- Storage rules

- Properties of electrode coating components

- Classification of electrodes for welding carbon and low alloy structural steels in accordance with DIN 1913 (German standard)

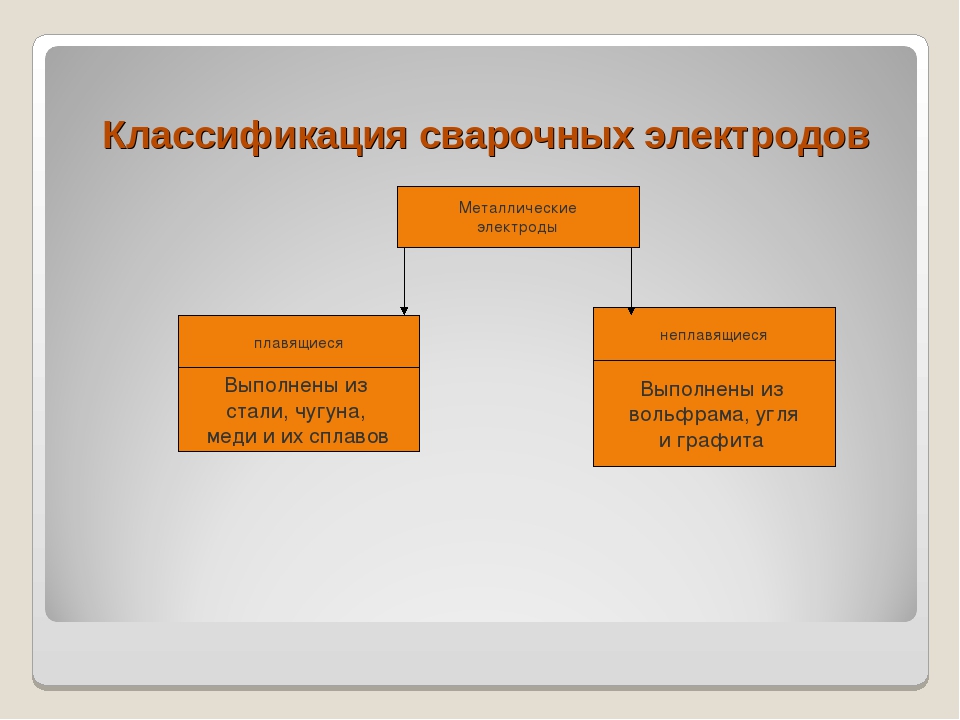

- Classification of steel coated electrodes for manual arc welding

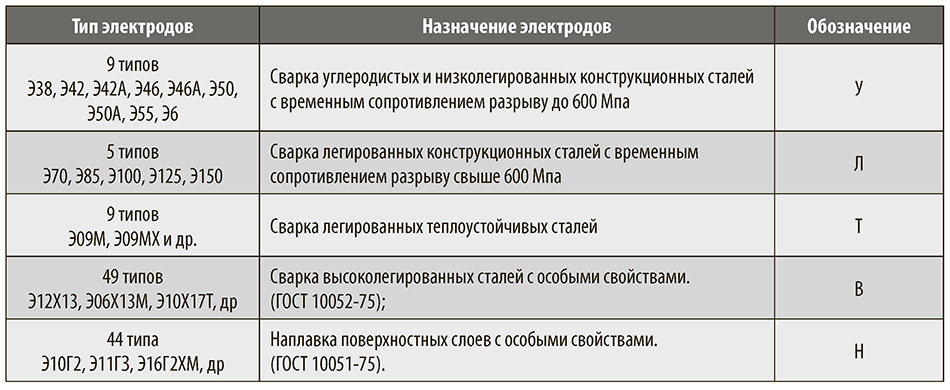

- Classification of coated electrodes, depending on their purpose

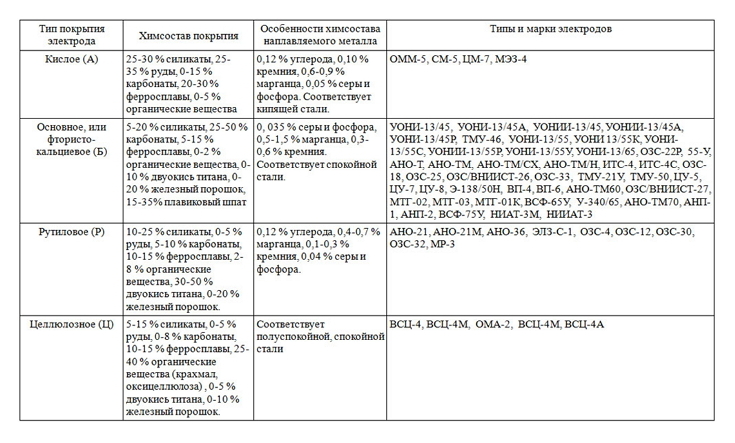

- Classification of electrodes, depending on the type of coating

- Classification of electrodes by coating thickness

- Classification of electrodes by quality

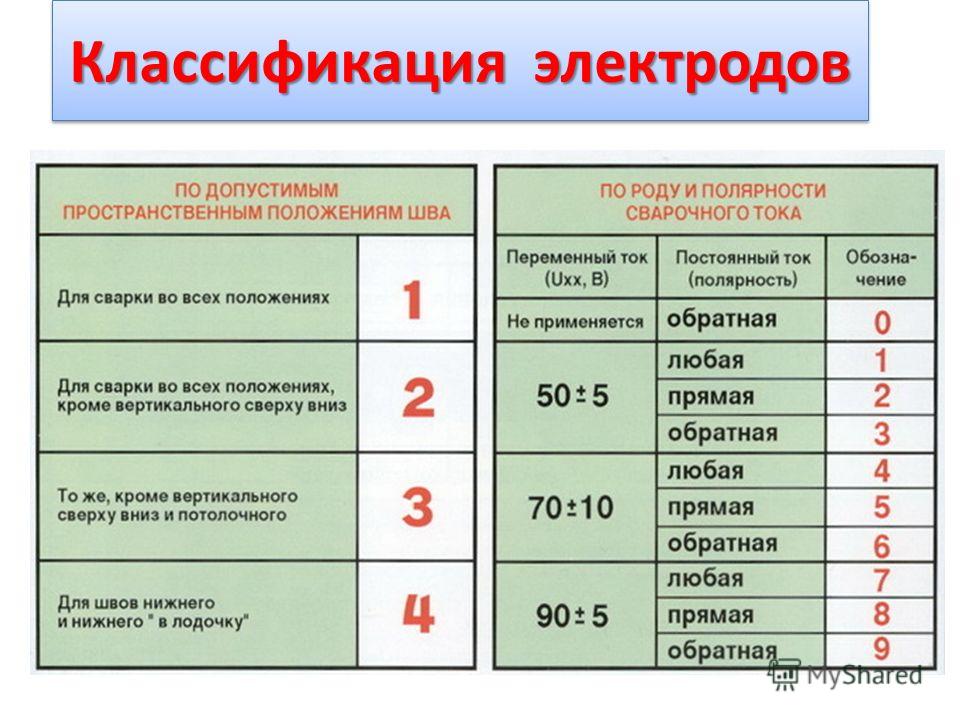

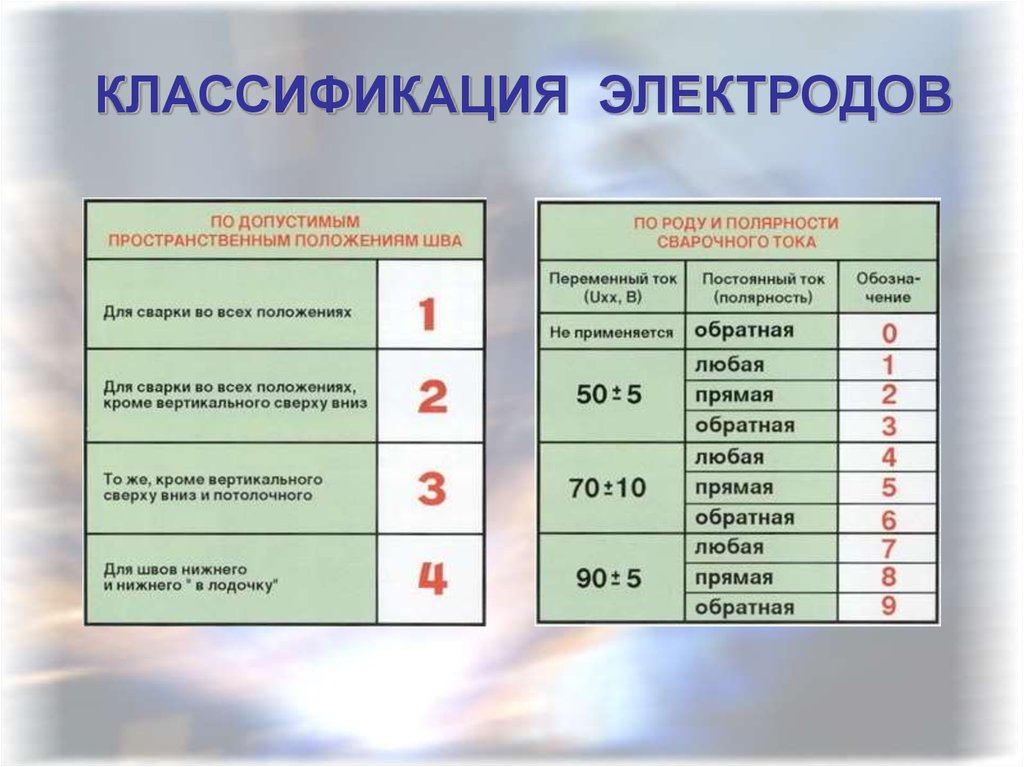

- Classification of electrodes by spatial position during welding

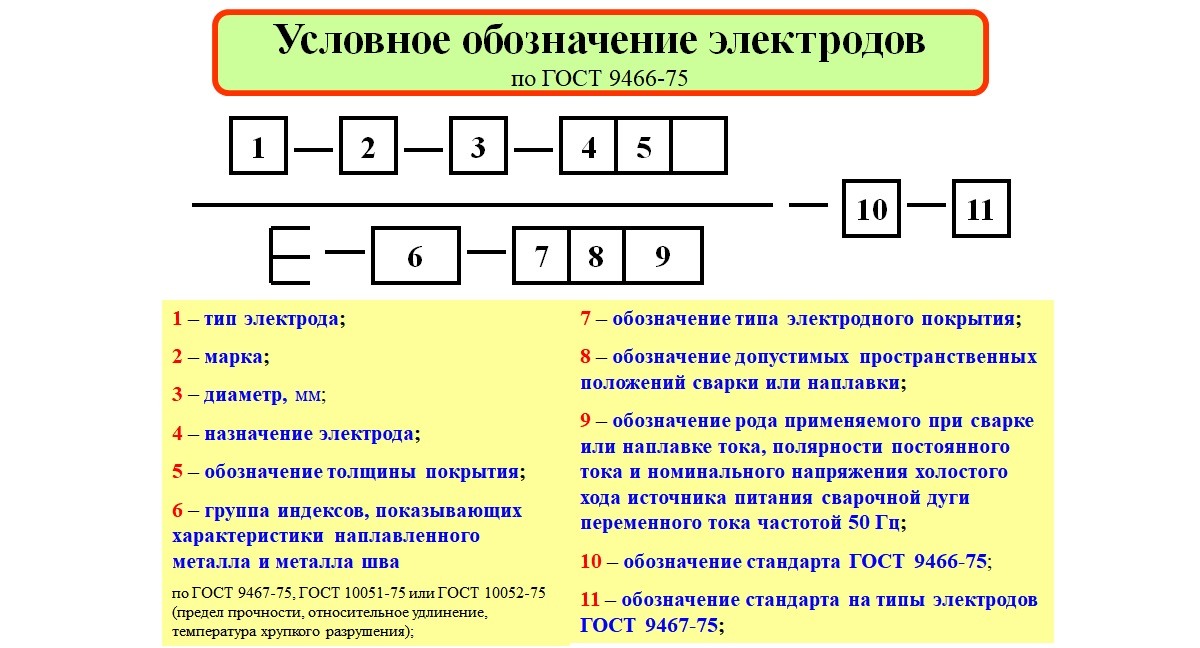

- The denominator is a coded designation (code):

- A GROUP OF INDICES INDICATING THE CHARACTERISTICS OF THE WELD METAL OR WELD METAL

- DESIGNATION OF COATING TYPE

- DESIGNATION OF PERMISSIBLE SPATIAL POSITIONS

- DESIGNATION OF CHARACTERISTICS OF THE WELDING CURRENT AND VOLTAGE OF THE POWER SUPPLY

- STANDARD FOR SYMBOL STRUCTURE

- STANDARD FOR ELECTRODE TYPES

- Using different types and brands of welding tools

- 3 How are coated electrodes classified?

- General information

- GOST

- Decryption

- Manufacturers

- Purpose of the electrode

- Types of coverage

- Electrode grades

- Baking, drying and storage

- Storage

Storage rules

Have you ever used a welding machine?

It was the case! Didn't happen

The main problem faced during storage is high humidity.The coating of the electrodes quickly absorbs moisture, as a result, it becomes impossible to work with such a filler material. The only way to correct the situation is to ignite the welding electrodes.

For this, there are special ovens or portable canisters with heating elements. At home, packages are recommended to be stored open (without polyethylene) at a temperature of 20-22 degrees, relative humidity 40-50%.

Wet electrodes can cause pores on the surface and inside the weld, and there will also be an increase in metal spatter.

For the correct choice of welding electrodes, you need to have a good understanding of which alloy you need to work with.

You should also carefully prepare the additive itself and the surfaces to be welded for the operation:

- Remove dirt and rust.

- Ignite the electrodes.

- Set the correct welding current.

Subject to the technology, it is possible to count on obtaining seams with the characteristics specified by the electrode manufacturer.

- What gasoline to use for a chainsaw? How to breed?

- How to choose a generator for a summer residence. Main criteria and review of the best models

- Pumping station for a summer residence. How to choose? Model overview

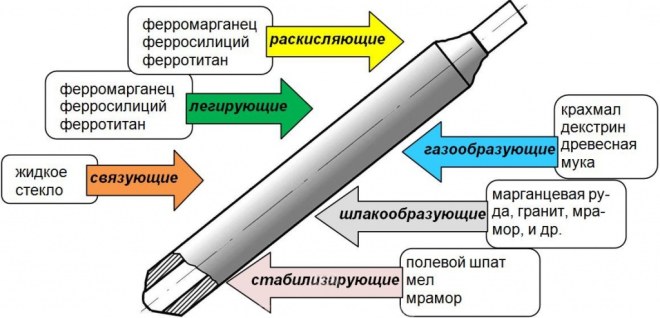

Properties of electrode coating components

In order for the seam to come out of good quality, special components are needed. So, when performing welding work, in the welding zone it is necessary to ensure the creation of the most suitable conditions for the quick and reliable connection of metal surfaces. We list the main tasks that electrodes with a special coating perform.

Arc stabilization

In order for the welding arc to have maximum stability, the electrodes are coated with special substances that have a low ionization potential.This leads to the fact that during welding, the arc is saturated with free ions, which stabilize the combustion process. Today, the electrode coating may include components such as potash, sodium or potassium liquid glass, chalk, titanium concentrate, barium carbonate, and so on. These coatings are called ionizing.

Protection of the welding area from atmospheric gases

The components that make up the electrode coating contribute to the creation of a protective cloud consisting of carbon dioxide and carbon monoxide, and also participate in the formation of a slag layer that forms on the weld and covers the weld pool from gases contained in the surrounding air. Gas-forming components include dextrin, cellulose, starch, food flour, and others. And slag is formed by kaolin, marble, chalk, quartz sand, titanium concentrate and so on.

Electrode Coating Components and Their Properties

In addition to protecting the weld from gases contained in the air, slag helps to reduce the rate of cooling of the metal and its subsequent crystallization, which in turn favorably affects the release of gases and unnecessary impurities from the welded metal.

Weld metal alloying

Alloying improves a number of properties of the weld. The main metals that contribute to alloying are titanium, manganese, silicon and chromium.

Melt deoxidation

During welding, it is very important to remove oxygen from the metal, for which special deoxidizers are used - these are substances that react with oxygen more efficiently than iron and bind it. These are titanium, molybdenum, aluminum or chromium added as ferroalloys to the composition of the electrode coating.

Linking all the constituent elements together

Coated electrodes need a strong connection between the coating and the rod, as well as between all the constituent elements of the coating. In this case, the main binding component is sodium silicate or liquid potassium glass. It is worth recalling that liquid glass (essentially silicate glue) also perfectly stabilizes the welding arc, which makes it an indispensable component of all types of electrodes.

Classification of electrodes for welding carbon and low alloy structural steels in accordance with DIN 1913 (German standard)

Table 38 Designation Structure

| E | 43 | 00 | RR | 10 | 120 | H | Electrode: E4300 RR10 120H |

| Code of strength and plastic properties of the deposited metal | |||||||

| Designation for impact strength of weld metal | |||||||

| Coating type designation | |||||||

| Type of coating, type of current, polarity, position of the seams during welding | |||||||

| Performance | |||||||

| H is the hydrogen content in the deposited metal less than 15 ml/100 g |

Table 39. Code of strength and plastic properties of the deposited metal

| Index | Tensile strength, MPa | Yield strength, MPa | Minimum elongation, % | ||

| 0,1 | 2 | 3, 4,5 | |||

| 43 | 430—550 | ≥330 | 20 | 22 | 24 |

| 51 | 510—650 | ≥360 | 18 | 18 | 20 |

Table 40. Symbol for weld metal impact strength

| Index | Minimum temperature, °C, at average burst energy (KCV) = 28 J/cm2 | Second index | Minimum temperature, °C, at average burst energy (KCV) =47 J/cm2 |

| Not regulated | Not regulated | ||

| 1 | +20 | 1 | +20 |

| 2 | 2 | ||

| 3 | –20 | 3 | –20 |

| 4 | –30 | 4 | –30 |

| 5 | –40 | 5 | –40 |

Table 41

| Index | Coating |

| A | Acid Coatings |

| R | Rutile coatings |

| RR | Thick rutile covers |

| AR | Rutile-acid coatings |

| C | Cellulosic coatings |

| R(C) | Rutile Cellulosic Coatings |

| RR(C) | Thick Rutile Cellulosic Coatings |

| B | Basic coatings |

| B(R) | Rutile-basic coatings |

| RR(B) | Thick rutile base coats |

Table 42Type of coating, indexes of the position of the seams during welding, type of current and polarity

| Index | The position of the seams when welding | Type of current and polarity | Coating type |

| A2 | 1 | 5 | Sour |

| R2 | 1 | 5 | Rutile |

| R3 | 2 (1) | 2 | Rutile |

| R(C)3 | 1 | 2 | Rutile-cellulose |

| C4 | 1(a) | 0 (+) | Cellulosic |

| RR5 | 2 | 2 | Rutile |

| RR(C)5 | 1 | 2 | Rutile-cellulose |

| RR6 | 2 | 2 | Rutile |

| RR(C)6 | 1 | 2 | Rutile-cellulose |

| A7 | 2 | 5 | Sour |

| AR7 | 2 | 5 | Rutile-sour |

| RR(B)7 | 2 | 5 | Rutile-basic |

| RR8 | 2 | 2 | Rutile |

| RR(B)8 | 2 | 5 | Rutile-basic |

| B9 | 1(a) | 0 (+) | Main |

| B(R)9 | 1(a) | 6 | Basic based on non-core components |

| B10 | 2 | 0 (+) | Main |

| B(R)10 | 2 | 6 | Basic based on non-core components |

| RR11 | 4 (3) | 5 | Rutile, productivity not less than 105% |

| AR11 | 4 (3) | 5 | Rutile acid, productivity not less than 105% |

| B12 | 4 (3) | 0 (+) | Basic, productivity not less than 120% |

| B(R)12 | 4 (3) | 0 (+) | Main based on non-main components and performance not less than 120% |

Table 43

| Index | The position of the seams when welding |

| 1 | All provisions |

| 2 | Everything except vertical top to bottom |

| 3 | Bottom and horizontal seams on a vertical plane |

| 4 | Bottom (butt and roller seams) |

Table 44 Welding current polarity

| Index | DC polarity | Transformer no-load voltage, V |

| Reverse (+) | — | |

| 1 | Any (+/-) | 50 |

| 2 | Direct (-) | 50 |

| 3 | Reverse (+) | 50 |

| 4 | Any (+/-) | 70 |

| 5 | Direct (-) | 70 |

| 6 | Reverse (+) | 70 |

| 7 | Any (+/-) | 90 |

| 8 | Direct (-) | 90 |

| 9 | Reverse (+) | 90 |

Table 45. Performance

| Index | Productivity (KWith), % |

| 120 | 115—125 |

| 130 | 125—135 |

| 140 | 135—145 |

| 150 | 145—155 |

| 160 | 155—165 |

| 170 | 165—175 |

| 180 | 175—185 |

| 190 | 185—195 |

| 200 | 195—205 |

Classification of steel coated electrodes for manual arc welding

Classification of coated electrodes, depending on their purpose

Electrodes for manual arc welding are made in accordance with the requirements

GOST9466. Depending on the application, according to GOST 9467, coated steel

arc welding electrodes are divided into the following groups:

U - for welding carbon and low-carbon structural steels with temporary

tensile strength 600MPa. For this purpose, according to GOST 9476, are used

the following brands of electrodes: E38, E42, E42A, E46, E50, E50A, E55, E60.

L - electrodes of this group are used for welding alloyed steels, as well as

for welding structural steels with a tensile strength of more than 600 MPa.

These are such brands of electrodes as E70, E85, E100, E125, E150.

T - these electrodes are designed for welding alloyed heat-resistant steels.

B - electrodes for welding high-alloy steels with special properties (GOST 10052). N

— electrodes for surfacing surface layers with special properties.

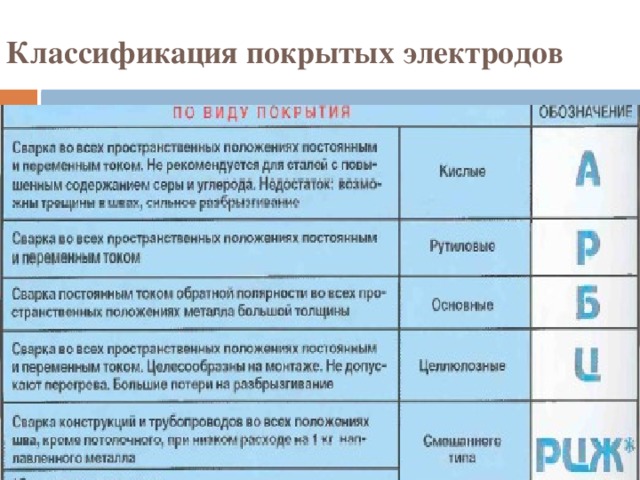

Classification of electrodes, depending on the type of coating

A - acid-coated electrodes (for example, ANO-2, SM-5, etc.). These coatings

consist of oxides of iron, manganese, silica, ferromanganese. These electrodes

have high toxicity due to the content of manganese oxide, but at the same time,

have high technology.

B - the main coating (electrodes UONI-13/45, UP-1/45, OZS-2, DSK-50, etc.).

These coatings do not contain oxides of iron and manganese. The composition of the coating

for electrodes UONI-13/45 marble, fluorspar, quartz sand, ferrosilicon,

ferromanganese, ferrotitanium mixed with liquid glass. When welding electrodes

with basic coating, a weld with high ductility is obtained. Data

electrodes are used for welding critical welded structures.

R - electrodes with rutile coating (ANO-3, ANO-4, OES-3, OZS-4, OZS-6, MP-3,

MP-4, etc.). The coating of these electrodes is based on rutile TiO2, who gave

the name of this group of electrodes.Rutile electrodes for manual arc welding

less harmful to health than others. When welding metal with such electrodes

the thickness of the slag on the weld is small and the liquid slag hardens quickly. This allows

use these electrodes to make seams in any position.

C - a group of electrodes with a cellulose coating (VTSs-1, VTSs-2, OZTS-1, etc.).

The components for such coatings are cellulose, organic resin, talc,

ferroalloys and some other components. Coated electrodes can

use for welding in any position. They are mainly used

when welding small metals

thickness. Their disadvantage is the reduced ductility of the weld.

Classification of electrodes by coating thickness

Depending on the thickness of the coating (the ratio of the electrode diameter D to the diameter

electrode rod d), electrodes are divided into groups:

M - with a thin coating (D / d ratio not more than 1.2).

C - with medium coverage (D / d ratio ranging from 1.2 to 1.45).

D - with a thick coating (D / d ratio ranging from 1.45 to 1.8).

D - electrodes with an especially thick coating (D / d ratio more than 1.8).

Classification of electrodes by quality

Classification by quality includes taking into account indicators such as accuracy

manufacturing, absence of defects in the weld made by the electrode, condition

the surface of the coating, the content of sulfur and phosphorus in the weld metal. AT

Depending on these indicators, the electrodes are divided into groups 1,2,3. The more

group number, the better the quality of the electrode and the higher the quality

welding.

Classification of electrodes by spatial position at

welding

There are 4 groups of electrodes, depending on the allowable spatial

locations of parts to be welded:

1 - welding is allowed in any position;

2 - welding in any position, except for vertical seams from top to bottom;

3 - welding in the lower position, as well as the implementation of horizontal seams and vertical

upwards;

4 - welding in the lower position and lower "into the boat".

In addition to the above methods of classification, GOST 9466 provides for the classification

electrodes depending on the polarity of the welding current, open circuit voltage

stroke, type of power source of the welding arc. Based on these indicators, the electrodes

are divided into ten groups and are designated by numbers from 0 to 9.

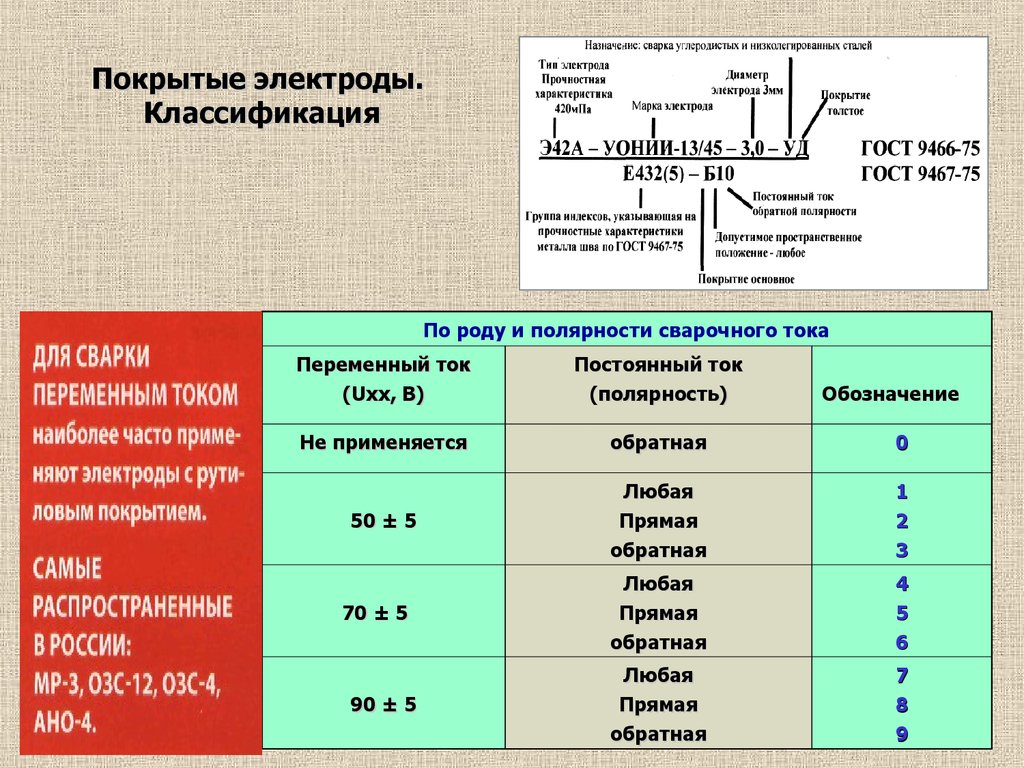

The denominator is a coded designation (code):

letter E - international designation of consumable coated electrode

A GROUP OF INDICES INDICATING THE CHARACTERISTICS OF THE WELD METAL OR WELD METAL

6.1. For electrodes used for welding carbon and low alloy steels with tensile strength up to 588 MPa (60 kgf/mm2)

6.2. In the symbol for electrodes for welding alloyed steels with a tensile strength of over 588 MPa (60 kgf / mm2), the first two-digit index corresponds to the average carbon content in the weld in hundredths of a percent; subsequent indices of letters and numbers show the percentage of elements in the weld metal; the last digital index, put through a hyphen, characterizes the minimum temperature °C at which the impact strength of the weld metal is at least 34 J/cm2 (35 kgf?m/cm2).

Example: E-12X2G2-3 means 0.12% carbon, 2% chromium, 2% manganese in the weld metal and at -20°C has an impact strength of 34 J/cm2 (3.5 kgf?m/cm2).

6.3.The conventional designation of electrodes for welding heat-resistant steels contains two indices:

- the first indicates the minimum temperature at which the impact strength of the weld metal is at least 34 J/cm2 (3.5 kgf?m/cm2);

- the second index is the maximum temperature at which the parameters of the long-term strength of the weld metal are regulated.

6.4. Electrodes for welding high-alloy steels are coded by a group of indices consisting of three or four digits:

- the first index characterizes the resistance of the weld metal to intergranular corrosion;

- the second indicates the maximum operating temperature at which the indicators of the long-term strength of the weld metal (heat resistance) are regulated;

- the third index indicates the maximum operating temperature of the welded joints, up to which the use of electrodes is allowed when welding heat-resistant steels;

- the fourth index indicates the content of the ferrite phase in the weld metal.

6.5. The symbol for electrodes for surfacing surface layers consists of two parts:

the first index indicates the average hardness of the deposited metal and is expressed as a fraction:

- in the numerator - Vickers hardness;

- in the denominator - according to Rockwell.

the second index indicates that the hardness of the deposited metal is provided by:

- without heat treatment after surfacing -1;

- after heat treatment - 2.

| Index | Hardness | Index | Hardness | ||

| according to Vickers | according to Rockwell | according to Vickers | according to Rockwell | ||

| 200/17 | 175 — 224 | up to 23 | 700 / 58 | 675 — 724 | 59 |

| 250 / 25 | 225 — 274 | 24 — 30 | 750 / 60 | 725 — 774 | 60 — 61 |

| 300 / 32 | 275 — 324 | 30,5 — 37,0 | 800 / 61 | 775 — 824 | 62 |

| 350 / 37 | 325 — 374 | 32,5 — 40,0 | 850 / 62 | 825 — 874 | 63-64 |

| 400 / 41 | 375 — 424 | 40,5 — 44.5 | 900 / 64 | 875 — 924 | 65 |

| 450 / 45 | 425 — 474 | 45,5 — 48,5 | 950 / 65 | 925 — 974 | 66 |

| 500 / 48 | 475 — 524 | 49,0 | 1000 / 66 | 975 — 1024 | 66,5 — 68,0 |

| 550 / 50 | 525 — 574 | 50 — 52,5 | 1050/68 | 1025 — 1074 | 69 |

| 600 / 53 | 575 — 624 | 53 — 55,5 | 1100/69 | 1075 -1124 | 70 |

| 650 / 56 | 625 — 674 | 56 — 58,5 | 1150/70 | 1125 -1174 | 71 -72 |

Example: E - 300/32-1 - Hardness of the deposited layer without heat treatment.

DESIGNATION OF COATING TYPE

A, B, C, R - see Electrode coatings; mixed type: AR - acid-rutile; RB - rutile-basic, etc.; P - others. If there is more than 20% iron powder in the coating, the letter Zh is added. For example: АЖ.

DESIGNATION OF PERMISSIBLE SPATIAL POSITIONS

1 - for all positions, 2 - for all positions, except for the vertical "top-down", 3 - for the bottom, horizontal on a vertical plane and vertical "bottom-up", 4 - for the bottom and bottom "in the boat".

DESIGNATION OF CHARACTERISTICS OF THE WELDING CURRENT AND VOLTAGE OF THE POWER SUPPLY

| DC polarity | Uxx AC source, V | Index | |

| Nominal | Previous deviation | ||

| Reverse | — | — | |

| Any | — | — | 1 |

| Straight | 50 | ± 5 | 2 |

| Reverse | 3 | ||

| Any | 70 | ± 10 | 4 |

| Straight | 5 | ||

| Reverse | 6 | ||

| Any | 90 | ± 5 | 7 |

| Straight | 8 | ||

| Reverse | 9 |

STANDARD FOR SYMBOL STRUCTURE

GOST 9466-75 “Coated metal electrodes for manual arc welding and surfacing. Classification and general specifications”.

STANDARD FOR ELECTRODE TYPES

GOST 9467-75 "Coated metal electrodes for manual arc welding of structural and heat-resistant steels".

GOST 10051-75 "Coated metal electrodes for manual arc surfacing of surface layers with special properties".

Using different types and brands of welding tools

Everything discussed above relates more to the marking of electrodes for RDS steel

It is important to give examples of rods used for a variety of ferrous and non-ferrous metals. Below are the most common types

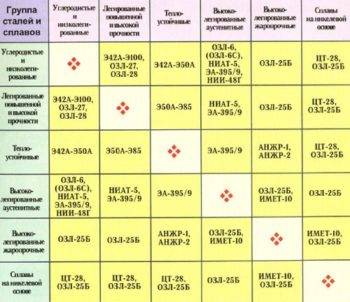

Types of electrodes are distributed depending on the metal to be welded and the specified typical mechanical characteristics of the weld.

Carbon low-alloy steels are welded with rods of types:

- E42: grades ANO-6, ANO-17, VCC-4M.

- E42: UONI-13/45, UONI-13/45A.

- E46: ANO-4, ANO-34, OZS-6.

- E46A: UONI-13/55K, ANO-8.

- E50: VCC-4A, 550-U.

- E50A: ANO-27, ANO-TM, ITS-4S.

- E55: UONI-13/55U.

- E60: ANO-TM60, UONI-13/65.

High strength alloy steels:

- E70: ANP-1, ANP-2.

- E85: UONI-13/85, UONI-13/85U.

- E100: AN-KhN7, OZSH-1.

High-strength alloy steels: E125: NII-3M, E150: NIAT-3.

Metal surfacing: OZN-400M/15G4S, EN-60M/E-70Kh3SMT, OZN-6/90Kh4G2S3R, UONI-13/N1-BK/E-09Kh31N8AM2, TsN-6L/E-08Kh17N8S6G, OZSh-8/11Kh31N11GSM3YuF.

Cast iron: OZCH-2/Cu, OZCH-3/Ni, OZCH-4/Ni.

Aluminum and alloys based on it: OZA-1/Al, OZANA-1/Al.

Copper and alloys based on it: ANTs/OZM-2/Cu, OZB-2M/CuSn.

Nickel and its alloys: OZL-32.

From the above list, we can conclude that the marking system is very complex, and is based on approximately the same principles for encoding the characteristics of the rod, its coating, diameter, and the presence of alloying elements.

The quality of the welding joint depends on a rational technological scheme. The following factors influence which types of electrodes to choose:

- The material to be welded and its properties, the presence of alloying elements and the degree of alloying.

- Product thickness.

- Seam type and position.

- Specified mechanical properties of the joint or weld metal.

It is important for a novice welder to navigate the basic principles of selecting and marking tools for steel welding, as well as operate with the distribution of rod grades for their intended purpose, know the main types of electrodes and use them rationally during welding

3 How are coated electrodes classified?

First of all, they are divided into six types according to the type of coating used:

- rutile - marking P;

- main - B;

- sour - A;

- mixed (denoted by two letters): RJ - iron powder plus rutile, RC - cellulose-rutile, AR - acid-rutile, AB - rutile-basic);

- cellulose - C;

- another is P.

Also, the specified State Standard subdivides the electrodes according to the ratio of their cross section and the cross section of the rod D / d (in fact, according to the thickness of their coating). From this point of view, the coverage can be:

- medium (C): D / d value - less than 1.45;

- thin (M) - less than 1.2;

- extra thick (G) - more than 1.8;

- thick (D) - 1.45–1.8.

By appointment, the electrodes are usually divided into those that are optimal for welding the following types of steels:

- structural alloyed, in which the resistance (temporary) to rupture is at least 600 MPa (indicated by the letter "L");

- structural low-alloy and carbon with a resistance of up to 600 MPa (marking - "U");

- highly alloyed, with special characteristics ("B");

- heat-resistant alloyed ("T").

Surfacing of special surface layers is carried out with electrodes marked with the letter "H".

The classification also provides for the division of products for performing welding activities into several types, depending on the chemical composition of the deposited metal and its mechanical parameters, as well as into three separate groups, described by the content of phosphorus and sulfur in the metal, the state of the coating and the accuracy class of the electrodes.

Among other things, the electrodes can have a different spatial position in which their use is allowed:

General information

OZL grade electrodes are consumable consumables for manual arc welding with a basic coating. The alloy metal rod has a range of diameters (mainly from 2.0 mm to 6.0 mm) for welding various thicknesses of materials.

The main coating of OZL electrodes well protects the surface of the welding seam with a DC power source.In this case, alloyed steels are welded at reverse polarity, at which less heat is generated. For such overheat-sensitive steels, the use of reverse polarity for consumables of the OZL brand is a way to obtain a high-quality weld.

IMPORTANT! When choosing consumables for welding ordinary mild steel, remember that consumables of the OZL brand are intended to a greater extent for welding heat-resistant steels. The melting temperatures are so different that when the liquid phase of the base metal is reached, the OZL electrode will not even begin to melt.

OZL consumables are very sensitive to the presence of moisture, therefore, additional calcination is required before use.

For the main coating, the welding process requires well-prepared surfaces to be welded - cleaned from rust and other contaminants, degreased. OZL consumables are very sensitive to the presence of moisture, therefore, additional calcination is required before use.

GOST

OZL electrodes must comply with the standards of GOST 9466 - 75 and GOST 10052-75. The first standard regulates the classification and general requirements for coated metal electrodes for manual arc welding.

Electrodes OZL-32

The second standard specifies the types of coated electrodes for manual arc welding of corrosion resistant, heat resistant and heat resistant high alloy steels. Both standards include consumables brand OZL.

Decryption

The symbol for the electrodes is formed on the basis of the data of the above standards.An example of the designation of consumables brand OZL - 6:

E - 10X25N13G2 - OZL - 6 - 3.0 - VD / E 2075 - B20

Numbers and letters correspond to the following main characteristics of OZL - 6:

- E - 10X25N13G2 - this designation determines the type of electrode according to GOST 10052 - 75;

- OZL-6 - a brand whose abbreviation indicates its origin (this one was created at a pilot plant for welding alloyed steels, many OZL consumables were developed at the Spetselectrod enterprise in Moscow);

- 3.0 - the numbers indicate the diameter of the rod;

- B - indicates the purpose for welding high-alloy steels with special properties;

- D - determines the thickness of the coating (in this case, thick);

- E - determines whether the electrode belongs to the coated ones for manual arc welding;

- 2075 - a group of numbers indicating some technical characteristics of the deposited metal, namely: "2" - no tendency to intergranular corrosion, "0" - no data on fatigue strength indicators when operating at maximum temperature, "7" - determines the value of the maximum working temperature of the welded joint (in this case 910°С -1100°С), "5" indicates the content of the ferrite phase (in this case 2-10%);

- B - indicates the coating of the electrode, in this case - the main one;

- 2 - the figure indicates the possibility of welding in the following spatial positions: in all positions, except for the vertical "top-down";

- - determines the method of welding, in this case on direct current of reverse polarity.

Manufacturers

The Russian market for coated electrodes for manual arc welding is saturated with a large number of Russian, European and Chinese manufacturers.Most of them in the assortment, in addition to other types, have electrodes of the OZL brands

We advise you to pay attention to the manufacturers that are included in the TOP list according to the results of surveys

Russian manufacturers:

- "Spetselektrod" Moscow;

- Shadrinsk Electrode Plant, Shadrinsk;

- Losinoostrovsky Electrode Plant, Moscow;

- Zelenograd Electrode Plant, Zelenograd;

- "Rotex" Kostroma, Krasnodar, Moscow and others.

Electrodes OZL-312 SpecElectrode

Producers from neighboring countries:

- PlasmaTech (Ukraine);

- VISTEK, Bakhmut (Ukraine);

- "Oliver" (Republic of Belarus) and others.

European manufacturers:

- «ZELLER WELDING» Düsseldorf (Germany);

- ESAB (Sweden);

- «KOBELCO» (Japan) and others.

Chinese manufacturers:

- Golden Bridge;

- S.I.A. "Resanta";

- "EL KRAFT" and others.

Purpose of the electrode

Table of types of electrodes for welding.

Table of types of electrodes for welding.

By appointment, the electrodes are divided for:

- work with steels with a high level of alloying elements;

- with an average content of alloying elements;

- structural steel welding;

- ductile metals;

- fusing;

- heat resistant steels.

Thus, it is possible to choose electrodes for each specific task.

Special attention should be paid to the protective coating. Coating of electrodes is an important component to which special requirements are imposed.

In addition, it is characterized by a certain composition.

They are a rod covered with a special shell. Power depends on what diameter it has.

The most popular are UONI electrodes. There are several grades of this material and all of them are used for manual welding.

UONI 13-45 allow to obtain seams of acceptable viscosity and plasticity. They are used for welding in casting and forgings. These rods contain nickel and molybdenum.

UONI 13-65 are suitable for working on structures with increased requirements. They can make connections in any position. The diameter varies from two to five millimeters, the larger it is, the greater the welding current.

In addition, the joints obtained with their help are characterized by high impact strength and cracks do not form in them. All this makes them the most promising in working with critical structures, which are subject to strict requirements.

In addition, these structures are resistant to temperature extremes, vibrations and loads.

An important feature of this type of rods is the significant resistance to moisture and the possibility of long-term calcination.

Types of coverage

Electrode coatings include the following components:

- deoxidizing agents;

- components for stable arcing;

- elements that provide plasticity, such as kaolin or mica;

- aluminum, silicon;

- binders.

All electrodes for spot or manual welding with a coating have a number of requirements:

- high efficiency;

- the possibility of obtaining a result with the necessary composition;

- slight toxicity;

- reliable seam;

- stable arc burning;

- coating strength.

Types of electrode coating.

There are the following types of electrode coatings:

- cellulose;

- sour;

- rutile;

- main.

The first type allows you to work in all spatial positions with direct and alternating current. They are most widely used in installation.They are characterized by significant spatter losses and do not allow overheating.

Rutile and sour allow you to cook in all positions, except for vertical, direct and alternating current. The second type of coating is not suitable for steels with high sulfur and carbon content.

The types of casings listed above imply the use of only one specific type of coating. However, combinations of several options are possible. Combinations can be made up of several types, depending on the problem being solved.

Combined shells belong to a separate class and are not included in the main four types.

There is also a classification depending on the thickness of the coating.

Each thickness is assigned a separate letter designation:

- thin - M;

- medium thickness - C;

- thick - D;

- especially thick G.

Of course, the rods are selected in accordance with the goals. The right choice guarantees the high quality of the work performed.

Electrode grades

Deciphering the marking of the electrode.

There are various brands of electrodes designed to solve certain problems. They are characterized by certain properties, which allows you to choose the most suitable material.

The OK-92.35 brand is characterized by an elongation of sixteen percent and a yield and strength limit of 514 MPa and 250 HB, respectively. The yield strength of OK-92.86 is 409 MPa.

Marks of electrodes for manual welding OK-92.05 and OK-92.26 have a relative elongation of 29% and 39%, and a yield strength of 319 and 419 MPa, respectively.

The yield strength of OK-92.58 is 374 MPa.

All of the above electrodes are used for manual arc welding on cast iron.Depending on the metal to be worked with, a special type of rod is also chosen. For example, for copper - ANTs / OZM2, pure nickel - OZL-32, aluminum - OZA1, monel - V56U, silumin - OZANA2, etc.

In addition, the welder also needs to control the quality of the parts to be welded. Depending on the material, working conditions, seam position and other factors, select the appropriate electrode that will provide the best connection quality.

Baking, drying and storage

When storing electrodes in a cold and humid place, dampness occurs. The presence of moisture makes it difficult to ignite, leads to sticking and destruction of the coating. These factors negatively affect the quality of work, so preliminary preparation is carried out.

Calcining and drying differ in temperature and method of heating. Baking electrodes is a thermal effect aimed at reducing the moisture content in the coating. Drying takes place at lower temperatures with gradual heating.

It is necessary to ignite:

- after moisture ingress;

- after long-term storage;

- when the electrodes were lying in a damp place;

- with difficulties in work caused by moisture content.

More than two times the electrodes must not be baked, otherwise the coating may separate from the rod.

Figure 14 - Thermal case

Drying helps to increase the temperature of the consumables before work so that the temperature difference does not spoil the weld pool and the seam is of high quality. The operation helps to create a tight connection in products under pressure. It is the gradual heating that helps to evaporate moisture and avoid the formation of limescale. The mode and duration of drying depend on the brand of electrodes and are indicated by the manufacturer on the package.Cooling should be with the oven to avoid sudden temperature changes.

Rutile and cellulose types of coating are less sensitive to moisture. Baking before work is optional. In case of saturation with moisture, cellulose electrodes are dried at t = 70 ° C and not higher to avoid cracks. Rutile ones are dried at 100–150 °C for 1–2 hours. The unpacked main electrodes are calcined for 1–2 hours at t=250–350 °C.

For heating, electric furnaces, thermal cases and thermos cases are used. The equipment allows you to regulate the temperature and provide heating up to 100–400 °C. For drying at home, an electric oven is suitable. The "original" way of drying is an industrial hair dryer. The electrodes are placed in a tube and a stream of hot air is directed into it.

Storage

Proper storage of electrodes will help not to lose properties and avoid drying. The storage location should be warm and dry, without sudden fluctuations. Even daily changes are accompanied by dew, which is quickly absorbed by the coating. The temperature should not fall below 14 ° C, and the humidity should be kept within 50%. The shelf life of electrodes, subject to storage conditions, is limited only by their condition.

Figure 15 - Homemade storage case

Figure 15 - Homemade storage case

The factory packaging has a sealed seal in a film that protects against moisture. Packs should be stored on shelves and racks, but not on the floor or near the walls. For long-term storage, it is recommended to keep the unpacked rods in thermal cases of a suitable size. Such containers can be purchased at a specialized store or made independently.