- Hood height standards

- Installation height of the hood above the gas stove

- Installation height of the hood above an induction or electric stove

- Mounting height of inclined models

- Features of installing other types of hoods

- Rules for the installation of gas appliances in the apartment

- The choice of equipment for the apartment

- Varieties of solenoid shut-off valves

- Correlation of cutoff parameters with the system

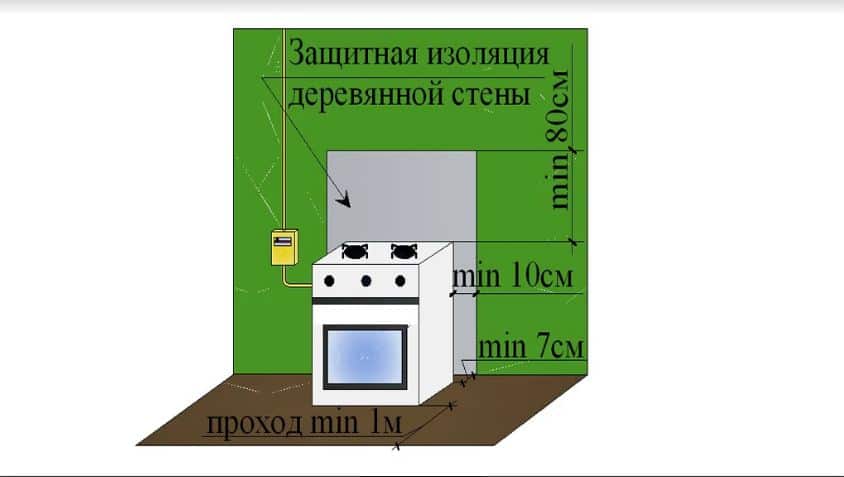

- Gas stove installation

- Requirements and norms for the installation of gas equipment in a private house

- Ventilation in rooms with gas equipment

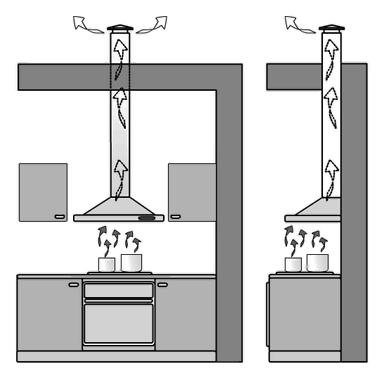

- Exhaust ventilation device

- Supply recirculation system

- Supply and exhaust recirculation system

- Why are thermal shut-off valves needed?

- Purpose of the thermal shut-off valve

- Where is a thermostatic valve used?

- The average gas pressure in the gas pipeline is how much

Hood height standards

Distance from hood to stove

The distance from the hob to the hood is determined by the type of cooking equipment and the location of the ventilation unit.

Moreover, the design features of the device, the size of the air outlet or the presence of additional elements on the panel do not affect this indicator. An exception may be the moments when the height of the ceiling in the room does not allow to comply with all recommendations.

First of all, you should take into account the height recommended by the manufacturer, adjusting it by 10 cm up or down.

Installation height of the hood above the gas stove

The optimum distance from the hob to ventilation is determined by system manufacturers and experts in the field. The ventilation system installation standards are based on practical experience, so it is worth adhering to them in order to improve the performance and increase the safety of using the device.

To determine at what height to hang the hood above the gas stove, you should refer to the accepted standards:

- for inclined systems, a suitable location of the hood above the stove is 0.55-0.65 m;

- other models are located at a height of 0.75-0.85 m.

The height of the hood above the gas stove, according to the standard, differs from similar parameters for other types of worktop. This is due to the peculiarities of the operation of a gas stove - with a low location of the hood, soot can form on it.

There is also a risk (albeit a very small one) of ignition of grease stains formed on the body of the equipment.

Installation height of the hood above an induction or electric stove

Everything is much simpler here, because the operation of the induction cooker is not associated with the use of open fire, so the hood is installed at a shorter distance. The installation height of the hood above the electric stove can be:

- 0.35-0.45 m for inclined models;

- 0.65-0.75 m when installing other ventilation systems.

When mounting the ventilation system, do not forget about the ease of use - any distance is adapted to a specific user.

Mounting height of inclined models

Inclined hoods are easy to use:

- for people who are tall - will not become an obstacle during cooking;

- for small rooms, because visually such a case occupies a smaller area, which significantly increases the space.

Another advantage of this design is that it does not protrude beyond the working surface and does not look bulky.

Features of installing other types of hoods

Distance of different types of hood to the stove

In addition to oblique, users actively use the following types of models:

Built-in system - installed directly in the cabinet. Model of small depth with a sliding part.

T-shaped and domed. Their difference is only in visual perception. The use of dome ventilation systems will be appropriate in spacious rooms - such a model is too voluminous for a small kitchen. Another name for such hoods is fireplace hoods. It is this word that marketers use to promote their products on the market. Such hoods often do not clean, but pump out the exhaust air.

Flat - this is the smallest system in terms of power. It takes up very little space - you can attach it above the electric stove directly under the kitchen cabinet. Perfect for a small kitchen. The best devices in this category have a retractable panel that increases the working area of the intake of exhaust air masses, which makes it work more efficiently without taking up additional space.

Island - are installed in large rooms when the stove is located away from the wall.

Regardless of the model chosen, the distance above the hob must comply with the standards that were indicated above. This will secure the use of the system and make it as efficient as possible.

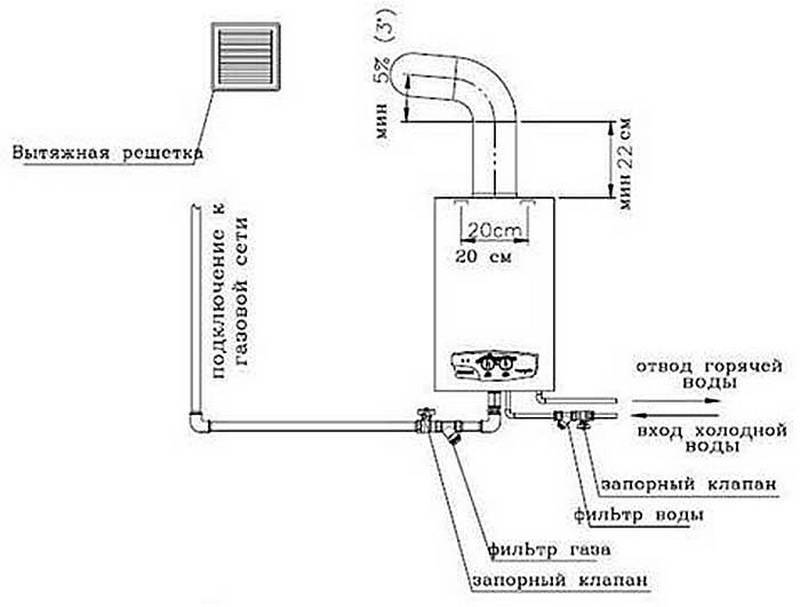

Rules for the installation of gas appliances in the apartment

The least problems with the arrangement of individual heating occur among the owners of new apartments that are not connected to a centralized heating system. In this case, there is no need to visit the heating network and there is no need to deal with disconnecting from the risers, and permission to install gas heating in an apartment building may be in the package of documents for real estate.

But in this case, you need to follow certain rules. First of all, having documents in hand, you cannot install gas equipment on your own - this work should be done by specialists. These can be not only employees of a gas supply organization, but also representatives of a company that licenses this type of activity.

After the installation is completed, the engineer of the company supplying gaseous fuels will check the correctness of the connection and issue a permit to use the boiler. Only then can you open the valve leading to the apartment.

Before starting, according to the requirements for installing a boiler in an apartment building, it is imperative to check the individual heat supply system. To do this, it is launched under a pressure equal to at least 1.8 atmospheres. You can control this parameter using the pressure gauge of the heating unit.

If the pipes are built into the floor or walls, it is advisable to increase the pressure and drive the coolant through them for at least 24 hours. Only after testing the system can you be sure that there are no leaks and reliable connections.

Air must be bled from the equipment before start-up.Since when installing a gas boiler in an apartment building, the systems are made closed, you need to use the Mayevsky taps available on the radiators. Air is bled in each battery, bypassing them several times in turn until there is no air left in them. After that, the system can be launched into operating mode - turn on the heat supply.

It is necessary to place an electrical outlet and another gas appliance at a distance of at least 30 centimeters from the unit.

The choice of equipment for the apartment

All elements of the system must be completed with permits, a Russian passport, a certificate and / or a declaration of conformity with the technical regulations of the Customs Union, which allow their use on the territory of the Russian Federation.

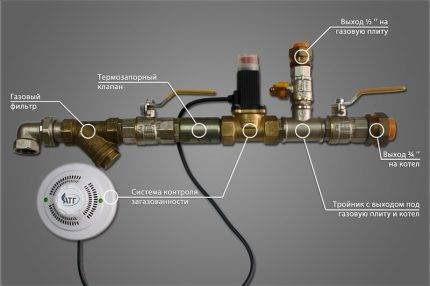

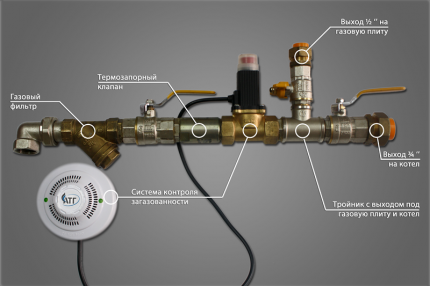

The gas protection system kit includes the signaling device itself (there may be two of them - from carbon monoxide and natural gas), a shut-off valve, connecting wires

The gas protection system kit includes the signaling device itself (there may be two of them - from carbon monoxide and natural gas), a shut-off valve, connecting wires

Purchasing a special kit is preferable to purchasing the instruments individually. In the first case, the elements of the kit are already coordinated among themselves in terms of parameters, adapted for work in domestic conditions, and provided with an instruction manual.

There are models of domestic and imported production on the market. Replacing and repairing the former is cheaper and easier to perform.

If you select equipment separately, please note that there are sensor models that are not designed to connect a solenoid valve. They signal a leak, they are able to inform the owner of the danger by sending SMS to the phone, but the gas is not blocked

Mounting a single sensor without a valve is inexpensive, you can install it yourself, but the reliability of protection against such a design is doubtful. And such a system will not comply with the current rules.

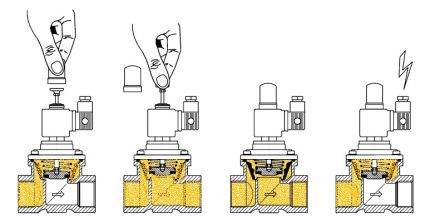

Varieties of solenoid shut-off valves

Two types of cutoffs are connected to the sensor: open (NO) and closed (NC). The former block the fuel supply only after the alarm in the system is triggered. The latter also react when there is a power outage.

It is possible to return the initial position of the valve after actuation either manually or automatically. In an apartment, valves with manual cocking are mainly installed on the gas pipe, they are simpler and cheaper.

Household gas cutters are most often made of brass or aluminum (silumin). They are suitable for various non-corrosive gases: natural, propane, liquefied petroleum

Household gas cutters are most often made of brass or aluminum (silumin). They are suitable for various non-corrosive gases: natural, propane, liquefied petroleum

Normally open manual shut-offs allow the equipment to operate while there is no supply voltage to the coil. The de-energized state prolongs their service life.

But due to the lack of voltage, such a device will not shut off the gas during a power outage, which is unsafe.

When working with a normally open valve, it is necessary to remove the protective cap, cock the valve up until it locks, put the cap back on. When power is applied, the breaker closes. To resume work, the procedure is repeated.

When working with a normally open valve, it is necessary to remove the protective cap, cock the valve up until it locks, put the cap back on. When power is applied, the breaker closes. To resume work, the procedure is repeated.

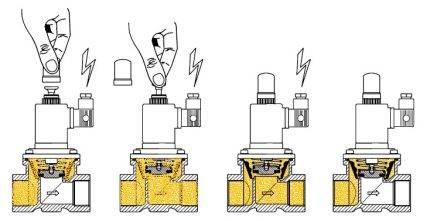

A normally closed gas valve closes in a second if the alarm is triggered or the electricity in the apartment is turned off. In this position, it remains until the elimination of dangerous factors.

The disadvantage of the variety is the constant voltage on the coil and its strong heating (up to 70 degrees).

When working with a normally closed valve, you must first apply power to the coil, remove the protective cap, cock the shutter until it locks, put the cap back on. When triggered, actions are repeated

When working with a normally closed valve, you must first apply power to the coil, remove the protective cap, cock the shutter until it locks, put the cap back on. When triggered, actions are repeated

On sale there are cut-off devices with electric impulse control. They work differently. In the open position, the valve is held by a latch. If the coil receives a current pulse from the sensor, the latch is released.

If a closing impulse is received during a power outage (e/p) and when the signaling device is triggered, the device acts as normally closed. If the pulse comes only from the sensor signal, The valve works on the normally open principle. and does not interrupt the gas supply when electricity is turned off. These algorithms can be changed using the alarm settings.

We have provided more information about the types of solenoid valve and the principle of operation of the device in our other article.

Correlation of cutoff parameters with the system

When choosing a device, the diameter of the pipe at the tie-in section of the valve matters. In most cases, a device with a Dn value of 15, 20 or 25 is suitable for domestic needs, which corresponds to 1/2 ″, 3/4 ″ and 1 ″ pipes.

If there is a boiler or column in the system that does not work when the mains voltage is turned off, a normally open valve is installed.

A normally-open cutoff is not convenient when paired with a sensor that automatically checks its outputs. The signaling device will send pulses, which will cause the valve to actuate

A normally-open cutoff is not convenient when paired with a sensor that automatically checks its outputs. The signaling device will send pulses, which will cause the valve to actuate

If the operation of the devices does not depend on the supply of electricity, a normally closed cutoff is mounted. It will not block the equipment in the absence of electricity and will not leave the room unprotected.

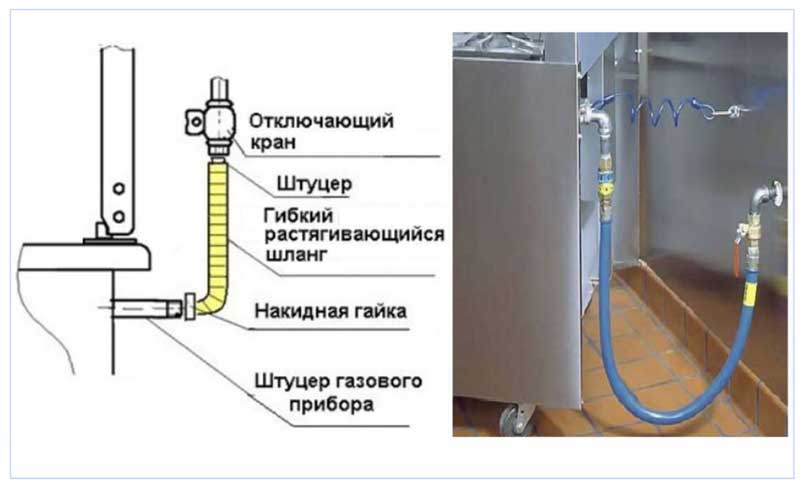

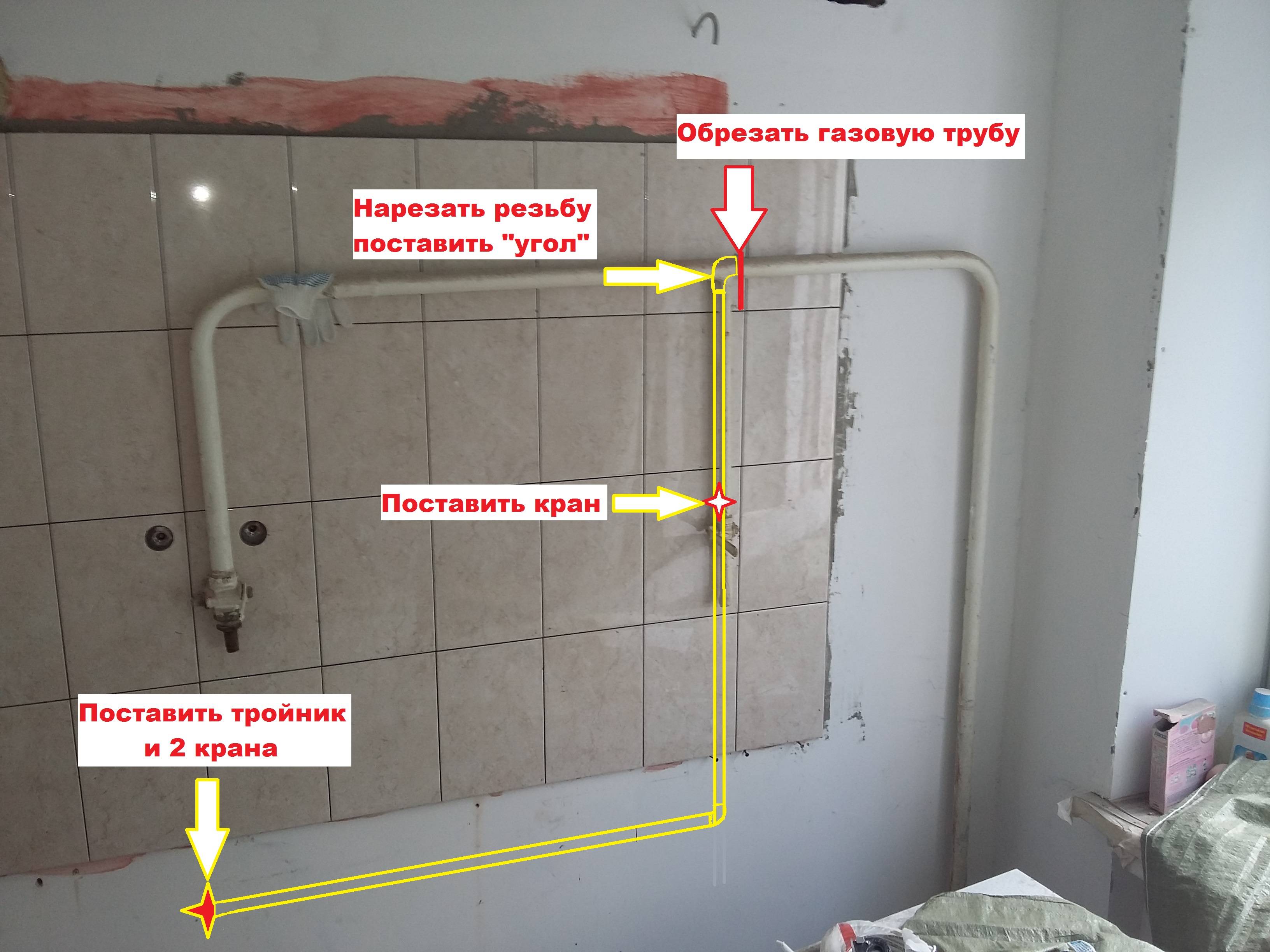

Gas stove installation

All work begins with an external inspection of the device - there should be no signs of serious mechanical damage on its surfaces. If there are, then it is quite possible that the internal connections were also affected - it is risky to use it, so expertise may be required. Better yet, return such happiness to the store if the fight is not your fault (and you can prove it), and replace it with a new one.

Table 3. Installing a gas stove

| Steps, photo | Description |

|---|---|

| Step 1 - unpacking | We take out all removable parts from the gas stove - grates, burners, baking sheets and shipping containers. If the comforters are still sealed with adhesive tape, then they can be assembled as is. Behind the stove we find a pipe for connecting a gas hose. It is necessary to remove the plastic transport plug from it. Carefully study the instructions - if the package includes a rubber gasket with a mechanical filter, then find it and install it on the inlet. This simple device will protect an expensive device from debris. |

| Step 2 - Hose Installation | We take the prepared hose, put a paronite gasket in the nut, wrap the thread of the pipe with fum tape in 5-6 turns and perform the installation. First, we tighten the nut by hand, and then we tighten it with an adjustable wrench, having previously fixed the gas pipe with a gas wrench. |

| Step 3 - attaching the hose to the stove | On modern stoves there is no drive - the connection is made simply through the nut. Also install the gasket, wind the seal and carefully tighten everything. |

| Step 4 - checking the tightness of the connections | We make a soap solution, which we then foam with a sponge.We coat the threaded connections on the pipe and the gas stove with foam on all sides, and see if bubbles are inflating anywhere. Naturally, the gas valve must first be opened. If a leak is found, then try tightening the nut a little. If this does not help, then turn off the gas, unscrew everything and check. Perhaps you forgot to put a gasket, or maybe there is a crack in the nut on the hose - the place where the bubbles appeared is inspected first. |

| Step 5 - test run of the stove | If everything is in order, then we proceed to testing the operability of the equipment. We light all the burners one by one. Everything is working? Wonderful! We push the plate inward and check its position with the help of a bubble building level. |

| Step 6 - adjusting the leveling feet | If the plate is not on the horizon, then the adjusting legs will help to align its position - we unscrew them until the desired readings are reached and make sure that the plate stands confidently, without staggering. |

We also recommend that you call a gas service worker after installation to check the correct installation and make all the necessary changes to the documents for the operation of the gas appliance. If this is not done, then during a scheduled inspection, you may face penalties.

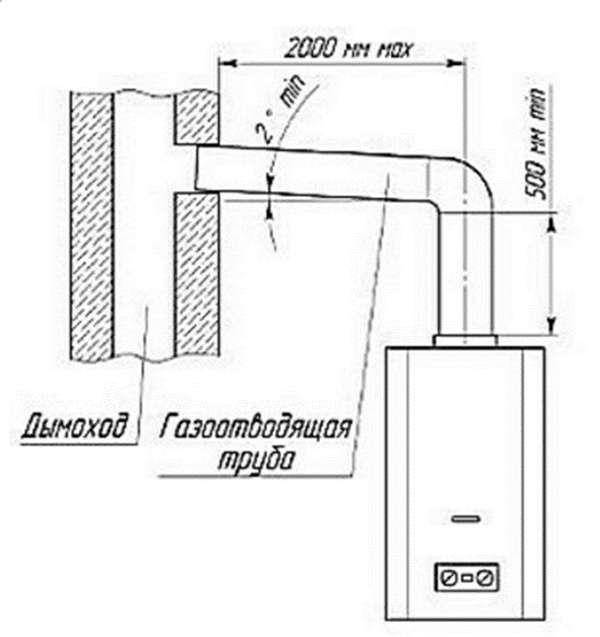

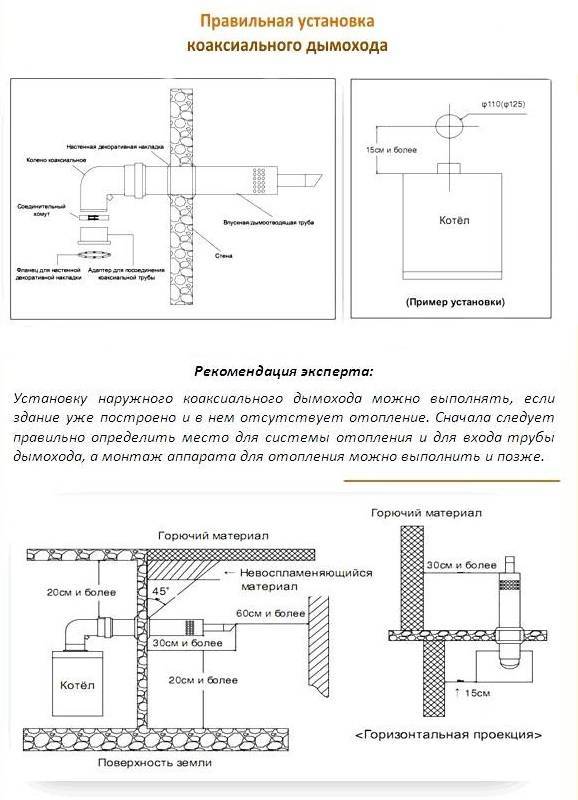

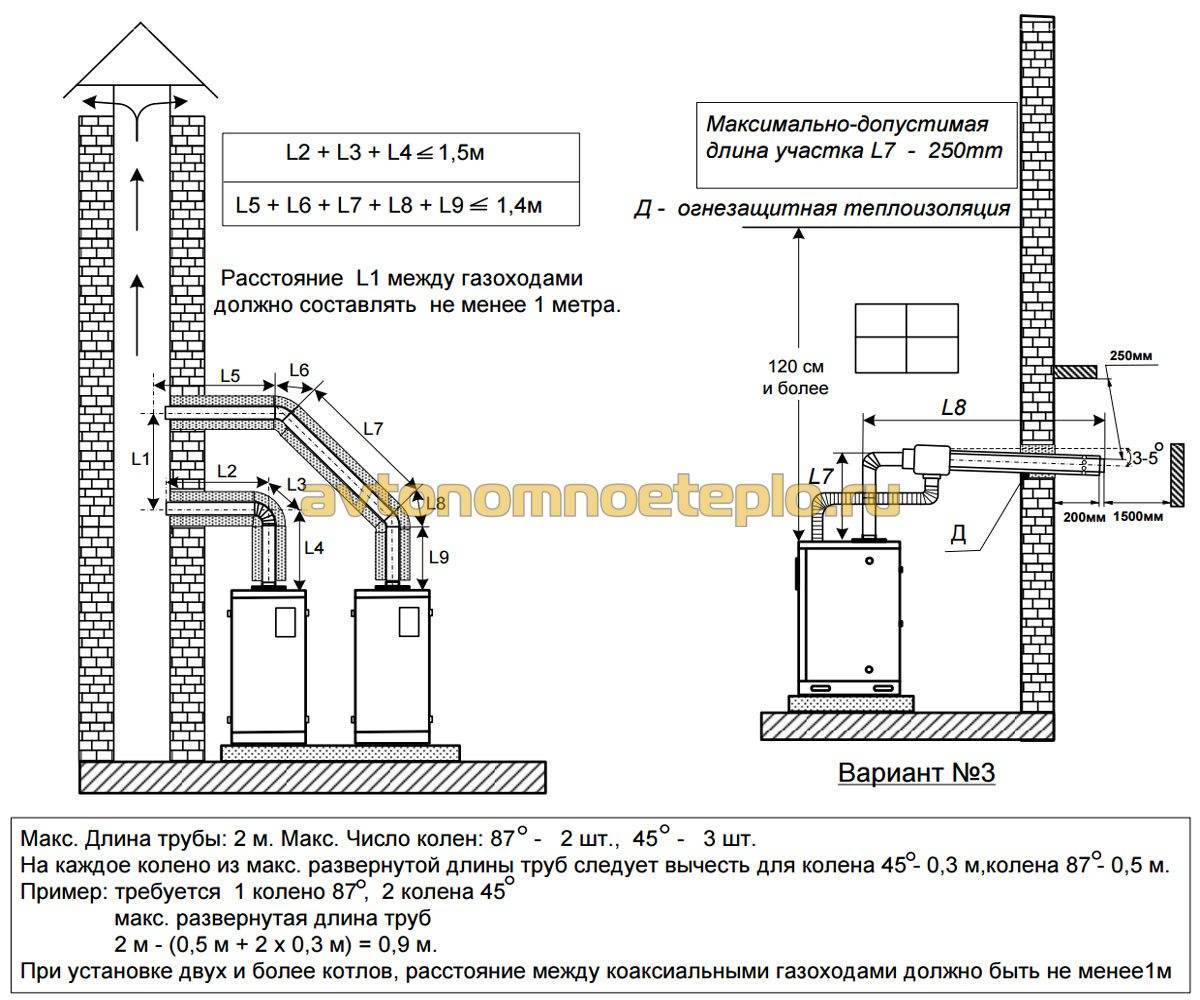

Requirements and norms for the installation of gas equipment in a private house

In principle, in his home, the owner is free to do whatever he wants - that's why he is the owner. But when it comes to installing high-risk devices, then all the requirements of the main regulatory documents are mandatory.What needs to be taken into account and what rules and regulations for the installation of gas equipment to comply with in relation to a private house will be the subject of consideration.

Big problems with the use of gas cylinders and the operation of, for example, burners, as a rule, do not arise. Further, the equipment connected to the central highway is meant. In a private house, this is, first of all, a heating boiler. Therefore, the emphasis is on gas appliances of this type.

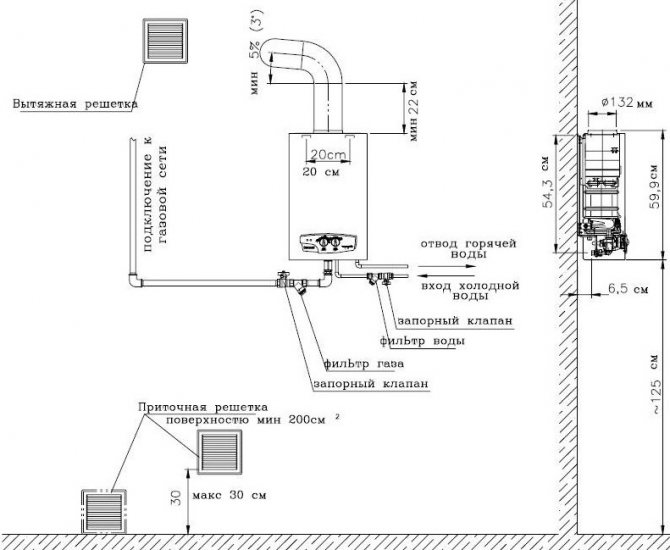

Ventilation in rooms with gas equipment

Designing a ventilation system designed for small-sized domestic premises with a boiler or gas stove will not cause difficulties. You can deal with it on your own.

Exhaust ventilation device

The action of exhaust ventilation is aimed at removing polluted air from the room.

For its installation, the following components are required: a fan, an air duct, a ventilation grill.

In summer, the efficiency of the exhaust ventilation system decreases. Its productivity can be increased by means of additional gaps in the doorways and opening the vents for ventilation.

In summer, the efficiency of the exhaust ventilation system decreases. Its productivity can be increased by means of additional gaps in the doorways and opening the vents for ventilation.

When choosing a fan, it is recommended to give preference to devices with a check valve. This will prevent air from entering the room from outside.

Air ducts are a pipe made of PVC or other materials. Its diameter should match the size of the fan.

When choosing a ventilation grill, you should pay attention that now there are many models on sale that differ in size, performance, design. Therefore, it is easy to choose the option that is ideal for the style of the room.

Supply recirculation system

Supply equipment provides fresh oxygen supply to the room with gas-using devices. The main element of such a system is the supply unit.

Its function is to supply oxygen from outside. At the time of passing through it, the air is filtered, heated or cooled if the device is additionally equipped with a heat exchanger.

For domestic use, low-power installations are suitable. The main advantage of this type of ventilation is noiselessness and comfort in operation. The simplest instance is a supply fan.

The performance of the supply ventilation system directly depends on the correctness of the calculations, the technical characteristics of the equipment and the design features of the room

The performance of the supply ventilation system directly depends on the correctness of the calculations, the technical characteristics of the equipment and the design features of the room

Inflows are divided into the following categories:

- Electrical device for ventilation. Provides not only filtration of incoming oxygen, but also its heating.

- Wall inlet valve. It can work in automatic mode and have an additional option of oxygen filtration. For installation, you will need to make a through hole in the wall of the building.

- Window inlet valve. It can be either mechanical or automatic. It is installed in the sash of a plastic window. Minus - the likelihood of icing at extremely low temperatures.

All listed types of supply ventilation are easy to assemble and operate. You can install the structure yourself.

Additional requirements regarding the supply system are put forward for rooms equipped with plastic windows that close hermetically.

The required extractor power is calculated using the following formula:

M \u003d O x 10, where

O is the volume of air, which is calculated as follows:

O = H x L x S.

H is the height of the room, L is the length, S is the width.

Supply and exhaust recirculation system

The mixed ventilation system ensures the simultaneous outflow of exhaust oxygen and the supply of fresh oxygen into the room. It is most often used in large-sized objects and houses, the total area of which exceeds 100 m2.

Units equipped with a recuperator will reduce fuel consumption by up to 90% due to the heating of the incoming air flow.

The supply and exhaust ventilation system is the most rational type that provides the right microclimate in the premises. Exhaust air must be removed through amenity rooms

For ease of installation, combined systems can have a vertical, horizontal or universal orientation. Installation is carried out after the completion of the plastering and puttying of the walls, but before the installation of the ceiling, since the entire infrastructure will be hidden under it.

As a rule, the supply and exhaust system includes the following components: an air intake valve, a cleaning air filter, a heater, a heat exchanger, a cooling unit, an external grille.

Why are thermal shut-off valves needed?

Thermal shut-off valves are devices that are shut-off gas fittings. They automatically shut off the gas pipeline leading to all gas-powered appliances.

All "stubs" are marked as KTZ with a certain set of numbers after the letters. The second number indicates the diameter of the gas pipe for which this mechanism may be suitable.

Purpose of the thermal shut-off valve

The main purpose of the KTZ is to shut off the gas supply to the equipment in case of fire. That helps not only to protect against an explosion, but also prevents the fire area from doubling or more.

If the shut-off valve is in the open position, then the device itself does not in any way prevent the passage of a combustible substance to the instruments and equipment.

Thermal locking mechanisms are mounted on pipelines, where the maximum pressure can be 0.6 MPa - 1.6 MPa.

Threaded type thermal shut-off valve. It is used for equipment with lower pressure (up to 0.6 MPa). They are most often used for household needs.

Threaded type thermal shut-off valve. It is used for equipment with lower pressure (up to 0.6 MPa). They are most often used for household needs.

KTZ flange type, which is used in pipelines with high pressure (close to maximum). Most often used in industrial facilities

KTZ flange type, which is used in pipelines with high pressure (close to maximum). Most often used in industrial facilities

Next, we denote the purpose of the valves, prescribed by the rules of fire authorities.

In the fire safety regulations, there is a regulation that implies the use of valves:

- On the equipment of all pipelines of natural gas. Any types of systems (complexity, branching), any number of consumer devices are assumed.

- To ensure the protection of various gasified objects and devices operating on gas. In this case, valves are applicable that are designed for automation (operation) when the temperature in the room reaches up to 100 ° C.

- Installation of thermal locking modules at the entrance to the room.

In accordance with PPB-01-03 (Fire Safety Rules), thermal locking devices must be installed in all rooms where there is a gas pipeline. However, this does not include buildings of the V category of fire resistance.

It is also not necessary to install a short circuit in buildings where pipelines are equipped with solenoid valves.They are usually placed outside the building, and if an ignition occurs inside the building, the gas analyzer is triggered, after which the gas supply is stopped.

It should be understood that KTZ is not just another Russian “trend”. The use of these devices at various facilities where gas equipment exists is mandatory in such countries as Germany, France, the USA, etc.

Where is a thermostatic valve used?

The field of application of thermal shut-off gas plugs is, first of all, pipelines supplying gas to devices of various purposes in which gas is burned (household and industrial devices, regardless of type).

The installation of a short circuit protection plant on any gas pipeline is not allowed outside the premises, after the installation of any other gas fittings, also on bypasses, in adjacent rooms and where the operating air temperature during the operation of gas equipment can reach more than 60 ° C.

It is important not to violate the installation rules - a shut-off valve is installed first on the gas pipeline, and only after it the rest of the gas fittings, instruments and equipment

You can place the valve in different positions, just pay attention to the arrow-pointer applied by the manufacturer on the body

Thermal shut-off valve with threaded connection. The arrows on the steel element when mounting on a gas pipeline must correspond to the direction of gas flow

Thermal shut-off valve with threaded connection. The arrows on the steel element when mounting on a gas pipeline must correspond to the direction of gas flow

Here you can see the location of the CTP on the pipeline. The installation of the valve must be carried out first at the inlet of the gas pipeline, or at the outlet from the riser

Here you can see the location of the CTP on the pipeline. The installation of the valve must be carried out first at the inlet of the gas pipeline, or at the outlet from the riser

In relation to the horizon, the location of the installed valve can be any. We will describe in more detail the rules for installing KTZ in more detail later.

Thermal shut-off valves have a special design that allows the device to automatically shut off the gas supply at the right time. If you get to know the design features of the valves, you can quickly understand the essence of their action. Next, we will analyze everything in more detail.

The average gas pressure in the gas pipeline is how much

To study the mode of operation of gas pipelines, gas pressure measurements are carried out at least twice a year, during the period of the highest flow rate (in winter) and the lowest one (in summer). Based on the results of measurements, maps of pressures in gas networks are compiled. These maps determine those areas where there is the greatest pressure drop of the gas.

On the way to the city, gas distribution stations (GDS) are being built, from which gas, after measuring its quantity and reducing pressure, is supplied to the distribution networks of the city. The gas distribution station is the final section of the main gas pipeline and is, as it were, the border between the city and main gas pipelines.

During a technical inspection, they monitor the oil level in the gear boxes, gearbox and counting mechanism, measure the pressure drop at the meters, and check for tight connections of the meters. Meters are installed on vertical sections of gas pipelines so that the gas flow is directed through the meter from top to bottom.

The gas enters the reception point at a pressure of 0.15-0.35 MPa. Here, first, its quantity is measured, and then it is sent to receiving separators, where mechanical impurities (sand, dust, corrosion products of gas pipelines) and condensed moisture are separated from the gas. Next, the gas enters the gas purification unit 2, where hydrogen sulfide and carbon dioxide are separated from it.

To check the operation of gas pipelines and identify areas with the highest pressure drop, gas pressure measurements are carried out. For measurements, gas control points, condensate-state collectors, inputs to houses or directly gas appliances are used. On average, one measuring point is chosen for every 500 m of the gas pipeline. All work on measuring gas pressure is carefully planned and carried out according to special instructions, which are approved by the chief engineer of the trust or office.

On fig. 125 shows a gas supply scheme for a large industrial enterprise. Gas from the high-pressure gas pipeline through a shut-off device / in the well is supplied to the central gas control point of the GRP 2. Gas flow is measured and reduced in it. In this case, high-pressure gas is supplied to shops No. 1 and 2, medium-pressure gas to shops No. 3 and 4 and the boiler room, and low pressure gas to the canteen (through the GRU). With a larger number of workshops and their considerable remoteness from the central hydraulic fracturing station, cabinet GRU 7 can be mounted in the workshops, ensuring the stability of gas pressure in front of the burners of the units. At high gas consumption in the shops, gas consumption metering units can be installed to control the rational and economical gas combustion.

To select part of the main gas and transfer it through the outlet gas pipelines under the necessary pressure to intermediate consumers, gas distribution stations (GDS) are built. Pressure regulators (spring or lever action), dust collectors, condensate collectors, installations for gas odorization (i.e., giving it an odor) and measuring the amount of gas supplied to the consumer, shutoff valves, connecting pipelines and fittings are installed on the GDS.The mass of piping and fittings for GDS with a capacity of 250-500 thousand m per hour reaches approximately 20-40 tons.