- From what and how are chimney blocks made?

- Block ceramic chimneys

- Installation Requirements

- Ceramic sandwich chimney

- Installation Requirements

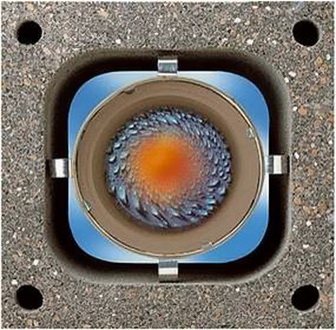

- Installation of a ceramic chimney - step by step video

- Advantages of a block chimney

- No. 5. Vermiculite chimney pipes

- How to make and assemble a sandwich pipe yourself?

- What to consider when choosing a material for a chimney?

- Types and designs

- Wall-mounted chimneys

- general information

- Device

- Production process

- Types and differences

- Mounting and connection

- Chimney from Schiedel

- Rules for choosing chimney parameters

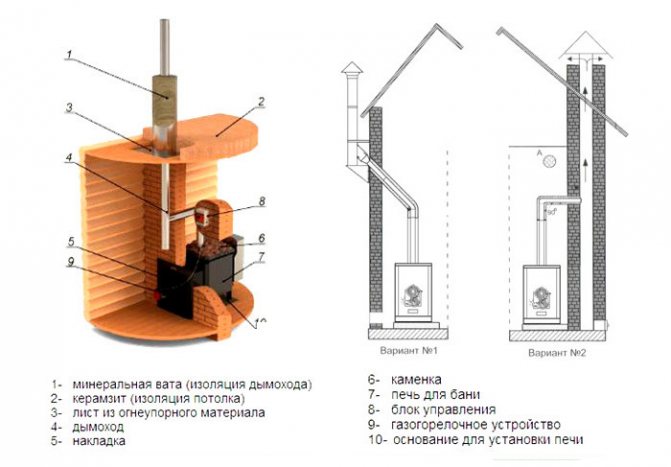

- How to install the UNI system in your sauna?

- Stage I. Getting ready for installation

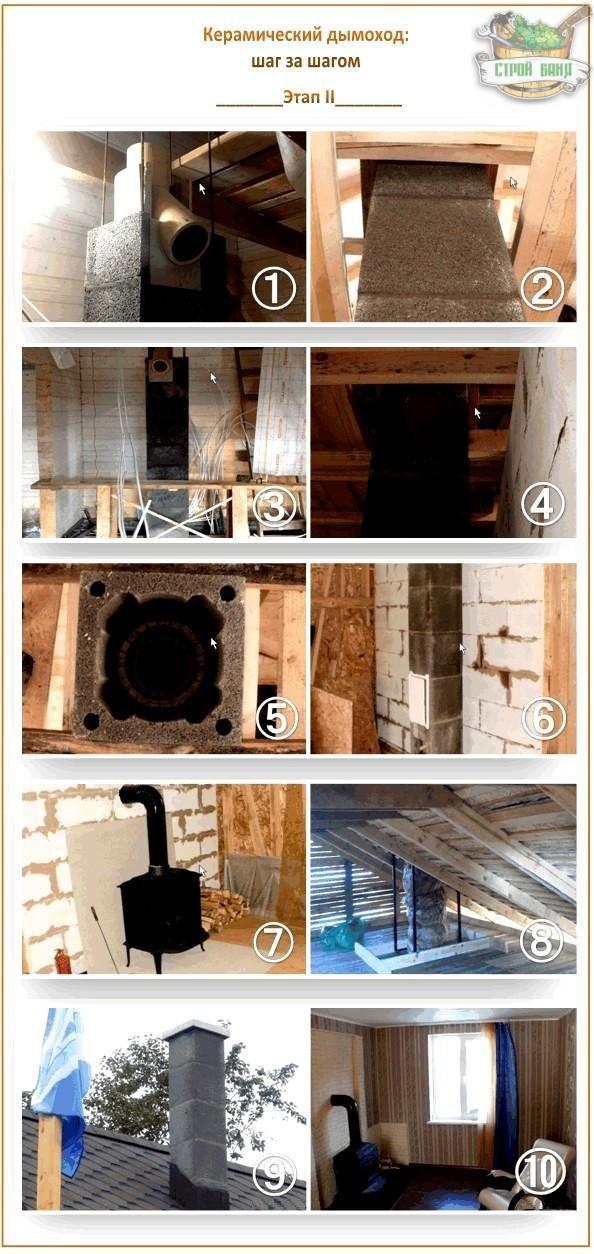

- Stage II. We connect the chimney

- Stage III. Sheathing a ceramic pipe

- Stage IV. We fix the chimney

- Stage V. Decorate the top of the chimney

- What is a ceramic chimney pipe?

- Where is this chimney used?

- Requirements for ceramic chimneys

From what and how are chimney blocks made?

Today, it is customary for manufacturers to take as a basis only three main production methods. At the same time, each is different due to some technological aspects and features. In addition, the division occurs according to the initial characteristics. So, chimney blocks, manufacturing methods:

In the manufacture, only the so-called light grades of concrete are used, in which the shaping process takes place in this way. I use an autoclave. After the form is filled, the “vibration machine” is taken to work in order to compact the mixture as much as possible and eliminate voids. According to their properties, they are intended not only for private households, but can also be used in industry, while having a fairly long service life.

The second type is clay firing. Clay from fireclay deposits is used. They are intended only for domestic needs in the private sector.

When buying, pay attention to the cracks formed, in which case it is better to refuse the blocks. Ceramic contributes to sufficient moisture, while the natural process of producing and maintaining the balance of the chimney takes place.

The third method of a more private kind, the so-called blocks, do it yourself

Such methods can significantly reduce the cost, while with the right approach and observance of technology, it is possible to create structural elements that are no different from production ones.

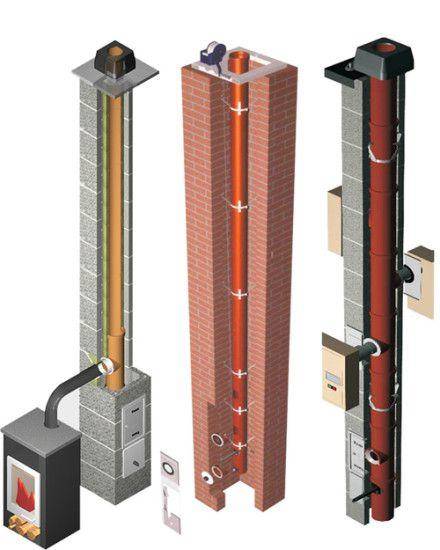

Block ceramic chimneys

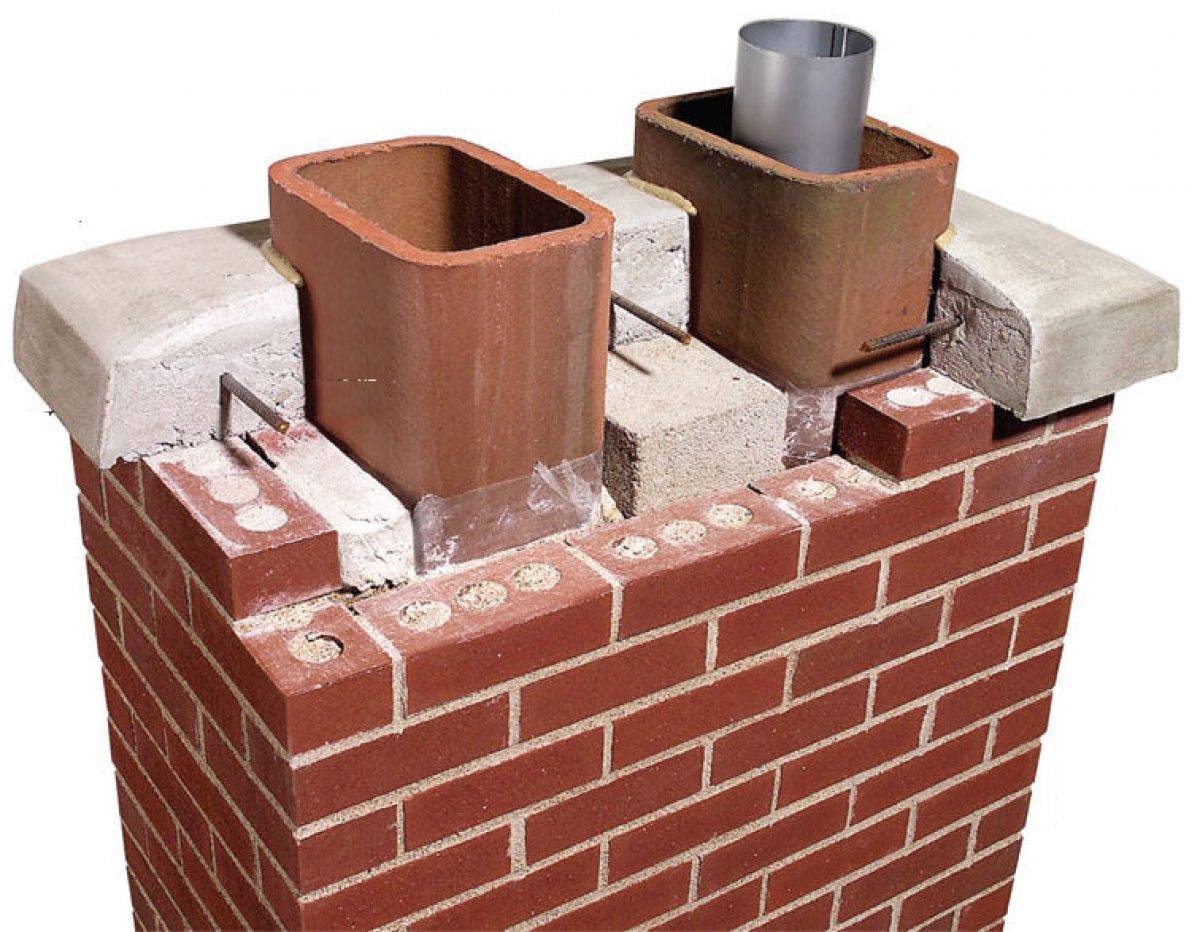

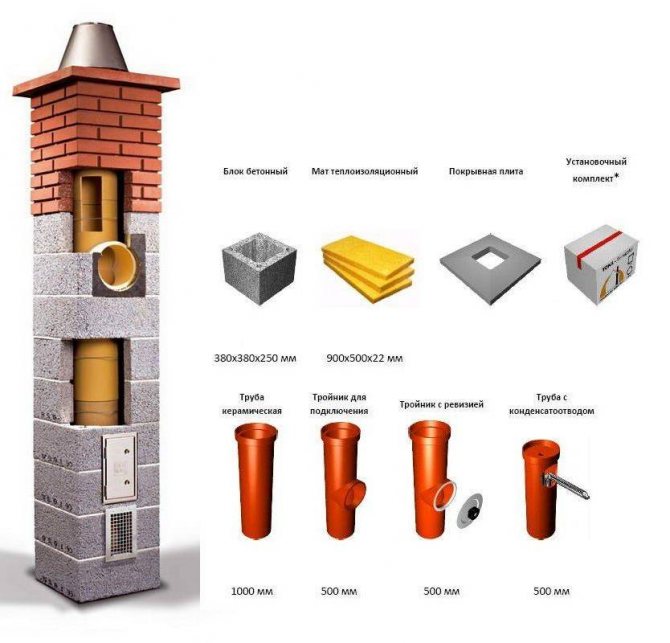

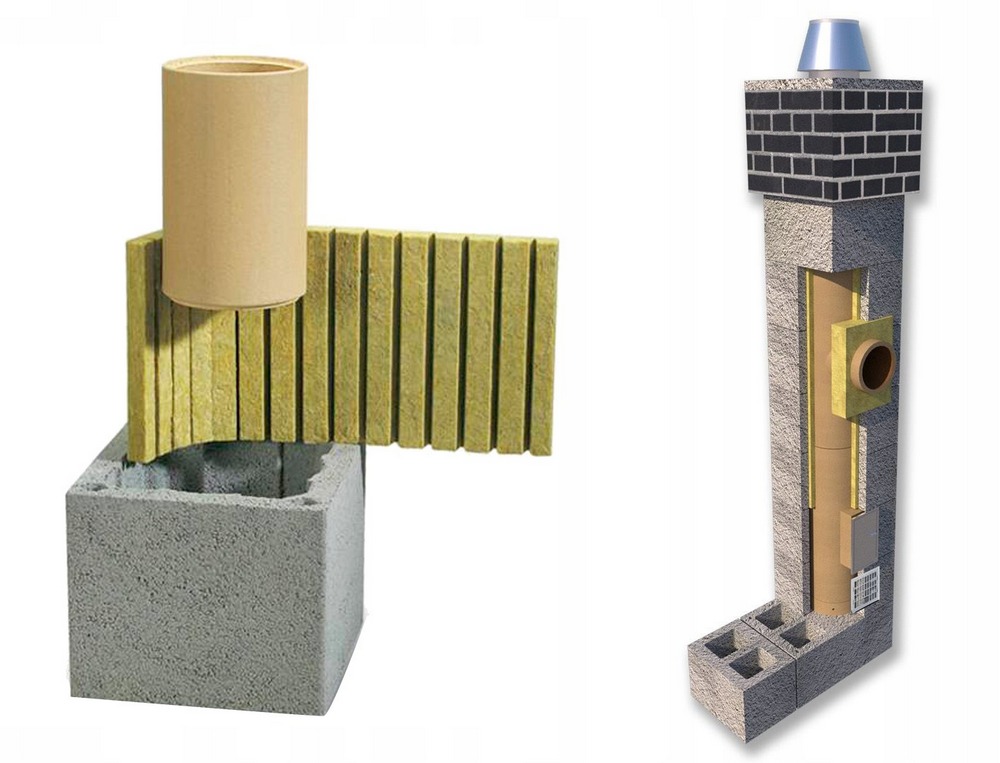

So, the installation of fireplaces and chimneys is sometimes carried out using special block ceramic pipes. Technical characteristics of block ceramic chimneys. The ventilation channels of these chimneys are represented by blocks made of lightweight concrete. To date, there is a wide selection of samples, and everyone can choose the right one for themselves in height and size.

These blocks are connected using vertical reinforcement, and a ceramic pipe and thermal insulation, represented by non-combustible materials, are placed inside.There may be several options for manufacturing a ceramic pipe, it all depends on the manufacturer, who recommends applying this or that technology to a particular sample. Therefore, there is no single device system.

Installation Requirements

Ceramic pipes are made in separate sections for further assembly. Therefore, when buying, you need to consider several important factors. Among them are the following:

- type of heating equipment;

- fuel used;

- dimensions of the room in which the boiler will be installed;

- diameter of pipes recommended by the manufacturer of the heating device;

- the shape and dimensions of the roof, the place where the chimney exits.

All these conditions must be announced to specialists in the sale of ceramic pipes in order to receive qualified assistance in selecting the type of product for the chimney and calculating the required dimensions.

The chimney can be installed both indoors and outdoors, adjoining the wall of the building. This type of installation is suitable for the location of the boiler room in a separate room.

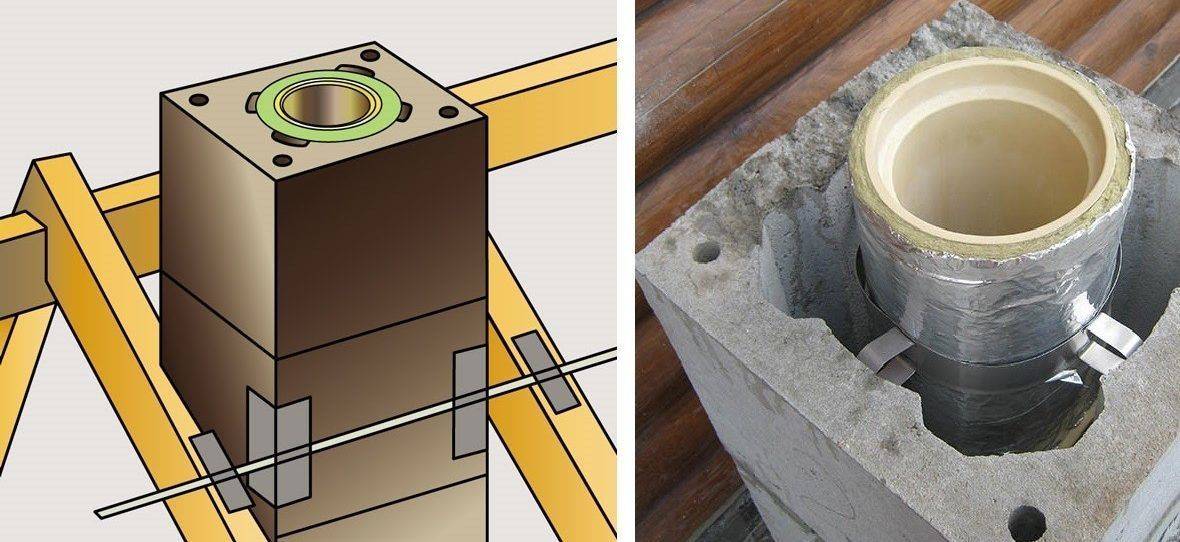

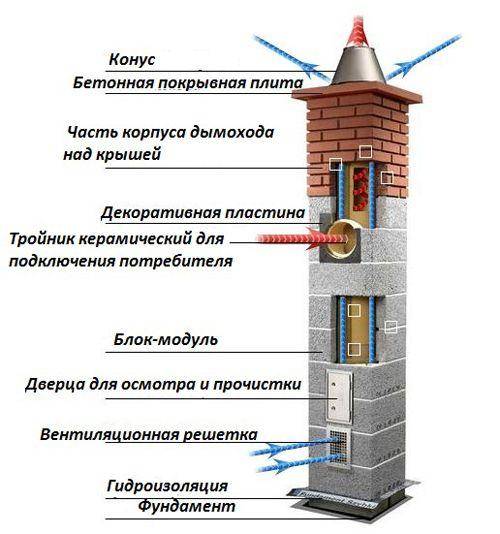

It is worth considering that the impressive weight of a structure made of ceramics requires a reliable foundation. Such chimney systems are not recommended for installation on ordinary ceilings. The surface of the base must be flat and without slopes. The foundation is erected by the standard method using concrete grade M250 and higher. After the maturation of the building material, it is covered with double rolled waterproofing, which protects the channel for the removal of combustion products from high humidity.

The design capabilities of ceramic pipes make it possible to bring several channels to the chimney from different sources of heating within the same building.The main thing is to provide for the presence of a ventilation grill and a section for collecting condensate in the lower part of the entire structure.

Channels to the chimney are usually connected using tees. They are also useful for installing a cleaning door.

When installing the system, you need to take care of the thermal insulation of pipe sections passing through unheated zones or ceilings. You can also install segments of sandwich pipes. In areas of products for the smoke channel, passing in heated places, thermal insulation is optional. Uninsulated parts of pipes are located at a distance of at least 60 cm from flammable objects.

In the device of the chimney system, it is worth paying attention to the height of the cylindrical product located above the roof surface. There is an erroneous opinion that traction increases with pipe lengthening, but in fact there should be a measure in everything. If the ceramic product is too long, under the influence of aerodynamics, combustion products will settle on its walls.

To calculate this process, you can not do without special knowledge

If the ceramic product is too long, under the influence of aerodynamics, combustion products will settle on its walls. To calculate this process, one cannot do without special knowledge.

The top of the pipe is decorated with a cap - an element that protects the chimney from debris and precipitation. It is recommended to give preference to a product of the correct conical shape, since it affects the aerodynamics of the exhaust gases.

Details of the chimney system are installed using a special solution prepared from a liquid and a dry mixture. When mixing, you should strictly follow the instructions, and during operation, do not allow the drying solution to be diluted with water.The mass is applied with an ordinary trowel or with a construction gun. The seams are rubbed to remove excess mortar.

If in the future it becomes necessary to create holes for the removal of pipes, you can use the grinder for sawing blocks.

Before installing the chimney system, it is important to study the plan of the house, consider the location of the joints between the elements in order to prevent the seams from getting into the ceiling. It is required to take into account the sequence of parts of the system, as well as calculate the dimensions of the required pipes

A free-standing product without a sandwich box must be fixed to stable structures using clamps installed every 1-1.2 meters, and the area above the roof should be strengthened with wire braces.

Ceramic sandwich chimney

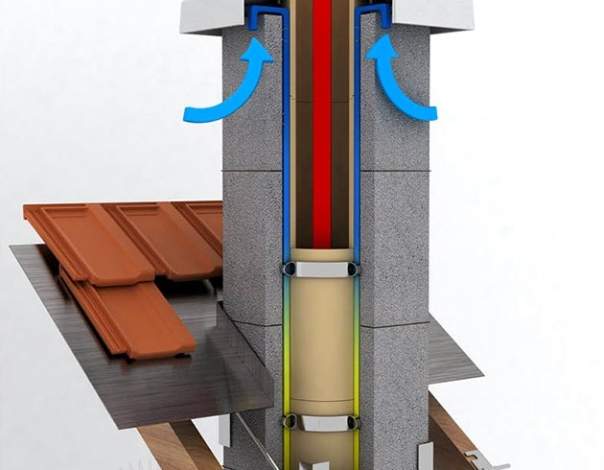

Ceramic pipes for the chimney, as a rule, are installed in a box of ceramic or concrete blocks, filling the gap between them with mineral-based insulation. Such a multilayer design is called a sandwich pipe and allows you to solve several problems at once:

Thermal insulation of the pipe reduces the temperature difference between its outer and inner surface, which reduces the formation of condensate. As a result, traction improves, the formation of soot and harmful smoke acids is reduced.

In places where the pipe passes through ceilings and roofs, fire safety requirements are met due to thermal insulation.

At the same time, the chimney itself does not heat up to dangerous temperatures from the outside, which is important when it passes through the residential upper floors of the house.

The appearance of such a chimney is attractive and, with minimal decoration, will not disturb the harmony in the interior.

Ceramic sandwich chimney

Installation Requirements

Ceramic chimneys are produced in the form of ready-made prefabricated elements, which are selected depending on the type of heating device - stove, fireplace or boiler - and have different operating conditions. Therefore, when buying a ceramic chimney pipe, be sure to tell the expert sellers the type of your heater, the fuel you use and the diameter of the pipe recommended by the boiler manufacturer. You will also need a plan of the house and its geometric dimensions: the height of the ceilings, the height and shape of the roof, and the place where the pipe exits through the roof. All this information is important for the correct selection of the height of the pipe and its type.

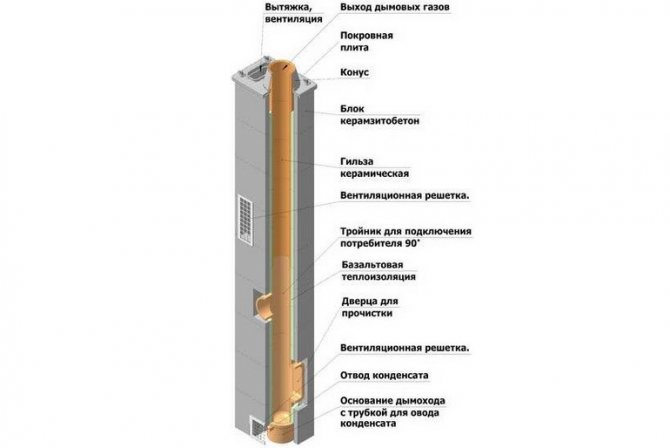

Chimney device with ceramic pipe

The chimney can be installed both inside the building and outside, at one of its walls - this is convenient when taking the boiler room into a separate room. Ceramic pipes and chimneys must be installed on the foundation, as ordinary ceilings may not support their weight. The foundation is poured in the usual way from concrete grade M250 and above, kept until the concrete matures. The base for the chimney must be flat and not sloped. Double rolled waterproofing is laid on top of the foundation - this is a prerequisite that protects the walls of the sandwich chimney from contact with moisture from the soil and foundation.

Chimney installation

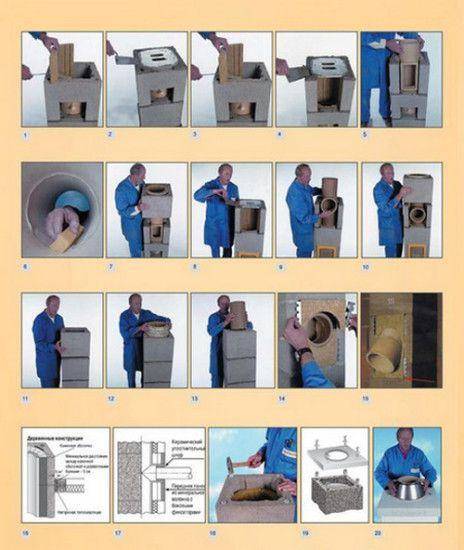

The steps for installing a ceramic chimney are shown in the figure.

Stages of installation of a ceramic chimney from prefabricated elements

Installation of a ceramic chimney - step by step video

Depending on the number and placement of heating devices, smoke channels from several consumers can be discharged into one chimney, so its shape may be different. But in any case, the lower element will be a module designed to collect condensate and a ventilation grill. In addition, it is necessary to provide tees for connecting smoke channels and for installing a cleaning door.

Elements of a ceramic sandwich chimney

A pipe passing through heated rooms in a house with constant heating may not be insulated. But in places of passage through ceilings and in unheated attics, a sandwich chimney is required. An uninsulated ceramic chimney pipe should be no closer than 0.6 meters from any combustible structures - this fire safety requirement cannot be neglected!

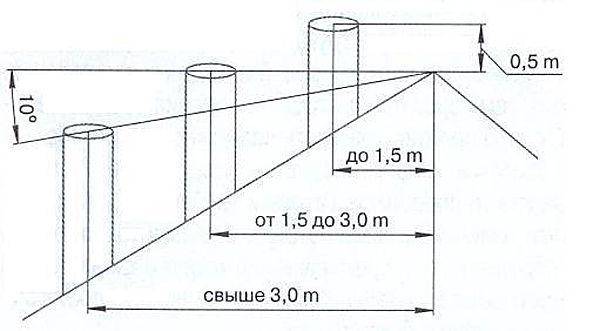

The part of the pipe that is above the roof surface must also have a certain height, which depends on its distance from the roof ridge. Many people make the mistake of thinking that the higher the pipe, the better the pull. In fact, the draft in the chimney is a complex aerodynamic process, the calculation of which requires special knowledge. It is much easier to use the simple scheme shown in the figure.

Roof pipe installation

The top of the pipe is necessarily crowned with a head, which prevents precipitation and foreign objects from entering it. Its shape is also important - it is involved in the aerodynamics of gas removal, so you should not cling to the pipe the first structure that comes across, it is better to purchase a cone specially designed for this.

All elements of the chimney are attached to a special acid-resistant solution. It is prepared strictly according to the instructions from a dry mixture and water.In no case should you dilute a solution that is already ready and beginning to harden with water! The mixture is applied with a trowel or with a construction gun to all seams between the elements of the chimney and carefully rubbed with a slightly damp sponge from the inside to remove excess mortar.

Fastening a ceramic pipe to a heat-resistant composition

Advantages of a block chimney

Until the end of the last century, chimneys were mainly laid out from hollow brick, since it is light, as well as from individual building blocks that differ from the usual brick in large sizes and material. But to use a decorated chimney block, which already has a given shape with a smoke shaft inside, they began not so long ago.

In fact, this is a ready-made factory chimney riser, cut into convenient fragments horizontally. Previously, high risers (up to 2.1 meters) were produced in the factory, but they were heavy, massive and very difficult to install. Now you can assemble a good chimney with your own hands from blocks, working alone and without rich experience and special knowledge.

First, try to evaluate the advantages that chimney blocks have:

- They greatly reduce the bearing load on the foundation of the pipe, which allows it to be lightened, saving money and reducing the labor intensity of the work.

- They can be erected quickly and simply, masonry can be done alone, without the involvement of assistants, since the material has a low specific gravity.

- Several pipes can be put into the smoke hole of this design at once, one of which can be taken under the supply of fresh air rich in oxygen to the furnace. You can also give the pipe under the ventilation of the steam room, under the second chimney, and so on.

- Some units have a special ventilation duct for large rooms to ensure the inflow of a large volume of air and to ensure good ventilation of the chimney.

- It is possible to remove heat from the inner metal pipe, this feature can be used when installing the heating system of the upper floors. For this purpose, special blocks with hatches are installed below and above the block pipe, into which heating pipes are supplied.

- To free up space in the room, the chimney block can be built into the walls.

Ready-made chimney from blocks

No. 5. Vermiculite chimney pipes

Not so long ago, vermiculite chimney pipes appeared on sale. These are stainless steel pipes coated inside with a 5 cm thick layer of vermiculite mineral. This mineral has low thermal conductivity, therefore, in fact, it is a natural heat insulator. Moreover, vermiculite is absolutely inert to aggressive combustion products.

Among other advantages of vermiculite pipes are high durability, relative ease of installation, no need for chimney insulation. The main disadvantage is the ability to accumulate soot, so you will have to clean the chimney often.

How to make and assemble a sandwich pipe yourself?

The finished chimney "sandwich" is a segment, each of which has a length of one meter and is inserted into the other during installation. And how exactly to assemble a chimney-sandwich and from what materials, now we will figure it out.

So, the design of the chimney sandwich is as follows: it is an inner and outer pipe, between which there is a layer of thermal insulation. The inner tube is made of stainless steel, but the outer tube can be made of a variety of materials, even copper and brass.But it is not recommended to take galvanized pipes for the chimney: in the heating-cooling mode, it will change its diameter, while stainless steel is practically not.

Most often, basalt fiber, or mineral wool, is used as a heater, which has good thermal insulation properties. Experienced stove-makers, for example, advise taking Rockwool WIRED MAT 80 basalt wool as thermal insulation. Its thickness can vary from 25 to 60 mm.

Expanded clay and polyurethane are also used as an internal insulation of such pipes. The only problem when laying thermal insulation between the outer and inner pipes is that the material has to be overlapped with an undercut of half the thickness and an overlap of 10 cm. Or you can fill everything manually if you can do it carefully.

Sandwich pipes are also connected in different ways: in a flanged way, bayonet and along a “cold bridge”, as well as “under smoke” and “through condensate”. The chimney is assembled “through the smoke” in order to fully guarantee that no carbon monoxide gases will get inside the house or bath. And “condensate” - so that the condensate formed due to the temperature difference can freely flow down the pipe.

In the first case, the smoke does not encounter any obstacles and quickly escapes under the influence of draft, but condensate can get inside the sandwich if the joints are carelessly sealed. Why the internal insulation will suffer a lot. But in the second method, the inner pipe of the sandwich enters the socket of the lower one, and moisture cannot get inside the pipe in any way. That's just smoke, if it finds even the slightest gap, it will find a way out. What to choose? Gas harms human health, and condensate harms the durability of the chimney.The only way out is, with any method, to carefully seal all the cracks and joints, and that's it.

For the internal pipes of the sandwich chimney, we recommend the installation “by condensate”, so that it does not fall on the seams of the pipe and there is no leakage. And, despite their double layer, sandwich pipes still need high-quality insulation from those areas that are most fire-resistant - from beams, roofs and ceilings. And as the first pipe, which is connected directly to the oven, a sandwich cannot be used.

So, knowing the technology, you can easily make a high-quality sandwich chimney with your own hands - from the materials you personally purchased (preferably with quality certificates).

What to consider when choosing a material for a chimney?

A chimney is a complex structure, consisting of a vertical pipe, an umbrella to protect against precipitation, a viewing window for maintenance, a condensate collection pan and other elements. The vertical pipe is considered the main part of the chimney, and the safety and efficiency of the furnace or boiler depends on it.

To choose the right chimney material, you need to clearly understand what fuel will be used: natural gas, diesel fuel, coal, firewood, peat or sawdust. Each of them has a different combustion temperature, temperature and composition of the exhaust gases. Therefore, when choosing a material for a chimney, the following parameters are taken into account:

-

flue gas temperature. Naturally, the material must withstand somewhat higher temperatures than those that are characteristic of the outgoing gases;

- corrosion resistance. During the combustion of some types of fuel, sulfuric and hydrochloric acid vapors are formed, which not every material can withstand.The more sulfur in the composition of the fuel, the more resistant to the effects of sulfur compounds should be the material. According to this parameter, chimneys are divided into three classes: the first - for the removal of gas combustion products, the second - firewood and liquid fuel with a sulfur content of up to 0.2%, the third - for coal, peat, diesel fuel;

- the presence of condensate in the chimney;

- flue gas pressure. There are designs designed to work with natural draft, and there are those that are designed to work with pressurized boilers;

-

soot fire resistance. The temperature in the chimney during the ignition of soot, if present, can briefly rise to 1000C - not every material can withstand this.

From all this it follows that:

- for wood stoves, solid fuel boilers, sauna stoves and fireplaces, it is necessary to choose a material that can withstand an operating temperature of about 700C and a short-term increase to 1000C. These are brick and less often ceramic chimneys;

- gas boilers require a chimney that can withstand temperatures of 200C with short-term rises to 400C. Usually metal pipes are used for this purpose;

- for boilers for liquid fuel and sawdust, such a material for the chimney pipe is required, which would calmly withstand temperatures up to 250C with an increase to 400C, and if we are talking about diesel fuel, then also resistant to the aggressive environment of exhaust gases.

Now let's look at the properties of the most popular materials that are used to equip the chimney pipe.

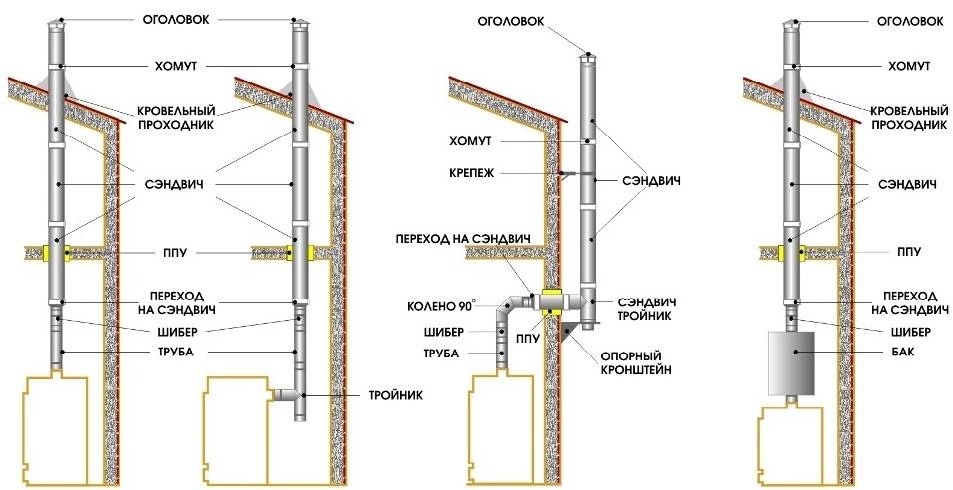

Types and designs

The most common types of chimneys:

- brick;

- smooth tube steel

- steel from a corrugated pipe;

- three-layer steel with insulation ("sandwich" pipes);

- asbestos-cement;

- concrete;

- ceramic.

Structurally, chimneys are:

- wall - built together with the building and pass inside the wall closest to the furnace;

- indigenous - a separate structure on a separate foundation;

- mounted - light chimneys are installed directly into the furnace or boiler;

The ceramic chimney is classified as indigenous, it has a significant weight and requires a reliable foundation. The design of the ceramic pipe is shown in the figure.

Recently, designs of the Shidel system have appeared, in which the air supply is integrated into the design of the chimney, the movement of air and flue gases is countercurrent, such chimneys replace the air supply to the heater.

Wall-mounted chimneys

general information

These chimneys are the most common and easiest to construct.

Such chimneys, like the 2 previous types, can be used for a solid fuel boiler installed in a private house or a stove in a bathhouse. They are installed directly on the stove or fireplace from above. Such chimneys are most often used in sauna stoves.

The advantages of such a chimney include the ability to make it from a steel or asbestos-cement pipe.

Device

The chimney device passes in a bathhouse or in a private house according to the same principle as described above. The only difference is that in this case it is not necessary to make smoke outlet sleeves, since the chimney is adjacent to the stove itself.

Mounted chimney in the form of a brick pipe

The wall-mounted chimney does not have a foundation; the furnace serves as the basis for it. There are a few tips, following which you can even make a chimney that meets all safety requirements.

So, when building a chimney yourself, you should:

- Lead the chimney on the roof so that it is as close as possible to the ridge of the building.

-

When choosing the height of the pipe, it is necessary to be guided precisely by the distance from the ridge. The optimum pipe height can be found from the following table:

- If there are nearby trees or wooden structures that may come into contact with the pipe, then it must be built up with ceramic pipe to reduce the risk of fire.

- At the end, the chimney must end with a visor that protects the pipe from precipitation.

- At the end, inside the chimney, you need to attach a net to prevent the escape of unburned fuel particles, such as paper.

Production process

A few words about production have already been said above. However, understanding the usefulness of ceramic products comes only after a complete acquaintance with the process. It is the presence of knowledge of this type that makes it possible to understand why it is beneficial to use ceramic pipes for sewer systems.

The formation of pipes begins with the collection of clay of special grades. All impurities, stones, sand, foreign particles are removed from it.

Next, the clay is cleaned and washed. The result of washing is a raw material ready for processing

It is very important to wash the clay with high quality, otherwise it simply will not seize in the oven.

Ceramic pipes for sewerage, storage and transportation scheme

The next step is the formation of the mixture. The clay is dried, mixed with fireclay, chemical additives and a small amount of water. We will not indicate the exact proportions, since each manufacturer uses his own recipe.

The resulting mixture is laid out in blanks, which are then placed in an oven. However, before that, the mixture in the blanks is pressed and dried again.Secondary processing affects the strength of the clay.

Dry clay in the form of pipes is sprayed with building glaze, and only after that it is sent to the kiln. The firing temperature is 1200-1400 degrees Celsius. Keep the pipes in the oven for several hours. They stay cold for a few more days.

Types and differences

The standard sewer ceramic pipe is available in several variations. The main division is by diameter. Pipes come in diameters from 100 mm to 800 mm.

In domestic conditions, products with a diameter of up to 200 mm are used. They are great for assembling risers, sewer outlets and even side branches of the central channel. Larger samples are branches of the main sewer, laid mainly in trenches.

Another point is the presence or absence of a bell. Ceramic sewer pipes, unlike plastic ones, may not have a socket type of connection. In this case, the pipelines are connected using a slightly different technology - using special mastics and locks.

Mounting and connection

You are probably interested in the question of how to form pipelines from ceramics? After all, for sure, the process of installing pipes is seriously different from working with plastic sewers.

The answer to this question is yes and no. There are differences in the workflow, but not all of them are significant. The general scheme of work remains the same. Consider the process of laying sewer pipes in a trench.

Stages of work:

Carefully transport pipes to their destination.

We ram the soil at the bottom of the trench.

We form a substrate of sand.

We lower the pipes with a crane.

We put them in working position.

We connect the segments with the help of mastics.

We check the tightness and quality of the connections.

We are testing the system.

Mounting in a socket from the standard one is practically no different. The only difference is that for sealing you will have to take other sealants. Silicone compounds will not work.

The absence of a socket puts us in front of the need to assemble the pipeline using clay “locks”. They are mounted on the edges of the pipes, then coated with mastics and dried.

Chimney from Schiedel

Schiedel ceramic chimneys have excellent properties and characteristics. The manufacturer produces a ceramic three-layer pipe, which is insulated with mineral wool, a stone block is installed on top of it.

This product is distinguished by its versatility and originality of its design. That is, ceramic will not spoil the external design of a building of any type.

The main advantage of this company's ceramic chimneys is that these structures can be installed at a distance of 5 cm from any flammable surface. The safety of using the product is ensured by a non-standard metal plate, which protects the chimney from overheating and prevents nearby buildings from igniting.

The Schiedel chimney pipe is light in weight and diameter. That is, during its installation there will be no problems, it will not clutter up the external space. Pipes can be built-in or external.

Important. In some cases, buyers try not to purchase ceramic chimneys due to their high cost. All of these are false statements.

The price of this product is low.

All of these are false statements. The price of such products is low.

Rules for choosing chimney parameters

The ceramic chimney pipe is made of separate blocks, which are well adjusted to each other, so there is no smoke leakage. Its height is calculated in advance, in accordance with current regulations. An excessive length of the chimney will not improve draft, but will only create complex aerodynamic turbulences that do not contribute to the effective operation of the exhaust system. The pipe is dialed, guided by the rules:

- height above a flat roof 50 cm;

- a pipe located 1.5 m from the ridge must rise 50 cm above it;

- at a distance of up to three meters, the edge of the chimney cannot be below the ridge line;

- being more than 3 m from the ridge, the pipe must reach the axis at 10 degrees from its horizon line;

- the diameter of the inner ceramic channel cannot be less than that of the flue pipe;

- the height of the pipe from the grate line to the outer edge is not less than five meters.

A ceramic chimney can be used to exhaust gases from several devices, but in any configuration, the lower module helps to collect condensate. Chimney elements are selected based on the type of heating device: fireplace, boiler or stove. The size of the pipe diameter is affected by the power of the boiler and the type of fuel. To calculate the required length of a ceramic chimney, you will need roof heights and ceiling values.

How to install the UNI system in your sauna?

The most modern and promising chimney system is the UNI ceramic chimney. Let's look at an example of how such a ceramic chimney is installed, and what nuances can be in its installation.Naturally, regardless of the country of manufacture, everything must be carried out in accordance with the Fire Safety Rules of the Russian Federation.

The very installation of a ceramic chimney is quite simple: starting from the base and moving up, you gradually install each component. And the inner tube of the top always goes inside the bottom.

Stage I. Getting ready for installation

So, the first thing to do is to clarify the connection point of the furnace. The base on which the ceramic chimney will be placed must be perfectly flat and strictly horizontal. A cement mortar is placed on it and a module with a gadfly is installed to connect the furnace or boiler

It is in it that there is a special ditch for draining condensate, pay attention

Stage II. We connect the chimney

We prepare an acid-resistant grout for joints according to this recipe: seven parts of a special powder and one part of water. We knead everything at an air temperature of + 20 ° C and use it for an hour and a half. In no case do not add water to an already prepared solution!

The solution is applied as follows: we put the tee on the module with the branch pipe and coat the junction well with the finished mixture. A tee in a ceramic chimney allows you to simultaneously inspect and clean the pipes.

Now we put the rest of the simple elements of the chimney. Then we level all joints with a damp sponge, remove excess mortar - so the internal seams will be smooth and even, soot will not settle and additional cleanings will not be needed.

If a ceramic chimney passes through an attic that is not heated, it must be additionally insulated.

Stage III. Sheathing a ceramic pipe

Experienced builders recommend sheathing a ceramic chimney in a bath not with GVL or fire-resistant drywall, but with cement-bonded particle boards (CPS). Also, experts consider glass magnesite (SML) to be far from the safest material for steam rooms - after all, it contains a significant proportion of MgClO2, magnesium chloride, and in a particularly humid environment this element is subject to hydrolysis with the release of hydrogen chloride. Outcome: razrazdannye respiratory organs of vacationers in the bath, decaying teeth and hoarseness of voice. Up to loss of consciousness - not without reason hydrogen chloride belongs to the third class of danger. That is why LSU is not produced in any country of the world, except China, and this says a lot.

Be sure to install the insulating plates themselves before starting the installation of the ceramic element. And for convenience, it is better to apply the sealant from the tube with a mounting gun - on both sides of the sleeve, into the groove of the upper edge of the ceramic pipe. You don't need to wet it. When you put the next element - remove the excess sealant.

Stage IV. We fix the chimney

If the chimney is 150 cm or more higher than the roof, the distance between the fastening points will be more than 4 m, it must be reinforced. The first and most common method: steel bars 10 mm in diameter, or a special set of reinforcing bars from the manufacturer. These are laid in existing holes and filled with liquid "cement milk". If you use what is at hand, then make sure that the "cement milk" spills over the entire length of the reinforcement.

The second popular method is external reinforcement, using steel corners and steel tape.An external welded corset is made for the chimney, and the chimney itself is located in it, as in a sliding support. So it is more convenient and warm.

And finally, the third way is the reinforcement of the ventilation duct. It is concreted from the base and reinforced with reinforcing bars. It turns out very, very reliable.

Stage V. Decorate the top of the chimney

The roofing part of the ceramic pipe in its shell is not very attractive. Therefore, it is covered with an imitation of some material:

- "Brick" masonry of heavy concrete.

- Brick lining.

- Cladding with tiles or slate.

- Facing with fibrous concrete, however, its supply to Russia has been temporarily stopped.

In principle, it is possible to finish the outer part of the chimney with any other material - as long as it is non-flammable.

Caring for a ceramic chimney is quite simple: twice a year, you need to check the draft and tightness of the joints of the modules, and, if necessary, clean the internal surfaces from soot. Believe me, this chimney has a lot less hassle than others!

What is a ceramic chimney pipe?

This is a multi-layer construction, which is durable, good thermal insulation characteristics. Ceramic chimneys consist of outer and inner shells, an intermediate layer of insulation. A feature of thermal insulation is fire resistance. If the chimney does not meet these requirements, its service life is reduced, and at the same time, the risk of a fire hazard increases.

The outer shell can be made of concrete or ceramic blocks. As a heater, any fire-resistant heat-insulating material is used. The inner shell is made of ceramic.Due to this, the surface in the pipe for removing combustion products is characterized by smoothness, which prevents excessive soot from settling on the walls of the chimney.

Due to the design features, they received the name "sandwich". Due to the presence of a layer of thermal insulation, the likelihood of condensation on the inner surface of the pipe is eliminated. Moisture contributes to the icing of the chimney in winter, which causes a decrease in its efficiency.

Holes are provided in the outer shell of the pipe. They are intended for reinforcing reinforcement. This increases the reliability of the design. The need for hardening arises from the presence of ceramic elements.

Where is this chimney used?

The main direction of application is the removal of smoke from objects of various purposes. The sandwich chimney is connected to the air duct of the boiler, stove, fireplace. The pipeline for the removal of combustion products is installed at facilities equipped with different heating systems. Boilers can operate on different types of fuel:

- firewood;

- gas;

- liquid fuel;

- solid fuels such as wood, coal, etc.

At the same time, the soot does not settle as intensively on the inner surface as on the walls of brick counterparts.

Requirements for ceramic chimneys

To ensure the reliability of the heating system, maintain its performance at the required level, the installation of pipes that discharge the products of combustion of the fuel of the stove, boiler or fireplace should be carried out provided that design installation rules in all areas from the heater to the roof. Requirements to ceramic chimneys:

- the total height should not be less than 5 m, on the contrary, the installation of a longer structure is welcome, as a result, draft in the sandwich chimney is increased;

- if the roof is flat, the top of the pipe should rise 1 m 20 cm above the surface (more is allowed, less is not);

- the top point of the ceramic chimney pipe cannot be located below the roof ridge;

- the end section of the pipe should rise 50 cm above the ridge, parapet;

- the inner diameter of the flue duct cannot be less than the size of the heater pipe, through which the products of combustion of fuel are discharged.

When installing a sandwich chimney, the properties of the roof covering should also be taken into account. For example, if the material is combustible, then the distance from the ridge to the top of the pipe cannot be less than 1 m, on the contrary, it is necessary to ensure safety during the operation of the heating system of the facility and make the chimney higher (1.5 m from the ridge).