- Installing a sandwich chimney

- How to accurately and correctly apply sealant

- Features of sealing sandwich chimneys

- Regulatory requirements for the installation of chimneys

- Norms for the installation of a smoke exhaust system

- Ceramic chimney

- Stainless steel pipe options

- Ceramic chimneys

- What to consider when choosing a material for a chimney?

- Chimney tests

- Video - Checking steel on chimneys

- Video - UMK chimney test

- Operating rules

- Brick chimneys - pros and cons

- Types and differences

- heat resistant

- Silicone seals

- Heat resistant

- Adhesive facing compositions

- Which view is better

- Popularity

- Asbestos-cement structure

- Stainless steel system

- Installation Recommendations

- brick chimney

- cast iron pipe

- Types of chimneys

- Brick

- galvanized pipe

- coaxial chimney

- Ceramic

- Stainless steel

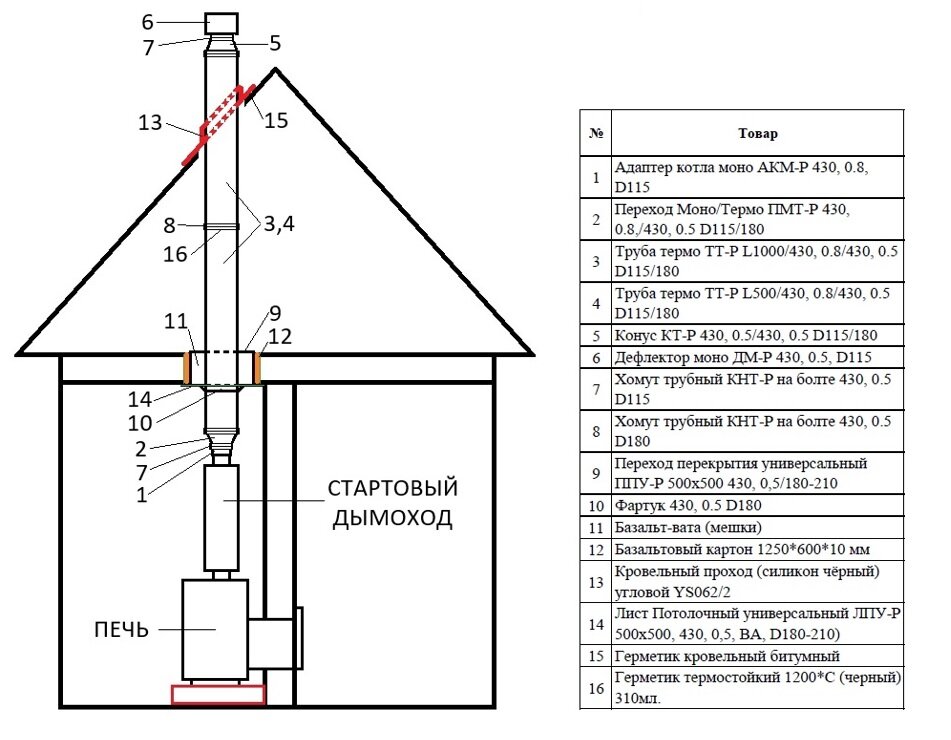

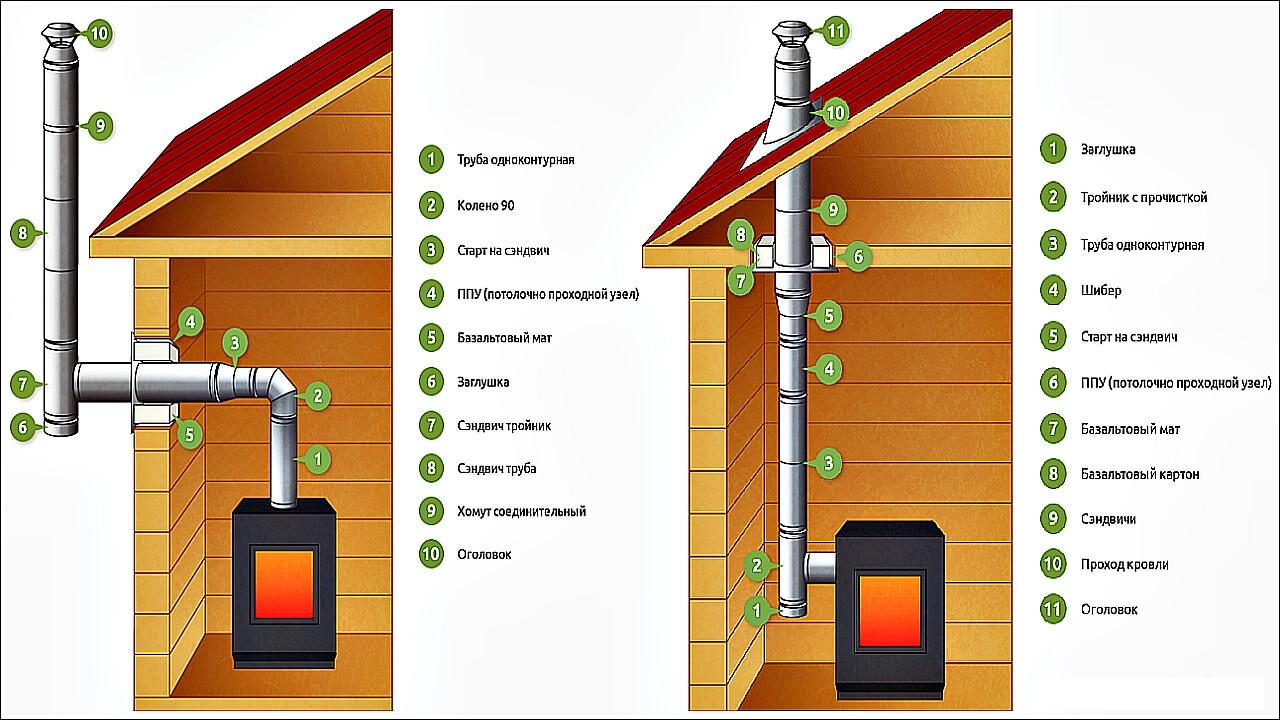

Installing a sandwich chimney

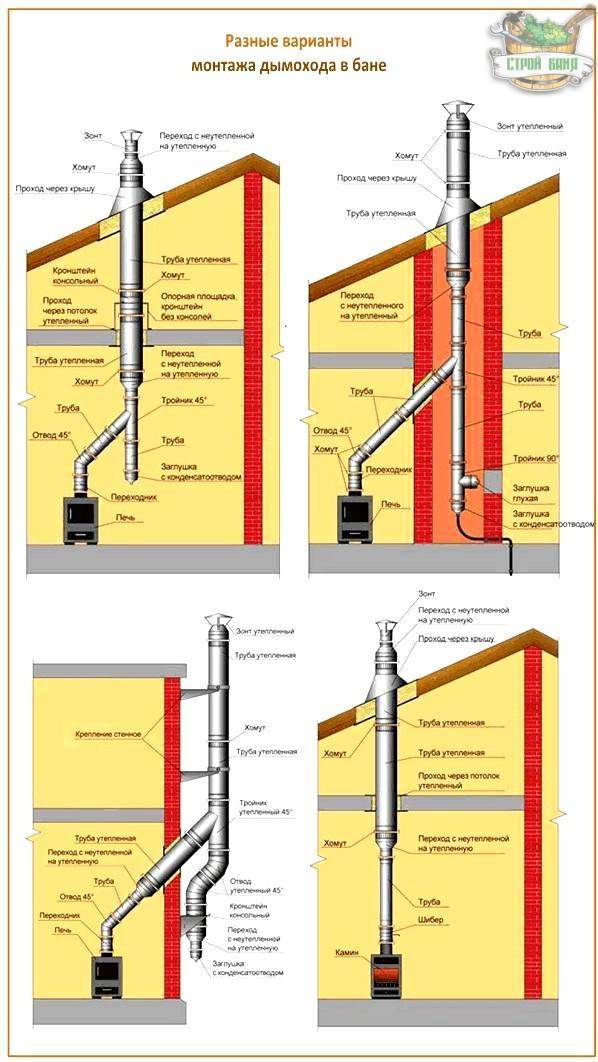

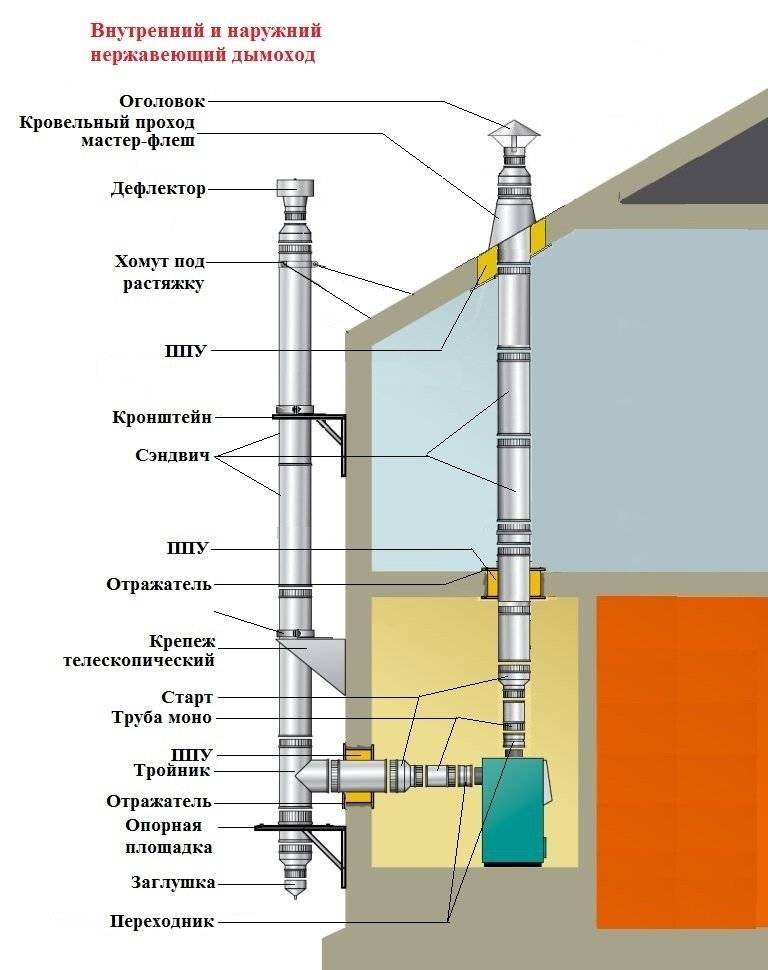

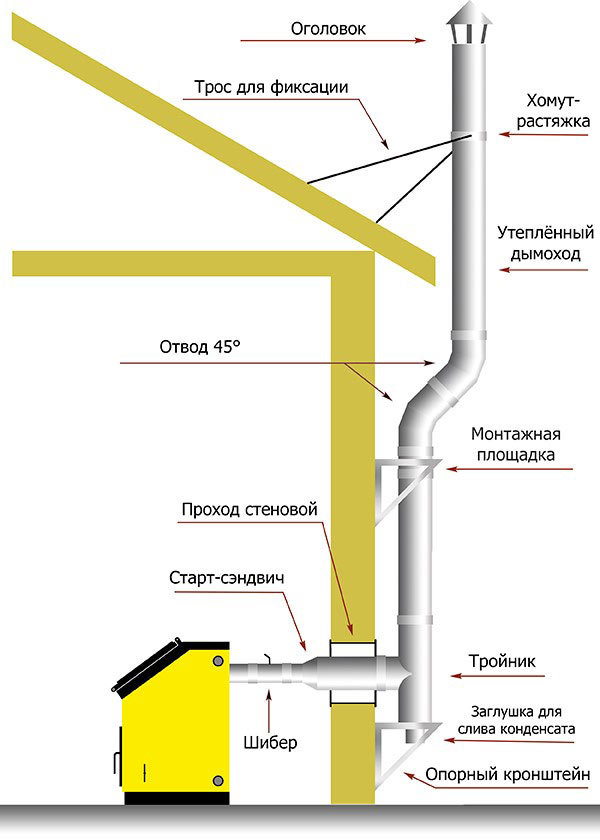

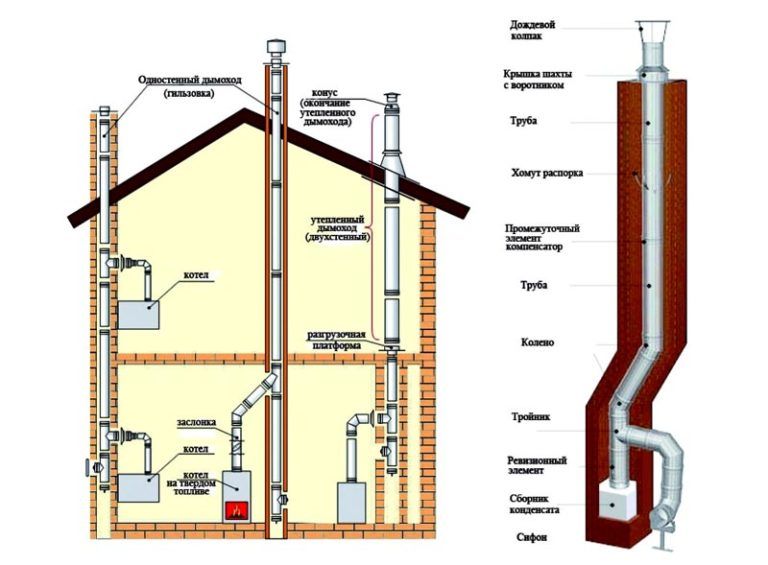

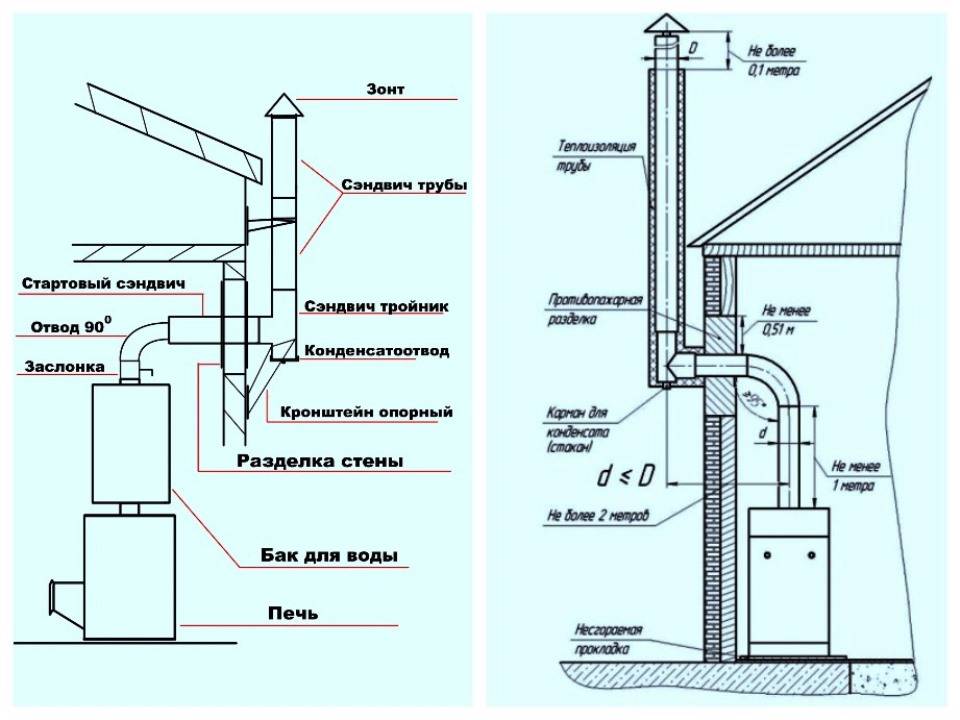

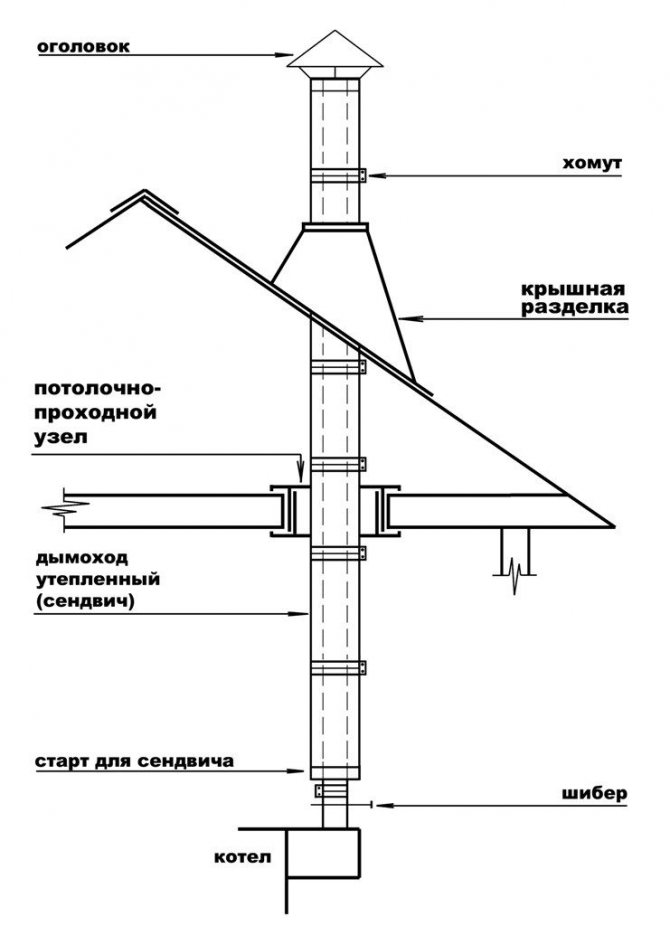

We have already said that the chimney can be connected independently. To do this, you need to bring the pipe through the roof or directly into the wall, and then lift it up through the rotary channel. In order to make combustion in the furnace better, first install a regular pipe, and then a sandwich chimney. From an ordinary pipe there is a strong radiation of heat. The temperature of the pipe is not less than the combustion temperature. To reduce the heat, the pipe is equipped with a brick mesh.Thus, after the end of combustion, the pipe heats the room for a long time, and the initial temperature is quite acceptable.

In some cases, water is heated through the chimney. Then a special tank is used, which is installed near the first pipe that comes from the furnace.

Assemble the sandwich panels in the direction of the smoke. If you look closely, each panel has a thicker end on one side, and thinner on the other - for connection. So the thick end is always installed on top so that smoke does not enter the house. Joints must be sealed. For this, a sealant is used. If this is not done, then oxygen can enter the chimney, which will ignite soot.

To install the chimney, you need to make a hole in the wall or ceiling - depending on the method of installing the chimney. It is forbidden to immediately install a sandwich panel to the branch pipe from the oven. A steel pipe is used as a connection

Otherwise, the sandwich chimney will quickly burn out.

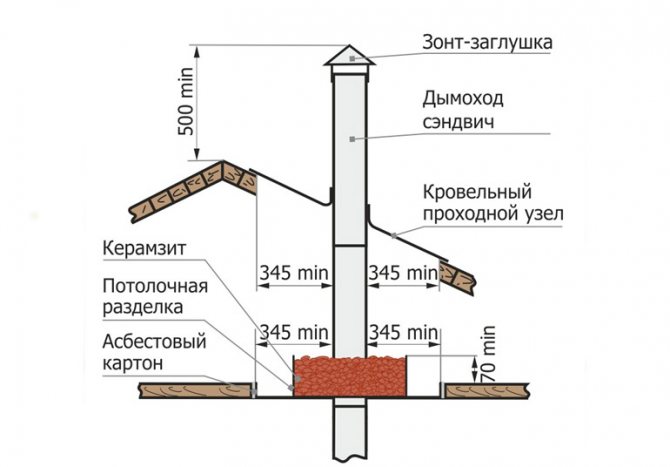

It is very important to correctly lead the chimney through the ceiling. After all, most often due to incorrect installation in this place, fires occur in the baths.

Minimum distance from the chimney to the ceiling must be at least 13 centimeters. If the walls are wooden - then 38 centimeters. Next, you need to fix the pipe in the ceiling area. Sometimes they use a profile corner and self-tapping screws. To prevent water from the roof from getting inside the room, a galvanized sheet is used, which is then sealed with silicone.

How to accurately and correctly apply sealant

When working with both types of polymers, it is necessary to prepare the surface of the chimney: clean, remove dust and dirt, and degrease.It is desirable to sand the steel with fine sandpaper to improve the adhesion of the polymer.

The surface under the heat-resistant sealant must be completely dry. The tube is filled into the gun and a small amount of silicone is squeezed onto the sealed joint. Allow to harden (approximate time is indicated on the package).

The base for the heat-resistant silicate polymer is prepared and lightly moistened. Apply sealant and let dry. Excess heat-resistant mass is removed until the sealant has hardened. You can pre-glue the masking tape along the joint, and remove it after application.

It is desirable to perform work in warm weather.

Features of sealing sandwich chimneys

Sandwich pipes have a metal surface. Both silicate and silicone polymers are used for their sealing.

A characteristic feature of sealing sandwich pipes is the need to seal both the inner and outer pipes. In addition to the general safety considerations that were given at the beginning of the article, it is very dangerous for a sandwich to get atmospheric moisture from the outside or condensate from the inside into the insulation.

The outer layer should be coated with silicone - it has excellent hydrophobic properties. For an internal joint, a heat-resistant sealant is selected depending on the type of heater and smoke temperature.

The sealing process itself is not particularly difficult - a bead of sealant is applied to the joined surfaces of the outer and inner layers and gently smeared with a layer of 1-2 mm using a spatula or a steel flat plate, then the chimney modules are joined together.

Regulatory requirements for the installation of chimneys

The main and only purpose of the chimney is to remove waste gases from the heating boiler to the atmosphere outside the building where the stove, boiler or fireplace is installed. At the same time, the efficiency of the heat-generating equipment directly depends on its proper installation.

You can put a boiler in the house with excellent efficiency, but make miscalculations when installing the chimney. The result is excessive fuel consumption and lack of comfortable air temperatures in the rooms. The chimney must have the correct section, location, configuration and height.

If the house has two boilers or a stove and a fireplace in different rooms, then it is better to make separate smoke exhaust pipes for each of them. The option with one chimney is allowed by SNiPs, but only a professional stove-maker can correctly calculate it.

The diameter of the chimney is selected depending on the heating equipment used. When installing the boiler, it is already set by the manufacturer with a drain pipe. It is forbidden to connect pipes of a smaller section to it, and it is simply not necessary to connect a larger one. In the second case, to increase traction, you will have to mount a gearbox, which costs a lot of money.

In case of fireplace or Russian stove from brick, everything is somewhat more complicated. Here you have to do engineering calculations taking into account the fuel used and furnace sizes. It is much easier to take a ready-made brick oven project that has been tested by time. Fortunately, there are many options with a well-defined order of brickwork.

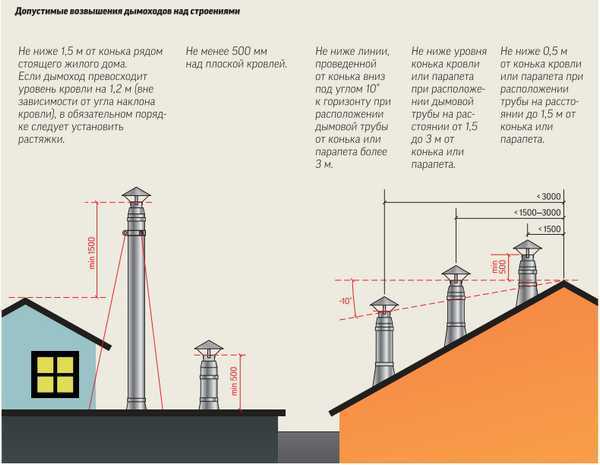

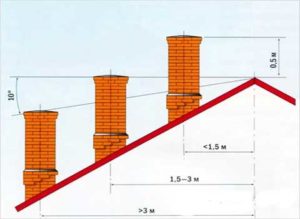

The height of the chimney pipe above the roof is determined by its distance from the roof ridge

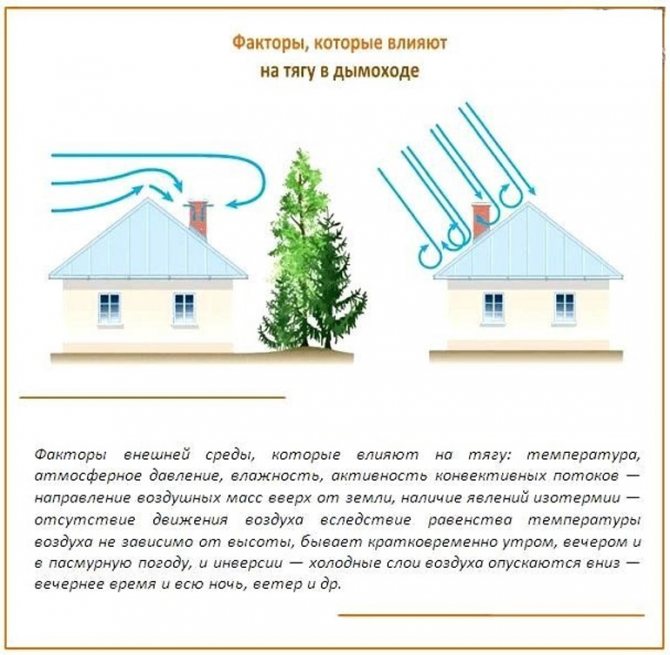

The higher and longer the chimney, the stronger the draft. However, this can lead to overheating and destruction of its walls. Plus, a strong increase in draft is a prerequisite for the occurrence of turbulence in the chimney, which is accompanied by a hum and low-frequency noise.

If the pipe is too low, the ridge can turn into an insurmountable obstacle to the smoke coming out of it. As a result, a reverse draft effect will occur with the flue gases tipping back into the furnace. How to normalize it will be discussed in this material.

During normal operation of the chimney, the horizontal wind flow, flowing around the section of the pipe above the roof, turns up. As a result, rarefied air is formed above it, which literally “sucks” smoke from the exhaust. However, the ridge of a pitched roof and even a tall tree in the immediate vicinity of the house can interfere with this process.

Norms for the installation of a smoke exhaust system

Building codes prescribe the chimney to be done as follows:

- Its length from the grate to the top point should be from 5 meters (an exception is possible only for buildings without attics and only under conditions of stable forced draft).

- The optimal height, taking into account all possible bends, is 5–6 m.

- The distance from a metal chimney to structures made of combustible building materials should be from a meter.

- The horizontal outlet immediately behind the boiler must not exceed 1 m.

- When passing roofing, walls and ceilings inside the house, a channel made of non-combustible materials should be equipped.

- To connect the metal elements of the pipe, the sealant should be used exclusively heat-resistant with a working temperature of 1000 ° C.

- The chimney must rise at least 50 cm above the flat roof.

- If a non-brick chimney is built 1.5 meters or more above the roof level, then it must be strengthened without fail with stretch marks and brackets.

Any slopes and horizontal sections will inevitably reduce the draft in the chimney pipe.If it is impossible to make it straight, then bends and displacements are best done from several inclined segments at a total angle of up to 45 degrees.

In addition to observing purely building rules that guarantee the high efficiency of the chimney and stove, it is also necessary to take care of fire safety, for which special indents and screens are made

In addition to observing purely building rules that guarantee the high efficiency of the chimney and stove, it is also necessary to take care of fire safety, for which special indents and screens are made

When arranging ventilation and chimney shafts in parallel in one structure above the roof, in no case should they be covered with a common cap. The outlet from the stove must necessarily rise above the ventilation pipe, otherwise the draft will decrease, and the smoke will begin to be sucked back into the house. The same applies to individual, but adjacent hoods and chimneys.

Ceramic chimney

Recently, stove masters have been actively introducing things that differ from classic brick ones. They are ceramic pipes up to 3 m long, light blocks with a hole, the diameter of which corresponds to their size, are supplied in combination with them. Compared to other materials, ceramics has the following advantages:

- High temperature resistance. Ceramic pipes "lock" the heat coming from the mixture of smoke with combustion products inside, preventing the external units from heating up. Therefore, they are considered the safest and most reliable. A ceramic chimney does not require additional thermal insulation due to the high heat absorption of the material.

- Resistant to moisture, corrosion and aggressive chemical compounds. They began to use ceramics for the construction of the chimney, noticing how inert the material is. Pipes from it serve at least 50 years without requiring special care.

- Easy assembly.You can install a chimney from ceramic pipes, unlike brick, by yourself. The main thing is to choose the right diameter of the additional elements that you are going to use. Reinforcement bars and cement mortar are required for installation.

- Versatility. Thanks to the variety of ceramic products, it is easy to choose the appropriate diameter for connecting to the inlet pipe of the heater. Therefore, chimneys made of this material are used for all types of stoves, fireplaces, gas boilers and boilers.

- Ease of care. The inner surface of the ceramic pipe has a dense, smooth structure, so that soot does not accumulate on it. The chimney of their ceramics is easy to maintain, as it does not require frequent cleaning.

Scheme of the smoke exhaust channel from ceramic pipes

Scheme of the smoke exhaust channel from ceramic pipes

External smoke exhaust duct ceramic pipes

External smoke exhaust duct ceramic pipes

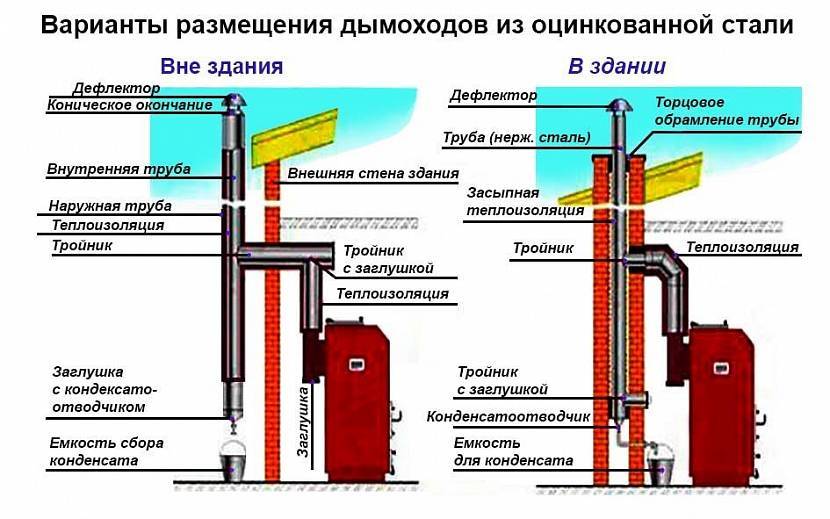

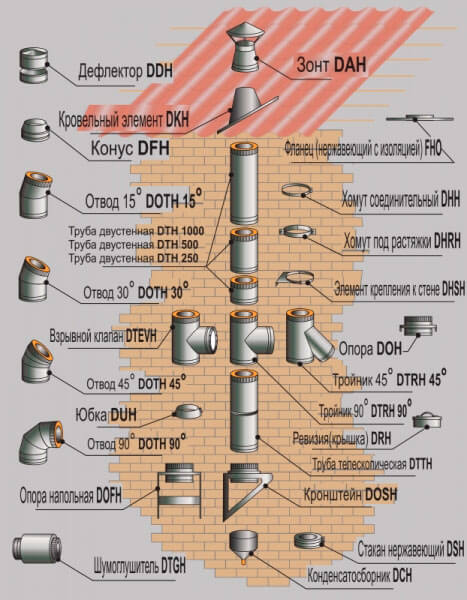

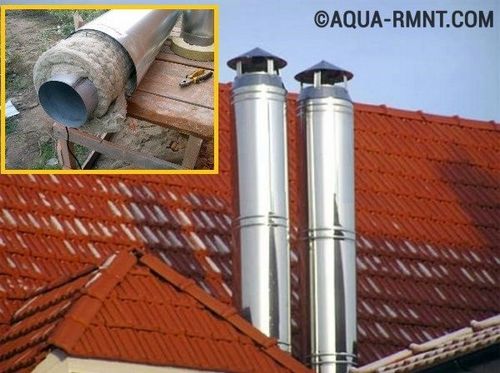

Stainless steel pipe options

To date, you can find as many as three options for this kind of chimney.

- Single-walled (thickness - 0.6-20 millimeters).

- Corrugated.

- Three-layer sandwiches (two pipes + insulation).

Let's take a look at each of the options their pros and cons in the form of a table.

| Pipe type | Advantages | Flaws |

|---|---|---|

| single layer | Low cost, smooth inner surface. | High heat transfer rates, condensation may form, the need to install thermal insulation. |

| Corrugated | Elasticity, some flexibility. | Low resistance to high temperatures, rapid wear, corrugated inner surface on which condensate can accumulate, not suitable for horizontal sections of the chimney, it is necessary to fix and install thermal insulation. |

| Three-layer | Low heat dissipation, versatility, easy assembly, tight joints. | The cost of this type of pipe is quite high compared to others. |

Each type of pipe has its own characteristics that hinder or help in choosing

Each type of pipe has its own characteristics that hinder or help in choosing

Ceramic chimneys

One of the most durable materials, due to the resistance to aggressive environments, high temperatures, lack of corrosion. Due to the smooth inner surface, soot and soot do not accumulate in the pipe, which simplifies the maintenance of the heating system.

A ceramic structure is most often hidden in a box made of expanded clay concrete. This solution eliminates overheating of the pipe, which indicates the fire safety of the chimney.

The main advantages of ceramic pipe:

• low thermal conductivity;

• resistance to temperature changes;

• lack of roughness on the surface;

• simple way of installation;

• long operational period.

Flaws:

• high weight, increasing the requirement for the foundation;

• installation methods are limited to the vertical position of the pipe.

What to consider when choosing a material for a chimney?

A chimney is a complex structure, consisting of a vertical pipe, an umbrella for protection against precipitation, a viewing window for maintenance, collection tray condensate and other elements. The vertical pipe is considered the main part of the chimney, and the safety and efficiency of the furnace or boiler depends on it.

To choose the right chimney material, you need to clearly understand what fuel will be used: natural gas, diesel fuel, coal, firewood, peat or sawdust. Each of them has a different combustion temperature, temperature and composition of the exhaust gases.Therefore, when choosing a material for a chimney, the following parameters are taken into account:

-

flue gas temperature. Naturally, the material must withstand somewhat higher temperatures than those that are characteristic of the outgoing gases;

- corrosion resistance. During the combustion of some types of fuel, sulfuric and hydrochloric acid vapors are formed, which not every material can withstand. The more sulfur in the composition of the fuel, the more resistant to the effects of sulfur compounds should be the material. According to this parameter, chimneys are divided into three classes: the first - for the removal of gas combustion products, the second - firewood and liquid fuel with a sulfur content of up to 0.2%, the third - for coal, peat, diesel fuel;

- the presence of condensate in the chimney;

- flue gas pressure. There are designs designed to work with natural draft, and there are those that are designed to work with pressurized boilers;

-

soot fire resistance. The temperature in the chimney during the ignition of soot, if present, can briefly rise to 1000C - not every material can withstand this.

From all this it follows that:

- for wood stoves, solid fuel boilers, sauna stoves and fireplaces, it is necessary to choose a material that can withstand an operating temperature of about 700C and a short-term increase to 1000C. These are brick and less often ceramic chimneys;

- gas boilers require a chimney that can withstand temperatures of 200C with short-term rises to 400C. Usually metal pipes are used for this purpose;

- for boilers for liquid fuel and sawdust, such a material for the chimney pipe is required, which would calmly withstand temperatures up to 250C with an increase to 400C, and if we are talking about diesel fuel, then also resistant to the aggressive environment of exhaust gases.

Now let's look at the properties of the most popular materials that are used to equip the chimney pipe.

Chimney tests

If you choose a chimney, then you need to know whether it is really of high quality and meets the parameters stated by the manufacturer. To do this, some manufacturers conduct tests and it's great if they post them on the Internet, this increases loyalty. To evaluate this criterion, we will search the social networks of manufacturers in search of videos with tests of chimneys.

TiS products

We found the Ferrum company on YouTube, where they periodically post reviews on any element of the chimney on the channel there is a video where they check steel on chimneys of various brands

Video - Checking steel on chimneys

The UMK manufacturer also has its own YouTube channel, where video reviews of chimneys are posted, including their testing. For example, the manufacturer conducted a series of tests, where they subjected 3 chimneys to high temperatures, from 3 different manufacturers in the same price segment.

Video - UMK chimney test

The TiS company is no exception with its YouTube channel, but unfortunately there were no chimney tests there, although they are “plus”, as they actively maintain their YouTube channel and constantly upload new videos.

Which manufacturer of sandwich chimneys is better in the tests category:

- Ferrum - 2 points;

- EMC - 2 points;

- TiS - 1 point.

Operating rules

In order for a chimney built on the basis of one or another type of material to serve faithfully for many years, it is necessary:

- ensure tight installation;

- control the temperature;

- adjust traction;

- equip a ventilation channel;

- insulate;

- protect the heads from the effects of environmental factors;

- clean from soot;

- give preference to fuel without foreign impurities;

- correctly burn fuel;

- avoid excessively intense combustion;

- do not overcool;

- periodically inspect.

Such simple recommendations will allow you to enjoy both durability and design efficiency, regardless of the material.

But keep in mind, the choice of raw materials is a very important event. In view of what it is not recommended to grab the first pipe that comes across, otherwise you can be very sorry later

Be carefull!

Warmth and comfort to your home, dear friends. See you again.

Wisdom Quote: There is nothing more annoying than a good example (Mark Twain).

Brick chimneys - pros and cons

Such pipes are laid out of solid red brick, usually inside buildings, external attached options are less common. Masonry mortar consists of clay, sand and cement.

Homeowners have to deal with brick flues in 2 cases:

- the project provides for the location of the smoke channel inside the house - next to the exhaust shafts of the ventilation unit;

- when erecting a stationary stove or a classic fireplace.

Classic house (left) and attached chimney (right)

Previously, red brick was considered an ideal material for building a chimney, but with the advent of new products, it has lost its leading position.Advantages of brick gas ducts:

- Presentable appearance, which remains for a long time - during the entire period of operation.

- The shaft passing inside the wall transfers part of the flue gas heat to the premises.

- Stones and binding solution are non-combustible materials.

- A properly folded pipe successfully resists heating up to 1000+ degrees during soot burning (an example is shown in the photo). But with repeated or prolonged exposure to high temperatures, the structure will begin to collapse and become a fire hazard.

The disadvantages of brick pipes are much more:

- The uneven inner surface of the channel contributes to the deposition and accumulation of soot, which ignites in the event of overflooding.

- The rectangular (or square) shape of the shaft plus the roughness of the walls increases the aerodynamic resistance of the pipe and reduces natural draft.

- The construction is quite heavy and bulky, requiring foundations. Building a chimney or stove entirely with your own hands is not an easy task, hiring performers is expensive.

- Due to the peculiarities of the masonry, the dimensions of the channel are tied to the dimensions of the bricks, for example, 14 x 14, 14 x 21 or 21 x 27 cm. The standard shaft sections are presented in the table.

- Working in tandem with a gas boiler, a brick chimney collapses under the influence of condensate.

Condensation is the main scourge of stone pipes. The water vapor contained in the products of combustion penetrates into the pores of the brick, condenses and is seized by frost. Further it is clear - the material is peeling, the chimney is destroyed. The physics of the process will be explained by a specialist in the video:

How to deal with the disadvantages of brick mines:

- make external thermal insulation of the street section of the pipe;

- lay a stainless steel sleeve inside the channel - make a combined gas duct;

- operate the chimney together with a solid fuel boiler or stove - gases quickly warm up the walls of the mine, condensate practically does not fall out;

- lay out double brick walls, the inner row is made of industrial stone of the ShB-8 type.

Irregularities in masonry and brick pores can be protected by gilding

Types and differences

All types of sealants for use at high temperatures are divided into two large groups - heat-resistant (silicone) and heat-resistant (silicate). They differ in chemical composition and permissible operating parameters.

heat resistant

heat resistant sealants are made on the basis of silicones – organosilicon oxygen-containing compounds. They withstand temperatures up to 300°C, at 100°C and above, heat-resistant silicones outperform all traditional elastic materials.

Silicones are durable, elastic, chemically inert, waterproof, resistant to biological influences, UV radiation. Can work with rapid temperature changes, non-toxic, environmentally friendly.

Heat-resistant silicones are available in the form of a reddish-brown paste. The color of the sealant is given by iron oxides. Operating temperatures may vary from 170 to 300 ° C, this information is indicated on the packaging.

Scope of silicone: sealing the outer surfaces of the chimney, the junction of the pipe and the roof, sealing non-through cracks on the brick surfaces of fireplaces and stoves, sealing pipes gas boilers with high efficiency and slight heating of flue gases.

Silicone seals

For the convenience of consumers, the industry produces a huge range of silicone seals - gaskets, membranes, cords, tubes, seals of various configurations.They are used to seal windows and doors, in household appliances, in cars, electrical engineering.

Silicone is used to make a master flash - an elastic seal for pipe passage through the roof. They produce special heat-shrink tapes - they are wrapped around the joints of the chimney modules, when heated, they melt and tightly fill the sealed joint.

Heat resistant

To seal and repair the internal surfaces of chimneys, combustion chambers, solid holes in brick pipes, joints of cast-iron and steel elements with stove masonry, assembling sandwich chimneys, refractory silicate polymers are used that can withstand temperatures up to 1200 ° C (for a short time - even up to 1500 ° C ).

Silicate sealants are black or black-gray in color and have a viscous consistency that cures within 15 minutes of application. The thickness of the seam can reach 15 mm. Heat-resistant silicates form an inelastic seam. Works are carried out at temperatures from 1 to 40 °C.

Adhesive facing compositions

The industry produces special heat-resistant compounds for lining furnaces, fireplaces and chimneys with tiles (ordinary, fireclay, clinker, porcelain stoneware), natural or artificial stone. They are usually made based on silicates, contain liquid glass, kaolin, cement, plasticizers, polymers.

Such mixtures withstand temperatures from -30 to +170 ° C and even higher. In industry, other high-temperature adhesives are also used, which require strong heating for drying, but they have not received distribution in everyday life.

Which view is better

Each type of sealant is designed for certain operating conditions and performance of certain functions.Silicones are used on the outer surfaces of chimneys, stoves and fireplaces, sealing elements of gas boiler pipes. Heat-resistant silicate polymers are used in any case, if the place of application of the sealant is heated to more than 300 °C. They can also be used to seal leaks in heating units, even for metal.

Popularity

We will check the popularity of chimneys using the Yandex.wordstat service. Using this service, you can track how many queries were in the search engine per month. We will determine by three phrases - chimneys *manufacturer*, buy chimneys *manufacturer*, pipes *manufacturer*

| Phrase/manufacturer | Ferrum | WMC | Yew |

|---|---|---|---|

| chimneys *manufacturer* | 2,786 impressions per month | 854 impressions per month | 1,099 impressions per month |

| buy chimneys *manufacturer* | 450 impressions per month | 155 impressions per month | 125 impressions per month |

| pipes *manufacturer* | 545 impressions per month | 339 impressions per month | 131 impressions per month |

The manufacturer Ferrum clearly comes off from the table above, it is searched on the Internet more often - 3 points.

The Teplov and Sukhov company has 1099 impressions, so they get 2 points.

And UMK - 1 point.

Obviously, Ferrum's marketers are actively investing in advertising, and perhaps because of this, Ferrum is somewhat more expensive.

Asbestos-cement structure

They are produced on the basis of asbestos, a fine-fibre non-combustible silicate mineral. They are distinguished by high corrosion resistance and low cost. An asbestos pipe will cost half as much as a brick one. This is where the advantages of the design end, but it has many disadvantages:

-

- A significant reduction in thrust, since there is no heat capacity supporting it.

- Increased formation and absorption of condensate.

- Inability to operate the structure at high temperatures. When the mark of 300 ° is exceeded, asbestos cement can burst and sometimes explode.

- The impossibility of arranging inspection hatches and removing soot from the device.

- Exclusively vertical mounting method.

Harmful effects of asbestos on the human body.

When the temperature rises above 300 degrees, the asbestos-cement pipe can burst and even explode. The consequences of such an explosion are visible in the picture.

Asbestos cement is a rather economical, but short-lived solution for low-power heating appliances, the upper segments of smoke channels intended for the passage of almost cooled gases, etc.

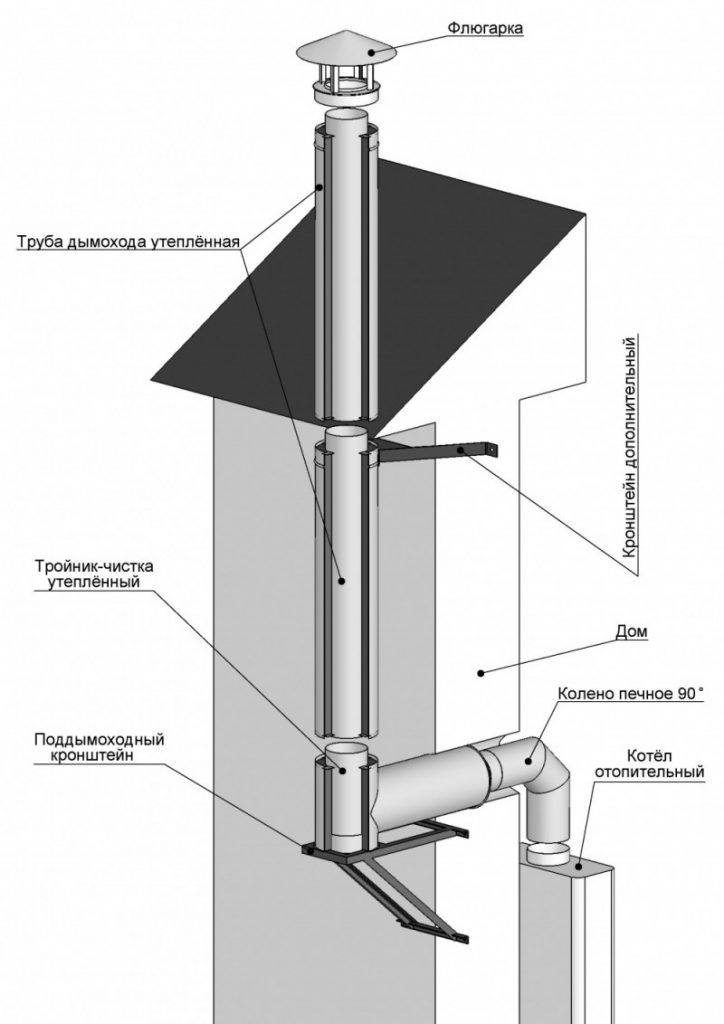

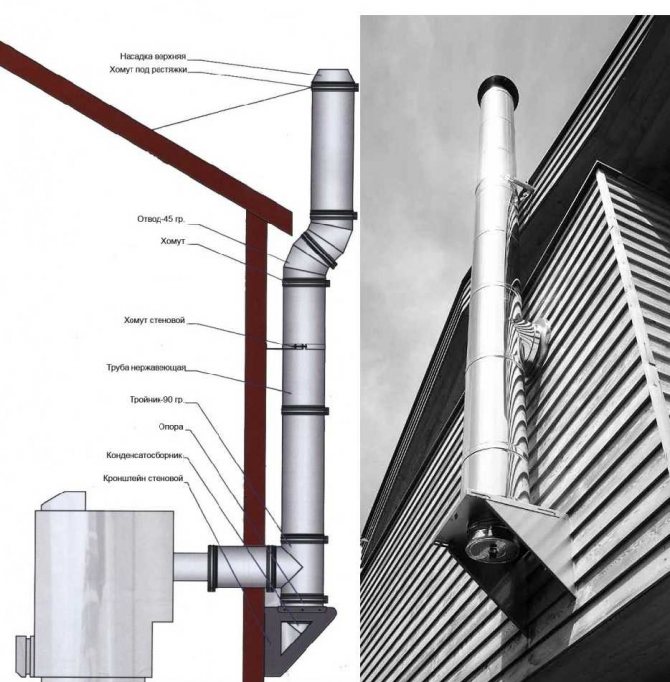

Stainless steel system

Manufactured from special alloy steel, it is resistant to corrosion in the atmosphere and in almost any aggressive environment. Has many advantages:

- Light weight, does not require the arrangement of the foundation.

- Ease of installation, which can be done from the inside or outside. In the latter case, the structure is fixed to the wall with special brackets.

- Long service life due to high corrosion resistance.

- Smooth inner surface that prevents the accumulation of soot.

- The structure can be installed during construction or mounted in a finished building.

Acceptable cost.

If a stainless steel chimney is mounted outside, it requires additional insulation. Otherwise, due to serious heat loss in the cold season, a large amount of condensate will form.

The disadvantages include the need to insulate the pipe, provided that it is mounted outside the house. Otherwise, heat losses occur, leading to the formation of a large amount of condensate, which can damage the heating system. In addition, some do not like the appearance of such chimneys. If desired, you can purchase a special casing that covers the pipe, which imitates any traditional material: tiles, bricks, etc.

Installation Recommendations

The recommendations below will help you properly install the chimney so that it functions without any difficulties.

- If you put a pipe with a height of five meters or more, then you can achieve good traction.

- The length of horizontal sections should be up to one meter, no more.

- Installation of a chimney on the street or in an unheated room involves the installation of thermal insulation material.

- If the chimney passes through a roof constructed with combustible materials, a spark arrester must be installed.

If you strictly follow the suggested recommendations, you can install a chimney without any problems.

If you strictly follow the suggested recommendations, you can install a chimney without any problems.

brick chimney

The traditional method can be erected at the time of construction of the house and have a very different shape, even round, provided that the inner walls are correctly processed.

Brick chimney

Brick chimney

The number of dignity can be replenished:

- reliability;

- durability;

- good heat dissipation;

- fire resistance;

- beautiful view.

But, there are also disadvantages:

- The accumulation of soot is much faster, due to the rough and uneven walls inside.

- Huge weight, which accordingly requires filling the "cushion".

- Under the influence of acids, condensate, the brick is gradually destroyed.

- High price.

Do not forget that the draft in such channels can be disturbed due to vortex flows.To minimize all the shortcomings, but at the same time get a monumental and reliable structure, a metal pipe can be inserted inside the brickwork. It will provide reliable smoke separation, and will not affect the protective frame. So the choice is up to the owner, which pipe in a private house is optimally mounted. If you use two configurations at once, think about the feasibility of such a massive structure. The price is quite huge, and for such funds you can install a more suitable configuration, such as a sandwich panel.

cast iron pipe

It is used as an alternative to classic brick buildings, because construction costs can vary by more than 70%. However, despite the low cost, there are very few significant advantages for such pipes. More and more disadvantages

- Fragility, due to the non-resistant material to an aggressive environment.

- The rapid burning of the walls leads to the fact that smoke can enter the room at first imperceptibly, through small holes.

- Extremely high weight. What an extra "cushion" is required.

In addition, do not forget, a cast-iron chimney emits significantly more condensate than any other and, accordingly, a cast-iron base does not cope with acids as well. As you can see, in such designs there are more and more shortcomings than real positive aspects for a person. Therefore, they are often used, wanting to save money, but you need to understand that later you will need frequent maintenance and repairs.

Types of chimneys

Pipes are made from different materials, which we will consider in more detail.

Brick

Classic brick chimneys for a gas boiler are still in demand, regardless of their many disadvantages and poor thermal performance.At the same time, they comply with sanitary standards and rules, which state:

-

The pipe is made of fireclay bricks.

-

For the construction of walls, a solution of clay or special glue is used.

-

To improve draft, the chimney rises above the level of the roof ridge.

Standards regulate the height of the pipe in relation to the roof ridge, depending on the distance between them

-

The masonry provides tightness.

-

At the inner hole, the deviation is no more than 3 mm per 1 m.

-

To protect against precipitation, a deflector is installed on the head of the pipe.

And also the chimney can have a mono design, which, due to low thermal characteristics, is repaired every 5-7 years.

galvanized pipe

A sandwich device is today the most effective chimney design option. The undoubted advantage of these chimneys is their resistance to aggressive environments and various mechanical influences.

The product consists of two pipes of different sizes, with one inserted into the other. Basalt wool is usually used as a filler between them.

coaxial chimney

Currently, gas boilers use closed-type combustion chambers. Here, air intake and smoke removal are produced by a coaxial pipe. This is an original device, relatively recently introduced, but already very popular among users.

The non-standard solution lies in the intake of air through a pipe that removes combustion products. It turns out that one pipe performs two functions due to the design features.

A coaxial chimney is a pipe in a pipe

And its characteristic difference from ordinary pipes is as follows ... A smaller pipe (60-110mm) is located in a pipe of a larger diameter (100-160mm) in such a way that they do not touch each other.

At the same time, the structure is a single whole due to the jumpers along the entire length and is a rigid element. The inner pipe serves as a chimney, and the outer pipe serves as fresh air.

Air exchange at different temperatures creates traction and sets the air mass in a directed motion. The air in the room is not used during the operation of the boiler, thus maintaining the microclimate in the room.

Ceramic

Such a chimney is a composite structure, including:

-

Smoke duct made of ceramic material.

-

Insulation layer or air space.

-

Claydite concrete outer surface.

This complex design is due to several reasons. First, the chimney pipe is too fragile to be left unprotected.

A ceramic pipe is always located inside a solid block.

Secondly, ceramics has a high thermal conductivity, and therefore it needs reliable insulation. The inner tube of a circular cross section has a smooth surface, while on the outer tube, roughnesses are allowed that do not affect the integrity of the product.

Typically, such chimneys are available in lengths from 0.35 to 1 m, depending on the manufacturer. The connection of the inner and outer pipes occurs by means of a lock, which is a thinning in external size from one end and an expansion of the inner pipe from the other side.

The expanded clay concrete outer surface is made of a square shape with a round hole inside.In addition, this product provides a place for a heater, which is held by metal jumpers. At the same time, they are fixed on the outer surface and make a reliable fastening for this pipe.

Stainless steel

A gas chimney made of steel seems to be more reliable than a brick one. They are resistant to corrosion, immune to temperature fluctuations, they are not affected by increased air humidity and aggressive environments.

Stainless steel chimney

In addition, such stainless steel pipes have a number of advantages:

-

Long period of operation.

-

Multifunctionality.

-

Relatively low cost.

-

Great strength.

-

Probable realization of a product of any complexity.

For chimneys made of this material, an assembly of modules is characteristic, which allows the replacement of a damaged segment if necessary. The installation of chimneys is made with the help of special bends, which allow them to harmoniously fit into certain elements of the roof.