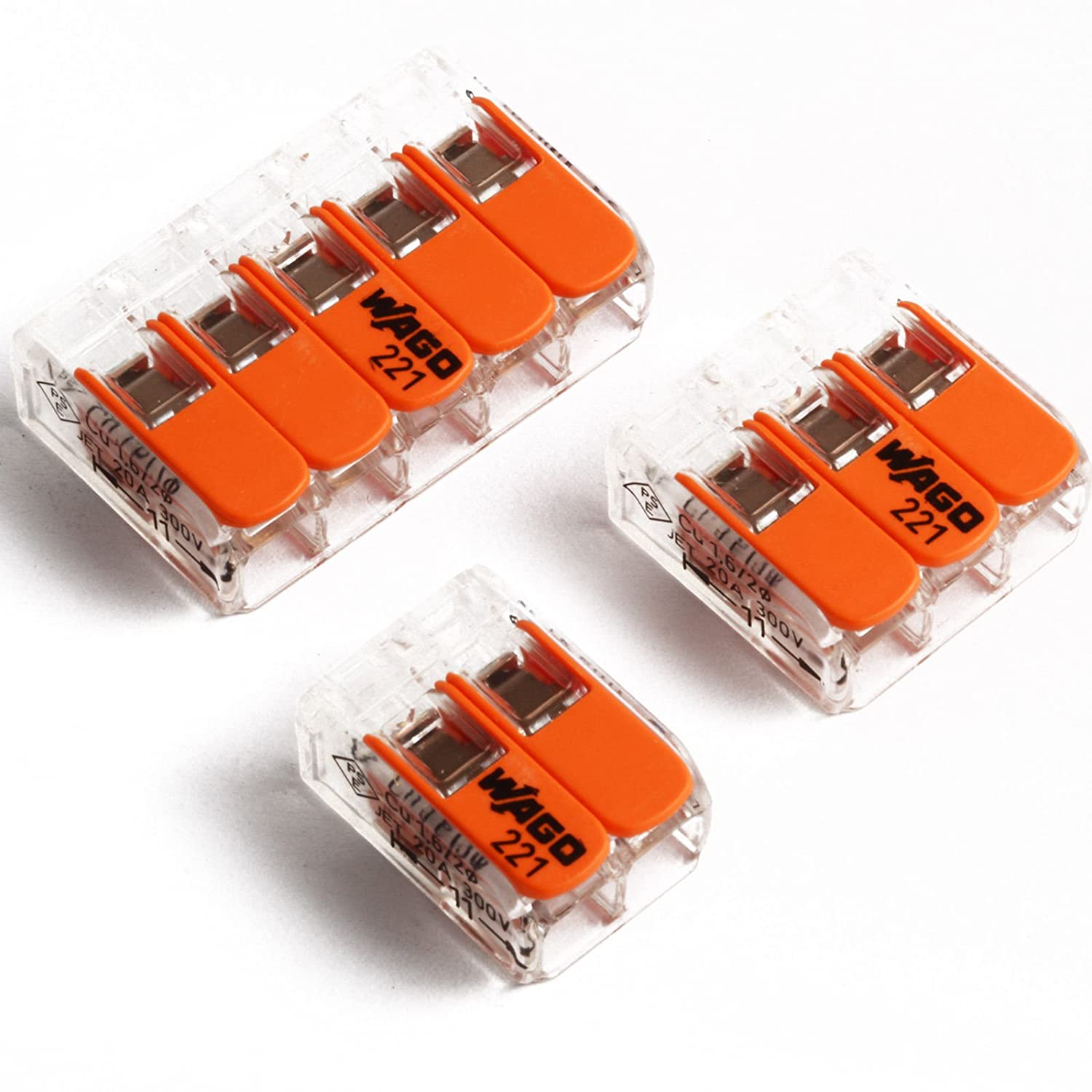

Wago 222

Vago 222 series, reusable

Vagov clips for reusable use, of course, are a little more expensive, but at the same time, they have more advantages. For example, if the installed electrical wiring in the apartment needs to be re-wired (scatter the premises on different machines, etc.), then if wago 222 terminal blocks were used in the junction boxes for connection, then this will not take much time.

To remove the wire, you only need to raise the flag and pull out the wire, since when the lever is raised, the clamp is open, and nothing in the case holds the end.For connection, it is necessary to insert it into the contact socket and lower the clamp, thereby securely fixing it in the contactor.

It should be noted that the resulting connection will be very tight and will not allow heating, provided that the size of the nest is correctly selected, since they can also be different. The most common for wiring in an apartment are spring terminals with sockets for wires with a cross section of 0.8–4 sq. mm.

Advantages and disadvantages

Such devices really facilitate and speed up the work of electrical installation. It makes sense to combine all the advantages in a list before deciding whether a similar type of connection is suitable for each specific case. So, the advantages of wago terminal blocks:

Wago is quick and easy to install. You just need to strip the wire. Moreover, the stripped part is required much shorter than when mounting on twists.

Fixing takes a matter of seconds, which is very important for an electrician. Due to the special plastic housing, additional insulation of the connection is not required

Dimensions of the triple connector vago 222 series

You can mount wires with different cross-sections, as well as those made of different metals (copper and aluminum). The contact will not oxidize over time, which means that the connection will not lose its density and will not heat up. Convenient and easy disassembly. If a wago 222 series terminal was used, unwiring the junction box is as easy as mounting

This is especially important when using brittle aluminum wire, which is rarely enough for twisting a second time.You can ring the wires, you can find the phase without unmounting the connection, for this there are special holes in the terminal block, where the multimeter probe freely enters

The installation turns out to be very aesthetic, which is also important, since if everything is neatly located in the junction box, then with the subsequent addition of consumers or re-switching, it will be much easier to figure out the wires. Accessibility of installation even if the wires are very short and full twisting is impossible. Such devices do not require maintenance during operation, and therefore are economical in terms of costs for periodic checks.

As for the shortcomings, we can name only one, which is inherent, probably, in any connection. This is the need for easy access to them. Well, since this is not critical, we can assume that there are no shortcomings at all.

Pros and cons of application

Practitioners of electricians were divided into two categories

Some focus on the advantages of the Vago terminal blocks, while others note mainly the shortcomings. In fact, the truth is somewhere between these two opinions.

Advantages of using Vago:

- fast screwless installation;

- the minimum set of necessary tools and materials;

- the terminal block is easy to buy even in a small electrical shop;

- accuracy and consistency of wiring;

- compliance with safety regulations.

Cons of terminal blocks:

- the need for periodic inspection;

- must be visually accessible;

- do not cope well with loads more than 1 kW;

- high contact resistance of contacts;

- risk of overheating and melting;

- high price.

The device and principle of operation of the block

In the basic configuration, the terminal clamp consists of two parts:

- Wire clamp mechanism.Made from tinned electrical copper. The task of the clamping mechanism is to fix the cable core and maintain reliable electrical contact between the wires.

- Insulating body. Made from flame retardant polyamide. Protects people and bystanders and wiring elements from contact with a live clamping mechanism.

Wago terminal device Additionally, Wago terminal blocks can be equipped with labels for marking, built-in diodes and protective sealing covers.

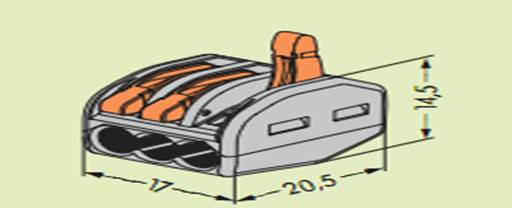

The principle of operation is to clamp the wire with a spring. Some connector models have a special lever (often orange) for this. It is needed to open the mechanism and allow the wire to get into the clamp area. For others, it is enough to simply insert the cable with the tip into the spring mechanism, and it will open on its own.

Note. There are grounding terminal blocks Vago

The wires that are connected to them are electrically connected to the DIN rail fastener. Such pads are used strictly only for grounding. They are easy to distinguish by the yellow-green body color and metal latches. If you connect a phase wire to such a terminal block, then there will be a short circuit to ground and a risk.

Ground terminal WAGO

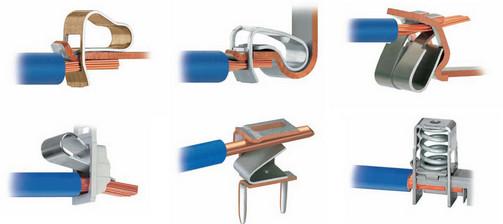

Varieties, their advantages and disadvantages

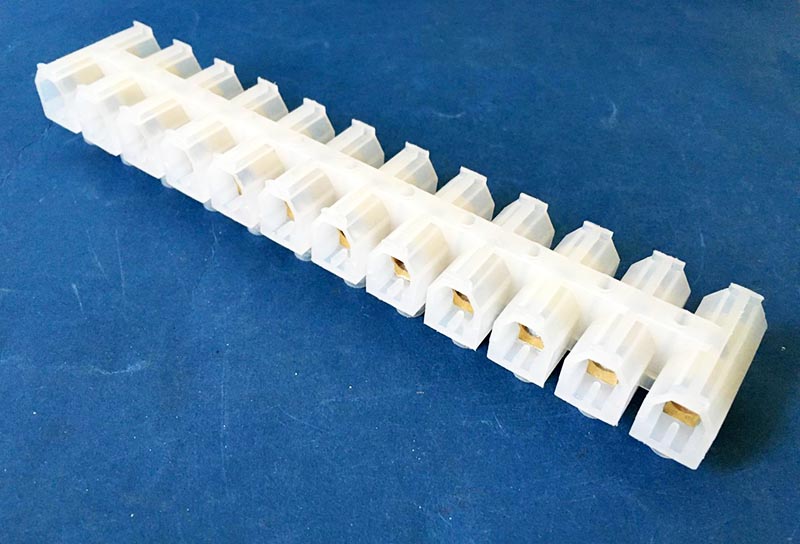

By design, Vago terminal connectors are flat, cross, hexagonal, bolted, spring, screwless and screw.Screw flat, cross and hex models are used to make electrical wiring, complement the junction box, fix car battery contacts, sockets, light switches, connect groups of lamps in some way or telephone wires, install powerful equipment.

Note! Screw bolt and spring terminal models are needed to connect the ground circuits on the player or surge protector. Required to protect the speakers of signaling, acoustic devices. They have a green screw and special wire grippers - “teeth”

They have a green screw and special wire grips - “teeth”.

Main types

Vago are distinguished by the absence of the need for additional installation devices, the ability to connect dissimilar wires (for example, aluminum and copper), the ability to connect conductors with different cross-sections within one connector. They also take up little space in the junction box and have an insulated housing. They are durable and can be dismantled and reused.

Design durability

The disadvantages are the possibility of fire or melting of products, high price. Interestingly, ignition occurs with non-original products. Distinctive features of the originals are the characteristic lever tone of the case, the rear markings and the wire stripping scheme in the center.

For lighting equipment

For lighting equipment, there are Vago terminal blocks of the 294 and 294 Linet series. They are needed to switch thin-core, single-core, stranded wires and not pre-prepare them. Thanks to a special plate, strain relief can be done.Support a maximum current of 24 amps. Also for lighting equipment there are models 272 and 293. In the first case, they are suitable for wires with a 2.5 mm cross section. In the second case, they are suitable for wires with a direct ground contact.

Connectors for lighting equipment

For electrical work

For electrical work, there are models of the 224, 243, 2273, 273/773, 222 and 221 series. The first are specially designed to connect solid conductors to stranded ones. The second is to serve low-voltage systems. Still others - to serve the wires in junction boxes. Fourth - to serve single-core conductors with a 2.5 mm cross section. Fifth and sixth - to connect and serve any conductors with powerful currents.

For electrical work

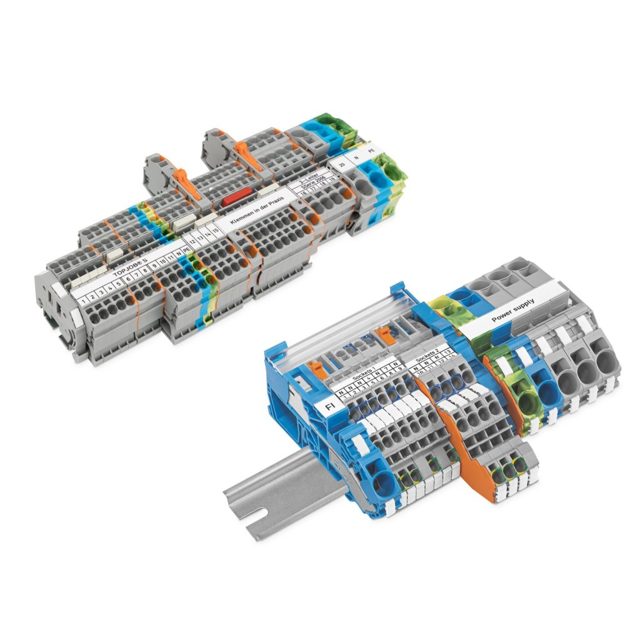

For base mounting

There are three types of connectors for installation on a mounting base - 862, 260-262 and 869. The first are designed for connecting four conductors and help in switching crimped, ultrasonic and unprepared cores. The latter are needed for side and front mounting. Still others have support legs or mounting flanges. Used for 4 mm terminals.

For base mounting

Advantages of Vago terminal blocks

In fact, the described terminal is a flat-spring type clamp, but after being finalized by Vago specialists, it received the following advantages.

- A separate clamp is provided for each cable.

- The dimensions of the terminal blocks are very compact.

- Due to the high quality of the connection, the possibility of inaccurate installation due to the "human factor" is completely excluded.

- Current-carrying elements are impeccably protected from accidental contact.

- During operation, the conductors are not damaged or deformed.

But the main advantage is still increased safety and reliability. After all, if, for example, hidden wiring is installed in the ceiling, then you want to be sure that it will not close, burn out inside the terminal block, or cause other troubles. But, despite such reliability, all described terminal blocks provide for the possibility of control and access.

What are WAGO terminal blocks for?

Everyone knows that when wiring, it often becomes necessary to connect several wires together at once. In this case, using terminal blocks to connect the wires is the best solution.

Unlike twists or solderings, which are, in fact, one-piece connections, Wago terminal blocks allow you to easily and quickly disconnect wires, change the circuit, connect an additional circuit or device. Of course, in especially critical cases, soldering can also be used, but in most connections that will work under normal conditions, the use of Wago terminal blocks is quite enough.

As already mentioned, working with Wago terminals does not require the use of additional tools. The only thing that may be required is a special tool for stripping insulation.

After that, the wire is simply inserted into the terminal block and fixed in it. Another important advantage of Wago terminals is that they allow you to securely connect or extend wires made of different materials and different sections.

As you know, it is unacceptable to connect, for example, copper and aluminum conductors using ordinary twisting.Among other things, the use of Wago terminal blocks saves space in a junction box or shield, and the connection itself is neat and reliable.

Terminal blocks Vaga, characteristics

When carrying out electrical work, the problem often arises of connecting several wires together at once. You can use the method of twisting and soldering wires, but such a connection will be unreliable and unsafe. The connection point may subsequently heat up and even cause a fire in the wiring. In addition, the connection of copper and aluminum wires by twisting is not allowed. The terminals of the German manufacturer WAGO eliminate these problems and differ in characteristics.

Unlike twists and solderings, Vago terminal blocks allow you to easily and quickly disconnect wires, change the circuit, connect an additional circuit or device. Working with Wago terminals does not require the use of additional tools. After stripping, the wire is simply inserted into the terminal block and fixed in it.

The main design feature of the WAGO terminal blocks is the absence of a traditional screw terminal. The fundamental difference between the screwless terminal block is that its installation does not require any tools and skills. The wire is easily inserted into its place and securely clamped by a spring.

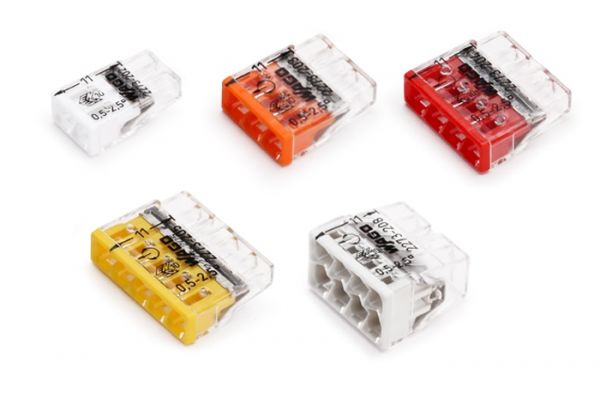

Internal construction of the WAGO terminal

The terminals are available in two versions: disposable, i.e. not allowing the reverse removal of the wire, as well as reusable, in which it is fixed by retracting a special clamp. WAGO terminals for junction boxes allow you to connect from one to eight conductors with a cross section of 1.0-2.5 sq. mm. or three conductors with a cross section of 2.5-4.0 square meters. mm.And terminal blocks for fixtures connect 2-3 conductors with a cross section of 0.5-2.5 square meters. mm.

WAGO 2273 series terminals are designed for single connection and only solid conductors. Used for connecting and branching solid conductors of aluminum and copper or stranded copper wire with a lug in AC electrical circuits. Used in junction boxes. They have reliable protection against accidental contact with current-carrying parts of the connection.

These terminal blocks can be produced with or without special conductive paste filling. The paste serves to prevent oxidation of aluminum wires. Paste terminals are easy to identify and are available in black or dark grey.

WAGO 224 series terminals are used to connect chandeliers, sconces, connects 2, 3 stripped copper and aluminum conductors from 0.5 mm2 to 2.5 mm2, both single-core and stranded. It is possible to measure the electrical parameters of the circuit without violating the isolation of the connection.

WAGO 222 series terminals are reusable. To fix the wires, special orange levers are used. They allow you to easily disconnect the contact when reconfiguring the circuit or testing the circuit. These terminals are designed for connecting and branching solid and stranded copper conductors in AC electrical circuits with a frequency of 50 Hz and voltage up to 380 V.

In order to connect the conductor, you need to lift the orange lever up until it locks. This opens a window for entering the conductor, then it is necessary to insert the conductor with the insulation removed into the inlet of the terminal and lower the lever to its original position.This makes it impossible to spontaneously disconnect the conductors from the terminal.

WAGO 243 series terminals are designed for connecting single-core copper conductors. They are widely used in junction boxes of low-current circuits of video surveillance, burglar alarm, fire fighting, telephony, telecommunications and others. Due to the grooves, they can be assembled into blocks of several terminals.

WAGO 862 series terminals are used to connect copper solid and stranded conductors. They are used when connecting various devices and devices. Fasten to a flat surface with self-tapping screws.

- Advantages of WAGO terminals:

- Quick and easy installation in seconds.

- Connection that does not require additional insulation.

- Ability to connect conductors of various cross-sections from various materials.

- If necessary, the connection can be easily redone.

- The ability to diagnose the circuit without breaking it.

- Accurate installation, connection in cramped conditions or if the accessible part of the wire is too short.

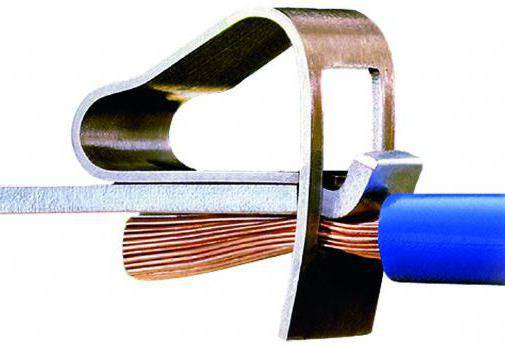

Wago and aluminum wires

In electrical engineering, there is a fundamental rule: you can not connect copper wires with aluminum. This contact forms a galvanic couple. As a result, the twist heats up, oxidizes and eventually burns out. In some cases, the combination of these metals can even cause a fire.

Specialists from Vago took care of this problem. Among their products are terminal blocks designed for connecting copper and aluminum wires. The secret of the product lies in a special conductive paste. It is applied to the clamps of the terminal block.This paste improves electrical contact and prevents heating and oxidation of conductors.

Connecting aluminum and copper wire with a clamp

Scope of use of Wago terminal blocks

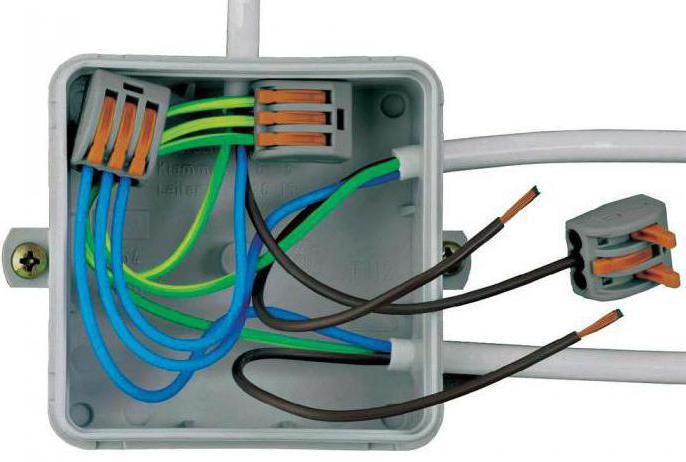

When installing electrical wiring on the scale of large objects and small rooms, it becomes necessary to connect segments of supply cables at nodal points. To do this, switchboards and junction boxes are mounted, into which the ends of the wires are inserted and switched there in the required order.

Therefore, special attention is paid to the connection of electrical wiring parts. One of the methods is twisting followed by soldering and winding a layer of insulating tape

The method is reliable, but laborious and time consuming. To speed up this process without losing the quality of the connection, various types of connectors were invented, which are also called terminal blocks. Most often these are screw-clamp structures in a non-conductive polymer housing.

Wago has come up with a different mechanism and offers a wide range of mounting elements for industrial and domestic facilities:

- terminals for DIN rail mounting;

- installation terminals for junction boxes;

- removable connectors;

- terminals for field mounting.

For work on the distribution of an electrical network with a voltage of up to 380 V, with a circuit load of up to 7 kW and a current of up to 32 A, it is convenient to use Vago clamps with the ability to switch wires with a diameter of 0.75 mm to 4 mm. Recently, clamps for wiring with a core cross section of up to 6 mm have appeared.

Wago terminal blocks are used in various fields.

Wago terminal blocks are used in various fields.

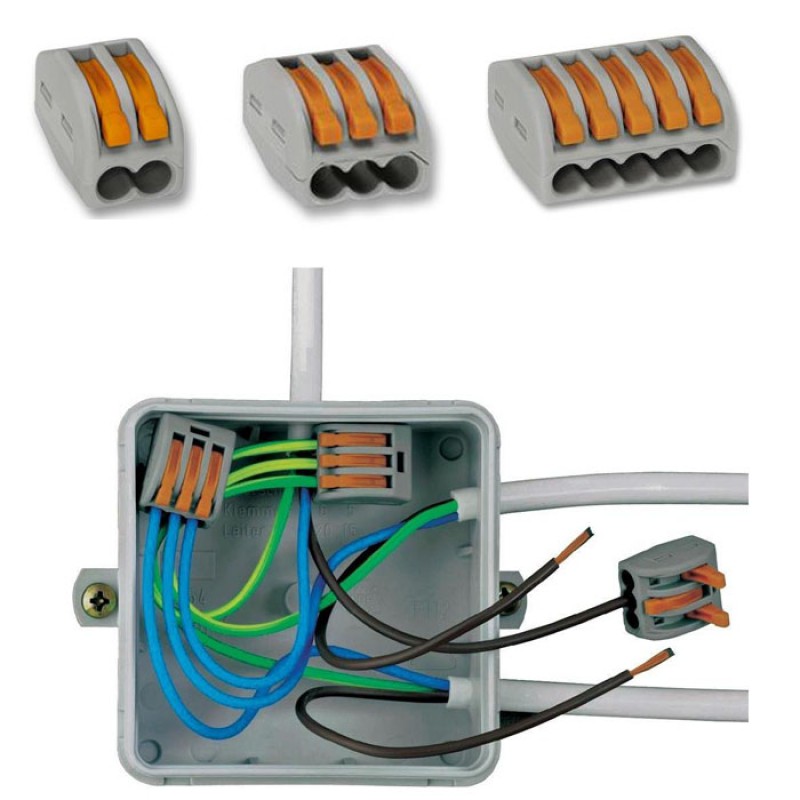

Example 4. Wago terminal blocks: how to use when installing a new junction box

I will give an example of how I make connections in the junction box when installing new electrical wiring.

Here is a cheap option.This is the hallway. Through the 20A machine, a cable with wires with a cross section of 2.5 mm² comes into the box, and diverges into 1 socket (2.5 mm²), lighting and a bell (1.5 mm²).

Initially, after the plasterers, we have this:

Connecting wires in a new junction box. We sign the wires. To the left, a VVG2x1.5 cable sticks out of the wall to the bell. Guess what terminals I will connect it through)?

We clean the wires, determine where we have what. As usual - white phase, blue zero, yellow-green - earth. For switches - white phase, blue is the first key, yellow-green - the second.

Connecting wires in a new junction box. the wires are stripped, the targets are determined

Connecting wires in a new junction box. The stripped wires are ready to be connected.

3-5 minutes - and you're done:

Connecting wires in a new junction box through Vago 773

Close the box with a lid

Now you can plaster and paint or wallpaper

Important - the box must be accessible, at least its location must be known. You never know what can happen in 20-30 years?

Don't forget to check everything!

Wago and aluminum wires

In electrical engineering, there is a fundamental rule: you can not connect copper wires with aluminum. This contact forms a galvanic couple. As a result, the twist heats up, oxidizes and eventually burns out. In some cases, the combination of these metals can even cause a fire.

Specialists from Vago took care of this problem. Among their products are terminal blocks designed for connecting copper and aluminum wires. The secret of the product lies in a special conductive paste. It is applied to the clamps of the terminal block. This paste improves electrical contact and prevents heating and oxidation of conductors.

Connecting aluminum and copper wire with a clamp

Connecting aluminum and copper wire with a clamp

HF device

KV is a spring clip-clamp, consisting of the following structural elements:

- Cases with holes (connectors) made on one of the ends for the entry of conductors.

Additional Information. Depending on the number of connectors, the vago terminal block is called two- or three-pin, five-wire, etc.

Samples of HF manufactured by WAGO

Samples of HF manufactured by WAGO

For the manufacture of the case, polymer dielectrics are used: modified polyamide and polycarbonate, which have the property of self-extinguishing.

- Spring retainer, made in the form of a plate of chromium-nickel spring steel bent in a certain way. The spring clip of the terminal block, due to the narrowly directed clamping force, ensures high-quality electrical contact of the copper bus with the surface of the current-carrying core of the cable.

- A copper bus, with the help of which the conductor cores pressed in the clamp are combined into a single electrical circuit.

Spring clamp device

Spring clamp device

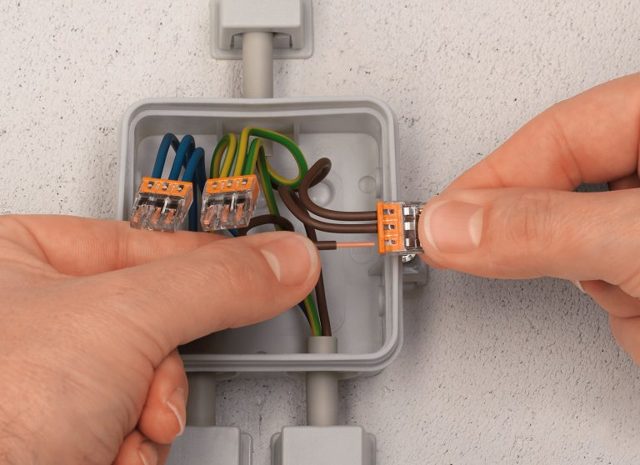

Vago installation recommendations

You don’t need to specially learn how to use the Vago terminal blocks, the installation process is quick and simple. It is much more important not to make a mistake in choosing and make sure that the products correspond to the parameters of the electrical circuits.

Consider the switching of wires using the example of transparent connecting terminals of the 773 series for 3 conductors:

- We clean the end of the wire by about 12 mm - remove the insulation.

- We insert the conductor into the socket, move it to the stop. Ideally, the end of the conductor without insulation should fit entirely into the housing.

- We check the reliability of fastening by slightly pulling the wire in the opposite direction.

Transparent plastic makes it possible to make sure that the core is installed correctly.

On the back of the Vaga for connecting electrical wires there is a special hole for testing. Thanks to him, without opening the case, you can use an indicator screwdriver to determine the technical parameters of the circuit.

When installing removable terminals, the design of which is distinguished by the presence of a lever, it is necessary to perform a couple of additional steps:

- remove the insulation;

- raise the "tongue" up;

- insert the conductor into the hole, push it all the way;

- return the lever to its place;

- visually or slightly pulling, we check the reliability.

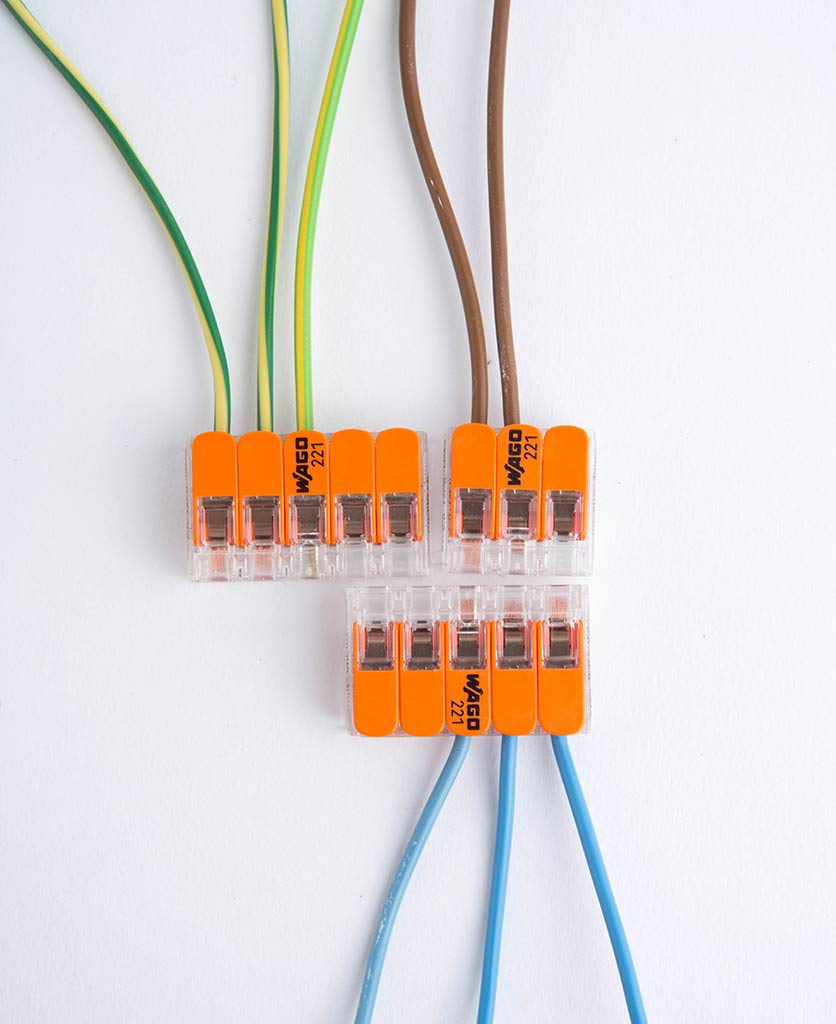

The 221 series terminals are the most convenient for installation: wide levers are easy to raise and lower with a light touch of your fingers.

Usually, special marks are applied to the terminal block housings to help strip the wires.

In order for the process of connecting wires to be quick and without a hitch, you need to remember a few simple rules:

Advantages and disadvantages of Vago clamps

An alternative mounting method is the use of quick-clamp terminal blocks. Terminal clamps "Vago" have a number of undeniable advantages when performing electrical work:

- Possibility of connecting aluminum and copper wires.

- Connection of wires of different diameters from 0.5 to 4.0 sq. mm.

- Use of stranded wires.

- Rated current up to 32A.

- Connection of up to eight wires in one group.

- Quick and easy installation without the use of special tools.

- Isolated electrical safety connection.

- Compact terminal block size.

- Possibility of visual control of connection through the transparent case.

- Separate models allow for collapsible connection.

- The presence of special holes in the housing for connecting instrumentation.

The only drawback of these connectors is their price, but it more than pays off in saving time during installation, reliability and durability of the connection. Also, a high mounting density can be achieved by using the Vago clamp (the photo shows the accuracy of mounting the terminal blocks in the junction box).

A few words for opponents of Wago terminal blocks

For those who talk about the fragility of such terminal blocks, the following can be said. It is enough to compare screw terminal blocks with self-clamping ones. The latter are much easier to install and save a lot of time. But that's not the point. Any screw clamp weakens due to the fact that at the slightest heating of the wire, the oxide on its surface burns out, reducing the cross section. This will lead to even more heating - and so on in a circle. Therefore, screw terminals must be pulled at least once a year, and preferably more often.

Such terminal blocks will have to be stretched periodically to avoid heating

Such terminal blocks will have to be stretched periodically to avoid heating

Now - as for Wago. The clamping springs of these terminal blocks exert constant pressure on the wire, which means that even when the oxide burns, the contact will not weaken.

Types of clips "Vago"

The company produces terminal blocks with clamping devices of the following types:

- Spring clips.

- FIT-CLAMPs.

- CAGE CLAMPs.

Flat spring clamp terminals are the simplest and most cost-effective solution for connecting wires. The clamp is a block of flat steel springs pressed into a polycarbonate body. Blocks are produced with the number of contacts from two to eight.The clamp is intended for a one-time connection of wires, re-use is undesirable, since the spring force is weakened.

FIT-CLAMPs use an indentation contact (IDC) to provide the fastest mounting option. These devices allow you to connect wires without stripping.

In terminal blocks with CAGE CLAMPs, the steel spring is separate from the conductive copper bar. For the manufacture of conductive platinum, tinned copper is used. This design of the clamp allows you to use any wire, including thin and stranded.

Types of terminal blocks

The most common and frequently used of the wago terminal blocks are the wago 222 and wago 773 series connectors, which simplify the work of both a novice electrician and an experienced one. It is necessary to understand what their difference is.

Wago 773 are, in fact, disposable terminal blocks with automatic clamping. Although many use them several times, with difficulty removing the clamped wire, such actions are still not recommended. The fact is that when the bare end is removed from them, the clamping mechanism itself is pulled out, after which, during subsequent use, the contact will not be so strong, although the wire will be clamped in the device.

Terminal blocks vago 773 series

Wago 222 is already a reusable version of such devices. The wire is inserted into the socket and fixed with a special flag. If necessary, the flag is moved away, and the wire is freely removed from the terminal block socket. Such devices do not take up much space in the junction box, are much more convenient and much safer in terms of contact heating, unlike simple twisting.

Similar wago terminal blocks, both 222 and 773 series, can have a different number of contact sockets. The most common when installing electrical wiring in apartments are 2, 4 and 6 wires. Indeed, rarely in home wiring can there be more in one connection. But even if this happens, you can also purchase less popular options that have connectors for 8 or 10 pins.

How to use Vago terminal blocks correctly

The main rule for working with WAGO terminal blocks is to use one terminal for one contact. First of all, the wires are cleaned from insulation by 1-1.2 cm. After that, they are inserted into the connector until it stops. If the connector has a clamp with a lever, then it must first be opened before insertion. When the wire is inserted, the lever is lowered down with force and the terminal strip is pressed.

It is important to ensure that the bare sections of the wire do not extend beyond the fixture. Otherwise, the contact will be broken, as well as the security of the connection.

Important! If something goes wrong, do not use the clamp a second time, even if it looks normal and functional. The same applies to their replacement, which is made from time to time.

Pliers for some terminal blocks

Thus, screw terminal blocks for connecting wires from WAGO are one of the best solutions on the clamping market. They are many times safer than twisting, rarely require any additional tools for work, except for certain types, when terminal pliers may be needed.

You will be interested in Determining the short circuit current

Advantages of Wago connecting terminals

advantage of spring terminal connections Wago spring terminals have many advantages, including:

- The quality of the contact of this terminal does not depend on the qualifications of the master who performed the wiring.

- The ability to quickly connect without the use of a specialized tool.

- Excellent protection against accidental contact with current-carrying surfaces.

- Highest contact reliability.

- Possibility to make changes to the wiring without breaking the connection.

- The presence of a separate socket for each wire.

- High vibration and shock resistance.

- Automatic regulation of clamping force on the wire.

- No need for care and special maintenance.

- The electrical conductors in these terminals have excellent resistance to damage.

- The terminals have a Rostest certificate and a permit from the State Energy Supervision Authority.

- Excellent value for money.

wire clamp During installation, the wire with insulation is inserted into the flat-spring drive until it stops in the corresponding hole, and at this moment the optimum pressure on the contact appears, which does not depend on the cross-sectional area of the conductor. The flat-spring mechanism perfectly presses the wire core to the bus, which completely eliminates its spontaneous shutdown. To carry out the necessary measurements, there is a special hole in the terminal housing, which will provide access and visual contact to the electrical bus. With the correct connection of the terminal, the possibility of touching the elements under voltage, as well as the occurrence of a short circuit, is completely excluded.

secure wire clamp

If necessary, you can disassemble the electrical connection, just pull out the wire with a slight movement by slightly turning it. In order to remove the flexible conductor, it is necessary to slightly squeeze the terminal, then pull on the wire. WAGO terminals allow you to quickly re-switch the electrical circuit without additional stripping of the insulation.

Advantages and disadvantages

The use of the Vago terminals when installing electrical wiring has its advantages compared to other methods.

- High speed of operation due to the simplicity and ease of installation of terminal blocks;

- Reliable fixation of the contact point of the connected cables;

- There is no need for additional isolation of the connection;

- Small size saves and organizes space in the junction box;

- When using reusable connectors, it is possible to quickly redo the connection.

However, “Vago” also has disadvantages, which include:

- the high cost of the product, which especially affects the costs for large volumes of work;

- according to the rules for the operation of electrical installations, free access must be provided to all points where Vago is installed;

- an abundance of cheap low-quality fakes.

Areas of use

Often, in the production of electrical installation, it is necessary to connect not two, but four or more wires. It is clear that it is almost impossible to solder such a thick twist. In this case, the best option would be to use such terminal blocks.

Another plus of their use is the ability to unmount the connection, which cannot be said about the soldered twist, where the wires will have to be cut. And when using wago connecting terminals, such a problem disappears, it will not be difficult to unplug the connection.It also allows you to add wires to the connection without unnecessary problems, such as removing the insulating tape.

Installation using such devices is carried out without the use of any additional tools, only a knife or a special device is useful in order to remove the insulation. After that, you only need to insert the cleaned end into the spring terminal block and fix it. This allows you to connect both different materials and wiring with different cross sections. Some of them are fixed automatically.

The connection will be as reliable as solder twisting, but it looks much neater. Well, even a child will figure out how to use them to connect the cable.