- Step 1. Choosing a high-quality drainage system

- Pros and cons of metal gutters

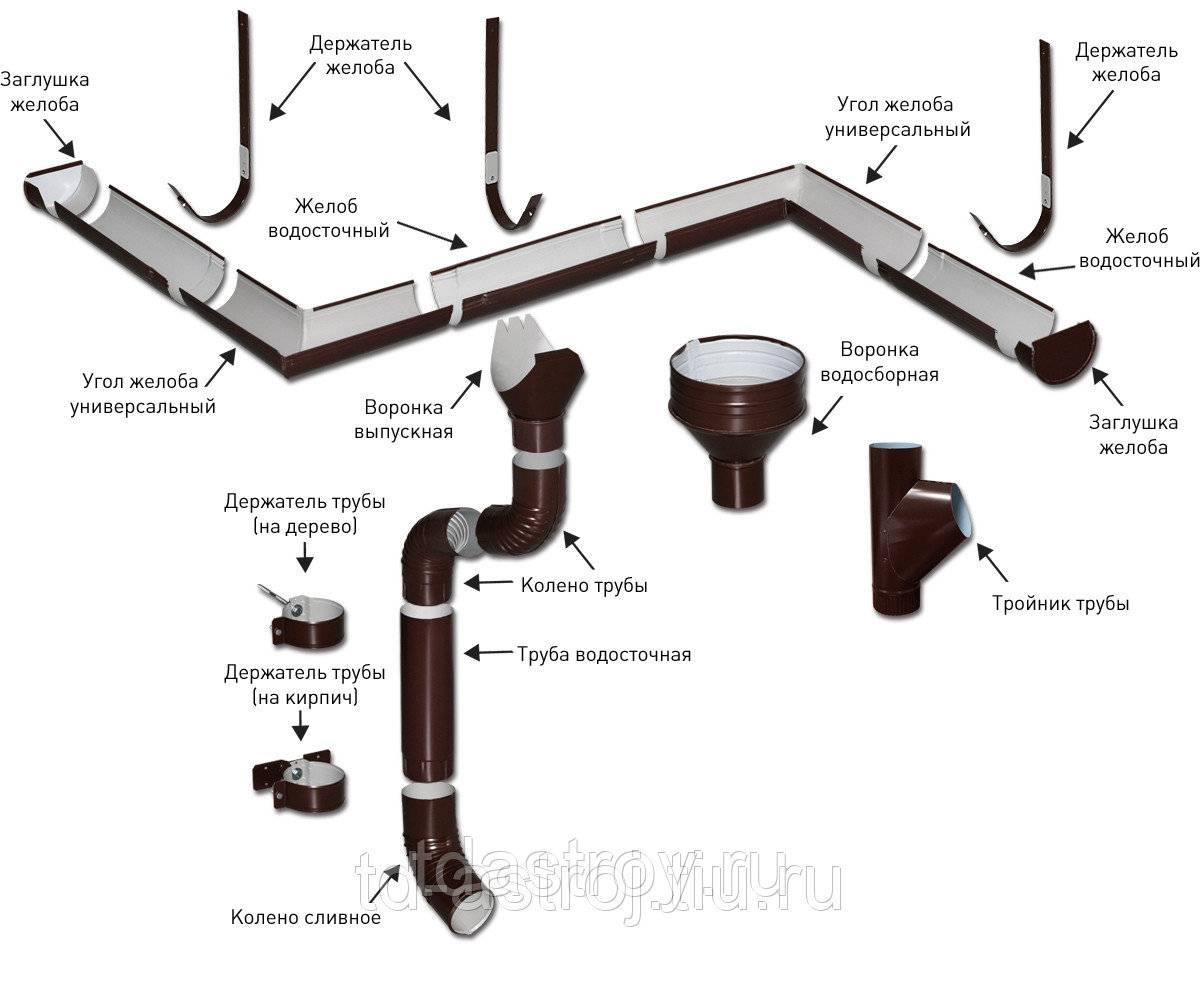

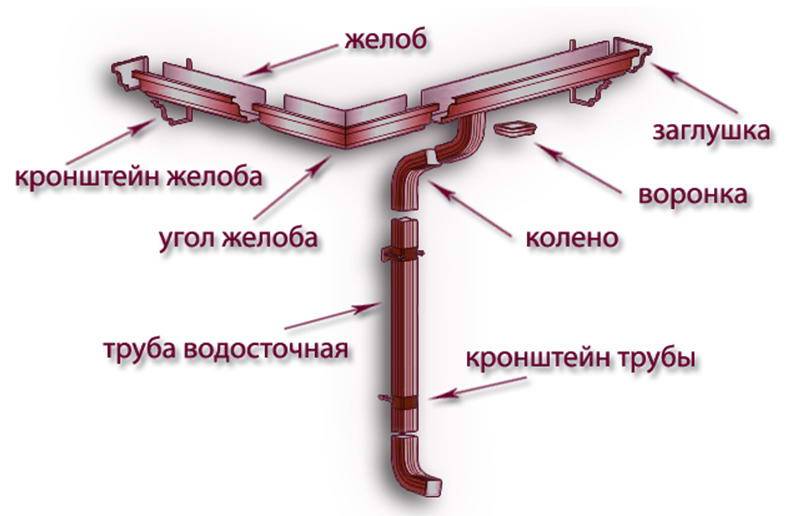

- Accessories for the drainage system

- How to choose gutters and their fragments

- The main elements of the drainage system

- plastic gutter

- funnel

- Drain pipe

- Drain pipe tip

- Drain pipe clamp

- Main elements

- Where to stop?

- Features of metal gutters

- steel gutter

- Copper drain

- Titanium-zinc gutter

- Aluminum drainage

- Structural strength ↑

- Drain metal

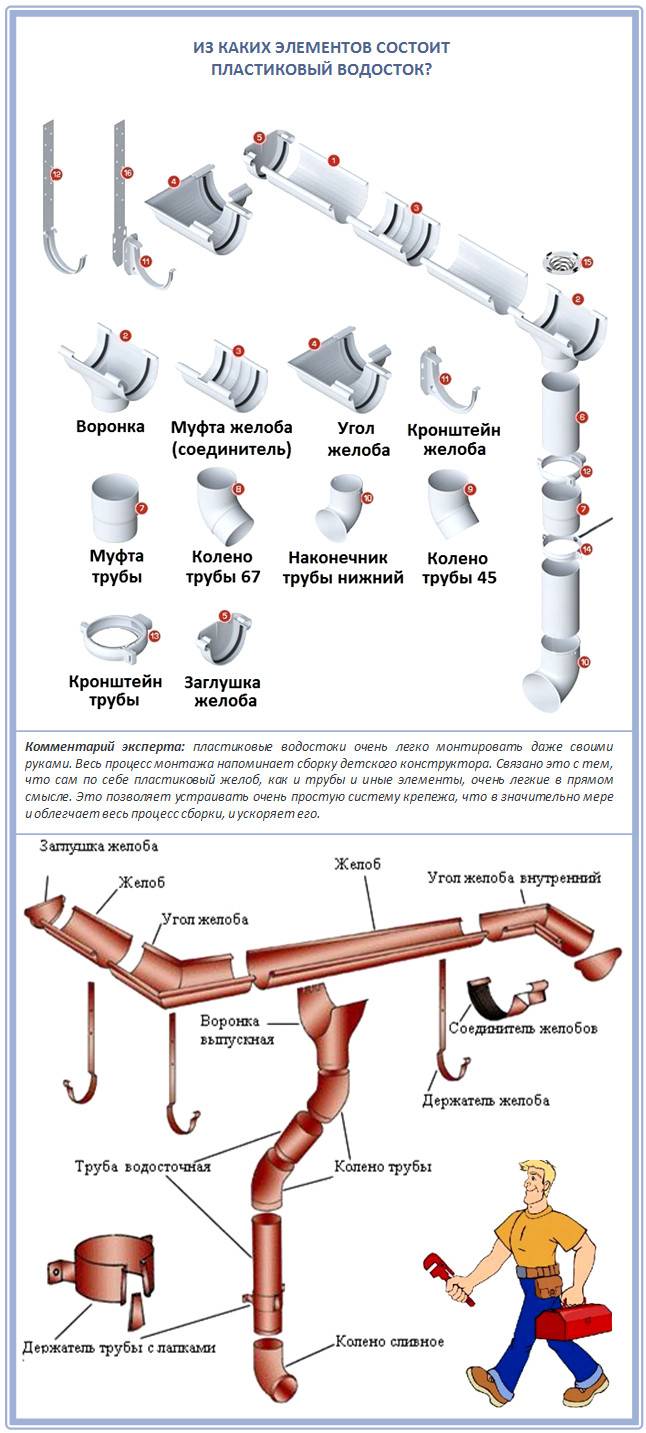

- plastic roof drains

Step 1. Choosing a high-quality drainage system

Modern drainage systems must meet a number of requirements, including not only mechanical strength, but also corrosion resistance and maximum tightness. That is why plastic gutters are considered the most practical today.

Their main advantage is that they can be easily matched not only to the roof covering, but also to the facade, and the color scheme is the richest among other materials.

And not only! But it is also important to know about certain disadvantages that can nullify all your work.

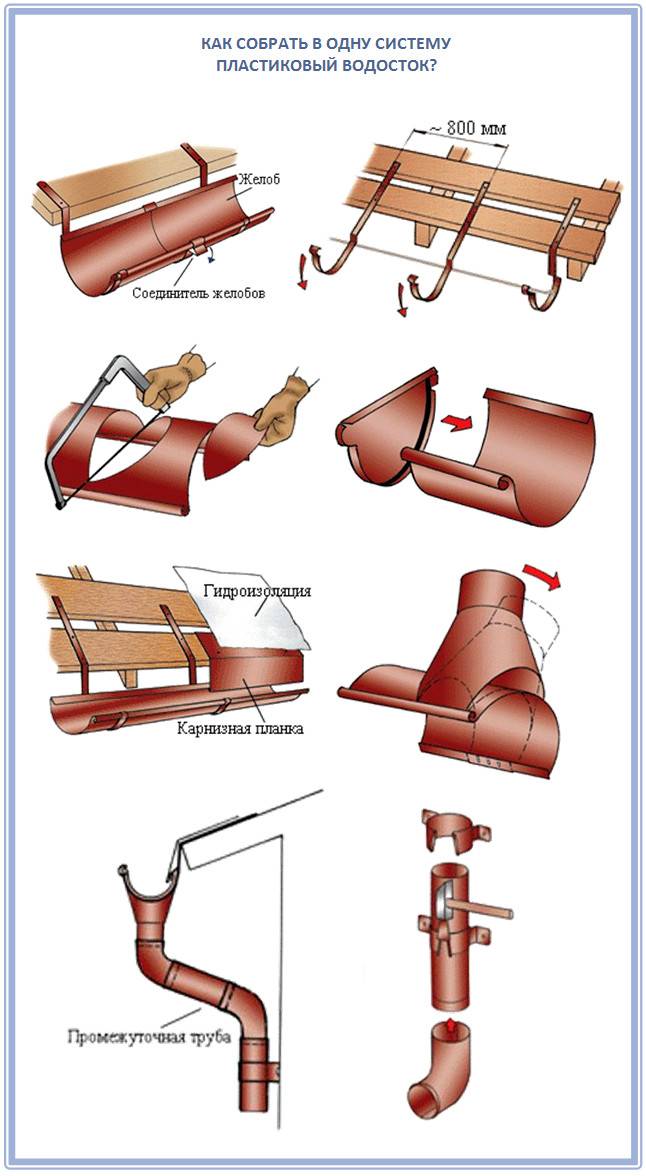

Modern plastic drainage systems include horizontal gutters, vertical pipes, elbows, pipe couplings, external and internal corners, funnels, docking elements, brackets, clamps and gutter plugs. Also, from different manufacturers, plastic drains are supplemented with their own details, such as a trash catcher.

In addition, the plastic drainage system does not corrode or scratch. And, if the drain is still torn off, then the deformed plastic gutter or pipe can simply be put in place, then when the metal one will have to be completely replaced.

And, finally, also a valuable advantage - in the small weight of such drains. Most often, industrial gutters have a length of 50 or 100 centimeters. In drainage systems, gutters are used with a height of 7.5 to 15 cm and a width of 10 cm.

Of the minuses, we note that plastic, in view of the peculiarities of its structure, is able to easily bend and deform during the period of temperature fluctuations. And in especially hot weather, plastic gutters even sag a little between the hooks if the mount was placed incorrectly and too far apart.

Although, according to modern manufacturers, these disadvantages are insignificant compared to the advantages of plastic gutters. But when it comes time to purchase such additional elements, you will encounter such moments on the market: bad plastic that easily bursts in the cold or blooms, poor-quality connection of pipes with gutters and ill-conceived details. And there may be an erroneous opinion that plastic gutters were of poor quality, as they are, and there is nothing better than native galvanization.

In fact, it is precisely because of these features that special chemical elements are added to the composition of plastic for the production of such products today, which allow the drain to acquire immunity to ultraviolet radiation. For example, among modern products on the Russian market, the Ruflex gutter system from Denmark, which was developed specifically for the climate of our country, similar PVC gutters from the Polish company Gamrat, the English Hunter, the Dutch Galeco, the Russian Ruplast and the Danish Aso Plastmo. And Ruflex gutters are considered especially durable and resistant to ultraviolet rays, the plastic formulation of which includes specially developed additives.

And modern PVC gutters are covered with a layer of acrylic or titanium dioxide during the production process. This is called the co-extrusion method, and this approach maximizes the resistance of normally brittle PVC to chemical rain, UV radiation, and frost. Moreover, the plastic of the gutters is stained even in the process of its manufacture, in its mass, and therefore the scratches on it are not only not noticeable, but also harmless.

In a word, a modern plastic drainage system is produced not at all from unreliable and flexible plastic, as many still think, but from a special unplasticized and impact-resistant PVC of a new technology.

These are the most modern drains that serve all 50 years! That is why it is so important to purchase gutters from well-known companies that value their reputation and not save on quality.

In addition to the main gutters and pipes, the modern plastic drainage system includes funnels, brackets, bends, plugs and even nets to retain debris:

Modern PVC gutters are assembled on rubber seals or on glue. The difference between these methods is huge: the adhesive joint is bad because it is quite difficult to fix it if you make mistakes, and it does not compensate for thermal expansion at all, but rubber copes with this 100%.

Therefore, the drains, which are connected to the seals, easily move during thermal expansion and allow you to replace at least all the details at any moment:

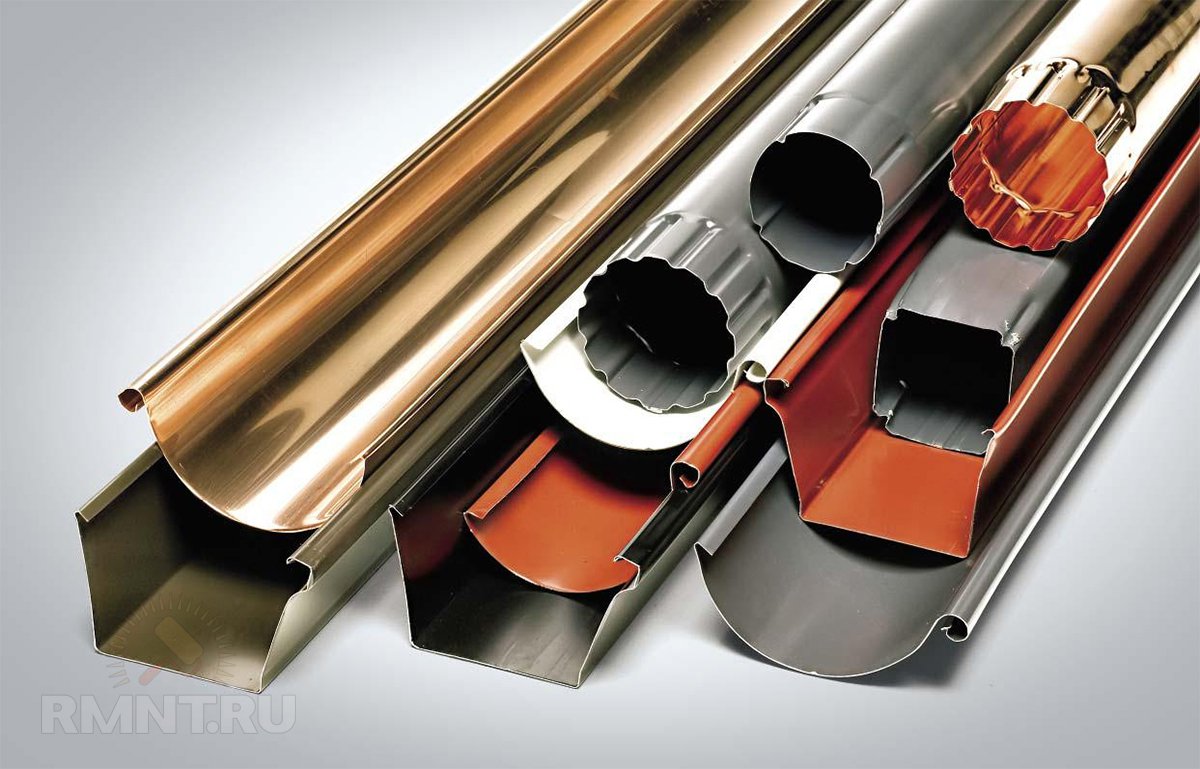

Pros and cons of metal gutters

Metal gutter systems are a classic option. They have been built for several centuries, and the first gutters had their own solution in the form of sculptural compositions. Until the middle of the last century, metal gutters were made in two versions: steel and copper. Today the market offers a wider choice.

Modern metal gutters are available in the following materials:

- Cink Steel;

- galvanized steel with a polymer coating;

- aluminum;

- titanium-zinc;

- copper.

Galvanized steel gutters are the easiest and most affordable option to arrange a drain, for example, for a do-it-yourself country house.

Galvanized gutters suspended on wire are a popular and cheap solution to the problem of drainage in outbuildings. When building new buildings, galvanized drainage systems are a budgetary, but not very popular solution. The service life of such gutters is 15-25 years.

Galvanized steel with a polymer coating is a more expensive and civilized drain. The polymer layer extends the life of the metal up to 50 years and allows you to get a wide range of colors according to the RAL scale. The advantage of metal-plastic gutters is that they can be matched to match the roofing.If, at the same time, the composition of the polymer is the same for the drain and the roof, then they will also burn out simultaneously.

The titanium-zinc alloy consists of 99.9% pure zinc, to which titanium, copper and aluminum are added in microdoses to give the metal ductility. The material is durable, since zinc oxidizes in air, becoming covered with a protective oxide film like copper.

Titanium-zinc and copper gutters are very close in their technical characteristics. They are practically not subject to corrosion, do not need additional care (except for cleaning, but this does not depend on the material). Both metals are plastic, which allows you to create a sealed drainage system of any configuration. The difference between them is in color. Titanium-zinc gutters are grey, matte asphalt color over time. Copper gutters are red, oxidize over time and become greenish.

Each metal has its pros and cons, but there are common characteristics for them.

We recommend that you read: Self-installation of a samovar-type heat exchanger on a chimney pipe

Advantages of metal gutters:

- Mechanical strength. The gutter system made of metal is resistant to weight loads when the water flows are intense and the gutters overflow. The metal does not deform under shock loads, for example, when snow and ice come off the roof.

- Temperature stability. The operating temperature range of metal gutters is from -70 to +120 degrees. This expands the zone out of use to the maximum. At the same time, the metal does not change its configuration, it has such a small coefficient of expansion that in the case of a gutter it can be neglected.

- Long service life.The most “short-lived” gutters are steel with a galvanized coating. They will stand for up to 25 years, but after 10-15 years of operation, their appearance deteriorates significantly. Long-livers are copper and titanium-zinc gutters. They have been serving for over 120 years.

- Ease of installation. All elements of the finished metal drain are connected by snapping. It does not require the installation of compensators, rubber seals.

Cons of metal gutters:

- The weight. Metal, even the lightest, is heavier than plastic. If for a new house the weight of the gutter system is not of great importance, then on an old roof, weight can become a selection criterion.

- Price. Metal gutters are more expensive than plastic ones. In the case of copper, the difference is estimated at times.

- Noise. This disadvantage can be called relative. Modern houses during the construction phase are protected from external noise. In old houses, noise is a serious inconvenience.

Metal gutters are suitable for any kind of roofing. They look natural on any type of building. Metal gutters is a time-tested solution to the problem of removing atmospheric moisture.

Accessories for the drainage system

Whatever gutters and pipes the owner chooses for his house, they need to be attached to the walls and roof with something. It is better to immediately purchase all fasteners and transition elements, along with the main design of the gutters. Therefore, to begin with, it is necessary to develop a project, calculate the required number of parts, their size and shape.

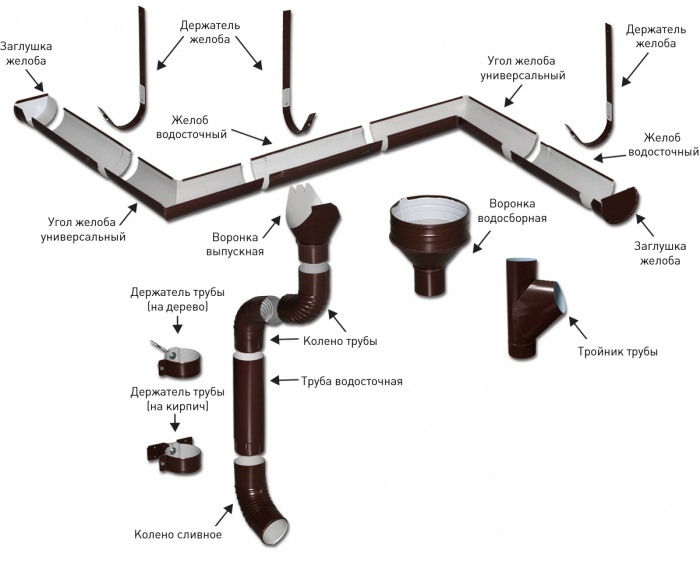

Any drain consists of several mandatory elements:

- gutters - guides of round, trapezoidal or rectangular section. The gutter is attached under the roof and is designed to collect water flowing from it.

- Water inlet - a funnel in which water is collected from connected gutters.

- The pipe can have a different configuration, consist of several parts. It is designed to drain water from top to bottom, to the ground, a drainage well or sewer.

- Drain - the lower part of the pipe, should not be lower than 300 mm from the ground.

- Fittings: couplings, tees, elbows, plugs, corners, adapters - are necessary to assemble the drain of the desired shape.

- Accessories, such as storm water inlets, drippers, nets, are designed to direct the flow and clean it of debris.

- Brackets - fasteners with which the gutter is attached to the overhang, the clamp holds the gutters on the facades. These parts are universal, suitable for gutters of any manufacturer.

Any structure for draining water from the roof must be assembled after careful calculations.

How to choose gutters and their fragments

The determining values for choosing a drain are:

- The material from which it is made (the pros and cons of each drain were mentioned above).

- The area of the slopes - depends on the configuration of the roof, is calculated from the frontal projection of each individual slope.

- Funnel drainage area - a parameter set by the manufacturer shows how much roof area one pipe with a funnel can drain water from.

After choosing the material, proceed to the sketch of the future drainage system. Calculate the area of each slope separately. By dividing this value by the capacity of the funnel specified by the manufacturer, the required number of risers is obtained. All gutters, funnels, pipes, fasteners are indicated on the drain drawing.

Advice!

Do not neglect small details and accessories when calculating the system.As practice shows, fittings and fasteners take up to 60% of the amount allocated for the purchase of gutters.

The main elements of the drainage system

The main elements of a plastic drainage system are gutters, pipes, water intake funnels, brackets, tips and clamps for vertical drainage, tees, corner elements, elbows.

plastic gutter

Gutters collect water that drains from the roof slope. They are fixed along the line of the cornice overhang of the roof in such a way that water from the slope falls exactly into the half-cylinder. The horizontal drain part is fixed with a slope of 2.5-3 mm per linear meter, the slope is directed towards the water intake funnel. If the slope of the house is longer than 10 m, then it is necessary to design drain pipes on both sides and the slope of the drainage system should also be directed in two directions.

The gutters have a semicircular (occasionally semioval) cross-sectional shape. Rarely rectangular. The edges of the gutters are bent - this gives each element greater rigidity, reduces deformation during operation and storage. The horizontal drain can be open or closed with a grate from above. The closed gutter design is more rigid, plus leaves, large debris do not get inside, the funnel grate does not clog, water can flow down unhindered.

The ends of the grooves are profiled in a special way (in the form of a lock) - this ensures a reliable connection of the elements to each other. The edge of the gutter is closed with a special end cap that prevents water from pouring out in the wrong place. The length of plastic elements is from 0.5 to 2-6 meters. Diameters - 90, 100, 120, 125, 130, 140, 150, 180, 200 mm.The diameter of the most common gutters is 125 mm, the depth is 62 mm. Sometimes the drain is connected with special couplings, not locks.

Plastic gutters are attached to the building with special brackets or hooks. EDPM gaskets are used to seal the system.

funnel

A vertical drain is connected to the gutter using a special element - a water intake funnel. Funnels must be equipped with gratings to protect the pipe from debris and leaves (the pipe is much more difficult to clean than an open structure).

Drain pipe

Drain communications are mounted vertically; elbows or bends are used to move the pipe to the side. Diameters: 50, 60, 65, 70, 75, 90, 100, 110, 120, 150 mm. The diameter of a plastic pipe is usually less than the diameter of the gutter, while the cross-sectional area of the pipe must be equal to or greater than the cross-sectional area of the duct (or the sum of the cross-sectional areas of the ducts). Gutter systems of small diameter are less visible on the facade.

Drain pipes are connected by inserting the narrower end of another element into the expanded upper end of one element. Less common is the connection to the socket (like sewer), even more rarely - the connection with the help of couplings.

If a drain pipe cannot be installed, then a large chain is used as a drain, through which water flows. Sometimes gargoyles are used - water is diverted away from the walls of the house and flows down from a great height without any structures.

Drain pipe tip

The lowest element of the drainage system is the tip, or drain outlet. It is located near the ground itself, the need for its installation arises when water is not discharged into the storm sewer, but to the blind area, the area near the house or directly to the ground.The shape of the tip should allow water to drain without splashing. The height of the edge of the tip above ground level (blind area) is 200 mm.

The lower part of the tip can be deepened into a drainage ditch. In this case, it is advisable to install a small sump with a revision. It will protect the storm sewer system from silting or clogging.

Drain pipe clamp

Clamps holding the drain pipe are attached to the wall of the building. In most designs, the clamps cover the pipe, are bolted together or secured with a latch (lock). The clamp should not rigidly clamp the pipe - it should be able to move freely when changing linear dimensions during heating or cooling.

Main elements

- Gutter. The main horizontal component of the system, designed to transport water from the roof.

- Funnel. The purpose is clear and obvious - the collection of water flowing through the gutters from the roof.

- Drain pipe. The most important vertical part of the system. It also plays a significant role in the aesthetic perception of the building.

- Elements of extension and connection (brackets, clamps, elbows, couplings, etc.). Supplied with main elements.

Important! Completion with materials and doborniks must always be carried out from one manufacturer or supplier. It is in this case that the maximum combination of all elements is ensured and, as a result, the optimal operation of the system

Where to stop?

The final choice should be made taking into account the whole range of evaluation criteria.

First of all, they proceed from the fact that the drainage system has its direct functions, and first of all it must cope with them. The rest is, to a certain extent, secondary.In addition, it does not determine the facade appearance of the building, but, on the contrary, it matches the existing (planned) roof and wall decoration.

Naturally, gutters and pipes should not be out of harmony with the overall exterior finish and style of the building.

You should immediately carry out all the necessary calculations in order to determine the list and number of necessary components. This will allow, having learned the prices in local stores, to assess their financial capabilities in terms of purchasing a particular system.

- In regions with difficult operating conditions (high probability of ice, heavy snow, severe frosts, etc.), preference should still be given to high-quality metal systems. But on the coast, plastic will still be better.

- For a roof made of corrugated board or metal tiles, a metal drain with an appropriate harmonizing color will be most appropriate. For soft roofing, on the contrary, plastic versions of systems suggest themselves.

- A copper gutter system on some “poor” roof will look absolutely ridiculous. And vice versa - a copper roof in combination with galvanized gutters. That is, one must intuitively understand the difference between harmony and obvious kitsch, "dust in the eye."

Well, for the rest - rely on your taste and, of course, financial capabilities

In this case, it is best to pay attention to the products of proven, reputable manufacturers who accompany their products with a good quality guarantee. These include the German company "Docke", the French "Nicoll", the British "Hunter", and, of course, the domestic "Alta-Profile", "Aquasystem", "Grand Line", "Metal Profile", "Marley".One of the leaders in the Russian market of polymer products, and in particular - drainage systems: Alta-Profil company

One of the leaders in the Russian market of polymer products, and in particular - drainage systems: Alta-Profil company

At the end of the publication - a video, which also gives advice on choosing drainage systems:

Features of metal gutters

Metal gutters were used for water drainage both in the past and in the modern world. At the same time, if a metal gutter system made of zinc or cast iron was previously common, today these alloys are not popular, since products made from them became unusable very quickly, because without a special coating such metals quickly rusted. Now users can purchase the following types of metal gutters:

- steel;

- aluminum;

- titanium-zinc;

- copper.

Each variety has its own special characteristics, therefore, depending on the specific material, the service life of the product and the price of the product may differ.

steel gutter

The most affordable option for a metal drain is a galvanized cold rolled steel system. The thickness of the metal is 0.5-0.7 mm, but this is quite enough to ensure high strength and durability of the drain. To extend the service life, as well as to give the structure a more decorative look, steel elements are coated on the outside and inside with one of the polymers, in particular, it can be:

- plastisol;

- pural;

- polyester.

Depending on the specific coating option, characteristics such as frost resistance, UV resistance, color fastness, and so on may vary. However, in general, this option has good performance, great color variety, affordable cost and long service life.

Copper drain

Copper is an environmentally friendly material that is easy to work with, as it is quite flexible and ductile, but at the same time strong. Products are not deformed under the influence of cold or heat, and there are no scratches or other mechanical damage on their surface. Thanks to these qualities, drainage systems can be given various forms, including non-standard ones. For the production of drainage elements, a copper sheet with a thickness of 0.55-0.9 mm is used. The copper system has the highest durability. These are reliable and durable products that are resistant to aggressive environmental conditions. However, their main drawback is that they are quite expensive and massive. Of course, if the financial issue is not a problem, then such a drain will really be able to maintain the integrity of the structure for many decades and at the same time become an exterior decoration.

Titanium-zinc gutter

This alloy is characterized by high corrosion resistance, durability and strength. However, its cost is comparable to the price of copper products. The composition of the alloy includes copper and aluminum, that is, materials characterized by ductility, and titanium is responsible for increasing corrosion resistance. The thickness of the metal used is 0.65-0.8 mm.

Aluminum drainage

Aluminum systems are considered the lightest of all types of metal gutters.Due to the low weight of the material, it becomes possible to increase the thickness of the elements. That is, the walls of the drains have a thickness of 1-1.6 mm, which makes the product as durable and reliable as possible.

In general, a metal drain is distinguished by high durability, strength, resistance to corrosion and mechanical damage, a wide variety of designs, is not afraid of exposure to the sun and cold, and caring for it is not particularly problematic. However, high cost, high weight and noise can be considered a disadvantage, especially if the system does not have an internal polymer coating.

Related video:

Structural strength ↑

Drain metal

Metal is a high strength material. However, much depends on what specific material is used: steel, aluminum, copper, titanium-zinc.

- Steel weirs are galvanized. Recently, as an additional protection, a polymer layer is also applied on top.

- Aluminum gutters are more ductile than required, but this drawback can be completely leveled by increasing the thickness of the metal.

- All components of the gutter system, including metal gutters on the roof, pipes, fasteners used, have a greater margin of safety than plastic.

- Clamps in a metal structure are able to withstand the weight of an adult and even more, on average about 180 kg, and at the same time the drainpipe does not move at all. They also provide their fixing rigidity.

- Hooks, in turn, guarantee the same rigidity of fastening to the gutters: they are “tightly” clamped.

plastic roof drains

It will not be possible to achieve the same with plastic structures due to the characteristics of the material itself.The installation instructions clearly state that neither pipes nor gutters should be tightly clamped. This requirement is due to the fact that plastic elements are subject to thermal deformation more than metal ones. This is due to the fact that the value of the thermal expansion coefficient of plastic is about six times greater.

On a note

Assume that a 10 m long plastic gutter is installed. When the temperature rises by 10°C, it lengthens by 25 mm.

Thus, it is obvious that the integrity of the structure with rigid fastening will be violated, therefore, freedom of movement of the gutters in the brackets must be ensured. The same applies to the PVC pipes themselves.

However, due to loose fastening, a backlash will inevitably form, as a result of which the gutter structure will continue to loosen further. That is why in the matter of strength, metal gutters will be the winner.