- Introduction

- Sewer hatches, their features

- Technical requirements

- 4 Types, basic parameters and dimensions

- Device and application

- polymer hatches

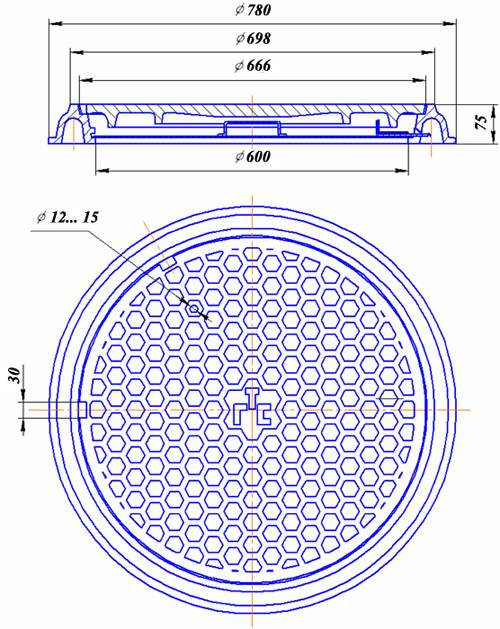

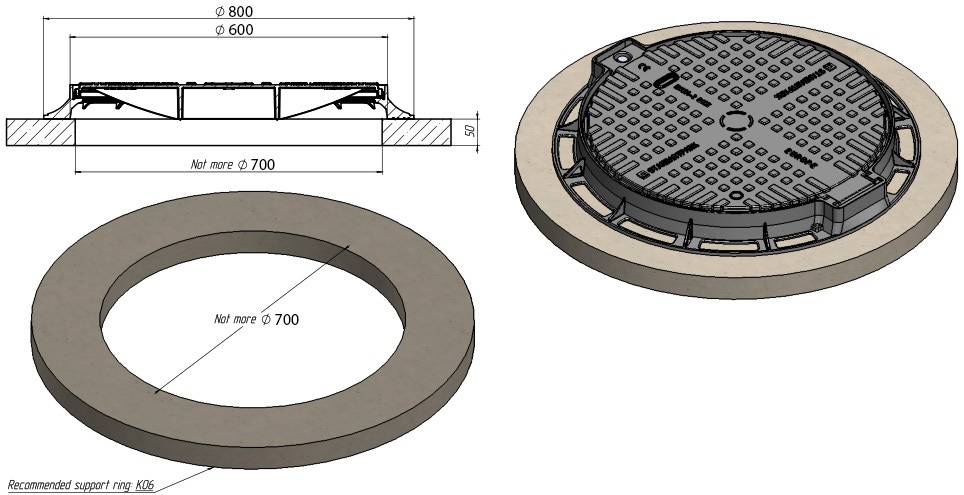

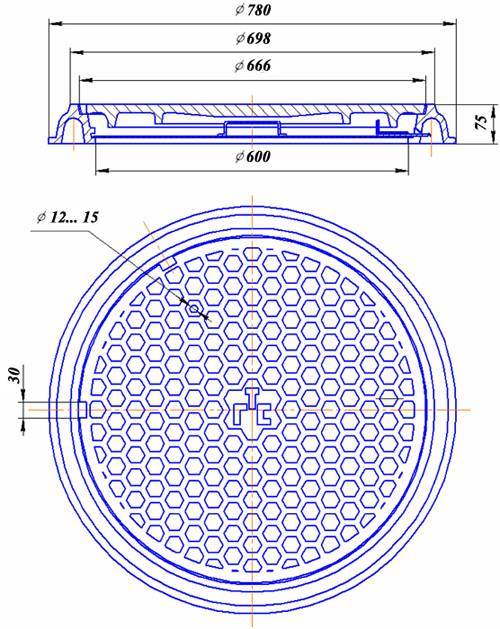

- Dimensions

- Dimension table according to load class

- Hatch size table according to weight

- Plastic hatches for tiles series LP

- Short description

- Choose by appearance

- Manhole device

- Specifications

- Advantages and types of polymer sewer covers

- Installation of a polymer-sand manhole on a well

- manhole cover

- Conclusion

Introduction

Introduction

The standard lists the types of hatches, strength loads that hatches must withstand and installation sites that are identical to the European standard: hatch L - class A15; hatch C - class B125, etc. This relationship is reflected in the symbol of hatches and storm water inlets: hatch L (A15); rainwater inlet DM1 (S250). The dimensions of the grating grooves of the storm water inlet and their location in relation to the curb stone are harmonized with the EN 124-1994 standard. The following people took part in the development: M.Yu. Smirnov, S.V. A.Glukharev and V.P.Bovbel (Gosstroy of Russia), L.S.Vasilyeva (GP CNS), Yu.M.Sosner.

Sewer hatches, their features

Before you begin to figure out why sewer manholes are made round, you need to deal with the wells themselves. These are engineering structures that are located along all lines of the outer part of the drainage systems. They are used for cleaning, repair work, network maintenance. The number of wells depends on the diameter of the pipelines - the smaller it is, the greater the risk of blockage. Therefore, more wells are needed. With a pipe diameter of 150 mm, the distance between the wells is taken equal to 35 m. If the diameter is 200-450 mm - 50 m, from 500 to 600 mm - 75 m, etc. A complete list of ratios is set out in SNiP 2.04.03-85.

Luke -

this is a separate design, which is purchased ready-made and mounted

on a prepared base. It is an integrated element of the road

covering, replacing it on your site and performing additional tasks.

From a design standpoint, it

is a double element - a support and a movable part. They are

installed above the inlet, which is present in the concrete pavement

well. The support serves as a structure that takes pressure from the passing

equipment and transferring it to a concrete base. This is one of the reasons why the sewer manhole is round -

when a car hits it, the pressure increases more smoothly, decreases

the danger of shifting the structure relative to the well.

A moving part is also involved

in the transfer of loads, while ensuring the safety of pedestrians and vehicles.

This is another answer to the question why the sewer cover is round. pressure on

the square is unevenly distributed. Deforming loads on corners can

destroy the item. Round shape is more stable.

There are different types:

- cast iron;

- concrete;

- plastic (polymer).

The first and second groups exist

for a long time, especially cast iron. Until now, in some old areas there are

protective structures made back in pre-revolutionary Russia.

Concrete products are designed to reduce the cost and simplify production. They do not consist only of concrete, the lid and socket are cast iron. A feature of such models is the possibility of partial repair in case of failure of the concrete base.

Technical requirements

Requirements

to sewer protective elements:

- ability to withstand load

(it is different for each model, it changes according to the size); - the deviation of the plane of the support element does not exceed

1°; - height deviation - no more than 1 mm;

- gap between the socket and the movable element -

no more than 3 mm (around the entire perimeter); - if a hinge is used, the full opening angle

not less than 100°; - to reduce shock loads between the movable

an elastic profiled gasket is laid between the part and the nest

(it is completed at the factory-manufacturer).

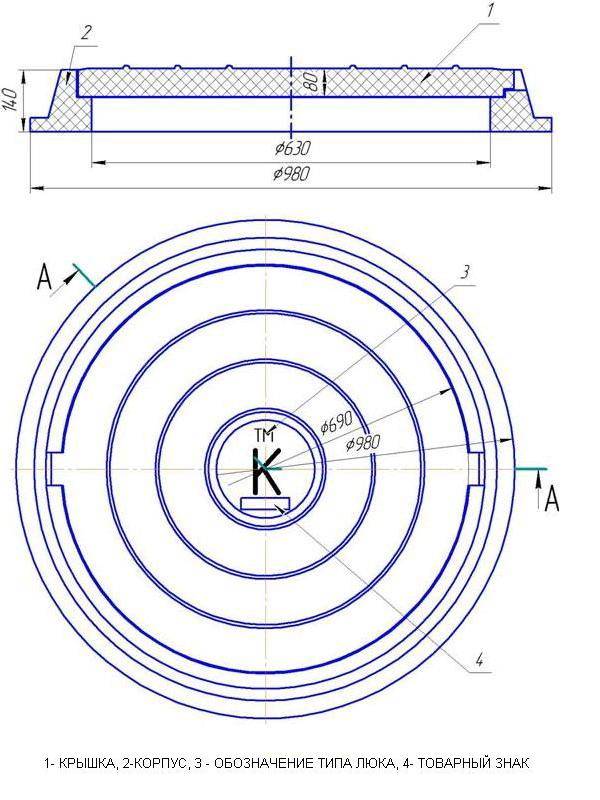

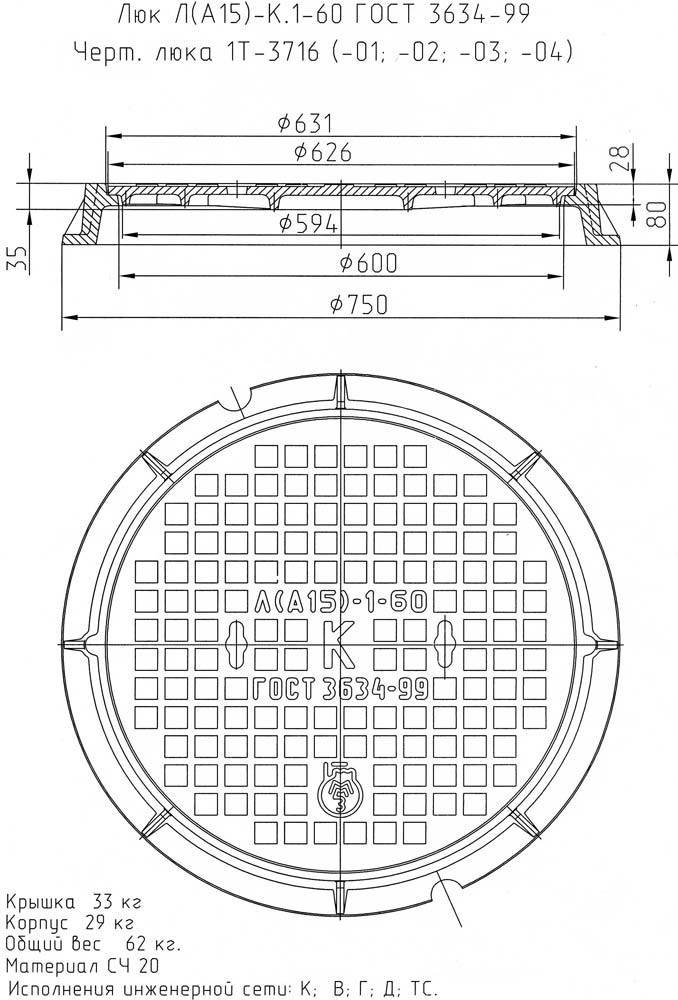

4 Types, basic parameters and dimensions

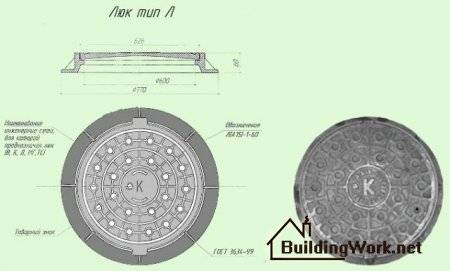

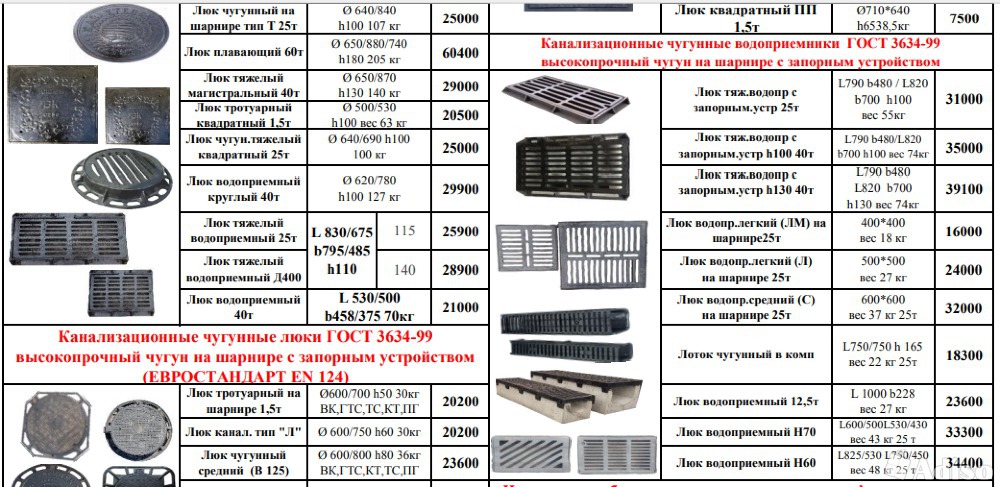

4.1 Types, basic parameters and dimensions of hatches, their installation location are indicated in Table 1 and in Appendix A. The hatch type is selected depending on the installation location. Table 1

| Type (designation according to EN 124) | Name | Full opening, not less than, mm | Installation depth of the cover in the housing, not less than, mm | Weight total, reference, kg | ||

| LM*(A15) | Lightweight sunroof | Green space, pedestrian zone | ||||

| L(A15) | Light hatch | |||||

| C(B125) | middle hatch | Parking lots, sidewalks and roadways in city parks | ||||

| T(S250) | heavy hatch | City highways with heavy traffic | ||||

| TM(D400) | Heavy main hatch | Trunk roads | ||||

| ST(E600) | Super heavy hatch | |||||

| Repair insert | Hatch bodies of types С(В125) and Т(С250) during repair work on roads (when increasing the height of the roadway) | |||||

| * For underground utilities with a channel depth of up to 600 mm from the outer surface of the manhole cover. |

4.2 By execution, hatches are subdivided:

1 - general purpose (Appendix A, Figure A.1);

2 - with a locking device on them (Appendix A, Figure A.2). The design of the locking device is agreed with the consumer;

3 - having a recess in the design of the cover for filling with concrete of a class not lower than B30 (Appendix A, Figure A.3);

4 - with a device for lifting the cover using a standard lifting mechanism. The design of the device must be agreed with the consumer;

5 - with reinforced sealing of the hull with anchor bolts or special lugs on the hull (Appendix A, Figure A.4). The design of anchors, tides and their number (at least two) is agreed with the consumer;

6 - with a cover consisting of two parts (Appendix A, Figure A.5);

7 - with a cover hinged to the body;

8 - with a square or rectangular shape of the hatch cover and (or) body.

4.3 Types, main parameters and dimensions of storm water inlets, their installation location are indicated in Table 2 and in Appendix B. The type of grate is selected depending on the installation location. Table 2

| Type (designation according to EN 124) | Name | Clear area, not less than, m | Lattice installation depth in the housing, not less than, mm | Weight total, reference, kg | ||

| Rain collector small | Pedestrian zone | |||||

| Large storm water inlet | Parking lots and roadways of city roads | |||||

| DB2**(W125) | ||||||

| Main storm water inlet | High traffic highways | |||||

| DM2(S250) | ||||||

| Heavy duty storm water inlet | High load areas (airfields, docks) | |||||

| DS2(D400) | ||||||

| On roads (airfields) with longitudinal slopes: * DB1 - 0.005; ** DB2 - 0.005. |

4.4 According to the design, storm water inlets are divided into:

1 - with a minimum width of the supporting part of the body along the contour (Appendix B, Figure B.1);

2 - with a minimum width of the longitudinal support part of the body adjacent to the road curb (Appendix B, Figure B.2); 3, 4, 5 - with a minimum width of the longitudinal support part of the body adjacent to the road curb, and one right (version 2) or left (version 3), or both (version 4) short sides; 6, 7 - with a minimum width of the short supporting part of the body adjacent to the road curb (version 5), or both short sides (version 6);

8 - with a single housing for two gratings (Appendix B, Figure B.3);

9 - with reinforced sealing of the hull, for which the latter is equipped with anchor bolts or special lugs on the hull (Appendix A, Figure A.4). The design of anchors, tides and their number (at least two) are agreed with the consumer;

10 - with a lattice hinged to the body.

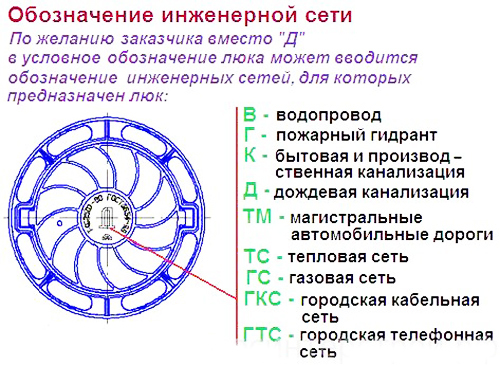

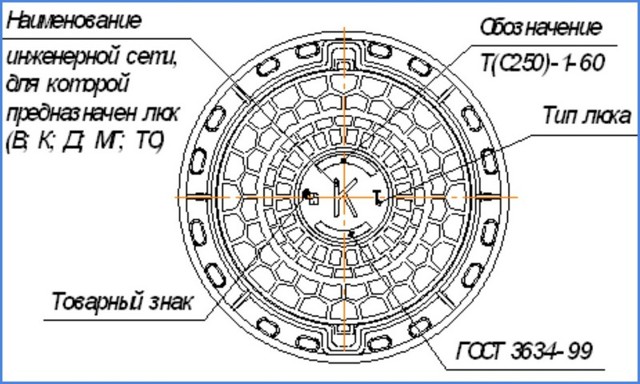

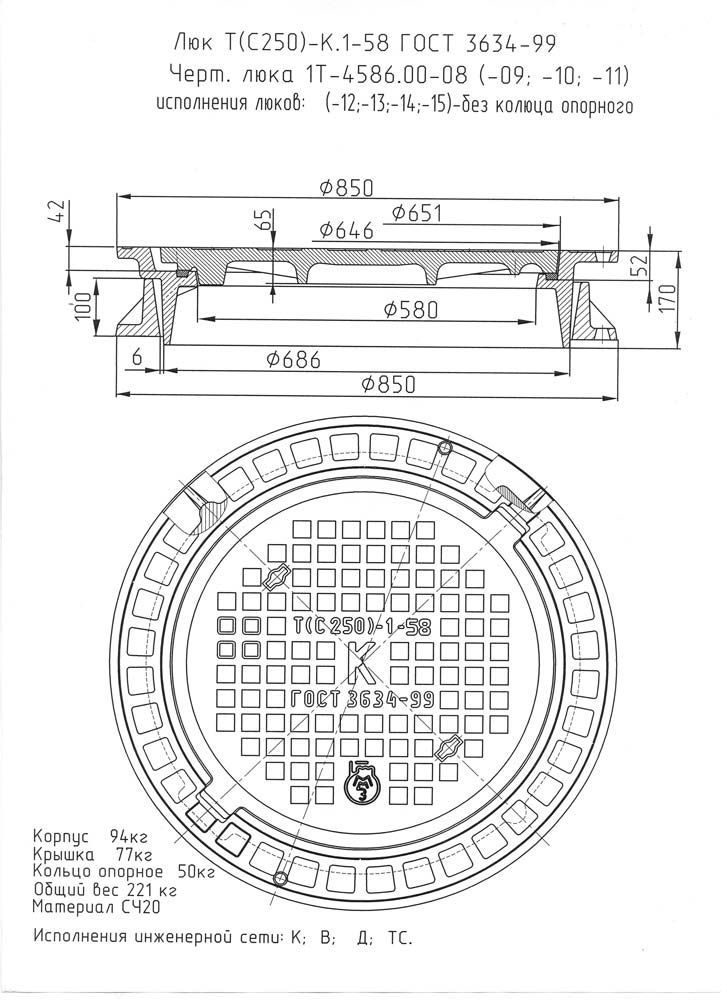

4.5 The symbol of a hatch or a storm water inlet should consist of the word "Hatch" or "A storm water inlet", its type, design or several versions, the overall dimensions of the manhole in centimeters and the designation of this standard. In addition, the designation of engineering networks for which the hatch is intended : B - plumbing; G - fire hydrant; K - household and industrial sewerage; D - rainwater drainage, TS - heating network, GS - gas network, GKS - city cable network (including GTS - as agreed with the customer).Examples of symbols:light hatch for the water supply network with a square cover and a manhole size of 60x60 cm

Luke L(A15)-V. 8-60x60GOST 3634-99;

middle manhole for sewerage with a locking locking device and a manhole diameter of 60 cm

Luke C(B125)-K.2-60GOST 3634-99;

repair insert for a heavy hatch of any design and names of engineering networks with a manhole diameter of 60 cm

Repair insert R.T-60GOST 3634-99;

large storm water inlet 2 with a minimum width of the longitudinal supporting part of the body adjacent to the road curb, with a hole size of 30x50 cm for roads with a longitudinal slope of 0.005

Storm water inlet DB1(V125)-2-30x50GOST 3634-99.

Device and application

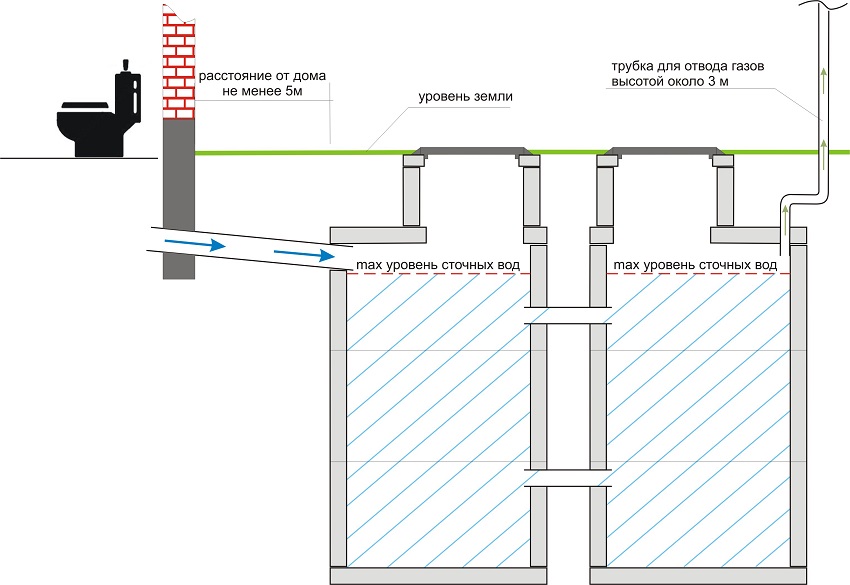

Initially, the wells looked like simple holes in the ground, which later began to be reinforced with stone or brickwork. After the appearance of concrete rings, this procedure was noticeably simplified, although the significant weight of individual elements imposed certain restrictions on installation work. In addition, in the course of operation, the joints between the concrete rings begin to gradually collapse, due to which the water in the well is polluted due to soil or runoff.A real breakthrough in the field of arranging well shafts was the emergence of polymer products.

Plastic wells for water

Depending on the function, polymer structures for water are divided into the following types:

Drinkable. Used in the construction of ordinary drinking wells. Conveniently, with the help of a plastic trunk, you can restore old earthen, brick or concrete structures. To do this, plastic rings of a smaller diameter are selected, and the space between the new and old structure is filled with sand.

Sewer. They are used for the construction of an autonomous sewer system when there are no central highways. Septic tanks can not be used here, since the bottom of sewer plastic wells is equipped with kinets - special trays at the bottom of the well, to which pipes are connected for uniform drainage.

The device of a plastic sewer well for water

Drainage. These plastic wells have a similar purpose to sewer products, but usually there are no knickets on them. To increase the degree of cleaning, it is recommended to form the bottom of structures with a uniform layer of sand and gravel 10 cm high.

Cumulative. Used as storage for rain or drinking water. The walls and bottoms of the storage wells are made completely sealed. For the reliability of the butt sections of structures of this type, they try not to bury below the aquifer.

Accumulative plastic well

Depending on the design features, plastic wells are divided into welded, prefabricated and seamless:

Welded. They are made from structured or two-layer pipes (they are characterized by increased rigidity).Basically, sewer systems are completed with welded wells.

Welded plastic wells

Prefabricated. Designed for assembly at the installation site from individual components. Most often, with their help, drainage is organized, cable and other communications of increased complexity are laid.

Prefabricated plastic well

Seamless. The main elements of these wells are a pipe and a bottom filter. With their help, drinking wells are equipped by immersing a polymer mine inside the aquifer. Good tightness of the walls allows you to protect water from pollution.

Seamless plastic wells

Any plastic well for water consists of a number of components that guarantee its functionality and safety.

These include:

- Bottom. In models of various purposes, it can be deaf, through or tray (cast water flow guides).

- Body. Wells, small in section, are equipped with plastic corrugations that can effectively withstand soil pressure and temperature fluctuations. If the diameter of the well shaft exceeds 100 cm, it is equipped with plastic rings. Additional stiffening ribs serve as protection against deformation of the structure when the soil is compressed.

- Neck. It is present mainly on plastic manholes.

- Luke. Their design may be different, depending on the purpose. To prevent debris and dirty water from entering the well shaft, completely blind hatches are used. Storm sewers are usually equipped with lattice covers.

Plastic well device

For the installation of plastic wells for water, only areas with an optimal climate and landscape are suitable.The lower part of such structures is not recommended to be buried below six meters, and only fine gravel and sand should be used for backfilling. It is not allowed to have tremors above 7 points on the Richter scale in the installation area. There is also a limitation on air temperature - it should not fall below -50 degrees. Before installation, you should study the regulatory requirements by soil composition.

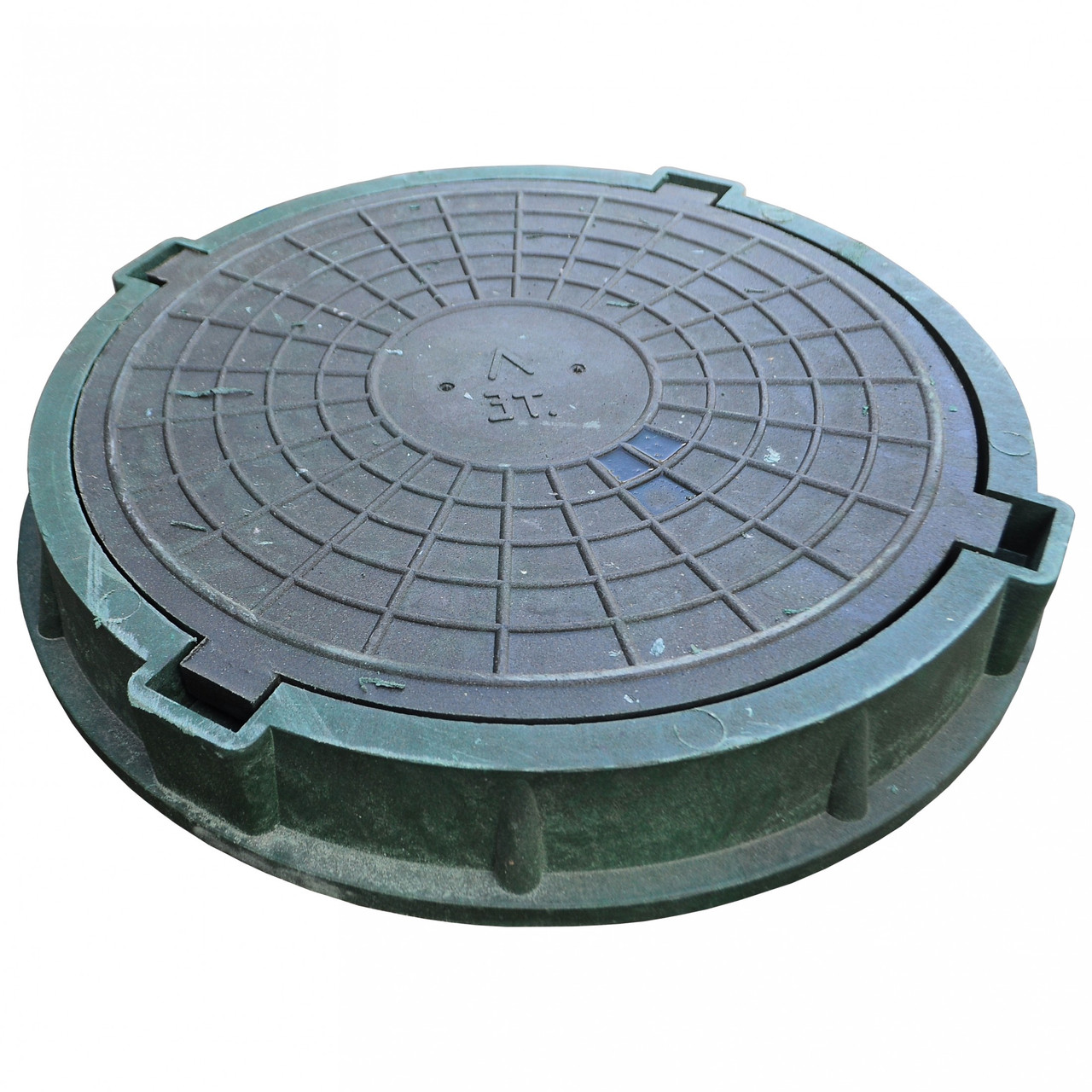

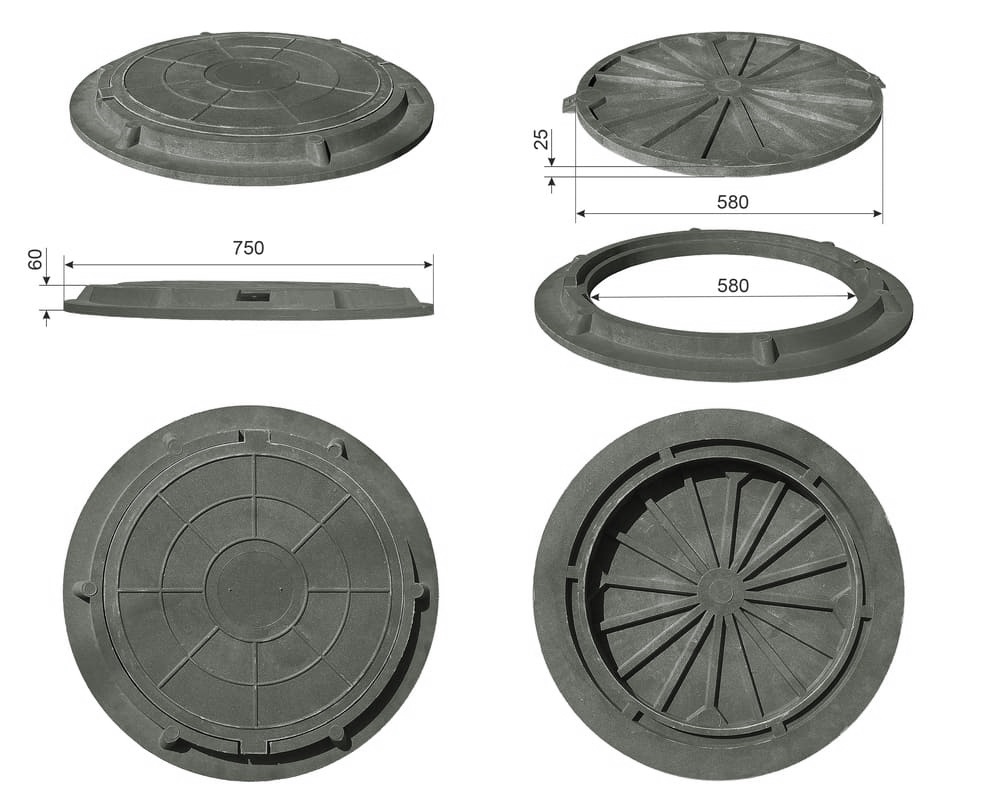

polymer hatches

Polymeric materials began to be used for the manufacture of sewer manholes relatively recently, and such models are almost as good as cast iron products in their characteristics. As a rule, if the area where the sewer well is located will not be subjected to high loads, then a polymer hatch is the most optimal solution. A typical sewer polymer hatch is shown in the photo.

Perhaps the only drawback compared to cast-iron hatches in this case is low strength: a standard plastic sewer hatch can withstand load up to 5 tons. Nevertheless, this indicator is quite enough in most cases, especially when building in private households.

Among the advantages of such structures:

- low weight, which often has to be compensated with a locking lock so that the hatch does not break out of its place;

- low price, especially against the background of cast iron products;

- the ability to choose the color of the hatch, which allows you to choose a model whose color will best match the conditions where it is located.

Polymer structures are the best solution for use in private homes.In addition to standard hatches, on the market you can find polymer-composite devices that have greater strength, but the cost increases accordingly.

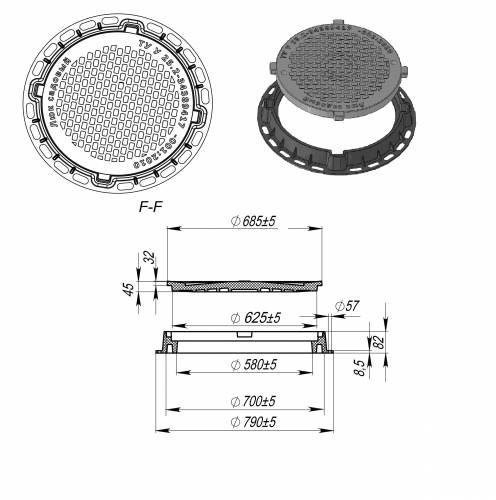

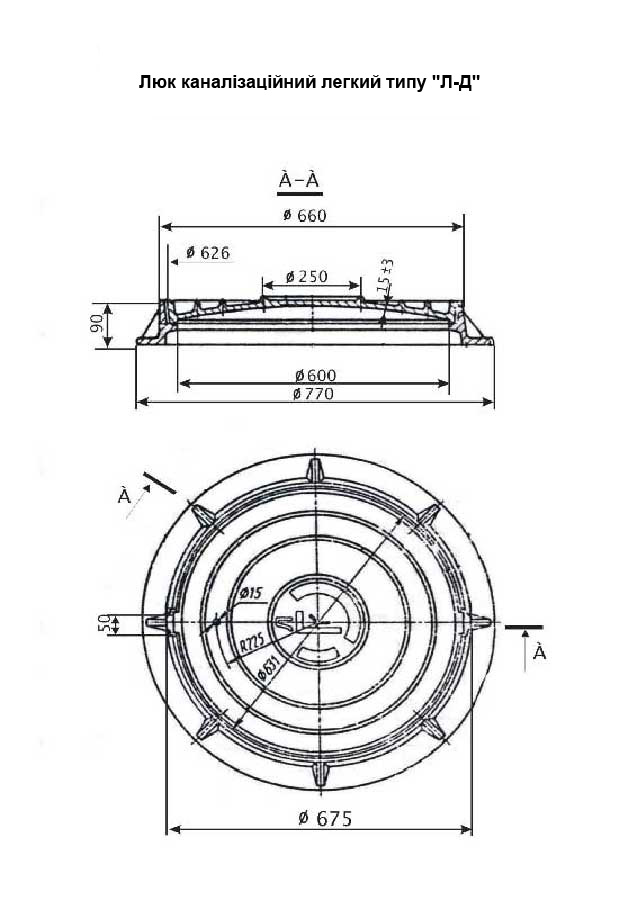

Dimensions

If we talk about round products, then the diameter of the manhole of the sewer well will be the decisive factor in this case.

There are two main indicators - the inner and outer diameter of the shell.

It is installed on the top of the manhole, must exactly match its dimensions.

Compliance with the neck is determined by the indicators of the internal diameter and the total area of \u200b\u200bthe base.

The size of the sewer well cover itself will slightly exceed the diameter of the shell, but the difference will be small.

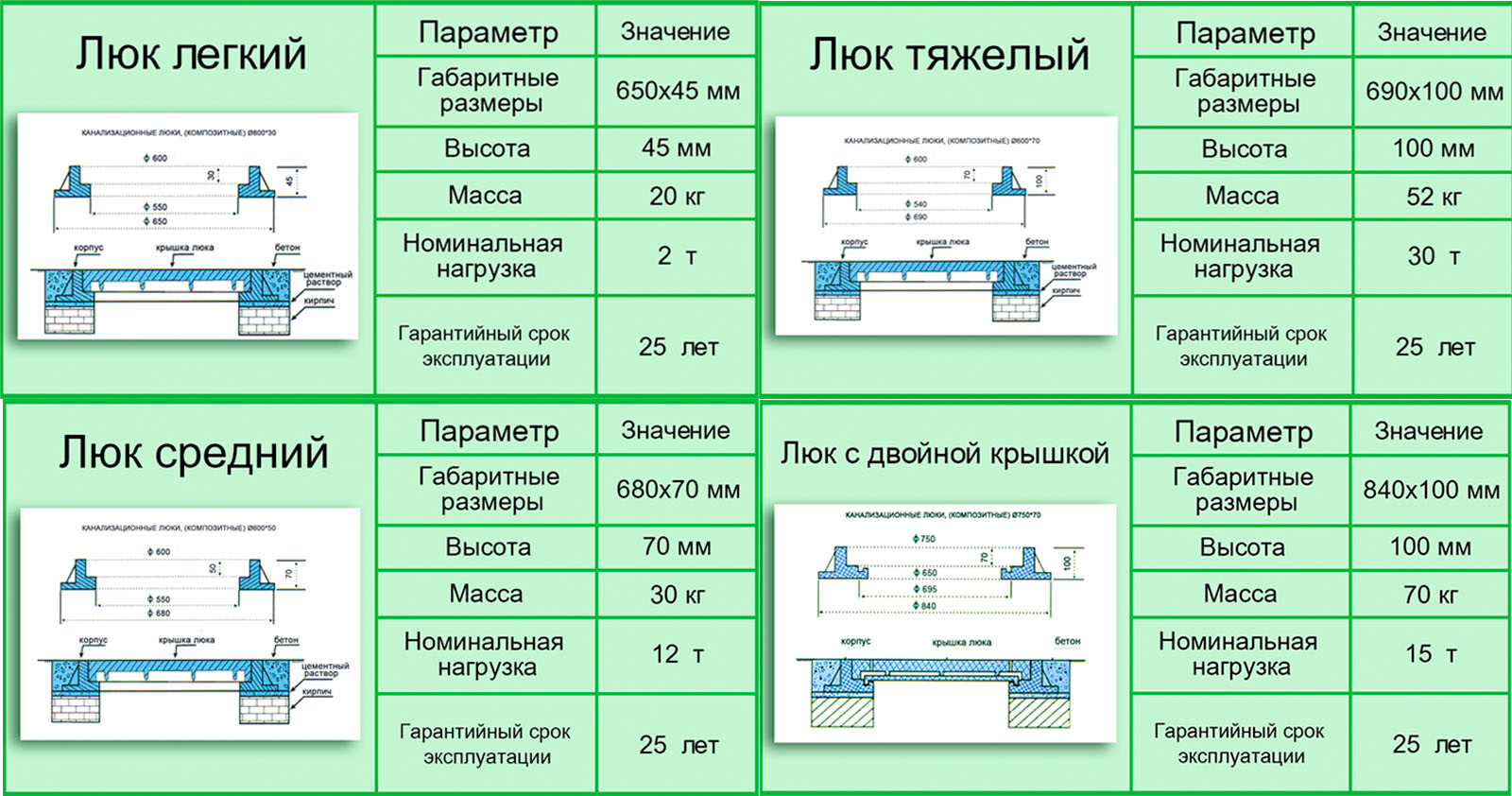

Dimension table according to load class

| TITLE | LOAD CLASS | WEIGHT, KG | LOAD,KG | PURPOSE | LIFE TIME | DIMENSIONS,MM |

|---|---|---|---|---|---|---|

| Garden light compact hatch | A15 | 11 | 1500 | For landscape gardening areas, courtyards of private houses, cottages and cottages | ~50 years | 540*540*80 |

| Green lightweight plastic | A15 | 10 | 1500 | Park areas, squares, adjacent territories | ~20 years | 750*750*80 |

| Polymer lightweight with locking device | A15 | 46 | 1500 | Pedestrian roads, park areas, plantings | ~20 years | 780*789*110 |

| Polymer lightweight compact | A15 | 25 | 1500 | Parks, squares, sidewalks | ~20 years | 730*730*60 |

| plastic lightweight | A15 | 44 | 3000 | Installation in manholes, park areas, squares | ~20 years | 750*630*115 |

| Plastic road medium | B125 | 50 | 12500 | Park roads, sidewalks and parking lots | ~50 years | 780*780*110 |

Hatch size table according to weight

| NAME | BODY SIZE,MM | LID SIZE,MM |

|---|---|---|

| Light hatches ( | 720*60 | 600*25 |

| Light hatches ( | 750*90 | 690*55 |

| Hatches are square ( | 640*640 | 600*600 |

| Light hatches ( | 750*90 | 690*55 |

| Medium hatches ( | 750*100 | 690*50 |

| Hatches are heavy ( | 800*110 | 700*70 |

All overall characteristics of hatches are specified in GOST 3634 99.In practice, it is possible to find cast-iron hatches with a diameter of 380-810 mm, and plastic ones with a diameter of 315 mm to 1 m.

A rectangular sewer hatch will have the dimensions specified by GOST 3634 99.

The minimum size of one side of such a product can be 300 mm. Further, it will increase in increments of 50 mm.

The maximum size indicator is 800 mm.

Rectangular sewer manhole

It remains only to choose such a sewer hatch that would correspond with the maximum accuracy to the shape and size of the neck of the cesspool in a particular case.

It is best to give preference to a plastic product, because it combines the best qualities, and increased hatch strength is not required in such a situation.

How to measure manhole cover size

Note! Some hatches are equipped with a special lock that restricts access to an inspection or sewer well. But, for private houses, the need for such locking mechanisms is not so high. But, for private houses, the need for such locking mechanisms is not so high.

But, for private houses, the need for such locking mechanisms is not so high.

Plastic hatches for tiles series LP

Plumbing hatches are installed in the opening of the viewing window. Today, the practice of using metal stealth hatches with a push mechanism is very widespread, but many people prefer to opt for a plastic LP hatch. There are arguments for this:

• plastic hatches LP under tiles are cheap;

• hatch LP has low weight and shallow depth, so it can be installed in a stretch ceiling or in a wall panel made of thin plasterboard;

• unlike metal hatches, which are mounted under the cladding, the plastic hatch is very easy to fasten in the opening with the help of spacers - even minimal experience is not needed for its installation.

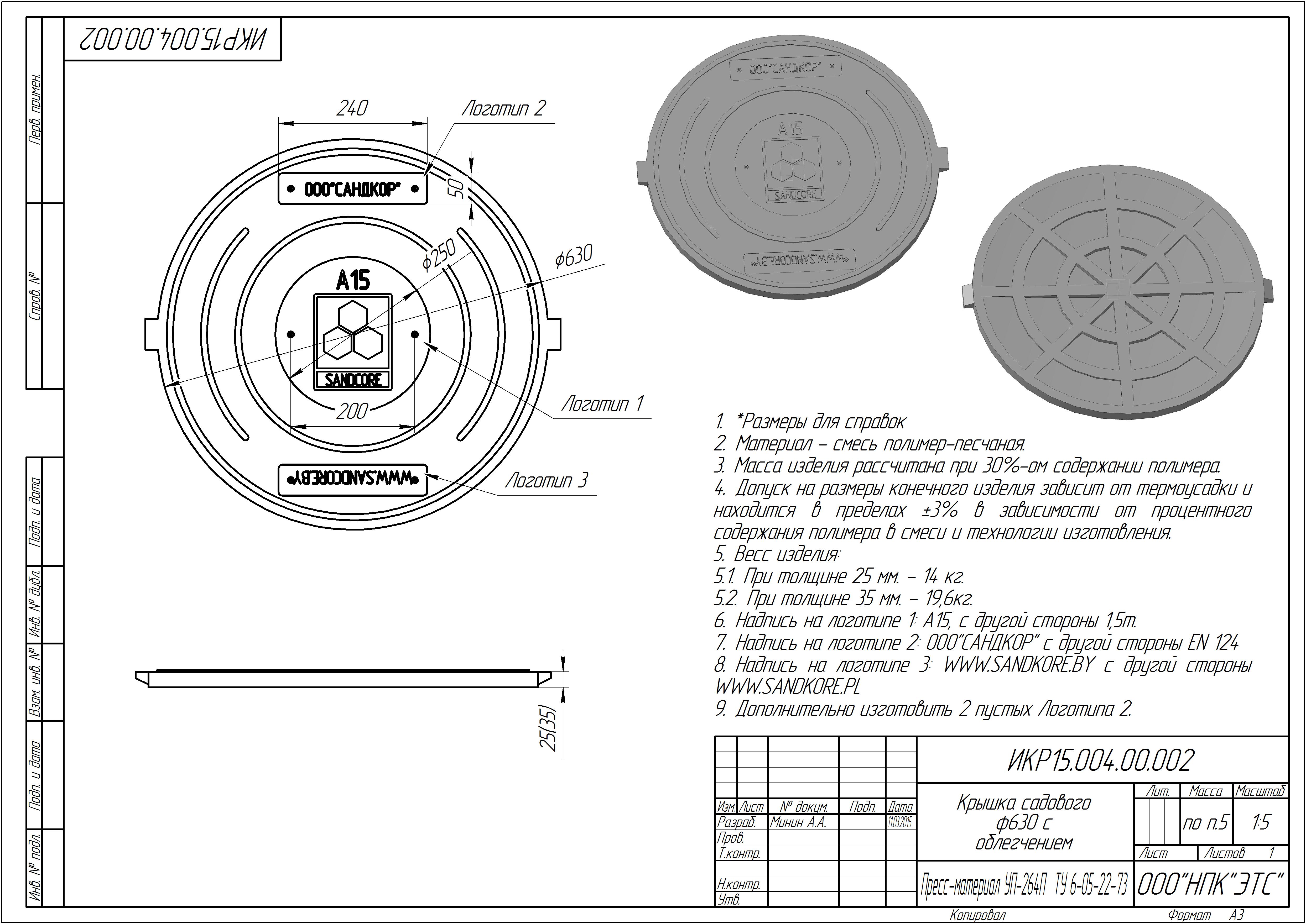

Short description

The manufacturing technology of polymer hatches is based on the method of casting and hot pressing of all material components (sand, thermoplastic polymers and dyes). This method of production allows you to get a product that has the highest performance and has a presentable appearance.

Similar products are used by city water utilities, heating networks and road enterprises. In large-scale and private construction, a sand-polymer manhole is also used for arranging sewers. GOST 3634-99 and sanitary and environmental standards, according to which the product is manufactured, establish clear dimensions and basic qualities of the finished product. For this reason, the buyer has no difficulty in replacing caps, and the product itself is completely safe for the environment.

Choose by appearance

The most common variant of the sewer manhole will be a round cover. It is the most convenient to use. In any position, it will not fall inward and will not give a large gap. At the same time, there are other types of hatch structures: in the form of oval, square and rectangular. But all of them have only a convex, less often flat structure.

Interesting fact. In America, sewer manholes in the form of triangles were introduced to ensure the flow of water in public places. However, such an invention was not supported by the safety control and did not receive distribution.

To date, sewer manholes are made from various materials. What do they all have in common:

- ribbed surface;

- quite weighty dimensions;

- convex or flat shape.

Manhole device

Sewer hatches are installed on top of manholes, which are divided into several types, depending on the type of communications:

- Drainage systems.

- Storm sewers.

- Electrical networks.

The observation well is arranged as follows:

- Work space;

- Mine;

- Luke;

- Lid.

The size of the working room can be different, it all depends on the type of communication for which it is intended. Its depth also depends on the depth of the network, the standard height is 1.8 meters.

The shaft is made round, with a diameter of 70 centimeters. The walls are laid out of concrete rings or bricks and equipped with a ladder.

The hatch, for security purposes and to prevent cluttering of the mine and the working room, is closed with a lid. Lids, until recently, were made only of cast iron, so they have a fairly solid weight.

A large mass of the structure is a necessary condition, so How does this help prevent it? spontaneous shifting under the influence of vibration from the movement of cars. The weight of cast iron hatches depends on their design and size.

So, for example, the mass of the hatch cover alone of the brand T (S250) is 53 kg, TM (S 250) is 78 kg, TM (D400) is 45 kg. So, these are quite heavy items that are not easy to lift.

There are ribs on the surface of the lid. This is done to increase durability and better grip on car tires and the soles of pedestrians. The lid can be flat or convex.

You may be interested in:

Specifications

When choosing a polymer cover, it is imperative to focus on each technical characteristic of such a product. The main features are considered to be:

- Weight (this parameter is especially important);

- Type of;

- Rated load.

It is important to have an idea of the load capacity class of the product, because this parameter determines the limit value of the load that the product is able to transfer without damage. Also, this value affects the choice of installation location. For example, a lid of type “L” is a lightweight product that can withstand an ultimate load of one and a half tons.

Accordingly, such covers are not allowed for installation on the carriageway. To close the shafts of the sewage system in the territory of courtyard passages or parking lots, medium and heavy structures are used. Such products are able to easily transfer loads in the range from 15 to 25 tons.

For example, a lid of type “L” is a lightweight product that can withstand a maximum load of one and a half tons. Accordingly, such covers are not allowed for installation on the carriageway. To close the shafts of the sewage system in the territory of courtyard passages or parking lots, medium and heavy structures are used. Such products are able to easily transfer loads in the range from 15 to 25 tons.

Advantages and types of polymer sewer covers

The basis for the manufacture of polymer hatches is a polymer sand mixture. The introduction of various additives makes it possible to obtain a protective device with the desired performance properties.Due to a number of advantages, this type of sewer hatches has become the most popular:

Dimensions of polymer manholes

- high rates of permissible mechanical load (up to 25 tons);

- high-precision pressing method ensures excellent tightness;

- several color versions allow you to organically fit the equipment into any landscape;

- long service life (20–50 years);

- ease of transportation and installation - one person can handle the installation;

- interchangeability of parts in case of damage - the sizes of covers are standardized;

- operating temperature from -50 to +50 degrees;

- resistance to chemicals;

- do not rust and do not fade;

- do not emit a metallic ring and do not spark when hit by a car;

- low cost compared to cast iron counterparts.

The whole variety of hatch models are classified according to several criteria.

Installation of a polymer-sand manhole on a well

The installation of a polymer sand hatch is quite simple and does not require special skills in the construction field, for work you will need a hammer drill with a 10 mm diameter metal drill and a regular drill for metal, a small building level, a hammer and a wrench are needed from a household tool. It is more reliable and easier to fix the rim on nut anchors with a diameter of 10 mm in the amount of 4 - 6 pieces and a length of 80 - 100 mm. Before installation, the base is prepared - for this, the top of the well is leveled with a cement-sand screed according to the level, then the work is carried out in the following sequence:

1) With a perforator with a drill for metal, 4 - 6 equidistant holes with a diameter of 10 mm are made in the annular shell.

2) Apply a circle to the well opening, mark with a pencil at the points of the drilled holes, if the hatch ring is heavy, it is easier to lay it, and without removing it, drill the concrete in place.

3) Make holes in the concrete of the well in the perforation mode of the desired depth, after which the anchor is driven into them with a hammer.

4) Take a wrench and tighten the anchor nuts tightly.

Rice. 10 Installation of PPL

Rice. 10 Installation of PPL

Plastic hatches for wells, unlike cast-iron counterparts, not only have advantages in decorative effect, many physical parameters and chemical characteristics, but also significantly win in price - their cost is 5 times lower. Due to this, composite products have completely replaced cast iron products from the sphere of domestic use; they are increasingly used by government organizations.

manhole cover

The cover is the main part in the design, which performs the main functions of the hatch. When choosing a cover, you need to carefully examine it for compliance with the dimensions of the shell. Also, the design should not have any protrusions or gaps.

There are also decorative covers for sewer manholes, which differ from traditional models in the presence of a special shape or pattern. The latter option is much more common, since its implementation is simple.

In any case, the use of decorative hatches allows you to hide the structure in the best possible way among the landscape of the site. The choice of a lid in this case depends entirely on personal preferences and the characteristics of the site: somewhere an imitation of natural stone is better suited, and for other cases a hatch with a sandy color will suffice.

There is not much point in discussing the cost of manhole covers, since it is rather problematic to find them for sale separately from the finished structure. That is why it is worth taking care in advance that the hatch does not disappear anywhere, otherwise you will have to reinstall the entire device.

Conclusion

So, we figured out why the hatches are round. You can answer this question in different ways. If you really become a bore, then you can calculate how much metal is needed to make a square cover for a hole into which a person would freely crawl. This value is then compared to the weight of the metal required to make the cap for the round hole. With the same cross section of the metal, it turns out that more metal will go to the square hatch due to the presence of corners in the square.

You can also calculate how evenly the forces are distributed when a car wheel hits the sunroof. It will turn out that the loads are distributed more evenly around the entire perimeter of the circle. In the case of a square or a triangle, this is not the case.

In general, now you know why manholes are usually round, and you understand what you need to answer if you are suddenly asked about this at an interview. Most likely, this is the only case when such information can help. However, if we are talking about an interview, then it is not at all necessary to answer correctly. You can answer with a joke, or even say that manholes from sewer wells are not always round, it's just the way it is in our country. Sometimes even the person who asks such a stupid question doesn't know why hatches are round at all. However, you now know the answer for sure.Despite many good versions, the most logical and plausible seems to be the version with the shape of the lid, because of which it simply cannot pass into the sewer hole.