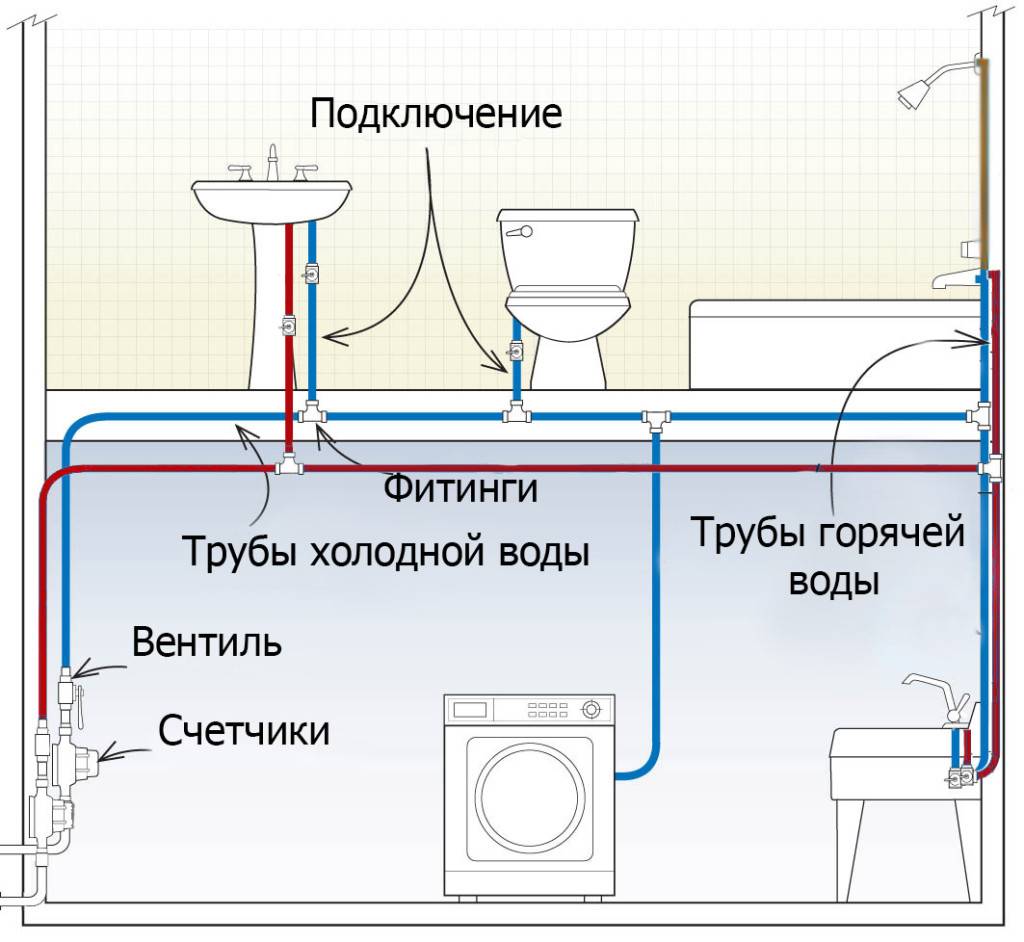

- General Installation Guidelines

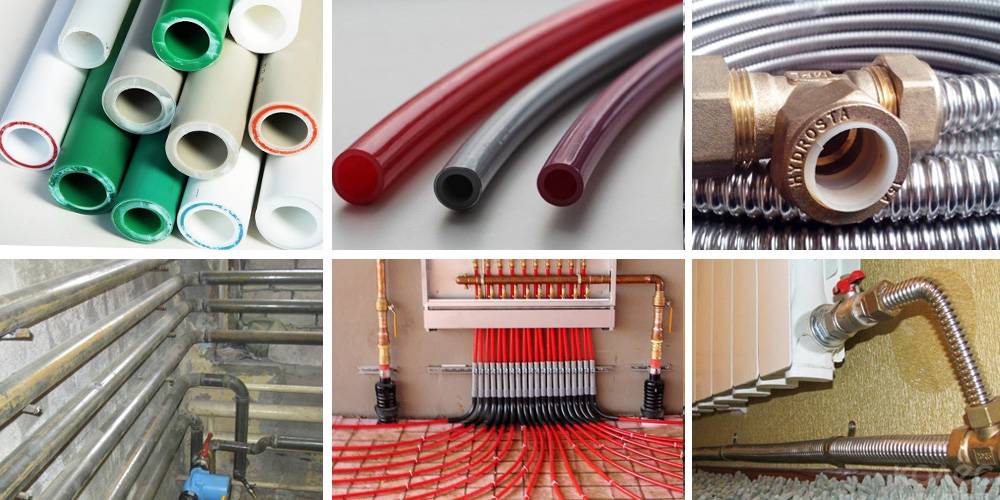

- Other types of polymer pipes

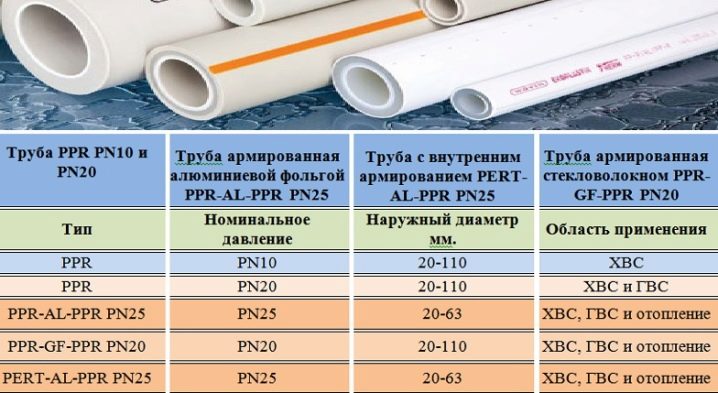

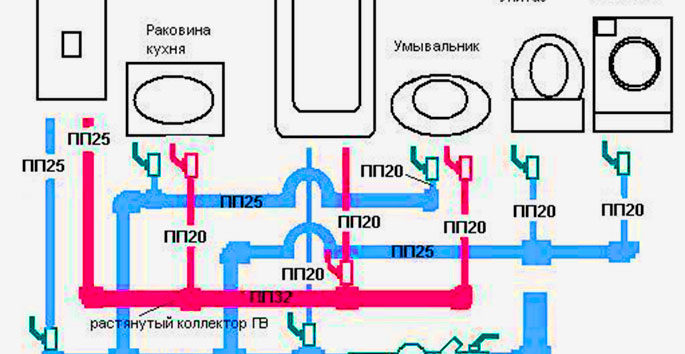

- Polypropylene pipes

- Polypropylene

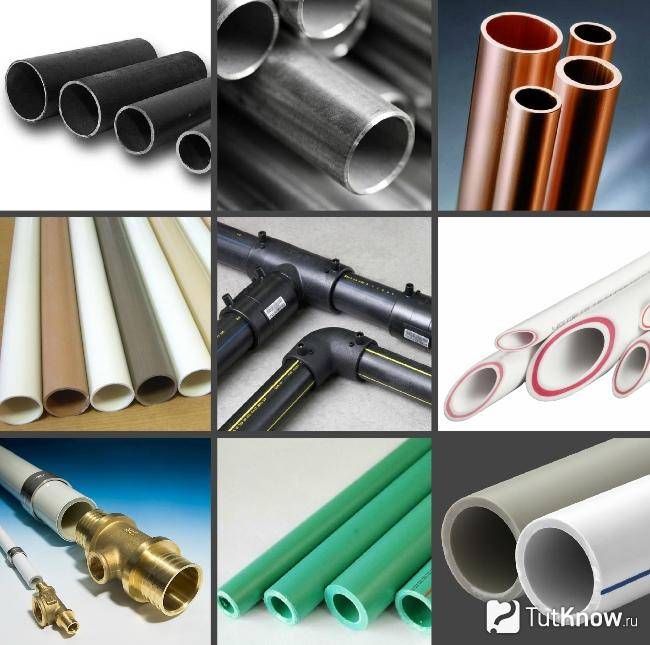

- Which pipes to choose

- Steel pipes

- steel galvanized

- Copper pipes

- Polyvinyl chloride pipes (PVC)

- Low pressure polyethylene (HDPE)

- Polypropylene pipes (PP)

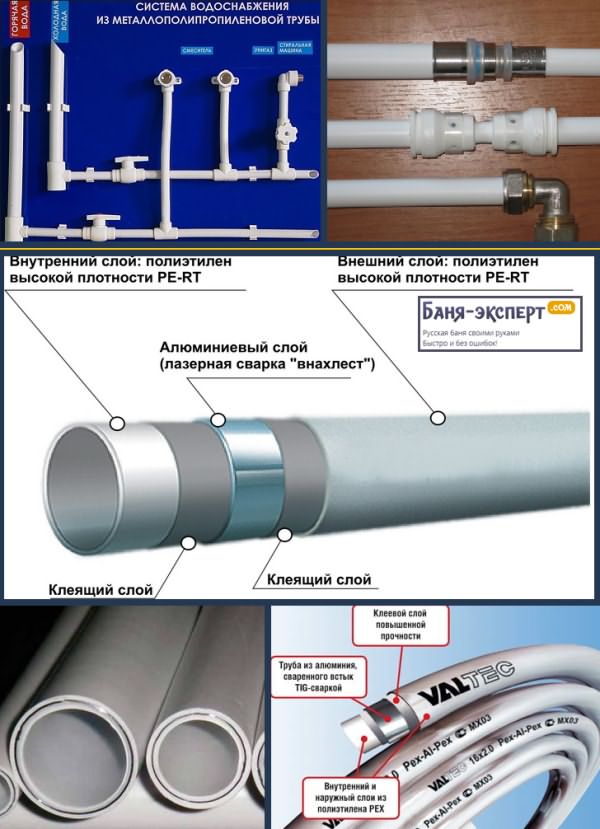

- Metal-plastic (MP)

- No. 2. What to consider when choosing heating pipes?

- Metal-plastic pipes - technical characteristics:

- Applications - coverage through technical features:

- Plastic: installation nuance, easy tie-in with fittings in an apartment and at home

- Steel pipes

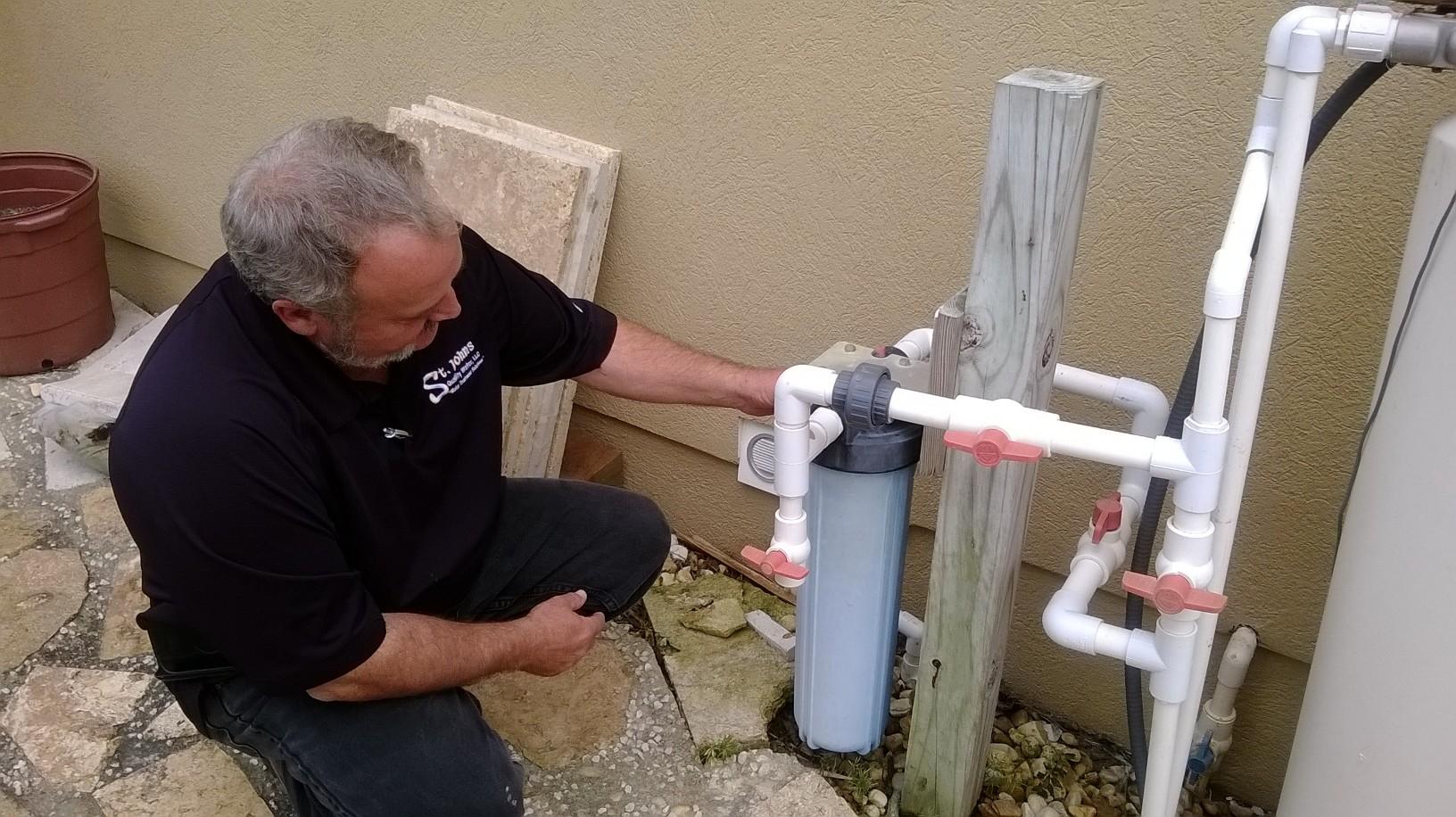

- Installation of external water supply

- Features of the implementation of welded joints

- Mounting technology with fittings and flanges

- Advantages of polymer pipes and technical products

- How to choose pipes

- Copper pipes

- No. 5. Stainless pipes for heating

- No. 1. What should be the heating pipes?

- Metal-plastic plumbing: advantages and disadvantages

- Performance characteristics

- Varieties of structures made of metal-plastic

- Dimensions and diameters

- What temperature can a metal-plastic pipe withstand

- What pressure can a metal-plastic pipe withstand

- Types of pipes for water supply and features of their choice

General Installation Guidelines

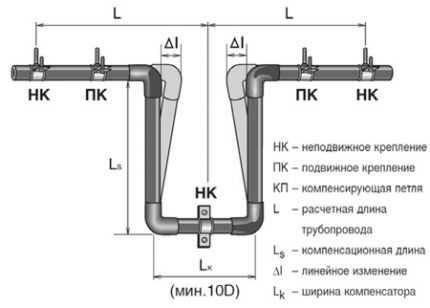

When choosing suitable materials, it is desirable to give preference to products with a one-piece connection. Compensation loops or U-shaped bends can be installed on sufficiently long sections.

After the installation is completed, access to each installed connection must be open, excluding soldered and welded seams. First of all, such requirements apply specifically to metal-plastic products. The duration of use of household appliances or individual elements of domestic plumbing will be extended in a situation where a filtering device is installed in the water pipe at the entrance to the building. Homeowners are given a choice of a large number of all kinds of communications, fittings, fixing elements, fittings, etc.

Other types of polymer pipes

In addition to polypropylene pipes, pipes made of other polymeric materials can also be used to create a plumbing system, although they are not so popular.

Polyethylene pipes are quite cheap, and they are very well suited for cold water supply, but only in non-pressure systems, since they can deform and even break due to the softness of the material. Installation of pipes is mainly carried out by welding, but with the obligatory use of compression fittings.

Cross-linked polyethylene is an improved version of polyethylene, pipes made of it can also be used for hot pressure water supply, but at a water temperature not higher than 60 degrees Celsius and a pressure of less than 10 atmospheres. Such pipes are connected only with fittings, welding is not required.

Polyvinyl chloride (PVC) pipes. Such pipes can also be used to create a plumbing system.They hold fairly high pressure well, but are not recommended for use at operating water temperatures over 40 degrees Celsius. They are more commonly used for sewers, but due to their relative cheapness, many homeowners prefer them for plumbing.

In conclusion, it should be said that in this study only the most popular types of pipes that are currently used to create home plumbing systems were considered. However, the range of such products is much wider, and each homeowner can choose exactly the type of pipes that best suits his purposes. This allows you not to overpay for the versatility of pipes, when you have to pay money for those qualities of the product that are completely unnecessary.

Share

- 5

shared

Polypropylene pipes

If the budget allocated for construction is not too large, then polypropylene pipes will be a good option for arranging a water supply system. They are cheaper than other polymer products, and in some places even surpass them in terms of characteristics: the operating temperature of polypropylene is +95 degrees, and the pressure is up to 20 atmospheres. In addition, it is worth noting the service life, which on average is about 50 years. It remains only to decide which polypropylene pipes are better in order to make the final choice.

The disadvantage of polypropylene products is the lack of plasticity, therefore, installation of the pipeline at an angle is possible only with the help of appropriate fittings. Permanent connections of such pipes are carried out using a special soldering iron.In any case, before purchasing, you need to carefully understand which propylene pipes are best for plumbing, and prepare the equipment necessary for installation.

Polypropylene

Polypropylene cold water pipes attract many homeowners with their affordable price. The cost of products can reach 20-25 rub per linear meter with a standard pipe diameter of 20 mm. To connect such pipes, special fittings are used, which are also affordable.

Other quality characteristics can also please users:

- The duration of the operational period of products, the temperature of the working environment in which does not exceed 20 degrees, can be 50 years or more.

- The operating pressure indicator can be from 10 to 20 kg / sq. cm;

- Welded joints are durable and tight.

Polypropylene pipes can be hidden in strobes or cement screed without any leaks in the near future.

Which pipes to choose

Since today it is easy to find pipes of almost any type, we will try to give characteristics to the most common and used in practice.

Steel pipes

Cheap, strong, but not durable enough, the reason for this is low corrosion resistance. It is declared that their service life is 25 years, but in practice, after 5-6 years they begin to clog with rust, defects appear in weak places. They are practically not used in modern water supply or heating.

steel galvanized

A little more expensive than steel, durable, service life up to 30 years (with skillful installation). Mounting with threaded connections is preferable, since corrosion resistance is violated during welding.The service life is also reduced when fittings made of other metals are used. They are mainly used in heating systems.

Copper pipes

Expensive, durable, very reliable, have antibacterial properties. They are often soldered together. Installation of unannealed pipes is difficult. Annealed can be connected using compression fittings, but the strength in this case is reduced.

Copper pipes are an excellent but costly choice for plumbing installations.

Polyvinyl chloride pipes (PVC)

Durable and frost resistant. They are mainly used as pressure pipes for water supply of water engineering facilities (pools, water parks), in energy, chemical industry, etc. Mount them with special glue. Due to the presence of chloride in the composition of this material, it is not recommended to use them in domestic water systems.

Low pressure polyethylene (HDPE)

Cheap flexible pipes for water supply from polyethylene. They do not rust, they are easy to install, but they also have disadvantages:

- can not be heated above 70C;

- become brittle at low temperatures;

- fittings are quite expensive for them.

Polyethylene pipes - a democratic way to organize water supply

Polypropylene pipes (PP)

Quite expensive, durable, but not very durable pipes for drinking water supply. Special multilayer polypropylene pipes can withstand temperatures up to 120C, but fittings for them (also made of polypropylene) usually withstand a maximum of 75-90C. They are not afraid of freezing, look good during installation.

The cost in the ratio "pipe-fittings-installation" is considered the most democratic. But these pipes also have disadvantages:

- they practically do not bend;

- during installation, you need a special soldering iron, the connections are non-separable;

- can not be mounted at temperatures below + 5C;

- transitional fittings "metal-plastic" are ten times more expensive than usual ones.

Polypropylene pipes and fittings

Metal-plastic (MP)

Not the most expensive, reliable, but not very durable pipes. They hold temperatures up to 90C, they are not afraid of freezing, they bend well, they look good, a minimum of tools is needed for installation. It is believed that this is perhaps the best option for self-modernization of the water supply system.

Main disadvantages:

- they are afraid of external shocks, they can break if they are inaccurately bent;

- fittings sometimes unwind from temperature changes in water.

Metal-plastic pipe

We hope that the article will really help you choose the most appropriate option for upgrading the water supply system in an apartment or house.

No. 2. What to consider when choosing heating pipes?

There are no universal pipes that would function equally well in different rooms. To select the best pipes for heating, i.e.

the most optimal and suitable in specific conditions, it is necessary to take into account the following factors:

- temperature and pressure in the system, which largely depend on what kind of heating is used, individual or centralized. In individual systems, the pressure rarely exceeds 2-3 atmospheres, and in centralized systems it can rise to 16 atmospheres;

- type of pipe laying, outdoor or hidden;

- total area of heated housing;

- design capacity of the boiler and type of fuel (for private houses);

- pipeline operating conditions. This refers to the presence of unheated premises in certain areas;

- the possibility of repair.

All characteristics of pipes depend on the material of their manufacture - this is the most important parameter that must be considered when choosing.

Metal-plastic pipes - technical characteristics:

- outer diameter 16-63 mm;

- wall thickness 2-3 mm;

- aluminum layer thickness 0.19-0.3 mm;

- the weight depends on the diameter, for example, one meter of a metal-plastic pipe with a diameter of 16 mm weighs 105 grams, and if the diameter is 63 mm, then the weight of one meter is 1224 grams;

Metal-plastic pipes withstand pressure:

- operating pressure 10 bar (at 95 °C);

- operating pressure 25 bar (at 25 °C);

- bursting pressure 80 - 94 bar (at 20 °C);

Metal-plastic pipes withstand temperatures:

- constant load +95°С;

- short-term load — up to +110°С;

- at a temperature of -40 ° C freeze;

- with manual bending, the minimum bending radius is 80-125 mm (depending on the outer diameter);

- when bending with a pipe bender - 45-95 mm (depending on the diameter);

- coefficient of linear expansion 1/°C - 0.26 x 10-4;

- thermal conductivity of metal-plastic pipes (the amount of heat that the material is able to pass through a square meter per second) W / m * K - 0.43;

- oxygen diffusion 0 g/m3 (does not let air through);

- service life: a) 25 years at 95°C; b) 50 years at 20°C;

- throughput is 1.3 times higher than that of steel.

The advantages of pipes made of metal-plastic

For anyone who decides to purchase this material, operational characteristics are much more important than technical ones. First the positives:

- ecological cleanliness;

- resistance to the formation of rust, stones or other deposits;

- the ability to maintain a newly acquired shape after bending;

- the possibility of profiling to wrap around the structural elements of the building;

- easy and quick assembly that does not require many tools;

- minimum waste;

- flexibility allows you to save on connection elements;

- low resistance to fluid flow due to the absence of roughness;

- compatibility with other materials;

- light weight for easy transportation;

- high levels of sound insulation;

- antistatic;

- resistance to condensate and freezing (metal-plastic withstands triple freezing);

- do not change the quality of the transported liquid;

- high maintainability;

- aesthetic appearance without painting.

All the advantages of metal-plastic pipes are obtained due to the unique design. The inner polyethylene layer makes it possible to bend the product. Aluminum provides rigidity and prevents oxygen diffusion. The absence of oxygen prevents rust from forming in boilers and radiators.

Flaws

When choosing and buying metal-plastic pipes, negative characteristics are just as important to consider as positive ones:

- with a hidden pipeline, threaded fittings cannot be used;

- metal-plastic does not tolerate ultraviolet rays;

- when freezing with water, the system will certainly burst, although they are suitable for installing an external pipeline. In this case, high-quality insulation is necessary.

Metal-plastic pipes are supplied in bays. The length of the pipe in the bay varies from 50 to 200 meters. You can buy any length, starting from a meter.

Applications - coverage through technical features:

- internal systems of cold and hot water supply, heating of apartments, houses and cottages;

- floor heating systems, sports grounds, swimming pools;

- transportation of gaseous and liquid substances (including caustic and poisonous) in industry, agriculture and transport;

- compressed air supply;

- air conditioning systems;

- protection of electrical wires and cables;

- construction and repair of river and sea vessels, railway cars;

- systems of watering, irrigation, collection of water from wells and wells.

A sufficiently long service life and an optimal ratio of cost and quality have allowed metal-plastic pipes to establish themselves as a successful alternative to metal and plastic products. After all, metal-plastic combined the positive qualities of both of these materials.

Increasingly, when creating plumbing and heating systems in residential buildings, metal-plastic pipes are used.

However, in order to make the right choice, it is important to know not only the features of the structure and operation of pipes consisting of a composite material, but also the pros and cons of these products.

Plastic: installation nuance, easy tie-in with fittings in an apartment and at home

Plastic pipes for water supply are the most practical option, both in terms of installation and further operation. Plastic water pipes are durable, last extremely long and do not require additional maintenance. Installation can be done even by an untrained person, the main thing is to follow the instructions and not confuse anything.

WATCH VIDEO

Plastic water supply is classified as follows:

The only negative that is observed here is that during installation you will have to cut a lot to make it beautiful. But here is the plus of plastic pipes - the material is durable, in acquisition and maintenance, therefore it is the best suited for plumbing.

Installation of plastic pipes is simple, specialists take inexpensive work for such work, but you can do this work yourself

It turns out that it is not so difficult to deal with the choice of pipes, the main thing is to first pay attention to future operating conditions, correctly measure the length of the pipeline for each room. Do not forget to calculate the pressure in the heating using the formulas, so that in the event of a jump, a breakdown does not occur and you do not accidentally flood your neighbors. It is not difficult to choose pipes for plumbing in an apartment, the main thing is to know all the nuances!

Steel pipes

Until recently, some decades ago, water pipes in our country were made of metal, namely, steel. And today in many houses you can find just such pipes, which, despite the shortcomings, are still used quite effectively. The main disadvantage of a steel pipe is its susceptibility to corrosion. To protect against it, the inner part is galvanized, zinc is not afraid of corrosion, therefore it reliably protects steel from the appearance of destructive rust for a very long time.

Good old steel water pipes

Good old steel water pipes

The second drawback is that such pipes are quite heavy. However, the positive qualities largely offset the shortcomings - steel pipes are very durable, withstand high pressure, and are suitable for pumping not only very hot water, but also steam. If the corrosion protection is performed with high quality, then steel pipes can serve without replacement and repair for many decades.

In everyday life, steel pipes, as mentioned above, are still used. These are the cheapest pipes that can be used to create a domestic plumbing system.True, very often they become clogged, but blockages can be dealt with using mechanical or chemical means - steel, even galvanized, is not scratched and is not afraid of chemistry, which destroys blockages. Connectors for the installation of such pipes are available in stores in a very large assortment, so even on this side, steel pipes are the most profitable option for creating a very durable, practical, but at the same time inexpensive domestic plumbing system.

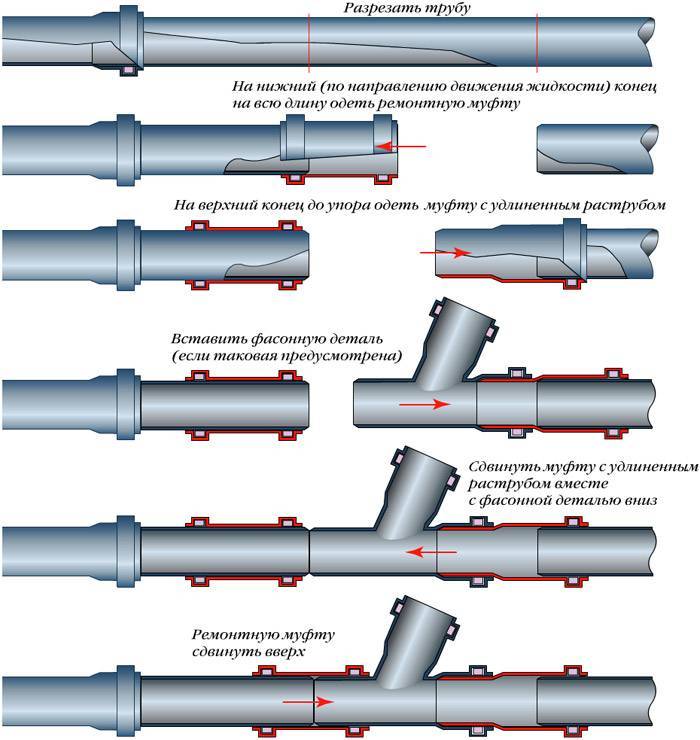

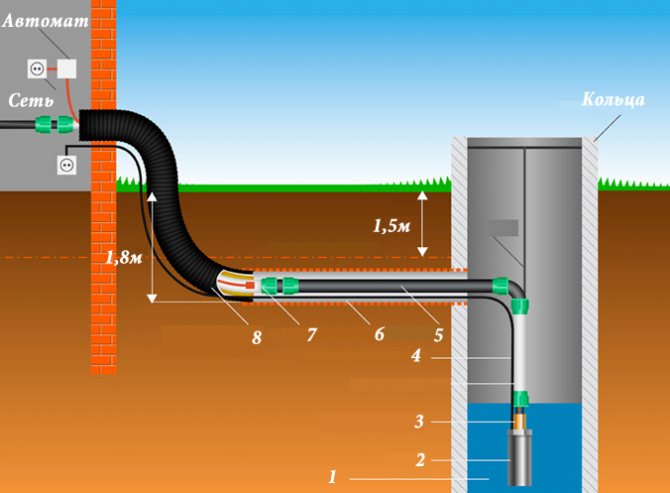

Installation of external water supply

Pipes are laid at the bottom of the dug trench in the direction from the source of drinking water to the house. The connection of plastic pipes to each other can be performed in two ways:

- by welding;

- using fittings and flanges.

Features of the implementation of welded joints

Butt or electrofusion welding can be used to fasten HDPE pipes. The connection with the help of an electric coupling is used when laying polyethylene pipes of small diameter and considerable length, as well as when inserting into an existing water supply system and installing a water supply system in cramped conditions.

Connection of HDPE pipes using electrofusion welding

Welding is more common and efficient. butt with a heated tool, which serve as welding machines of various capacities and modifications. This method provides high fixation strength of individual elements of the water supply system, which is comparable to similar parameters of a homogeneous HDPE pipe. The quality of the weld depends on the technical characteristics of the welding machine, the skill of the performer and the thoroughness of the surface preparation of the material.

Butt welding of outdoor water pipes

When working with welding equipment, with the help of which polyethylene pipes for external water supply are connected, the following rules must be observed:

- the surface to be treated must be clean, dry and degreased;

- all work is carried out at a temperature of at least +5 ° C;

- to improve the quality of the seam for pipes with a diameter of more than 50 mm, it is desirable

- chamfer at a 45° angle.

To cut the pipes into parts of the required length, it is better to use special scissors for plastic, which allow you to get even cut edges.

Scissors for cutting plastic pipes

Mounting technology with fittings and flanges

Flange connections are used to connect plastic pipes with a diameter exceeding 63 mm in conditions where the use of welding is limited, as well as when connecting shut-off and control equipment. They are easy to install and come in a wide range of sizes. Connect HDPE pipes using flanges and fittings as follows:

- using scissors or a pipe cutter, the edges of the pipes are cut at a right angle according to the previously applied markings;

- clean the resulting surfaces from dirt, for which you can use liquid soap or dishwashing detergents;

- the fitting is partially disassembled by unscrewing the union nut three or four turns, and then the pipe is inserted into it to the applied basting and the nut is screwed on.

Compression fittings

Pay attention to the force applied to connect the pipe and fitting. It must be significant so that the bonding point is airtight.

Advantages of polymer pipes and technical products

Consider the main advantages of technical pipes:

- Light weight makes the installation process much easier;

- Pipes are resistant to corrosion;

- The connection of pipe structures is carried out both by welding a seam and using special PVC fittings. This will greatly reduce the installation time;

- Long operating period;

- Due to the elasticity of the pipes will not burst when iced;

- Any homeowner can install a plumbing system from such pipes on their own without prior professional training;

- Absolute material safety. No toxic harmful substances are emitted;

- Relatively low cost of pipe structures made of HDPE.

Advantages of polymer products:

- High duration of the operational period;

- Relatively light weight;

- Corrosion resistance;

- Low thermal conductivity;

- Plaque does not form on a smooth surface;

- High throughput of products;

- Assembly and installation can be done without any difficulty.

Polymer pipes can be used for about 30 years. Propylene pipes are characterized by high throughput. Metal structures can become clogged after some time.

How to choose pipes

When choosing products, you need to take into account the visual characteristics of the pipes, as well as other features:

- The materials must be homogeneous, not contain any inclusions;

- The pipes must be marked and indicated GOST, in accordance with which they were manufactured;

- Unpleasant smell in such pipes should be completely absent;

- The wall thickness must be the same along the entire length of the product;

- The surface of the pipe must be smooth.

With the full compliance of the selected pipe with all the above points, the product can be called of sufficient quality. Such a pipe is great for installing a line in a cold water supply system. Poor quality products can only be used to meet the simplest technical needs.

A pipe that can be installed in a cold water supply system is marked with a blue strip along the entire length of the product, painted in black. Pipes used for such purposes are also painted blue.

HDPE pipes for cold water supply systems are often marked by embossing or imprinted, the following information is indicated on the products:

- Purpose and GOST;

- Overall dimensions, or the ratio of wall thickness and diameter;

- Product strength factor. PE100 high quality manifolds. PE80 pipes of a lower class;

- Manufacturer's name;

- The footage is not indicated by all manufacturers.

The cost of products also requires attention in the process of choosing the right product. If the price per meter of pipe is lower than the market average, then the buyer is faced with a fake, or a product designed for simple household needs.

Copper pipes

It is today that copper has risen in price a lot, and in Soviet times copper pipes could be bought very inexpensively. Another thing is that they were not sold as widely as we would like, but whoever needed it could always order such pipes in the workshop. But today copper has risen in price greatly, so only those people who perfectly understand their advantages and do not spare money for reliability install plumbing systems from it.And the advantages of copper over steel are as follows - copper pipes are very light, they do not corrode, they do not create blockages, they are almost eternal, even if they are used in hot water systems. In addition, they look great, and they can not be hidden under the wall cladding.

Copper water pipes

Copper water pipes

However, such pipes, in addition to their high cost, also have disadvantages - copper pipes have thin walls, therefore high-pressure water systems cannot be made from them.

In addition, copper is a soft material, and the pipe can be easily damaged by crushing it with careless handling. In addition, connectors that would be suitable for assembling copper piping are rare in stores even today, in the absence of, it would seem, any shortage.

No. 5. Stainless pipes for heating

Corrugated pipes made of alloyed stainless steel are devoid of many of the disadvantages of a steel counterpart. They are used for arranging heating systems in new houses, as well as for reconstructing the heating system in old ones, they have gained great popularity in arranging underfloor heating, hot and cold water supply. Such a wide scope is explained by the main feature of this type of pipe - the ability to bend.

Advantages:

- stainless corrugated pipes are resistant to corrosion, do not collect scale on the walls, are durable;

- resistance to water hammer and external mechanical influences;

- slight thermal expansion;

- flexibility, and such a pipe bends with little or no reduction in the inner diameter. This is convenient when space for mounting the heating system is limited.In addition, complex system configurations can be installed with a minimum number of connections. This feature has made stainless pipes very popular in the arrangement of water heated floors;

- high heat transfer;

- relatively simple installation;

- wide scope of use.

The downside, as you might guess, is only one - the cost, but it pays off with durability and ease of installation. Another unpleasant feature is the low durability of the sealing rings, about 30 years.

No. 1. What should be the heating pipes?

The purpose of heating pipes is clear even to a child. They must transport hot water from the boiler, whatever it is, to the radiators. This is a very important part of the heating system, the quality of which affects not only our comfort, but also safety.

The following minimum set of requirements is put forward for heating pipes:

- strength and durability. During the entire service life of the pipe must maintain integrity. If minor damage occurs and oxygen penetrates through them, the pipes can begin to rust from the inside and become clogged. Large damage will lead to leakage of the coolant, and this, in most cases, is hot water. The consequences of all this can be catastrophic;

- low noise in work, because constantly listening to the sounds of water bubbling is a test for the nervous system;

- aesthetics. It is not always possible to hide pipes in the walls or disguise them, so they should not frighten with their appearance and, moreover, spoil the interior.

Metal-plastic plumbing: advantages and disadvantages

If you deal with the advantages and disadvantages of a water supply system from metal-plastic pipes, then the latter will be many times more. Let's make a reservation right away - for comparison, we take into account materials of approximately the same price category and the same quality - so to speak, the golden mean. Let's start with what is more - with the disadvantages.

- fragility. We are not talking about the pipe itself, and not even about its fittings - this refers to the ability of pipes to perform their main tasks of transporting water without leaks. With this, metal-plastic pipes have big problems - after a year of operation, leaks appear. You have to tighten the nuts, change the rubber seals in some fittings, and some even replace them with new ones. And the most interesting thing is that this process is endless and repeats from year to year. Things are a little better with a metal-plastic pipe assembled on compression fittings - instead of nuts, a special press is used to connect the elements of the system. The main catch in such systems is that you need to use all the elements (including the press) made by one manufacturer.

-

The unreliability of the pipe itself - the aluminum insert, designed to make the pipe strong and reliable, does not have a solid structure. In most cases, it is twisted and easily torn even when the pipe is bent with a special spring. For a cold water supply, this is not critical, but if hot water is supplied through such a pipe, then problems may arise. If you already choose this material, then carefully study the characteristics of the water pipes that you are going to buy and make sure that the aluminum insert is seamless.

These two main shortcomings drag along with them all the other troubles, which are expressed in the impossibility of laying such a pipe in a hidden way and similar problems. In principle, the shortcomings of this pipe can be listed further, but I don’t see the point in this - two main ones are quite enough to refuse to use this plumbing system in residential premises.

Of the advantages, one can note a simple assembly, available for self-implementation, as well as a low cost of material.

Characteristics of water pipes

Performance characteristics

To figure out which material is better for a metal-plastic pipe or a variety of polyethylene, it is better to immediately compare the technical characteristics of each type:

| Characteristics | MP pipes | Polypropylene products | PVC structures |

| Max pressure | 15 atmospheres | 30 atmospheres | 120 atmospheres |

| pressure to work | 10 atmospheres | From 16 to 25 atmospheres, depending on the selected diameter | 100 atmospheres |

| Maximum temperature | 120 °С | 120 °C, at 140 °C the material begins to melt | 165 °С, begins to melt at 200 °С |

| constant temperature | 95 °С | From 40 to 95 degrees depending on the selected diameter | 78 °С |

| Thermal conductivity | 0.45 W/mK | 0.15 W/mK | 0.13 to 1.63 |

| Life time | 50 years | 10 to 50 years, depending on operating temperature and pressure | 50 years |

Varieties of structures made of metal-plastic

- Metal-plastic pipes reinforced with aluminum foil - during production, first the foil sheets are welded together by ultrasonic welding, then, using an adhesive (natural or synthetic), the manufacturer connects two layers of cross-linked polyethylene and an aluminum layer, which makes them more flexible, but less durable and with a lower index temperature stability.

- MP products reinforced with a rigid mesh frame - since not only different metals can act as the central link, but also forms that are different in the way they are made (mesh, wire, strips), the technology of each type will be different. The technological process of production is as follows - when stretching the longitudinal reinforcement from plastic, a transverse winding of the metal frame occurs, which is welded to the surface of the inner layer of the future product using a special electrode. Further, the structure is again filled with a melt of the upper layer of plastic. This method of production occurs without gluing with various types of adhesives, which increases the duration of the service life.

In comparison with other types of polyethylene structures, metal-plastic structures serve without constant repairs.

Dimensions and diameters

The most commonly used diameters metal-plastic pipes are from 16 to 26 mm. However, the manufacturer produces fittings with a larger diameter - up to 63 mm.

When choosing the right size of a metal-plastic product, it is necessary to be guided by the future place of operation, so metal-plastic pipes with an inner diameter of 16 mm and 20 mm are better suited for plumbing (16 mm pipes are used for taps to plumbing).

To build large heating or plumbing distributions for residential buildings, metal-plastic pipes with a size of up to 40 mm can be used, but structures with an outer diameter of 63 mm are used in industrial, metal and oil industries.

The dimensions of MP products can tell about their capabilities, which often differ from each other precisely depending on the diameter. Table of sizes and specifications:

| Diameter (outer layer) | 16 | 20 | 26 | 32 | 40 |

| Inner diameter | 12 | 16 | 20 | 26 | 33 |

| Wall thickness, in mm | 2 | 2 | 3 | 3 | 3,5 |

| Weight of 1 meter, in kg | 0,12 | 0,17 | 0,3 | 0,37 | 0,463 |

The parameters of 16 mm fittings and the price for it often allow craftsmen to use this variety without fear in residential buildings and multi-apartment houses.

Metal-plastic products with a diameter of up to 40 mm can be found on sale in coils (coils) from 50 to 200 meters long.

What temperature can a metal-plastic pipe withstand

The wall thickness and the selected reinforced composition of the finished fittings determine what temperature the metal-plastic pipes can withstand. The normal temperature for operation will be 60-95 degrees, however, with pressure and temperature drops, the MP design will be able to cope with a temperature of 120 degrees.

At a temperature of 140 degrees, the walls and fittings for MP structures melt, which leads to deformation of products and the formation of leaks.

The heat output of a metal-plastic pipe of 0.45 W / mK is a decisive factor when choosing products for creating underfloor heating.

What pressure can a metal-plastic pipe withstand

Since the production of products uses low-density polyethylene, MP pipes withstand pressure up to 15 atmospheres, main working pressure - 10 atmospheres.

When building plumbing or heating structures in private homes, the pressure can drop to 7-8 bar. With this indicator in apartment buildings, wall breaks are possible.

Such indicators allow the use of metal-plastic structures in the production metals at great depths, as they can withstand the pressure of several layers of earth rocks.

Types of pipes for water supply and features of their choice

How to choose pipes for plumbing construction? When choosing pipes for water supply, many factors must be considered. Consider the main criteria that should be considered when choosing these products:

- material strength;

- price;

- resistance to temperature changes (pipes for hot and cold water can be made of different materials);

- pressure resistance;

- anti-corrosion qualities;

- features of the installation of communications from a particular material;

- operational period.

Depending on the material of manufacture, water pipes are divided into:

- metal;

- metal-plastic;

- polymeric.

In turn, metal pipelines can be made from the following metals:

- steel;

- copper.

Of the metal pipes for water supply, steel pipes are the most popular.

And plastic products can be made from such materials:

- polypropylene (PP);

- polyethylene (PE);

- polyvinyl chloride (PVC).

Each of the types of water pipes has its own advantages and disadvantages. In this regard, their choice is made individually, depending on the specific case.