- Supply ventilation systems

- System characteristics

- Device and principle of operation

- Principle of operation

- Duct calculation

- Duct air conditioner with fresh air supply

- Choice of location and installation features

- Installation steps

- Calculation and selection methods

- For rooms with ceiling heights up to 3 meters

- For rooms with a ceiling height above 3 meters

- Selection Tips

- Planning a ducted air conditioning system

- Design

- Planning a ducted air conditioning system

- The principle of operation of supply-type ventilation

- Air filtration

- Microprocessor control system

- Fresh air conditioners for apartment

Supply ventilation systems

Ventilation systems for domestic premises can have different configurations and cost from several hundred to tens of thousands of dollars. The most simple and inexpensive of them:

- window valve, installed at the top of the plastic window frame and allowing fresh air to naturally enter the room.

- Supply fan, which is mounted in a window or hole in the outer wall. In our climatic zone, such fans are practically not used in residential premises.

The disadvantage of such simple systems is that in winter the room will

too cold air can enter, which can lead to people getting sick, wallpaper peeling off, furniture and parquet drying out. To prevent this from happening, air with a temperature of at least + 18 ° C should be supplied to the living quarters.

(this, by the way, is a requirement of SNiP), so in the ventilation system it is necessary

there must be a heater with an automatic system that regulates its power and protects it from overheating. In addition, the ventilation system must have an easily removable air filter (otherwise, the house, along with fresh air

a large amount of dust will fall) and good sound insulation. These requirements are met by stacked ventilation systems assembled as a constructor from separate components: a fan, a silencer, a filter, a heater and an automation system. However, stacked systems take up a lot of space (usually a separate room is required for their placement - a ventilation chamber) and require qualified design, installation and commissioning. That is why for the ventilation of country houses, apartments and small office premises more often use monoblock air handling units.

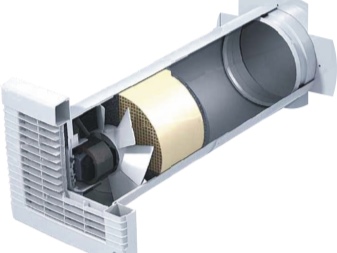

The supply unit (PU) is a compact ventilation system, all components of which are assembled in one soundproof

case (monoblock). Thanks to this design, monoblock air handling units got rid of many of the shortcomings inherent in stacked systems. Their small size and low noise level made it possible to place them on balconies or even directly in residential premises, and the selection and adjustment of all components at the production stage made complex design and commissioning unnecessary.

Next, we will talk about what they are, as well as how

choose the right air handling unit for an apartment, country house

home or office space.

System characteristics

I decided for myself that I need at least 80 m3 per room, with two people. If you want to feel fresh, then you need about 120 m3.

Forced ventilation:

- four rooms, from 80 to 120 m3 per room

- the hood is carried out in native exhaust channels (2 channels: kitchen + toilet, bathroom)

- ability to balance air flow between rooms

- filtration requirements EU5-EU7

Conditioning:

- the purpose is to cool the incoming air

- air intake from the street - up to 300 m3

- recirculation in the apartment - up to 300 m3

- air supply to each room (three rooms) up to 200 m3

Total:

- in ventilation mode from 320 m3 to 480 m3 per apartment.

- in air conditioning mode up to 600 m3 per apartment.

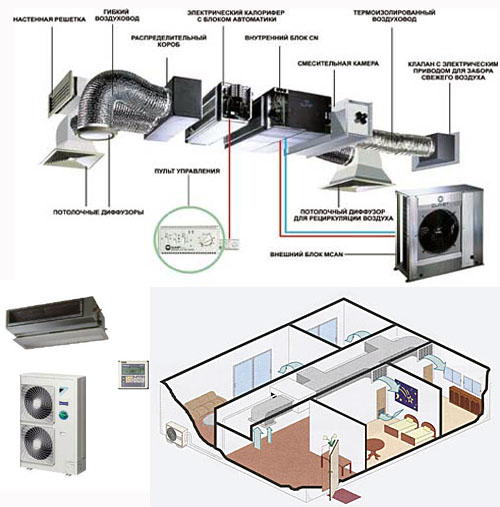

Device and principle of operation

An air conditioner with an air supply can be of several varieties.

Among consumers, devices with a system of forced inflow of air masses are in demand, the location of the block of which is channel or wall. The difference between the design of such systems and standard ones is:

- air duct - it connects the indoor unit to the external one;

- purification of the supplied air mixtures.

Duct air conditioners for ventilation are equipped with heaters, which are designed to heat the flow of air masses, regardless of the time of year. They can be water or electric. Supply air conditioner equipment:

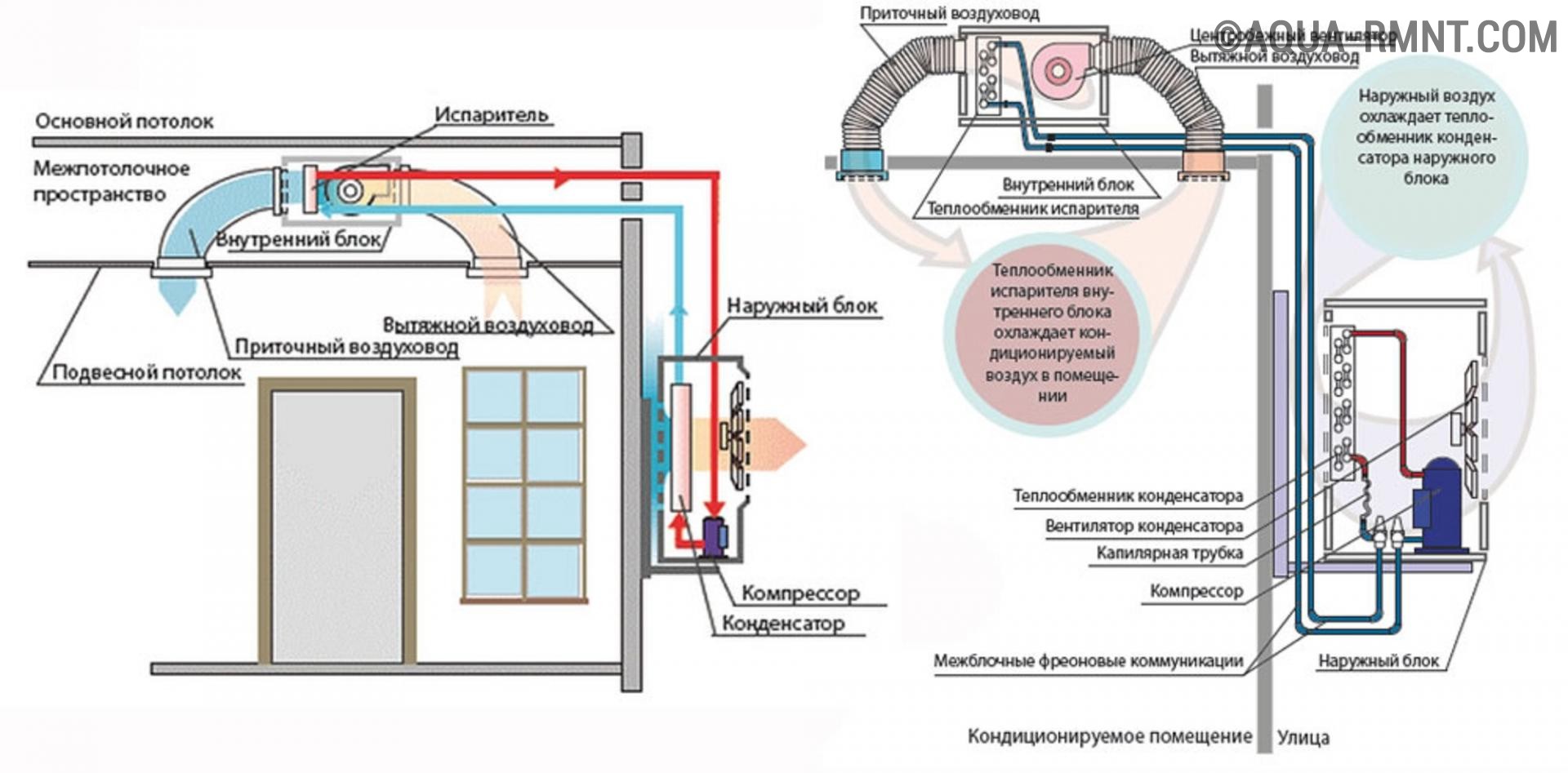

Indoor (evaporative) block

It consists of a heat exchanger, fan, filter, electronic control unit.

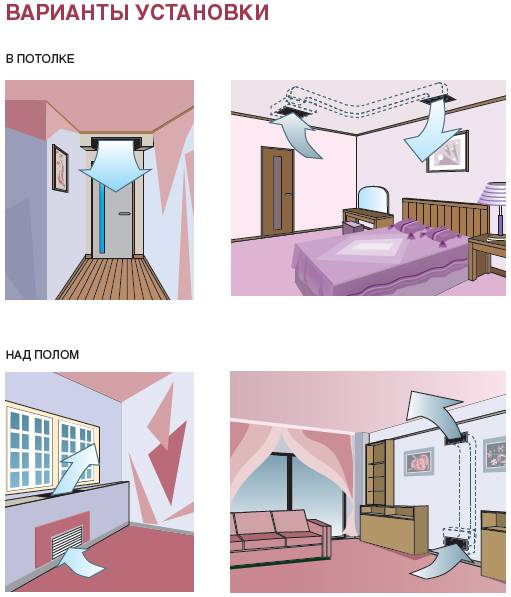

If the air conditioner is wall-mounted, the indoor unit is mounted on the wall.

If the ventilation unit is a duct unit, the indoor unit is mounted in a box or above a false ceiling. Installation, therefore, does not violate the design of the room, because all the equipment is hidden behind the ceiling, while the air supply is carried out through decorative grilles.

Outdoor unit

It consists of a compressor, a condenser heat exchanger, an air cooling fan, a suction turbine, and a chamber for mixing air masses.

The outdoor unit is mounted outside. If such a unit is equipped with a centrifugal fan, it can be installed indoors.

Principle of operation:

- Fresh air flows to the conditioner through the external block by means of the soaking-up turbine.

- Through the air ducts, fresh air enters the mixing chamber of the indoor unit.

- With the help of the chamber, the process of mixing incoming fresh air flows and outflows of air masses of the room is carried out.

- The already mixed air is then cleaned.

- Before air flows are supplied to the room, they are additionally processed (heating, cooling, humidification, etc.) according to the parameters set by the user, which can be maintained automatically.

Principle of operation

Air inlets also include two blocks. The main elements of the first of them are:

- cooler;

- filter;

- fan;

- control Panel.

Elements of the second - remote module:

- Heat pump;

- compressor and condenser unit;

- microprocessor control.

The connector of the considered blocks is a freon pipeline. A heater with electronic control is also connected to the indoor unit.

Air is simultaneously taken from both the room and the street. They enter the mixing chamber, where, respectively, mixing takes place.The resulting air passes through the filters and is processed according to the specified mode, that is, it is cooled, heated or dried. And finally, he goes back into the room. Thus, the air inside is not only cooled, but also refreshed.

Duct calculation

The calculation of the duct air conditioning system is quite complicated and should only be entrusted to qualified specialists. In short, the procedure looks like this:

- For each room, a heat engineering calculation is made, on the basis of which the required cooling capacity is determined.

- The cooling capacity determines the approximate volume of cooled air that the air conditioner should supply to a given room. For models with cooling capacity up to 20 kW, approximately 165 cubic meters of air must be supplied to provide 1 kW of air. m / h, for more powerful (up to 40 kW) this figure is about 135 cubic meters. m/h

Knowing the diameter of the air ducts, the material and the speed of air movement (it depends on the volume of supply), the aerodynamic resistance of each branch and the entire system as a whole is determined.

Duct air conditioner with fresh air supply

The device of the channel system is two-module. One block, compressor-condenser, is outside the perimeter, evaporator is located inside the room. Between themselves, they are connected by copper tubes with freon and electrical wiring. The evaporation unit can be hidden in the lining of the room. Air conditioners with the function of fresh air inflow from the street produce air exchange into the room for 2-3 hours. Physiologically, the air becomes healthy, saturated with oxygen. These air conditioners include systems from Daikin "Ururu Sarara".Hitachi and Haier created their own models with an influx of fresh air.

The technology for cleaning and mixing air flows is complex. In a special block outside the perimeter, the air taken from the street passes through a manganese catalyst, adsorption of impurities, including odors, occurs. There is a filter at the inlet to the air conditioning system, on which small debris, insects and other external dirt remain. After the gas flows are mixed and passed through a photocatalytic filter, where they are biologically disinfected. Clean air is enriched with vitamins and hyaluronic acid. The healing product is fed into the room.

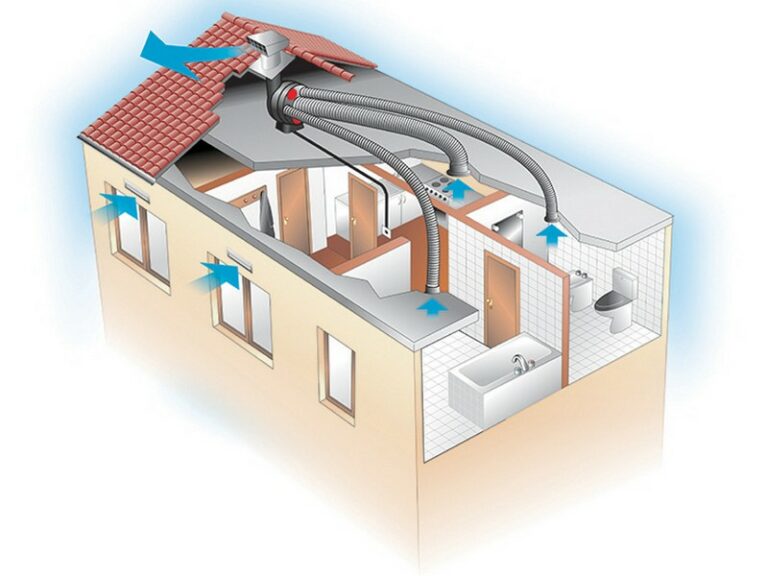

Choice of location and installation features

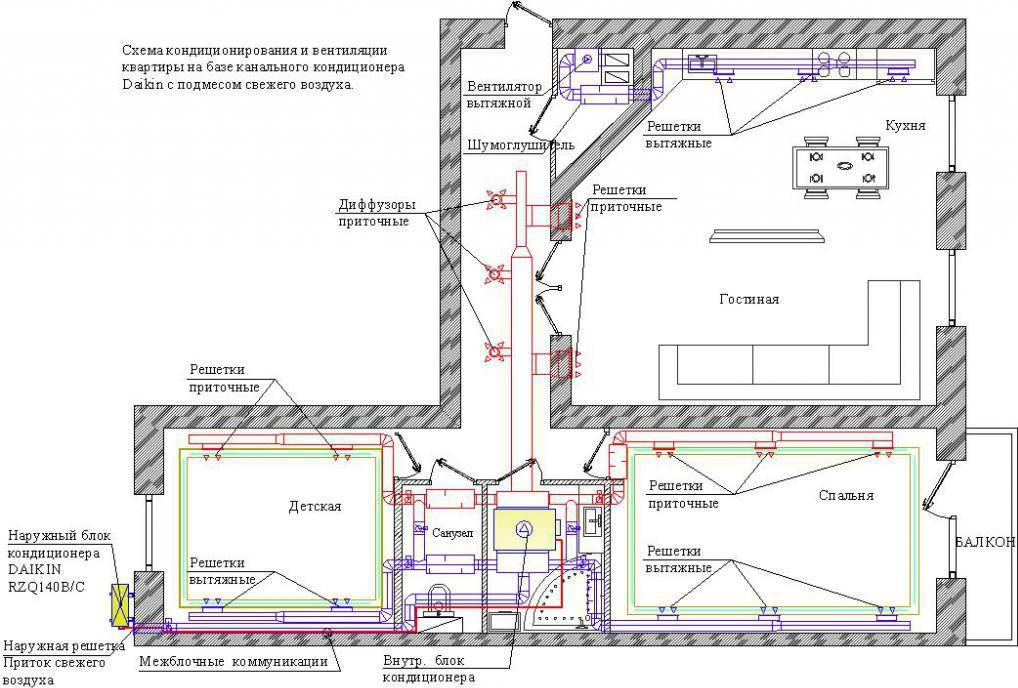

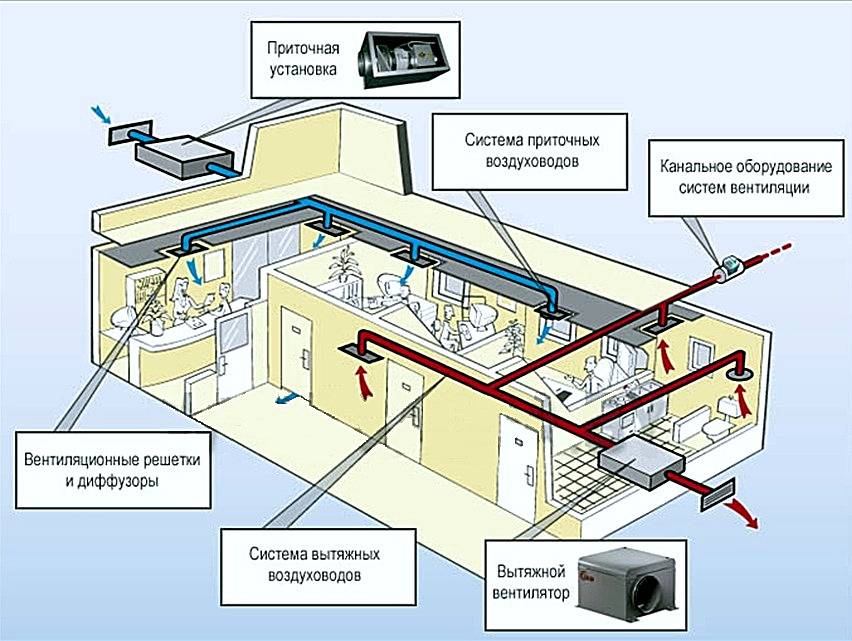

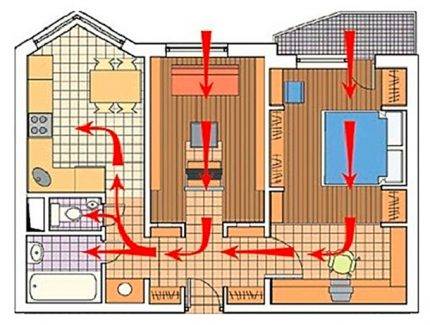

Before installing duct ventilation, a system design should be drawn up. It should indicate the installation site of the launcher itself, the location of air ducts, ventilation grilles, etc.

It is important to take into account the direction of air flow. The place of entry of fresh air masses should be residential premises, such as a living room, study, bedroom, etc.

As a result, unpleasant odors from the bathroom or kitchen will not enter the living rooms, but will be immediately removed through the exhaust grilles. Air streams can intersect with each other, reflect from the surface of furniture, etc.

It is better to think over these points in advance so that the trajectory of the movement of air flows is as efficient as possible.

In winter, the heating temperature of the air coming from the street must be correlated with the amount of heat in the room. If the house is well heated, air heating can be left at a minimum level.

But if for some reason the power of the heating system is not enough, the injected air should be warmed up more strongly.

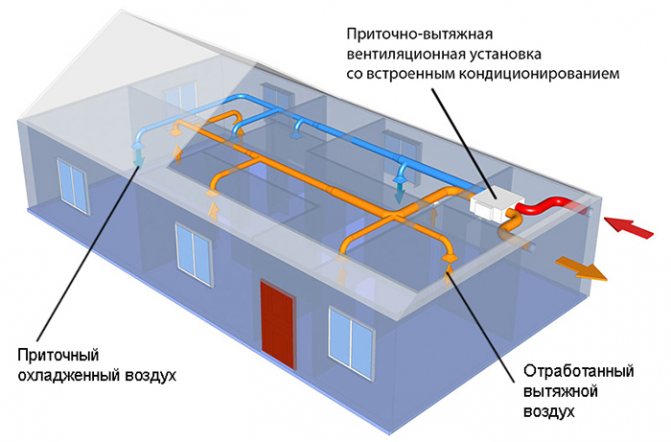

This diagram shows the correct movement of air masses during ventilation: fresh air enters the living quarters, and exhaust flows are removed through grilles in the kitchen and bathroom

This diagram shows the correct movement of air masses during ventilation: fresh air enters the living quarters, and exhaust flows are removed through grilles in the kitchen and bathroom

When choosing a supply unit, you should decide on the purchase and installation of additional fine filters. Typically, such devices are equipped with class G4 filters, which are capable of retaining relatively large contaminants.

If there is a need or desire to get rid of fine dust, you will need another filter unit, for example, class F7. It is installed in the system after the supply installation.

Each supply ventilation unit has a coarse filter. Replacement of filters is carried out through the inspection hatch, to which there must be free access

If the supply ventilation unit is not equipped with fine filters, then they are purchased separately.

Even if the owners of the house for some reason refused to install such elements, it is still recommended to provide a place in the system in case such installation is needed in the future.

The launcher must be installed in such a way that it is accessible for regular maintenance and periodic repairs.

Particular attention should be paid to the location of the inspection hatch through which the filters are replaced. The hatch should open freely, leaving enough space for manipulation with the filter elements.

When installing the supply ventilation, you will need a special tool and a diamond drill to drill the wall. Hole sizes can be up to 200mm

When installing the PU, it is necessary to drill the outer wall. A perforator is usually not suitable for such work; work is performed with a diamond drill with constant water cooling.

In order not to damage the interior decoration of the room, it is better to drill from the outside.

Installation steps

Manufacturers usually provide mobile floor air conditioner with supply ventilation mode instructions for assembly. No complex installation work is required, since the entire device is in one housing that will stand indoors. All that remains is to correctly assemble the parts, following the recommendations. More difficult may be the issue with the withdrawal of the ventilation pipe.

Arrangement of ventilation

Arrangement of ventilation

There are three options for arranging ventilation. You can lead the pipe out the window, prepare a special hole previously made in the wall in advance, or send it to the ventilation shaft. In addition, if you plan to use the air conditioner in several rooms, moving it from room to room in turn, then you should think about how to make a pipe outlet in each of them, and where the equipment will be placed so that it does not interfere with anyone.

Each variant of the withdrawal device has its own characteristics:

- The most practical is the ventilation shaft, but this is not always possible due to the location of the ventilation holes, since the length of the air pipe should not exceed two meters.

- It’s not so simple with taking it out the window, you can’t stick the pipe out the window and leave it, because in this way hot air will come back into the room, respectively, this will nullify the entire operation of the device.Therefore, it will be necessary to install a special impervious panel to which the pipe will be connected. In the non-working state, a plug is installed on the hole. Such a panel can usually be bought at the same store that sells air conditioners.

- You can specially make a hole in the wall for this, organizing a branch for the pipe. This is convenient because you can place it almost anywhere. The cross-sectional area of the hole must not be less than that of the duct. It is better to close the walls with a piece of pipe or PVC film.

When the outlet is ready for use, it remains only to assemble the air conditioner according to the instructions, remove all protective films and connect it. You can turn on the device only a few hours after assembly, and the device must be placed vertically. It is also worth reading the instructions carefully, since different models may have their own nuances that must be taken into account so that the device can work properly.

One of the advantages of mobile air conditioners is that, unlike split systems, they do not require any permits to be installed. Therefore, anyone can afford such an acquisition. In addition, this is a great option for those who live in rented apartments - when moving, you can take the air conditioner with you.

Calculation and selection methods

The simplest and fastest method for calculating a split system is based on the area of \u200b\u200bthe room. For 10 sq. meters - 1000 W of cooling capacity. However, it must be borne in mind that such a calculation gives an error of about 30% and can be applied to rooms with a ceiling height of not more than 3 meters and rooms without a large number of people and equipment that generates a large amount of additional heat.More accurate calculations are made using formulas that take into account the characteristics of the premises.

For rooms with ceiling heights up to 3 meters

N

cd

= 35*

F

pom

+ 150*

n

of people

+ 350*

n

technology

+

q

*

F

windows

,W

-

F

pom

- area of \u200b\u200bthe room (m 2); - 35 - the value of heat gain through external walls (W / m 2);

- n

of people -

150 —

heat gain from one person in a calm state (W); - n

technology -

F

windows

- window area (m 2); - q

- the coefficient of the average daily heat that falls on the window.

- if the windows face north - 40 W / m 2

- if the windows face south - 366 W / m 2

- if the windows face west - 350 W / m 2

- if the windows face east - 309 W / m 2

For rooms with a ceiling height above 3 meters

N

cd

=

q

*

V

pom

+ 130*

n

of people

+ 350*

n

technology

,W

-

V

pom

- the volume of the room (m 3); -

n

of people

- the number of people in the room; - 130 - heat gain from one person in a calm state (W);

-

n

technology

- the number of equipment (computers); - 350 - heat gain from one computer (W);.

- q

- coefficient of average daily heat in the room.

q - coefficient of average daily heat is equal to:

- if the windows face north - 30 W / m 2

- if the windows face south - 40 W / m 2

- if the windows face west - 35 W / m 2

- if the windows face east - 32 W / m 2

The calculation results are also not entirely accurate and may give an error in the calculations within 10-15%, but usually this is enough for the practical selection of equipment. For more accurate calculations, it is necessary to refer to the special academic educational literature, which provides the appropriate formulas for the calculation.

The second indicator that must be considered when choosing a ducted air conditioner is the static air pressure. Since the air intake from the room and the air supply to the room are carried out by the indoor unit through air ducts of different lengths and designs, it is necessary to correctly calculate the losses in them, as well as when they turn, in the distribution and intake grilles in order to correctly select the indoor unit by the value of the static head. Otherwise, the entire pressure of the air flow will be lost to overcome such resistances. All resistances must be taken into account and an indoor unit with a static head of 20% more than the losses must be selected. Such losses depend on the speed, section and type of duct. Losses also occur in the air inlet and outlet grilles, which are also calculated as a function of the air volume flow. For a more accurate calculation of losses, you can use specialized reference literature or contact qualified specialists.

If it is necessary to supply fresh air, it must be taken into account that the maximum amount of fresh air admixture for ducted air conditioners is up to 30%. When the air conditioner works for heat in winter, its stable operation takes place at outdoor temperatures up to minus 10 ÷ 15 C. If the outdoor air temperature is below minus 20 C and the air conditioner works for heat, then additional heating of fresh air is necessary in some other way.

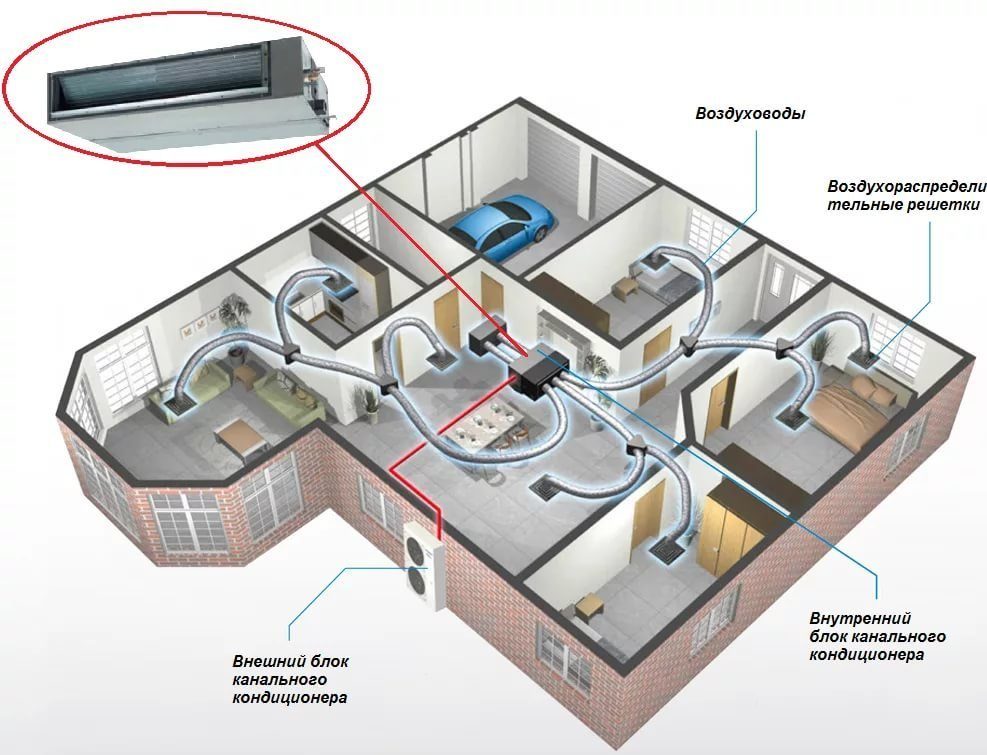

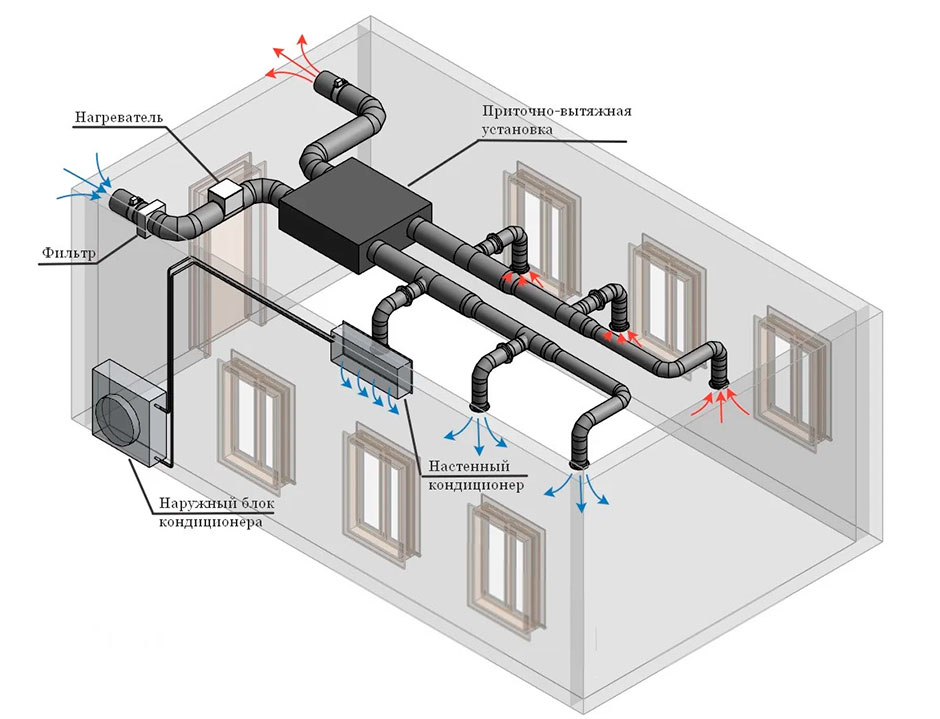

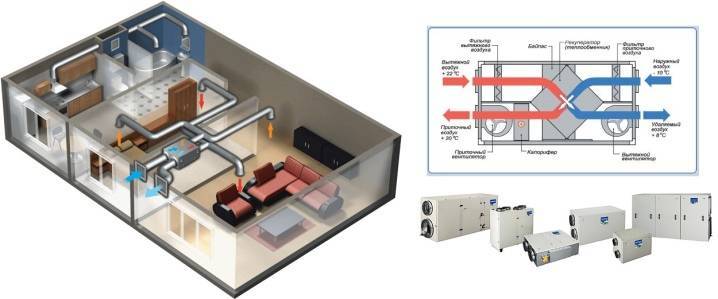

Thinking about installing a modern split system in their house or apartment, people often wonder how the channel split system works? The principle of operation of the duct air conditioner

based on the transmission and filtration of air masses using a system of air shafts.

The difference from a conventional air conditioner is that such equipment is mounted in an air duct system. In this regard, it is necessary to plan the installation of channel equipment under construction

or major renovation.

Before delving into the intricacies of work, it is necessary to understand what this system is, because many simply do not know what a duct-type air conditioner is. Ducted air conditioning is a special split system that maintains the required temperature in medium and large rooms. It consists of 2 main blocks

:

- internal;

- external.

The outdoor unit contains a compressor, a fan and a condenser heat exchanger. The internal one includes an evaporator heat exchanger, a fan with an electric motor, a volute diffuser, a liquid collection tray, an air chamber and pipes for communications. In addition to these two blocks, the system should include air ducts and grilles, but they are already selected individually for each room.

Selection Tips

But it is extremely difficult to choose the right duct ventilation device for an apartment or for a house, just by getting acquainted with the information provided by the manufacturers.

Rather, you can make a choice, but it is unlikely that it will be the right one. It is imperative to pay attention to the reviews of other consumers. It is their opinion that allows you to identify the strengths and weaknesses of each option.

For obvious reasons, it is better to use independent engineers and designers, rather than those offered by the manufacturer, dealer or sales organization.

Professionals will take into account:

- glazing characteristics;

- the area of the glazed space;

- total serviced area;

- purpose of the premises;

- necessary sanitary parameters;

- the presence of a ventilation system and its parameters;

- heating method and technical properties of the equipment;

- the level of heat loss.

The correct calculation of all these parameters is possible only after studying the features of the object itself and a number of measurements. Sometimes you have to use special software for designing air ducts and selecting good duct equipment. Only when the necessary properties of the channels, the need for air intake and the optimal installation locations have been determined, it is possible to take up the choice of the air conditioner itself. It makes no sense at all to take this choice without a project - it’s easier to throw money down the drain in the literal sense

You also need to pay attention to:

- functionality;

- current consumption;

- thermal power;

- possibility of air drying;

- contents of delivery;

- having a timer.

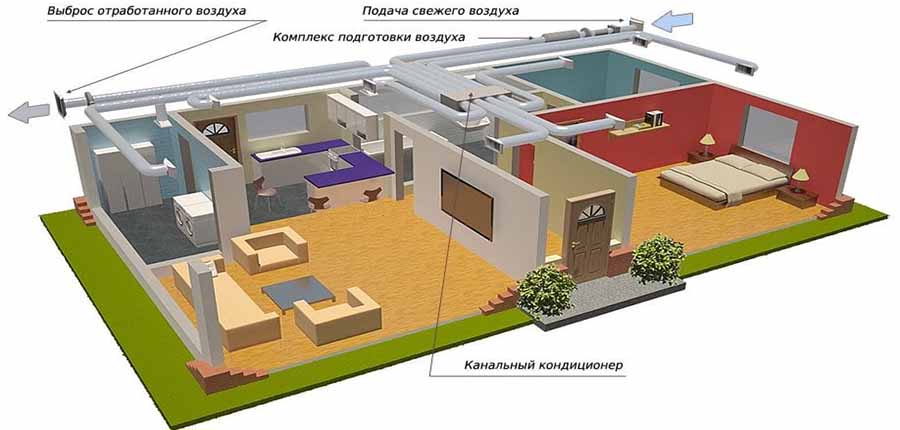

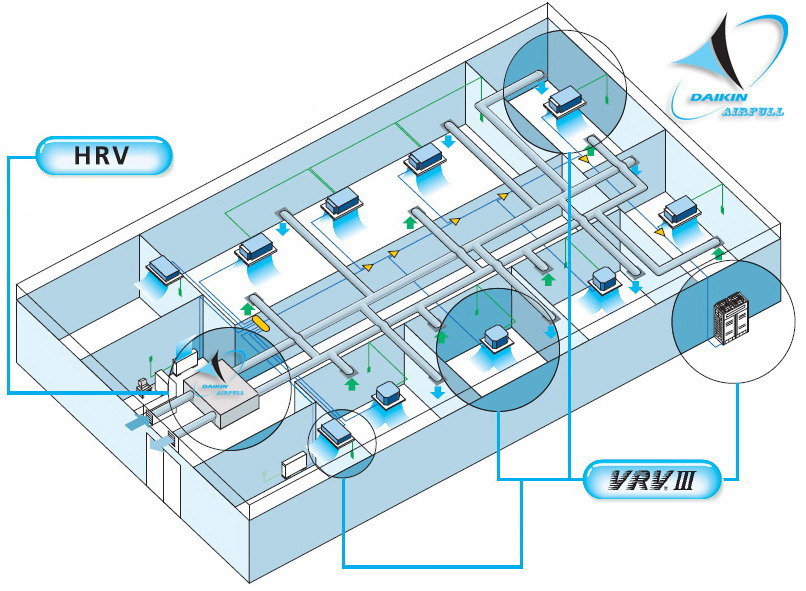

Planning a ducted air conditioning system

The duct system consists of two subsystems: one - supply - cooled air is distributed to the premises, the other - exhaust - heated air from the premises is delivered to the air conditioner. Diffusers are installed on the supply air ducts, grilles on the exhaust air ducts.

When designing an air conditioning system, consider the following:

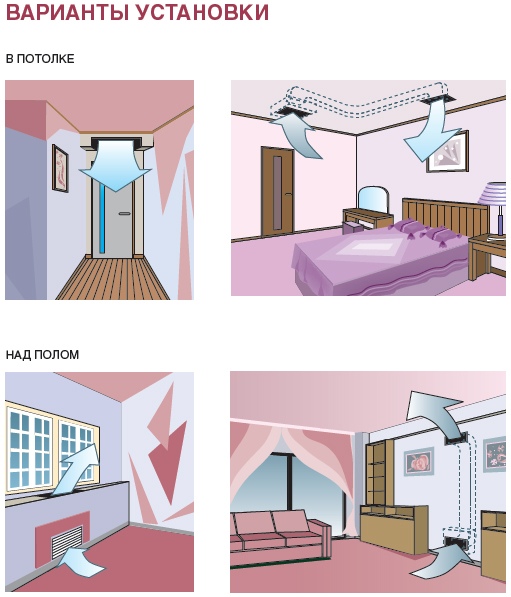

Both diffusers and grilles should be located on top - on the ceiling or at the top of the wall, but at the same time they should be on opposite sides of the room.

Air ducts should be located behind the false ceiling and inside the partitions.

Each duct should be laid so that it has as few turns as possible - they increase aerodynamic drag.

The optimal cross-sectional shape of the duct is a circle. In a rectangular channel, the air forms vortices at the corners, which leads to an increase in aerodynamic drag. However, rectangular ducts, even square ones, have a lower height for the same cross-sectional area, so they are more preferable in a room with low ceilings.

Air ducts made of plastic and galvanized steel provide the least resistance to air flow

The latter are non-combustible, which is important for rooms with a high degree of fire safety. But if desired, the air duct can be made independently even from cardboard. Plywood is often used for the same purpose.

The easiest way to install flexible corrugated ducts, but it is recommended to use them only as a last resort. On long sections, they sag, and at the attachment points they are pinched, so that the aerodynamic drag of the track eventually increases greatly.

Diffusers and grilles should be selected so that at the maximum supply of cooled air, its speed in them does not exceed 2 m/s. Otherwise, the airflow will produce a noticeable noise. If the diameter or shape of the duct does not allow you to use the diffuser that you think is suitable, use a special adapter

For the same purpose, plywood is often used. The easiest way to install flexible corrugated ducts, but it is recommended to use them only as a last resort.On long sections, they sag, and at the attachment points they are pinched, so that the aerodynamic drag of the track eventually increases greatly.

Diffusers and grilles should be selected so that at the maximum supply of cooled air, its speed in them does not exceed 2 m/s. Otherwise, the airflow will produce a noticeable noise. If the diameter or shape of the duct does not allow you to use the diffuser that you think is suitable, use a special adapter.

In places of branching on lines with less aerodynamic resistance, diaphragms should be installed, with the help of which their cross-sectional area can be partially blocked. Such an adjustment will make it possible to balance the system. Without it, almost all the air will rush into the channel with the least resistance.

With a significant duration of the air ducts, it is necessary to provide inspection hatches for removing dust.

Easily removable elements should be provided in the lining of the suspended ceiling and partitions, by dismantling which you can get access to the diaphragms and inspection hatches in the air ducts.

To avoid the formation of condensate, the supply air ducts must be wrapped with heat-insulating material from the outside.

Design

The unit is presented in the form of a monoblock assembly consisting of a housing, a heat exchanger, a drop catcher, and a condensate collection pan.

- The body is galvanized. Its dimensions are standard, they correspond to the standard size rows of rectangular air ducts. Easy installation thanks to flange bolting

- The components of the heat exchanger are located directly in the mill. It consists of a series of copper tubes through which various refrigerants pass, as well as aluminum plates, providing an expansion of the cooling space.

- The air masses passing through the heat exchanger, having given up their energy, are cooled, and are converted into condensate on the cold surface of copper pipes and aluminum plates.

- The collection of excess moisture provides a drop catcher. It includes plastic ribs through which condensate enters the pan located at the bottom of the case. The efficiency of the droplet eliminator is ensured by the movement of air flows greater than 2.5 m/s; at minimum rates, it can not be used.

For uninterrupted draining of condensate, the tray is mounted only in a horizontal position. Drainage of excess moisture is carried out in the pan, where additional thermal insulation and a drainage tube are provided.

Planning a ducted air conditioning system

The duct system consists of two subsystems: one - supply - cooled air is distributed to the premises, the other - exhaust - heated air from the premises is delivered to the air conditioner. Diffusers are installed on the supply air ducts, grilles on the exhaust air ducts.

When designing an air conditioning system, consider the following:

Both diffusers and grilles should be located on top - on the ceiling or at the top of the wall, but at the same time they should be on opposite sides of the room.

Air ducts should be located behind the false ceiling and inside the partitions.

Each duct should be laid so that it has as few turns as possible - they increase aerodynamic drag.

The optimal cross-sectional shape of the duct is a circle.In a rectangular channel, the air forms vortices at the corners, which leads to an increase in aerodynamic drag. However, rectangular ducts, even square ones, have a lower height for the same cross-sectional area, so they are more preferable in a room with low ceilings.

Air ducts made of plastic and galvanized steel provide the least resistance to air flow

The latter are non-combustible, which is important for rooms with a high degree of fire safety. But if desired, the air duct can be made independently even from cardboard

For the same purpose, plywood is often used. The easiest way to install flexible corrugated ducts, but it is recommended to use them only as a last resort. On long sections, they sag, and at the attachment points they are pinched, so that the aerodynamic drag of the track eventually increases greatly.

Diffusers and grilles should be selected so that at the maximum supply of cooled air, its speed in them does not exceed 2 m/s. Otherwise, the airflow will produce a noticeable noise. If the diameter or shape of the duct does not allow you to use the diffuser that you think is suitable, use a special adapter.

In places of branching on lines with less aerodynamic resistance, diaphragms should be installed, with the help of which their cross-sectional area can be partially blocked. Such an adjustment will make it possible to balance the system. Without it, almost all the air will rush into the channel with the least resistance.

With a significant duration of the air ducts, it is necessary to provide inspection hatches for removing dust.

Easily removable elements should be provided in the lining of the suspended ceiling and partitions, by dismantling which you can get access to the diaphragms and inspection hatches in the air ducts.

To avoid the formation of condensate, the supply air ducts must be wrapped with heat-insulating material from the outside.

The principle of operation of supply-type ventilation

Good air exchange in a residential area is essential. It is far from always possible to organize effective ventilation at home in a natural way. In such a situation, forced ventilation is considered one of the best options for living quarters.

Excessive sealing is a characteristic feature of modern apartments. Plastic windows are installed everywhere, which, unlike wooden ones, do not let air masses through at all. This also applies to the entrance doors, which, when closed, block out cold, dust, noise, and fresh air.

An air conditioner with a fresh air inflow function or a window valve will help to partially solve the problem. However, they only supply air to one room.

Artificial, otherwise mechanical, supply ventilation is a system of means by which the necessary amount of fresh air is forced into the room. At the same time, the air flow is heated to a comfortable temperature and filtered to remove possible contaminants.

The simplest version of the supply ventilation unit can be made by hand, but its efficiency will be lower than that of the industrial production model

Air filtration

After a year of operation, I was puzzled by the issue of replacing filters. I decided to look in the market for analogues.

Option 1 - buy filter material and sew the filter yourself.

- I dismantled one old filter and made a pattern - sheet size 350x2000 mm.

- below photo material:

- Material of progressive density. Loose on the outside, very hard on the inside.

- NF300 - very similar to what the original filter was made of. It bends easily, it is easy to sew a filter out of it.

- NF500/PS is very dense, even rigid. To make something similar to the original out of it will not work.

- NF400/P - just what you need

- Haven't done any sewing yet.

Option 2 - order the filter assembly.

The workmanship is excellent, it fits perfectly into the original FFR 200 case. I decided for myself that I would order it - this is a 2-3-fold saving on the original.

Microprocessor control system

The electronic control system automatically maintains the desired parameters of the air conditioning and ventilation system at any time of the year. In summer, the air is cooled and the set temperature is maintained in the room. In autumn and spring, the air conditioner switches to the "heat pump" mode and effectively heats the air without turning on the heaters (electric or water). If the outside temperature drops below 0C, an additional heater (duct-type air conditioner) is switched on. The electronic heater control module allows you to smoothly adjust its power depending on the outside temperature, which ensures minimal power consumption.

Fresh air conditioners for apartment

Another type of split system is the supply and exhaust air conditioner in the Hitachi product line, they are not very powerful, air exchange reaches only 8 m 3 per hour, but this amount is enough for a bedroom. An example of a supply and exhaust split system is the Hitachi RAS-10JH2 air conditioner.The model has an inverter compressor, 2 pipes are used - supply and exhaust. Air is removed forcibly, fresh air from the street can be heated. The remote control has separate options for supplying air from the street and removing exhaust. One mode is chosen, then the system is tuned to an equilibrium state.

Haier offers 2 models of premium fresh air conditioners: Aqua Super Match AS09QS2ERA and LIGHTERA HSU-09HNF03/R2(DB). In these units, the supply air system is an optional extra. But having bought the equipment, it is possible to provide air renewal with a flow rate of 25 m 3 / hour. Both models of conditioners have the built-in function of an admixture of air from the street. To do this, the external unit has a pressure fan and a chamber for mixing two gas streams. A flexible hose with outdoor air can be introduced directly into the room in one way or another.