- Installation Recommendations

- Peculiarities

- All about installation and connection

- Installation of a caisson from concrete rings

- Installation of a metal caisson

- Installation of a plastic caisson

- What materials are made from

- Metal caisson

- Advantages

- Flaws

- Plastic caisson

- Advantages

- Flaws

- Misconceptions about plastic caisson

- Caisson from reinforced concrete rings

- Why rarely used:

- Brick caisson for a well

- Table: tools for building a brick caisson

- Preparation for the installation of a brick caisson

- Step-by-step instructions for making a brick caisson

- What is a caisson

- Types of caissons

- The device and features of pits for wells

- How to make a caisson yourself

- Monolithic concrete structure

- Caisson from concrete rings

- Budget camera made of bricks

- Sealed metal container

Installation Recommendations

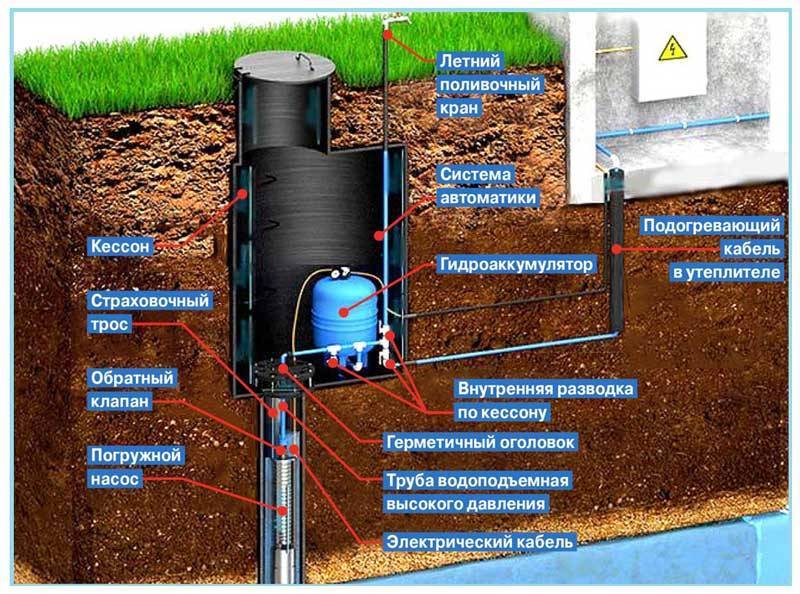

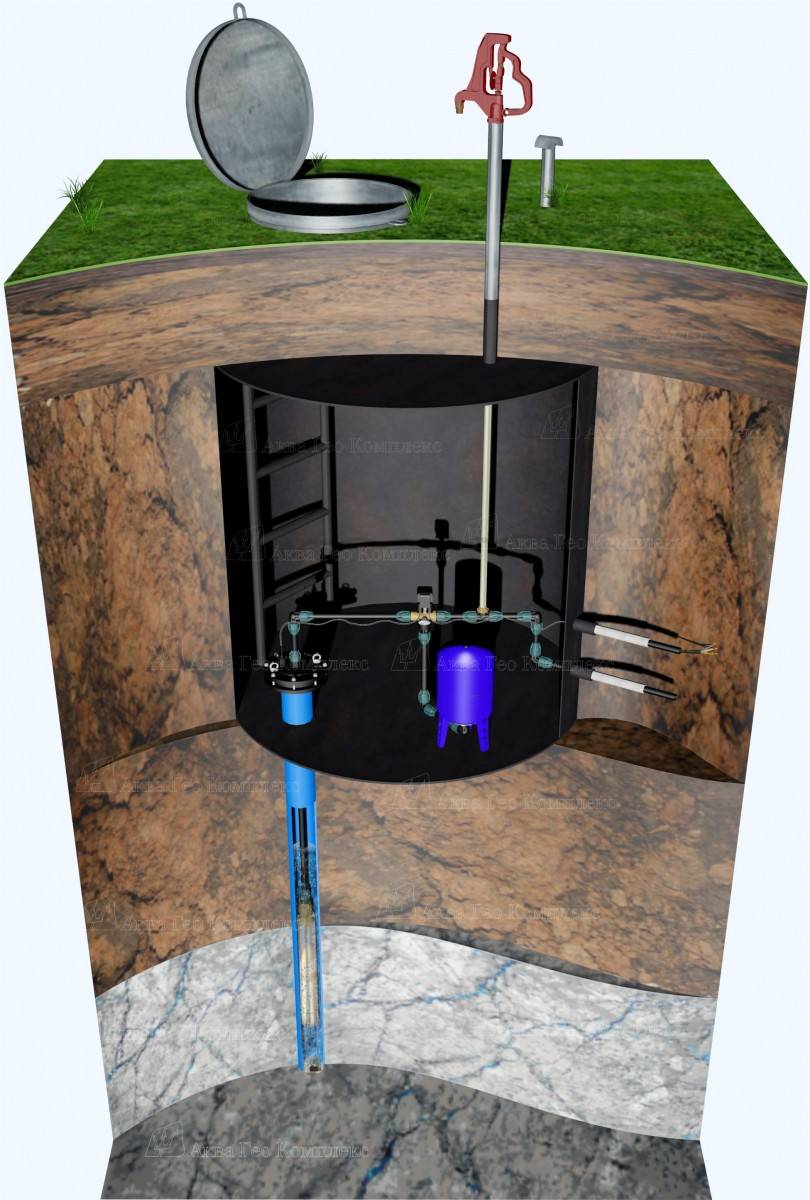

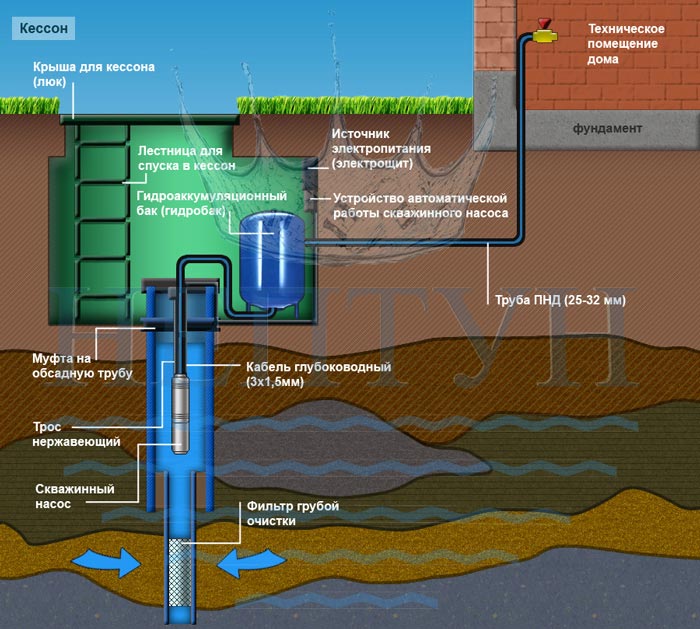

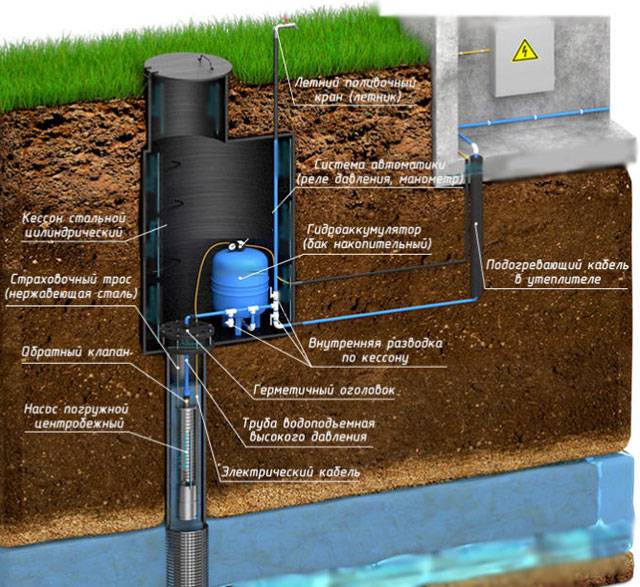

The main reason why a caisson is needed for a well is the need to protect its head from damage and the need to place equipment (for more details: "How to install a well head - theory and practice"). This design does not allow storm drains and various contaminants to penetrate into the water intake area.

Also, installing a camera on a well is much more profitable than operating surface structures, since it does not require heating, and this has a positive effect on operating costs, but provided that it is located below the freezing depth.

But otherwise the caisson cannot be equipped, because if you install it higher, then in frost it will be squeezed out of the ground. True, this problem in some cases occurs with a buried camera. This is especially true for areas that have problems with a high occurrence of the aquifer.

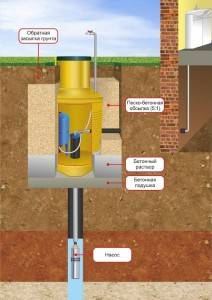

Therefore, experts strongly recommend "anchoring" both light plastic structures and metal products that are more stable. Technologically, this is easy to do. A concrete base is poured under the chamber for the well, and then its bottom is attached to it using anchor bolts.

In high-lying areas that are not dangerous for flooding, you can do without making a slab, it will be enough to create a sand cushion. True, in this case, the presence of a heavy base will not be superfluous and it is better to always equip it, regardless of the geological features of the territory.

The camera is always installed strictly vertically - compliance with this requirement is mandatory. The height of the structure should be about two meters, so it will be convenient to work, you can place the necessary equipment and deepen the product below the soil freezing mark.

Such a distance is quite understandable, since then the frost will not damage engineering communications. The bayonet of a shovel is used as a guide. But the pipeline with water is buried at a greater depth - below the freezing mark.Surface entry into the building is possible only in the case of thermal insulation of the pipe section from the freezing level to the point of entry into the property.

Taking into account what the caisson for the well is for, the equipment placed in it must be placed above the floor at a low height in case flooding suddenly occurs.

All electrical devices in the chamber should be grounded and it is desirable that an RCD be provided in the electrical circuit. According to experts, security cannot be superfluous, and in some cases it is not enough.

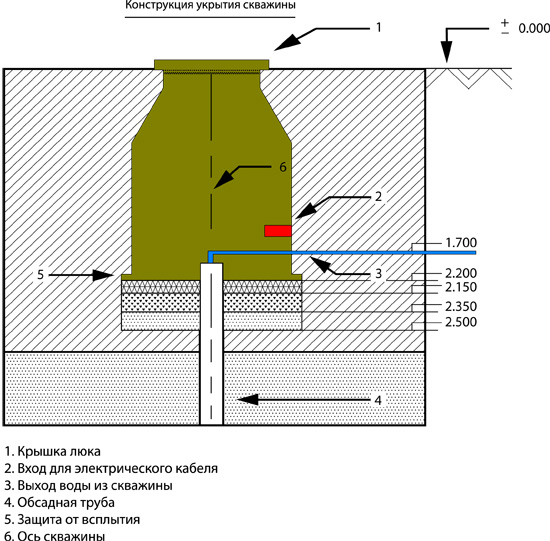

The casing pipe of the well enters the caisson through a sleeve that is slightly larger than its diameter. For example, taking into account the modern assortment, a 146 mm sleeve is required for a pipe with a cross section of 133 mm.

The well pipe should not be flush with the bottom of the structure, but be a little higher by about 40 - 50 centimeters in case flooding occurs. The sleeve and the casing at the junction must be sealed.

A special sealed cover is placed on the well, called a cap, in which there are holes designed for the cable of the submersible pump and the HDPE pipe coming from the pumping equipment. The power cable of the pump is attached to it.

The cover protects the wellbore, preventing debris and dirt from accidentally getting into it. The entrance to the chamber is usually closed with a hatch. Its design features depend on the personal preferences of homeowners. In any case, it is preferable to equip the caisson with two hatches in order to save heat.

The outlet under the pipe of the water source is usually punched in place, it does not have to be in the center.Its displacement is allowed to make it asymmetric. But at the same time, one should not forget that the well outlet and the structure hatch must be made coaxial for the convenience of repair and installation of equipment. In other words, the entrance hatch is best placed directly above the head of the well.

Peculiarities

Initially, caissons were intended for carrying out various works under water. They were a closed chamber into which water did not penetrate. The shape of such objects, as a rule, was round or square. At present, the main feature of the caisson, which is its water resistance, has remained unchanged. However, today the range of its application has become wider. For example, caissons are rightfully recognized as useful elements of autonomous water supply.

If you want to use water from your own well all year round, you cannot do without a high-quality caisson (or a special borehole adapter). It is possible to install it yourself, although this is not as easy as it might seem.

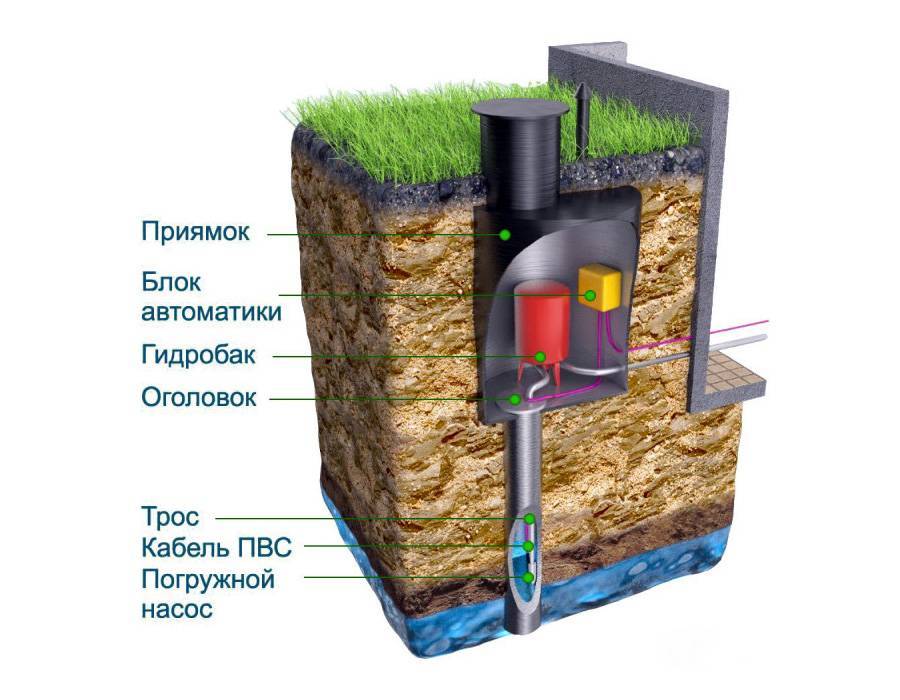

Caissons are sealed, which protects the head of the well from groundwater. This feature plays an important role because it protects the household from the flow of liquid from the neighboring sewer when the tap is turned on. This is due to the fact that the end of the well casing does not cross the ground surface, but is located at a depth of approximately 2 m. It is in this place that the groundwater is located.

A similar depth of the well head is due to the freezing of the soil (its depth is approximately 2 m). Of course, in this matter a lot depends on the area in which the house is located.In addition, the appropriate depth of the head is also necessary so that in winter the water comes out of the taps without freezing. The equipment itself with this design is also reliably protected from destructive freezing.

Round-shaped caissons are common in our time. Such products have a diameter of 1 m and a height of 2 m. The dimensions of these items are explained by the fact that the well is located at a depth of 2 m, and in order to have access to it, the hatch of the caisson is brought to the surface of the earth.

Today, caissons are made from different materials, but the most common and reliable options are made of iron. Such units are not afraid of mechanical damage or temperature changes, however, they are susceptible to corrosion, and therefore require high-quality protective treatment. In addition to iron, there are also brick, concrete and plastic models of caissons. Each of them has its own distinctive features.

All about installation and connection

In order for the caisson chamber to perform its protective functions well, and also to serve as long as possible, a number of rules must be observed during its installation. Before starting work, you should carefully consider the layout of the external pipeline.

It is necessary to take into account the ways of laying other underground communications, the depth of groundwater and the level of soil freezing in winter. Installation features also depend on the design of the caisson and the material from which it is made.

Installation of a caisson from concrete rings

Rings are mounted in two ways:

- Laying the required number of rings on the surface of the earth, around the head of the well.Their number is selected depending on the design depth of the caisson for the well. The rings are stacked on top of each other, and covered with a concrete cover on top. Next, the soil is sampled from inside the future caisson chamber, as a result of which the rings deepen under their own weight. When they descend to the desired depth, the casing pipe is cut so that it protrudes 0.5-1 m above the bottom of the resulting chamber. The bottom of the caisson is concreted or covered with coarse gravel, and the top cover and walls are insulated.

- The second option provides a different installation process. Initially, a pit of the required depth and diameter is dug around the well. The protruding part of the casing is cut to the desired level so that it protrudes slightly above the bottom of the chamber. And only after that is the laying of reinforced concrete rings at the bottom of the pit. Docking seams are carefully sealed with cement mortar and smeared with moisture-proof mastic. With the last step, the chamber is insulated, and the outer sinuses are covered with soil.

The difficulty in installing concrete rings can only be the need to use a crane. Renting construction equipment increases the cost of work, and it will not always be able to freely travel to the site of the well on the plot.

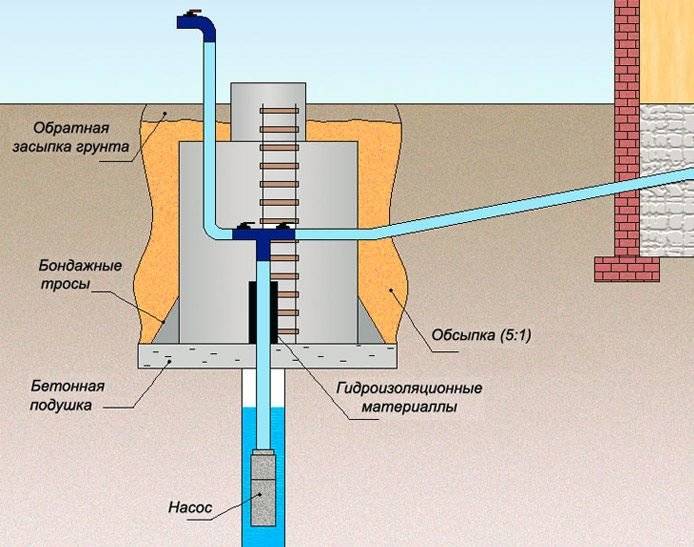

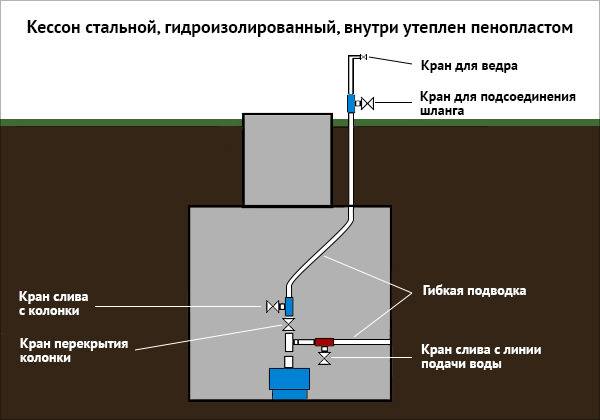

Installation of a metal caisson

Metal structures are also very heavy, so for their installation you will have to use a crane or winch. Initially, a pit of the required depth and dimensions is dug. Its bottom is leveled, and a base is laid on it in the form of a concrete pour, or a sand and gravel cushion.

Before starting the installation, the metal caisson is carefully treated from the outside with waterproofing compounds to prevent corrosion. After installation in place, it is recommended to insulate its walls and cover in order to avoid excessive heat loss.

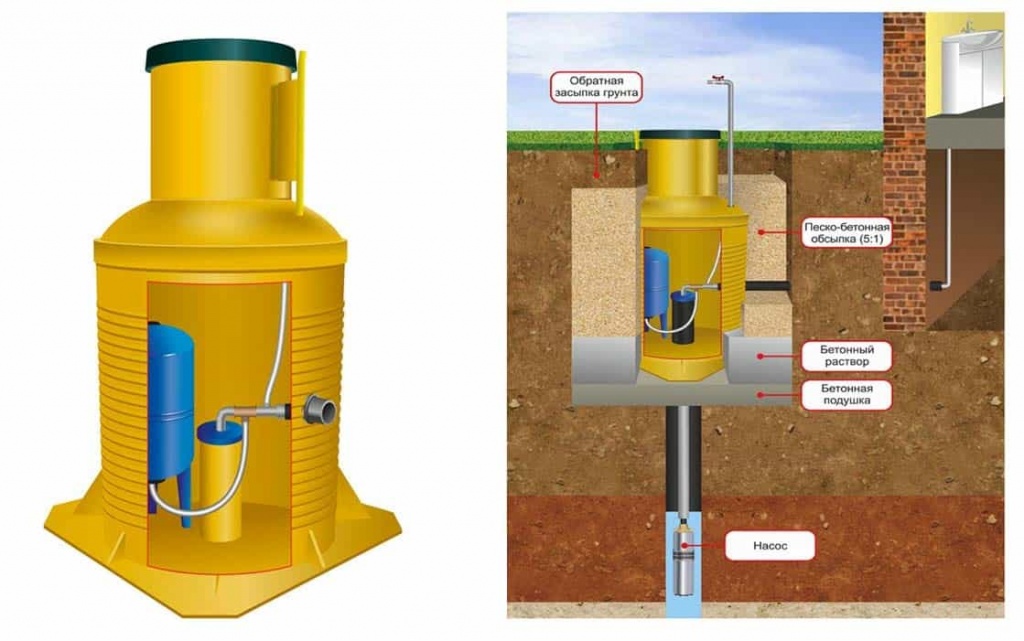

Installation of a plastic caisson

The installation process of ready-made polymer caissons is in general similar to the installation of metal chambers. The procedure here is the same, with the exception of the need for waterproofing. Another feature of plastic caisson chambers is the possibility of squeezing them out of the ground when the soil is heaving.

Therefore, to increase the mass, their bottom is poured with concrete, or covered with a sand and gravel cushion. To fix a lightweight structure into the ground, “anchors” are also used in the form of reinforcement hammered into the ground.

Polymer-sand modifications have a prefabricated structure consisting of several elements. They are attached to each other with thorn-groove joints. Installing them on top of each other is exactly the same as when installing concrete rings. After the installation work is completed, an external pipeline is connected to the installed caisson, the upper edge of the casing pipe is cut to the desired level, and a head is placed on it.

What materials are made from

The most common caissons are round metal. For specific needs, they can be square or rectangular. Less commonly, caissons are made of plastic and reinforced concrete rings.

Metal caisson

Steel box treated on the outside with an anti-corrosion coating with a metal thickness of 3-6 mm.

Advantages

tightness

We pay special attention to the quality of workmanship and the quality of welds;

Due to the tightness, it is possible to install equipment for a well, including electrical equipment, in it;

Ease of installation (relative to concrete rings and plastic caisson);

Mechanical strength, resistance to soil pressure;

Reliable fixation in the ground. Ground loading on the body plus welding with the casing string prevents the caisson from surfacing;

Service life up to 50 years. Our technology of hermetic water drainage from the caisson, in which the metal does not come into contact with water, and internal anti-corrosion treatment allows the caisson to operate as long as possible without repair.

Our technology of hermetic water drainage from the caisson, in which the metal does not come into contact with water, and internal anti-corrosion treatment allows the caisson to operate as long as possible without repair.

Flaws

- Great weight;

- The need for welding. Our caisson can be equipped with a compression joint and sealed bends. In this case, there is no need for welding, which greatly facilitates the installation process;

- Susceptibility to corrosion. Poor anti-corrosion treatment and unskilled installation significantly reduce the life of the caisson.

Plastic caisson

Recently, the method of arranging a well with the help of a plastic caisson is gaining popularity. Let's look at its advantages and disadvantages.

Advantages

- The weight. Compared to a steel caisson or concrete rings, it is several times lighter:

- The weight of a plastic caisson is ≈ 50 to 100 kg, depending on the manufacturer;

- Weight of a metal caisson Ø1 m. ≈ 250 kg;

- The weight of 2 concrete rings with an inner diameter of Ø1 m and a total height of 1.8 m is ≈ 1200 kg.

- Does not corrode;

- The service life is more than 50 years.

Flaws

- Weak strength. Plastic under the pressure of the soil is deformed, in flooded soils, the caisson may emerge. In this regard, the installation is carried out according to a certain technology, hence the following drawback;

- Difficulty of installation:

- Installation is carried out on a reinforced concrete base with a thickness of 10 cm or more, followed by fastening to it. This is necessary to prevent the caisson from surfacing;

- Sprinkling is done with a sand-concrete mixture (cement mortar), to protect against soil pressure and maintain the shape of the caisson.

Misconceptions about plastic caisson

- Good thermal insulation. The non-freezing of water in the caisson is ensured by the heat coming from the ground, and not by thermal insulation. Undoubtedly, the thermal conductivity of metal is higher than that of plastic, only in the case of a caisson this does not matter much;

- Good waterproofing. The plastic caisson itself is airtight, but it must be connected to the casing string and pipeline, and sometimes there are difficulties with sealing these branches. As in most cases, the human factor plays an important role here. Good waterproofing directly depends on the qualifications of the installer, however, as with a steel caisson;

- Low cost.

Let's compare:

| Plastic | Steel | |

| average price | 41000 rubles | 24000 rubles |

| Excavation | For the same size, the prices are equal | |

| Installation work | • Installation in a pit • Sealing taps A plus + Before starting work, it is necessary to make a reinforced concrete base + Sprinkle with sand-concrete mixture + take into account the time required for additional work (2-3 days) | • Installation in a pit • Sealing taps |

| Total: | The total cost of equipment and installation of a plastic caisson two to three times higher than for a steel caisson. |

Caisson from reinforced concrete rings

Reinforced concrete rings for well construction are rarely used by installation organizations.

Why rarely used:

- Inconvenience of installation due to the large weight of concrete rings;

- Structural leaks. Theoretically, it is possible to perform work on waterproofing the base, rings and joints; this will require full access to the outer surface of the caisson in the finished state, which is quite labor-intensive;

- For maintenance, it is necessary to provide for the installation of a drainage pump (make a recess), in case of flooding.

A reinforced concrete caisson allows water to be drained from the well below the freezing depth, in all other respects it is inferior to the capabilities of a metal and plastic caisson.

Brick caisson for a well

The brick laying of the caisson is perhaps the most common way of constructing a container. To do this job, you will need the following tools:

Table: tools for building a brick caisson

| Name | Purpose |

| Solution container | Mixing the components of a concrete or masonry mortar, its mixing |

| Shovel shovel | Same |

| Trowel (trowel) | Laying brick walls |

| Stitching | Formation of seams during masonry |

| Rammer | Compaction of concrete in the manufacture of slab base |

| Capacity | Supply of masonry mortar to the place of work |

| Plumb and level | To control the location of the slab in space and maintain brickwork. |

To complete the work you will need materials:

- About 1.2 cubic meters of sand and the same amount of gravel for the drainage layer.

- Edged board with dimensions 125x25x6000 mm in the amount of 8 pieces for the manufacture of formwork for the slab. Stakes and stops can be made from improvised material.

- Components of concrete mortar grade 200: cement, sand, gravel, water. The calculation of the quantity is based on the following parameters: the thickness of the plate is 25 centimeters, the size is 2.7x2.7 meters. The volume of the solution will be: 0.25x2.7x2.7 \u003d 1.8 cubic meters.

-

Reinforcement bars with a diameter of 6–8 mm. Reinforcement of the slab is made with a mesh of 10x10 or 15x15 centimeters in two layers. The first is placed 5 centimeters from the drainage layer, the second is approximately 15 cm above the first. The grid sections are interconnected with a knitting wire. Grids will be needed: 2.7x2.7 \u003d 7.3 m2.

- Brick. The masonry area with a height of 1.8 m will be 2.7x2.7x1.8 = 13.2 m2. To do this, you need 13.2x51 \u003d 660 bricks at a consumption rate of 51 pieces per square meter of masonry. The thickness of the seam in this case is 12 millimeters.

- Standard concrete slab for the cover of the caisson 3x3 meters in size with an inlet - 1 piece.

- Expanded clay. To insulate the wall of the caisson and compensate for seasonal ground movements, claydite fills the niche between the wall and the ground, which will require about 8.5 cubic meters of this material.

- Mastic bituminous for the device of a waterproofing of walls outside.

In addition to the above, you will need material for the formwork of the casing hole, which can be made from improvised materials.

Preparation for the installation of a brick caisson

Preparatory measures consist in digging a pit for the installation or manufacture of a container. The marking of the contours is carried out taking into account the exit of the casing pipe in a certain place.It should be noted that between the walls of the caisson and the ground, a gap of 25-30 centimeters is needed for backfilling with expanded clay.

Step-by-step instructions for making a brick caisson

The brick caisson is made in the following order:

- Backfilling the drainage layer of sand and gravel alternately. Each layer must be compacted and spilled with water to seal.

-

Installation of formwork along the contour of the slab and in the opening for the exit of the casing. The thickness of the base plate should be about 25 centimeters.

- Reinforcement installation. For this design, it is enough to lay the reinforcing mesh in one layer.

- Pouring concrete. Concrete grade 200 is used. Further work can be continued after at least 7 days.

-

Wall laying in half brick. It is preferable to use silicate material or gas-filled blocks.

- Waterproofing device. For it, you can use bituminous mastic, applied in two layers.

-

Filling with expanded clay. The material used is a fraction of 5-10 millimeters.

- Floor slab installation.

- Installation of the entrance hatch.

- Removal of excavated soil and land reclamation.

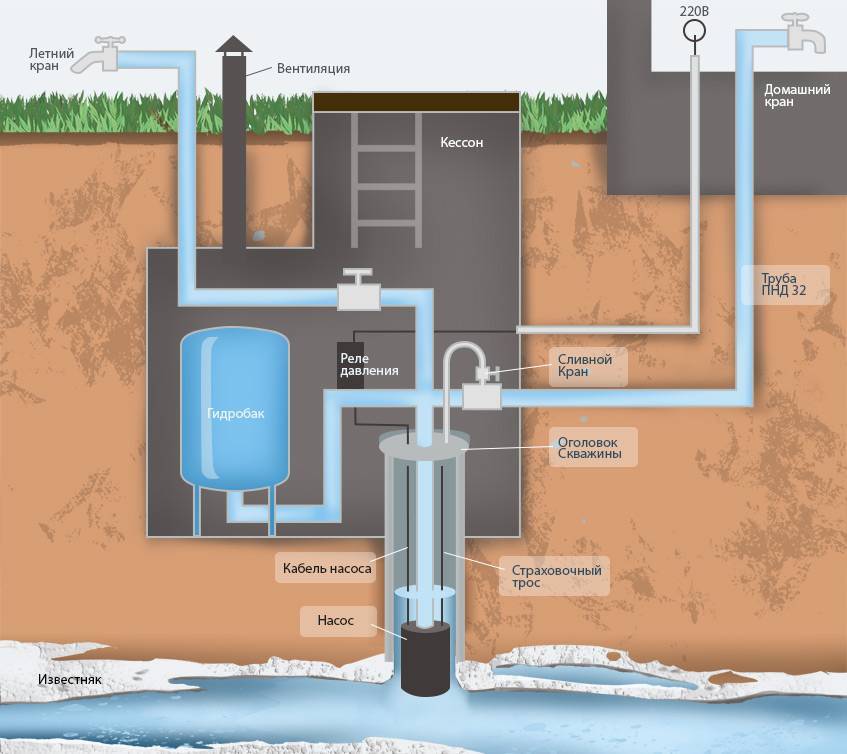

What is a caisson

In order for an autonomous water supply system to please with its reliable, trouble-free operation, when arranging it, it is necessary to think over not only technical points, but also issues related to the installation and protection of equipment from external factors. Despite the fact that underground water aquifers lie at considerable depths, equipment for uninterrupted water supply is installed on the surface. Of course, if the water intake takes place near the house, then it is possible to install a hydraulic accumulator and automation in the basement of the building.If the well is located at a considerable distance, then it is necessary to protect the pipes, wellhead and pumping equipment from moisture and low temperatures.

The caisson is an integral part of the autonomous water supply system of a suburban area

In order to prevent the harmful effects of precipitation and frost on the devices of the autonomous water supply system, a caisson is installed above the well. In fact, it is a large insulated reservoir, equipped at a sufficient depth. Thanks to the insulation of the walls and the lid of the tank, all the equipment installed in it can function all year round. The advantages of this structure include not only the possibility of installing and protecting a hydraulic accumulator and automation devices, but also providing convenient access for their maintenance and repair.

Types of caissons

Standard dimensions of caissons of various types

Caissons can be metal, concrete (reinforced concrete) or brick. Very convenient to install and operate are plastic containers that have appeared in the distribution network in recent years. In form, all protective structures can be divided into several types:

- round pits - most often made of concrete rings or plastic;

- square caissons - welded from metal sheets, brick, concrete or plastic tanks;

- rectangular tanks - made mainly from the same materials as square products, but are used in case of installation of additional equipment - expansion tanks, filters, etc.

Metal caissons are at the top of the rating of devices of this type. Most often, structural or stainless steel, as well as aluminum-based alloys, are used for their manufacture. Due to its strength, the metal perfectly resists mechanical stress, and its flexibility allows it to resist the appearance of cracks. For the manufacture of metal caissons, rolled steel with a thickness of at least 3 mm is used. After welding, the caisson is painted inside, and an anti-corrosion coating is applied on the outside. This allows the containers to serve for decades, justifying the rather high cost of manufacture.

Plastic caisson has many advantages over other designs

Plastic containers have the highest performance, excellent hydro and thermal insulation, low weight and long service life. Their cost is lower than metal and reinforced concrete counterparts. If you look for an option suitable for making your own hands, then there is nothing simpler and cheaper than a caisson built of brick or concrete.

The device and features of pits for wells

The caisson, first of all, must provide positive temperatures inside, so the tank is made airtight, and it is insulated by installation in the lower, non-freezing layers of the soil. Since the head necessary for access to pumping equipment is brought to the surface, the caisson is equipped with a heat-insulated hinged lid or a removable hatch. Often the drain door is a double structure - one head cover is equipped at ground level, and the second is about 20 - 30 cm higher.In addition, the design is equipped with ventilation, outlets (the so-called sleeves, nipples or barrels) are provided for the neck of the well, water supply and input of the supply cable. Often, an outlet with a ball valve is installed next to the lid - a kind of water column. This design allows the selection of water for irrigation and household needs in the summer.

Schematic representation of a caisson for a well

When constructing a caisson, the size of the pressure tank and the installed equipment must be taken into account. Depending on this, the casing pipe entry is shifted away from the center of the tank to provide convenient access for servicing the water supply system. All barrels are oriented in the right direction at the installation stage and carefully sealed to prevent groundwater from entering the structure.

How to make a caisson yourself

To do it yourself, first you need to decide on the material, system parameters.

Monolithic concrete structure

A square shape is suitable for the device, it is also much easier to build formwork.

First you need to decide on the size of the pit, which is dug under the structure. The length and width are standardly equal, so they can be calculated as follows: measure the size of the caisson from the inside, add the thickness of 2 walls (10 cm).

It is also necessary to calculate the depth of the pit, which should be 300-400 cm more than the height of the chamber. If everything is calculated, then the drainage layer can be installed at the bottom of the pit.

If further concreting of the base of the structure is not planned, then the following procedure is chosen

But when it is necessary to fill the bottom with concrete, the height must be taken into account.In addition, the pit should be such that the surface of the cover of the structure is flush with the soil. In order to have more space for a person when repairing the system, it is best to place the camera not in the middle in relation to the casing, but on the side

And the equipment will be conveniently placed

In order to have more space for a person when repairing the system, it is best to place the camera not in the middle in relation to the casing, but on the side. And the equipment will be conveniently placed.

Construction of a monolithic concrete caisson.

The work is carried out as follows:

- Start by digging a hole. At this point, you can immediately dig a trench for water pipes to the house. Then they begin to install drainage, which consists of 2 layers: sand (up to 10 cm high) and crushed stone (up to 15 cm). With such drainage, even if water gets inside the caisson, it will not stay inside, but will quickly go into the soil.

- After you need to equip the formwork. Often the wall of the pit is used as the outer layer of the formwork. The side of the pit must be covered with polyethylene to avoid seepage of water from the concrete into the soil. After you need to make a frame using reinforcement.

- Mix concrete solution. Pour it in small parts, compacting well with an electric vibrator. If there is no device, then you can use a pin, a thin pipe and weld the handles. This device is quickly lowered into the concrete, and then slowly pulled out to get rid of air and water bubbles, thereby making the concrete denser.

- After that, it is necessary to dry the structures, regularly spraying the surface with water so that the concrete does not crack. If it's hot, you can cover it with a damp cloth.

- After a week, the formwork can be removed. And in 4 weeks to install the equipment.

Caisson from concrete rings

The borehole system of concrete rings provides for the following:

- First, the pit is prepared. The calculations are the same as in the previous manufacturing method.

- Fill the bottom with concrete and drill a hole for the pipe.

- They take concrete rings, which are pre-coated with a special waterproofing compound. Let dry.

- After each ring is lowered into the pit, while connecting the joints with a mixture for bonding. The seams are foamy.

- There may be voids around the structure that need to be filled.

From concrete rings, a caisson for a well.

Budget camera made of bricks

Brick caisson device:

- First, a foundation pit is dug out, a strip foundation and a trench are installed at the bottom, which are covered with sand and rammed.

- It is necessary to lay waterproofing on the foundation (for example, roofing material).

- Brick laying starts from the corner, be sure to fill the seams with a special solution.

- After bringing the masonry to the desired height, let it dry, plaster.

Sealed metal container

The process is like this:

- Dig a hole again, suitable for the size and shape of the chamber.

- A hole for the casing pipe is cut out at the bottom.

- Install the cover, clean the seams of slag. The seams must be double-sided to ensure the tightness of the caisson.

- The structure must be treated with a protective layer.

If necessary, the chamber can be insulated, after which the caisson can be lowered into the pit and a column, sleeves, and cable can be installed. The sleeve is welded, everyone falls asleep.