- No. 6. The size of sewer PVC pipes: diameter, thickness, length

- Kinds

- Sewer plastic pipes: diameters, prices

- Types of plastic sewer pipes

- Dimensions and diameters

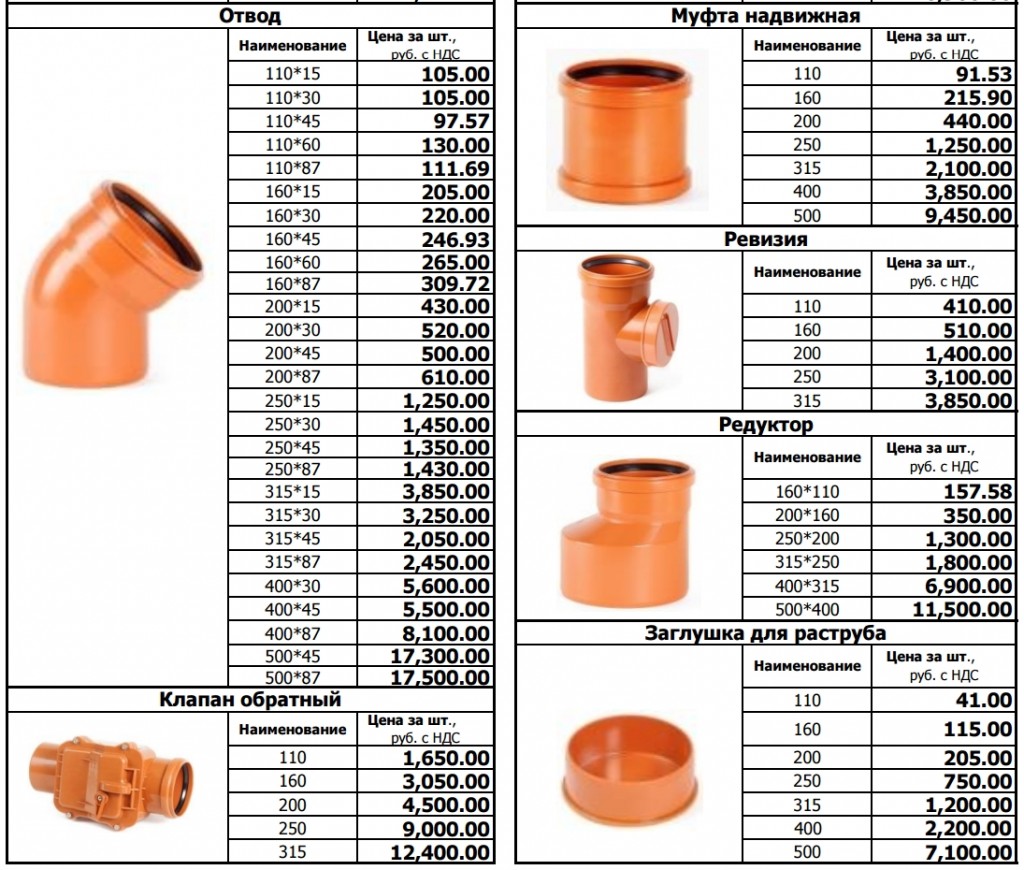

- Varieties of fittings for PVC sewerage

- Sewer fitting dimensions and installation recommendations

- PVC pressure and non-pressure pipes

- Advantages of PVC pipes

- Corrosion resistance

- Antibacterial properties

- Little chance of clogging

- Durability

- light weight

- Easy installation

- Low cost

- Advantages of HDPE pipes

- What is a pressure pipe

- Classification of sewer PVC pipes

- Advantages of PVC pipes

- Corrosion resistance

- Antibacterial properties

- Little chance of clogging

- Durability

- light weight

- Easy installation

- Low cost

- The use of plastic products in sewer communications

- Classification of sewer fittings

- Features of pressure and non-pressure pipes

No. 6. The size of sewer PVC pipes: diameter, thickness, length

The selection of the diameter of the sewer pipe is a matter of increased importance. If you take pipes smaller than required, they will not provide sufficient throughput

What this means is probably not worth explaining.In the best case, the wastewater will go badly, in the worst case, it will start to come out in some places. In fear of facing similar consequences, many decide to play it safe and take pipes with a diameter that is much higher than required. Efficiency compared to pipes with a correctly selected diameter will increase slightly, but the costs and area that must be allocated for these pipes increase greatly.

Before you go shopping, you need to draw up a diagram of the sewer system and mark on it all the points for draining the liquid. The more drainage points there are, the larger the drain pipe should be.

However, when choosing pipes, it is necessary to take into account not only their diameter, but also the length, as well as the wall thickness.

In order to correctly select the diameter of the PVC sewer pipe, it is ideally necessary to calculate the estimated volume of effluents, but often this calculation is neglected, using parameters tested by millions:

- pipes from a shower cabin, bathtub, washbasin and bidet can be 40-50 mm in diameter;

- for a kitchen sink - 32-50 mm;

- for the toilet - 110 mm;

- for dishwashers and washing machines - 25 mm;

- central riser - 110-160 mm;

- pool - 200-300 mm.

The diameter of the sewer pipe that exits the apartment must be at least the diameter of the common line. For houses up to 5 floors, these are pipes with a diameter of 110 mm, for taller buildings - 160-200 mm. External sewerage cannot have a diameter of less than 110 mm, which must be remembered when arranging the sewerage of a private house. As a rule, in summer cottages and in country houses, pipes with a diameter of 110-200 mm are used to equip the outer part of the sewerage system.If a sewer system is being built to serve several houses, it is better to take a larger diameter - about 315 mm. Pipes with a diameter of 630 mm are suitable for arranging the main sewer section for serving a small village.

The wall thickness depends on the loads on the pipes. For internal non-pressure sewage, pipes with walls of 1.2-2.2 mm are suitable. They have a diameter of up to 110 mm and belong to the SN2 strength class. SN4 pipes are the most widely used. They are used for arranging both external and internal sewage. Such pipes with a diameter of 50 mm have walls of 2.6 mm, with 110 mm - already 3.2 mm. Suitable for organizing a common house riser, as well as external free-flow sewage in a private house. If it is necessary to equip a pressure sewer, it is better to take pipes with the thickest possible walls (class SN8). With a diameter of 90 mm, the wall thickness is 3-6.6 mm.

The choice of length depends on the length of the pipeline. It is better to reduce all connections to a minimum, but you should not buy too long pipes either - this is economically unprofitable, and inconvenient. Usually PVC pipes are sold in sections of 0.5 m, 1 m and 2 m, but you can find products with a length of 3 m and 0.3 m. Some manufacturers offer pipes with a length of 6 m and even 12 m, it is convenient to equip them with external sewage.

Remember that the junctions of individual sections are the most dangerous, so try to make the installation so that there are as few connections as possible. This is where a good estimate will help. In which case, the length of the pipe can be reduced using a hacksaw.

With the help of PVC pipes, you can assemble a sewer system of any complexity.Not only different pipe diameters come to the rescue, but also all kinds of adapters, elbows, tees, crosses, reductions, plugs, etc.

Kinds

These pipes are divided into several types. First of all, they differ in functionality. Electrical pipes have average indicators of flexibility and strength. Single-layer ones are distinguished by increased flexibility, two-layer ones - with special strength and resistance to chemicals, which makes them indispensable for arranging sewerage. Double-layer hoses are used to protect cable ducts and can be used in areas where there is a possibility of damage.

And also pipes are divided by weight. There are three varieties:

- lungs;

- heavy;

- superheavy.

Light pipes are used exclusively for outdoor work, heavy pipes are used for underground communications, and super-heavy pipes are used in areas where special strength is needed, for example, under highways and in places where the railway passes.

The most commonly used material from which the products are made can be as follows:

- plastic;

- PVC;

- PDN;

- uPVC.

Plastic pipes are resistant to corrosion and various temperatures, do not wear out when in contact with sand and gravel, and are also easy to install. PVC pipes are based on polyvinyl chloride, due to this they tolerate ultraviolet radiation well and have high strength, they are not grounded. They are also flame retardant, non-conductive and resistant to aggressive substances such as acids and alkalis.

UPVC pipes consist of unmodified polyvinyl chloride and are mainly used in the installation of external sewage systems, they are resistant to corrosion and chemical elements, easy to process, and can be operated at temperatures from -5 to +60 degrees. PVC-U pipes used for pressure sewerage do not have a socket and must be joined by welding.

Cast iron 110 mm pipes are used primarily for draining toilets. The diameter of such products depends on the wall thickness. They can be bell-shaped and bell-shaped.

HDPE pipes are made of low pressure polyethylene. An example is the commonly used double-wall corrugated d110. It is able to withstand heavy loads, can be installed in various ways, and is easy to install. However, the product has a feature - it fits exclusively into the ground or inside concrete structures.

Corrugation should not be used in areas with a constant too low temperature. However, this disadvantage is more than offset by a large number of advantages. For example, it is not affected by the temperature of the liquid used and its differences, chemical and acid solutions, short-term exposure to frost. Such pipes practically do not clog, which eliminates the need for frequent cleaning.

The double-walled corrugated pipeline is easy to install and connect to various types of structures. The use of fittings also simplifies the installation process of products. It can be used in outdoor advertising, as well as in high-voltage cable installation.

Sewer pipes can have different colors, and this distinguishes them in terms of use and type of work.If the product has a gray color, it should be used when arranging an intra-house pipeline, while pipes that are laid on the street are painted in red.

Sewer plastic pipes: diameters, prices

Every owner wants everything to work in his household, nothing to break, and to be easy to maintain and install. And sewerage is no exception. It is necessary that it requires as little attention as possible - it is very inconvenient if it clogs, but it is no less unpleasant to clean it.

If you want to have a trouble-free sewage disposal system, pay attention to plastic sewer pipes. They are gradually replacing cast iron ones, and all because they cost less, are easier to install, have a large assortment - different diameters and lengths, almost no deposits form on their smooth walls, and even the service life is about 50 years. This whole bunch of properties determines their popularity.

This whole bunch of properties determines their popularity.

Plastic sewer pipes are made from various polymers and their compositions.

Types of plastic sewer pipes

Under the general name "plastic" products are sold from different types of polymers:

- polyethylene (PE):

- high pressure (HPV) - for internal sewerage wiring;

- low pressure (HDPE) - it is possible to lay outside, in trenches (they have greater strength);

- polyvinyl chloride (PVC);

- polypropylene (PP)

And a number of other thermoplastics and their combinations, but they are rare - people prefer to use already known materials.

The material of plastic sewer pipes is selected depending on the application.For example, polypropylene is more suitable for sewerage wiring inside a house or in an apartment. It has a higher operating temperature range - it normally tolerates media up to 70 ° C, for a short time - up to 95 ° C. In the presence of various household appliances that drain waste hot water into the sewer, this will not be superfluous. PVC pipes, which have lower prices, are more appropriate when laying outdoor sewers - here the drains are usually already mixed, so the temperatures are lower and PVC can endure them without harm (working up to + 40 ° C, short-term increase to 60 ° C).

An example of an intra-house wiring of sewerage from plastic pipes

Also, sewer pipes are smooth and corrugated. Moreover, not only bends from siphons can be corrugated. There are profiled pipes for sewerage with an internal smooth wall and an external ribbed one. They have greater strength - they better tolerate compressive loads (they have increased ring stiffness), they can be buried to a greater depth. Are issued with diameters from 110 mm to 1200 mm.

Dimensions and diameters

Sewer plastic pipes, unlike water and gas pipes, are produced in the form of segments, 50 cm, 100 cm, 200 cm long, etc. - up to 600 cm. The maximum length is 12 meters, but some manufacturers can make longer lengths on request. When laying long routes, this is convenient - fewer connections, fewer possible problems (leaks or blockages).

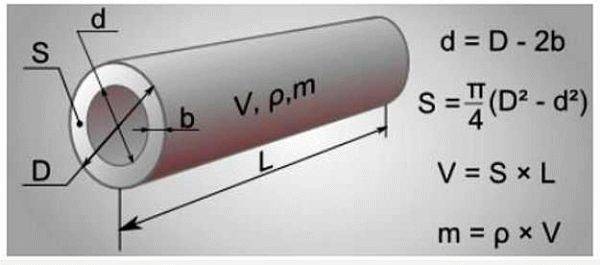

Other important characteristics of plastic pipes are the diameter and wall thickness. In the marking, they usually go side by side: there are numbers 160 * 4.2. What stands for: the outer diameter of the pipe is 160 mm, the wall thickness is 4.2 mm.It is worth remembering here that manufacturers indicate the outer diameter of plastic pipes, and for many calculations and planning, you need to know the inner diameter. It is easy to calculate it: we subtract twice the wall thickness from the outer one: 160 mm - 4.2 mm * 2 = 151.6 mm. In calculations and tables, a rounded result usually appears - in this case - 150 mm.

Parameters of sewer plastic pipes

In general, the industry produces plastic pipes for sewerage with a diameter of 25 mm or more. The maximum section depends on the type of pipe (smooth or corrugated) and the material from which it is made. For example, smooth sewer PVC pipes can be up to 630 mm in diameter, and profiled two-layer pipes can be up to 1200 mm. But these dimensions are useless for homeowners or apartment dwellers. In private housing construction, diameters up to 100-110 mm are mainly used, rarely up to 160 mm. Sometimes, for a large cottage with a large number of plumbing fixtures, a pipe 200-250 mm in diameter may be needed.

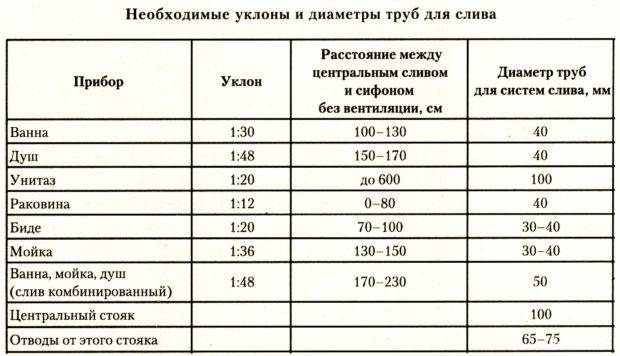

How to choose a diameter for connecting plumbing fixtures

According to the rules, it is necessary to make a calculation; it is completely spelled out in SNiP 2.04.01085. This is a complex matter, it requires a lot of data, so few people really think it is right. Over the years, the practice gained has made it possible to derive the average diameters of polyethylene sewer pipes for each of the plumbing fixtures. You can safely use these developments - all calculations usually come down to these dimensions.

Varieties of fittings for PVC sewerage

Consider the types of fittings for internal sewage, equipped with a rubber o-ring:

- Coupling - used to connect two parallel pipes to each other, there are also revision couplings, which have an opening window for cleaning the system.

- Reduction (adapter between different diameters) - used for joining pipes whose dimensions do not match, as well as for connecting cast iron products with plastic ones.

- Tee - allows you to perform a parallel or inclined branch from the main pipeline, are available with an angle of inclination of 45, 65 and 90 degrees.

- Two-plane cross - performs two perpendicular branches to pipes of identical or different diameters, angles of inclination - 45 and 90.

- Single-plane cross - used to equip two parallel branches, angles 45 and 90. With the help of crosses, drain pipes from bathtubs, sinks and plumbing fixtures are most often connected to the main riser.

- Elbow - allows you to perform a turn in the laying of two parallel pipes, angles of 30, 40 and 90 degrees.

- Compensation pipe - used during repair work to replace a damaged section of the pipeline, which is previously cut out.

- Plug - blocks the transported liquid during the repair or revision of the pipeline.

- Aerator (sewer valve) - is installed on the upper end of the sewer riser, blocks the release of sewer gases into the room through the toilet, which can occur due to air discharge inside the riser, in which the water seal is sucked out of the siphon.

Varieties of sewer fittings

For the installation of external sewerage, in addition to the same assortment of connecting elements as when laying the internal system, the following types of shaped structures are used:

- non-return valve - designed to block the reverse flow of the circulating fluid in the external pipeline, it is mandatory to complete pipes laid with a slope of less than 2 cm;

- two-knee siphon - connects two parallel pipes, forming a bend at the junction, which creates an obstacle to the reverse flow of sewer gases.

Sewer fitting dimensions and installation recommendations

Technical requirements and dimensions of PVC connecting fittings are given in the following regulatory documents:

- GOST No. 18559 - for non-pressure sewage;

- GOST No. 52135 - for pressure systems.

Fittings must be dimensioned according to the diameter of the pipes used. The following sizes of shaped structures for external sewerage are presented on the market:

- couplings - diameter 110-400 mm (revision coupling up to 315 mm), length 12-33 cm;

- bends - ∅ 110-400 mm, distance between sockets 1.5-9 cm;

- a tee for 450 - ∅ 110-400, the length of the side sockets is 14-53 cm, the height from the end part to the beginning of the protrusion of the socket is 14-50 cm;

- check valve - ∅ 110-250, length from 30 to 52 cm;

- two-legged siphon - ∅ 110-200 mm, length 51-82 cm.

PVC fittings for installation of internal sewerage have a diameter range from 50 to 200 mm. To fix the pipes on the walls, plastic clamps are used, which are seated on the supporting structure with the help of two anchors.

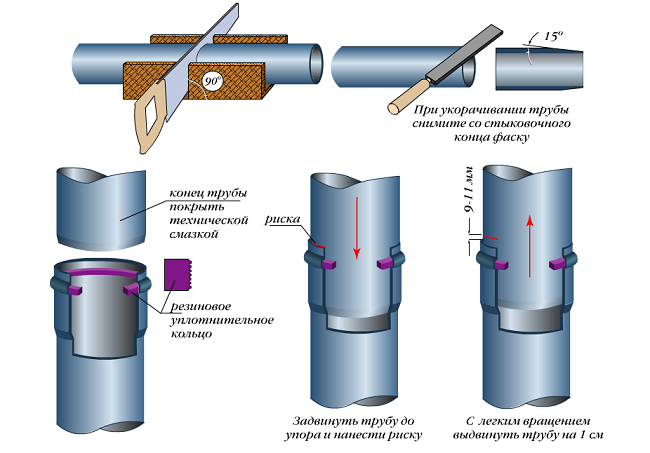

Installation and connection of plastic pipelines must be carried out in compliance with the following requirements:

- Cutting PVC pipes of large sizes is carried out using a special tool - a pipe cutter, which can be replaced with a grinder or a hacksaw. The main thing is that the cut is perpendicular to the axis of the pipe, since a tight connection cannot be made if there are gaps at the junction.

- After cutting, the pipe edge must be deburred with a file and sandpaper.

- When using glued fittings, the mating areas must first be degreased, after which glue can be applied. The composition is applied in an even layer with a brush, excess glue when joining structures is removed with a rag.

- If rubber sealed fittings are used, the contact surfaces must be coated with silicone sealant before installation, which will reduce the risk of leakage. You need to install the pipe not to the stop, but so that a compensation gap of 1 cm is formed. You will need to perform a preliminary docking and mark the entry boundary on the pipe.

Technology of socket connection of sewer pipes

If the connection of pipes with fittings is done correctly, the sewer pipeline will not require repair throughout its entire service life.

PVC pressure and non-pressure pipes

There are two types of materials:

- polyvinyl chloride (PVC for sewage);

- polyvinyl chloride, its service life is much longer, and in terms of characteristics it is more preferable.

Pressure products are manufactured using unplasticized polymeric material. They are designed for pressure of different levels: 1.24-4.14 MPa.Pipes of this type are used in organizing the outflow of sewage, technical and household wastewater, and transporting drinking water. Main characteristics:

- resistance to corrosion, including electrolytic, caused by stray currents;

- light weight;

- service life - about 50 years;

- due to the smoothness of the inner walls, the likelihood of blockage is reduced, the clearance decreases much more slowly than in the case of cast iron / steel products;

- high resistance to aggressive environments;

- heat resistance is +160…+170°С.

Non-pressure communications withstand a pressure of no more than 0.16 MPa. They do not tolerate exposure to temperatures above + 45 ° C. Such products are represented by the following types: single-layer, three-layer. Non-plasticized CPVC (chlorinated polyvinyl chloride) is used in the production. Both pressure and non-pressure products are available with a socket, which allows you to create a more reliable connection.

The considered varieties are non-combustible. The main difference between PVC communications is that the thermal conductivity value is the same as insulating materials. This improves the efficiency of the insulation. In addition, products of these types do not contain harmful substances, which contributes to the expansion of their scope. When installing, it is recommended to use fittings made of the same material. As a result, the probability of violation of the integrity of the pipeline during the linear expansion of polyvinyl chloride is significantly reduced.

Advantages of PVC pipes

Competitors of plastic pipes are products made of cast iron, asbestos cement, ceramics, etc. All of them are good in their own way and have certain advantages.

And yet it is pvc pipe that is in great demand.They have advantages that are inherent only to them and are not available to other analogues.

Benefits include:

- Corrosion resistance;

- Antibacterial properties;

- Small chance of blockage;

- Durability;

- Light weight;

- Easy installation;

- Low cost.

Corrosion resistance

Since liquid is transported through the pipeline, anti-corrosion properties play an important role. Unlike metal, plastic is not subject to oxidation and rust formation. The metal pipe is covered with several protective layers against corrosion.

However, over time, these layers are damaged and the pipes begin to rust. This threatens to repair or even completely replace the pipeline. Polyvinyl chloride does not need additional treatment with protective agents.

Antibacterial properties

Another advantage of plastic is its resistance to microbial growth. Not pure water passes through the pipes every day, but drains with the presence of organic substances in them. Such an environment is an excellent breeding ground for bacteria.

In the course of their life, bacteria release substances that adversely affect the surface of pipes made of other materials. Bacteria practically do not multiply on plastic, and even if this happens, it still retains its original properties. This is due to the fact that polyvinyl chloride is not affected by acids and alkalis.

Little chance of clogging

Almost all sewer pipes are produced with a smooth inner surface. However, over time, roughness and irregularities may appear on their walls. Often this is due to the fact that there is garbage in the drains or household chemicals are used.

After some time, sediment begins to appear and they “overgrow”, that is, a blockage forms. Plastic pipes have a smooth surface that is not susceptible to chemicals.

And even if a blockage still forms, it can be safely dissolved by any means without fear of damaging the pipe.

Durability

Given the above advantages, we can conclude that PVC pipes will last longer than similar ones made from other materials. The average service life is more than 30 years. As practice shows, this period is much longer.

light weight

Plastic itself is a lightweight material and plastic pipes have the same properties. Their transportation does not require heavy vehicles. And loading and unloading operations can be easily carried out by one person, if the segments are long, then two.

Easy installation

Based on the fact that the weight of the products is small, and they themselves are equipped with a simple fastener system, even an unprepared person can cope with the installation of sewage.

Low cost

A PVC pipe is cheaper than its counterparts, for example, from metal, by 30-35 percent. This is due to the fact that the so-called recycled materials are most often used in their production.

The disadvantage is considered weak frost resistance. They do not tolerate frost below 15º C, but at temperatures down to -10º C, plastic is much more practical than metal.

All PVC pipes have these advantages for both external and internal sewerage. However, the external ones have a few more features, which will be discussed below.

Advantages of HDPE pipes

Depending on the system in which HDPE sewer pipes work, they are divided into:

- HDPE pipes for internal sewerage. Using these pipes for laying sewerage indoors, they get a number of advantages. The smooth inner surface of the pipes avoids silting and blockages, which maintains the throughput of the network with its small diameter. The laying of this pipe is possible even in the vicinity of a hot water supply. Elasticity makes it possible to almost completely eliminate the use of corrugations.

- HDPE pipes for outdoor sewerage. These pipes have a number of characteristics. Resistant to conditions of low temperatures. Durable, withstand the load from soil pressure. Elastic, not afraid of the impact of heaving soils.

Depending on the operating conditions, pipes can be divided into groups:

What is a pressure pipe

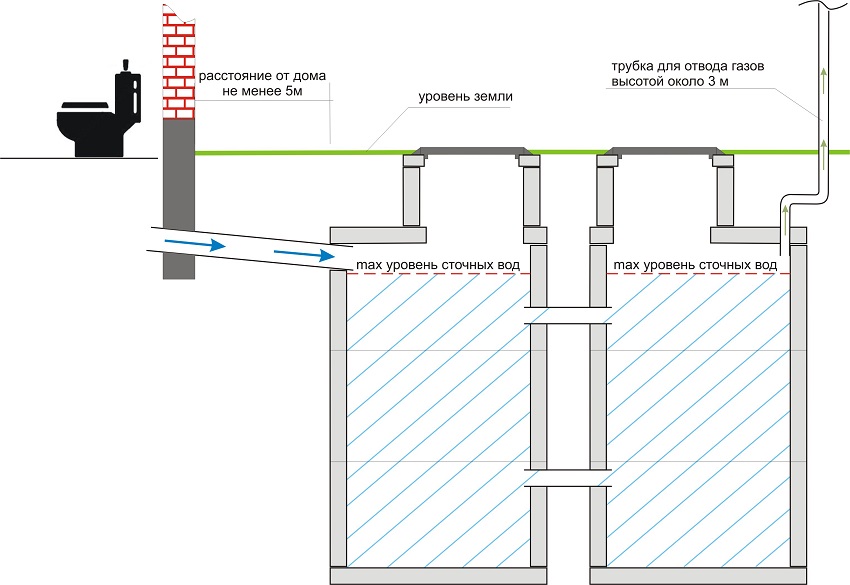

The pressure sewer pipe differs from the usual one in that it can withstand quite a lot of pressure created by the pump. Pumps are responsible for the forced transportation of water to a treatment plant or when pumping sludge from a septic tank or cesspool.

In private houses. a forced drainage system is rarely used, only in cases related to the features of the relief, mainly pumping stations are used in multi-storey buildings or houses with a large area. Thus, it turns out that pressure pipes are used only in those areas that are connected to a septic tank or other storage tank.

The features of these models include:

- large diameter - to reduce the risk of blockages;

- thicker wall - protects pipes from pressure drops;

- stiffeners are possible.

For the production of pressure pipes, a wide variety of materials can be used, but PVC products are in great demand.

Video: Pressure sewer.

Classification of sewer PVC pipes

Red sewer pipes can be classified according to several criteria: the method of manufacture of products, the use of finished products and ring stiffness.

According to the manufacturing method, such pipes are:

- single-layer - as the name implies, they consist only of a PVC layer;

- multilayer - usually contain two layers of PVC and a reinforcing layer; all layers are glued together.

According to the method of application, the products are divided into:

There are the following categories of stiffness of red pipes:

- Thin-walled lightweight class L (2 kN/m2).

- Thin-walled medium hardness class N (4 kN/m2).

- Thick-walled rigid class S (8 kN/m2).

Light pipes in the arrangement of sewer systems are laid to a depth of up to 2 m, medium-hard - up to 6 m, products of increased rigidity - up to 8 m.

The value of the ring stiffness itself is the maximum allowable load per unit area, causing a deviation of the vertical diameter of no more than 4% without taking into account the lateral thrust.

Pipelines made of PVC pipes are classified, considering the amount of load, the location of the contour and operating conditions, into three groups:

- Light pipelines. Settled under sidewalks and park areas.

- Pipelines of medium type. Mounted under sections of roads with not too busy traffic.

- Heavy pipelines. They are laid under buildings and roads with heavy traffic.

According to the shape of the surface, red pipes are:

- corrugated - multilayer, with a smooth inner surface and a dense outer shell; are distinguished by special elasticity;

- smooth - simple single-layer products.

Advantages of PVC pipes

Corrosion resistance

Polyvinyl chloride is characterized by increased resistance to temperature extremes, oxidation, which means that rust does not form on the walls under any conditions. For comparison, metal products are always covered with protective materials before laying in the ground, often in several layers. With prolonged use and under the influence of negative external factors, such communications rust, which significantly reduces their service life. For this reason, polymer products are used much longer, in addition, the cost of their maintenance is lower.

Antibacterial properties

Harmful microorganisms practically do not multiply on the inner surfaces of PVC pipes. This is facilitated by smooth walls, resistance to acids and alkalis. For comparison, metal communications are highly susceptible to the influence of aggressive substances. The degree of roughness of the inner walls is high, deposits accumulate on the surface, which is a favorable environment for the propagation of organic microflora.

Little chance of clogging

The risk of blockage in the pipes is minimal. This is due to the smoothness of the inner surface. Such communications can be damaged only when passing drains containing large litter. However, even in this case, internal layers are formed slowly. If a blockage appears in some area, it will not be difficult to remove it by any of the available mechanical or chemical means without losing the communication properties. This ensures long-term operation of products without the need to replace them throughout the entire service life.

Durability

The service life of sewer systems varies from 30 to 50 years, sometimes it lasts longer, which is the main feature of such pipes. It all depends on the conditions in which the pipeline operates. For example, if communications are not affected by boundary temperatures or pressures, maintenance is periodically carried out (cleaning of internal surfaces), you can count on a longer period. In each case, PVC products are used much longer than their metal counterparts.

light weight

This is the main advantage of such communications. Given that they are light, transportation can be arranged by one person. If products of average diameter are used, there is no need to use special transport. The light weight of PVC pipes allows you to lay them yourself.

Easy installation

To perform such work does not require special knowledge. In order to connect the plastic pipeline, a rubber seal must be used. In this case, two products are joined by means of a socket method. As a result, the fastening reliability is high, and the applied forces are minimal. Work can be performed without the participation of a specialist. Installation does not take much time.

Low cost

PVC products are inferior to metal counterparts in price. They are cheaper by 30-35%. This made polyvinyl chloride pipes common. At the same time, they have their drawbacks, for example, the low frost resistance of the sewerage system, but with careful isolation, this minus is leveled.

If you are interested in the question of why the cost of PVC products is much lower than metal counterparts, you should know that recycled materials are often used in their production.Given that such communications have many advantages, we can conclude that they are the most suitable option for installation.

The use of plastic products in sewer communications

For the arrangement of sewer systems are used pipes and fittings from such materials such as PVC (polyvinyl chloride), PE (polyethylene) and PN (polypropylene). Unlike steel and cast iron products, which are connected by welding, plastic pipes are much easier to install, since their joining does not require special equipment.

The advantages of plastic sewer fittings include:

- low weight, which facilitates their transportation and installation;

- long service life - the operational life of a polymer pipeline reaches 50 years, which is achieved due to the complete resistance of the material to corrosion and chemically aggressive substances;

- wide temperature regime - PVC plastic sewage can be used to drain hot drains with temperatures up to 95 degrees;

- an extensive range of fittings, different shapes and sizes of which allow you to form a sewer pipeline of any configuration.

Assortment of fittings for sewer systems

PVC fittings are shaped elements used to connect individual pipes to each other, as well as to connect shut-off and control valves to the pipeline. Sewer fittings are sized according to the diameter of pipes on the market.

According to the provisions of GOST No. 21.604 “Water supply and sewerage”, the following dimensions of PVC pipes must be used for laying internal sewerage:

- bath drain pipe - diameter 40 mm (laid with a slope of 1:30);

- shower - diameter 40 mm (slope 1:48);

- toilet bowl - diameter 110 mm (slope 1:20);

- sink - diameter 40 mm (slope 1:12);

- bidet - diameter 40 mm (slope 1:20);

- sink - diameter 40 mm (slope 1:36);

- combined drain for shower, bath and sink - diameter 50 mm (slope 1:48);

- central riser - diameter 110 mm;

- outlets from the central riser - 60 mm.

Large diameter pipes for outdoor sewage

For the installation of external communications, pipes with a diameter of 160-200 mm should be used. Sewer pipes and PVC fittings are selected so that their dimensions match each other.

Classification of sewer fittings

The variety of connecting elements used for the installation of pipelines is classified according to two parameters - the scope and method of connection. According to the scope of application, the designs are divided into fittings intended for the installation of internal sewage systems, and products for external systems.

Depending on the connection method, sewer fittings are classified into:

- bell-shaped (a rubber sealing ring is installed inside the plastic structure), which ensures a strong fixation of the pipe and the tightness of the entire system;

- for bonding, without sealing ring.

Socket connection of sewer pipes

In terms of reliability and durability of the connection, adhesive fittings win, since the rubber seal during operation can lose elasticity and shrink, as a result of which a gap is formed between the walls of the connected structures, which causes leaks.

As an adhesive for installing PVC sewers, compositions based on a mixture of polyvinyl chloride and tetrahydrofuran are used, which, after curing, form a material similar in performance to the plastic from which the pipes themselves are made.

Proven adhesive compositions for the installation of polymer pipelines - "Tangit", "Vinilit", "Phoenix" and "Marx", the current VSN 35-86 "Instruction for the installation of plastic pipes" recommends using the "GIPC-127" glue.

Features of pressure and non-pressure pipes

Non-pressure products are designed to function in areas of the system with normal load. Most of the sewers are characterized by such conditions. Therefore, it is possible to assemble the circuit mainly from such cheaper pipes.

In those sections of the system where drain liquids are distilled using a pump, that is, under increased pressure, it is necessary to use pressure-type products that can withstand heavy loads. The same applies to areas with particularly difficult operating conditions.

The use of a pump in self-contained sewer circuits is necessary as it helps to clean the system. The pressure created by it is not constant and is characterized by an alternate increase and decrease, which creates a special load on the pipeline. Therefore, in places of sewerage located in the area of \u200b\u200bthe pump, more expensive, but safe pressure pipes should be installed.