- Criterias of choice

- Types and categories

- type of instalation

- Location

- Equipment management

- The nature of sewage

- Type of pumping equipment

- Hydraulic pump in a forced sewer system

- General information

- Operating principle

- The station has operating modes

- Installation instructions for KNS

- Rules for the installation of sewer installations

- Fecal pump: design, types, purpose

- The principle of operation of the fecal pump with a grinding mechanism

- Types of pumps

- Installation methods

- Installation

- How the station works

- How to Calculate Receiving Volume

- Installation, start-up and commissioning - how it happens

- KNS service

- Typical installation errors

- KNS service

- Types and types of KNS

Criterias of choice

A huge number of household types of stations are presented on the pumping equipment market, which differ in technical characteristics.

It is important to pay attention to the following:

- power - there are models from 500 to 2000 W;

- productivity depends on power - the higher it is, the more water the station is able to pump out per unit of time; for a private house, you need to buy a device with a capacity of about 2000 l / h;

- the volume of the accumulator - can be from 15 to 60 liters; the larger the capacity, the less often the pump will turn on;

- the presence of protection against dry running and overheating - such functions sometimes save devices from combustion;

- materials for the manufacture of the body and internal parts - cast iron, steel or plastic; in more expensive models, the body and impeller are steel.

If you need to place the device close to living areas, since there are no other options, it is recommended to choose a cast-iron case - it dampens sound better than a stainless steel case, although steel products look more attractive on the outside. Inside the cast iron is covered with a protective layer against corrosion. The material is less subject to vibrations, therefore it lasts longer than technoplastic. In addition, he is not afraid of mechanical damage.

Types and categories

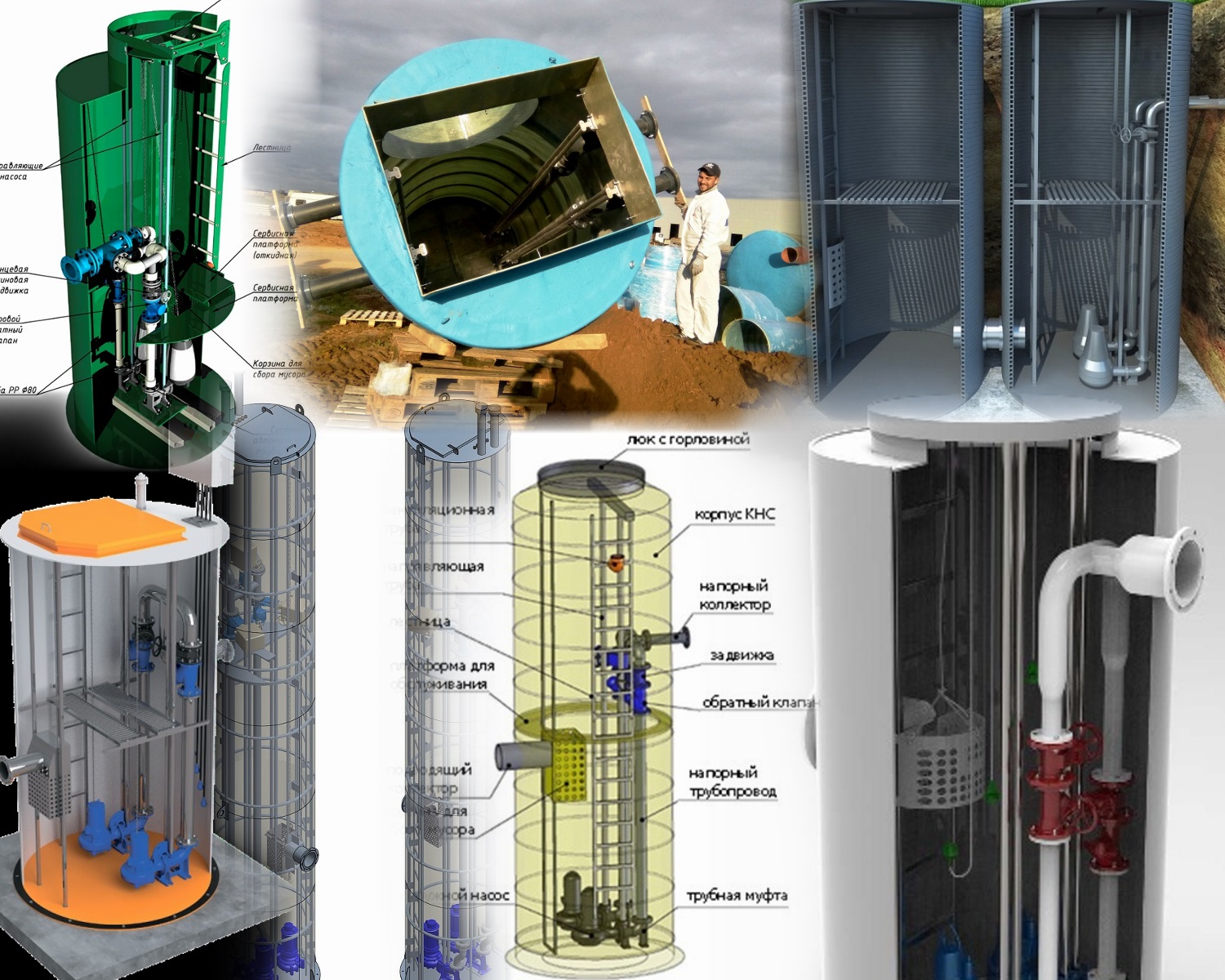

Sewer stations are classified according to several criteria.

type of instalation

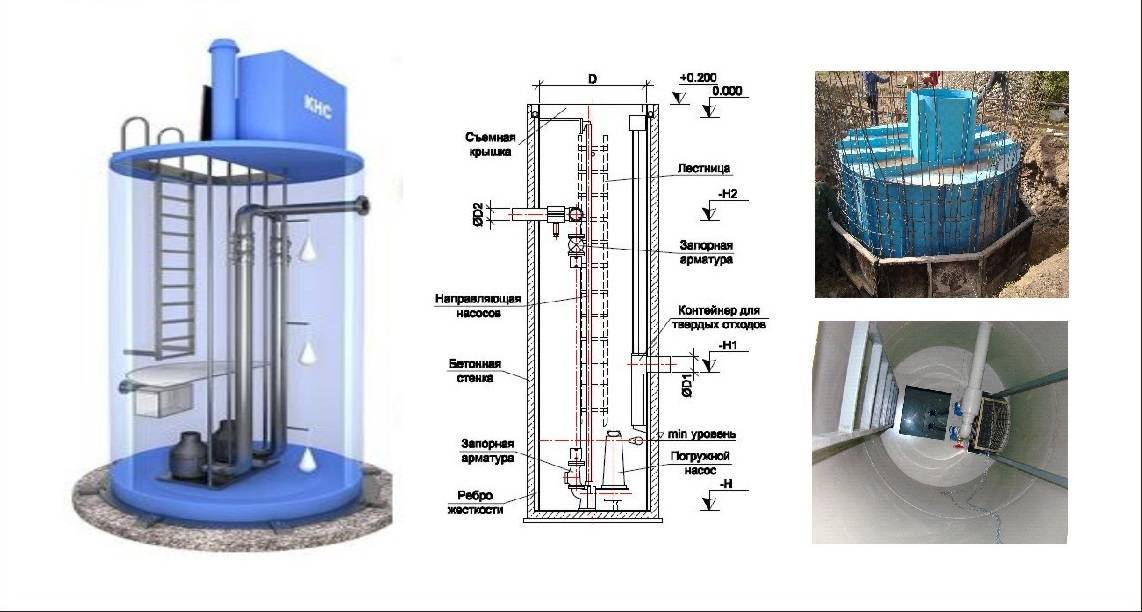

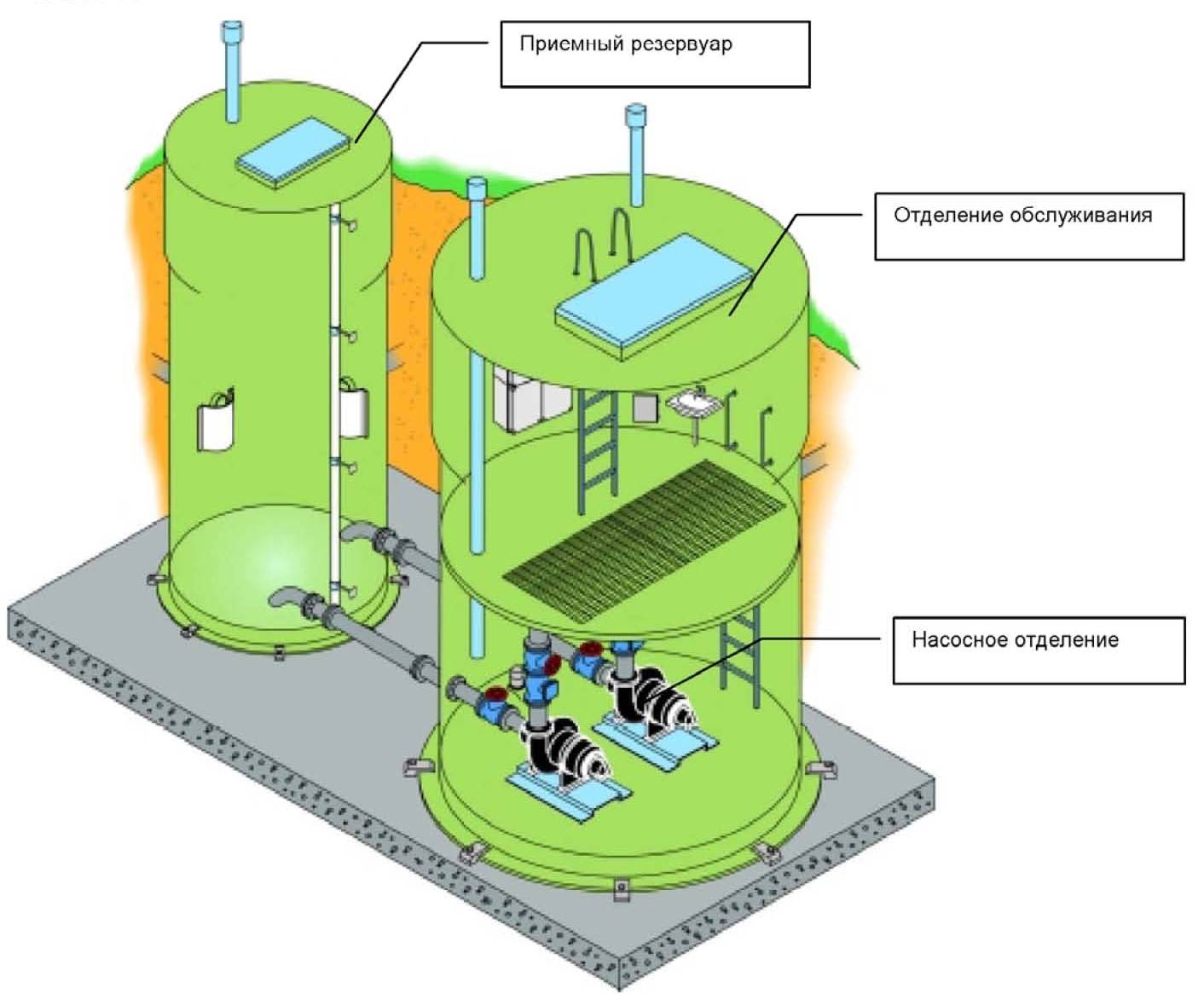

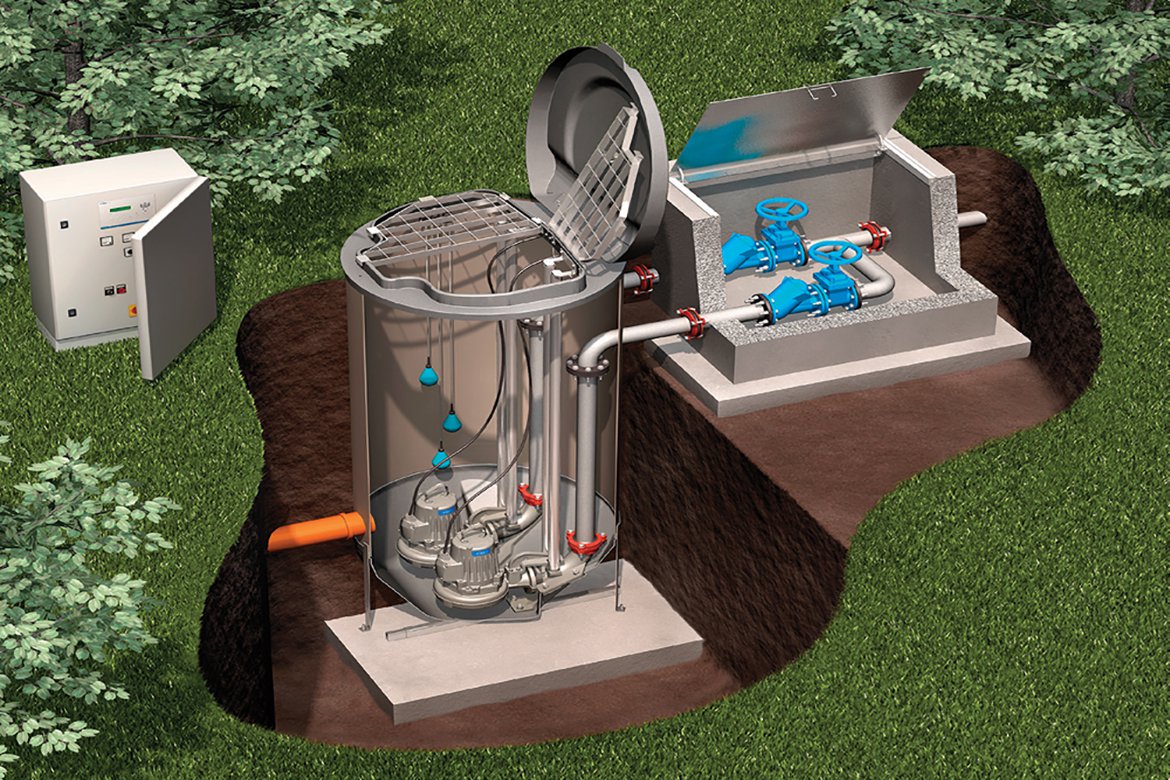

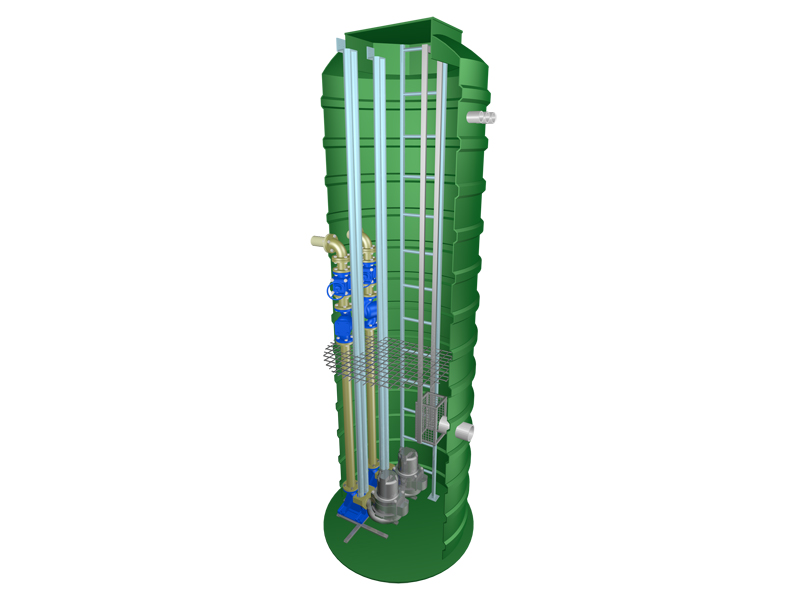

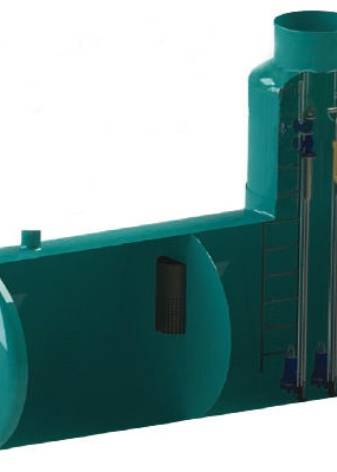

KNS may have vertical and horizontal execution. The latter are often equipped with a self-priming pump, which forcibly pumps contaminated masses into the KNS casing and removes them after cleaning. Sometimes a reservoir tank may have an additional horizontal compartment on the bottom. This design contributes to the uniform distribution of silt deposits on the bottom tank and increases the time of its filling.

This, in turn, allows you to clean the tank less often, which significantly saves time and money.

Location

By location relative to the ground surface, the SPS can be buried, partially buried and have a ground location. Ground stations are mini-sets located in kitchens, bathrooms and toilets.Buried ones are traditional models with a storage tank dug into the ground, and for partially buried tanks, a tank equipped with sensors, a pump and valves is located in the ground along the neck. Automatic monitoring and control system while brought to the surface.

Equipment management

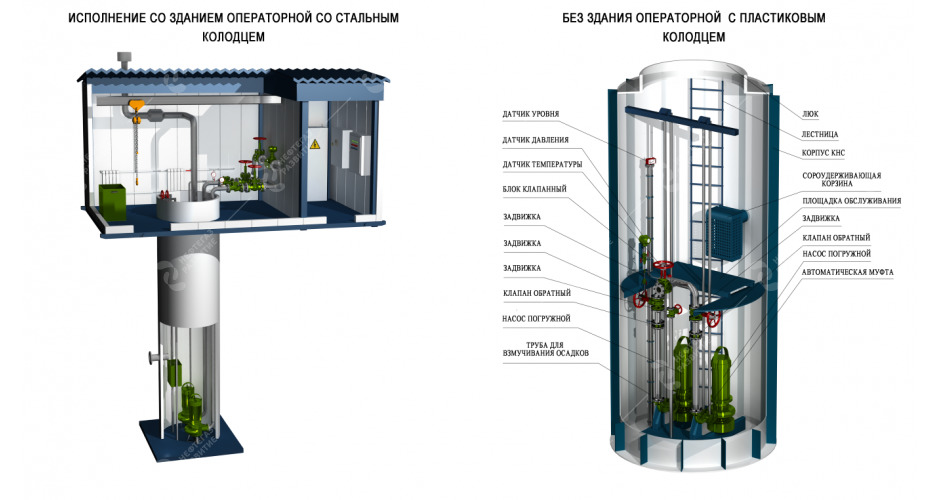

KNS are equipped with manual, remote and automatic control.

- With the manual method, the switching on of the modular equipment is carried out manually by the workers of the stations, who independently check the level of sewage in the tank.

- With remote control, data on the state of the system and the height of the liquid level are sent to the control panel. It is very convenient to control the radio-controlled station: the equipment does not require the constant presence of a person, and in the event of a malfunction, it promptly reports about it.

- The automatic control system is the most common, and consists in controlling the station using relays and sensors, which can be located both on the station body and nearby on the shield.

The nature of sewage

Wastewater is divided into domestic, industrial, storm and sedimentary.

- For industrial waste, tanks and pumps must be made of materials with increased resistance to chemical aggressive substances and high temperatures.

- Stations for the removal of storm water into the sewer are equipped with additional systems for cleaning sand and mechanical debris that rain flows can bring.

- SPS for sedimentary wastewater is used at wastewater treatment plants and is equipped with specialized devices that process sedimentary deposits.

Type of pumping equipment

Three types of pumps are installed on the sewage pumping station.

Submersible pumps with a pressure function require complete immersion in water. The devices have a sealed housing, which is made of high-strength, non-corrosive materials. Fecal pumps are efficient and quite easy to use, they do not need to be additionally fixed or equipped with a platform for them. The device is able to operate at low temperatures, and the cooling of its engine occurs naturally from the surrounding liquid.

Hydraulic pump in a forced sewer system

To choose the right pump, you need to understand all its modifications and take into account many factors.

Most often, sewerage is designed so that the drains in it move by gravity. But not always a local septic tank or an input to a centralized sewage system is located below the sewer pipeline and all plumbing fixtures in the house.

Waste water cannot rise upwards by itself, it is necessary to “force” it with a pump.

Pumping equipment is installed when, due to the relief or other features of the local area, external sewer pipes cannot be laid at the desired slope.

It is also possible with the completion or redevelopment of the building. The configuration of internal pipelines and the volume of effluents are changing, the latter can no longer be removed from the residential building on their own.

The most popular version of the sewerage device with forced pumping of wastewater provides for an intermediate storage device in the basement of the cottage. As it fills to the brim, the pump turns on, pumping the liquid out into the street for further cleaning or removal.

But you can also install a compact pumping unit, which turns on only when drains are drained.However, if it breaks down, the house will actually remain without sewerage.

The task of the forced sewage pump is to pump out domestic wastewater and stimulate their movement to the street collector, which is located above the storage or treatment plant (+)

Compared to a gravity system, the use of pressure pumps provides a number of advantages:

- Ease of maintenance. The frequency of cleaning pipelines is reduced, since the intensive movement of wastewater contributes to their self-cleaning.

- Equipment location variability. Sanitary and household appliances with a connection to the sewer can already be placed anywhere without taking into account the need to form a slope towards the outlet of the sewer, and then the drive or septic tank.

According to the technical regulations (SNiP number 2.04.03-85), the smallest diameter of the pipes of the external main of the pressure sewer network is taken to be 150 mm if a combined drain is arranged.

These are networks that transport storm drains together with household black and gray ones. Household gravity systems are arranged from pipes of a similar size.

If fecal sewage is discharged separately, the diameter of the pipeline is assumed to be filled to 0.7 of its maximum height. This distance is necessary for ventilation and the possibility of removing unpleasant and explosive gases.

The size of the sewer pipeline must be taken into account when choosing a pump in order to accurately select the unit for the upcoming load.

A forced system is volatile and costs more money than a gravity system.If the family is small, then the drive is not filled immediately, the sewer pump will be enough to turn on from time to time.

However, with large volumes of wastewater, pumping equipment must operate almost constantly. In this case, a power outage can cause serious problems.

Most of the costs for sewerage pump manages to fight off through the use of cheaper and thinner pipes, as well as reducing the cost of their installation. But after installation, this equipment needs constant maintenance, which requires some money.

If an uninterruptible power supply is added to the circuit in case of a power outage, then the benefit is zero.

For the installation of a forced sewer system of a small private house or cottage, which drains a mixture of black and gray drains, a fecal pump is suitable. It will cope with the pumping of combined sewer water

If it is possible to get by with a gravity sewer option, then it is worth doing it. A pressure system with a sewage pump for viscous and contaminated liquids should only be selected as a last resort

And special attention should be paid to competent choice of pumping equipment

General information

Attention! In winter, stagnant drains in pipes can lead to ice jams. If there are large inclusions in the wastewater, then the low speed of the water cannot make them move, which leads to their accumulation in the pipes, further to the formation of plugs

Particularly susceptible to this are sections with turns, or with a change in the diameter of the pipes. If the terrain has nuances, then it is difficult to lay the pipeline straight, you need to go around buildings, etc.

If there are large inclusions in the wastewater, then the low speed of the water cannot make them move, which leads to their accumulation in the pipes, further to the formation of plugs. Particularly susceptible to this are sections with turns, or with a change in the diameter of the pipes. If the terrain has nuances, then it is difficult to lay the pipeline straight, you need to go around buildings, etc.

If there are large inclusions in the wastewater, then the low speed of the water cannot make them move, which leads to their accumulation in the pipes, further to the formation of plugs. Particularly susceptible to this are sections with turns, or with a change in the diameter of the pipes. If the terrain has nuances, then it is difficult to lay the pipeline straight, you need to go around buildings, etc.

Operating principle

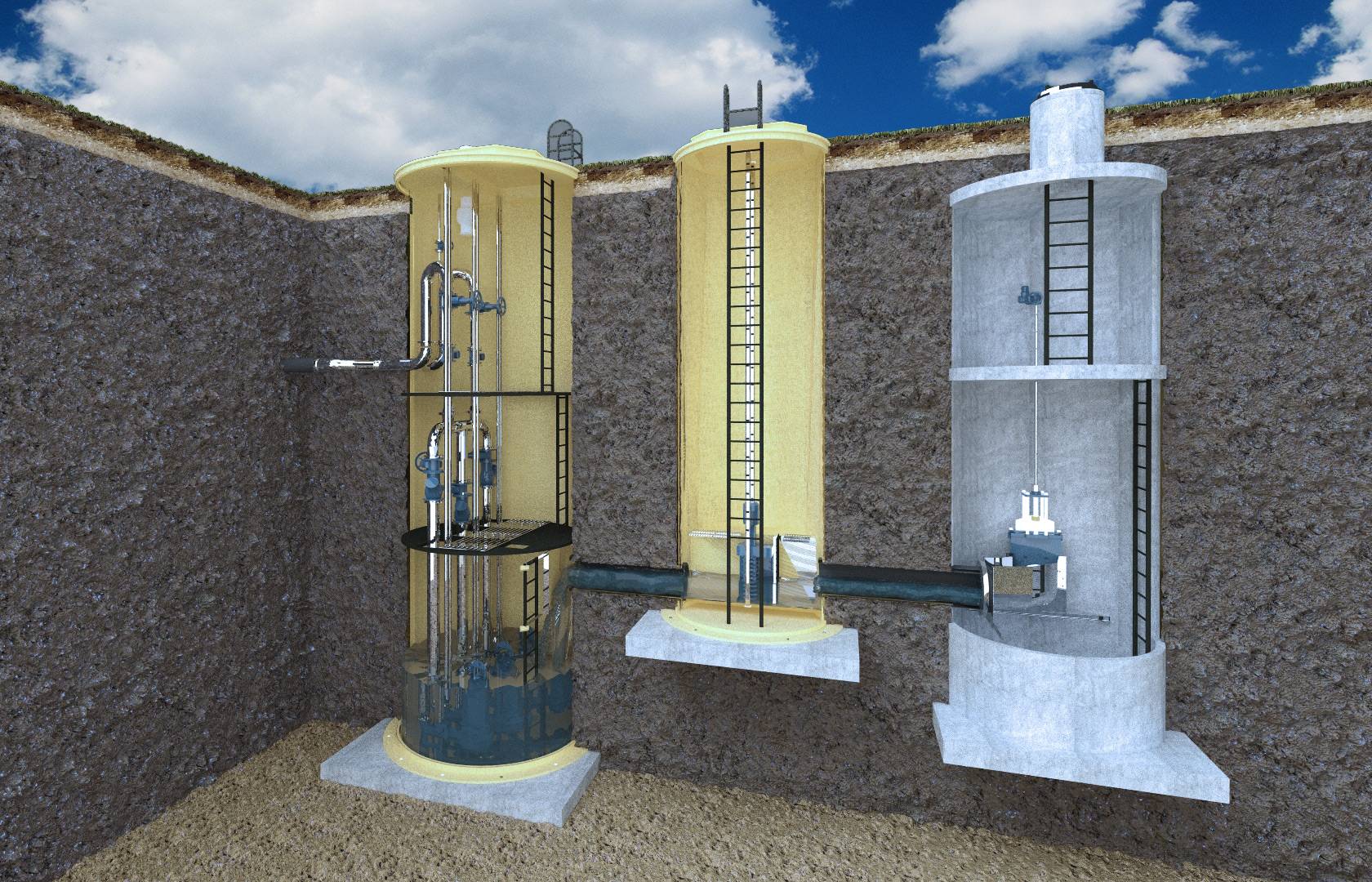

Pumping stations for sewage can be domestic, industrial. Devices for industrial facilities are represented by complex engineering equipment; it is not recommended to install it in a country house. The volumes of wastewater in a private house are very small for the performance level of this type of station.

For a country house, devices of medium complexity are suitable. The devices are small in size. For installation, the type of waste must be taken into account. In the home sewer there are drains from the toilet, which include large items, household drains from the kitchen, water after washing in a typewriter.

AT operating principle there are such mechanisms: from plumbing, drains enter the storage tank. When the drains reach the maximum level, the pump is activated to divert the drains into the pipes of the sewer system. The station has an automatic mode of operation, so you do not have to constantly monitor the process.

The pipeline is equipped with a reverse valve. It protects the system from the penetration of liquid in the opposite direction. Debris particles accumulate in the waste basket. It is periodically necessary to remove debris from it when routine cleaning and maintenance are carried out.

The station has operating modes

Of them:

1. in normal mode, when the effluents do not exceed the standard volume, then one pumping equipment is working.

2.peak mode, when all residents use water at once. Then all the pumps that are installed in the storage tank are activated.

3. in emergency mode, when a lot of liquid is supplied, or if two pumps break down, then a signal is received that the station cannot cope with the loads.

Pump station units

The pumping station has certain nodes. These include the following elements:

1. pump, or units of this type.

2. storage tank.

Pumping equipment can be placed behind the toilet or near the exit from the room. Compact models have a beautiful body design, do not spoil the interior of the bathroom. The accumulation tank can also be small in size, or vice versa serve a house with several floors.

Installation instructions for KNS

Installation of household sewage pumping stations is carried out exclusively by qualified workers, due to the high requirements for the accuracy of work and compliance with the sequence of actions. Violation of the rules can lead to damage to the tank or pipes suitable for it. Next, we will consider step-by-step instructions for installing KNS for people who want do it yourself.

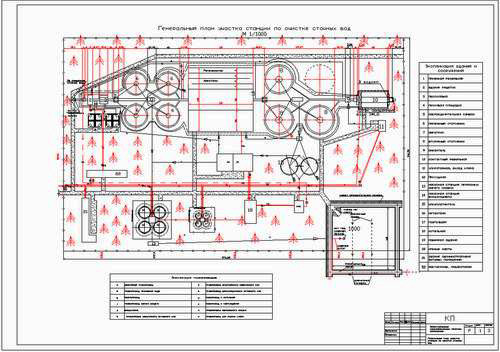

The first step is to select the location of the SPS. SNiPs require a tank to be dug in at least 20 meters from the walls of a residential building. If geodetic levels allow, then it is advisable to choose a site higher so that a lot of groundwater does not accumulate under the station.

KNS should not be installed on the front side of the house, near children's playgrounds and near picnic areas

The second thing is to dig a hole, taking into account the diameter of the container and the place for convenient installation work. If the soil is taken out by an excavator, then work must be stopped 20-30 cm above the design level.Further, it is necessary to extract the earth manually with a shovel to maintain the integrity of the soil.

When digging a hole for a sewer tank, you do not need to make it huge. It will be enough to have a diameter of 1.5-2 meters larger than the size of the container itself

The third step is to select the type of foundation for the installation of the sewage pumping station and its installation. To do this, after digging a hole, an assessment of the water content of the soil is performed. If the soil is dry, then formwork can be made and poured with a 30-centimeter layer of concrete. And if groundwater constantly seeps into the pit, then only a finished reinforced concrete slab with a thickness of at least 30 cm is suitable for the foundation.

The concrete base must be strictly horizontal, so when laying the finished concrete slab, you need to take care of this in advance.

SPS tanks have a skirt or paws for attaching to the foundation. Anchor bolts are used as fasteners, although when pouring concrete on the ground, metal rods can also be embedded in the mixture, on which the container mount can then be mounted.

Do not save on the size of anchor bolts. Their optimal length is 200 mm, and their diameter is 20 mm. And metal rods before laying in liquid concrete must be bent with a hook or the letter G

The fourth step is to install the SPS tank on the foundation, fix it and connect it to the drain pipe of the internal sewerage of the house. With a vertical type of station and a large amount of groundwater, it is required to load the tank with concrete. To do this, concrete is poured around the tank 20 cm above the level of the first stiffener of the station.

It should be borne in mind that after pouring concrete it will be impossible to change the tank, so it is necessary to calculate its volume, taking into account the expansion of the house and the increase in the number of its residents

The fifth step is filling the station with fine soil, the maximum grain size of which is 32 mm. Each layer of earth should be no more than 50 cm. After filling the next belt, it is filled with water to shrink and compacted.

This completes the external installation of the KNS. After fixing in the ground, pumps, sensors, check valves and other auxiliary equipment are installed inside the station.

For safety reasons, it is recommended to close the hatches of sewer tanks with locks, because during the game, children can hide in them and lose consciousness

It would not be superfluous to carry out a critical level alarm system in the house domestic wastewater in the tank, which will warn of malfunctions in the operation of the station.

Rules for the installation of sewer installations

Requirements may vary for each specific model. Therefore, before starting work, we strongly recommend that you carefully read the documentation.

A short list of recommendations looks like this:

- If a vertical section of the pressure pipeline is required, then it must be located directly next to the pump. Otherwise, there is a risk of blockage.

- The pressure pipeline must be rigid with one-piece connections. For example, a polypropylene pipe PN10 with an outer diameter of 32 or 40 mm.

- The horizontal pressure section is made with a slope towards the riser.

- All branch pipes included in the device must be laid with a slope of 3° towards the device.

- Avoid using 90° elbows. Bends must be smooth and performed using 45° bends.

- If you have several pumps, then each of them should have its own entrance to the riser.

- The pump must be accessible for service.

These are the most universal requirements for the installation of such equipment. However, each individual model may have its own installation nuances. Therefore, you need to carefully read the passport and think about everything.

We are waiting for your orders!

Fecal pump: design, types, purpose

The fecal pump is manufactured in a corrosion-resistant housing, its main feature is the installation of a grinding mechanism on the drive shaft. It can be a knife or a cutting edge. Sewage pumps with a grinder operating from 220 V are installed in apartments, private houses and institutions where there is a risk of pipeline clogging. Their flow channels have a large diameter and are capable of receiving effluents with fractions up to 10 cm. Start and stop of the equipment is controlled by automation.

The principle of operation of the fecal pump with a grinding mechanism

The equipment is installed near the toilet, after draining the water enters the storage chamber. A special sensor detects the increasing air pressure and sends a signal to the relay that starts the electric motor. At the same time, the knives are turned on, which grind the garbage. The liquid under pressure is sent to the outlet pipe and transported through it to the riser. After pumping out, the sensor detects a decrease in pressure and turns off the engine relay.

Fecal pump with grinder

Types of pumps

Stations equipped with such a pump are compact, versatile, operate silently, and are easy to maintain. The units are produced taking into account the conditions in which they will have to pump wastewater. Sewage pumps for the home are divided into four groups:

- A device with a grinder for pumping low-temperature domestic wastewater. The unit is designed for drains with large fractions, for example, from the toilet. It is installed in the toilet on the basement floor, when the riser is located far away, and the overall level of the sewer system is higher than that of the devices placed here. When the storage tank is filled with drains, pumping and operation of the knives are switched on. The liquid is forcibly sent to the general system.

- A unit without knives, designed for hot drains from a bath or sauna, as well as a shower and a washing machine. Estimated water temperature up to 90 degrees.

- Pump without cutting parts for pumping wastewater from a swimming pool or flooded basement. The model has the most affordable price.

- Equipment with a grinder for transporting hot drains. A universal unit that can be used in a private house or bath if there is a toilet.

Installation methods

- Submersible sewage pump - installed in a sewage pit or tank, completely immersed in liquid. The most popular option for domestic use.

- Semi-submersible - the pumping part of the unit is lowered into the water, and the engine remains on the surface. This model can be used for pumping water at high temperatures.

- Outdoor - the device is installed near the sewer well, into which intake hoses are lowered. Such equipment can be moved to the right place.

Submersible pump installation

Installation

Installation of the sewage pumping station begins with digging a pit. With the right tools and at least one assistant, dig a hole for tank can do it yourself. The calculation of the depth is made individually and depends on the type of installation and the size of the tank. The optimal position of the tank is when the lid of the tank protrudes from the ground by 80-100 cm.

A sand cushion is formed at the bottom of the pit and a reservoir is installed on top. After the tank is installed and leveled, they begin to connect the pipes and backfill the pit. It is necessary to compact the earth around the tank very carefully, tamping each layer in turn. The backfill density should be 90% of the natural density of the surrounding soil.

After the tank is firmly in place, the installation of the pumps begins and the floats are adjusted. As an example, the floats of the first level are usually located at a distance of 15-30 cm from the bottom of the tank. However, this is a recommended height and may be subject to change based on the intended number of drains and tank size. The next float is installed a meter - one and a half higher than the previous one, after which they begin to install the electrical cable, perform grounding, equip ventilation and connect power.

After all work has been completed, a test run of the system is carried out using clean tap water. In the event of a successful test, you can proceed to the construction of a protective pavilion, and in the absence of the need for construction, you can immediately put the station into operation. The pavilion can be built from metal or brick.

How the station works

The functioning of the sewage pumping station begins from the moment when the lower compartment is filled with effluents above a predetermined level.In this case, the station starts. At the same time, pumps are turned on that pump waste into a distribution tank, then they enter the pipeline and into the sewer - this is the principle of operation of any SPS.

Watch the video, how it works:

If two or three people live in the house and the amount of waste is small, then one pump is enough. When the volume increases, a second unit can be connected. In this case, the station goes into the maximum load mode, which should be taken into account when designing the cleaning system. The ability to use one or two pumps at once makes it possible to save energy, extending the working life of the station.

If the SPS is unable to cope with the volume of water, then a signal is sent to the operator's console requiring a specific decision on the maintenance of the SPS.

How to Calculate Receiving Volume

The design of a sewage pumping station with submersible pumps involves a number of calculations and the selection of equipment. A suction volume calculation must be performed to ensure correct pump operation. To do this, use the manufacturer's formulas. Of course, it is better if this work is done by professionals. After all, a typical project sewage pumping station requires complex calculations such as:

- Water consumption

- Building a schedule of receipts during the day

- Knowing the allowable amount of liquid used, the volume of waste is obtained

- Find the minimum and average tributaries

- Determine the pressure

And only after completing the calculation of the KNS, you can proceed to the choice of the pump model, taking into account the highest volume of inflow and the value of the pressure.

Next, a pump and pipeline operation schedule is built to determine the maximum pressure point and an analysis of the equipment operation in emergency situations is carried out.

The last stage in the preparation of a typical design of the sewage pumping station is to find the volume of the tank. To do this, a graph is built that displays the inflow and outflow of water by one pump, moreover, by the time that passes between the largest and smallest inflow.

Installation, start-up and commissioning - how it happens

The installation of a sewage pumping station cannot be called simple, because the stations are quite complex equipment, so it is better to entrust these works to employees of specialized enterprises.

The installation of the sewage pumping station must be carried out in a pit, the dimensions of which correspond to those indicated in the attached instructions. At the same time, its bottom is reinforced with reinforced concrete slabs or poured with a concrete solution. To this base, the installation of the SPS is carried out with anchor bolts.

The next stage is the connection of pipelines: inlet and outlet. And they complete the installation work by connecting the power cable, according to the documentation for the design of the SPS.

The installation of pumps is carried out in accordance with the attached instructions and, upon completion, commissioning is carried out. They consist in the installation and configuration of sensors, which are also performed during the maintenance of the sewage pumping station. Moreover, the lower one should be located at a distance of 500 mm from the bottom, and the third and fourth in such a way that they are included in the work when the drains reach the cut of the tray in the supply pipeline, which should be taken into account when designing the sewage pumping station.

Watch the video, installation and installation:

In addition, during the adjustment process, the operating time of the second pump is regulated; it cannot exceed 10 minutes.Adjustment work is carried out by two people - one adjuster controls the readings of the sensors on the console, and the second is engaged in their adjustment.

After completing the adjustment, the performance of the pumps is checked empirically. For this, they produce pumping water from reservoir.

KNS service

Many are interested in the question of whether it is possible to carry out preventive work at sewer stations yourself? Experts do not recommend performing KNS maintenance on their own. Since the operation of the station is fully automated, its maintenance consists in carrying out scheduled preventive inspections and routine maintenance, which must be carried out by professionals in the maintenance process in order to avoid breakdowns. They also carry out the current repair of the sewage pumping station.

Typical installation errors

Damage to the tank walls, nozzles or suitable pipes can occur due to incorrect tank installation, tilting or improper backfilling. Such problems threaten manual excavation of the container and considerable financial costs.

Therefore, typical errors should be analyzed in advance so as not to repeat them when installing your own SPS.

- Incorrect backfilling of the soil. Possible errors: filling with frozen soil or large stones, lack of layer-by-layer tamping. The consequence may be a subsidence of the earth with damage or displacement of the internal pipeline.

- Different type of backfill from different sides. If, on the one hand, a sand machine was poured into the pit, and on the other, the earth, then over time the container may skew with damage to the outer pipes or the tank itself.

- Incorrect assessment of the amount of groundwater, due to which there is a strong subsidence of the entire sewage pumping station with rupture of pipes and damage to the reservoir.

- Using wedges to level foundation slabs. The consequence may be a gradual displacement of the tank to the side with a rupture of the pipes.

Only people with a geodetic education and experience in installing such structures can assess the correctness of the installation of the SPS. Therefore, you should not trust the installation of this expensive equipment to non-specialized organizations.

KNS service

As part of the high-capacity sewage pumping station, there is a filtration system, which is represented by a pre-treatment tank. It accumulates heavy fractions, as well as objects of large size. They are there before entering the transfer chamber. In such designs, a hatch is usually provided through which people, using a shovel, provide effective cleaning of the receiver. For the reason that in pumping station may not be only household waste, but also sewage, for the efficient operation of the equipment, it is necessary to clean the receiver once a month.

Types and types of KNS

The main part of any sewer system is pumping equipment, which can be of the following types:

- Self-priming;

- submersible;

- Console.

And the pumping station itself, given its location, happens:

- Partially buried;

- Buried;

- Ground.

In addition, all sewer stations are of two types: main and district. As for the main sewage pumping stations, they are used for pumping waste directly from a settlement or enterprise. But the regional ones are intended for waste disposal to a sewer or treatment plant.

Also, KNS are divided into remote, automatic and manually controlled.

Remote work in such a way that it is possible to control and regulate their work from an equipped control room. Automatic fully controlled by sensors and devices. And as for the manual ones, all the work lies with the attendants.

Pumping stations also differ in the type of pumped effluent into four groups:

- The first group is intended for domestic waste water. It is used to divert wastewater from public buildings and residential households.

- The second group is for industrial wastewater.

- The third group is for storm networks.

- The fourth group is for precipitation.

Depending on the power of the KNS, there are mini, medium and large. Mini stations are mainly applied directly to the bathroom room or toilet. They are a small sealed container that is attached to the toilet. most popular are medium pumping stationsThey are used for both domestic and industrial purposes. Household differ from industrial ones in that only one pump can be installed in them. But industrial stations must be equipped with two pumps. Large sewage pumping stations are used exclusively in urban systems. They are equipped with the most powerful pumps in terms of parameters.