- Introduction

- Varieties of polymer hatches

- Types of manholes

- Cast iron manholes

- Plastic hatches

- Composite and polymer-composite hatches

- Rules for choosing sewer manholes

- Advantages of composite plastic materials

- Varieties of polymer wells

- Mounting

- Varieties of cast iron hatches

- Installation of a sewer hatch

- What is it, what is it used for

- What are hatches made of?

- Metal well covers

- Hatches made of polymer plastic

- Concrete well covers

- Functions and purpose

- Cast iron

- Polymer

- Plastic

- Concrete

- Installation steps

- Conclusions and useful video on the topic

Introduction

Introduction

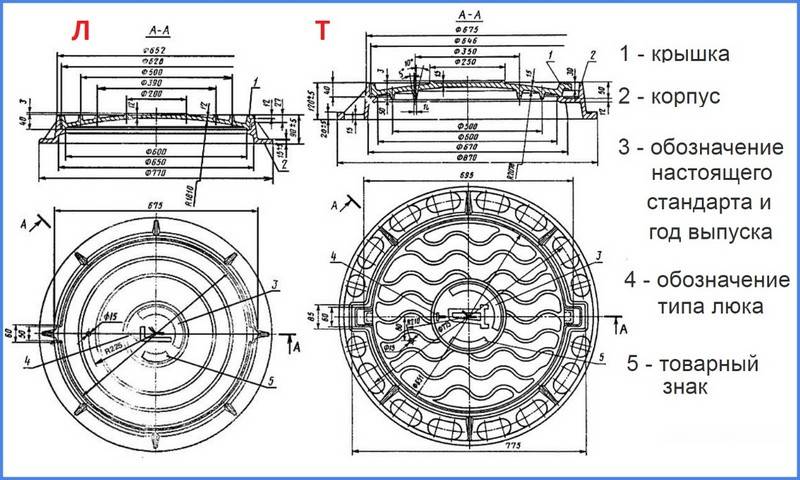

The standard lists the types of hatches, strength loads that hatches must withstand and installation sites that are identical to the European standard: hatch L - class A15; hatch C - class B125, etc. This connection is reflected in symbol for hatches and storm water inlets: hatch L (A15); rainwater inlet DM1 (S250). The dimensions of the grating grooves of the storm water inlet and their location in relation to the curb stone are harmonized with the EN 124-1994 standard. The following people took part in the development: M.Yu. Smirnov, S.V. A.Glukharev and V.P.Bovbel (Gosstroy of Russia), L.S.Vasilyeva (GP CNS), Yu.M.Sosner.

Varieties of polymer hatches

So, the main criterion for choosing this device is the load that the polymer-sand manhole can withstand. The weight of the structure is the main indicator of this ability: the larger it is, the stronger the product. According to this parameter, hatches are divided into 5 classes:

- type "L" (garden variety);

- type "L" (light);

- type "C" (medium);

- type "T" (heavy);

- type "TM" (heavy, trunk).

Hatches with the mark "L" (garden) have a small weight (up to 25 kg) and are able to withstand loads of not more than 1500 kg. Most often they are installed on sidewalks and lawns.

Products "L" (light) weigh about 45 kg and withstand loads of 3000 kg. They are designed for installation in car parks, pedestrian and green areas.

Hatch (polymer-sand) "C" class is able to withstand moderate loads (up to 7500 kg), while its weight is 52 kg. The scope of this design is city parks, parking lots, sidewalks.

Heavy products (groups "T") can already be mounted on roads where there is moderate traffic. Their weight is 57 kg, and the maximum allowable load is 15,000 kg.

Massive trunk hatches can withstand up to 25,000 kg of load, so they can be used on any highway. The mass of such a cover is 60 kg.

In addition to the difference in load, polymer hatches may differ in shape. Most often, round covers are produced (this is due to the fact that the underground well shaft is usually round), however, the manufacture of square products is also possible (on order).

Types of manholes

All types of sewer hatches are divided depending on the material of manufacture. You can purchase the following products:

- hatches made of cast iron;

- plastic hatches;

- hatches made of composite and polymer-composite materials.

Cast iron manholes

The cast iron sewer hatch is distinguished by the following qualities:

- durability (can serve more than 80 years);

- high strength (withstands loads up to 90 tons);

- resistance to large temperature changes.

The main disadvantages of hatches made of cast iron are:

- cost, which is several times higher than the price of other types of hatches;

- large mass, which complicates the processes of transportation and installation.

Cast iron hatch has high durability

Cast iron hatches differ in:

- trunk - able to withstand loads up to 40t. Mostly installed on high-speed roads;

- heavy - designed for roads with heavy traffic;

- medium - used in residential areas and on yard roads;

- light - installed in pedestrian areas, on lawns. Light hatches withstand a load of no more than 1.5 tons.

When arranging the sewerage of a country house, it is advisable to use cast-iron hatches only on the roadway.

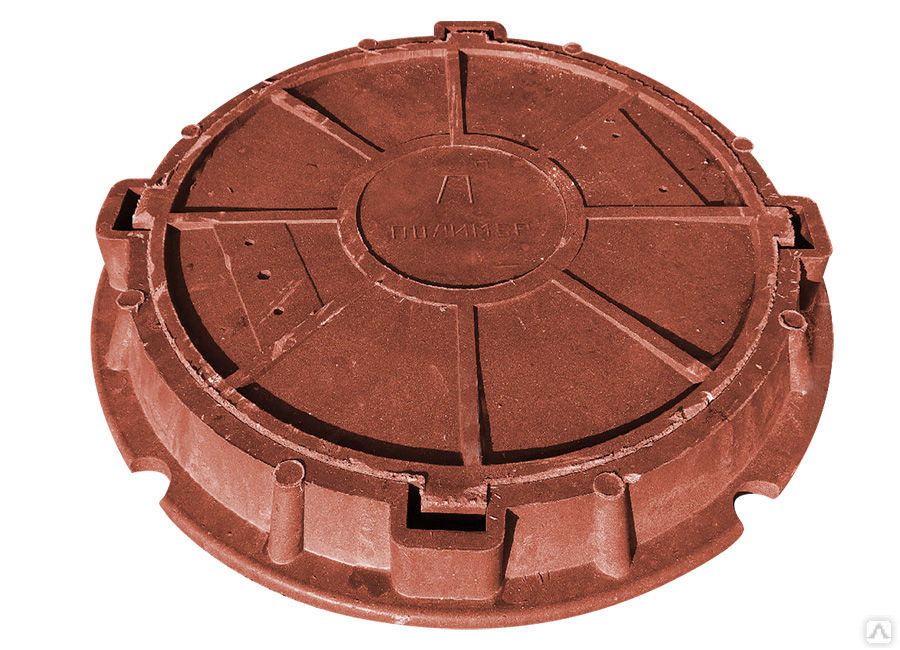

Plastic hatches

The plastic sewer hatch has the following advantages:

- long service life (about 50 years);

- high strength and wear resistance. Hatches are not affected by temperature changes and are resistant to aggressive environments;

- light weight contributes to the possibility of self-installation;

- large selection of colors and shapes. The plastic decorative sewer hatch is optimally suited for arranging parks and lawns.

The main disadvantage of plastic hatches is their inability to withstand heavy loads, so they cannot be installed in driveways and parking lots.

Plastic hatches, thanks to the color range, will fit into the design of any site

Composite and polymer-composite hatches

Composite sewer hatch can be made of:

- fiberglass;

- polyester resin;

- powder filler.

Polymer-composite hatches for sewer wells are produced by pressing under the influence of temperature. The starting materials are plastic and sand.

Composite hatches cannot withstand high loads

Hatches made of composite materials have:

- service life of more than 20 years;

- high resistance to temperature fluctuations (from -60ºС to +60ºС), exposure to oil products and other harmful substances;

- protection against the harmful effects of corrosion;

- increased sound insulation.

Such hatches have the lowest cost, but can only be installed in places with a small load (parks, squares, lawns, sidewalks, and so on).

The choice of a certain type of hatch should be based on the load produced at the place of its installation and the price characteristic.

Rules for choosing sewer manholes

When choosing a hatch for drainage, storage and inspection sewer wells, first of all, you need to pay attention to the shape. If the outlet neck of the communication system is made in the form of a circle, it will need a round part

A square or rectangular hole is best closed with an element of the same shape.

Modern industry offers sewer manholes with an original pattern on the lid. They not only perform the function of protecting internal communications, but also act as an original design element.

When the hatch is planned to be placed in a place subjected to serious mechanical stress, it is worth choosing a model made of cast iron. It will cost more than composites and polymers, but will last longer and withstand the constant pressure of passing heavy trucks.

For private household conditions, it is not necessary to spend money on such a hatch, even if the owners have a heavy vehicle. One-time trips will easily transfer both composite and polymer counterparts.

In the immediate vicinity of residential buildings with low traffic intensity, it is better to install composite or polymer hatches. They have soundproofing properties and do not make sharp sounds when a car passes over them.

For installation in an open area, it is better to choose models equipped with a locking element. Which is able to protect the cast-iron hatch from theft for the purpose of subsequent sale for recycling.

Polymer and composite parts cannot be sold for profit, but they can be carried away by hooligans or teenagers. Therefore, such models will not interfere with a reliable lock or latch.

Advantages of composite plastic materials

The composite-polymer hatch is a relatively new invention. This product is easy to use and very practical. Therefore, it is gradually gaining popularity.

An open sewer hatch is a great danger. It is easy to fall into a well without a cover, and this is fraught with not only injuries, but even death. Storm wells are especially dangerous, in which it is easy to choke. Poorly closed hatches are also a danger. According to statistics, children most often fall into sewer wells. Therefore, they definitely need to be explained that hatches cannot be stepped on.

Composite manholes are made from sand, polyester resins, fiberglass and powdered filler. Also, some products may contain plastic, which is made by recycling old plastic containers.

Such products are a new word in the arrangement of the sewer system. They have many advantages.

Advantages of using composite hatches:

- Such products are quite durable. Their service life is 20 years. And under good operating conditions, this figure increases several times.

- Composite-polymer hatches weigh relatively little. Their weight is two times less than that of the cast-iron version.

- Polymer hatches are not afraid of temperature changes. They tolerate frost and heat very well.

- Upon impact, such products do not strike a spark. Therefore, they are absolutely fireproof.

- The hatches made of composite materials provide excellent sound insulation. They are not afraid of chemical influences.

- These products come in a variety of designs. They are available in a fairly impressive range of colors. In addition, they are absolutely not subject to corrosion.

- Hatches of this type are inexpensive.

These products also have their downsides. They are not suitable for installation on highways and are not so resistant to mechanical stress.

Varieties of polymer wells

First of all, all polymer wells differ in size, which directly affects the daily disposal of sewage. In addition, wells can be either with free access or without access at all.As for polymer wells with free access, they imply unhindered inspection or repair, and for those that are produced without access, maintenance is possible only from above.

Also, polymer wells differ from each other in texture and purpose. They may be the following:

- Smooth single-walled;

- Smooth double-walled;

- Corrugated single-wall;

- Corrugated double-walled;

- Combined.

According to their purpose, they are:

- Prefabricated manholes - designed for maintenance and technical inspection of storm or utility sewers.

- Sewer - used to control and gain access to sewer pipes.

- Storm type - serve to collect storm drains.

- Sedimentary type - used to treat wastewater from precipitation.

- Drainage - are used in the corresponding system as connecting and rotary elements.

- Differential - used to change the level of the pipeline. In turn, they come with a vertical, stepped and cutting tip pipe.

- Caissons - designed for installation of pumps, locking equipment or electrical devices in the depths of the earth.

- Collector - serve to connect sewer, storm water or drainage systems.

- Telecommunication - serve to control the junction of cables and other equipment. Such wells are prefabricated and welded.

Polymer wells, depending on the functions performed, are divided into the following types:

- Swivel;

- Lookouts;

- Stormwater;

- Mud;

- Cumulative.

Each of these types has its own characteristics.

When choosing a polymer well, you should pay close attention to its purpose immediately before buying

Rotary wells serve to clean pipes and are installed on lapels, inspection wells provide access to hydraulic communications, and storm wells are needed to drain rainwater. Accumulative polymer wells completely replace cesspools and prevent the penetration of an unpleasant odor into the site, and mud wells purify water from dirt and sediment.

In order to determine the number of polymer wells for a particular sewer system, it is necessary to strictly follow SNiP.

In addition, when purchasing a polymer well, you must also take care of the following functional details:

- Polymer hatches, which are mainly used for private households and places with rarely passing traffic;

- Lids - used to protect the well from the penetration of dirt and debris;

- Necks - used to narrow the top of the well, which are central, as well as offset;

- Stairs - used for quick access to the well;

- Anti-freezing funnels - serving to prevent the penetration of cold air inside;

- Garbage containers - necessary for collecting garbage on the inner surface.

In addition, polymer wells are:

- From polyethylene - they are used for such sewer systems as stormwater, household and common alloy. Such wells are characterized by good tightness, corrosion resistance, ease of installation and long service life.

- FROM polypropylene - are very popular. The rings of these wells have different diameters, and the pipes are double-layer and single-layer.As for double-layer pipes, they have an external corrugated layer, which significantly increases the protection of the product from adverse conditions. In addition, corrugated pipes are distinguished by a longer service life, environmental safety, durability and ease of installation.

- Polymer-sand - this type of material appeared on the construction market relatively recently, so it has not yet become popular. Such wells are made from a composite material, which includes plastic and sand. Such wells are distinguished by high tightness, which is achieved due to the special connection of the elements.

Mounting

The installation of different types of polymer products also has its own characteristics. Thus, a light-type polymer-sand manhole is mounted to a depth of 25-45 mm, and medium-weight structures - to 60 mm. Heavy hatches deepen the most - they are mounted 85 mm below ground level.

The installation process of the polymer structure begins with the installation of the ring (on the concrete floor). It is poured with cement mortar and left to dry completely. Next, the master installs the hatch cover itself.

A blind area is being built around the well (with a slight slope). It is needed to prevent the penetration of moisture into the collector. usually varies from 1 to 1.5 meters. You can greatly facilitate the process of installing the hatch by purchasing a product with special grooves for fastenings.

«High-quality products for any task"

Our company brings to your attention polymer-sand hatches of our own production with various operational and technical characteristics.The assortment put up for sale forms the perspective of a well-thought-out choice of a polymer hatch for a well in accordance with further conditions of use.

Today you can buy polymer hatches for wells of the following modifications:

Hatch polymer - Type L

| Characteristics | |

| Clip diameter | 750 mm. |

| Cover thickness | 40 mm. |

| Cap diameter | 630 mm. |

| Clip height | 115 mm. |

| Product weight | 30 kg. |

| 3 t. | |

| Cost (retail) | 800 rubles / piece |

| Hatch polymer price (wholesale) | 600 rubles / piece |

Lightweight polymer sand hatch (L). This model is intended for use as a cover for wells of various types, located outside of highways and road sections with increased load. The main area of use of polymer hatches of this type is landscape perimeters and adjacent territories.

Hatch polymer - Type C

Hatch polymer - Type C

| Characteristics - polymer sand manhole | |

| Clip diameter | 750 mm. |

| Cover thickness | 40 mm. |

| Cap diameter | 630 mm. |

| Clip height | 115 mm. |

| Product weight | 40 kg. |

| 6 t. | |

| Cost (retail) | 900 rubles / piece |

| hatch polymer price - wholesale | 650 rubles / piece |

Medium type polymer hatch (C).

This popular category of well hatches is capable of withstanding weight loads up to 6 tons. Accordingly, such products can be used on roads with an average traffic load and in any pedestrian areas.

Hatch polymer - Type T

| Characteristics - polymer hatch | |

| Clip diameter | 750 mm. |

| Cover thickness | 40 mm. |

| Cap diameter | 630 mm. |

| Clip height | 115 mm. |

| Product weight | 46 kg. |

| 15 t. | |

| Cost (retail) | 1000 rubles / piece |

| hatch polymer price - wholesale | 700 rubles / piece |

Heavy hatch of a well polymeric (T). This type (load up to 12 tons) is intended for use without any significant restrictions, including installation on city roads, gas stations and other facilities with medium traffic, with the exception of freeways and highways.

Varieties of cast iron hatches

Cast iron hatches are the most common type. They have been used to protect sewer wells for a very long time. And despite the availability of more modern options, they still remain popular.

Cast iron products are often stolen. Therefore, in our time, they are often poured from above with a concrete solution. This makes them more difficult to open.

Cast iron hatch is quite expensive. However, it has a lot of advantages, because of which many people still prefer such a product to more modern counterparts.

Advantages of cast iron hatches for sewer wells:

- The service life of their cast iron products is extremely long. At least 80 years old.

- Such products are not afraid of mechanical impact. In addition, they are able to withstand loads up to 90 tons.

- Hatches made of cast iron are not afraid of temperature changes. They are able to withstand both very high and very low temperatures.

Among the disadvantages of such products can be noted their high cost. In addition, the cast-iron hatch weighs quite a lot. And they are often stolen.

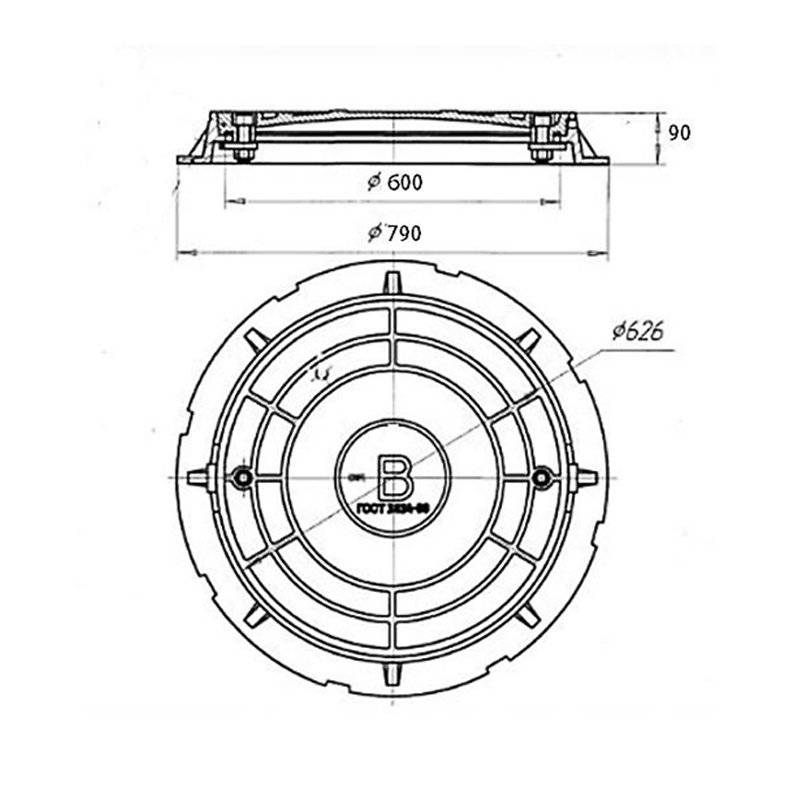

Installation of cast iron hatches is quite simple. It is complicated only by their severity. The dimensions and diameter of the products depend on the indicators of the well. The installation and area of a concrete hatch depends on its type.

Types of cast iron hatches:

- Main cast-iron hatches can withstand loads up to 40 tons. They can be installed on roads with high-speed traffic.

- Heavy hatches made of cast iron weigh a lot. Such 180 kg products are placed on roads with very heavy traffic.

- Medium-heavy manholes are placed in residential areas with little traffic. They are able to withstand loads up to 12.5 tons.

- Light cast iron manholes for sewerage are installed on footpaths. They can withstand loads up to 1.5 tons.

The cast-iron hatch is usually installed on a concrete well. To open it, a hole is usually made in it. In this case, the lid is opened by prying with a hook. If there is no such hole, then to open the hatch, you need to weld a handle to it. After all the work is completed, it will have to be cut.

Installation of a sewer hatch

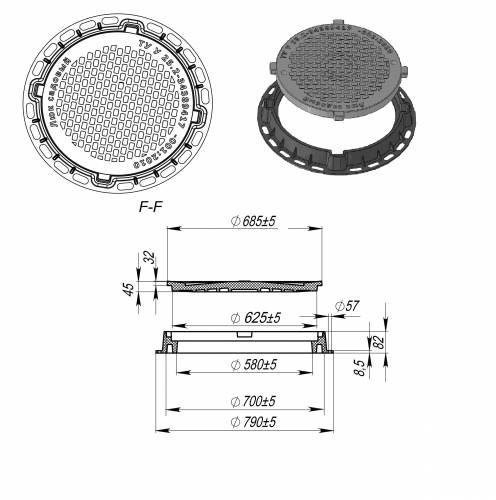

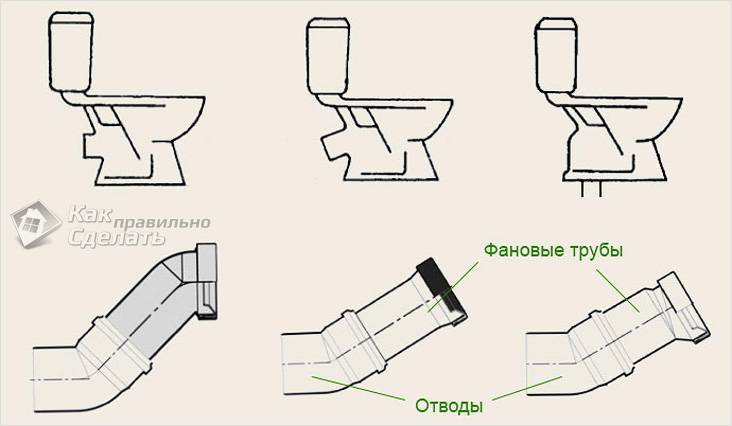

Any sewer hatch consists of a formwork and a cover.

Manhole parts

The installation of sewer hatches comes down to the correct installation of the formwork (the second name is the shell). To do this, perform the following steps:

- it is required to provide full access to the last ring of the well. Most hatches are installed flush with the surrounding surface. You can break this rule on lawns, flower beds, that is, in places where the hatch does not interfere with the free movement of pedestrians and vehicles. To provide access to the upper well ring, excavation or removal of the asphalt (tile) coating is often required;

Excavation of asphalt for the installation of a hatch

- formwork is installed and fixed on the upper ring of the well. The shell must be set strictly according to the level.Otherwise, water from the lawn or other coating will fall into the well, which is not acceptable. The formwork is fixed with metal or stone elements. Plastic sewer hatches in the formwork have special holes for the best fastening. Cast iron hatches are not equipped with such devices;

Formwork fixing

- formwork is poured with cement mortar. To prevent the mixture from getting inside the well, a simple device was invented. An automobile chamber is installed in the upper ring of the well and pumped up to the maximum. Such a device fits snugly against the well ring and does not allow cement mortar to penetrate inside;

Formwork pouring

- After the solution has completely dried, the chamber can be removed and the manhole cover can be installed.

Most modern hatches are equipped with covers that are inserted into special grooves, so it makes no sense to dwell in detail on how to insert the cover into the groove.

The installation of a sewer hatch installed with a protrusion from the surface layer is considered to be fully completed after the blind area has been arranged around it. This device is recommended to be equipped at a distance of 1 - 1.5 m around the hatch cover.

Sewer manhole with equipped blind area

To make a blind area, you need:

- remove the top layer of soil around the sewer manhole at the required distance;

When removing the soil, it should be taken into account that the blind area should be made with a slight natural slope in the direction opposite to the well.

- at the bottom of the prepared pit, a sandy base is laid out and compacted;

- the remaining distance is filled with durable concrete.

What is it, what is it used for

A sewer manhole is equipment designed to protect mines and wells, engineering communications, drainage and sewer systems from pollution, damage and to prevent theft of a communication cable. Plastic products are used for the availability of maintenance of communication networks and for the safety of pedestrians in places where wells are located.

Plastic sewer hatches are made by pressing from recycled high-pressure polyethylene and low-pressure polyethylene with the use of modifying additives, as a result of which they have a stable beautiful color, are resistant to precipitation, temperature changes. They are made from durable, environmentally friendly material that is safe for humans.

They consist of a cover that opens 180 degrees and is fixed with bolts and a body. Covers are flat and convex. To prevent opening and penetration of unauthorized persons to the wells, a locking device is provided. This is the cheapest and most suitable option for their use on the territory of summer cottages, individual houses, cottage villages, in landscape gardening areas, sidewalks. They are also used in the construction of external communication networks, stadiums, parks.

What are hatches made of?

Modern technologies have not left aside this part of the public utilities. If quite recently only cast-iron manholes were used to cover sewer shafts, today you can increasingly find products made of composite materials. Their sizes are standardized - the holes in the floor slabs of mines of various types have a single format.

The choice of material for the manufacture of covers is determined by the conditions in which they will be used. First of all, the cover on the well must be strong and reliable so that an accident does not occur.

Metal well covers

Cast iron covers for wells have a long and successful history of use. They are resistant to the most extreme weather conditions for which the climate of our country is famous. The only downside to these products is their attractiveness to scrap collectors. This problem can only be solved by closing the hatch with a lid with a lock.

Cast iron covers have the following advantages:

- long service life, which can reach 100 years;

- the ability to withstand extreme loads without loss of aesthetic and practical characteristics;

- significant weight, which eliminates hatch shifting even with strong horizontal pressure;

- resistance to aggressive environments (fire, fuel, acid and alkali).

Today, metal covers are installed exclusively on the roadway. On private farmsteads, lighter products are used, which have a very affordable cost.

Hatches made of polymer plastic

Plastic hatches appeared relatively recently, but managed to gain popularity with a large army of private developers and utility companies. The reason for this is an impressive list of advantages of polymer hatches.

The plastic cover for the well has the following positive properties:

- environmentally friendly material that does not emit harmful substances even when heated;

- a large selection of color solutions used in the design of products;

- light weight, making installation and removal of the cover a simple event;

- a plastic hatch is several times cheaper than analogues made of cast iron;

- quite decent strength, allowing without damage to withstand the weight of a car.

Since the plastic hatch weighs little, locking locks are used to prevent it from leaving the nest. In order to increase the weight of well covers, sand is added to the polymer. Increased strength is achieved by using fiberglass. However, this solution leads to an increase in the cost of polymer-composite products.

Concrete well covers

Reinforced concrete products are made to order in cases where hatches have a non-standard configuration. This happens when sewage tanks are made independently or serve for specific tasks. The sizes and shapes of reinforced concrete covers can be very diverse.

These products have the following features:

- the ability to make a shelter for hatches that have non-standard sizes and shapes;

- low cost, since inexpensive materials are used in production;

- the possibility of manufacturing plates on their own directly at the place of their installation.

When installing reinforced concrete slabs on the necks of wells, care should be taken, since the product may crack or crumble from impact. But even if this happens, it is possible to produce an analogue in a short time

Functions and purpose

Its main task is to protect against the ingress of debris, dirt, foreign objects, drains and other contaminants into the collector. Otherwise, the sewer system will quickly become clogged and not fulfill its main function.Among other things, its presence allows for scheduled maintenance of the engineering network or troubleshooting in the event of a blockage.

According to their purpose, they are divided into:

- Lightweight, with a permissible load of up to 3 tons. Mainly for the pedestrian zone.

- Heavy, with a permissible pressure of up to 20 tons. They are used for highways.

- Super-heavy, with a maximum pressure of up to 60 tons. Scope of application - airfields.

The cover is made of different materials:

Cast iron

This is a classic solution for the arrangement of the sewer system. The cast iron lid is heavy. Because of this, difficulties arise during installation, as well as during their maintenance.

This is a classic solution for the arrangement of the sewer system. The cast iron lid is heavy. Because of this, difficulties arise during installation, as well as during their maintenance.

However, their excellent performance characteristics completely cover the shortcomings. On average, it will last up to 100 years with a maximum load of up to 100 tons. It is distinguished by a low price, it is used in the arrangement of highways and territories where the movement of lifting equipment is expected.

Polymer

Manhole sewer, also known as polymer sand.

Manhole sewer, also known as polymer sand.

In its production, a composite material from polymer and sand raw materials is used.

It is mainly used in the arrangement of underground communications:

- Heating network.

- telephone networks.

- Gas pipelines.

- Cable networks.

Due to its low weight, the polymer-sand cover is convenient to transport, mount and lift at the time of maintenance of certain communications. The material used perfectly copes with thermal, acid-chemical and atmospheric loads.

Plastic

They have minimal weight. Due to this, it is easy to work with it during installation.Mainly used for garden or landscaping.

They have minimal weight. Due to this, it is easy to work with it during installation.Mainly used for garden or landscaping.

May be green or any other color. Due to this, it will not be conspicuous, but successfully disguised. The PVC cover has a low cost in comparison with analogues. At the same time, the plastic hatch is able to cope with a load of up to 1.5 tons. Also allowed for installation in stadiums, squares and parks.

Concrete

You will not find such a sewer hatch for sale. They are made to order.

You will not find such a sewer hatch for sale. They are made to order.

To do this, a hole is preliminarily prepared, its dimensions are measured, and then the pouring process is carried out. You can do it yourself, the main thing is to prepare the form. There are varieties of concrete slabs / covers, where there is immediately a round hole. As a rule, they are effective when laying large sewer pipelines that serve entire areas.

Pros and cons of each type:

| View | pros | Minuses |

| cast iron |

|

|

| Polymeric |

| |

| Plastic |

| |

| Concrete |

|

|

Installation steps

Check also these articles

-

A comfortable sofa is the key to a comfortable sleep and a cozy atmosphere

-

Buffer tank in the heating system - what is it for?

-

Features of a sewer septic tank for a summer residence

-

Metal fence - the right solution for creating a high-quality fence

- A ring, or shell, is installed on the cover of the sewer shaft. This structural element reduces the load on the plate by almost three times. You can also use not a factory-made part, but ordinary brickwork. But, in the event that the brick crumbles, the lid will fall into the mine.

- In order to properly install the ring, it is worth using a level and setting the structure strictly horizontally. In order to avoid deformations or subsidence, it is impossible to install the structure at an angle.

- Around the entire perimeter, the outside of the ring should be concreted. The concrete mix must be completely dry.

- The unit is mounted in a ring. The entire work surface must be covered with grease or lithol. This technique will make it possible to open the hatch without problems even at sub-zero temperatures.

Conclusions and useful video on the topic

The video below will allow you to better understand the possibilities of polymer hatches

By the way, you should pay attention to checking the product under pressure, since according to the profile GOST, the procedure must be carried out before selling

Polymer hatches are modern and quite practical products that can make the life of users more comfortable. In addition, they have high performance, durability and affordable cost.

But their capabilities, in comparison with cast-iron counterparts, are still limited. Therefore, when choosing, you should be vigilant and not overestimate their capabilities so as not to incur financial losses.

Are you choosing a plastic manhole for arranging a sewer well in the country and want to clarify a couple of points about choosing? Ask your questions under this publication - our experts and other site visitors will try to help you.

Or maybe you recently purchased polymer roofs, installed them yourself and now want to share your experience with newcomers to this business? Tell us about the models you have chosen for your needs, add photos of installed hatches below our article.