- The work of the mechanism

- Testing the toilet flush system after installation

- Quality fittings for the toilet bowl with bottom connection

- Varieties of check valves

- What is a vacuum toilet and how does it work

- Possible malfunctions and their elimination

- No water in the tank

- Constant flow of water into the toilet

- Noisy filling of water in the tank

- Installation and replacement of drain fittings

- Types of check valves and the principle of their operation

- Swivel (petal)

- Lift check valve for sewerage

- Ball check valve

- Wafer type

- Valve or fan pipe

- A private house

- Apartment house

- Types of toilet valves

- Valve classification

- Additional functions of drain valves

- Types of fittings for flush cisterns

- Separate and combined options

- Materials for the manufacture of devices

- Place of water supply

- Flush Troubleshooting

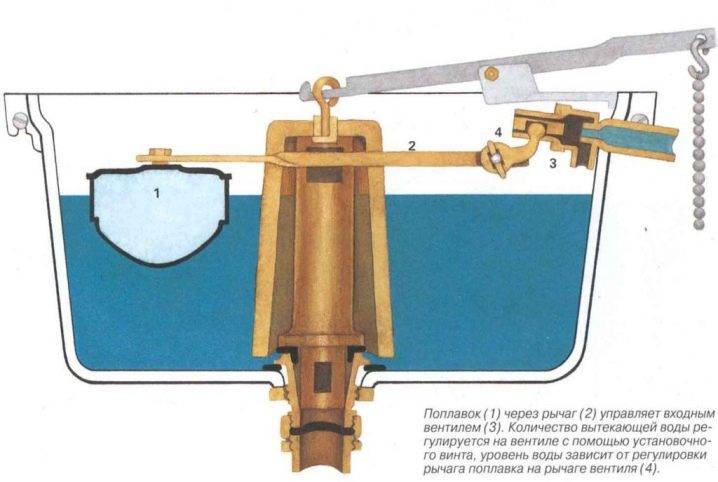

The work of the mechanism

The principle of operation of the entire flushing device is no different from the long-used sample. The drain from the tank in modern versions of the toilet bowl is absolutely identical to the drain in the corresponding devices of the Soviet era. A set of liquid in the tank comes from the water supply of the apartment. To turn off the water supply to the toilet, there must be a shut-off valve. Malfunctions with the toilet happen no less than with plumbing, and most importantly - they do not coincide in time.Here, in order to troubleshoot the toilet, it is necessary to block the line from the water supply.

If water is drained from the tank, then the float is in the lower position of the tank, opening the way for water inlet through the inlet valve. As the fluid level in the tank rises, the float rises, gradually closing the inlet valve. Reaching a certain level of liquid in the tank, the pop-up float through the rocker connected to the valve membrane completely blocks the flow of water into the tank. At the same time, the membrane valve of the bleeder, located on the stem of the bleeder, is pressed against its seat by the pressure of the liquid level. With serviceable fittings, the descent system does not let fluid out of the tank.

To activate the flush, you need to pull the lever or press the release button on the tank. The release valve opens. Water rushes into the toilet bowl. The dual-mode cistern has two release buttons: low volume per flush and full flush. After emptying the tank, the inlet float is in the lower position and opens the inlet valve. The cycle of the system is repeated.

Testing the toilet flush system after installation

After installing or repairing the flush mechanism of the toilet cistern with a button, the system is tested. The first step is to check for visible leaks. To do this, it is necessary to drive the water in the plumbing device several times. Water should not unnecessarily flow into the toilet bowl, and you should also make sure that there are no leaks under it. In case of their detection, it is necessary to fix the fasteners as firmly as possible.

Next, it is checked whether the water level in the tank has reached the desired level. If this does not happen, the toilet bowl is adjusted.The filling valve should work normally, not stick. You can verify the quality of its work by making sharp impacts on the mechanism down or up.

Next, you need to evaluate the operation of the system by ear. If a hiss, hiss, or other harsh sound is emitted, the flap valve is closed. The problem is eliminated by lowering or raising the element using a screw driven by a screwdriver.

To ensure the normal operation of the system, the water level in the tank is adjusted. The float, which is held by a thick wire, should be placed so that it is located 1-2 cm below the edge of the reinforcement. For a larger set of water, the metal lever must be bent with an arc down. To lower the liquid level, the product is bent in the opposite direction.

After installing the drain system, it must be tested.

After installing the drain system, it must be tested.

If the float lever is made of plastic, it is adjusted by a special screw that rotates until the float is in the desired position. The optimal level of liquid in the tank is considered to be at which the water will be 3 cm lower than the overflow hole.

The correct position of the buoy indicates that water does not overflow through the system and does not go into the toilet bowl unnecessarily. After adjustment, the lid is installed on the tank and fixed with a button.

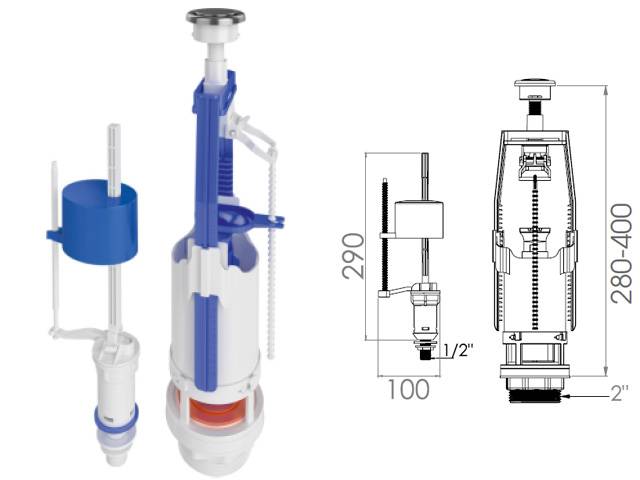

Quality fittings for the toilet bowl with bottom connection

Among the wide variety of designs of modern toilet bowls, only one remains unchanged - the toilet bowl drain system, which operates on the basis of only 2 possible mechanisms today.A filling mechanism with a bottom connection, operating on the basis of a shut-off or drain device, which includes a guide, a float, a rod, a glass and a membrane (less often a piston, inlet) valve. The basic principle of operation of such a mechanism lies, as a rule, in blocking the flow of the medium (in this case, water), which happens in the toilet bowl with each use. When, when draining water, the float lowers, thereby affecting the inlet valve, which, when opened, allows water from the water supply to fill to the required level, it closes again, blocking the flow.

The fitting opens the water supply when the tank is empty, and shuts off the water when the tank is full

The fitting opens the water supply when the tank is empty, and shuts off the water when the tank is full

It should be noted that today the most common are lateral supply systems.

But, as for the mechanism with a bottom connection, the most common is the shut-off valve for the toilet, due to its efficiency and practicality. The side supply mechanism, the main difference of which is that the water supply system has a water supply connection not from below, but from the side, includes the same membrane valve, lever and trigger.

The main qualities of fittings for a toilet bowl with a lower connection are:

- A nice visual effect, because often when using such a system, the toilet bowl is decorated with an eccentric design, and can have an unusual shape, which easily hides the system itself.

- Such a system creates practically no noise.

- Comparative simplicity of the whole design, which determines the reliability and long-term operation.

At the same time, it can be noted that among all the obvious advantages, there are also disadvantages, which are rather complicated installation and the close complexity of the entire system, which creates difficulties in repair, since this entails the need to repair the entire flush tank, which is the best option for breakdown.

Varieties of check valves

Modern check valves are usually divided according to the principle of operation of the locking mechanism. It is necessary to take into account the characteristics of each of them when choosing sanitary fittings.

Petal devices are equipped with a spring-loaded rounded membrane located at the top of the housing. It rises when water moves freely along the contour. But if the liquid begins to flow in the opposite direction, then the shut-off valve turns and presses firmly against the rim of the outlet.

So the pipeline is completely blocked. Some models are equipped with a manual lock, in which an additional gasket is installed, controlled by a button.

Many rotary valves are larger than a conventional pipe. During installation, both strongly narrowed and expanded areas can be formed, in which severe congestion will then occur.

To eliminate them, there is a special removable cover located on top of the device. For this reason, this type of device is not suitable for the sewer circuit.

The ball check valve for sewerage is equipped with a ball-shaped shut-off assembly.

On top of the body there is a small recess in which the ball is located with the free flow of water through the pipe.If the flow of drains stops abruptly, then it immediately rolls out and completely blocks the pipeline, preventing the reverse flow of dirty liquid.

It is also worth noting that this type of check valve is not intended for installation in a vertical sewer riser.

Such mechanisms are most popular with a bell diameter of 50 mm. They are able to withstand a lot of pressure, so they are often mounted in multi-storey buildings.

What is a vacuum toilet and how does it work

If you want to achieve maximum comfort and at the same time save water, then you should pay attention to such an interesting toilet model as a vacuum. Outwardly, it is almost indistinguishable from the usual standard device, but its mechanism works a little differently and allows you to drain less water at a time than a typical toilet.

The fact is that in the drain operation, not only water is used here, but also air.

Today, vacuum toilets are used more and more often. They have gained popularity due to the fact that they are convenient to use in many establishments, such as:

- Shopping centers;

- Hotels;

- Educational establishments;

- Transport;

- Airport or railway station;

- Stadiums;

- Treatment centers;

- Multi-storey buildings and structures;

- Museums.

An additional advantage of vacuum toilets is their ability to absorb odors, as well as the fact that they do not require too many large diameter pipes to install. This makes them more versatile, with the ability to install anywhere. For the installation of conventional toilets, pipes with different cross sections are often required, which makes it difficult to install them in some places.

Vacuum models are preferred in vehicles for a reason. This is due to the way they work.The air supply in them is regulated by special pumps that create a vacuum. When someone presses the drain key, the valve is activated, it opens, and then the air is simply sucked in. It not only contributes to a better removal of the contents of the bowl, but also removes unwanted odors.

In order to control the cleanliness of the flush, water is additionally supplied to the bowl in the amount of one liter. This is usually sufficient for the final cleaning of the toilet bowl. The water drains quickly and the valve immediately returns to its place.

Possible malfunctions and their elimination

Before you figure out the possible causes of the breakdown of the inlet valve, you need to turn off the tap of the water supply system, open the tank lid and drain the remaining water from the tank. If necessary, pull out the device itself.

No water in the tank

- Reason #1: clogged holes. In this case, you should disassemble the device, clean and rinse its elements.

- Reason number 2: low water pressure or its jumps. In this problem, it must be taken into account that with a weak flow of water and a high location of the tank, the liquid will not approach the filling chamber, the float will pop up, but the water will not shut off. You can try to increase the inlets by 3 mm, and in the case of constant surge pressure, it is better to purchase a stem valve.

Constant flow of water into the toilet

- Reason #1: skewed float. Repair consists only in fixing the intake valve in place.

- Reason number 2: violation of the tightness of the gasket (damage to the membrane or stem). In this case, a complete replacement of the mechanism is necessary.

Noisy filling of water in the tank

Reason #1: Disconnecting the water silencer. To correct the situation, the muffler should be adjusted to a special fitting.

Installation and replacement of drain fittings

Before proceeding with the installation or replacement of fittings, you need to prepare the necessary tools: pipe and other wrenches, pliers. As additional materials, a sealing tape, gaskets of different diameters, flexible pipes are required. If the cistern has two openings, a decorative cap will be required to cover the unused opening.

Part of the reinforcement is installed even before the installation of the tank, and after the other part. The first stage involves the installation of the base of the drain mechanism. It is fixed with a plastic nut. Next, a rubber seal is put on the nut and the tank itself is attached.

The next step is to mount the device responsible

for the flow of water and the connection of hoses from the water supply.

During installation, the float, levers, and valve must be adjusted. Set the float so that it provides the volume of water required for draining. The foam float is easy to adjust - it is moved along the bar. Plastic - by changing the angle between the slats.

How the installation of fittings looks like can be seen in the following video:

Types of check valves and the principle of their operation

The main task of the check (shut-off) valve is to block the flow going in the opposite direction. To do this, a movable barrier is placed in these mechanical devices. The basic principle of operation is that in a calm state, the mechanical damper is lowered down, blocking the lumen of the sewer pipe and preventing the reverse flow from passing. When drains appear, it rises (moves to the side), the drains leave, and it closes again. By the type of this barrier and the principle of its operation, this equipment differs.

Swivel (petal)

In sewer valves of this type, a spring-loaded round membrane (plate) is installed. If the flow moves in the “right” direction, it turns, rising up does not interfere with drains. If the movement starts in the other direction, the membrane (plate) is pressed against the rim inside the valve, tightly and hermetically blocking the pipe lumen. Some models have a manual shutter. This is the second membrane, which can be controlled using a button mounted on the body.

Due to the shape of the membrane, such shut-off valves are also called flap valves, and sometimes you can hear the term “slams” - this is because of the way they work - the membrane slams if there is no drain.

The figure shows how the check valve for sewerage works.

The device itself is larger than the pipe on which it is installed. So in the pipeline there is first an expansion, and then a narrowing of the lumen, and these are potential places for blockages to form. To be able to quickly eliminate blockages, a removable cover is made in the upper part of the check valve body. By removing it, the problem can be quickly eliminated.

Lift check valve for sewerage

This type of locking device for a sewer pipe is so named because when the drains pass in the “correct” direction, the locking element rises. Drains press on the plate blocking the passage, compressing the spring, which rises. There are no drains - the spring is unclenched, the passage is locked. When effluents come in from the "wrong" side, there is no way to open the passage. This is achieved by a non-linear hull shape.

Scheme of the device of the lifting sewer valve

The lift check valve is more reliable, but its design is such that it often clogs and requires periodic cleaning. Why do you need to remove the cover (unscrew four bolts), clean or replace the mechanism.

Ball check valve

Another option for a locking device in a check valve is a ball. In these devices, the internal structure of the case plays an important role. Its upper part is designed in such a way that when passing through the drains, the ball rolls into a special recess in the body, opening the passage.

The structure of the ball check valve for sewerage

When it is dry in the pipe, it blocks the section; when the flow passes in the opposite direction, it blocks the lumen of the pipe. The main drawback of this design is the leakage of drains during flooding - the ball and the side wall of the body do not always fit perfectly, which leads to the fact that some of the drains still seep through. But mass flooding and a geyser from the toilet will not be for sure.

Why you need an air valve in the sewer and how to install it, read here.

Wafer type

Many people like this type of check valves more because of their miniature size. This is a very small cylinder, inside of which a rotary damper is installed. It may consist of two parts that are attached to the central rod, or it may look like a small plate, attached to the housing wall in one place with the help of a spring.

Wafer Type Check Valve

Despite its compactness, it is better not to install this type of check valve on the sewer: this is plumbing equipment and it will not work well on the sewer. The second disadvantage is the impossibility of quick cleaning - the design is such that you can get to the valve only by disassembling the connection.

Valve or fan pipe

And now let's decide whether the vacuum valve can completely replace the fan pipe. We will also split this question into two:

Is it possible to supply sewerage in a private house with a valve instead of ventilation? Is it possible do-it-yourself dismantling of the sewer riser on the top floor of an apartment building above a cross or tee and install a fan valve instead?

A private house

Installing a valve instead of ventilation is possible, but undesirable. Why?

- There is no escape from the traction created in the risers. The slightest violation of the tightness of the sewer - and the smells of sewage will saturate the kitchen and bathroom. With ventilation running, any gap between the piping of the plumbing fixture and the socket of the pipe will, on the contrary, draw air out of the corresponding rooms;

- When connected to the central sewer, the fan pipe contributes to the ventilation of the manhole through the outlet. In particular, the content of methane falls under the cover. The argument is not far-fetched: every year several people die by suffocation in a well;

- If you use a septic tank, ventilating it through a vent pipe will help activate the vital activity of aerobic bacteria and, therefore, improve the processing of wastewater with a decrease in solid sediment and odors.

Apartment house

I strongly do not recommend disassembling the outlet of the riser to the roof. Even with the replacement of the fan pipe with a vacuum valve. You see, the benefit of such a solution will only be the ability to make the cabinet above the toilet a little more spacious; but the righteous anger of the neighbors below, the housing organization and representatives of the municipality will fall on your head.

Why?

The mechanism in a nutshell is:

- After dismantling the fan pipe and installing the valve, the ventilation of the riser will stop, but the draft in it will not go anywhere. Meanwhile, the connections of the washbasins with the comb in most apartments are leaky. Amber that suddenly appears will arouse the interest of residents on the floors below you and a bunch of complaints to the housing office or the management company;

- The locksmith who came to the call first of all examines the outlet of the fan pipe to the roof. After making sure that it is missing or cut off at the level of the attic, he will pay a visit to the top floor - to you;

- Based on the results of the inspection of the riser, an act will be drawn up on the unauthorized reorganization of engineering communications, affecting the interests of other residents;

- The consequence will be an order to restore the original configuration of the riser with the possible imposition of an administrative penalty.

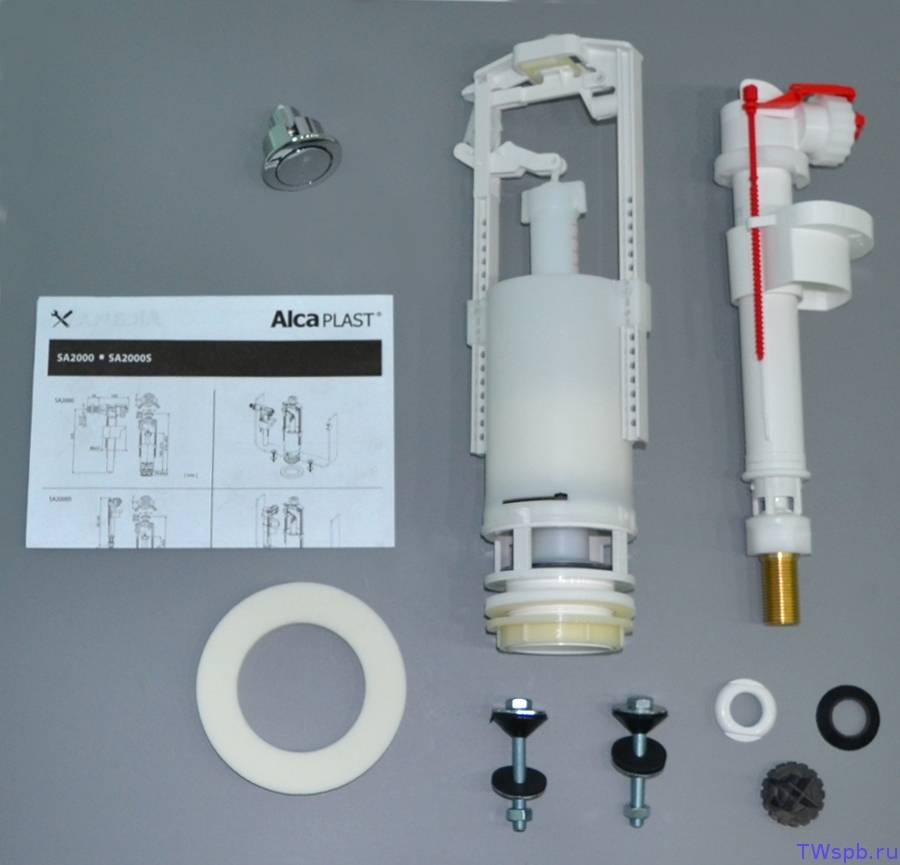

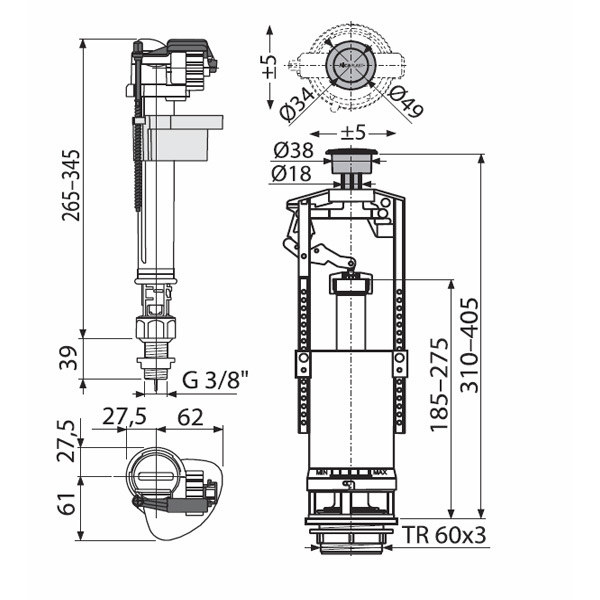

Types of toilet valves

The inlet valve (aka filling, filling or filling) is used to supply water and stop filling when the limiter is reached. The outlet valve (aka drain) takes on the functions of flushing water, adjusting the volume and flow rate.

Each inlet valve for the toilet cistern must have a shut-off device to shut off the water. The design of some inlet valves for a toilet bowl with a bottom connection provides for a check valve that prevents water from entering the tank into the plumbing system when the water supply is turned off.

All inlet and outlet valves for the toilet, in turn, are divided into various types, material and design features. Since sanitary fittings are constantly being improved, models with completely new characteristics appear, the following information and classification should be considered approximate.

Valve classification

By material

Inlet and drain valves are made of the following materials:

- entirely made of plastic;

- mainly made of plastic with individual elements made of steel or brass (nipple thread, rocker arm and other details).

In terms of reliability, modern models for a drain tank with plastic threads, supplied to the market by well-known manufacturers, are not inferior to metal ones.

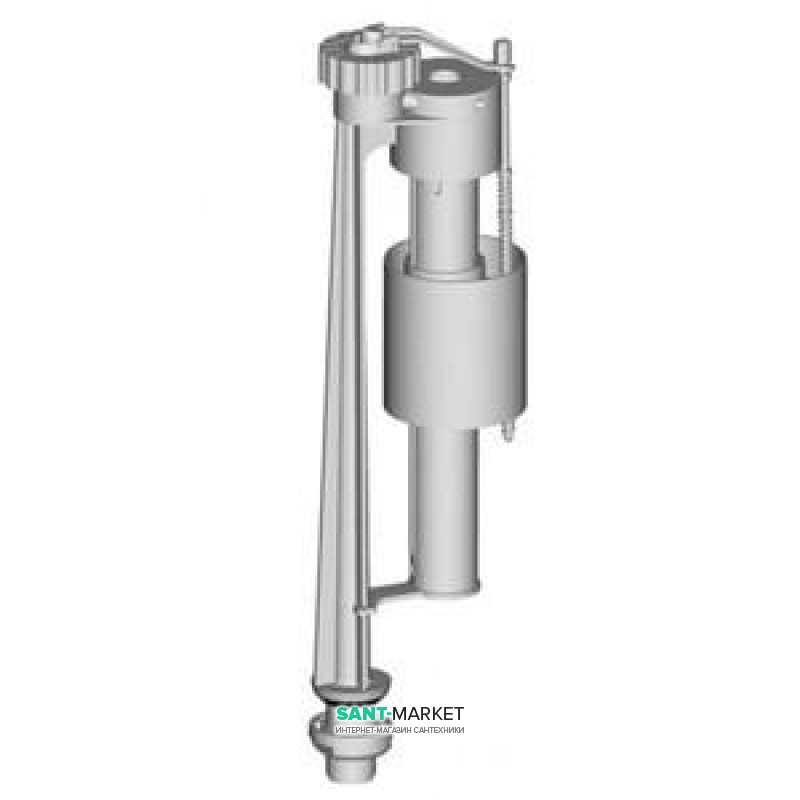

By location

The following installation options for filling valves for the toilet are possible:

- with a lower water supply - attached to the bottom of the drain tank;

- with lateral eyeliner - attached to the side wall of the tank;

- 2 in 1 - the valve has a removable fitting attached from the bottom or side, it is possible to mount it to the bottom and side wall.

By type of construction

Types of filling valves for the toilet:

- with a side connection and a conventional float on a long metal rocker, the design is familiar from Soviet toilet bowls, for valves of a later time, to reduce noise, the filling goes through the tube;

- with a lower water supply and a float on a long rocker, is a modernized version of the previous model, is rare;

- with lateral eyeliner and a vertical stand along which the float moves;

- with a lower water supply and a vertical stand for a float;

- the previous version, supplemented by a check valve.

Types of drain valves according to the method of flush control:

- Mechanical. The simplest option, it works when you press a button, lever or pull the handle.

- Pneumatic. It looks like a mechanical one, but the transmission of forces occurs through an air duct through air pressure, which allows you to move the flush button to any convenient place.

- Electronic.Allows you to connect smart functions, adjust settings. Runs on batteries or mains power, many models have a backlight. Flushing occurs when the electronic button is pressed, the pressing itself is softer than that of the mechanics.

- Touch (automatic, non-contact). It is triggered by the movement or presence of a person. In residential areas, drain valves with mechanical control of water inlet are most often found.

They are divided into the following types:

- Push. Flushing water occurs when you press the button located at the top. In turn, it is divided into three types:

- single-mode - the collected water from the tank is discharged entirely;

- dual-mode - equipped with a double button with full flush and low flush modes, designed for different volumes of water;

- with the "stop" function - when pressed, flushing occurs, when the button is pressed again or released, depending on the model, flushing stops, which saves water.

- Exhaust. The descent of water occurs when lifting up the exhaust handle. Models with the "stop" function stop the descent by gently pressing the handle from top to bottom.

- Lever. It is triggered by pressing the handle located on the body of the tank, or by pulling the handle with a chain connected to the lever.

Additional functions of drain valves

- the "Breather" function in the push-button mechanism - prevents the formation of a vacuum in the drain tank during flushing in the absence of special air supply holes in the body, which guarantees the intensity of the water flow during descent;

- flush speed adjustment - avoids splashes from the toilet bowl;

- button eccentric - designed to adjust the position of the shutter button if the button and drain hole are not located exactly opposite each other.

Types of fittings for flush cisterns

The principle of operation of a conventional tank is not complicated: it has a hole through which water enters and a place where water is discharged into the toilet. The first is closed by a special valve, the second - by a damper. When you press the lever or button, the damper rises, and the water, in whole or in part, enters the toilet, and then into the sewer.

After that, the damper returns to its place and closes the drain point. Immediately after this, the drain valve mechanism is activated, which opens the hole for water to enter. The tank is filled to a certain level, after which the inlet is blocked. The supply and shutoff of water are regulated by a special valve.

A cistern fitting is a simple mechanical device that draws water into a sanitary container and drains it when a lever or button is pressed.

There are separate and combined designs of fittings that collect the volume of water necessary for flushing and drain it after activating the flushing device.

Separate and combined options

The separate version has been used for many decades. It is considered cheaper and easier to repair and set up. With this design, the filling valve and the damper are installed separately, they are not connected to each other.

The shut-off valve for the tank is designed in such a way that it is easy to install, dismantle or change its height.

To control the inflow and outflow of water, a float sensor is used, in the role of which even a piece of ordinary foam is sometimes used.In addition to a mechanical damper, an air valve can be used for the drain hole.

A rope or chain can be used as a lever to raise the damper or open the valve. This is a typical option for models made in retro style, when the tank is placed quite high.

In compact toilet models, control is most often carried out using a button that needs to be pressed. For those with special needs, a foot pedal may be installed, but this is a rare option.

In recent years, models with a double button have been very popular, which allow you to empty the tank not only completely, but also halfway to save some of the water.

The separate version of the fittings is convenient in that you can repair and adjust individual parts of the system separately.

Combined type fittings are used in high-end plumbing, here the drain and inlet of water are connected into a common system. This option is considered more reliable, convenient and expensive. If this mechanism breaks, the system will need to be completely dismantled for repair. The setup can also be a little tricky.

The fittings for the toilet cistern with side and bottom water supply are different in design, but the principles of setting up and repairing them are very similar

Materials for the manufacture of devices

Most often, toilet fittings are made of polymeric materials. Usually, the more expensive such a system is, the more reliable it is, but this method does not give clear guarantees. There are fakes of well-known brands, and quite reliable and inexpensive domestic products. An ordinary buyer can only try to find a good seller and hope for good luck.

Fittings made of bronze and brass alloys are considered much more reliable, and it is much more difficult to fake such devices. But the cost of these mechanisms will be much higher than that of plastic products.

Metal filling is usually used in high-end plumbing. With proper configuration and installation, such a mechanism functions smoothly for many years.

In bottom-fed toilets, the inlet and shut-off valve are very close. When adjusting the valve, make sure that the moving parts do not touch.

Place of water supply

An important point is the place where water enters the toilet. It can be carried out from the side or from below. When water is poured from the side hole, it produces a certain amount of noise, which is not always pleasant for others.

If the water comes from below, it happens almost silently. The lower water supply to the tank is more typical for new models released abroad.

But traditional cisterns of domestic production usually have a lateral water supply. The advantage of this option is the relatively low cost. The installation is also different. The elements of the lower water supply can be installed in the tank even before its installation. But the side feed is mounted only after the tank is installed on the toilet bowl.

To replace the fittings, they are selected taking into account the option of supplying water to the sanitary tank, it can be side or bottom

Flush Troubleshooting

Malfunctions in the operation of the piston for the toilet most often occur due to the failure of its individual components. For example, inefficient operation of the float is often observed due to its distortion, wear of the membrane, or the formation of a through hole.After removing the tank cover, try to adjust the float by carefully inspecting its mount and setting it in the desired position.

If the problem lies in the piston of the drain device, for example, due to its wear, you will have to change it, following a certain sequence of actions:

- Release all water from the tank.

- Disconnect the valve from the plumbing system.

- Remove the piston.

- Remove the valve.

- Install a new device with the same operating principle.

- Fill the tank with water.

- Adjust the float and check the system for proper operation.