- Types and categories

- type of instalation

- Location

- Equipment management

- The nature of sewage

- Type of pumping equipment

- When to use the pump

- Device diagram

- Features of the operation of sewer stations

- How the station works

- How to Calculate Receiving Volume

- Installation, start-up and commissioning - how it happens

- KNS service

- Types and types of KNS

- Features of installing a sewer station

- What is KNS?

- How does the KNS work?

Types and categories

Sewer stations are classified according to several criteria.

type of instalation

KNS can have vertical and horizontal execution. The latter are often equipped with a self-priming pump, which forcibly pumps contaminated masses into the KNS casing and removes them after cleaning. Sometimes a reservoir tank may have an additional horizontal compartment on the bottom. This design contributes to the uniform distribution of silt deposits on the bottom of the tank and increases the filling time.

This, in turn, allows you to clean the tank less often, which significantly saves time and money.

Location

By location relative to the ground surface, the SPS can be buried, partially buried and have a ground location.Ground stations are mini-sets located in kitchens, bathrooms and toilets. Buried ones are traditional models with a storage tank dug into the ground, and for partially buried tanks, a tank equipped with sensors, a pump and valves is located in the ground along the neck. At the same time, an automatic monitoring and control system was brought to the surface.

Equipment management

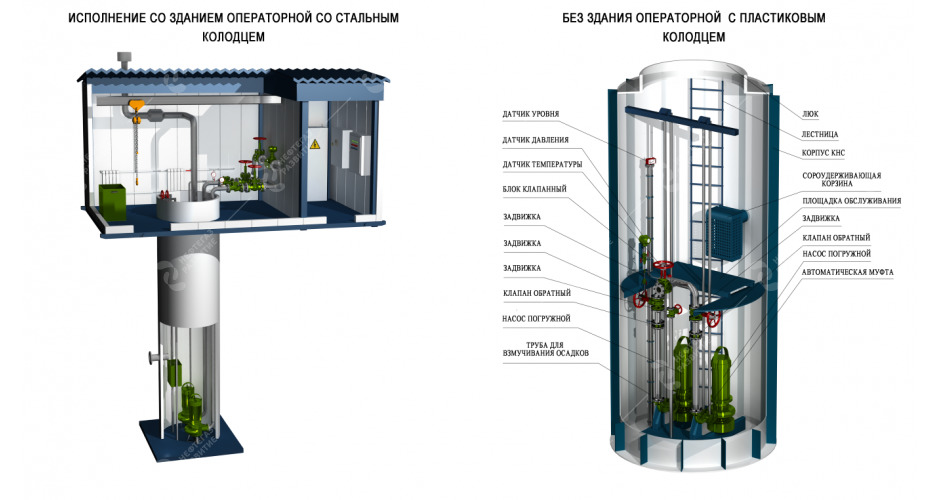

KNS are equipped with manual, remote and automatic control.

- With the manual method, the switching on of the modular equipment is carried out manually by the workers of the stations, who independently check the level of sewage in the tank.

- With remote control, data on the state of the system and the height of the liquid level are sent to the control panel. It is very convenient to control the radio-controlled station: the equipment does not require the constant presence of a person, and in the event of a malfunction, it promptly reports about it.

- The automatic control system is the most common, and consists in controlling the station using relays and sensors, which can be located both on the station body and nearby on the shield.

The nature of sewage

Wastewater is divided into domestic, industrial, storm and sedimentary.

- For industrial waste, tanks and pumps must be made of materials with increased resistance to chemical aggressive substances and high temperatures.

- Stations for the removal of storm water into the sewer are equipped with additional systems for cleaning sand and mechanical debris that rain flows can bring.

- SPS for sedimentary wastewater is used at wastewater treatment plants and is equipped with specialized devices that process sedimentary deposits.

Type of pumping equipment

Three types of pumps are installed on the sewage pumping station.

Submersible pumps with a pressure function require complete immersion in water. The devices have a sealed housing, which is made of high-strength, non-corrosive materials. Fecal pumps are efficient and quite easy to use, they do not need to be additionally fixed or equipped with a platform for them. The device is able to operate at low temperatures, and the cooling of its engine occurs naturally from the surrounding liquid.

When to use the pump

Pumping unit for

sewers are needed to divert effluents under pressure. It is used in

systems located below the laying level of the collector. Such situations

arise if the building is located in a lowland, on a difficult terrain or when

transfer of wastewater through any facilities. For example, when the line crosses

freeway, and it is impossible to use horizontal drilling. Have to do

a vertical portal that bypasses the roadbed from above. Effluent supply according to

vertical pipeline is possible with the help of special equipment -

mud pump.

Basic system design

wastewater disposal is based on the independent movement of wastewater under the action of force

gravity. Gravity networks are cheap, do not require the use of electrical appliances.

However, for their operation it is required to provide a height difference between the initial and

endpoints. This is not always possible, the features of the relief interfere, previously

laid communications or other obstacles.Installing a sewer pump allows

organize the supply of pressurized wastewater to a tank located on the top

the point where the fluid can move by gravity.

Installation of a sewage pump is necessary in

following cases:

- the location of the house in a lowland, a fold of relief;

- the need to transfer wastewater from the basement

premises or from sites located lower than the street sewerage network; - bypassing highways, exclusion zones

electrical cables or communication wires, gas communications; - tracing a line on a hillside, a necessity

lifting wastewater to a higher point; - drainage from industrial installations or

rainwater systems.

In addition to these cases, pumping stations are often used to divert effluents from apartments where reconstruction, redevelopment or repair is being done. In addition, the pump is often used in rooms where the installation of sewerage was carried out with errors and violations of technology. This requires the installation of pressure lines capable of withstanding the operating pressure of the pump. The principle of operation of the sewer installation is to increase the pressure in the pipeline. Drains get the opportunity to move inside a vertical or inclined pipe in the direction from the lowest point to the highest. To avoid blockages in the pressure pipe, some models are equipped with shredders. They grind large inclusions, organics or foreign objects, creating a homogeneous suspension.

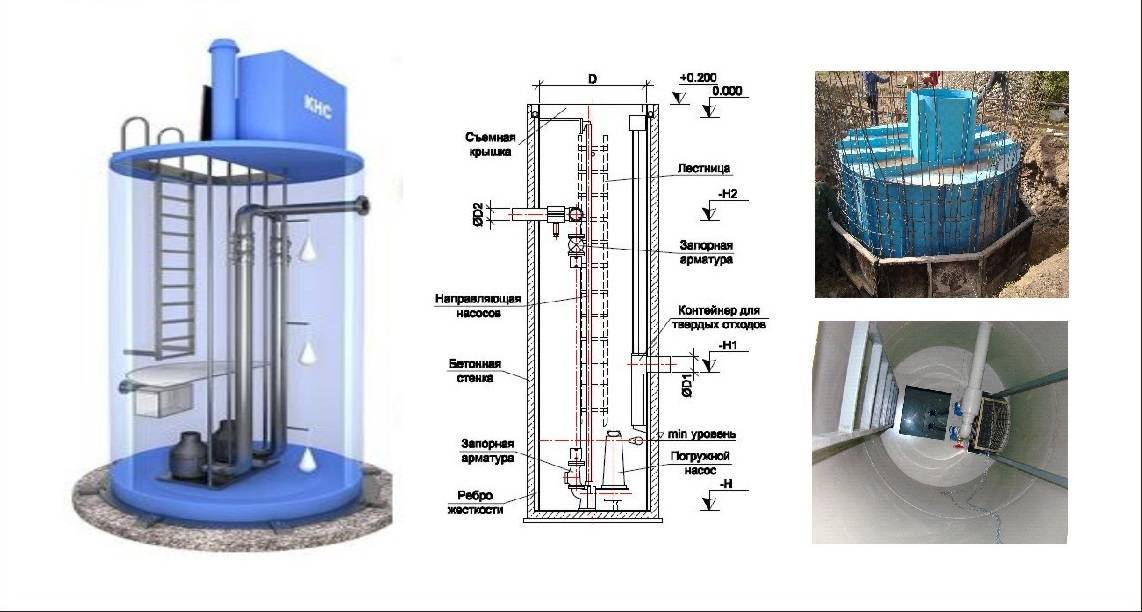

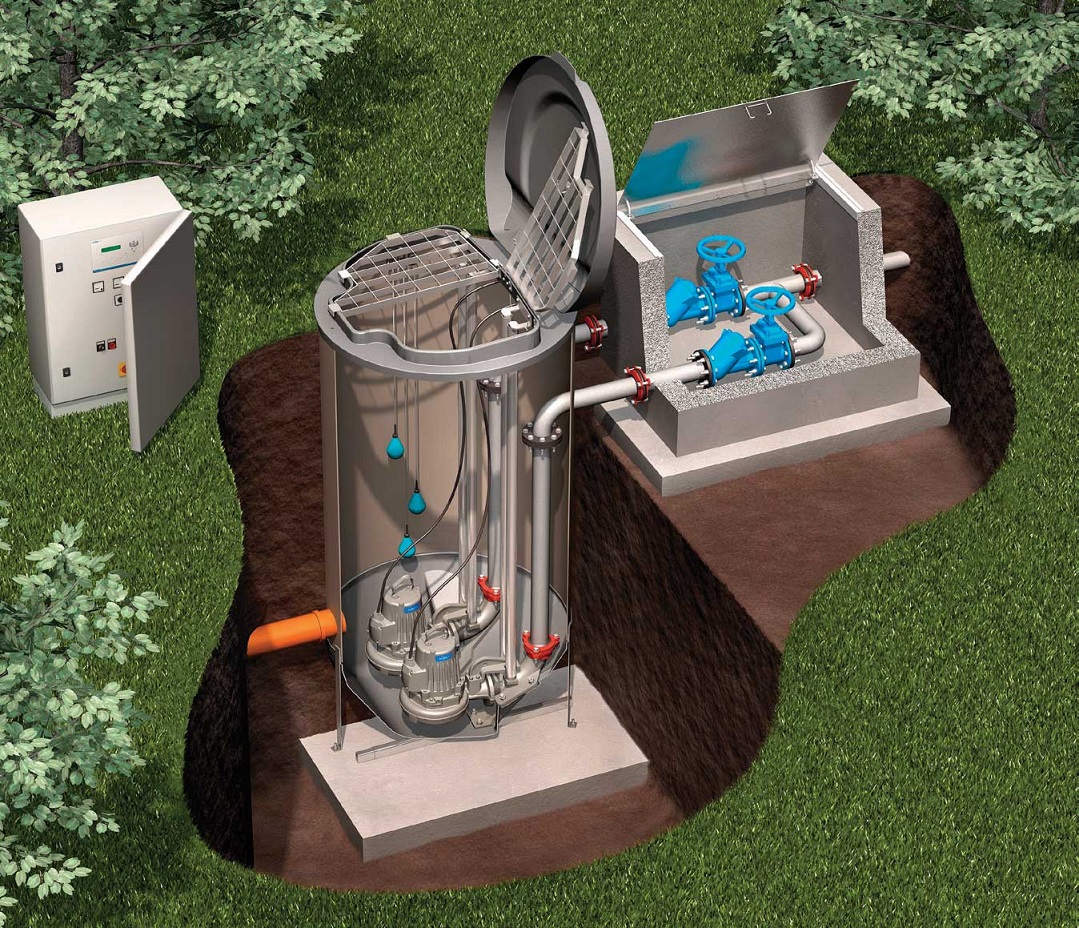

Device diagram

Different types of pumping stations for sewage differ from each other in design, but regardless of the modification, their main elements are a pump and a sealed tank in which waste products are collected. The tank with which the sewer pumping station is equipped can be made of concrete, plastic or metal. The task of the pump, which is equipped with a sewer station, is to raise the wastewater to a certain level, after which they enter the storage tank by gravity. After the tank is filled, wastewater is pumped out of it and transported to the place of their disposal.

SPS device of the middle class

Often, the design scheme of a household sewage pumping station includes two pumps, while the second of them is a backup and is used in cases where the main one is out of order. Several pumps are mandatory equipped with sewage pumping stations serving industrial and municipal enterprises, characterized by a large volume of wastewater. Pumping equipment for SPS can be of various types. Thus, domestic sewage pumping stations are usually equipped with pumps with a cutting mechanism, with which the fecal matter and other inclusions contained in wastewater are crushed. Such pumps are not installed at industrial stations, since solid inclusions contained in the wastewater of industrial enterprises, getting into the cutting mechanism of the pump, can lead to its breakdown.

The device and connection of a small-sized SPS, located indoors

In private homes, mini sewage pumping stations are often installed, the pumps of which are connected directly to the toilet bowls. Such an aesthetically designed KNS (a real mini-system equipped with a pump with a cutting mechanism and a small storage tank) is usually installed directly in the bathroom.

Serial models of sewage pumping stations are equipped with polymer tanks that are buried in the ground, while the neck of such a tank for sewage pumping stations is located on the surface, which facilitates scheduled inspections, maintenance and repair of the tank, if necessary. The neck of the storage tank before the start of operation of the SPS is closed with a lid, which can be made of polymeric material or metal. The connection of such a tank to the sewer system, through which wastewater enters it, is carried out using nozzles. In order for wastewater to enter the storage tank evenly, a special bumper is provided in its design, and the water wall is responsible for ensuring that no turbulence occurs in the liquid medium.

KNS are divided by layout into horizontal (left) and vertical (right)

In equipping sewer pumping stations for a private house, there are control devices and automatic control mechanisms. Additional elements supplied by industrial sewage systems and installations for servicing the home sewer system include:

- a source that provides backup power to the equipment that is part of the SPS;

- pressure gauges, pressure sensors, elements of valves;

- equipment that provides cleaning of pumps and connecting pipes.

According to the design, KNS are with submersible pumps, dry design and multi-section

Features of the operation of sewer stations

When choosing a sewer station suitable for your home, you should remember that different models are designed for different operating conditions. For example, a mini-pump designed to connect to a toilet should not be used to remove drains from a kitchen sink or bathroom.

In addition, if the mini-KNS is designed to be connected to a standard toilet, most likely it will not be possible to use it with a wall-mounted toilet model. Proper operation of the sewage pump equipped with a solid waste grinder deserves careful attention.

Some owners believe that if the SPS has such a function, then any solid waste can be sent to the sewer. This is a dangerous delusion. Of course, if some kind of garbage, for example, personal hygiene products, gets into the toilet, the shredder will process them without much difficulty.

However, it is not designed to carry this kind of load all the time. The grinder must process mainly fecal waste, which has a completely different density, it cannot be used as a garbage disposal. A large amount of pollution not intended for this technique can quickly disable it.

Before purchasing a specific KNS model, you must carefully read its passport and technical specifications.

Particular attention should be paid to the operating conditions of the device, for example, what temperature of the drains the system is designed for

Drainage from a kitchen sink, bathroom, shower, and automatic washing machine or dishwasher can be quite hot. In order to prevent grease from kitchen drains from penetrating the system and creating problematic congestion in it, it is advisable to place a grease trap under the sink.

There are compact models of sewage pumping stations that can be installed under the kitchen sink. But you can not connect a washing machine or dishwasher to such a device.

It is necessary to take into account the permissible drain temperature set by the manufacturer for each specific model. So, sewer pumping stations, into which warm but not too hot sewage can be drained, are suitable for connecting to a shower cabin, bathtub, toilet bowl, bidet, kitchen sink, etc.

However, if you have an automatic washing machine, you should choose a model of a sewage pumping station for your home, into which wastewater with a temperature of 90 degrees or higher can be drained. It should be borne in mind that the mode of operation of such equipment usually involves boiling.

All this also applies to the dishwasher, from which almost boiling liquid can flow into the drain. In addition to the current needs of the house, you should evaluate your plans so that you do not have to buy and install a new sewer station.

If you plan to purchase a dishwasher in the future, it is better to immediately choose a KNS designed for drains with elevated temperatures.

Pay attention to the number and location of pipes.For every new household appliance that may come in the future that needs to be connected to the sewer system, there must be a corresponding outlet

Otherwise, it simply has nowhere to connect.

How the station works

The functioning of the sewage pumping station begins from the moment when the lower compartment is filled with effluents above a predetermined level. In this case, the station starts. At the same time, pumps are turned on that pump waste into a distribution tank, then they enter the pipeline and into the sewer - this is the principle of operation of any SPS.

Watch the video, how it works:

If two or three people live in the house and the amount of waste is small, then one pump is enough. When the volume increases, a second unit can be connected. In this case, the station goes into the maximum load mode, which should be taken into account when designing the cleaning system. The ability to use one or two pumps at once makes it possible to save energy, extending the working life of the station.

If the SPS is unable to cope with the volume of water, then a signal is sent to the operator's console requiring a specific decision on the maintenance of the SPS.

How to Calculate Receiving Volume

The design of a sewage pumping station with submersible pumps involves a number of calculations and the selection of equipment. A suction volume calculation must be performed to ensure correct pump operation. To do this, use the manufacturer's formulas. Of course, it is better if this work is done by professionals. After all, a typical project of a sewage pumping station requires complex calculations, such as:

- Water consumption

- Building a schedule of receipts during the day

- Knowing the allowable amount of liquid used, the volume of waste is obtained

- Find the minimum and average tributaries

- Determine the pressure

And only after completing the calculation of the KNS, you can proceed to the choice of the pump model, taking into account the highest volume of inflow and the value of the pressure.

Next, a pump and pipeline operation schedule is built to determine the maximum pressure point and an analysis of the equipment operation in emergency situations is carried out.

The last stage in the preparation of a typical design of the sewage pumping station is to find the volume of the tank. To do this, a graph is built that displays the inflow and outflow of water by one pump, moreover, by the time that passes between the largest and smallest inflow.

Installation, start-up and commissioning - how it happens

The installation of a sewage pumping station cannot be called simple, because the stations are quite complex equipment, so it is better to entrust these works to employees of specialized enterprises.

The installation of the sewage pumping station must be carried out in a pit, the dimensions of which correspond to those indicated in the attached instructions. At the same time, its bottom is reinforced with reinforced concrete slabs or poured with a concrete solution. To this base, the installation of the SPS is carried out with anchor bolts.

The next stage is the connection of pipelines: inlet and outlet. And they complete the installation work by connecting the power cable, according to the documentation for the design of the SPS.

The installation of pumps is carried out in accordance with the attached instructions and, upon completion, commissioning is carried out. They consist in the installation and configuration of sensors, which are also performed during the maintenance of the sewage pumping station.Moreover, the lower one should be located at a distance of 500 mm from the bottom, and the third and fourth in such a way that they are included in the work when the drains reach the cut of the tray in the supply pipeline, which should be taken into account when designing the sewage pumping station.

Watch the video, installation and installation:

In addition, during the adjustment process, the operating time of the second pump is regulated; it cannot exceed 10 minutes. Adjustment work is carried out by two people - one adjuster controls the readings of the sensors on the console, and the second is engaged in their adjustment.

After completing the adjustment, the performance of the pumps is checked empirically. For this, water is pumped out of the tank.

KNS service

Many are interested in the question of whether it is possible to carry out preventive work at sewer stations yourself? Experts do not recommend performing KNS maintenance on their own. Since the operation of the station is fully automated, its maintenance consists in carrying out scheduled preventive inspections and routine maintenance, which must be carried out by professionals in the maintenance process in order to avoid breakdowns. They also carry out the current repair of the sewage pumping station.

Types and types of KNS

The main part of any sewer system is pumping equipment, which can be of the following types:

- Self-priming;

- submersible;

- Console.

And the pumping station itself, given its location, happens:

- Partially buried;

- Buried;

- Ground.

In addition, all sewer stations are of two types: main and district. As for the main sewage pumping stations, they are used for pumping waste directly from a settlement or enterprise. But the regional ones are designed to divert effluents to a collector or treatment plant.

Also, KNS are divided into remote, automatic and manually controlled.

Remote work in such a way that it is possible to control and regulate their work from an equipped control room. Automatic fully controlled by sensors and devices. And as for the manual ones, all the work lies with the attendants.

Pumping stations also differ in the type of pumped effluent into four groups:

- The first group is intended for domestic waste water. It is used to divert wastewater from public buildings and residential households.

- The second group is for industrial wastewater.

- The third group is for storm networks.

- The fourth group is for precipitation.

Depending on the power of the KNS, there are mini, medium and large. Mini stations are mainly used directly in the bathroom or toilet. They are a small sealed container that is attached to the toilet. The most popular are medium pumping stations, they are used both for domestic and industrial purposes. Household differ from industrial ones in that only one pump can be installed in them. But industrial stations must be equipped with two pumps. Large sewage pumping stations are used exclusively in urban systems. They are equipped with the most powerful pumps in terms of parameters.

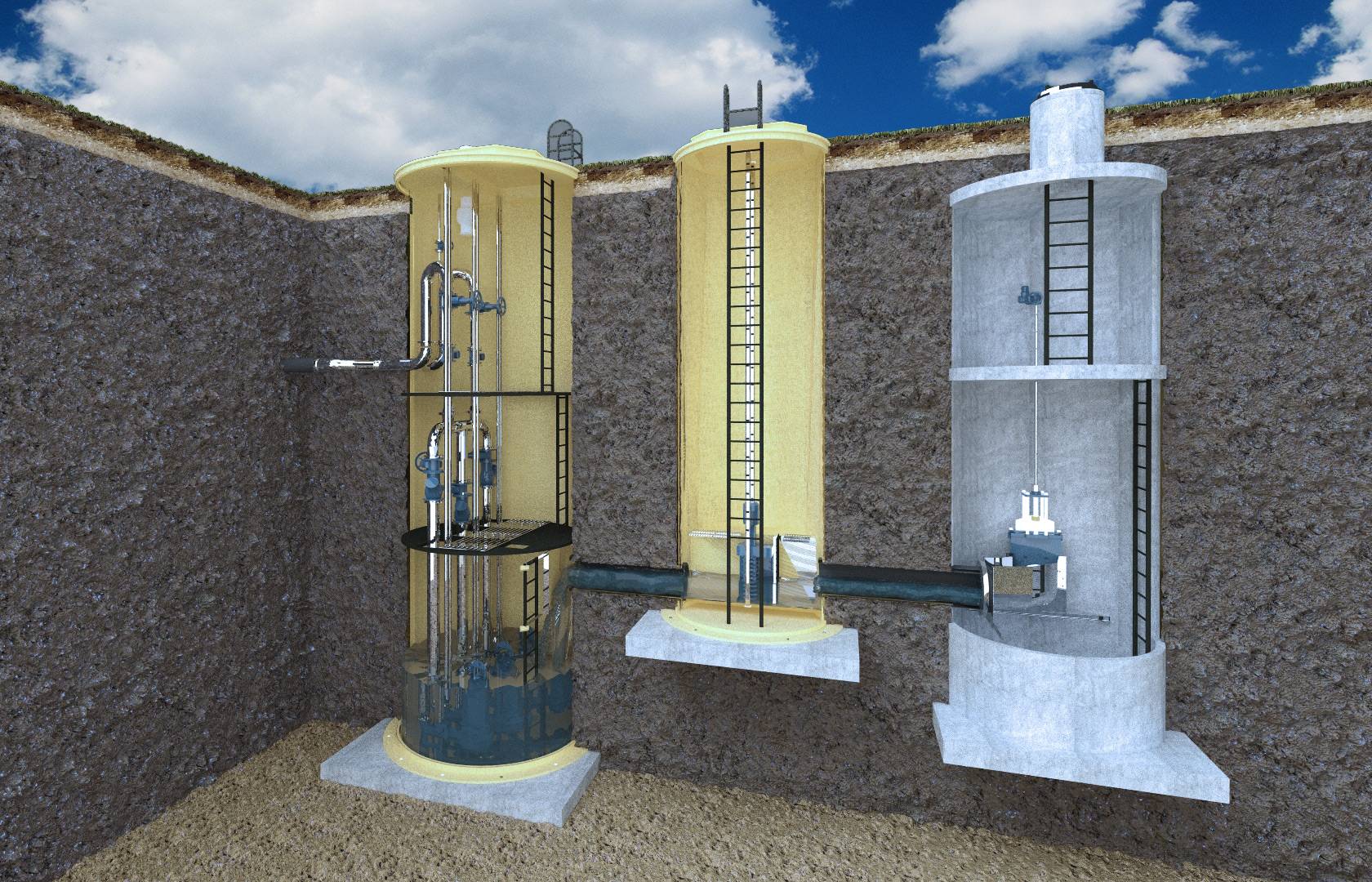

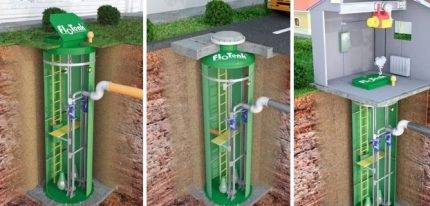

Features of installing a sewer station

Installing a pumping station is a time-consuming and rather complicated task. The SPS tank should be installed at the correct depth. Then the soil is poured around the tank and rammed in such a way that its density is as close as possible to the natural density of the surrounding soil.

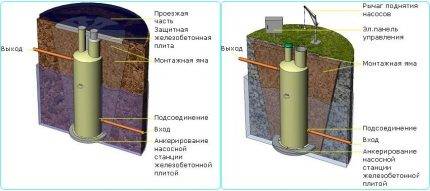

The diagram shows two options for installing large sewage pumping stations. In any case, the device must be protected from bad weather and other external influences.

The diagram shows two options for installing large sewage pumping stations. In any case, the device must be protected from bad weather and other external influences.

In general, the installation of a large sewage pumping station can be represented as the following steps:

- Digging a pit.

- Sand cushion laying.

- Soil compaction.

- Installation of a storage tank in a pit.

- Connection of all pipelines necessary for the operation of the sewage pumping station.

- Installation of a sewer pump.

- Configuring the operation of float sensors.

- Summing up electrical cables, arrangement of grounding.

- Backfilling and tamping of soil.

- Installation of a protective cover.

The depth of the pit should be about half a meter more than the height of the storage tank with the lid. The fact is that the KNS cover should protrude about one meter above the surface, but a sand cushion one and a half meters thick should be laid on the bottom of the pit. When determining the depth of the pit, these parameters should be taken into account.

Large sewer pumping stations are installed in an underground pit so that the cover of the device protrudes about one meter above the ground

Large sewer pumping stations are installed in an underground pit so that the cover of the device protrudes about one meter above the ground

The width of the pit for the sewage pumping station should be such that not only does the tank fit freely there, but there is also room for the necessary installation work. Of course, digging a pit that is too spacious does not make sense, it's just unnecessary work.

The excavation is usually covered with layers of sand and each layer is compacted so that its density matches the density of the surrounding soil by at least 90%.

Upon completion of the installation of the sewage pumping station, it is covered with sand, which should be compacted in layers, creating a density close to the state of the surrounding soil

As mentioned earlier, float sensors are installed at four levels:

- normal degree of filling - 0.15-0.3 m from the bottom of the tank;

- pumping equipment shutdown level - 1.65-1.80 m;

- the level at which the sewer pump turns on is approximately 3.0-3.5 m;

- tank overflow level - 4.5-5.0 m.

After all the elements are installed, it is necessary to check the operation of the system.

To do this, you need a certain volume of ordinary clean water. The liquid can be taken from the water supply or a source of autonomous water supply. If for some reason this is not possible, water is simply brought in a tank.

When installing a sewage pumping station, a sufficiently deep and spacious pit should be dug; a sand cushion is first placed on the bottom of the pit

To check, water is fed into the storage tank until it is full, then the water is poured into the sewer. At the same time, they monitor the operation of float sensors and the operation of pumping equipment, which should turn on and off in automatic mode.

At the same time check all connections for tightness. If a leak is detected, the connections should be resealed.

If there is not enough experience in electrical installation work, they should be entrusted to a specialist. Without fail, the SPS must be grounded

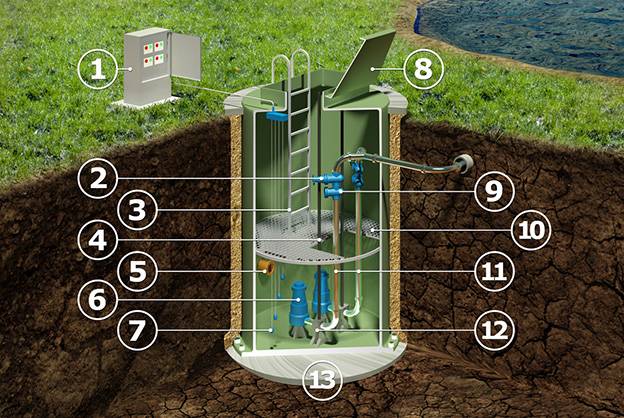

What is KNS?

SPS or sewer station is a device for the forced removal of solid and liquid effluents. Such devices are most often used for industrial purposes.

But there are a number of KNS specially designed for domestic use. They are usually installed in private households with autonomous sewerage or where it is necessary to ensure the transportation of waste to the riser of a centralized sewer system.

Household SPS models can differ markedly in appearance, but their design and principle of operation are quite similar. Such designs are a sealed container designed to collect waste.

A high degree of impermeability of the reservoir is an important requirement to protect groundwater from pollution by runoff. It provides a system of nozzles, as well as a special pump designed for pumping fecal matter

Works sewer pumping station as follows. Effluent enters the storage tank. With the help of a sewage pump, sewage, including solid accumulations, is moved through pipes for further disposal, for example, into a central sewer riser, into a tank of a sewage truck, etc.

This diagram clearly shows the device of a small household sewer pumping station, which can be connected directly to the toilet

KNS are equipped with pumps of various types, including submersible and surface cantilever or self-priming.

Submersible, as the name implies, lower containers with sewage inside. Usually these are very durable units that can work for a long time in an aggressive environment.For such pumps, it is not necessary to equip a place on the surface, as well as additional pipes are not needed to connect them to the system.

But maintenance of a submersible pump can be somewhat difficult. The unit is cooled by the liquid in which it is located; such devices do not often need repair and maintenance. Moreover, submersible models of sewage pumps can work even in very cold environments. For them, the so-called dry installation is considered acceptable.

Pumps with a chopper are used in sewer stations to facilitate the movement of effluents through the system, making their composition more homogeneous.

Self-priming pumps have a wide clearance for the passage of the pumped medium, they are recommended for use with heavily polluted drains. The flange-mounted electric motor greatly facilitates the operation and maintenance of this type of device.

Some types of sewer pumps are equipped with a special heating element. This allows them to be used even at temperatures below zero.

Console pumps are used mainly for industrial treatment plants. For the installation of such a device, a separate foundation is required. Console sewer pumps are considered extremely reliable and convenient, but it is better to entrust their installation and connection to an experienced specialist.

In household sewage pumping stations, one or two pumps can be used, it all depends on the specific situation. If it is necessary to grind solid waste fractions, pumps with a cutting mechanism are used.

It should be understood that such a mechanism is not an omnivorous meat grinder. A piece of rag accidentally dropped into the drain can lead to serious blockage and even damage to the pump.

The so-called mini KNS deserve special attention - these are pumping stations of a relatively small size, designed to be connected to only one object, usually a toilet. They are a complex of a small storage tank and a pump with a cutting mechanism. Such sewer stations are usually installed directly under the toilet.

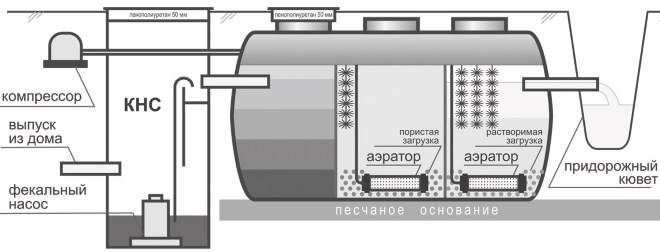

How does the KNS work?

The CNS has a fairly simple principle of operation.

- Waste water from the sewer system enters the receiving part of the installation, from where it is pumped into the pressure pipeline.

- Through the pressure pipeline, wastewater is transported to the distribution chamber, from where it is then pumped to the treatment plant system or to the central sewer.

Scheme of sewage treatment of a private house using SPS

In order to prevent wastewater from returning to the pump through the pipeline, the sewage pumping station is equipped with a check valve. In the event that the volume of wastewater in the sewer pipeline increases, an additional pump is switched on at the station. If the main and additional pumps for the sewage pumping station cannot cope with pumping the volume of wastewater, then the device automatically turns on, signaling an emergency situation.

The principle of operation of the SPS for industrial use provides for automatic control of such installations, which is provided by float-type sensors installed at different levels of the station's receiving tank. SPS equipped with such sensors operates according to the following principle.

- When the level of effluents entering the tank reaches the level of the lowest sensor, the pumping equipment remains turned off.

- When the tank is filled with sewage to the level of the second sensor, the pump automatically turns on and starts pumping wastewater.

- If the tank is filled with wastewater to the level of the third sensor, then the backup pump is turned on.

- When the tank is filled to the fourth (uppermost) sensor, a signal is triggered, indicating that both pumps involved in the sewage pumping station cannot cope with the volume of wastewater.

Scheme of automatic control of the work of the sewage pumping station

After the level of wastewater pumped out of the tank drops to the level of the lowest sensor, the system automatically turns off the pumping equipment. The next time the system is turned on for pumping wastewater from the tank, the backup pump is activated, which allows both pumping devices to be operated in a gentle mode. The operation of the station can also be switched to manual control mode, which is necessary in cases where the maintenance of the sewage pumping station or its repair is carried out.