- Production of ceramic pipes

- Applications

- Characteristics

- Dimensions

- What is the product made from?

- Building a chimney for a barbecue

- Basic requirements for chimneys

- For fireplaces

- For a traditional bath

- For boilers and gas water heaters

- Building regulations

- Fire safety requirements for chimneys

- Traction force

- Distances to combustible building structures

- Installation Requirements

- Some useful tips from experts

- Features of ceramic structures

- GOST requirements

- Technological nuances in working with a ceramic pipe

- Features of sewerage installation

- Cutting ceramic pipe

- The use of ceramic chimneys

- Why is a ceramic chimney better / worse than other pipes?

- Chimney Requirements

Production of ceramic pipes

So, in order.

To begin with, we will study the technology for the production of ceramic pipes, so that it is more understandable for you, we will describe the process in stages:

- For the processing and preparation of raw materials, the same equipment is used as in the manufacture of bricks. This process includes: Grinding clay - removal of lumps.

- The introduction of special additives that increase the strength of products.

- Preparation of mass for the formation of products.

On the so-called pug mills, the molding mass is evacuated and compacted.Products are molded on screw vertical vacuum presses in a plastic way. This equipment does:

- Formation of products.

Connecting socket.

Cutting the product to a given length.

This is followed by drying with firing. These processes take place in special:

- tunnel dryers.

The use of such equipment in production can significantly increase the quality of products.

tunnel ovens.

At the end, the ceramic product is glazed from the inside and outside by dipping into a special pool.

Applications

Due to its excellent quality and performance characteristics, ceramics are used in various areas of production and in the household sector.

According to the intended purpose, these products are divided into:

At the same time, do not be surprised if you are offered not round pipes at all.

- Ceramic pipes for sewerage. Distinctive features: High wear resistance.

- Not susceptible to corrosion.

- They are not sensitive to temperature changes.

- They are not afraid of the aggressive effects of sewer fecal or chemically saturated industrial effluents.

- Practical and easy to fit.

A separate column can be distinguished ceramic sewer pipes intended for the installation of drainage systems. The features of these products are:

- The presence of holes along the entire length (perforation).

High strength under various loads in the ground.

Sufficient flexibility of ceramic drainage systems due to the connection with special couplings.

Possibility of use on almost any part of the landscape for drainage.

Products of large diameters with increased tightness and strength are used in microtunnelling. This method of laying pipelines allows you to arrange engineering communications without disturbing the pavement of roads and pedestrian sidewalks. In addition to sewerage, they are used in the creation of systems:

- Water supply.

Heating mains.

Gas supply.

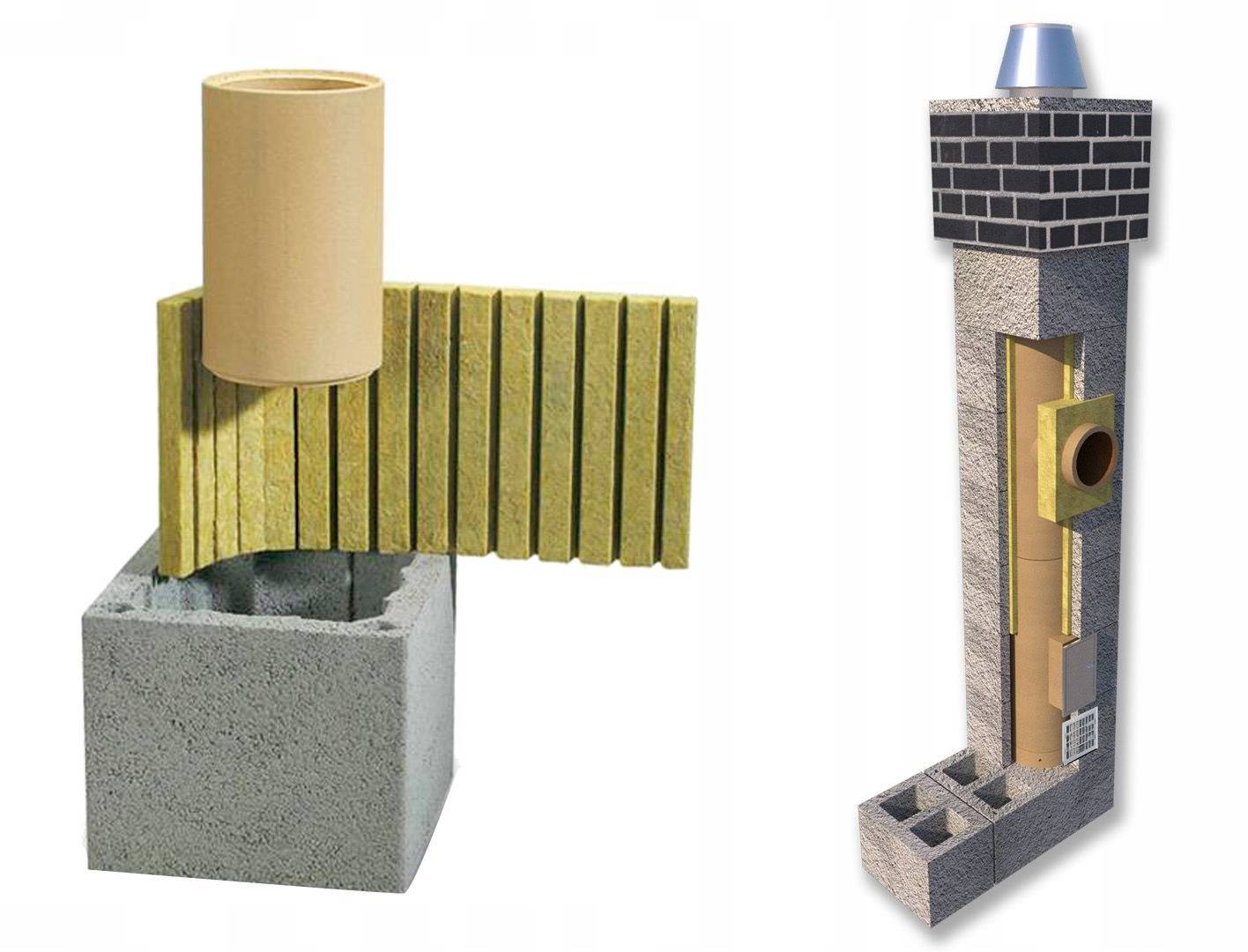

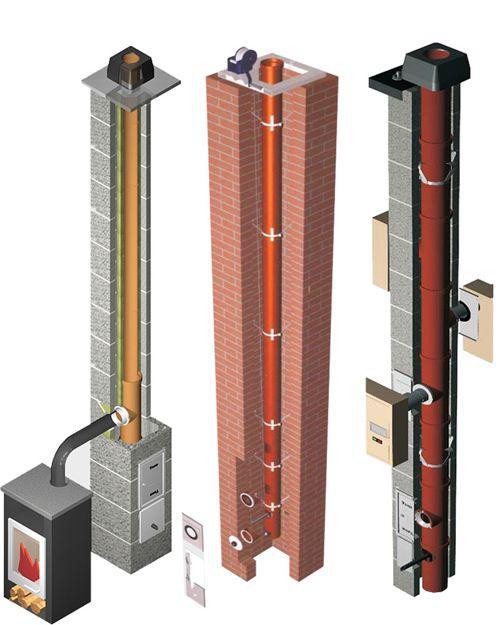

A ceramic chimney pipe that utilizes combustion products from various equipment, such as, for example, boilers (gas, diesel, wood), stoves, etc. The ceramic chimney is assembled from individual elements, and then covered with a protective layer of steel with an anti-corrosion coating or expanded clay.

Chimneys should be insulated and insulated so as not to lose "precious" heat

Without exception, all ceramic products, regardless of the scope of application, are distinguished from their counterparts by the following:

- Relatively low price of products.

- The durability of the structures created from them (you will not need repairs in the next 5-10 years).

- Environmental safety for human health and the environment - the background is not disturbed.

- Thermo-chemical resistance to various influences.

You can try to cut a damaged product, but, as a rule, this does not help, the element will have to be thrown away

Characteristics

GOST describes in detail all the requirements and characteristics of ceramic pipes. The emphasis is on the following design properties:

- In terms of strength, ceramics are comparable to metal products. However, there is a risk that the structure will burst in the event of a strong impact.

- Zero chance of rust formation, the design is invulnerable to chemical irritants and water.

- Low degree of thermal conductivity, which ensures the operation of the sewer system at low ambient temperatures, which is great for external sewerage in a private house.

- Resistance to high temperatures is one of the requirements according to GOST 286-82 for sewer ceramic construction.

Dimensions

There are several state standards for ceramic pipe sizes:

- diameter is from 10 to 60 cm;

- possible thickness from 1.9 to 4 cm, allowable pipe length from 100 to 150 cm.

What is the product made from?

Previously, a variety of materials were used to create sewer systems. Metal structures made of cast iron were considered the main ones, however, due to the low service life, they were looking for ways to increase the period of use of this material.

A later version is plastic pipes, the disadvantage of which is considered to be poor resistance to certain aggressive environments. For this reason, earthenware was again used to create sewer systems.

The ceramic sewer pipe is presented in the form of a fired ceramic structure, the surface of which is treated with a special material that provides protection against the effects of aggressive acids. Roasting takes place at a temperature of 1300 degrees Celsius. Before firing, large foreign bodies are removed from the source material, then the clay is dried.

Building a chimney for a barbecue

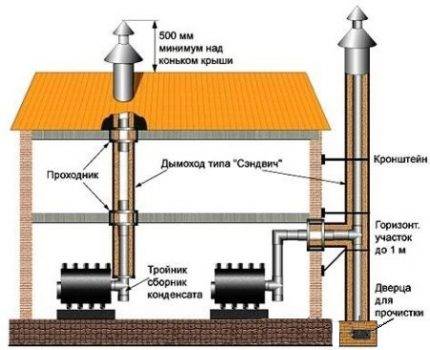

Chimneys by type of location are divided into:

- mounted - installed above the heater and are actually its vertical continuation;

- free-standing (root) - the smoke channel is located vertically on the side of the unit, a separate foundation is built under it;

- wall channels - a chimney is designed in the wall of the house.

The chimney can be brought out through the wall, it is possible to do this even in an already built building

In relation to the building, the location of the chimney can be as follows:

- External. Its advantages: ease of installation both in a new house and in a previously built one; service availability.

- Internal. Advantages: the internal location provides good draft, the chimney can be in the most vertical position.

Disadvantages of the internal location: additional work during the passage of the smoke channel through interfloor and roof ceilings, very careful observance of fire prevention measures in these areas. Such a chimney will also occupy a useful area of \u200b\u200bthe room.

In a country house, a question may arise with the construction, choice of materials and size for the chimney, not only for the fireplace, but also for the barbecue. The construction of a chimney must be thought out, the first step will always be a drawing of its plan on paper.

The simplest solution for building a barbecue chimney is to use cement mortar and reinforcing metal bars. The core of the chimney is bent and then welded from metal rods. The metal frame is cemented, entangled with a mesh. The solution is applied to the rods from the inside and outside.

The drying time of the cement mortar used in the construction of a barbecue and a chimney for it is 3-4 days. Until this time, it is impossible to kindle a fire in the firebox, otherwise the walls of the structure will crack and the barbecue will be unsuitable for further use.

Basic requirements for chimneys

For fireplaces

Chimneys for fireplaces must meet all the basic requirements that apply to standard stoves. There are not so many fundamental differences in the operation of these systems, and the fuel they use is, for the most part, the same.

It often happens that fireplaces can be used not only as a decorative element of the interior, but they can be fully used for heating. To do this, you can use a tricky trick: use a radiator pipe during installation, which can significantly increase the amount of heat transfer. Of course, this will not solve the problem of heating the entire house, but with its use, the heat will be much greater than without it.

As with most other designs, chimneys for fireplaces are designed to effectively remove spent combustion products, and therefore this process should work flawlessly and be done as simply as possible.

The simplest solution in this case would be to install a direct chimney that runs strictly vertically. But such a solution is not always available, in this case, the bends should go at an angle that does not exceed 45 degrees. If in the future the chimney needs to be cleaned, then a special elbow is usually installed, which will facilitate this operation.

It is also important to remember that not only the shape and location of the chimney is of great importance, but other factors are equally important. In the place where it passes, you need to take care of maximum safety and an appropriate level of thermal insulation, since in the process of work the smoke goes out through the pipe and heats up the chimneys for fireplaces

Therefore, it is necessary to protect all walls and nearby ceilings from fire with the help of special layers of thermal insulation. Most often, for these purposes, lay the material, which is based on basalt. However, if ceramic pipes are used immediately, then a basalt gasket can be omitted, since such protection is already available in this design.

For a traditional bath

When installing chimneys in conventional baths, some safety requirements for the entire system must be met. Obviously, chimneys in such places require enhanced thermal insulation. In this case, for reliability and safety, all walls that are located close to the boiler must be covered with sheet metal, which will prevent their ignition.

The draft in the chimney must be good enough and able to maintain combustion processes at the proper level. At the same time, the heat should not go outside, and the smoke should not go into the dressing room or penetrate into the steam room, if any.

For boilers and gas water heaters

Few of the developers study and are well versed in building codes and rules for installing chimneys for gas boilers and water heaters. Meanwhile, the solution of technical issues is a priority in the construction and repair of exhaust systems.

Chimneys for a geyser or boiler must meet the following requirements:

- comply with existing standards (SNiP);

- be as tight as possible (there should be no leakage of carbon monoxide);

- have a separate channel (if, nevertheless, two devices are connected to one channel, then you need to maintain a distance between them of at least 750 mm);

- be sufficiently resistant to moisture (modern powerful boilers produce from 1 to 3 thousand liters of condensate per year, and since the temperature of the exhaust gases is rarely above 100 ° C, the condensate hardly evaporates at all and, flowing down the walls, destroys the brick );

- improve traction (you should be aware that the rough inner surface of the pipes significantly impairs traction, and the round section of the exhaust duct, with a diameter not exceeding the cross section of the gas exhaust pipe, is ideal for increasing traction);

- go up and not have at the same time coverings and visors.

It is easy to fulfill the necessary requirements during the repair or construction process, but it is much more difficult to correct all the shortcomings and errors during subsequent operation.

Building regulations

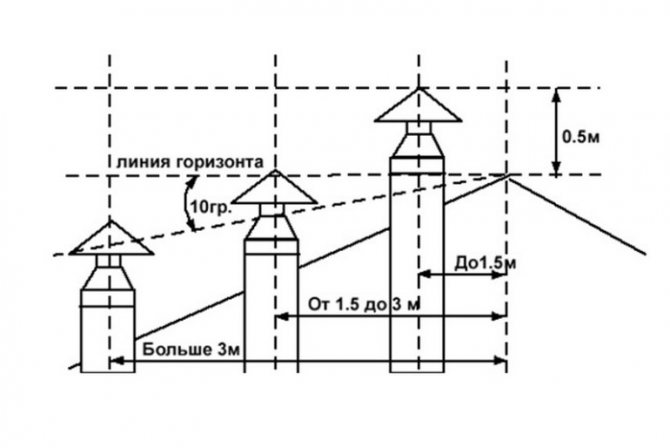

SNiP 41-01-2003 defines the requirements for the design of chimneys. The main and indispensable rule: the height from the grate to the head must be at least 5 m.

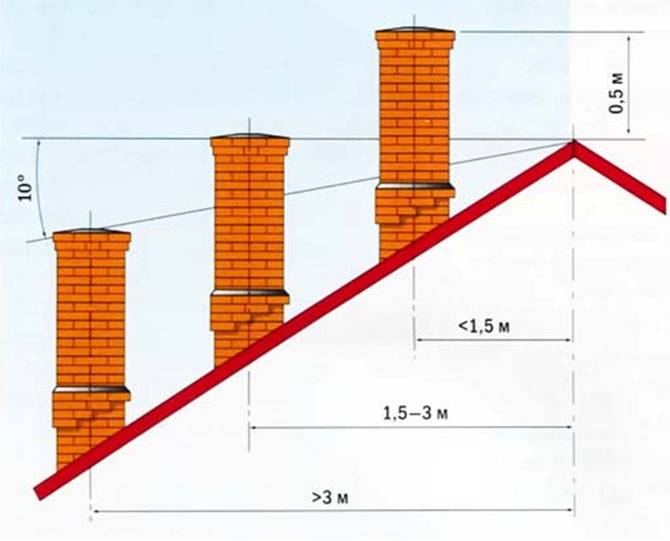

Regarding the roof, the height of the pipe in a private house should be:

- for flat roofs - at least 1000 mm from the level of coverage;

- with a pitched roof with a distance from the ridge to the head (horizontally) of 1.5 m - at least 500 mm; at a distance of 1.5 m to 3 m - flush with the ridge; at a distance of more than 3 m - the angle between the horizontal and the line passing through the top of the pipe and the ridge should not exceed 10 °;

- the length of one horizontal section should not exceed 1000 m; they should be as few as possible. For ceramics, there should be no horizontal sections at all.

Fire safety requirements for chimneys

The distance from the outer walls of the chimney to the structures of walls, roofs and ceilings made of combustible materials for brick and "sandwich" should be at least 130 mm; for ceramics not less than 250 mm.

The chimney must be equipped with a mesh spark arrester in the following cases:

if the roof is covered with roofing material, shingles, ondulin, other combustible materials.

Traction force

Factors affecting traction force:

- chimney height;

- warming;

- supply of fresh air to the furnace;

- the state of the smoke channel (soot settled on the walls or not);

- smoothness of the walls of the smoke channel.

Traction must be checked periodically; the smoke channel should be regularly cleaned of soot. In the case of ceramics, this is usually done once or twice a year.

Distances to combustible building structures

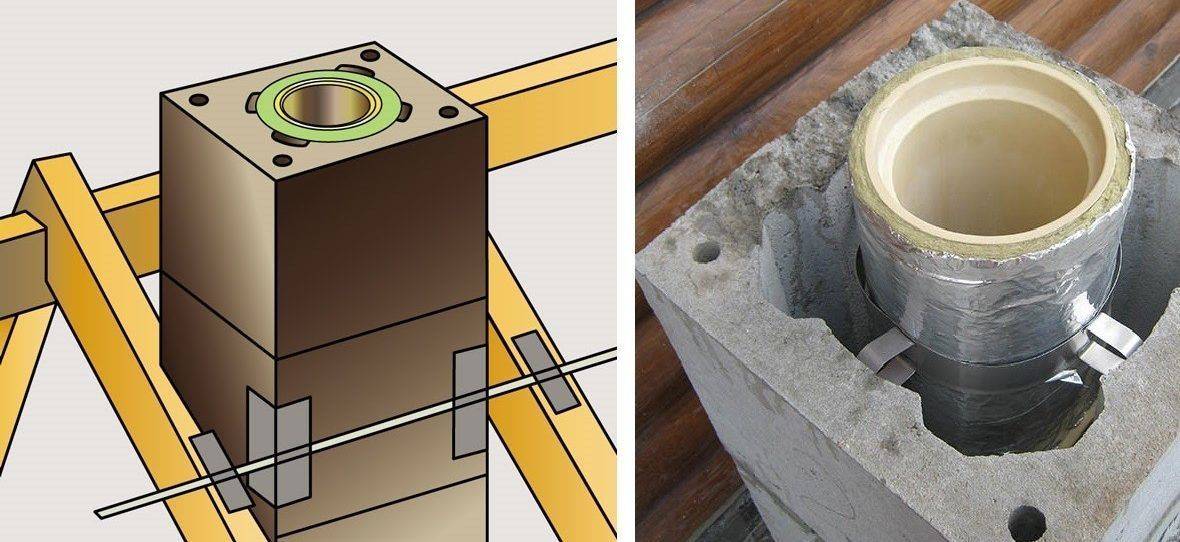

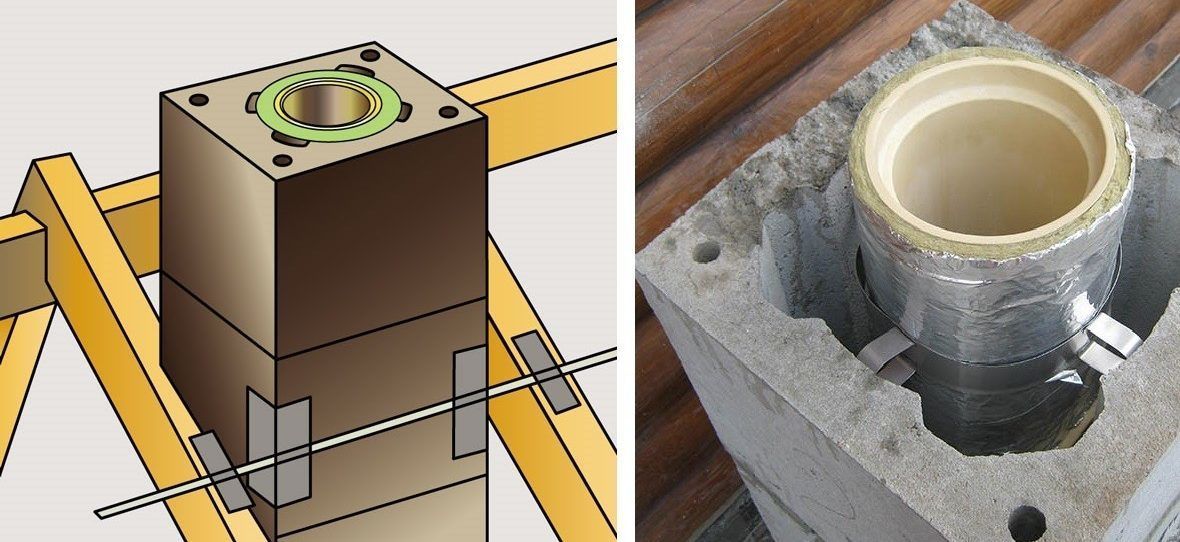

The prescribed distance between the chimney and combustible parts of the building, which prevents a fire in the event of overheating or fire inside the chimney, is regulated by the belonging of the chimney to a certain fire resistance class. Fire-resistant multi-layer chimneys with an internal ceramic pipe are, as a rule, class G50, i.e. the required distance to combustible building structures is 50 mm.

In places where the chimney is extensively and not only on separate surfaces adjacent to parts of the building made of flammable materials, the necessary distance to these structures should be taken into account, which is at least 5 cm; the space between such elements must be constantly open or well ventilated. In exceptional cases, insulation with non-flammable materials is allowed.

Ceilings with beamed ceilings, attic floor beams and similar structures, parts of the building made of flammable materials with a small area of contact with the chimney must also be located at a distance of at least 5 cm from the structure of the chimney itself (it is permissible to use insulation from non-combustible materials with a thickness of 2 cm).

For combustible materials with a rather small area of contact with the chimney, such as flooring, skirting boards and roof battens, it is not necessary to take into account the distance. The chimney should be located no closer than 20 cm from the windows.

The distance from the outer surface of the chimney to other combustible elements of the building is regulated by legislation. In most countries, including Russia, this distance should be at least 50 mm. This space must be kept open or sufficiently ventilated (Fig. A - C). In some exceptional cases, it is permissible to fill it with non-flammable insulating material.

Elements of the system that are outside the main structure of the chimney,

must be at least 20 cm away from parts of the building made of or with flammable materials. Exceptions are:

- this element of the system is sheathed with thick non-flammable insulation, at least 2 cm thick, or

- the temperature of the exhaust gases of the heater does not exceed 160 ° C.

Installation Requirements

Ceramic pipes are made in separate sections for further assembly. Therefore, when buying, you need to consider several important factors. Among them are the following:

- type of heating equipment;

- fuel used;

- dimensions of the room in which the boiler will be installed;

- diameter of pipes recommended by the manufacturer of the heating device;

- the shape and dimensions of the roof, the place where the chimney exits.

All these conditions must be announced to specialists in the sale of ceramic pipes in order to receive qualified assistance in selecting the type of product for the chimney and calculating the required dimensions.

The chimney can be installed both indoors and outdoors, adjoining the wall of the building. This type of installation is suitable for the location of the boiler room in a separate room.

It is worth considering that the impressive weight of a structure made of ceramics requires a reliable foundation. Such chimney systems are not recommended for installation on ordinary ceilings. The surface of the base must be flat and without slopes. The foundation is erected by the standard method using concrete grade M250 and higher. After the maturation of the building material, it is covered with double rolled waterproofing, which protects the channel for the removal of combustion products from high humidity.

The design capabilities of ceramic pipes make it possible to bring several channels to the chimney from different sources of heating within the same building. The main thing is to provide for the presence of a ventilation grill and a section for collecting condensate in the lower part of the entire structure.

Channels to the chimney are usually connected using tees. They are also useful for installing a cleaning door.

When installing the system, you need to take care of the thermal insulation of pipe sections passing through unheated zones or ceilings. You can also install segments of sandwich pipes.In areas of products for the smoke channel, passing in heated places, thermal insulation is optional. Uninsulated parts of pipes are located at a distance of at least 60 cm from flammable objects.

In the device of the chimney system, it is worth paying attention to the height of the cylindrical product located above the roof surface. There is an erroneous opinion that traction increases with pipe lengthening, but in fact there should be a measure in everything. If the ceramic product is too long, under the influence of aerodynamics, combustion products will settle on its walls.

To calculate this process, you can not do without special knowledge

If the ceramic product is too long, under the influence of aerodynamics, combustion products will settle on its walls. To calculate this process, one cannot do without special knowledge.

The top of the pipe is decorated with a cap - an element that protects the chimney from debris and precipitation. It is recommended to give preference to a product of the correct conical shape, since it affects the aerodynamics of the exhaust gases.

Details of the chimney system are installed using a special solution prepared from a liquid and a dry mixture. When mixing, you should strictly follow the instructions, and during operation, do not allow the drying solution to be diluted with water. The mass is applied with an ordinary trowel or with a construction gun. The seams are rubbed to remove excess mortar.

If in the future it becomes necessary to create holes for the removal of pipes, you can use the grinder for sawing blocks.

Before installing the chimney system, it is important to study the plan of the house, consider the location of the joints between the elements in order to prevent the seams from getting into the ceiling.It is required to take into account the sequence of parts of the system, as well as calculate the dimensions of the required pipes

A free-standing product without a sandwich box must be fixed to stable structures using clamps installed every 1-1.2 meters, and the area above the roof should be strengthened with wire braces.

Some useful tips from experts

Experienced builders recommend paying attention to a number of points when installing a ceramic chimney:

-

- Carefully check the integrity of each ceramic element. If a crack is found, do not try to repair it with a sealant or other binder. These measures are effective only for a short time, and in order to eliminate the defect later, it will be necessary to dismantle the entire chimney expensively.

- Chimney joints should not be under ceilings so that they can be inspected.

- It is necessary to ensure that the first block is correctly installed in a horizontal plane and fits snugly to the base. To do this, a suitable material is laid on the foundation, such as porcelain stoneware tiles, etc.

- In the course of work, the exact vertical position of the structure should be constantly checked.

- The point of connection to the boiler should be determined in advance, since it is very difficult and not always possible to change the height of work or the angle of connection.

- First, the insulation is mounted, and then the ceramic elements are installed.

- Before applying sealant to a ceramic chimney block, the surface must be thoroughly cleaned. Remove excess sealant immediately.

- To avoid unnecessary costs, the installation of the chimney is carried out before the start of finishing work inside the room, as well as before the completion of roofing work.

When installing a ceramic chimney in a wooden building, the inevitable shrinkage of the building should be taken into account.

Before applying the sealant to the surface of the ceramic chimney block, it must be cleaned of possible contaminants. Remove excess sealant immediately.

All work should be carried out carefully, constantly monitoring the correctness of their implementation. If the technology is observed accurately and suitable materials are selected, a chimney with a ceramic pipe will faithfully last for several decades.

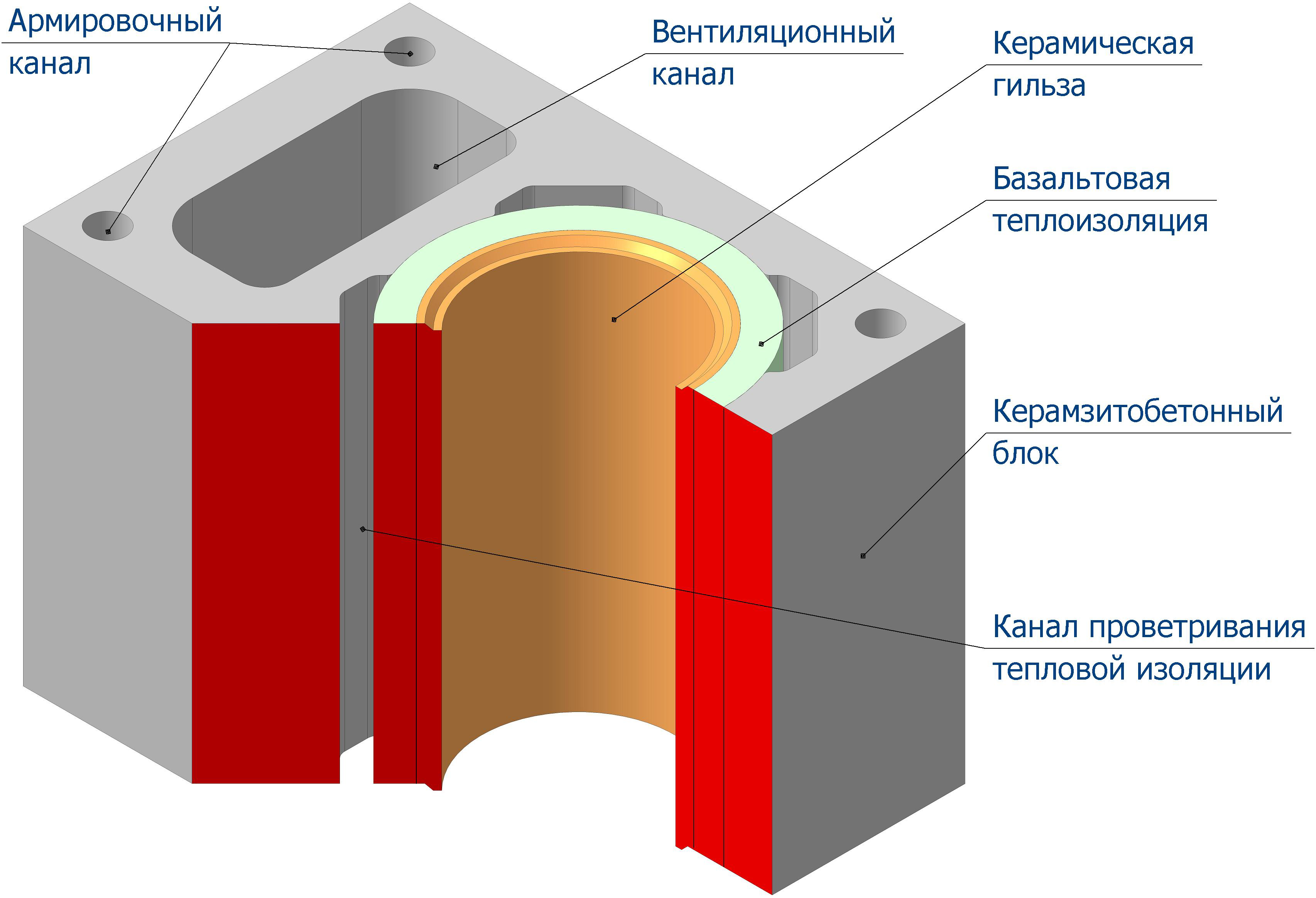

Features of ceramic structures

The use of ceramic components for the installation of a chimney is an ingenious solution in its own way. Fired clay is resistant to almost any temperature, so such chimneys can be used for boilers running on liquid or solid fuels.

This feature of the material makes it versatile in application. Especially for low-temperature boilers, a separate version of such a chimney has been developed.

Fired clay endures sudden changes in temperature with amazing resistance, the service life of such a chimney reaches three decades. One of the main advantages of ceramics is a high level of fire safety. The smooth walls of the structure accumulate a minimum amount of soot and other foreign products, which significantly reduces the risk of fire.

A ceramic chimney consists of many elements. In addition to the details of a ceramic pipe with a heater sleeve and a concrete frame, you need an adapter for connecting to the furnace, an inspection hatch, a cap, etc.

A ceramic chimney consists of many elements. In addition to the details of a ceramic pipe with a heater sleeve and a concrete frame, you need an adapter for connecting to the furnace, an inspection hatch, a cap, etc.

The ceramic walls of the chimney perfectly retain heat and resist the effects of moisture condensed on the walls, even if this moisture contains acids or other corrosive substances.

If installed correctly, combustion products never enter the room through random cracks. Smoke is removed completely and with a high degree of efficiency.

Ceramics not only prevents the transfer of heat to surrounding objects, but also accumulates part of the thermal energy. Such structures can be placed both inside the building and outside. In the latter case, it is necessary to take care of additional insulation of the structure.

Private housing construction is practically the only area of application for ceramic chimney systems. They cannot be installed in multi-storey buildings.

The ceramic chimney is wrapped in a layer of insulation with refractory characteristics, and reinforced on the outside with concrete blocks, which are additionally reinforced with metal rods

It is worth remembering that such devices, compared with analogues, are quite expensive. Another problem that can arise with a ceramic chimney is the prohibition on bends. The ceramic chimney must be installed in a strictly vertical position. If this is not possible, then another type of chimney will have to be preferred.

The ceramic chimney structure weighs a lot. That is why, if the weight of the chimney exceeds 400 kg, it will be necessary to install a separate foundation for it, which should not be connected with the common base of the building. However, such installation is allowed on monolithic foundations, but it is still necessary to correlate the increased load with the overall bearing capacity of the foundation.

If it is planned to install a ceramic chimney not on the ground floor, but above, you need to calculate the load and compare it with the bearing capacity of the ceiling.

A chimney made of ceramic elements is suitable for both indoor and outdoor installation, but it should only be located vertically

A chimney made of ceramic elements is suitable for both indoor and outdoor installation, but it should only be located vertically

The installation of a ceramic structure looks relatively simple, but it still requires effort and a very careful attitude. If a steel structure can be assembled literally in one day, then it will take two or three days to install ceramics of the same length.

In addition, such a chimney cannot be disassembled and installed in a new place, but steel systems are reusable.

GOST requirements

Quite stringent requirements are imposed on ceramic pipes, which are strictly regulated in GOST 286-82. In accordance with this regulatory document, they must comply with the following characteristics:

- The diameter can be a minimum of 100 and a maximum of 600 mm, which does not allow them to be used for internal sewage.

- The wall thickness varies from 2 to 4 cm, and the length is up to 1.5 meters.

- Elements must have a regular, rectilinear shape. Permissible deviations for products with a cross section of up to 250 mm - 11 mm per linear meter, 300 mm - 9 mm per 1 m / p.

- The connection of individual elements is made using a socket or couplings. If a socket connection is used, then inside the socket and on the other side of the pipe, only on the outside, there must be notches in the amount of 5 pieces.

- Ceramic pipes must have good water-repellent properties, the permissible level of water absorption is not more than 8%.

- The inner surface is covered with a layer of special glaze, with a chemical resistance coefficient of 90-95%.

- Products must necessarily pass hydraulic tests and withstand pressure from 240 to 350 MPa.

Based on all of the above, it becomes clear that the use of ceramic sewer pipes for private housing construction is not entirely advisable. They are more suitable for highways through which chemically aggressive effluents or high temperatures are transported.

Technological nuances in working with a ceramic pipe

As mentioned above, the ceramic pipe does not like negligence. Therefore, the first rule for the installation of a product of any functional orientation is a thorough inspection and, if necessary, a rejection of products with manufacturing defects or those received during transportation.

There are also larger-scale products, only not many construction organizations can offer these products (pictured)

The following section is a ceramic pipe work instruction that will help you do the work yourself.

Features of sewerage installation

The ceramic pipe for wastewater disposal is non-pressure, therefore it must be laid with a certain design slope to ensure gravity flow

However, it is important not to make this slope too steep, this contributes to the accumulation and appearance of precipitation on the inner walls of the products. Also, an insufficient angle makes it difficult for fluids to move.

In addition to the absence of cracks and chips, ceramic sewer pipes must:

- Be straight throughout its entire length, although slight millimeter deviations are acceptable.

- Do not have deviations of the main geometric parameters - roundness of the cross section, ovality of the socket, etc. Or those must be within the specified tolerances.

A few simple installation rules that ensure the quality of ceramic pipeline laying:

Lay sewers in places where construction is not planned in the future, or placement of a recreation area, parking

- Pipe laying is carried out from the manhole.

- The sockets on the product must be directed against the flow of drains.

- Joints at the junction of pipeline sections are hermetically sealed with a resin or bitumen-impregnated hemp strand. The strand is placed in two or more turns with a soft shockless seal.

Cutting ceramic pipe

If you need to cut pipes, you can use:

- An ordinary angle grinder (grinder) with a diamond disc or a cutting nozzle for stone. After cutting, the ends should be carefully processed with sandpaper.

- Special pipe cutters. To work with a ceramic pipe, a chain tool is used that can cut a product with a diameter of 50 to 150 mm, and some models with an extended chain even up to 300 mm. The chain is fixed in the place of the cut on the pipe and is rigidly pulled together by a ratchet mechanism. In this case, the cutting rollers "bite" into the body of the pipe and at the moment of maximum stress it bursts.

The pipe cutter is easy to use, the main thing that the manufacturers of this tool ask is to store the chain in moisture-proof places

The use of ceramic chimneys

Chimneys made of ceramics have found their field of application, which requires not only resistance to high temperatures, but also anti-corrosion resistance to chemicals. So, the main areas of use for:

- Fireplaces.

- Furnaces.

- Boilers (coal, firewood, gas).

- Liquid fuel boilers.

In addition to pipes that are designed to exhaust gases with temperatures above 300 degrees, there is also a separate group of channels where the maximum temperature does not exceed 200. These are the so-called low-temperature boilers, where the installation of ceramics is allowed with a temperature threshold of no more than 200 degrees.

Ceramic chimney after installation

Ceramic chimney after installation

Why is a ceramic chimney better / worse than other pipes?

The interest that ceramic chimneys for furnaces arouse among developers is quite understandable. Here are some advantages that set them apart from steel and brick chimneys:

- the possibility of using fuel of all types;

- solid service life;

- excellent ability to accumulate heat;

- rapid heating of the chimney;

- excellent traction;

- the highest resistance to various types of corrosion;

- very high level of fire safety, etc.

Thanks to the ceramic chimney, combustion products are removed very efficiently, and heating costs are reduced due to high-quality thermal insulation. This type of chimney is not afraid of precipitation, it does not form smudges, it is very easy to maintain. Ventilation is carried out using a supply air grille, which is mounted at the bottom. At the base there is also a special container into which the resulting condensate is discharged.

The outer layer of a ceramic chimney, as a rule, is made of hollow expanded clay concrete blocks, which have special holes for mounting fittings

Nothing in the world is perfect, and this also applies to ceramic chimneys. Here are the main disadvantages of ceramic pipes to consider when deciding on the type of chimney for your home:

- relatively high price;

- complex installation requiring mandatory professional skills;

- the smoke channel must be strictly vertical, bends are not allowed;

- significant physical weight of the structure.

Due to the high load on the foundation, ceramic chimneys usually require their own foundation, which is not connected to the foundation of the house. The exception is when the building is being built on a very solid monolithic foundation, but even in this case, careful engineering calculations of the bearing capacity of the foundation will be required. The same calculations will be needed if the chimney is not mounted on the foundation, but on the ceiling between floors.

Chimney Requirements

The key requirement for the device of the chimney is the correct choice of the pipe section and its height.

Another important condition is the strictly vertical location of the pipe and its reliable sealing, and, if necessary, thermal insulation when installed next to the bearing wall.

The requirements for the design of the chimney apply both to its internal part and to its external part (the one where the pipe is located above the roof surface).

The following requirements are imposed on the internal part of the structure:

- pipe material must be resistant to high temperatures and corrosion;

- the design must be strictly sealed in relation to exhaust gases and combustion products;

- the pipe can only be connected to one fireplace or stove equipment (it is forbidden to cut an exhaust ventilation outlet into it, etc.);

- the internal section of the chimney must be constant, without narrowing and expanding;

- the diameter of the chimney pipe must be equal to the cross section of the chimney of the fireplace insert;

- the minimum height of the chimney is 3.5-5 meters (depending on the height of the building).

For the outer part of the structure, the requirements are as follows:

- it is advisable to install the exit of the chimney pipe above the roof at the level of the ridge or next to it;

- the height of the outer part of the pipe should not be less than 50 cm;

- if the distance from the ridge to the chimney is greater than 1.5 m, then the height of the pipe must be equal to the height of the roof ridge.