- What types of glue can be and methods for performing adhesive installation

- hot melt adhesive

- Adhesive for cold gluing

- Scope of application

- The main types of adhesives

- Working with a cast iron radiator with a leak

- Why is a cleanup needed?

- Connection of pipes made of metal-plastic and PP

- Tools and materials

- Coupling

- Connection with compression fittings

- Flanging

- About polypropylene

- Overview of popular brands and manufacturers

- Cosmoplast 500

- Dow Corning 7091

- WEICON Easy-Mix PE-PP

- Tangit

- Genova

- Griffon

- Gebsoplast

- Reasons for the formation of defects when gluing polypropylene and PVC pipes

- Common Mistakes

- How to glue polypropylene pipes

- Peculiarities

- Step by step bonding of polypropylene pipes

- Brief instruction

- Kolner KPWM 800MC

- Criteria for choosing an adhesive for PVC sewer pipes

- How to glue polypropylene

- Rules for installing PVC pipes on glue

- Working with a cast iron radiator with a leak

What types of glue can be and methods for performing adhesive installation

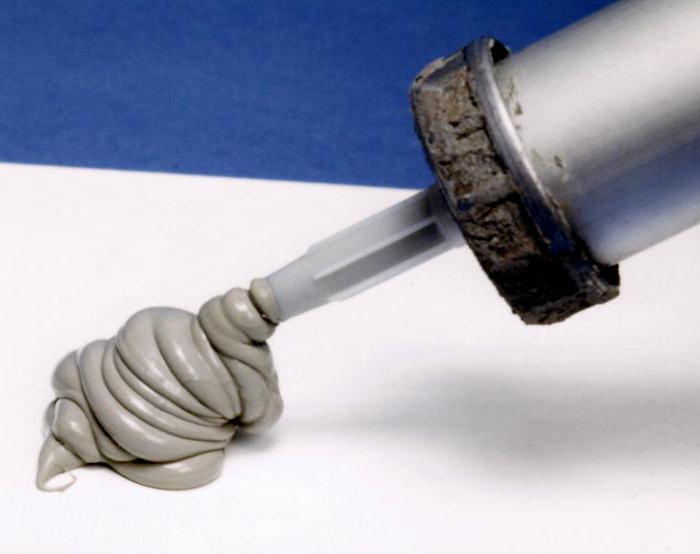

The chemical compositions used for adhesive mounting of plastic pipes can be divided into two groups.

hot melt adhesive

This glue is used, as a rule, when working with sewer pipes.Adhesive compositions of this type can be successfully used when connecting both PVC water pipes and air vents.

If such an adhesive is used correctly, then the result is a high-quality connection, characterized by great durability. As a rule, these adhesive compositions are accompanied by the corresponding manufacturer's instructions. Following it, you can achieve the correct use of the substance and, as a result, completely sealed joints can be obtained.

ATTENTION!!! Adhesive for the installation of PVC plastic sewer pipes is a flammable substance

Therefore, it is especially important to adhere to fire safety rules. Moreover, this substance should not be allowed to come into contact with the skin.

Moreover, this substance should not be allowed to come into contact with the skin.

Even if the seams are not processed clearly enough, the connection of pipes using this adhesive will always be of high quality. But to perform the installation, you need a special soldering iron for plastic. However, it is not at all necessary to acquire a highly professional tool. A small amateur soldering iron will be quite sufficient to achieve an excellent result.

A soldering iron is needed to warm up the ends of the assembled pipeline elements. The device, as a rule, is completed with a set of nozzles, which make it possible to mount pipes of various sections. The tool includes two main elements:

- heating elements;

- sole.

To make high-quality soldering, you need to familiarize yourself with all the temperature conditions of the tool. And in each case, choose the appropriate mode. For example, if we are talking about plumbing, then the heating temperature should be 260 ° C.

Adhesive for cold gluing

Cold bonding is the second welding method. The adhesive used in this case for the installation of plastic pipes can be:

- universal;

- or specialized.

So that you know the difference between these adhesives, let's clarify that:

- specialized glue can only be used for gluing pipes;

- universal glue can be used when working with any products consisting of polyvinyl chloride. For example, linoleum can be soldered without problems with universal cold welding glue.

If the installation of plastic pipes is carried out using cold welding, then the socket method is most often used.

Mix the adhesive thoroughly before use. To ensure a better connection, the narrow parts of the pipes are made a little rough during manufacture. During installation, the operations are performed in the following order:

- The glue is thoroughly mixed.

- The inside of the socket is degreased.

- An adhesive composition is applied to the pipe and, finally, chemical welding itself is performed.

Especially high quality must be the processing of the surfaces to be glued. In particular, they must be cleaned of any contamination. If this is neglected, the connection may not be of very high quality.

As a rule, the glued parts hold for about 15 seconds. During gluing, they cannot be rotated or moved relative to each other. Excess glue can be removed with any napkin.

ATTENTION!!! To ensure the reliability of the connection, the movement of the newly glued elements must be avoided for a quarter of an hour. Filling the mounted system with water is possible only after a day.

Scope of application

Depending on the types of pipes (pressure, non-pressure, acid-resistant), they are used:

- Non-pressure pipes are applicable in the arrangement of domestic, storm and industrial sewage systems, and with their help it is possible to lay a sufficiently extended system, with modest dimensions, capable of evacuating a large amount of wastewater.

The sewer pipe has a maximum working pressure limit of 15 MPa. In practice, the pressure in the systems ranges from 0.5 to 0.63 MPa.

PVC pipes are used in the arrangement of sewer systems

- Pressure PVC pipe for glue is used in the arrangement of water treatment systems for civil facilities (fountains, water parks, swimming pools), for laying cold water supply systems in multi-apartment and private residential buildings, for arranging irrigation water pipes, etc.

Adhesive PVC pipes are used in the creation of many objects, including the arrangement of such beautiful pools

The adhesive pipeline is able to withstand operating pressure up to 2 MPa. At higher values, the glue joint may not withstand, and the pipe will burst.

- Acid-resistant PVC pipes are used to transport chemical liquids, water in metallurgy, energy, chemical and food industries, etc.

The main types of adhesives

If you need glue for plastic, then you should know that it has two varieties: thermosetting and thermoplastic composition. The basis of the first are epoxy, thermoset and polyester resins. The second category of adhesives can be divided into two directions, the first is made on the basis of rubbers, while the second is based on resins.

Thermoplastic compounds soften materials and dissolve under the influence of temperature.If we compare them with thermosets, they do not change their chemical structure when glued, which is a significant plus. Glue for polypropylene can also be divided by the number of components, such mixtures can be one- or two-component. The first are presented in finished form in one package. This includes Moment glue for polypropylene. And the second is packaged in two packages, each of which contains ingredients for mixing. As an example of a one-component composition, consider Cosmoplast 500, which is used to connect profiles in window production. If you need a two-component composition, then you can use an epoxy adhesive for plastic, which is made on the basis of a hardener and epoxy resin. The two-component adhesive has the advantage of a long shelf life. The reason is that before joining the ingredients do not come into contact and curing does not occur.

Working with a cast iron radiator with a leak

It happens that the heating battery has leaked - the threaded joint has deteriorated, a leak has appeared on the section. Repair will require epoxy glue and bandage. The material is impregnated with glue, applied to the hole area. After setting, you can paint over this area in the main color. This measure is considered temporary, and after turning off the heating, it is better to replace the radiator.

Cold welding of batteries is also used. A special tool is kneaded in the hands, applied to the site of injury. It quickly melts, seizes and allows the “patch” to exist until the heating is turned off.

Do not try to glue radiators with a strong leak, which led to an emergency.It is better to immediately call a team of specialists who will stop the leak and change the radiator to a new one.

Carrying out construction work today is impossible to imagine without the use of high-tech materials. The invention of polymers led to the emergence of new pipes. Such products are characterized by high strength and durability. And the ease of installation ensured a high demand for plastic pipe products in many industrial areas. We are talking, first of all, about PVC pipes, a special place among which is occupied by adhesive products.

Joining PVC pipes with glue is called cold or chemical welding.

Why is a cleanup needed?

The principle of welding pprc pipelines is to heat the polymer material to a viscous state. Then there is a contact of the hot pipe with the coupling, the result is a soldering of the connection. However, reliability may be reduced if there is aluminum foil used for reinforcement in the contact zone. In this place there will be no contact of polymers, which can lead to depressurization.

- Removing the foil layer in the soldering area will not reduce the maximum pressure value.

- If this is not done, the gradual destruction of the joint is possible. The risk increases with frequent water hammer in the water supply system.

- Older models of polypropylene pipes have an outer layer of foil. Their diameter is larger than the standard by 1.8-2 mm. Without stripping, the pipe will not fit into the socket of the coupling.

A similar technology is used for all types of polypropylene pipelines. An exception is the use of products with fiberglass reinforcement.When heated, it partially melts and does not reduce the reliability of soldering. But for such models, it is necessary to increase the heating time depending on the diameter.

Important: the heating temperature for nozzles of different diameters is the same - up to + 280 ° C. The contact time with the soldering iron is from 5 sec (16 mm) to 80 sec (160 mm).

Connection of pipes made of metal-plastic and PP

Metal-plastic pipes differ from polypropylene ones in the structure of the material and installation technology. Therefore, beginners may have difficulties with docking. In order to avoid problems in the form of leaks, we recommend that you carefully read the materials.

Tools and materials

To make the transition from metal-plastic to polypropylene, you will need the following tools:

- wrench;

- gas key;

- tow (combed linen);

- silicone sealant;

- mounting paste.

The list depends on the type of joining of parts.

Coupling

The union connection of the metal-plastic pipe with PP is suitable for pipelines with a diameter of less than 40 mm. In addition to the threaded fitting, you will need an American (detachable element). Installation must be carried out according to the following plan:

- Break the American into two parts.

- Wrap tow on the part with external thread, then coat with silicone sealant.

- Screw this part into the female part of the fitting.

- Do the same work with the second fitting with an external thread, which then needs to be screwed into the other half of the American.

- Connect the two parts of the detachable part using an adjustable or gas wrench.

When using this type of docking of MP and PP products located in the wall, it is additionally necessary to equip an opening niche.

Connection with compression fittings

Connecting pipes with compression fittings is the easiest and cheapest way.But it is worth considering the restrictions on the temperature of the water that will flow through the pipeline - it should not exceed 50 ° C. The disadvantage is the impossibility of working in cramped conditions.

Bilateral compression elements are a plastic cylinder with threads on both sides and two union nuts with o-rings. These parts can be used to attach system elements of different diameters.

The process looks like this:

- Insert the pipes into the fitting holes on both sides.

- Tighten nuts.

Flanging

Flange joints can also be used to join two pipes made of different materials. This method is suitable for a pipeline with a diameter of more than 40 mm. Such a connection involves the installation of flanged valves.

There are no such accessories for metal-plastic systems, so you will have to use an end fitting with an external thread and a flange with an internal thread. The installation process itself must be performed as follows:

- The flange is screwed onto the fitting using tow.

- Fit fasteners are mounted on the water supply.

For polypropylene products, special flanges are used that are soldered onto them.

About polypropylene

Polypropylene is a polymerization product belonging to the class of polyolefins. It has a solid structure and white color. In simple terms, this is plastic used in various areas: everyday life, construction, etc. Today this material is the most demanded, because of its wear-resistant properties and versatility. It is indispensable in high-tech products, and is also useful for:

- electricity;

- electronics;

- medicine;

- construction;

- polygraphy;

- automotive industry;

- furniture industry;

- creation of plastic utensils and packaging.

Polymer products are found everywhere. They have firmly entered people's lives, but in this article we will take a closer look at polypropylene pipes, namely their gluing. After all, not everyone knows how to glue polypropylene pipes.

Overview of popular brands and manufacturers

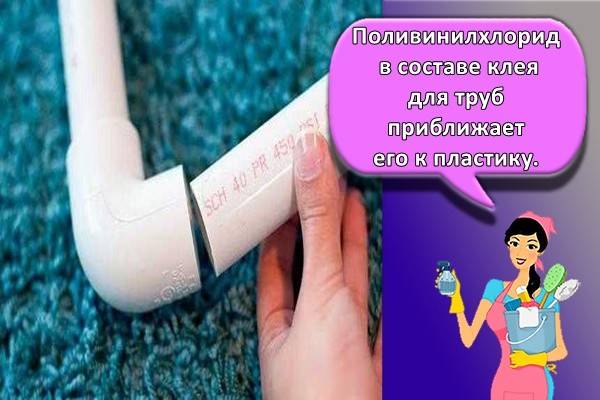

Polyvinyl chloride in pipe adhesive brings it closer to plastic. For a flexible connection of hot water communications, styrene-butadiene rubber is added. Thanks to the additive that increases the strength of the adhesive, the joints will withstand water hammer and high water pressure. Methacrylate increases the resistance of compounds to the alternation of low and high temperatures.

Manufacturers add various substances to the main composition that affect the hardening time, transparency, consistency and service life of the adhesive. Various brands offer ready-made products or components for preparing the mixture.

Cosmoplast 500

A one-component composition is used for the installation of home and industrial communication systems. Glue Features:

- suitable for connecting parts at an angle of 45 degrees;

- resistant to chlorine, heat and water;

- dries in 3 seconds;

- hardens in 16 hours at a temperature of +20 degrees.

Glue is applied to one of the two surfaces to be glued. Minus means - liquid consistency. Therefore, the walls of a sealed crack can diverge from the pressure of water.

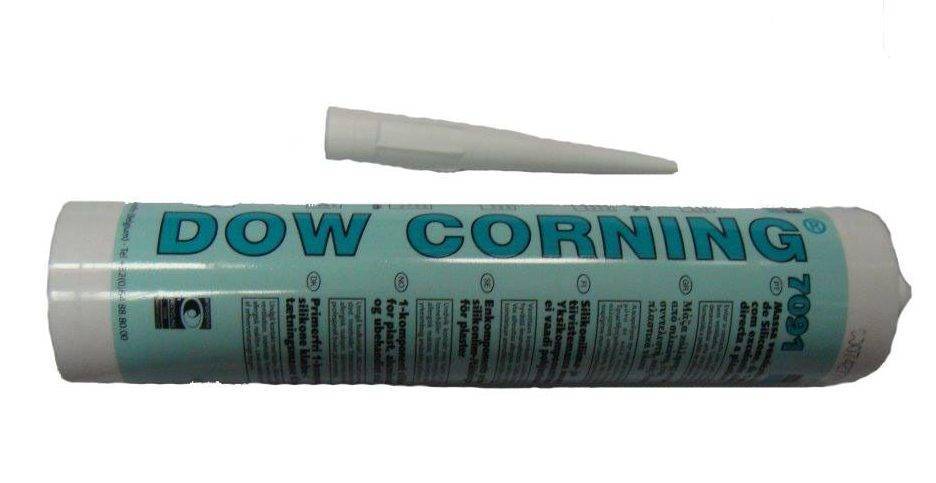

Dow Corning 7091

Adhesive sealant has the following characteristics:

- liquid;

- transparent;

- resistant to temperatures up to +180 degrees.

The universal agent works like glue when applied with a layer of 5 millimeters. A dense paste 25 millimeters thick tightly closes the cracks. It is possible to correct surfaces within 15 minutes after pasting.

WEICON Easy-Mix PE-PP

The two-component composition includes acrylate. Adhesive of high adhesion can be applied to the uncleaned surface. The compound hardens within a day at room temperature.

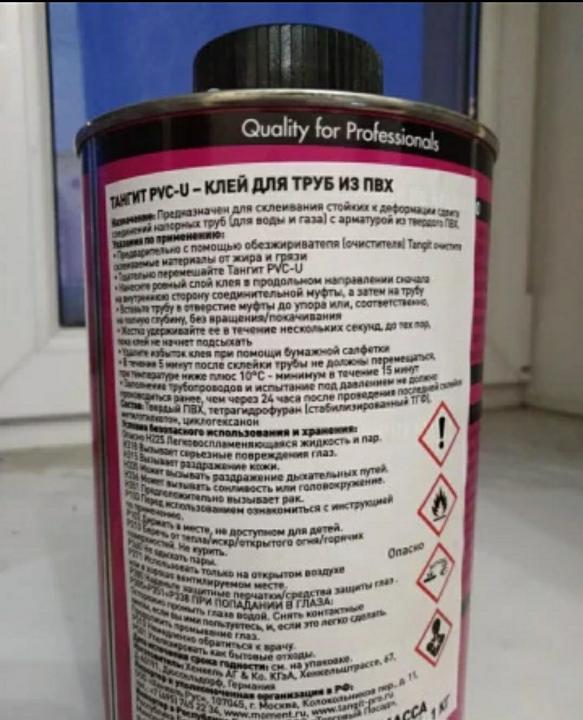

Tangit

Properties of the German tool for the installation of water-pressure communications and gas pipelines:

- transparent;

- dries in 4 minutes;

- gains strength after 24 hours.

The adhesive is certified to work with potable water. A brush is included with the package.

Genova

The American manufacturer offers a universal tool for mounting any plastic pipes and fittings. The glue dissolves the top layer of surfaces, and after hardening connects them into a solid solid structure. The composition is also suitable for the assembly of water supply systems for swimming pools and drinking.

Griffon

The Dutch brand of adhesives and solvents offers a special fast curing agent for joining pipe, fitting and fitting structures. Liquid emulsion connects parts with a diameter of up to 40 centimeters and fills voids with a thickness of 0.6 millimeters.

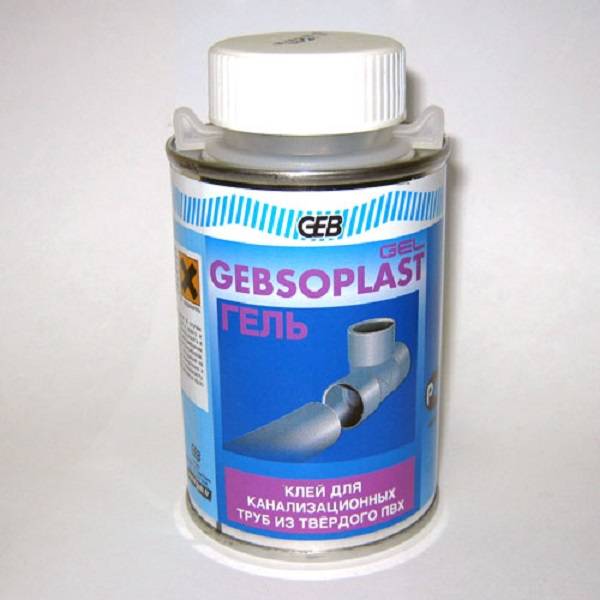

Gebsoplast

Sewer and water pipes, mounted with French glue-gel, will withstand a pressure of 40 bar and temperatures up to 90 degrees Celsius.

Tool properties:

- does not flow down a vertical surface;

- does not contain chlorine;

- hardens within 24 hours;

- brush as a gift.

Glue connects pipes of different purposes and types:

- household drains from dishwashers and washing machines;

- systems with valves;

- rainwater drainage channels;

- underground communications;

- industrial pipes.

The product is produced in plastic and iron cans of 250, 500 and 1000 milliliters, as well as in a tube of 125 milliliters. The manufacturer does not recommend shaking the glue, as the product liquefies.

Reasons for the formation of defects when gluing polypropylene and PVC pipes

The surface is partially not glued as a result of the uneven application of the mixture, as well as the presence of significant irregularities in the treated areas.

The surface is partially not glued as a result of the uneven application of the mixture, as well as the presence of significant irregularities in the treated areas.

Overdried layers of adhesive composition lead to the fact that the connection of the pipeline elements did not occur. Installation must be carried out within the time specified in the instructions.

A soft adhesive layer occurs as a result of installation at low air temperature or insufficient time for the adhesive to cure. The solvent has not been completely removed from the adhesive formulation.

The adhesive layer has a porous structure with insufficient mixing of the mixture and the formation of air inclusions.

Weak fixation of the glued elements leads to skew and displacement of the pipeline connections. Pollution on the bonded surface makes it difficult to fix the adhesive at the joints.

Before work, you need to familiarize yourself with the information on the methods of applying glue for a polypropylene pipe and the conditions for its storage. When repairing a piping system made of PVC and other plastic products, it is necessary to choose the right special adhesives. This will allow you to install with great efficiency and avoid defects.

Common Mistakes

Among the errors that occur during welding, we single out the most frequent:

- Insufficient pre-cleaning of parts. This leads to a weakening of the joint.

- Misalignment of pipe and fitting. In 1-2 seconds, this flaw can be corrected; after the joint has solidified, this cannot be done.

- Inconsistency of the material of the welded products.It turns out an unreliable and short-lived connection.

- Violation of work technology, non-compliance with temperature and heating time.

You can avoid mistakes if you take into account the recommendations of specialists, comply with the requirements for the performance of work, and do not violate the technology of the welding process.

Such work is quite within the power of a technically competent person who is able to work with his hands.

If you haven’t done this before, you can invite a plumber to the first stage and take a closer look at his actions.

Views: 654

How to glue polypropylene pipes

For the connection process you will need:

- PVC pipe;

- pipe cutter;

- adhesive agent;

- a special gun for easy application of glue produced in tubes;

- brush (natural bristles) for applying the mass, packaged in jars.

- Mark the desired length on the pipe.

- According to the marks with a pipe cutter, pipes are cut.

- The edges are cleaned with sandpaper to roughen, which provides better adhesion.

- Mark with a marker to what distance the connection will occur.

- Degrease the ends with acetone or alcohol.

- Apply a thin layer evenly adhesive solution.

- The connection is made according to the marks.

- If there are surpluses, they are removed.

- Wait for complete drying (about a day).

- Check - pressurized water supply.

During operation, it is necessary to maintain an operating temperature of 5-35 degrees.

Recommended videos on the topic:

In case of emergency repairs, you will need to turn off the water supply, since the flow will not fully correct the problem. After that, the leakage site is dried, cleaned and degreased.

Fine sandpaper is used to clean the plane to roughen it so that the adhesion is better.Next, the adhesive is evenly distributed and a sealing tape is applied in a spiral. Water is filled into the system after the repair joint has dried.

In the process of work, fuzziness may arise:

- Bad adhesive. Occurs due to the application of the adhesive solution not on the entire plane or the application was uneven.

- Non-gluing. Occurs due to overexposure of the adhesive layer without bonding.

- The softness of the connection. It is possible that during the commissioning of the product, the pipes did not wait for complete drying, or the temperature regime was not observed during operation.

- The porosity of the connection. Occurs when air appears in the adhesive layer, which indicates poor pre-mixing.

Peculiarities

Quite often, the assembly and installation of pipes made of polymeric materials is performed by diffusion welding or, to put it differently, by soldering pipes. In the case of using a hot glue compound, the adhesive will require preheating. Also, this method involves the use of a special soldering machine, which will ensure the most tight connection.

The composition for plastic pipes, the so-called cold welding, is becoming more and more popular with ordinary buyers every day.

The undeniable advantages of adhesive bonding:

- the risk of leaks is practically reduced to zero due to the fact that the parts are connected at the molecular level;

- gluing is one of the cheapest ways to connect pipes, which will not increase the cost of repairs;

- the use of glue does not require any special skills, and such a process can be done independently;

- using glue, you can mount both polyethylene and polypropylene, as well as metal-plastic pipes.

The principle of interaction of all adhesive compositions and polymer pipes is approximately the same: the adhesive compositions partially dissolve the PVC material, firmly binding the particles, since the adhesive contains special additives that improve adhesion. At the moment of bonding, the solvent evaporates, the molecular chains of the polymer are intertwined, and the output is a hardening composition that gains strength over time.

Step by step bonding of polypropylene pipes

Connecting pipes with glue requires choosing the right means, as well as studying the instructions for use, which is located on the back of the tube.

Stages of gluing polypropylene pipes and general rules for the work.

Required tools:

- cordless pipe cutter, precision scissors or saw with fine teeth;

- glue gun or brush;

- roulette;

- clutch.

Before gluing the pipes, you need to close the general tap and prepare all the necessary fixtures. Then you can start the process.

Step-by-step instructions on how to glue polypropylene pipes:

- cut pipes of the required size;

- clean the bumps and burrs with fine sandpaper;

- connect the parts and put marks in the bonding areas;

- degrease the joints;

- apply glue with a gun or brush (it all depends on the consistency of the product);

- connect the pipeline and remove excess glue;

- for a strong construction, it is necessary to use a sleeve, over the butt bonding. It is evenly placed on both pipes and glued to the same glue.

To check the connection, a test is performed after 24 hours. A strong pressure of water is allowed into the pipeline.In the case of a positive result and correctly done work, there will be no leaks.

> When buying glue for polypropylene, you need to study for what type of work it is suitable, namely for repair or plumbing installation. When choosing high-quality adhesive masses, you can assemble water pipes and sewerage systems that will last without leaks for many years.

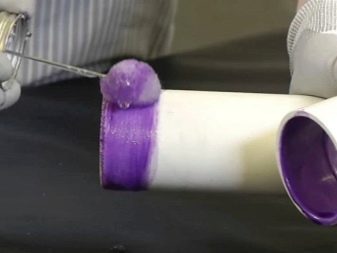

Brief instruction

First, fittings and pipes are prepared for welding, which require processing. The foil layer must be removed when it comes to reinforced products. It is necessary to degrease all the parts that will then need to be soldered.

Video 3. Soldering PVC pipe on the wall with a soldering iron

On the one hand, a connecting element is mounted on the heater of the welder, and the pipe itself is fixed at the other end. The coupling is used somewhat differently.

The main thing is to observe when welding the time required for the processing of certain parts. Do-it-yourself rearrangement, fixation and heating require compliance with certain time intervals.

Parts will not be deformed only if each action is performed smoothly. On the welding machine, you need to set the operating melting temperature. Usually it is equal to 260 degrees. Otherwise soldering is impossible.

It is necessary to wait some time after the completion of the process for the structure to cool down. When using a coupler, observe the same requirements.

Video 4. Do-it-yourself soldering PVC pipeline

Kolner KPWM 800MC

The plastic pipe welding equipment is equipped with 6 nozzles with a special coating, which makes welding easier. The device consumes 800 W of power, which indicates its efficiency and reliability.Heats up instantly to operating temperature of 300°C. Attached are the nozzles necessary for plumbing, a massive stand for stabilizing and fixing the soldering iron and a container for storing equipment and accessories. After soldering, it is necessary to hold the connection for a short time to pair and cool the welded elements. It features a long, 2-meter cable. The body is made in yellow.

Among the advantages it should be noted:

- Optimum weight and size of the device;

- The presence of an auto-shutdown function;

- Decent price tag.

The soldering iron has only one drawback, which is the unsteadiness of the substrate and does not affect the functionality. The stand can be made by hand.

Criteria for choosing an adhesive for PVC sewer pipes

The right choice of adhesive will provide a secure connection that is as good as a solid pipe. It is necessary to consider for what purposes the substance is chosen. In order not to spoil the appearance of the pipes, you need to give preference to transparent compositions.

What you should pay attention to when choosing glue:

- Type of substance (cold or hot gluing);

- Setting time of the material;

- Mode of application;

- Storage period.

The composition of the adhesive consists of polyvinyl chloride. It provides the adhesion and adhesive function of the substance. After applying the glue, the substance begins to solidify. During this time, impurities evaporate, and the PVC molecules of the compound adhere to the molecules of the pipe. This is how a unified education is obtained.

The setting time of the substance during hot gluing should be 1 minute at a temperature of 40 degrees and 4 minutes at a room microclimate. A hot joint is characterized by a long solidification period. The mixture will dry after half an hour, harden - 2.5 hours. But the full polymerization will take a whole day.

How to glue polypropylene

Before proceeding to installation work pipelines made of polypropylene, you must do the following:

- Determine the need for materials necessary for the production of work;

- Purchase and deliver them;

- Prepare the necessary tools (pipe cutter, files, hacksaw, grinder, paint brushes, sandpaper, puncher, screwdriver, screwdrivers, hammer, tape measure, marker), as well as personal protective equipment (gloves, glasses, respirator);

- Prepare the workplace (provide comfortable and safe working conditions).

After completing these measures, proceed directly to the installation in the following order:

- Marking pipes according to the required dimensions.

- Cutting according to the markup.

- Cleaning from burrs and contamination of the ends and seats of the connected pipelines.

- Assembling the pipeline "dry" and marking the fitting dimensions for fittings couplings.

- Degreasing the surfaces to be joined with a solvent or acetone.

- Application of adhesive in a uniform thin layer with a brush or gun (depending on the type and consistency of the selected adhesive).

- Assembly in the required sequence of pipeline parts according to the marks with mandatory fixation for 20 seconds.

- Removing excess glue.

- Fixing the assembled pipeline to building structures using brackets and clamps (it is allowed to move the glued pipeline units no earlier than 20 minutes).

- After a day, perform a hydraulic test of the pipeline.

This is interesting: Types of adhesives for laying roofing material: we paint all the nuances

Rules for installing PVC pipes on glue

The optimum ambient temperature during the installation of PVC pipelines on glue is in the range from 0 to 35 ° C, at lower rates, the gluing time is increased. For installation, you will need scissors for cutting polymeric materials, sandpaper, a sharp object or a special chamfer for removing external or internal chamfers on a pipe fragment.

The instructions for installing a PVC pipeline on an adhesive composition consist of the following items:

- To start the installation of adhesive PVC pipes, it is necessary to cut the pipes of the required length. Before cutting the pipe to the required length, allowances are left at the ends of the pipe segment in order to securely fix the pipe in the fittings. These tolerances must correspond to the depth of the pipe entering the fitting during gluing.Fig. 11 Physico-chemical parameters of Bailey adhesive PVC adhesive pipes can be easily cut with a pipe cutter or a conventional wood saw. After sawing the pipe, burrs may form at its ends, which must be removed.

- Before gluing the surface of the ends of the pipes, it is necessary to roughen them: the outer end of the pipe and the inner surface of the fitting are treated with sandpaper. The treated ends are degreased with methylene chloride, which partially dissolves the pipe material.

- The glue is thoroughly mixed with a hard rod or wood chips.

- Glue PVC pipes after preparing the ends of the pipes, glue is applied to 2/3 of the socket depth and to the entire length of the calibrated end of the pipe. The glue is applied quickly, in a uniform thin layer using soft brushes 30-40 mm wide in the longitudinal direction on the outer shell of the pipe and the inner socket of the second pipe or shaped part.

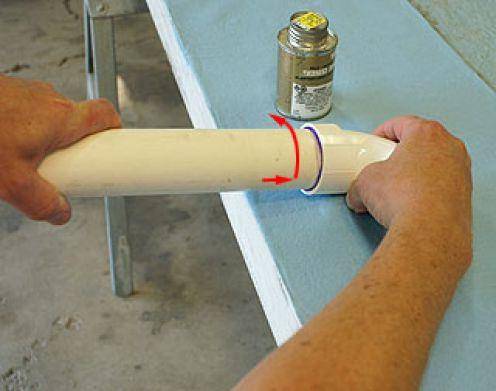

- After applying glue to both connected elements, it is necessary to immediately insert the pipe into the socket (coupling) until it stops, then, in order to obtain better contact between the surfaces, turn it 1/4 turn. It should take no more than three minutes to degrease the pipe, apply glue and insert the pipe into the joint. The elements to be joined must be pressed and held in this state for at least one minute.

- With proper bonding, an extruded thin bead of glue should appear around the joint. When gluing, the pipe material copolymerizes to form a homogeneous joint. It takes several hours to fully stabilize the connection.

- If the ambient temperature is below 0 ° C, the time interval for holding in a stationary position is increased by two to three times.

- To precisely match the parts, you should connect them first without applying a solvent. Then make marks on them in the form of lines. Then separate them, smear them with a solvent and reconnect them by aligning the marks on the parts to be glued. In case of an installation error, the connection should be disassembled in the first seconds, after which the surfaces should be immediately cleaned with a degreaser.

- Inspection or operation of PVC pipelines is allowed 24 hours after assembly.

Rice. 12 Stages of assembling a PVC pipeline with glue

p>

Working with a cast iron radiator with a leak

It happens that the heating battery has leaked - the threaded joint has deteriorated, a leak has appeared on the section. Repair will require epoxy glue and bandage. The material is impregnated with glue, applied to the hole area. After setting, you can paint over this area in the main color. This measure is considered temporary, and after turning off the heating, it is better to replace the radiator.

Cold welding of batteries is also used. A special tool is kneaded in the hands, applied to the site of injury. It quickly melts, seizes and allows the “patch” to exist until the heating is turned off.

Do not try to glue radiators with a strong leak, which led to an emergency. It is better to immediately call a team of specialists who will stop the leak and change the radiator to a new one.

Carrying out construction work today is impossible to imagine without the use of high-tech materials. The invention of polymers led to the emergence of new pipes. Such products are characterized by high strength and durability. And the ease of installation ensured a high demand for plastic pipe products in many industrial areas. We are talking, first of all, about PVC pipes, a special place among which is occupied by adhesive products.

Joining PVC pipes with glue is called cold or chemical welding.