- Features of sewer pipes

- Classification of pipes by type of material

- View # 1 - plastic products

- Option #1 - polyvinyl chloride (PVC) pipes

- Advantages of PVC pipes

- Corrosion resistance

- Antibacterial properties

- Little chance of clogging

- Durability

- light weight

- Easy installation

- Low cost

- 160 or 110 sewer pipe which one to choose

- Sewer pipes come in different sizes. The following pipe sizes are distinguished:

- Polymer pipes for sewerage:

- Types and characteristics

- PVC sewerage

- Polypropylene (PP)

- corrugated polyethylene

- Asbestos-cement

- Concrete

- metal

- Cast iron sewer

- Ceramic products

- Materials for the production of pipes

- The material used for the production of sewer pipes

- metal

- Steel

- Cast iron

- Ceramic

- Concrete

- Asbestos-cement

- PVC

- Polypropylene

Features of sewer pipes

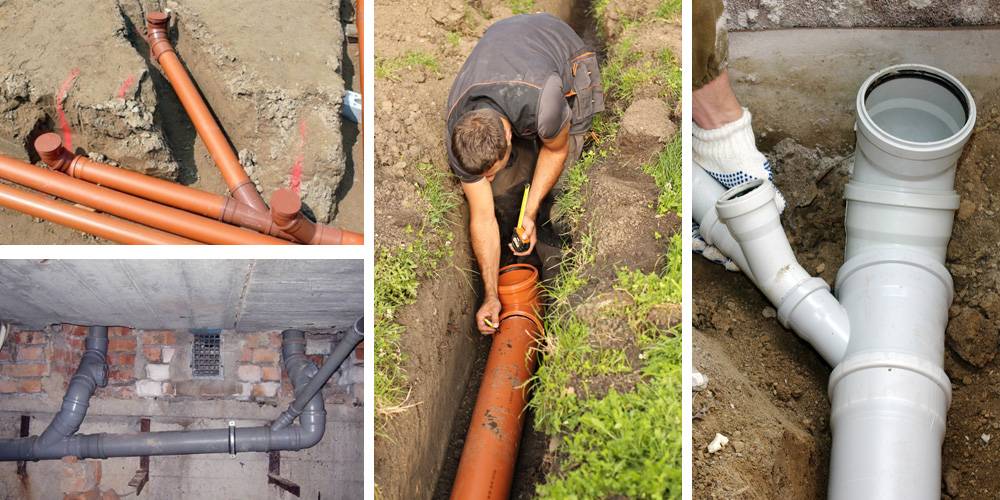

Pipeline for private or multi-storey building outdoor type, must meet several parameters:

The pipe material must be well tolerated by temperature changes;

It is very important that the pipes were frost-resistant, and also tolerated high temperatures and direct sunlight normally;

Be sure to consider the stability of the system to work in aggressive environments;

The material must be wear resistant.

Previously, regardless of the type of sewage, metal pipes were used, but they are not suitable for outdoor installation due to the fact that they do not tolerate frost well and are susceptible to corrosion. At the moment, the building materials market offers pipelines from the following materials:

- Plastic;

- Cast iron;

- Reinforced concrete;

- ceramic compounds.

Despite external reliability, cast iron or reinforced concrete pipes are very fragile. They are rarely used in private construction, also because of their high weight. Therefore, for their installation, you need to use additional lifting equipment. Ceramics are known for their excellent durability and are not susceptible to corrosion. But at the same time, ceramic compounds become brittle under the influence of low temperatures. Also, ceramic pipes are sold only up to 2 meters long. For a standard sewer, you will need to use a large number of connections, which will significantly reduce the strength of the entire system.

The most commonly used plastic pipes. There are the following types of plastic, which is used for the manufacture of gutters:

- PVC (polyvinyl chloride);

- Metal-plastic;

- Polypropylene;

- Polyethylene.

Related video:

In general, experts recommend using polyvinyl chloride (PVC) or unplasticized polyvinyl chloride (UPVC). These polymers are obtained by processing vinyl chloride in a special way, their main difference is that in the first version there are plasticizers, and in the second - no. It should be noted that PVC can tolerate low ambient temperatures, while PVC-U is used only in the range from 0 degrees to 45.If you opted for PVC pipes, it is better to install them in thermal insulation.

Polypropylene sewer pipes for outdoor sewage have a number of advantages: low price, easy installation, durability. Unlike PVC options, they perfectly tolerate sub-zero temperatures, while not cracking, but slightly expanding (even if water freezes in them).

Gray metal-plastic options are most often not suitable for outdoor work due to poor transfer of temperature changes. In addition, their cost is much higher than that of classic plastic pipelines. A good selection of such communications is provided by the Rehau catalog.

Plastic sewer polyethylene pipes for outdoor sewage are known not only for their low price and durability. In addition, they are well tolerated by chemicals, are used at low temperatures, and do not lend themselves to corrosive processes. Available options are offered by the domestic company Egoplast.

To connect plastic pipelines to each other, special fittings are used - fittings. They are used both for internal work and for external work, the main difference is the material and certain alloys. In order to install outdoor sewer pipes, you need to buy orange parts.

Classification of pipes by type of material

The most popular among users are plastic pipes for sewerage. But, in addition to plastic, external sewer pipes can be made from other materials. Let's look at the features of each type of pipe, highlighting their advantages.

View # 1 - plastic products

Sewer polymer pipes appeared not too long ago, but they have become widespread, displacing traditional analogues in the profile market.

Such components have a number of undeniable advantages:

- light weight, facilitating transportation, storage, laying;

- a smooth inner surface that facilitates the unimpeded passage of runoff water and prevents the settling of salts and other deposits. Due to this feature, with proper installation and operation, blockages almost never form in plastic pipes;

- wear resistance - plastic pipes do not rot, do not corrode;

- operation - such products have a sufficient service life, although less than their cast-iron counterparts (maximum 50 years).

Most often, for the manufacture of external sewer systems, components made of the following materials are used.

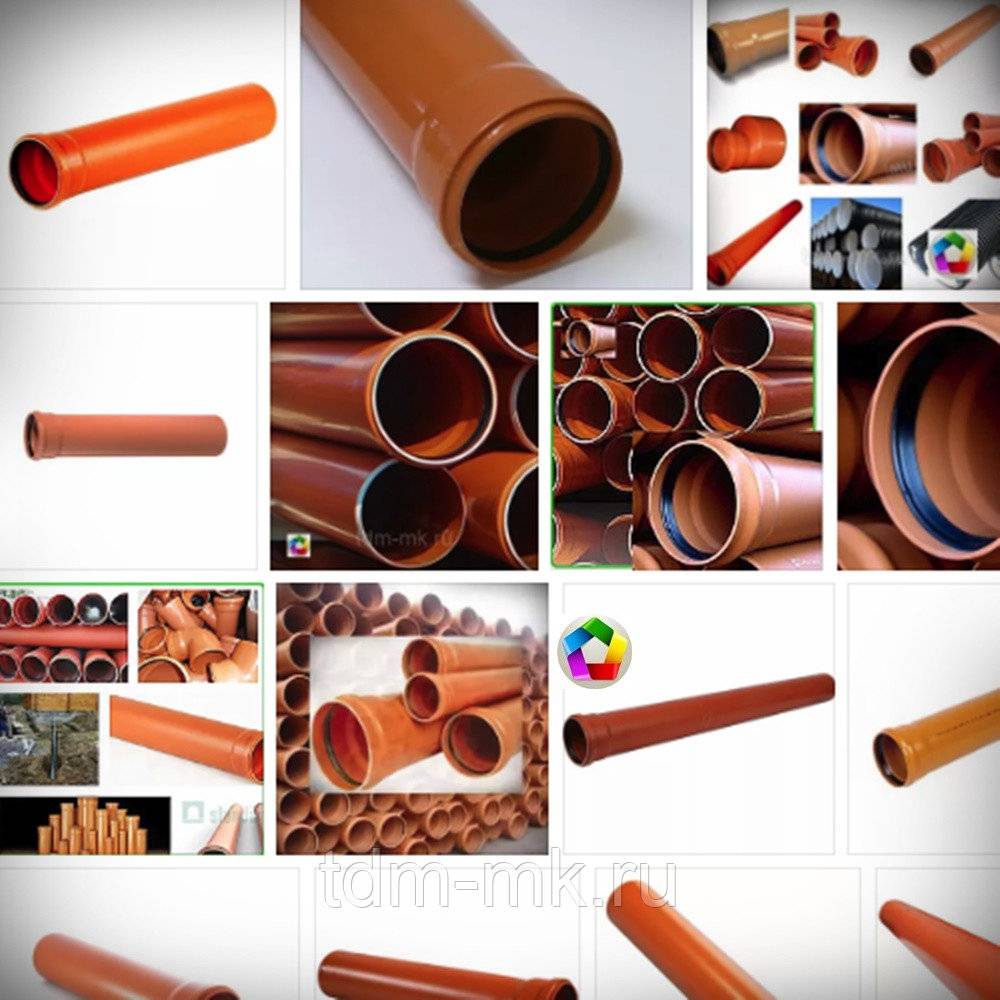

Option #1 - polyvinyl chloride (PVC) pipes

Polyvinyl chloride (PVC) is an affordable popular plastic that is widely used for the production of various products, including pipes for internal / external networks.

Such components are especially recommended for sewer systems that require a large flow area (collector, culvert, storm).

Among the most significant disadvantages of PVC pipes are:

- Sensitivity to aggressive materials. If it is planned to remove acids and oils through such components, it is better to purchase special PVC-U pipes with special properties.

- Thermal elongation of the material. Because of this property, it is not advisable to install such parts for transporting hot liquids (over 60 degrees C).

PVC pipes have the following positive properties: good resistance to mechanical stress, high strength and UV resistance, making such products suitable for open areas.

There are two types of PVC pipes:

- Pressure, high pressure (

According to the stiffness class, PVC components are divided into the following categories:

- Rigid pipes (class S) with a maximum wall thickness, designed for installation at a depth of up to 8 meters. This type can be used for any work, but is most often used in industry.

- Medium-hard products (class N) are used at a depth of 2-6 meters. They are suitable for pipeline installation under not too busy roads.

- Light components (class L) sufficient to create systems that are laid at shallow depths (0.8-2 m). Not suitable for laying under the roadway.

The most common pipe for external sewage is a product with a diameter of 10-11 cm. In this case, sewage from a country house is easily transported through the network.

Pipes made of unplasticized polyvinyl chloride are used in underground laying of external communications where it is known that there will be no significant load on communications.

If this factor is taken into account, then the scope of PVC products is quite wide:

Advantages of PVC pipes

Corrosion resistance

Polyvinyl chloride is characterized by increased resistance to temperature extremes, oxidation, which means that rust does not form on the walls under any conditions.For comparison, metal products are always covered with protective materials before laying in the ground, often in several layers. With prolonged use and under the influence of negative external factors, such communications rust, which significantly reduces their service life. For this reason, polymer products are used much longer, in addition, the cost of their maintenance is lower.

Antibacterial properties

Harmful microorganisms practically do not multiply on the inner surfaces of PVC pipes. This is facilitated by smooth walls, resistance to acids and alkalis. For comparison, metal communications are highly susceptible to the influence of aggressive substances. The degree of roughness of the inner walls is high, deposits accumulate on the surface, which is a favorable environment for the propagation of organic microflora.

Little chance of clogging

The risk of blockage in the pipes is minimal. This is due to the smoothness of the inner surface. Such communications can be damaged only when passing drains containing large litter. However, even in this case, internal layers are formed slowly. If a blockage appears in some area, it will not be difficult to remove it by any of the available mechanical or chemical means without losing the communication properties. This ensures long-term operation of products without the need to replace them throughout the entire service life.

Durability

The service life of sewer systems varies from 30 to 50 years, sometimes it lasts longer, which is the main feature of such pipes. It all depends on the conditions in which the pipeline operates.For example, if communications are not affected by boundary temperatures or pressures, maintenance is periodically carried out (cleaning of internal surfaces), you can count on a longer period. In each case, PVC products are used much longer than their metal counterparts.

light weight

This is the main advantage of such communications. Given that they are light, transportation can be arranged by one person. If products of average diameter are used, there is no need to use special transport. The light weight of PVC pipes allows you to lay them yourself.

Easy installation

To perform such work does not require special knowledge. In order to connect the plastic pipeline, a rubber seal must be used. In this case, two products are joined by means of a socket method. As a result, the fastening reliability is high, and the applied forces are minimal. Work can be performed without the participation of a specialist. Installation does not take much time.

Low cost

PVC products are inferior to metal counterparts in price. They are cheaper by 30-35%. This made polyvinyl chloride pipes common. At the same time, they have their drawbacks, for example, the low frost resistance of the sewerage system, but with careful isolation, this minus is leveled.

If you are interested in the question of why the cost of PVC products is much lower than metal counterparts, you should know that recycled materials are often used in their production. Given that such communications have many advantages, we can conclude that they are the most suitable option for installation.

160 or 110 sewer pipe which one to choose

Installation and installation of sewerage is a very important point in the design and construction of any house, cottage or any other building. Pipes are the backbone of every sewer system. Therefore, you must choose them correctly!

To begin with, consider what should be the pipes for sewage "ideally".

1. Durable. This quality is simply necessary for all types of pipes. Since most often sewers are built for more than a dozen years, therefore strength is the most important point.

2. Resilient. That is, pipes must be resistant to various external factors and influences that may affect their service life. Pipes must be invulnerable to: various chemicals and reagents, to lower and higher temperatures, to fire, to various damages (mechanical), to ultraviolet radiation, and if at least one of the listed factors negatively affected the pipes, they should not be used in sewerage.

3. Convenient for installation. This moment is also an important indicator. Pipes must be mounted securely and simply.

4. Smooth. If inside the surface of the pipe it has roughness and irregularities, then their clogging is just a matter of time

Therefore, pay attention to this important parameter.

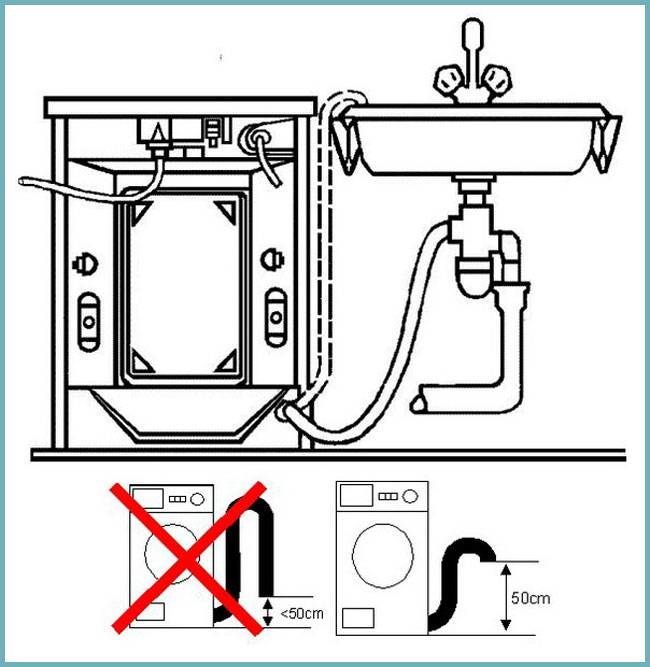

Sewer pipes come in different sizes. The following pipe sizes are distinguished:

Ø 32 - outlet from sink, bidet, washing machine

Ø 40 - outlet from the sink, bathtub, shower

Ø 50 - internal wiring in the apartment

Ø 110 - outlet from the toilet, riser

Now we know how high-quality sewer pipes should look like, which will serve you for many years. But what material should they be made from?

Polymer pipes for sewerage:

- Resistant to high temperatures

- Have maximum throughput

- Have smooth walls

- Have increased strength and wear resistance

PVC pipes (polyvinyl chloride) are durable and resistant. They are gray or orange. They are best used for internal sewage, for external it is necessary to use only with a heater. But the disadvantage of such pipes is poor resistance to aggressive influences and temperature extremes. The permissible temperature should not exceed 40°C.

From the strength class, the following types of PVC pipes are distinguished:

SN2 - lungs. They are laid in trenches up to 1 meter deep.

SN4 - medium. Can be installed in trenches up to 6 meters

SN8 - heavy. Mounted in ditches with a depth of more than 8 meters.

Polypropylene pipes (pp). These pipes are the most common, as they have a fairly low cost and are easy to install. Usually they are gray. Compared to PVC pipes, they have greater rigidity and resistance to heat. In external sewerage, this type of pipe is not used.

Advantages of polypropylene pipes

- Service life - 50 years

- Complete tightness of connections

- Chemical and corrosion resistance

- light weight

- Easy installation

- hydraulic smoothness

- wear resistance

- High temperature resistance

- Reduced thermal conductivity

- Low cost

- No painting required

Corrugated polyethylene pipes. These are plastic pipes, which are most often used in external sewage. The diameter of these pipes is quite large Ø250 - Ø 850 mm. The inner side of such pipes is smooth, and the outer side is corrugated. Thanks to the corrugated layer pipes are very durable and resistant to compression, which usually occurs when subjected to various loads.

There are a large number of manufacturers of sewer pipes on the modern market. For outdoor sewage, we recommend sewer pipes - POLYTRON, from the company "EGOengineering". These are orange pipes. They are of excellent quality, made from high quality raw materials. POLYTRON sewer pipes have a small mass, which significantly reduces the cost of their transportation to the installation site. They are also very easy to install. They have great resistance to aggressive environments, which is also a definite plus.

On our website, you can also get acquainted with such a novelty as the low-noise sewage system POLYTRON STILTE.

We write about the life of our company, about new products, give advice. Subscribe to newsletter

Thank you for subscribing to us!

Types and characteristics

For laying sewer systems, manufacturers offer finished pipes, tees, corner products, adapters, crosses. The materials used in production determine several varieties of products. These can be polymer, metal or ceramic components.

PVC sewerage

PVC pipes have a smooth surface, sufficient strength for internal and deep sewerage, are not afraid of ultraviolet radiation, can last more than 50 years and are inexpensive. The classification of types of PVC sewer pipes is based on strength indicators:

PVC pipes have a smooth surface, sufficient strength for internal and deep sewerage, are not afraid of ultraviolet radiation, can last more than 50 years and are inexpensive. The classification of types of PVC sewer pipes is based on strength indicators:

- SN2 - lungs.

- SN4 - medium.

- SN8 - heavy.

Regarding the application, there are restrictions due to poor resistance to low and high temperatures exceeding +40 degrees Celsius.The material becomes brittle and elastic, which leads to cracks and deformations. During burning toxic substances are released.

Polypropylene (PP)

Compared to PVC pipes for sewerage plastic polypropylene pipes inferior in strength, therefore, they are used only for laying inside the building without external mechanical load. The permissible drain temperature is +80 degrees Celsius. The smooth surface contributes to the free flow of the medium, which is important for the circulation of drinking water. Inside the dwelling, it is better to lay noise-absorbing products (for example, under the rehau or politek brand).

Compared to PVC pipes for sewerage plastic polypropylene pipes inferior in strength, therefore, they are used only for laying inside the building without external mechanical load. The permissible drain temperature is +80 degrees Celsius. The smooth surface contributes to the free flow of the medium, which is important for the circulation of drinking water. Inside the dwelling, it is better to lay noise-absorbing products (for example, under the rehau or politek brand).

corrugated polyethylene

Structurally HDPE pipes represented by a solid corrugation and a built-in smooth-walled channel. This design provides increased rigidity of products, which is important for deep laying (up to 16 m.). According to the technical characteristics, the material is similar to the plastic counterpart. It is used more often for the construction of engineering communications for the transportation of hot waste.

Structurally HDPE pipes represented by a solid corrugation and a built-in smooth-walled channel. This design provides increased rigidity of products, which is important for deep laying (up to 16 m.). According to the technical characteristics, the material is similar to the plastic counterpart. It is used more often for the construction of engineering communications for the transportation of hot waste.

Asbestos-cement

Asbestos in the composition of the cement mortar plays a reinforcing role. Products belong to the most budget option for a sewerage device. Contact with water has a positive effect on the strengthening of the walls. Pipes have a low coefficient of thermal expansion and do not corrode. The characteristics are relevant for pressure systems and outdoor laying.

Asbestos in the composition of the cement mortar plays a reinforcing role. Products belong to the most budget option for a sewerage device. Contact with water has a positive effect on the strengthening of the walls. Pipes have a low coefficient of thermal expansion and do not corrode. The characteristics are relevant for pressure systems and outdoor laying.

Concrete

For the manufacture of pipes, as a rule, M350 concrete is used. It is characterized by water absorption up to 3%, 200 cycles of freezing and thawing and high compressive and tensile strength. The material does not rot, does not burn, does not corrode, is resistant to chemical environment and low temperatures.It is used in the industrial, hydrotechnical and urban planning sectors with a low degree of aggressiveness.

For the manufacture of pipes, as a rule, M350 concrete is used. It is characterized by water absorption up to 3%, 200 cycles of freezing and thawing and high compressive and tensile strength. The material does not rot, does not burn, does not corrode, is resistant to chemical environment and low temperatures.It is used in the industrial, hydrotechnical and urban planning sectors with a low degree of aggressiveness.

metal

Such products are represented by steel-rolled products with a galvanized anti-corrosion coating. The material has high strength, long service life, withstands temperature extremes in a wide range and is relatively inexpensive. However, it is rarely used in the private sector due to its heavy weight. More often a sewer pipeline of this nature is laid at industrial enterprises chemical and oil refining type.

Such products are represented by steel-rolled products with a galvanized anti-corrosion coating. The material has high strength, long service life, withstands temperature extremes in a wide range and is relatively inexpensive. However, it is rarely used in the private sector due to its heavy weight. More often a sewer pipeline of this nature is laid at industrial enterprises chemical and oil refining type.

Cast iron sewer

Cast iron is an alloy of iron and carbon. The material is characterized by higher strength, pressure endurance and corrosion resistance compared to steel. It also has a service life of over 80 years.

Cast iron is an alloy of iron and carbon. The material is characterized by higher strength, pressure endurance and corrosion resistance compared to steel. It also has a service life of over 80 years.

For laying sewers, a negative fact is the rough inner surface, which makes it difficult to transport wastewater and contributes to the formation of plaque. In the private sector, cast iron is rarely used due to its significant weight, high cost and the need to additionally resort to sealing agents. More often, such pipes are used for the internal construction of risers and sewers in multi-storey buildings.

Ceramic products

The production of ceramic pipes is based on the processing of clay. The raw material has water resistance, resistance to aggressive environment in terms of temperature, chemicals, corrosion. Among the advantages, an unlimited service life is also noted. However, brittleness complicates installation work, the installation of fittings and limits the installation in places of increased mechanical stress. Application ceramic pipes actual for sewerage devices in industrial areas, at strategic sites.

The production of ceramic pipes is based on the processing of clay. The raw material has water resistance, resistance to aggressive environment in terms of temperature, chemicals, corrosion. Among the advantages, an unlimited service life is also noted. However, brittleness complicates installation work, the installation of fittings and limits the installation in places of increased mechanical stress. Application ceramic pipes actual for sewerage devices in industrial areas, at strategic sites.

Materials for the production of pipes

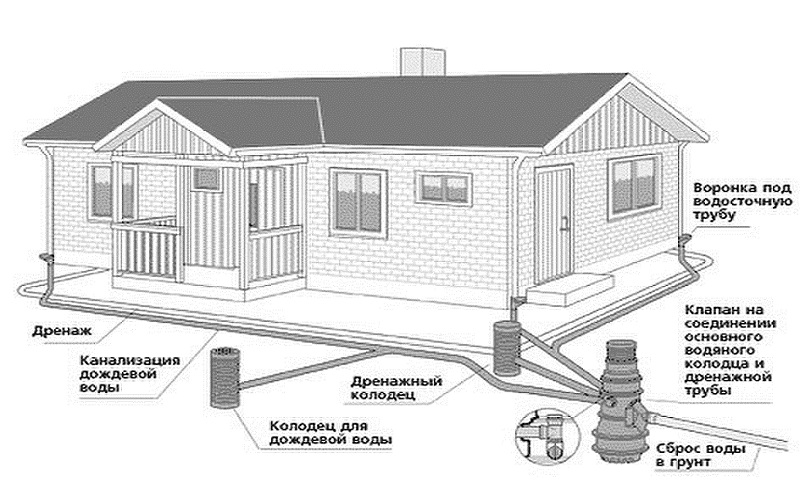

From external networks, water enters the purification structures that are available in any city. Effluent is treated by said systems and subsequently diverted to designated discharge points.

The key indicator by which sewer goods are classified is the material of manufacture. Sewer pipes for outdoor sewage are made from both familiar proven and more modern materials. At the moment, the sewer pipe is made from:

Asbestos cement. Cost-effective, corrosion-resistant, thermally and chemically stable and light in weight

It is important to note the high fragility of the material, which makes it difficult to transport and assemble such products. The inner surface cannot boast of special smoothness, and this directly affects the throughput

It should also be noted that asbestos cement is a material that has carcinogenic properties.

Concrete or reinforced concrete. A waste pipe of this type is distinguished by its environmental friendliness and at the same time a large weight, due to which special equipment is required to install the system. Basically, products of this type are relevant for the construction of external communications (private houses) in order to install a local sewer.

Cast iron. Such products have been used for a long time, and they can boast of a considerable number of positive properties.But they have a drawback - they are afraid of corrosion and weigh a lot, so equipment is required for installation and transportation. Their inner surface quite rough, which eventually leads to clogging. Cast iron products are even ribbed, but they are not relevant in sewer networks, as they are used in heating systems. Pipes for outdoor plumbing made of cast iron are gradually losing their popularity, due to the emergence of more modern options.

Ceramics. This is a fragile, heavy and expensive material (a complex production technology that uses natural clay, fireclay, kaolin and mandatory firing at high temperatures). Such sewer pipes for external sewerage also have positive properties: a smooth inner surface, water resistance, resistance to many aggressive chemical compounds.

Types of sewer pipes and connections, as you know, are different, but it is plastic that has recently been most in demand. What are plastic sewer pipes:

- From polyethylene. For their production, high-strength polyethylene is used, and the products themselves have a regular, corrugated or two-layer look. As for the last two options, they are most suitable for laying outdoor sewers. Ordinary types are ideal for internal communications - they can easily bend without losing their performance.

- From polyvinyl chloride. PVC sewer pipes for external sewerage are also suitable for arrangement and internal networks. The first type is orange, and the second is gray.A material such as PVC is not afraid of low temperatures, however, if it is more than +40 degrees outside, their physical properties change. PVC-U pipes for outdoor sewerage are popular because they are lightweight and low cost.

- From polypropylene. Such products, in comparison with the previous version, are not afraid of high temperatures. This material is used for the production of sewerage fan products and outdoor products;

- From fiberglass. Their properties are almost the same as those of the above materials. Their difference is high cost.

The material used for the production of sewer pipes

Now consider the material of manufacture in order to assess how one or the other meets all the requirements. Today the market offers a wide range of pipe products for sewer systems:

- ceramic;

- metal;

- asbestos-cement;

- concrete;

- from polyvinyl chloride (PVC);

- from polypropylene.

And despite the large selection of products, only three are the most popular and most commonly used: cast iron pipes, PVC and polypropylene. Other species are less common, but still used.

metal

By metal pipes are meant cast iron and steel.

Steel

Steel products meet almost all requirements and have a lot of advantages:

- durable;

- withstand high temperatures;

- easy to process;

- low cost.

However, despite this, they have disadvantages that make their use in private housing construction unprofitable. Here are just some of them:

- large mass;

- corrosion.

The main scope of their application is the petrochemical and chemical industry, where they are actually and successfully used for transporting waste, etc.

Cast iron

Compared with the previous ones, cast iron pipes are less afraid of corrosion, but the cost of this option will be higher. Most often used when installing a riser in apartments of high-rise buildings, as well as for diverting wastewater to a collection point.

Advantages:

- high strength;

- long service life - more than 80 years, and this is a theory, but time-tested data;

- good plastic properties;

- resistant to heavy loads.

Cons that significantly limit its use:

- rough inner surface makes it difficult to transport wastewater;

- big weight;

- the need to use additional materials for sealing joints;

- price.

Ceramic

The main scope of ceramic pipes is external sewerage. They transport household, industrial and rainwater. They are resistant to chemicals and corrosion, not afraid of fire, strong and durable.

However, complex installation, fragility and a number of other disadvantages led to the displacement of this material by others, more modern and practical. You can learn more about them from this article: Ceramic pipes.

Concrete

The reinforced concrete pipe is used in hydrotechnical, civil and industrial construction, for the transportation of non-aggressive effluents by gravity. In their production, heavy concrete of the following grades is used: W6, F200, B25, M350.

Main advantages:

- compressive and tensile strength;

- water resistance;

- not afraid of low temperatures;

- low price - compared to steel pipes;

- chemical resistance;

- are not subject to rotting and corrosion.

The depth of laying reinforced concrete products varies from 2 to 6 meters.

Asbestos-cement

Asbestos-cement sewerage - products of Russian manufacturers. It is considered the cheapest of all types. Asbestos cement is one of the varieties of reinforced concrete, where evenly distributed asbestos fibers play the role of reinforcement.

This material is tensile, so it can also be used for pressure systems. It is not afraid of corrosion, and when exposed to water, it compacts and becomes stronger.

PVC

According to experts, PVC pipes are strong enough and durable, they are not afraid of UV radiation. They are distinguished by an affordable price, ease of installation and an almost perfectly smooth inner surface of the walls.

Minuses:

- When the temperature rises above 70 ° - deformed.

- They become brittle at low temperatures.

- They are afraid of fire, when burning, it releases a dangerous gas.

PVC pipes, depending on their strength, are divided into several classes:

- lungs - SN2;

- medium - SN4;

- heavy - SN8.

The permissible temperature regime of the passing liquid should not exceed 40 ° C, the service life is reduced from high temperatures.

Polypropylene

To date, it is this material that is considered the most optimal for the construction of a sewer pipeline inside a building. This conclusion can be reached by evaluating the advantages of polypropylene pipes:

- high strength;

- long service life;

- resistance to aggressive influences;

- simple installation;

- perfectly smooth inner surface;

- low cost.